Page 1

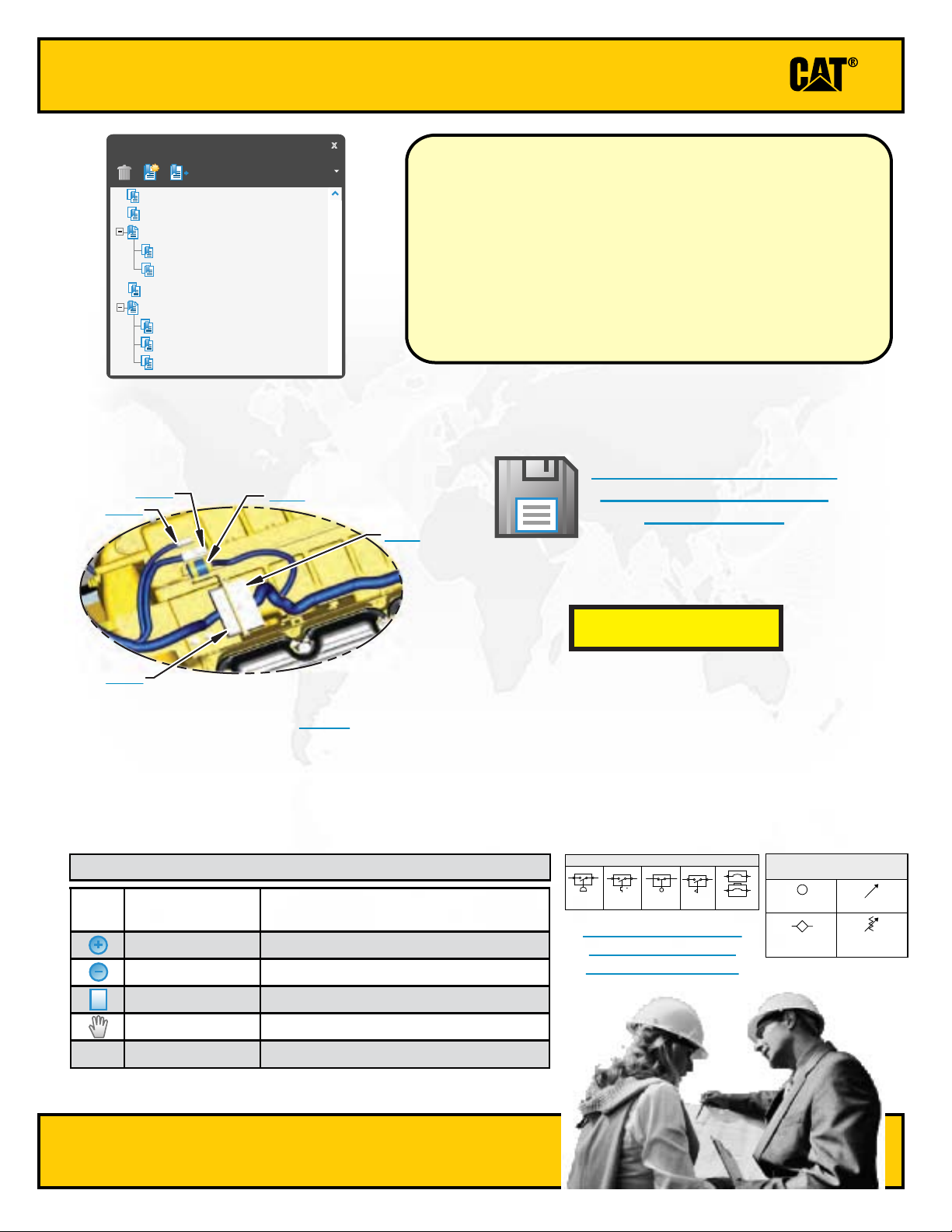

INTERACTIVE SCHEMATIC

ELECTRICAL SYMBOLS

Bookmarks

Features

Cover Page

Tables

Component

Connector

Schematic

Machine Views

Chassis View

Cab View

Engine View

X

Options

The Bookmarks panel will allow you to

quickly navigate to points of interest.

EC-C2

EC-C3

E-C60

E-C61

*This document is best viewed at a

screen resolution of 1024 X 768.

To set your screen resolution do the following:

RIGHT CLICK on the DESKTOP.

Select PROPERTIES.

CLICK the SETTINGS TAB.

MOVE THE SLIDER under SCREEN RESOLUTION

until it shows 1024 X 768.

CLICK OK to apply the resolution.

*Due to different monitor sizes and PDF reader preferences

there may be some variance in linked schematic locations

Click here to save a copy of

this interactive schematic

to your desktop

EC-C1

Click on any text that is BLUE and

underlined. These are hyperlinks

that can be used to navigate the

schematic and machine views.

HOTKEYS (Keyboard Shortcuts)

FUNCTION

Zoom In

Zoom Out

Fit to Page

Hand Tool

Find

“CTRL” / “+”

“CTRL” / “-”

“CTRL” / “0” (zero)

“SPACEBAR” (hold down)

“CTRL” / “F”

KEYS

VIEW ALL CALLOUTS

When only one callout is showing on a

machine view, clicking on this button will

make all of the callouts visible. This

button is located in the top right corner

of every machine view page.

BASIC HYDRAULIC

COMPONENT SYMBOLS

Pressure

Switch

T

Temperature

Switch

Level

Switch

Flow

Switch

Circuit Breaker

Click here to view the

Schematic Symbols

and Definitions page

Pump

or Motor

Fluid

Conditioner

(Adjustable)

Variability

Spring

Page 2

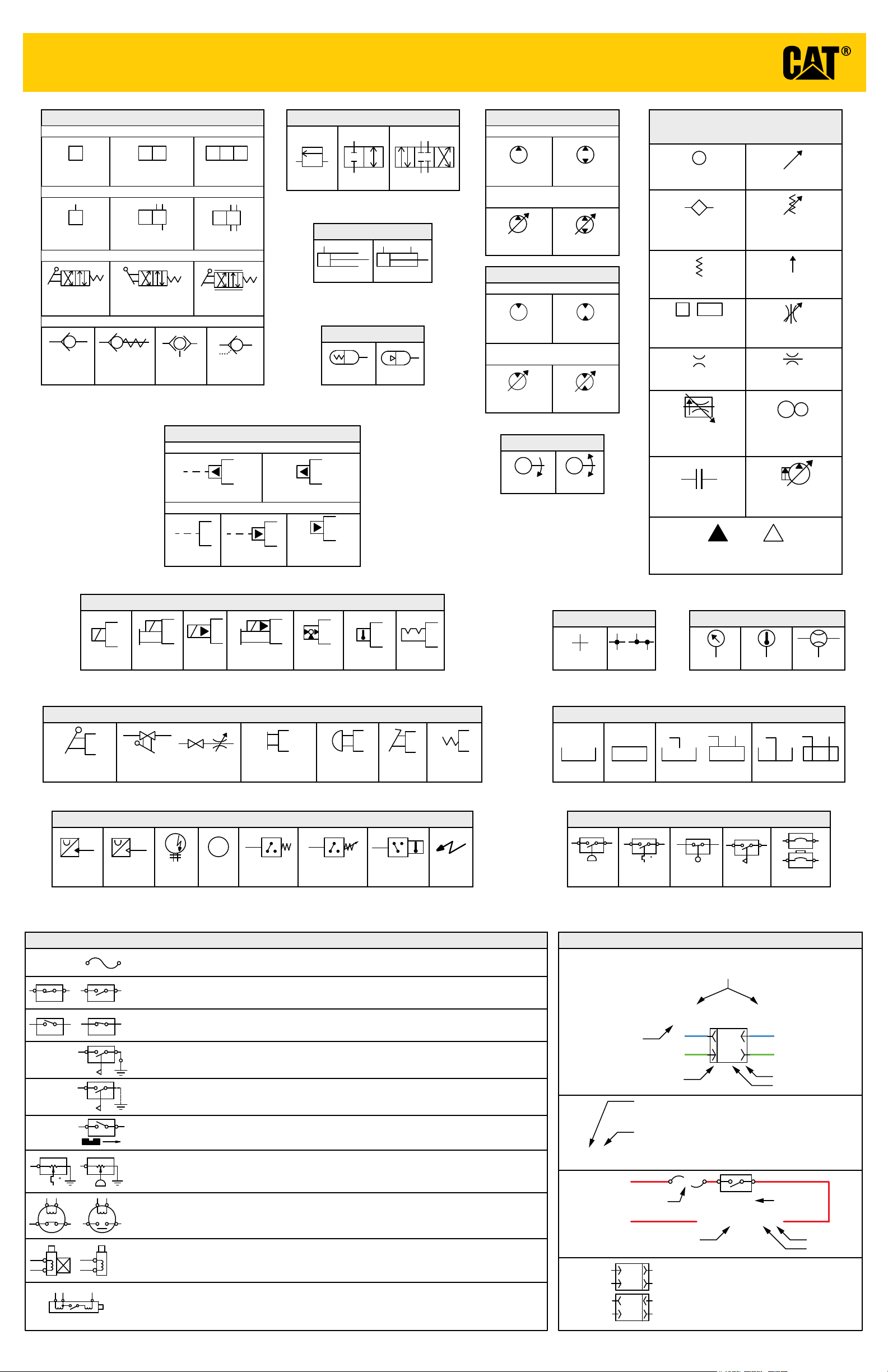

SCHEMATIC SYMBOLS AND DEFINITIONS

One Position

Two-way

A B

P T

Normal Position

Basic

Symbol

VALVES

ENVELOPES

Two Position

PORTS

Three-Way

CONTROL

A B

P T

Shifted Position

CHECK

Spring

Loaded

Shuttle

Three Position

Four-Way

Infinite Position

Pilot

Controlled

PILOT CONTROL

RELEASED PRESSURE

INTERNAL PASSAGEWAYS

FLOW IN ONE

DIRECTION

Infinite

Positioning

FLOW ALLOWED IN

EITHER DIRECTION

Two

Position

CYLINDERS

Single Acting

Double Acting

ACCUMULATORS

Spring Loaded

Gas Charged

PARALLEL

FLOW

Three

Position

CROSS

FLOW

PUMPS

FIXED DISPLACEMENT

Unidirectional

Bidirectional

VARIABLE DISPLACEMENT

NON- COMPENSATED

Unidirectional

Bidirectional

MOTORS

FIXED DISPLACEMENT

Unidirectional

Bidirectional

VARIABLE DISPLACEMENT

NON- COMPENSATED

Unidirectional

Bidirectional

ROTATING SHAFTS

BASIC HYDRAULIC

COMPONENT SYMBOLS

Pump

or Motor

Fluid

Conditioner

Spring

Control

Valves

Restriction

Line Restriction

Variable and Pressure

Compensated

Variability

Spring

(Adjustable)

Pressure

Compensation

Line Restriction

(Variable)

Line Restriction

(Fixed)

AUX.

MAIN

2-Section

Pump

External Return

Simplified

Solenoid

Solenoid

or Manual

Solenoid

and Pilot

Push-pull Lever PedalGeneral Manual Push Button SpringManual Shutoff

Internal Return

REMOTE SUPPLY PRESSURE

Complete

Internal

Supply Pressure

COMBINATION CONTROLS

Solenoid and

Pilot or Manual

Servo

MANUAL CONTROL

Thermal

Detent

Unidirectional

Bidirectional

Attachment

Pump: Variable and

Pressure Compensated

Hydraulic Pneumatic

Energy Triangles

MEASUREMENT

Pressure

Temperature

Flow

Crossing

LINES

Joining

FLUID STORAGE RESERVOIRS

Vented Pressurized Return Above Fluid Level Return Below Fluid Level

Transducer

(Fluid)

T

HYDRAULIC SYMBOLS - ELECTRICAL

Transducer

(Gas / Air)

G

Generator

M

Electric

Motor

Pressure

Switch

Pressure Switch

(Adjustable)

Temperature

Switch

Electrical

Wire

BASIC ELECTRICAL COMPONENT SYMBOLS

Fuse: A component in an electrical circuit that will open the circuit if too much current flows through it.

Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). The circle indicates

Switch (Normally Closed): A switch that will open at a specified point (temp, press, etc.).

Ground (Wired): This indicates that the component is connected to a grounded wire.

The grounded wire is fastened to the machine.

Ground (Case): This indicates that the component does not have a wire connected to ground.

It is grounded by being fastened to the machine.

Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes the contacts of

a normally open reed switch; it opens the contacts of a normally closed reed switch.

Sender:

A component that is used with a temperature or pressure gauge.

The sender measures the temperature or pressure.

Its resistance changes to give an indication to the gauge of the temperature or pressure.

Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity.

Solenoid: A solenoid is an electrical component that is activated by electricity.

It has a coil that makes an electromagnet when current flows through it.

The electromagnet can open or close a valve or move a piece of metal that can do work.

Magnetic Latch Solenoid: An electrical component that is activated by electricity and held latched by a

that the component has screw terminals and a wire can be disconnected from it.

No circle indicates that the wire cannot be disconnected from the component.

It has a coil that makes an electromagnet when current flows through it.

The electromagnet can open or close the switch part of the relay.

permanent magnet. It has two coils (latch and unlatch) that make electromagnet

when current flows through them. It also has an internal switch that places

the latch coil circuit open at the time the coil latches.

ELECTRICAL SYMBOLS

Pressure

Switch

T

Temperature

Switch

Switch

HARNESS AND WIRE SYMBOLS

Wire, Cable, or Harness Assembly Identification:

Includes Harness Identification Letters and Harness

Connector Serialization Codes (see sample).

AG-C4

Part Number: for

Connector Plug

Harness Identification Letter(s): (A, B, C, AA, AB, AC, ...)

Harness Connector Serialization Code: The "C" stands for

"Connector" and the number indicates which connector in the

harness (C1, C2, C3, ...)

L-C12

3E-5179

Fuse (5 Amps)

Harness identification code:

This example indicates wire group 325,

wire 135 in harness "AG".

1

2

1

2

111-7898

Plug

5A

Deutsch connector: Typical representation

of a Deutsch connector. The plug contains all

sockets and the receptacle contains all pins.

Sure-Seal connector: Typical representation

of a Sure-Seal connector. The plug and receptacle

contain both pins and sockets.

Level

Flow

Switch

L-C12

3E-5179

1

2

9X-1123

325-AG135 PK-14

Circuit Breaker

Receptacle

Pin or Socket Number

Component

Part Number

Wire Gauge

Wire Color

Page 3

RENR7157-07

October 2012

320D and 323D Excavator

Hydraulic System - Attachment

320D:

MDE1-UP

A6F1-UP

A8F1-UP

A9F1-UP

KGF1-UP

TDH1-UP

DHK1-UP

FAL1-UP

KLM1-UP

CXY1-UP

JGZ1-UP

323D:

PBE1-UP

LFL1-UP

System 3 Prime

Printed in U.S.A.© 2012 Caterpillar, All Rights Reserved

Page 4

COMPONENT TABLE

Component Locations

Description

Attachment: System 3 Prime

Valve GP - Control (Auxiliary) 259- 7378 1

Valve GP - Negative Flow 171- 0188 2 E-1

Valve GP - Pilot (Foot Pedal Pressure and Flow) 206- 3336 3 F-6

Valve GP - Relief (With Block - Work Tool) 177- 2653 4 E-4

Standard 320D and 323D

Accumulator GP - Pilot Manifold Note B 5

Block Note B 6 C-7

Cylinder GP - Boom Note A 7 F-1

Cylinder GP - Bucket Note A 8 F-2

Cylinder GP - Stick Note A 9 E-2

Filter GP - Case Drain Note B 10 A-4

Filter GP - Pilot Hydraulic Note B 11 A-4

Filter GP - Return Oil Note B 12 A-5

Manifold GP - Control Note B 13 B-5

Motor GP - Left Travel Note B 14 F-3

Motor GP - Right Travel Note B 15 F-2

Motor GP - Swing Note B 16 F-5

Pump GP - Main Hydraulic Note B 17 B-2

Sensor AS - Left Pump Pressure Note B 18 B-2

Sensor AS - Right Pump Pressure Note B 19 A-2

Switch AS - Pilot Pressure Note B 20 A-7

Switch AS - Travel Pressure (LH) Note B 21 E-7

Switch AS - Travel Pressure (RH) Note B 22 E-7

Swivel GP Note B 23 E-3

Tank GP - Hydraulic Oil Note B 24 A-5

Valve GP - Cooler Bypass Note B 25 A-6

Valve GP - Joystick (LH) Note B 26 B-7

Valve GP - Joystick (RH) Note B 27 B-6

Valve GP - Load Control (Boom Cylinder) Note B 28 D-2

Valve GP - Load Control (Stick Cylinder) Note B 29 D-5

Valve GP - Main Control Note B 30 C-2

Valve GP - Pilot Travel Note B 31 E-7

Valve GP - Pressure Reducing (Boom/Swing) Note B 32 B-3

Valve GP - Shuttle Note B 33 A-7

Valve GP - Swing Cushion Note B 34 E-5

Valve GP - Travel LH Counterbalance Note B 35 E-3

Valve GP - Travel RH Counterbalance Note B 36 E-2

Part

Number

Machine

Location

Schematic

Location

C-6

B-4

Note A: Refers to parts manual for specific cylinder information.

Note B: Part numbers are located on the Main Hydraulic System Schematic

according to the effectivity of the machine.

Page 5

TAP TABLE

Tap Locations

Pressure, Sampling, and Sensor

Tap

Schematic

Description

Number

CC Left Pump Negative Flow Signal Pressure E-1

DD

EE

FF

GG

HH

JJ

KK

SOS

Right Pump Negative Flow Signal Pressure

Left Pump Delivery Pressure

Right Pump Delivery Pressure

Pilot Pump Delivery Pressure

Left Pump Power Shift Pressure

Case Drain Pressure

Right Pump Power Shift Pressure

Hydraulic Oil Sampling Port

Location

E-1

B-2

A-2

A-4

B-1

B-1

A-1

A-3

Page 6

Tap

Number

CC

DD

EE

FF

GG

HH

JJ

KK

SOS

Tap Locations

Pressure, Sampling, and Sensor

Description

Left Pump Negative Flow Signal Pressure

Right Pump Negative Flow Signal Pressure

Left Pump Delivery Pressure

Right Pump Delivery Pressure

Pilot Pump Delivery Pressure

Left Pump Power Shift Pressure

Case Drain Pressure

Right Pump Power Shift Pressure

Hydraulic Oil Sampling Port

Schematic

Location

E-1

E-1

B-2

A-2

A-4

B-1

B-1

A-1

A-3

RP

RT

(3) VALVE GP

PILOT (FOOT PEDAL PRESSURE AND FLOW)

206-3336

PG

DR

(16) MOTOR GP

SWING

(14) MOTOR GP

LEFT TRAVEL

(15) MOTOR GP

RIGHT TRAVEL

(8) CYLINDER GP

BUCKET

(7) CYLINDER GP

BOOM

(31) VALVE GP

PILOT TRAVEL

TP

TT

TRAVEL(L) TRAVEL(R)

BACKFWDBACK FWD

T1 T5

aL1 aR1

(21) SWITCH AS

TRAVEL PRESSURE (LH)

T2 T4 T6 T3

bL1

bR1

(22) SWITCH AS

TRAVEL PRESSURE (RH)

1

3

2

aR2

RCV-C

MU

BG AG

Pp3

T1

T2

Pp3

T1

T2

AR3 BR3 AR4 BR4

(9) CYLINDER GP

DR

A1B1

STICK

SINGLESINGLE

AG BG AGBG

AL3 BL3

(2) VALVE GP

NEGATIVE FLOW

171-0188

A1

HL

A2

B1

B2

CC

HR

B A

BL2

(34) VALVE GP

SWING CUSHION

AL2

RCV-D

A B

(35) VALVE GP

TRAVEL LH COUNTERBALANCE

(4) VALVE GP

RELIEF (WITH BLOCK - WORK TOOL)

AB

(36) VALVE GP

TRAVEL RH COUNTERBALANCE

BL1 AL1 BR1 AR1

(23) SWIVEL GP

177-2653

P

(1) VALVE GP

CONTROL (AUXILIARY)

259-7378

FA1

(29) VALVE GP

LOAD CONTROL

(STICK CYLINDER)

Pa1

FB1

RCV-A

AL4

T aL4

SP3

SDr

SPi

BL3 AL3

SP2

BL3

STSP1

R2

aL3

(IN)

AL2

aL2 aL1

AL1

BL1BL2

(L)(R)

(BACK)

Di4 Pi4

aR1 aR1

(BACK)

Pa1

BR2

AR2

aR3

(CLOSE)

T

DD

BR4

Pi1

BP3

BPi BP2

BDr

(28) VALVE GP

LOAD CONTROL

(BOOM CYLINDER)

RCV-B

AR5

BTBP1

BR5

aR5

R3

R1BR4

(IN)

AR4

BR3BR1AR1

AR3

aR4

(DOWN)

(6) BLOCK

HL

F2

F2

Pb1

(UP)

(UP)

BOOM (2)

(FWD)

(OUT)

STICK (1)

SWING

(FWD)

TRAVEL (L)

Di2 Pi2 Pi3 Di3 DST Di1

TRAVEL (R)

bR2

ATCH

(OPEN)

BUCKET

PL

bL4 bL3 bL2 bL1 bR1 bR3 bR4

PR

BOOM (1)

(30) VALVE GP

MAIN CONTROL

bR5

(OUT)

STICK(2)

HR

RENR7157-07

(26) VALVE GP

JOYSTICK (LH)

24 Page, (Dimensions: 34 inches x 28 inches)

STICK SWING

OUT

JL1

(33) VALVE GP

SHUTTLE

IN

JL3

A1 A2 A3 A4 A5 A6 A7 A8

B1 B2 B3 B4 B5 B6 B7 B8

JLP

R L

JL2 JL4

JLT

JRP

JRT

BUCKET BOOM

OPEN CLOSE DOWN UP

JR1JR2 JR3JR4

RCV-B

RCV-A

(27) VALVE GP

JOYSTICK (RH)

(13) MANIFOLD GP

(25) VALVE GP

COOLER BYPASS

RCV-C

E

RCV-D

CONTROL

(17) PUMP GP

EE

MAIN HYDRAULIC

(18) SENSOR AS

LEFT PUMP PRESSURE

M2G2

RCV: RETURN CHECK VALVE

Pn2

Ps2

Dr2

HH

PsM2

G4

JJ

Dr1

DrM

G3

PsM1

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

RIGHT MAIN PUMP OUTPUT

PILOT PUMP OUTPUT

LEFT MAIN PUMP OUTPUT

TRAVEL SPEED CONTROL CIRCUIT

SUPPLY LINE

DRAIN / RETURN LINE

LEFT AND RIGHT MAIN PUMP POWERSHIFT CIRCUIT

ATTACHMENT CONTROL CIRCUIT

RIGHT TRAVEL MOTOR CONTROL CIRCUIT

LEFT TRAVEL MOTOR CONTROL CIRCUIT

SWING MOTOR CONTROL CIRCUIT

BOOM CYLINDER CONTROL CIRCUIT

BUCKET CYLINDER CONTROL CIRCUIT

STICK CYLINDER CONTROL CIRCUIT

SWING BRAKE CONTROL CIRCUIT

LINE PATTERNS

P2 Pi1

P1

DR3 DR4

(TRAVEL)

P-IN

PSA2

Pi2

DR1

(SWING)

DR5

PSA1

T-OUT1

DR2

T-OUT2

DR6

(LOCK)

PAC

B1 B2A1 A2

P1 P2

(5) ACCUMULATOR GP

PILOT MANIFOLD

PL

(32) VALVE GP

A2

PRESSURE REDUCING

T

(BOOM/SWING)

S3

S1

M

Ps1

Pressure Line

Pilot / Load Sensing Pressure

(11) FILTER GP

PR

A1

KK

PILOT HYDRAULIC

Pn1

G

INOUT

A3

Pi

F

T

YY

G1 M1

(12) FILTER GP

RETURN OIL

PG PC

Pm

Callout Number

(Machine Location from

Component Locations Table)

(52) VALVE GP - CONTROL

138-1234

Drain / Return Lines

Component Group

CALLOUTS

Taps (Pressure, Sampling, Sensor - by letter)

Part Number

Component

Name

aR3 aR4 bR3 bR4 bL3 bL2 bL4 aL2

(20) SWITCH AS

PILOT PRESSURE

(24) TANK GP

HYDRAULIC OIL

(10) FILTER GP

CASE DRAIN

GG SOS

FF

(19) SENSOR AS

RIGHT PUMP PRESSURE

THIS SCHEMATIC IS FOR THE 320D AND 323D EXCAVATOR HYDRAULIC SYSTEM

ATTACHMENT: SYSTEM 3 PRIME

MEDIA NUMBER: RENR7157-07

SCHEMATIC PART NUMBER: 259-7473, CHANGE: 01, VERSION: HE

Components are shown installed on a fully operable machine with the key and engine off,

and with parking brake set.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations.

Page 7

STANDARD MACHINE COMPONENT LOCATIONS

VIEW ALL CALLOUTS

1

28

29

5

13

32

5

14

25

15

35

36

1

25

28

24

29

27

26

4

24

6

16

26

20

34

27

33

23

3

7

7

21

22

31

9

8

9

13

32

14

15

35

36

4

16

34

23

6

20

33

3

21

22

31

8

Page 8

NEGATIVE FLOW VALVE GP

VIEW ALL CALLOUTS

FWD

30

B

TOP VIEW

2

CC

DD

VIEW B

RIGHT SIDE VIEW

Page 9

MAIN PUMP AND FILTER

VIEW ALL CALLOUTS

EE

JJ

17

12

10

KK

FF

HH

18

11

GG

SOS

19

Loading...

Loading...