Page 1

QV-R40

INDEX

AUG. 2003

(without price)

QV-R40

R

Page 2

CONTENTS

SPECIFICATIONS ....................................................................................................................................... 1

BLOCK DIAGRAM ...................................................................................................................................... 4

TEST MODE ................................................................................................................................................ 5

PROGRAM VERSION UPGRADING .......................................................................................................... 6

1. How to confirm the program version ............................................................................................. 6

2. How to update the firmware............................................................................................................ 6

3. How to restpre the firmware ........................................................................................................... 7

4. How to install the firmware ............................................................................................................. 7

ADJ Tool ..................................................................................................................................................... 8

1. How to use USB ADJ Tool .............................................................................................................. 8

2. Lens Replacement ......................................................................................................................... 10

3. MAIN PCB Replacement............................................................................................................... 10

4. Current consumption .................................................................................................................... 11

VCOM DC ADJUSTMENT ........................................................................................................................ 12

THE COUNTERMEASURE FOR "SYSTEM ERROR" ............................................................................. 15

DISASSEMBLY ......................................................................................................................................... 17

EXPLODED VIEW ..................................................................................................................................... 23

PARTS LIST .............................................................................................................................................. 24

PRINTED CIRCUIT BOARDS ................................................................................................................... 25

SCHEMATIC DIAGRAMS ......................................................................................................................... 26

Page 3

SPECIFICATIONS

Image Files Format Snapshots: JPEG (Exif Ver.2.2); DCF (Design rulefor Camera File system) 1.0 standard;

DPOF compliant

Movies: AVI (Motion JPEG)

Recording Media 10 MB built-in Flash memory

SD Memory Card

MultiMediaCard

Image Size Snapshots: 2034 x 1712 pixels

2240 x 1680 pixels

1600 x 1200 pixels

640 x 480 pixels

Movies: 320 x 240 pixels

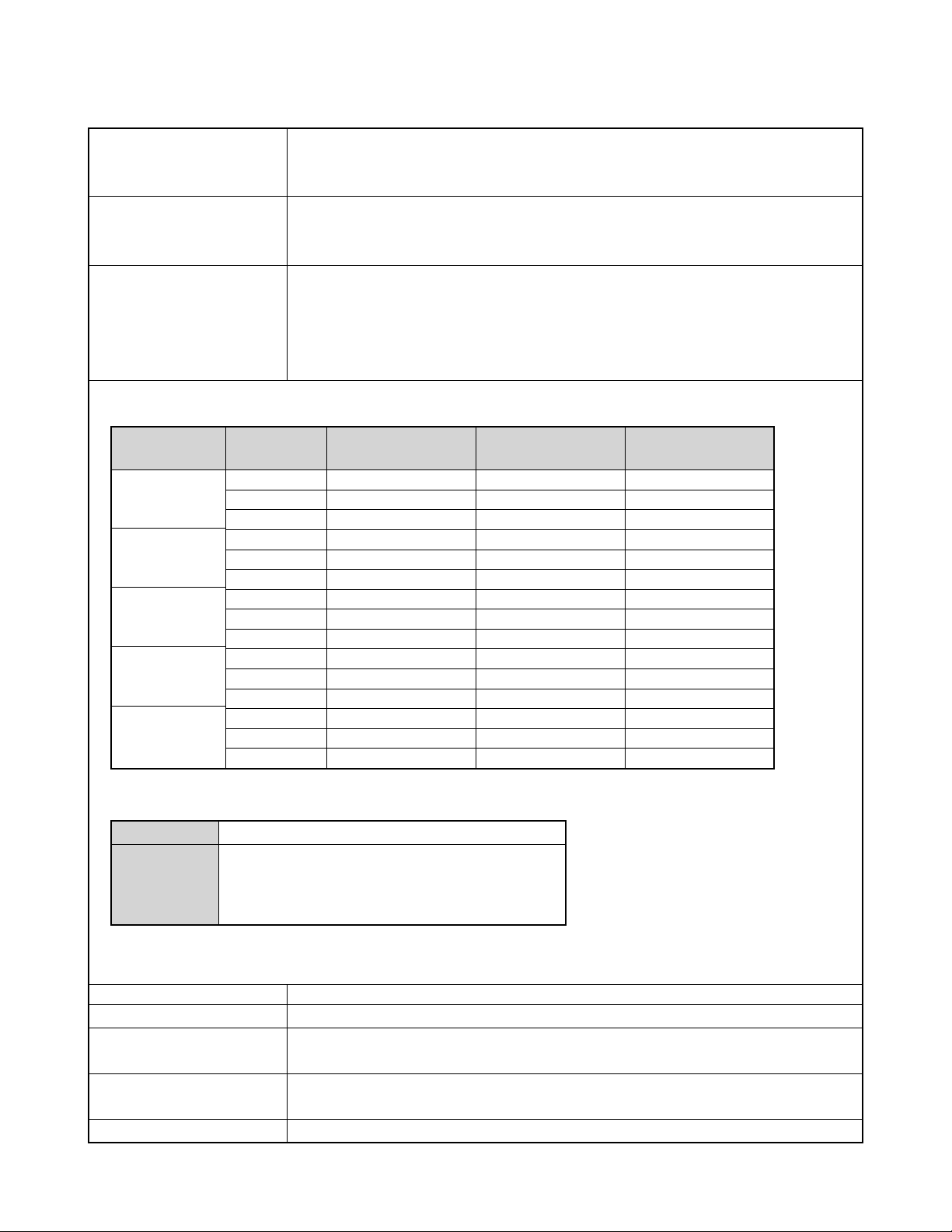

Approximate Memory Capacity and File sizes

• Snapshots

File Size

(pixels)

2304 x 1712

2240 x 1680

1600 x 1200

(UXGA)

1280 x 960

(SXGA)

640 x 480

(VGA)

Quality

Fine

Normal

Economy

Fine

Normal

Economy

Fine

Normal

Economy

Fine

Normal

Economy

Fine

Normal

Economy

ApproximateImage File

Size

1800 KB

1400 KB

1000 KB

1800 KB

1400 KB

1000 KB

1050 KB

710 KB

370 KB

680 KB

460 KB

250 KB

190 KB

140 KB

90 KB

Built-in flash memory

10MB

4 shots

6 shots

8 shots

4 shots

6 shots

8 shots

8 shots

12 shots

24 shots

13 shots

20 shots

35 shots

46 shots

61 shots

98 shots

SD Memory Card*

64MB

30 shots

40 shots

54 shots

30 shots

40 shots

54 shots

53 shots

79 shots

154 shots

82 shots

126 shots

220 shots

294 shots

386 shots

618 shots

• Movies (320 x 240 pixels)

Data Size

Recording Time

* Based on Matsushita Electric Industrial Co., Ltd. products. Capacity depends on card manufacturer.

* To determine the number of images that can be stored on a memory card of a different capacity, multiply the capacities in

the table by the appropriate value.

Delete Single-file, all files (with protection)

Effective Pixels 4.0 million

Imaging Element 1/1.8-inch square pixel color CCD

Lens/Focal Distance F2.8 (W) to 4.9 (T); f= 8 (W) to 24mm (T)

Zoom 3X optical zoom; 3.2X digital zoom (9.6X in combination with optical zoom)

One Movie: 30 seconds maximum

Total Movie Time:

60 seconds maximum (built-in memory)

410 seconds maximum (SD 64MB memory card)*

150KB/second max.

(Total pixels: 4.13 million)

(equivalent to approximately 39 (W) to 117 (T) for 35mm film)

— 1 —

Page 4

Focusing Contrast-type Auto Focus (AF Mode (AF Area: Spot or Multi), Macro Mode),

Infinity Mode; focus lock; manual focus

Approximate Focus Range Normal: 60 cm to ∞ (infinity) (2´ to ∞)

(from lens surface) Macro: 10 cm to 70 cm (3.9˝ to 27.6˝)

In the Macro mode, the optical zoom range is 1x to 1.2x.

Manual: Wide-angle:10 cm to ∞ (infinity)

(3.9˝ to ∞)

Telephoto: 60 cm to ∞ (infinity)

(23.6˝ to ∞)

Exposure Control Light Metering: Multi-pattern center-weighted, spot by CCD

Exposure: Program AE

Exposure Compensation: –2EV to +2EV (1/3EV units)

Shutter CCD electronic shutter; mechanical shutter, 1/8 to 1/2000 second

(Changes in accordance with recording mode and ISO sensitivity setting.)

• Shutter speed is different for the following Best Shot scenes.

Night Scene: 1 to 1/2000 second

Fireworks: 2 seconds (fixed)

Aperture Wide-angle: F2.8/4.8, auto switching Telephoto: F4.9/8.4, auto switching

White Balance Automatic, fixed (4 modes), manual switching

Self-timer 10 seconds, 2 seconds, Triple Self-timer

Built-in Flash Flash Modes: AUTO, ON, OFF, Red eye reduction

Flash Range: Wide Angle Optical Zoom: 0.4 to 2.9 meters (1.3´ to 9.5´)

Telephoto Optical Zoom: 0.4 to 1.7 meters (1.3´ to 5.6´)

(ISO Sensitivity: “Auto”)

Recording Functions Snapshot; Best Shot; Movie

Monitor Screen 1.6-inch TFT color LCD

84,960 pixels (354 x 240)

Viewfinder Monitor screen and optical viewfinder

Timekeeping Functions Built-in digital quartz clock

Date and Time: Recorded with image data

Auto Calendar: To 2049

World Time City; Date; Time; Summer time; 162 cities in 32 time zones

Input/Output Terminals AC adaptor terminal (DC IN 3V) USB port (Mini-B)

Power Requirements Two AA-size lithium batteries

Two AA-size rechargeable nickel-metal hydride batteries (HR-3UA)

AC adaptor (AD-C30)

Approximate Battery Life:

Type of Operation

Continuous Recording

Continuous Playback

• The above figures are approximations only.

• The above guidelines are based on the following battery types:

Rechargeable Nickel-Metal Hydride: HR-3UA SANYO Electric Co., Ltd.

Lithium: Energizer

• Battery life varies with brand.

The values noted above are approximate values until power fails at normal temperature (23°C (73°F)). The above does

not guarantee that you will be able to achieve this level of operation. Low temperatures shorten battery life.

AA-size Ni-MH Batteries HR-3UA

220 shots (110 minutes)

230 minutes

AA-size Lithium Batteries FR6

180 shots (90 minutes)

290 minutes

— 2 —

Page 5

Power Consumption DC 3V Approximately 3.8 W

Dimensions 88 (W) x 60.5 (H) x 32.7 (D) mm (3.5˝ (W) x 2.4˝ (H) x 1.3˝ (D))

(excluding projections)

Weight Approximately 160 g (5.6 oz)

(excluding batteries and accessories)

Bundled Accessories Rechargeable nickel-metal hydride batteries (HR-3UA); Charger unit (BC-5H); AC power cord;

USB cable; Strap; CD-ROM; Basic Reference

Rechargeable nickel-metal Rated Voltage: 1.2 V

hydride Battery (HR-3UA) Rated Capacitance: 2000 mAh

Operating Temperature

Range: 0 °C to 40 °C (32 °F to 104 °F)

Dimensions: 14.35 (diameter) x 50.4 (H) mm (0.56˝ (diameter) x 1.98˝ (H))

Weight: Approximately 29.0 g (1.0 oz) * Each battery

Special battery charger Power Requirement 100 to 240V AC, 0.08A, 50/60Hz

unit (BC-5H) : Inlet Type Output DC 1.2V, 550mA

Charging Temperature 0°C to 40°C (32°F to 104°F)

Chargeable Battery type

Full Charge Times Approximately 4 hours

Dimensions 71 (W) x 75 (H) x 28 (D) mm (2.8˝ (W) x 30˝ (H) x 1.1˝ (D))

Weight Approximately 75 g (2.6 oz)

Rechargeable nickel-metal hydride batteries (HR-3UA)

(excluding projections)

Special battery charger Power Requirement 100 to 240V AC, 0.08A, 50/60Hz

unit (BC-5H) : Plug-in Type Output DC 1.2V, 550mA

Charging Temperature 0°C to 40°C (32°F to 104°F)

Chargeable Battery type

Full Charge Times Approximately 4 hours

Dimensions 71 (W) x 75 (H) x 28 (D) mm (2.8˝ (W) x 3.0˝ (H) x 1.1˝ (D))

Weight Approximately 77 g (2.7 oz)

Power Supply

• Use only the special HR-3UA rechargeable nickel-metal hydride batteries to power this camera. Use of any other type of

battery is not supported.

• This camera does not have separate batteries for the clock. The date and time settings of the camera are cleared whenever

power is totally cut off (from both the batteries and AC adaptor). Be sure to reconfigure these settings after power is

interrupted.

LCD Panel

• The LCD panel is a product of the latest LCD manufacturing technology that provides a pixel yield of 99.99%. This means

that less than 0.01% of the total pixels are defective (they do not turn on or always remain turned on).

Lens

• You may sometimes notice some distortion in certain types of images, such as a slight bend in lines that should be straight.

This is due to the characteristics of lens, and does not indicate malfunction of the camera.

Rechargeable nickel-metal hydride batteries (HR-3UA)

(excluding projections)

Options

AC adaptor AD-C30

Soft case QSC-40OE, QSC-40LR, QSC-40BU, QSC-40BN

* Refer to the sales section for the details of the options.

— 3 —

Page 6

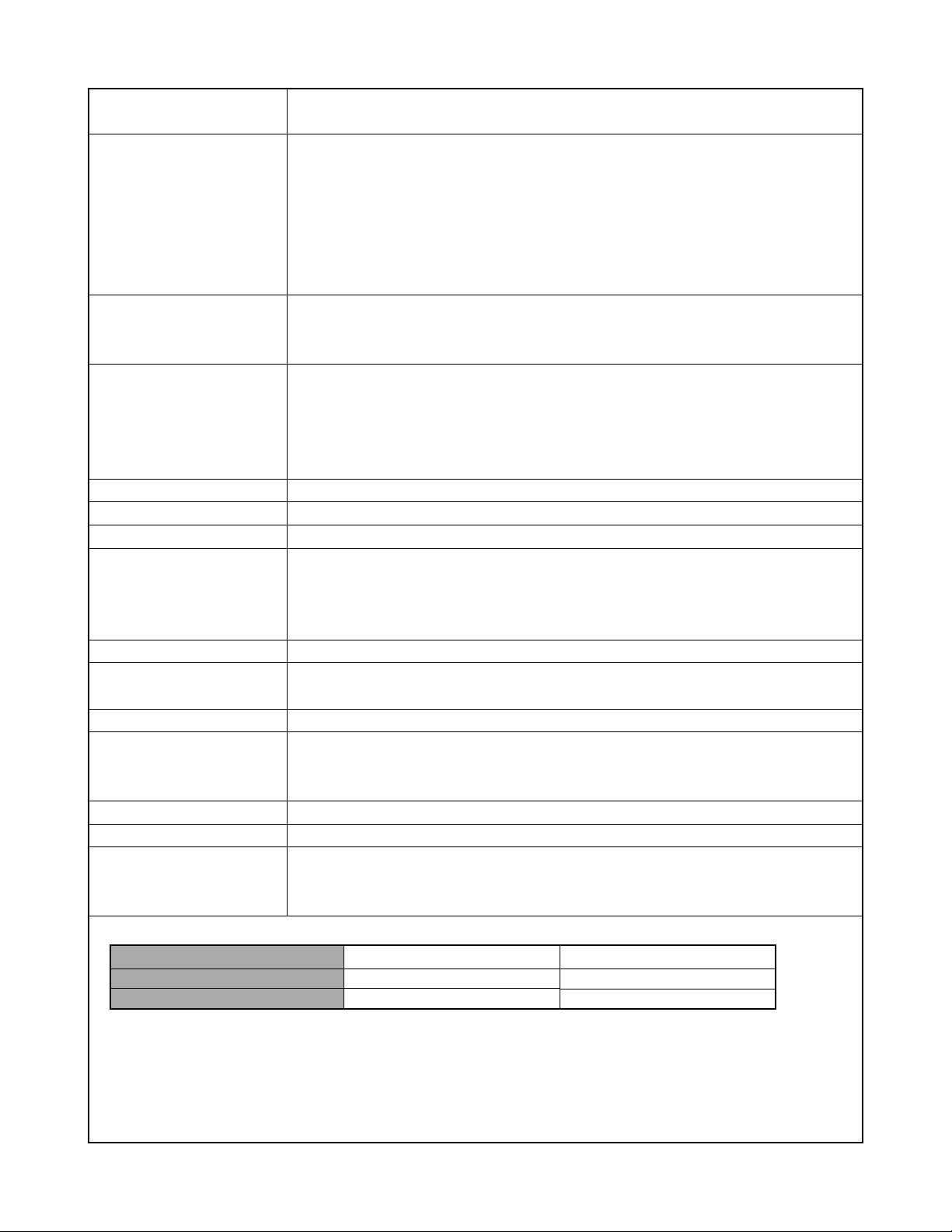

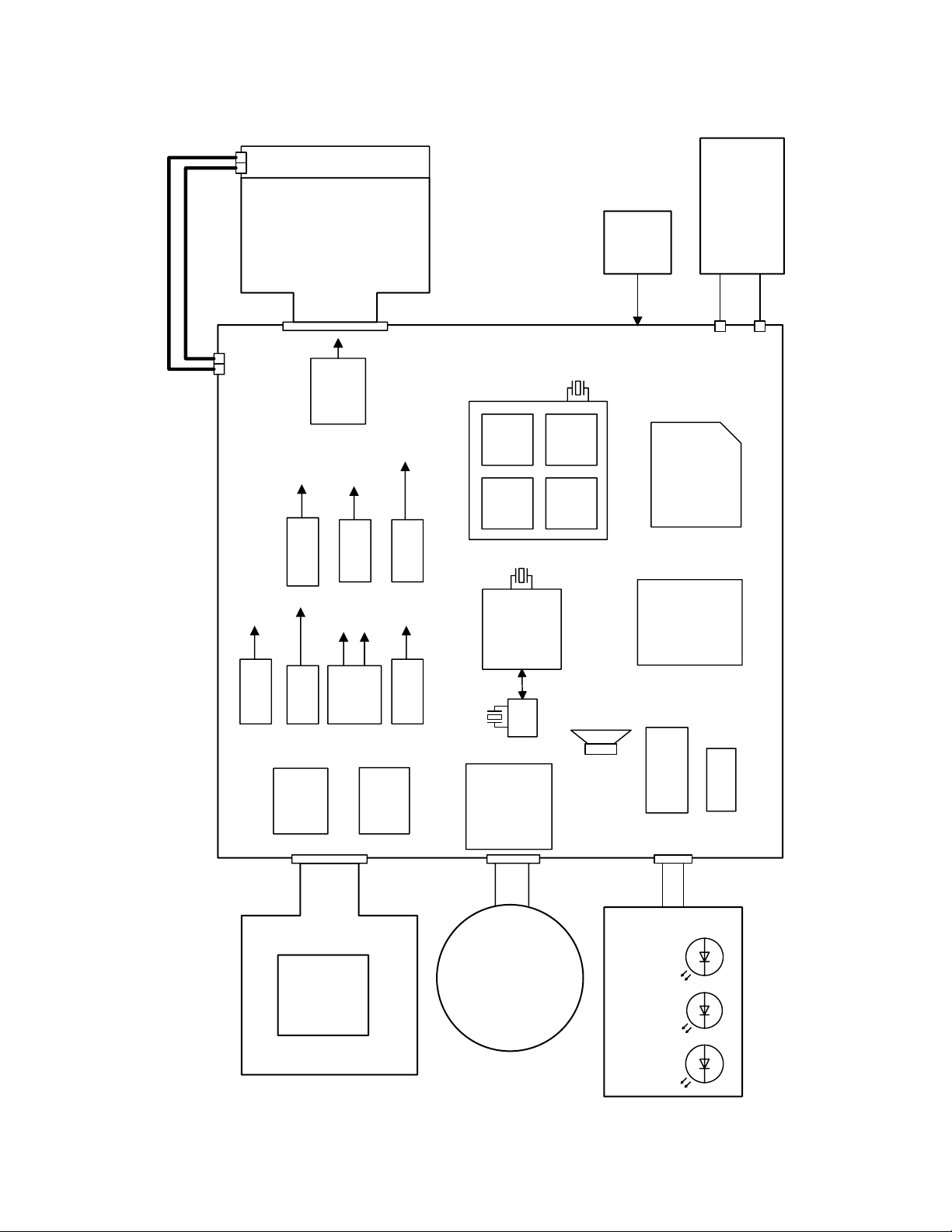

BLOCK DIAGRAM

MAIN-PCB

Motor Driver

M50235HP

DOWN

Converter

VCC1.5

BACK UP

Capacitor

KONIKA

Lens Unit

× 3

SD

CCD

4Mpix

1/1.8"

ICX406AQF-D

15.0 V

-7.5 V

5.0 V

3.3 V

15.0 V

-7.5 V

C-FPC

ST-UNIT

Dry-Battery

(3.3V-2.1V)

+

-

Adapter

3.0V

20pin

20pin

VCOM

Amp

NJM2125

R

Self Timer

G

R

WIDE,TELE

21pin

SHUTTER

POWER

BUZZER

R-LEDG-LED

33pin

15V

BL (LED × 2)

1.6" Digital I/F

LCD

VGH:15.0V

VSH:5.0V

VDD:3.0V

VCC15

VEE7.5

EVCC3.3

VCC5

VCC3.9

VCC3-1

VCC3-4

3.3V

1.5V

Stack MCM

HJ931602LP

13.5MHz

76C

SH

FLA

SH

SD

RAM

8bit micon

M37516M4H

4.0MHz

3.3V

32KHz

RTC

AD80069KCP RL

3.3V

V.Driver

CXD3440EN

CDS

SW

RIGHT

OK

DOWN

REC

LEFT

UP

MENU

PLAY

DISP

USC Jack

UP

Converter

UP

Converter

UP

Converter

UP

Converter

UP

Converter

UP

Converter

— 4 —

Page 7

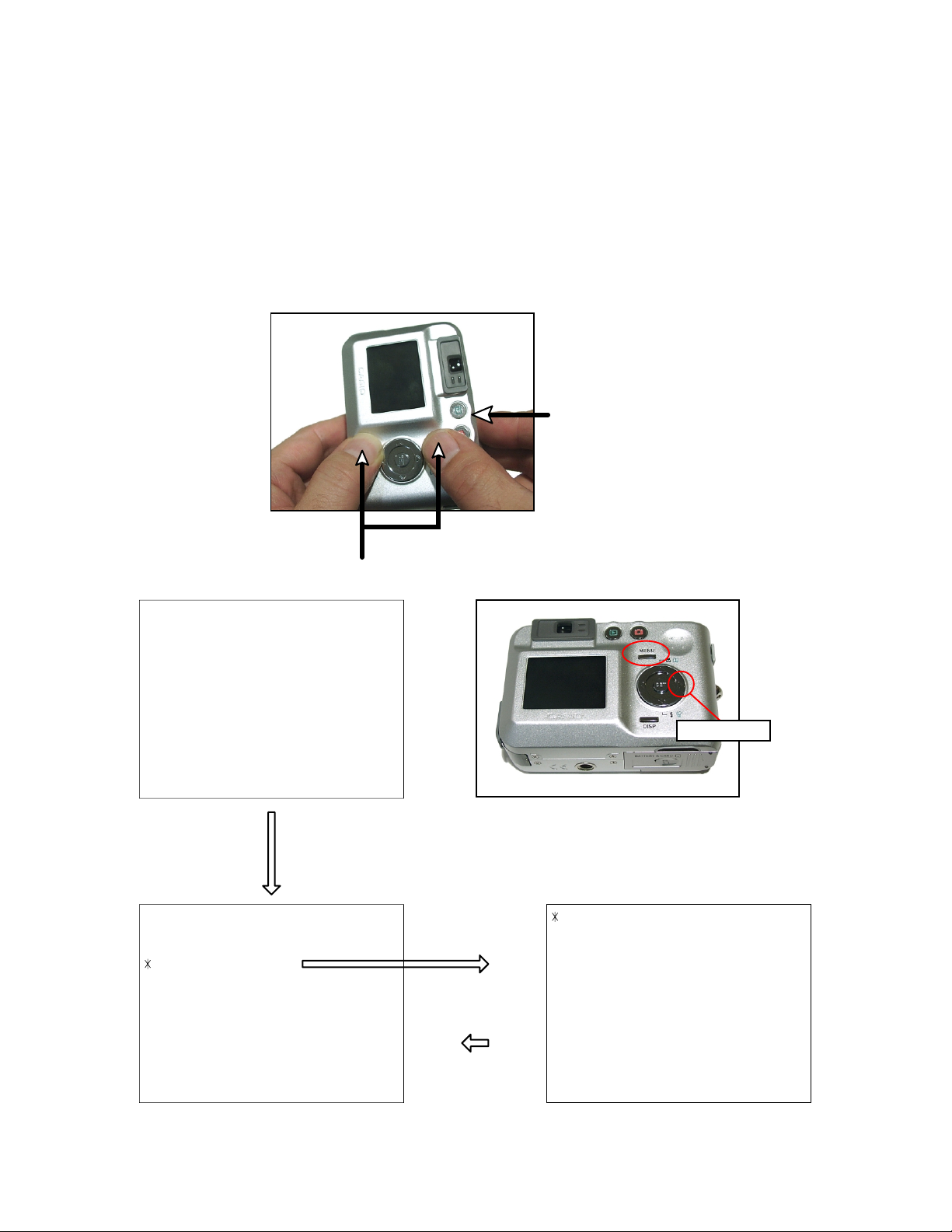

TEST MODE

Note: Do not perform the menu item unless explained here. (It may damage the internal data and

camera becomes unusable.)

Booting

To boot the test mode

While firmly pressing down both "MENU" and "DISP" buttons, Turn the power on.

2 "POWER" button

++ KX864 ++

PR : 03.07.08.11.35

LD : 2.00

MI : 94

"Right" button -> "Right" button "MENU" button

1 :VERSION INFO

2 :VIDEO OUT

3 :USB TCC TEST

4 :TEST MENU

5 :BEEP TEST

6 :TASK-2 TEST

7 :ROM UPDATE

8 :ADJ TEST

9 :REC-INFO

10 :TEST SCRIPT

11 :LAST MEMORY

1 "MENU" + "DISP" button

"SET" button

"MENU" button

"Right" button

1 :KEY CHECK

2 :VOCM CHECK

3 :MEMORY CHECK

4 :COLOR CHECK

5 :UGAIN CHECK

6 :VGAIN CHECK

7 :MESSAGE CHECK

8 :LED CHECK

9 :SW&JACK CHECK

10:MIC CHECK

— 5 —

Page 8

PROGRAM VERSION UPGRADING

■ Introduction

Update the program using an SD card.

Note: Make sure to use a fully charged battery.

MAIN PCB becomes unusable if power down or an error occurs during program transmission.

1. How to confirm the program version

■ The program version can be confirmed in the test menu (refer to the previous page).

■ Turn the power on while pressing MENU button.

The following program version can be found.

Check the LCD display.

2. How to update the firmware

1. Prepare the memory card which contains the software for upgrading QV-R40 firmware in the root directory .

firmware: QV-40.bin

The firmware is included in the service CD-ROM.

The location is as follows: QV/Soft/Adj-soft/Qvr40/FirmUP

2. Insert the above memory card in the camera and then set a fully charged battery in the camera.

3. While pressing MENU, press power switch. Keep pressing MENU until “PROGRAM UPDATE” appears in

the camera LCD.

• The following appears.

• The version for the firmware update software in the memory card appears at the bottom.

PROGRAM UPDATE

YES

NO

NEW VERSION IS

(Example)

VER 1.00

(As of August. 2003)

Note: This does not appear when the battery is low.

Make sure to charge the battery fully.

4. Align the white cursor to “YES” by the cross key of G and H, and press SET of the center of the cross key.

• “NOW LOADING” appears in the LCD and the update starts.

5. “COMPLETE” appears after the update finishes.

6. Remove the memory card after turning the power off once. Turn the power back on again while pressing

MENU, and check the version.

VER 1.00

(As of August. 2003)

7. If the version is correct, turn the power off.

8. Finally, check the operation by recording, playing back and deleting an image.

— 6 —

Page 9

3. How to restore the firmware

1. Prepare the following firmware restoration program and change its name as follows;

kx864r030708.hbn mercury.bin

The program is included in the service CD-ROM.

Location: QV/Soft/Adj-soft/Qvr40/Recover

2. Copy the above file to the root directory in the memory card.

3. Insert the memory card into the camera.

4. Set a fully charged battery in the camera.

5. Turn the power on while pressing the shutter release button.

The LED next to the optical finder changes from green/red blinks green blinks green lights.

6. When the green LED lights, the firmware restoration is finished.

Remove the battery.

7. Turn the power on again while pressing MENU and DISP buttons.

The firmware is successfully restored if the following version appears.

PR: 03.07.08.11.35

8. Finally, start the camera normally to check the operation by recording, playing back and deleting an image.

4. How to install the firmware

Initially, firmware is not installed in the PCB supplied from the parts center. Install the firmware into PCB

after replacing one as shown in the procedures below.

NOTE: The camera does not turn on (only LED lights green) if the firmware is not installed in the PCB.

<Writing the firmware 1>

1. Copy the following software to the root directly of the SD card.

kx864r030708.hbn

QV-R40.bin

2. Change the name “kx864r030708.hbn” to “mercury.bin”.

3. Insert the SD card into the camera.

4. While pressing the shutter release button, insert the batteries.

The LED next to the optical finder changes from “green/red blink” -> “green blinks” -> “green lights”.

5. After the LED lights green, turn the power off and remove the batteries.

<System Initialize>

1. Boot the test mode.

2. Press the [>] button twice and then press [MENU].

3. Select “7 : ROM UPDATE” and then press [SET].

4. Select “5 : SYSTEMINITIALIZE” and then press [SET].

5. When the following message appears, press [SET].

SYSTEMINITIALIZE

START….

PUSH OK KEY?

6. The system initialize is performed and the following error message appears.

“SYSTEM ERROR”

7. Turn the power off.

<Writing the firmware 2>

1. While pressing [MENU], turn the power on.

2. When “PROGRAM UPDATE” appears, select “YES” and then press [SET].

3. “NOWLOADING” appears while the firmware is updated.

4. When “COMPLETE” appears, the firmware update is complete.

5. Turn the power on and off to check if the camera normally functions. If there is no problem, the firmware

update is successful.

— 7 —

Page 10

ADJ Tool

■ Introduction

Make sure to perform the adjustment when replacing the lens unit or the MAIN PCB.

The necessary software, driver and setting are explained in using USB ADJ Tool "adj864.exe".

Note that the tool, drivers etc. are available only for Windows.

1. How to use USB ADJ Tool

1-1. Prepare the necessary software, driver and DLL file.

(1) Prepare the following three files.

• Commom test driver for CASIO/PENTAX

[testmode_pentax_casio] folder uusbd.dll

uusbd.inf

uusbd.sys

• ADJ data read/write tool "adj864.exe2"

• Commom DLL for USB test "uusbd.dll"

(2) Place the commom test driver for CASIO/PENTAX in an appropriate place.

(3) After downloading the common DLL for USB test, copy it to the same directory as that of the ADJ data

read/write tool or under "c:windows/system.

1-2. Set the camera so that it recognizes the USB test mode.

(1) Enter the test mode and then the initial test selection screen.

Turn the power on while pressing both "MENU" and "DISP".

Press "RIGHT", "RIGHT" and "MENU.

(2) Move the cursor to "3:USB TCC TEST" and press "SET".

(3) Move the cursor to "1:USB TCC ON" and press "SET".

(4) Press "MENU" button and leave the test mode.

(5) This enables the camera to recognise the USB test mode flag.

(6) When the USB test mode flag is ON, the test menu appears first when the camera power is turned on.

* If the USB test mode flag should be OFF, set "2: USB TCC OFF" in the test menu.

1-3. Install the USB driver for the USB test mode in the computer.

(The following is an example using the Windows Me.)

(1) Prepare the USB driver for the USB test mode.

(2) Turn the camera power on which is set in the USB test mode and let it enter the USB test mode as

shown in 1-2.(the test menu appears right after the power is turned on).

(3) Connect the camera in the above status to the computer by the USB cable.

(4) "A wizard for the new hardware" appears.

(5) Check "Designate the place for the driver (for users with sufficient knowledge)" and press "Next".

(6) Check "Search for the optimum driver for the device (recommended)".

(7) Check "Designate the place to search" , designate the place which contains "inf" file in the driver by

pressing "Reference" button, and then press "Next" button.

(8) When "Universal USB Driver (VMEM manufacturer's name)" appears upon message "Searching for

the driver file for the following devices" , press "Next" button.

(9) The file copy starts.

(If a message "uusbd.Inf cannot be found" appears during the file copy, designate the same place as in

the step 7).

(10) Press "Complete" button.

(11) Right-click "My computer", select "Property" and open "Device manager". If "Universal USB Driver

(VMEM manufacturer's name)" can be found in "USB device for UUSBD", the computer has successfully

recognised the driver.

(12) The test driver can be used for both CASIO/PENTAX. Installing the test driver into either one enables

the other one to recognise it.

— 8 —

Page 11

NOTE: How to uninstall the USB driver for the USB test mode

• Connect the camera while in the USB test mode to the computer so that the computer recognises the

camera.

• Right-click "My computer", select "Property" and open "Device manager".

• Select "USB device for UUSBD" , and then "Universal USB Driver (VMEM manufacturer's name)".

• Press "Delete" button and delete the driver.

• When using Windows98/98SE/Me, delete the following three files;

(NOTE! Do NOT delete "usbd. inf" and "usbd.sys", whose names are much alike the following.)

C:windows / inf / uusbd.inf

C:windows / inf / other / KashiwanoUUSBD.inf

C:windows / system32 / drivers / uusbd.sys

• The driver has been successfully deleted.

1-4. Use the USB ADJ Tool

(1) Prepare ADJ data read/write tool "adj864.exe".

(2) Copy the common DLL for USB test to the same directory as that of the ADJ data read/write tool

"adj864.exe" or under "c:windows / system".

(3) Turn the camera power on which is set in the USB test mode and let it enter the USB test mode (the test

menu appears right after the power is turned on).

Connect the camera to the computer by the USB cable.

(4) Boot "adj864.exe" and use it as follows;

• Read ADJ data from the camera. Press "read from the camera".

• Write ADJ data into the camera. Press "write into the camera".

• Save ADJ data which is read. Press "File" and "Save", and save it with an appropriate name.

• Open ADJ data which is saved. Press "File" and "Open", and open the necessary file.

— 9 —

Page 12

2. Lens Replacement

Make sure to perform the following procedure after replacing the lens.

A floppy disk with the lens data is bundled in the spare parts of the lens unit.

1 Enter the TEST mode.

1.Turn the power on while pressing both "MENU" and "DISP" buttons.

2.Press "RIGHT" button, "RIGHT" button and "MENU" button while

the program version is displayed.

3.Select "3.USB TCC TEST", and press "SET" button.

4.Select "1. USB TCC ON", and press "SET" button.

5.Turn the power OFF.

2 Connect the camera to the computer by the USB cable.

3 Boot "adj864.exe" .

4 Click "ADJ ALL READ", and display the data on the "adj864.exe".

5 Find the No.430, "V-COM DC".

6 Write down this value(data).

7 Replace the Lens unit.

8 Perform the above 1 to 3

9 From "File/Open", open the bundled floppy disk, and transfer the data to

the "adj864.exe".

0 Find the No.430,"V-COM DC"

A Change the data to the former value.(Refer to 6).

B Click "WRITE" button of "ADJ ALL".

C After adjustment, change "1. USB TCC ON" to "2. USB TCC OFF".

5

9

3. MAIN PCB Replacement

Make sure to backup ADJ DATA before replacing the MAIN PCB.

Firmware is not installed in spare parts.

1 Enter the TEST mode.

1. Turn the power on while pressing both "MENU" and "DISP" buttons.

2. Press "RIGHT" button, "RIGHT" button and "MENU" button while the program version is displayed.

3. Select "3.USB TCC TEST", and press "SET" button.

4. Select "1. USB TCC ON", and press "SET" button.

5. Turn the power OFF.

2 Connect the camera to the PC by the USB cable.

3 Boot "adj864.exe" .

B

— 10 —

Page 13

4 Click "ADJ ALL READ", and display the data on the "adj864.exe".

5 Save the data.

6 Replace the MAIN PCB.

7 Writing the Firmware

Write the firmware into a spare part after replacing one.

NOTE: If a battery is inserted without the firmware, only LED lights

green and the camera does not operate.

1. Write the firmware

a)

Copy the following restoration software and the firmware to a SD card.

Restoration software: kx864r030708.hbn

Firmware: QV-R40.bin

b) Copy both the restoration software and the firmware into the root

directory of the SD card.

c) Change the name of the restoration software to "mercury.bin".

d) Insert the SD card.

e) While pressing the shutter key, insert a fully charged battery.

f)

The LED changes from "green/red blink" "green blinks" "green lights".

g) After the LED lights green, the firmware is written.

h) Remove the battery.

2. Initialize the system

a) Enter the TEST mode.

b) Select "7:ROM UPDATE" and press SET button.

c) Next, select "5:SYSTEM INITIAL" and press SET button.

d) The following message appears.

SYSTEM INITIALIZE

START

...

PUSH OK KEY?

e) Press SET button and System is initialized.

But the message, "SYSTEM ERROR", still appears on the monitor.

3. Write firmware again

Refer to the "How to update the firmware" on page 6.

Write the firmware.

If the TEST mode boots automatically, change "USB TCC ON" to

"USB TCC OFF".

8 Perform the above 1 to 3.

9 Open the file which is saved above, and display the data on the

"adj864.exe".

0 Click "WRITE" button of "ADJ ALL".

A After adjustment, change "1. USB TCC ON" to "2. USB TCC OFF".

5

4

9

4. Current consumption

(1) Current consumption (DC in = 3.00 ± 0.05 [V])

• Make sure that current consumption is less than 450 mA in PLAY mode.

• Make sure that current consumption is less than 700 mA in REC mode.

• Make sure that current consumption is less than 500 µA when power is turned OFF.

(2) The battery indicator changes according to the voltages as follows.

• DC in = less than 2.40 ± 0.02V: (PLAY mode)

• DC in = less than 2.33 ± 0.02V: (PLAY mode)

• DC in = less than 2.24 ± 0.02V: (PLAY mode)

— 11 —

0

Page 14

VCOM DC ADJUSTMENT

■ Purpose

Readjust the VCOM value to minimize the flicker of the LCD after replacing the LCD or the main PCB.

■ Necessary tools

1. Camera (Charge its battery fully)

2. Photo diode (S2281-01) : See Fig 1.

3. Photo sensor amp (C2719) : See Fig 2.

4. BNC-BNC cable (E2573) x 2 : See Fig 3.

5. 9-volt alkaline battery (6LR61Y) x 2 : See Fig 4.

6. Oscilloscope

■ Preparation

1. The three tools can be obtained from the following global site.

Photo diode (S2281-01)

Photo sensor amp (C2719)

BNC-BNC cable (E2573)

www.hamamatsu.com/

2. 9-volt alkaline battery is a standard one, but can be obtained from the following global site as well.

www.panasonic.co.jp/global/

Fig1 Photo Diode (S2281-01) Fig2 Photo Sensor Amp (C2719)

Fig3 BNC-BNC Cable (E2573) Fig4 6LR61Y

— 12 —

Page 15

■ Procedure

1. Camera setting

a) Turn the power on while pressing MENU and DISP.

After pressing “Right” key twice, press MENU.

Figure (a) appears.

b) Select “8 : ADJ_TEST” and then press SET.

(See Figure (b).)

c) Next, select “1. VCOM” and then press SET.

(See Figure (c).)

Figure (a)

1 :VERSION INFO

2 :VIDEO OUT

3 :USB TCC TEST

4 :TEST MENU

5 :BEEP TEST

6 :TASK-2 TEST

7 :ROM UPDATE

8 :ADJ TEST

9 :REC-INFO

10 :TEST SCRIPT

11 :LAST MEMOR

Figure (b)

1:VCOM 7f

2:SHUT

3:AWB

.

.

.

Figure (c)

VCOM ADJ START?

<<START>>

PUSH OK KEY?

<<STOP>>

PUSH PW KEY?

Y

Figure (d)

d) Pressing SET causes the right figure to appear.

(See Figure (d).)

This value is an example and differs by products.

OK -> Register Write

VCOM = 0x7f

2. Connecting the TOOL

a) Place two 9-volt alkaline batteries in C2719.

b)

Connect the output terminal of C2719 to the channel terminal of the oscilloscope by the BNC-BNC cable.

c) Connect the input terminal to the Photo Diode by the BNC cable.

d) Turn the oscilloscope and C2719 on.

* Pull the ON/OFF switch of C2719 this way and raise/lower it. (See below Figure.)

— 13 —

Page 16

3. Measurement

a) Connect S2281-01 to the camera’s LCD monitor (see below).

AC Waveforms appear on the monitor screen of the oscilloscope.

* Change the Rf range of C2719 in case the range does not match.

Photo diode

S2281-01

INPUT OUTPUT

Oscilloscope

Photo sensor amp

CAMERA

BNC-BNC cable

LCD

Minimize the

ripple components

b) After AC waveforms of the oscilloscope appear , minimize it by pressing the camera’s up/down buttons

(see the picture).

Make sure to visually check if it has been minimized.

"Up" button

"Down" button

After it has been minimized, press SET key.

The screen in the right figure appears and the new VCOM

is written (VCOM adjustment is finished.).

This value is only an example, and differs by products.

Return to the previous display by pressing MENU or PW key.

OK -> Register Write

VCOM = 0X80

LAST MEMORY SET!

— 14 —

Page 17

THE COUNTERMEASURE FOR "SYSTEM ERROR"

■ Purpose

System error may occur when the battery is removed while data is written to the internal memory.

If "SYSTEM ERROR" appears on the monitor, execute the following operation.

1. Back up the ADJ DATA.

2. Initialize the system.

3. Write the firmware.

4. Initialize the system again in order to initialize ADJ DATA.

5. Write the firmware again.

6. Return the backed up ADJ DATA.

7. Check the operation in the test mode.

■ PROCEDURE

1. Back up the ADJ DATA(Refer to the page 10 to 11).

a) Enter the TEST mode.

Turn the power on while pressing both "MENU"and "DISP" buttons.

Press "RIGHT" button, "RIGHT" button and "MENU" button.

b) Select "3.USB TCC TEST", and press "SET" button.

c) Select "1.USB TCC ON", and press "SET" button.

d) Turn the power OFF.

e) Connect the camera to the PC by the USB cable.

f ) Boot "adj864.exe".

g) Click "ADJ ALL READ", and display the data on the "adj864.exe".

h) Save the ADJ data.

Proceed to the next operation even if ADJ DATA cannot be saved.

2. Initialize the system.

a) Enter the TEST mode.

b) Select "7:ROM UPDATE" and press SET button.

c) Next, select "5:SYSTEM INITIAL" and press SET button.

d) The following message appears.

SYSTEM INITIALIZE

START

PUSH OK KEY?

e) Press SET button and System is initialized.

But the message, "SYSTEM ERROR", still appears on the monitor.

3. Write firmware.

Refer to the "How to update the firmware" on page 6.

Write the firmware.

If the TEST mode boots automatically, change "USB TCC ON" to "USB TCC OFF".

4. Initialize the system again.

Operation is the same as 2.

Proceed to the next operation even if "SYSTEM ERROR" appears on the monitor.

5. Write the firmware again.

Operation is the same as 3.

...

— 15 —

Page 18

6. Return the backed up ADJ DATA.

a) Select "USB TCC ON".

b) Connect the camera to the PC by the USB cable.

c) Boot "adj864.exe".

d) Open the file which is saved above and display the data on the "adj864.exe".

e) Click "WRITE" button of "ADJ ALL".

7. Operation check

Boot TEST MODE.

Select "8:ADJ TEST" and press SET button.

a) When ADJ DATA can be backed up;

If both "3:AWB" and "6:KIZU" are OK, adjustment is completed.

In case "3:AWB" or "6:KIZU" is not OK, repeat the operation 2 and 3.

b) When ADJ DATA can not be backed up;

"AWB" and "KIZU" are "????".

Check the images in the REC mode and Play mode.

Adjustment is completed if the camera works properly.

After check, boot TEST mode again.

Select "3.USB TCC TEST", and press "SET" button.

Select "2.USB TCC OFF", and press "SET" button.

Replace the Main PCB if the camera does not recover.

— 16 —

Page 19

DISASSEMBLY

■ There are several types of screws. Make sure to use the

correct ones.

■ It is a good idea to sort them as shown in the figure when

disassembling.

1. Remove the batteries.

■ Removing the rear panel

2. Remove six screws.

Screws (S3)

Screws (S4)

3. Remove the rear panel.

4. Remove the connector cover and the AC jack cover.

Screws (S2)

Screws (S3)

AC jack cover

Rear panel

Connector cover

— 17 —

Page 20

5. Remove one screw (S1) and then the strap board.

Screw (S1)

■ Removing the front panel unit

6. Remove two screws (S2).

Strap board

Screws (S2)

7.

While opening the case in the direction of the arrow, remove the electronic block from the front panel unit.

NOTE: Make sure that the hooks are snapped together

when assembling.

Hooks

Make sure to discharge the strobe condenser when

removing the front panel.

Electronic block

Front panel unit

— 18 —

Page 21

■ Disassembling the front panel unit

8. Remove two screws (S3) and then remove the tripod sock.

Screws (S3)

9. Remove four screws (S5) and then remove the cam ring and the upper case.

Tripod sock

Screws (S5)

Screws (S5)

10. Remove two screws (S2) and then remove the center case.

Screws (S2)

Upper case

Cam ring

Center case

— 19 —

Page 22

■ Removing the LCD

11. Remove two screws (S6).

12. Unsolder the power cord.

13. Remove the connector.

14. Remove the LCD unit.

Screws (S6)

Connector

NOTE: Make sure to insert the connector tightly when

assembling, or the display will be defective.

Red cord Black cord

■ Removing the PCB

15. Unsolder the earth board and the clamp board.

Earth board

NOTE: Temporarily fixing the earth board by a screw

makes it easier to solder when assembling.

Clamp board

— 20 —

Page 23

16. Unsolder two battery plates.

17. Unsolder the earth cord.

18. Remove the connector.

19. Remove two screws (S7).

Battery plates

Earth cord

Screws (S7)

20. Remove the connector.

21. Remove the PCB.

Connector

PCB

■ Disassembling the battery case

22. Remove one screw (S8) and then remove the battery case.

Screw (S8)

— 21 —

Battery case

Page 24

23. Remove one screw (S9) and then disassemble the battery case (See the figures below for the position of

the hooks).

Screws (S9)

Battery cover

■ Removing the lens unit

24. Remove two screws (S10) and then remove the lens unit.

Strobe unit

(with CAPA holder)

Screws (S10)

Lens unit

NOTE: Insert the convex portion into the concave portion tightly as shown in the figures below

when assembling.

C

A

B

Insert A into B tightly. Insert C into D tightly.

— 22 —

D

Page 25

EXPLODED VIEW

1

2

4

3

5

6

7

8

9

S2

S2

10

12

13

17

20

Battery

16

S1

15

14

11

S3

S3

18

S3

19

S2

S4

S2

S3

— 23 —

Page 26

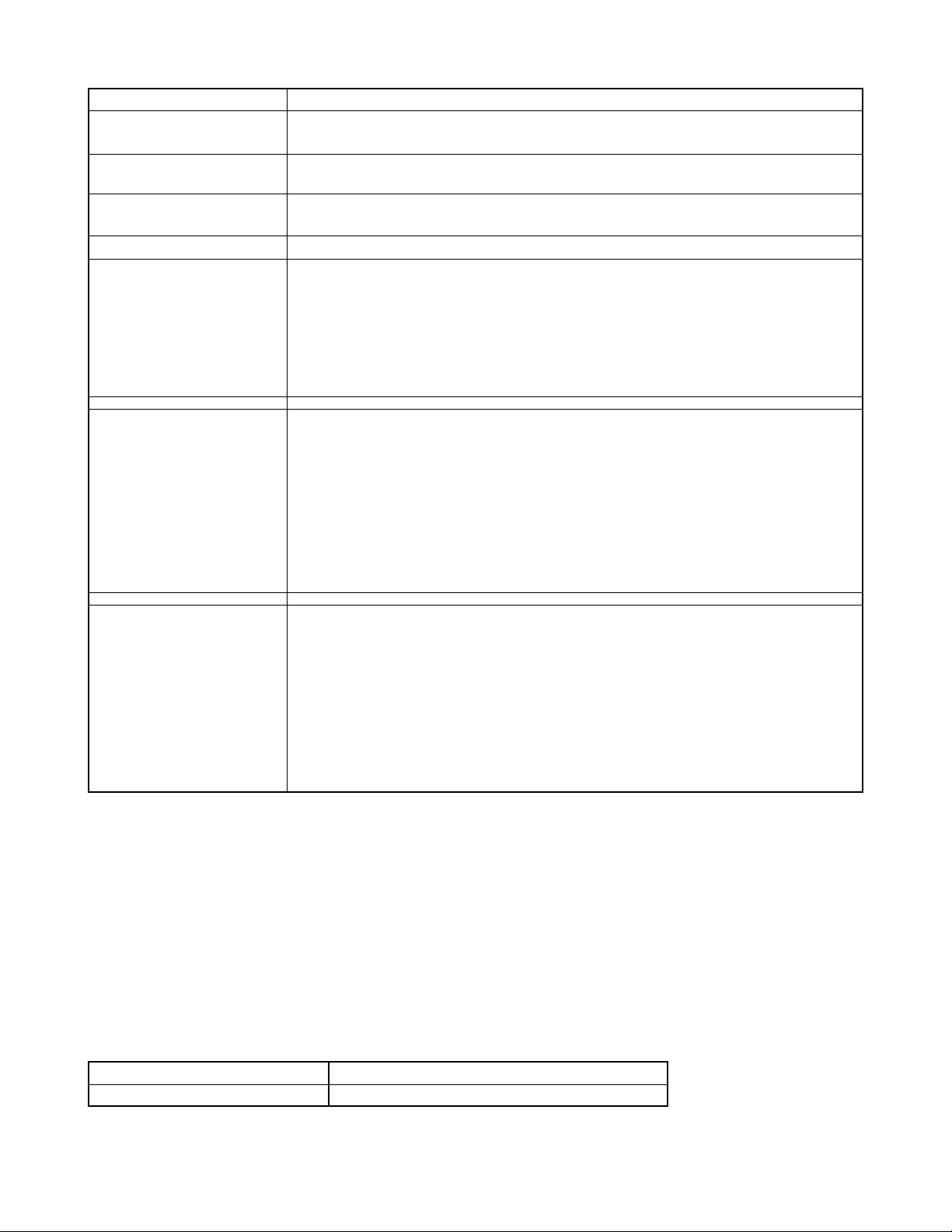

PARTS PRICE LIST

QV-R40

N Item Parts Code Parts Name Specification QTY Price R Remark

Code

N 1 10133290 PCB ASSY TK-RJK505187*001 1 DY A

N 2 10127443 COVER/JACK RJK504662-001V01 1 AE C

N 3 10126467 STRAP BOARD RJK504626-001V01 1 AK C

N 4 10126481 STROBE UNIT XEST-K864-1 1 CM C

N 5 10135336 EARTH BOARD RJK504747-001V01 1 AA C

N 6 10133294 BATTERY BOX ASSY TK-RJK505189*001 1 BJ C

N 7 10133299 LENS UNIT TK-RJK505195*001 1 DY A FD attached

N 8 10133296 UPPER CASE ASSY TK-RJK505191*001 1 AT C

N 9 10133297 FRONT PANEL ASSY TK-RJK505192*001 1 CY B

N 10 10126471 GRIP RJK504661-001V01 1 AI C

N 11 10134229 TAPE RJK504706-001V02 1 AA C

N 12 10126466 CAM RING RJK504660-001V01 1 BE C

N 13 10126478 TRIPOD SOCK RJK504763-001V01 1 AM C

N 14 10133295 CENTER CASE ASSY TK-RJK505190*001 1 BX B

N 15 10127445 COVER/CONNECTOR RJK504663-001V01 1 AE C

N 16 10127436 HOLDER/CAPACITOR RJK504693-001V01 1 AB C

N 17 10133293 COVER/BATTERY ASSY TK-RJK505188*001 1 AR B

N 18 10133292 REAR PANEL ASSY TK-RJK505183*001 1 CM B

N 19 10135338 LABEL/RATING RJK504669-001V01 1 AA C

N 20 10133291 LCD ASSY TK-RJK505182*001 1 DG B

- S1 10086282 SCREW RJK502970-001V01 2 AA C

- S2 10086285 SCREW RJK502971-001V01 5 AA C

N S3 10131119 SCREW RJK502970-004V01 2 AA C

- S4 10086284 SCREW RJK502970-003V01 5 AA C

ACCESSORY

N - 10136902 CD-ROM CK864DCA01R 1 AH C

- - 10090421 CABLE/USB UC-K861-LG10 1 AQ C

N - 10136903 AC CORD CBL-K864-AC-JU 1 AI C Blade type

N - 10136905 AC CORD CBL-K864-AC-EU 1 AJ C Euro type

N - 10136906 AC CORD CBL-K864-AC-UK 1 AX C UK type

N - 10136907 AC CORD CBL-K864-AC-CH 1 AJ C China type

N - 10126486 CHARGER NC-MDR01JUCA 1 BV C *1

N - 10126488 CHARGER NC-MDR01WCA 1 BV C *2

N - 10127402 NI-MH BATTERY HR-3U-KSO-4E 2 AR B

- - 10090412 STRAP ST-K861 1 AF C

*1: Blade type AC cord is built-in.

*2: AC cord is not built-in.

- 24 -

Page 27

PRINTED CIRCUIT BOARDS

MAIN PCB

— 25 —

Page 28

MAIN PCB (1/2)

SCHEMATIC DIAGRAMS

— 26 —

Page 29

MAIN PCB (2/2)

— 27 —

Page 30

CASIO TECHNO CO.,LTD.

Overseas Service Division

6-2, Hon-machi 1-Chome

Shibuya-ku, Tokyo 151-8543, Japan

Loading...

Loading...