Page 1

Cerrar SIS

Page 1 of 3

325D L Excavator A3R00001-UP (MACHINE) POWERED BY C7 Engine(SEBP4513 - ...

16/4/2019

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/...

Pantalla anterior

Producto: EXCAVATOR

Modelo: 325D L EXCAVATOR A3R

Configuración: 325D L Excavator A3R00001-UP (MACHINE) POWERED BY C7 Engine

Especificaciones

C7 Engines for Caterpillar Built Machines

Número de medio -SENR9938-30 Fecha de publicación -01/05/2014 Fecha de actualización -06/06/2014

i04371168

Connecting Rod

SMCS - 1218

Page 2

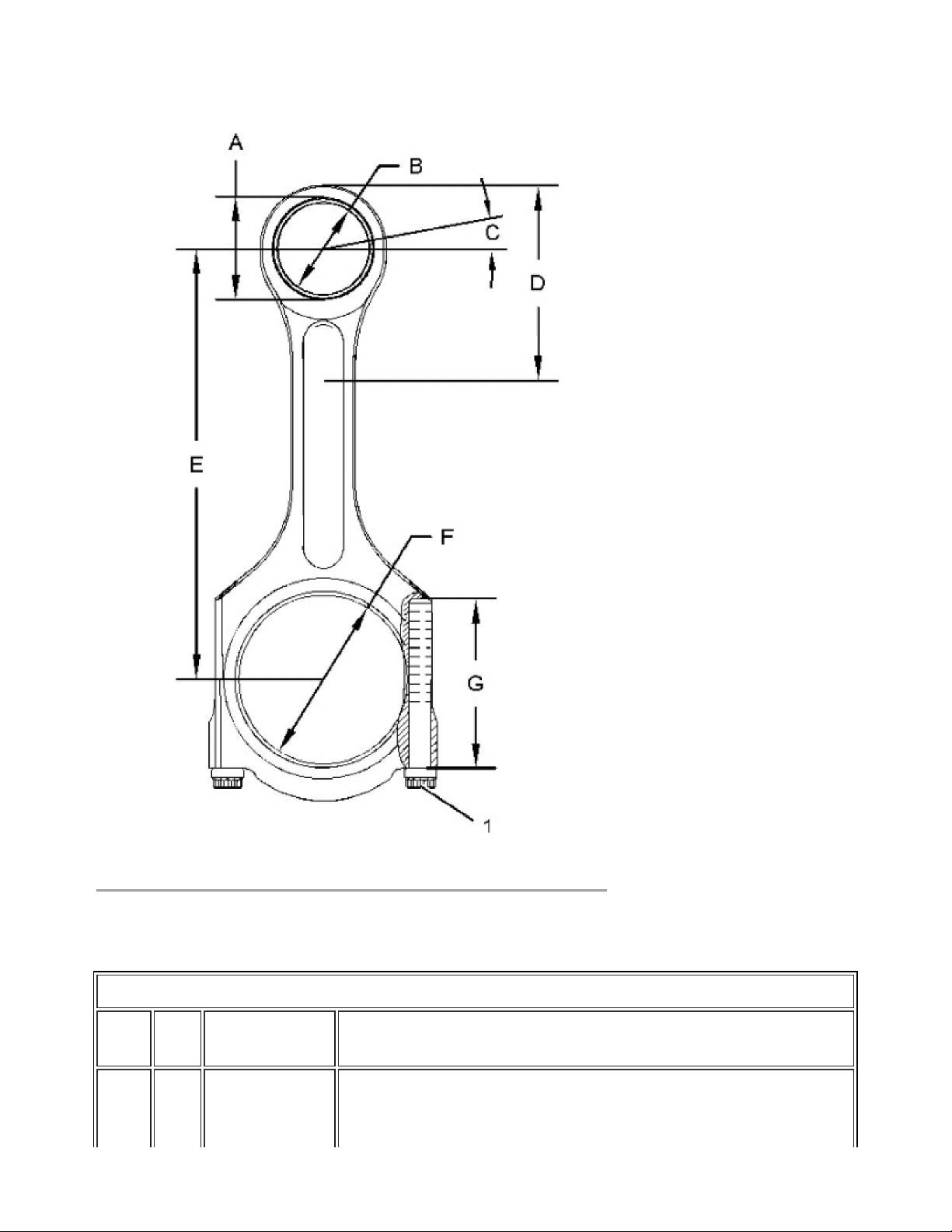

Illustration 1 g01405580

Page 2 of 3

325D L Excavator A3R00001-UP (MACHINE) POWERED BY C7 Engine(SEBP4513 - ...

16/4/2019

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/...

Table 1

Specification for 213-3193 Connecting Rod

Item Qty

A 1 211-0595

Part Specification Description

Handle the fractured connecting rod with care. Use a soft jawed

Connecting

vise in order to hold the connecting rod while loosening the

Rod

Page 3

connecting rod cap bolts. Use a soft faced hammer in order to tap

the connecting rod cap, if necessary.

Page 3 of 3

325D L Excavator A3R00001-UP (MACHINE) POWERED BY C7 Engine(SEBP4513 - ...

16/4/2019

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/...

Bore for piston pin bearing is

43.191 ± 0.013 mm (1.7004 ± 0.0005 inch).

B 1

2W-0027

Bearing

C - -

D - -

E - -

F - -

G 2

229-6266 Bolt Length of the bolt is

After installation, bore in the bearing is

40.028 ± 0.008 mm (1.5759 ± 0.0003 inch).

The bearing joint for the piston pin bearing must be positioned to

the angle above the centerline on either side is 12 ± 5 degrees.

Before installation of the piston pin bearing, connecting rod small

end must be heated from

175 to 260 °C (347 to 500 °F).

Distance for heating the connecting rod for the installation of the

piston pin bearing is

75 ± 5 mm (3.0 ± 0.2 inch).

Distance between the center of the connecting rod bores is

200 mm (7.9 inch).

Bore in the connecting rod for the bearing for the crankshaft

connecting rod journal is

75.000 ± 0.013 mm (2.9527 ± 0.0005 inch).

65.0 ± 0.5 mm (2.56 ± 0.02 inch).

- - -

Copyright 1993 - 2019 Caterpillar Inc.

Todos los derechos reservados.

Red privada para licenciados del SIS.

Use the following procedure to tighten the connecting rod bolts:

1. Before installing the rod cap, clean the mating surfaces of the

connecting rod with compressed air or a steel brush.

2. Lubricate the seating faces of the cap with 4C-5599 Anti-Seize

Compound or clean engine oil.

2. Install new bolts (1) and torque each bolt to

70 ± 5 N·m (50 ± 4 lb ft).

3. Place an index mark on each connecting rod cap bolt and tighten

each bolt for an additional turn of 120 ± 5 degrees.

Tue Apr 16 15:26:55 EST 2019

Loading...

Loading...