Page 1

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM)

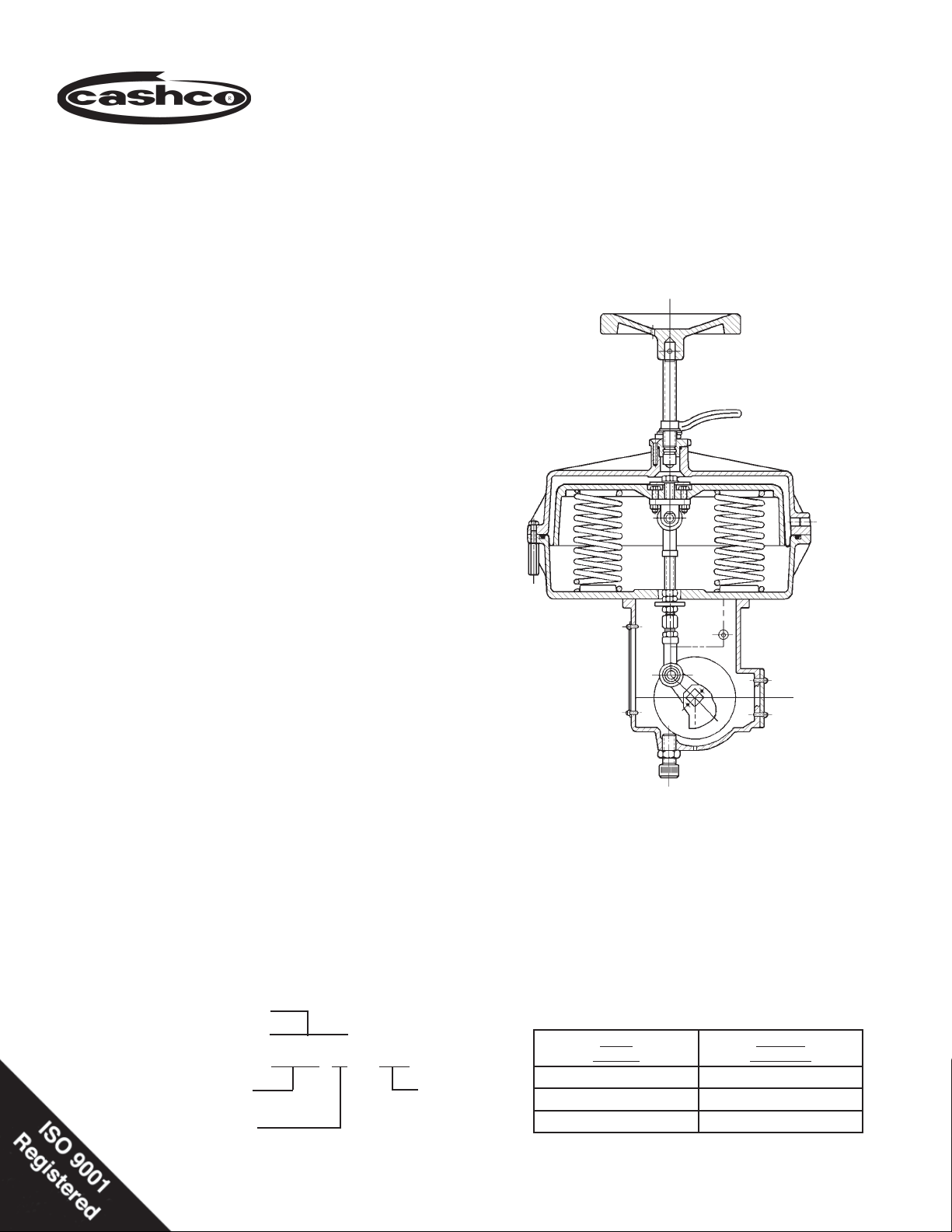

MODEL 148

SPRING/DIAPHRAGM ROTARY ACTUATOR

I. DESCRIPTION AND SCOPE

Models 148D and 148R are multi-spring, single

acting, spring opposed, rotary ac tu a tors used with

Cashco rotary control valves. Re gard less of fi nal

installed fail ure action, the ac tu a tor is always pressurized on “top” of the traveling diaphragm plate.

Cashco has adopted a convention as follows in

identifying its rotary actuators:

“D” = Direct Action = ATC-FO Action

“R” = Reverse Action = ATO-FC Action

IOM-148

12-13

SECTION I

Model 148 actuator is fi eld reversible by arrange-

ment of actuator with respect to valve stem and with

respect to valve plug/disc orientation. Some dis as sem bly is required, but no new parts are required.

Reference the technical bulletin of the valve body

these actuators are unitized with for operating/

installation/se lec tion specifi cations; i.e. available

bench settings, strokes, etc.

Figure 1

Model 148 Actuator

SECTION II

II. MODEL NUMBERING

The basic Model Number identifi es the actuator size and action. To identify a unique Model Number, another series

of 2-character modifi ers is added to the basic number. This number will identify which basic valve body the actuator

may be used on and which set of range springs is utilized. See Table 1.

Basic Model No.

148 in2 size

Reverse Action

(ATO-FC)

1 4 8 R - 0 1

Modifi er

Valve

Product

Ranger QCT -00 through -09

Premier EZO -00 through -09

Premier Unlined -00 through -09

Modifi er

Series No.

Page 2

TABLE 1

ACTUATOR MODEL NO. vs. VALVE BODY MODEL

(Model 48 included for clarity)

Full Actuator Model No.

Basic

Actuator

Model No.

48R

or

48D

148R

or

148D

148R

or

148D

148R

or

148D

* Metric body size in parenthesis.

III. INSTALLATION

Available

Bench Settings

Modifi er

Number

-01 5-15 (.34-1.03) 20 (1.4)

-01 5-13 (.34-0.90) 20 (1.4)

-02 10-26 (.69-1.79) 36 (2.5)

-03

psig (Barg) psig (Barg)

7.5-

19.5

(.52-1.34) 27 (1.9)

Air Supply

Pressure

SECTION III

Unitized Products*

1”-2” (DN25-50) Ranger QCT

3”-4” (DN80-100) Premier EZO or

Premier Unlined

3”-4” (DN80-100) Ranger QCT

6” (DN150) Premier EZO

or Premier Unlined

4”-8” (DN100-200) Ranger QCT,

10” (DN250) Premier EZO

8” (DN200) Premier EZO,

8”-12” (DN200-300) Premier

Unlined

A. Orientation:

1. Recommended actuator major axis ori en ta tion

with any model of Cashco rotary control valve

is upwards with the valve in a horizontal pipe

and the valve stem also horizontal; i.e. position

“A” for ATO-FC, or position “B” for ATC-FO.

2. Both Ranger QCT and Premier EZO/Unlined

control valve products incorporate an ex tend ed

Position A

Position B

valve body bon net and a mounting yoke to

allow the actuator to be far enough away

from the valve body or mounting fl anges to

in cor po rate a minimum of 2" (50 mm) thickness of in su la tion. It should not be necessary

to install thermal insulation to any portion of

Model 148 actuator. The maximum ambient

temperature for installation is 180°F (83°C);

the minimum ambient temperature is -20°F

(-29°C).

Position A

Position B

FIGURE 2: Mounting position of Ranger QCT to Model

148 Actuator with Model 73N-B P/P Positioner.

2

FIGURE 3: Mounting position of Ranger QCT to Model

148 Actuator with Models 9540R P/P or Smart Positioner’s PS2 and 991.

IOM-148

Page 3

Position A

Position A

Position B

FIGURE 4: Mounting position of Premier EZO or Pre-

mier Unlined to Model 148 Actuator with Model 73N-B

P/P Positioner.

3. A 1/4"–NPT female connection for pneumatic

LOAD is located on the side of the actuator’s

upper diaphragm casing near the casing

fl ange joint. Reference specifi c Ranger-TB or

Pre mier-TB for location of the connection.

4. Reference the valve body instructions — IOMRang er, IOM-Premier for ad di tion al instructions on in stall ing unit in the process piping.

B. Air Supply:

1. Recommendation is that a desiccant dried,

instrument quality air supply be used. Such

a supply is recommended for outdoor in stal la tions, and is required in areas of freezing

weather conditions.

Position B

FIGURE 5: Mounting position of Premier EZO or Pre-

mier Unlined to Model 148 Actuator with Models 9540R

P/P or Smart Positioner’s PS2 and 991.

2. If air supply contains moisture and/or lu bri -

cat ing oil, the air should be fi ltered with a

co a lesc ing type of fi lter prior to use in stroking

the actuator.

3. Connection for the air loading pressure is 1/4"

female NPT. A suitable pipe thread sealant is

recommended to be used when installing the

pipe or tube fi tting. Exhibit care to prevent the

sealant from getting inside the tube/pipe.

4. If an alternate gaseous fl uid is used as a source

of loading pressure (i.e. natural gas, ni tro gen,

etc.), this gas MUST NOT BE COR RO SIVE

to the aluminum casing material.

IV. OPERATION

A. General:

1. Actuators supplied with 5-13 psig (0.34-0.90

Barg) benchset range are designed to op er ate

with or without a positioner. A 3-15 psig (0.21-

1.03 Barg) instrument output signal would be

required to operate without a positioner.

2. On larger valve body sizes the benchset

range is essentially 1.5–2.0 times that of

the 5-13 psig (0.34-090 Barg); i.e. 7.5-19.5

psig (0.52-1.34 Barg) or 10-26 psig (0.69-

1.79 Barg). Either a signal booster or a

positioner will be required for full rotation

(0°–90°) by the actuator.

IOM-148

SECTION IV

3. If an “installed characteristic” other than the

“inherent characteristic” is desired, a positioner

plus a “char ac ter iza tion cam” is required. The

inherent characteristic of Rang er QCT control

valves is linear; for Premiers the inherent

characteristic is equal percent.

4. See Tables 2 through 4 for available actuator

models with benchset ranges per valve type

and body size. (Note: Model 48 actuators

included for clarity.) Proper MAX I MUM air

supply pressures are also indicated.

3

Page 4

TABLE 2

RANGER QCT

ACTUATOR BENCHSET RANGES

Valve Body Size Actuator

in.

1”, 1-1/2” & 2”

3” & 4”

4”, 6’ & 8”

*Model 48 included for clarity

Valve Body Size Actuator

in.

3” & 4”

6”

8”

10”

*Model 48 included for clarity

(DN)

(25, 40 & 50)

(80 & 100)

(100, 150, & 200)

(DN)

(80 & 100)

(150)

(200)

(250)

Model

No.*

48R-01 ATO-FC

48D-01 ATC-FO

148R-01 ATO-FC

148D-01 ATC-FO

148R-02 ATO-FC

148D-02 ATC-FO

ACTUATOR BENCHSET RANGES

Model

No.*

48R-01 ATO-FC

48D-01 ATC-FO

148R-01 ATO-FC

148D-01 ATC-FO

148R-03 ATO-FC

148D-03 ATC-FO

148R-02 ATO-FC

148D-02 ATC-FO

Failure

Action

TABLE 3

PREMIER EZO

Failure

Action

Benchset Range Supply Pressure Qty of

psig (Barg) psig (Barg)

5-15 (.34-1.03) 20 (1.4) 6

5-13 (.34-.90) 20 (1.4) 4

10-26 (.69-1.79) 36 (2.5) 8

Benchset Range Supply Pressure Qty of

psig (Barg) psig (Barg)

5-15 (.34-1.03) 20 (1.4) 6

5-13 (.34-.90) 20 (1.4) 4

7.5-19.5 (.52-1.34) 27 (1.9) 6

10-26 (.69-1.79) 30 (2.1) 8

Range

Springs

Range

Springs

Valve Body Size Actuator

in.

3” & 4”

6”

8” & 10” (200 & 250)

*Model 48 included for clarity

4

(DN)

(80 & 100)

(150)

TABLE 4

PREMIER UNLINED

ACTUATOR BENCHSET RANGES

Model

No.*

48R-01 ATO-FC

48D-01 ATC-FO

148R-01 ATO-FC

148D-01 ATC-FO

148R-03 ATO-FC

148D-03 ATC-FO

Failure

Action

Benchset Range Supply Pressure Qty of

psig (Barg) psig (Barg)

5-15 (.34-1.03) 20 (1.4) 6

5-13 (.34-.90) 20 (1.4) 4

7.5-19.5 (.52-1.34) 27 (1.9) 6

Range

Springs

IOM-148

Page 5

V. MAINTENANCE

A. General:

1. Hereafter, all maintenance, disassembly, etc.,

is as sumed to be done in an indoor shop.

2. Most actuators are a sub-assembly that is

unitized with a body sub-assembly. Ref er ence

should be made to the IOM for the correct

body utilized.

3. Where the body is not being disassembled,

special care MUST be exhibited to prevent

valve stem rotation during any disassembly

or reassembly for all types of valves. Following this procedure will ensure not damaging

seat ing surfaces.

4. Remove all instrument tubing and in ter con nect ed electrical wiring. Label “ends” to en sure

proper reconnection.

5. All indicated Item Numbers that are with re spect to IOM-Ranger, IOM-Premier EZO or

IOM-Premier Unlined will be in parenthesis

and underscored; i.e. (20); the same is true

for Model 73N-B P/P positioner parts.

6. All Item Numbers that are with respect to this

IOM-148 are not underscored; i.e. (19).

7. Item Numbers that relate to the Models 9540

or Smart positioners ((PA)) are in a double

set of pa ren the sis and are underscored; i.e.

((3)).

B. Separation of Body Assembly (BA) from Ac-

tu a tor Assembly (AA):

1. Place completely joined valve assembly (AA)

(BA) upon a fl at work surface with suf fi cient

room to move the individual sub-as sem blies

(AA) (BA) around. Place matchmarks on valve

yoke (12), dust cover plate (23), arm housing

(4) and ac tu a tor lower casing (2) to use as

ref er enc es at re-assembly.

2. Remove cover plate (20) away from arm

hous ing (4) by removing four machine screws

(36).

3A. Units with Model 73N-B P/P Positioner or No

Positioner, and No Travel Limit Switch:

a. Remove the two cap screws (31) se cur ing

the travel indicator dial lens (14) and travel

indicator dial (15) using a 3/16" allen key

wrench. Using a sharp pointed tool, hook

under the edge of lens (14) and in di ca tor

dial (15) to remove.

b. Remove cap screw (32) and lock tooth

washer (55) se cur ing the bright orangecol ored travel in di ca tor (16) to the upper

IOM-148

SECTION V

end of valve stem (Rang er (7)), (Premier

(3.2)) using a 7/32" allen key wrench.

Re move travel in di ca tor (16) off of pro trud ing lo ca tor pin (51).

c. If equipped with a Model 73N-B P/P

positioner, re move the four cap screws

(33) that secure the positioner assembly

(PA) to the arm housing (4) using a 3/16"

allen key wrench. Remove positioner as sem bly (PA) and feed back range spring

(102). Loop a 6" piece of fi ne wire around

the feedback linkage subassembly (72).

Place one screw (33) back into a tapped

open ing. Pull wire taut and wrap around

pro trud ing screw (33) to keep the linkage

(72) from interfering with further dis as sem bly.

3B. Units with End-of-Shaft Model 9540R Posi-

tioners:

a. Remove clear indicator cover ((22)) by

removing two cap screws ((A3)).

b. Remove red plastic pointer ((34)) by pull-

ing outwards from hub of post-end screw

((23)).

c. Make a matchmark on the char ac ter iza-

tion cam ((24)) at the point where the

cam follower ((31)) touches. Using a

wrench remove post-end screw ((23))

that se cures characterization cam ((24)).

Pull feedback lever ((13)) downwards;

re move cam ((24)) and adhered to lock

toothed washer ((28)) and shouldered

wash er ((27)).

d. Remove the positioner unit ((I/P)) ((P/P))

from the baseplate ((26)) by removing cap

screws ((11)) with lock washers ((12))

from side and back of baseplate ((26)).

e. Remove the four cap screws ((78)) se cur-

ing the bracket ((76)), baseplate ((26))

assembly and coverplate (13) to the arm

housing (4).

3C. Units with End-of-Shaft Model 991 or PS2

I/P Positioners:

a. Remove cap screws (31) securing the

positioner mounting bracket ((9)) to

coverplate (13).

b. Set positioner / bracket assembly off to

the side.

c. Remove set screw ((16)) and washer

((17)) from end of the valve stem (Ranger

(7) or (Premier (3.2)) securing carrier

linkage ((3)) to stem.

d. Remove linkage ((3)) from end of stem.

5

Page 6

4. For ATO-FC valve action, it is necessary to

remove “stem windup” - use either a. or b.

a. Rotate manual handwheel operator

(MHWO) handwheel (58.1) ap prox i mate ly

1-3 revolutions CW (viewed from above

handwheel) until interconnecting arm and

stem linkage (5, 10) of actuator “relax”.

b. Pressurize actuator casing (1) only

until the in ter con nect ing arm and stem

linkage (5,10) “relax”. DO NOT OVERPRES SUR IZE.

NOTE: Do not remove the drive coupling ((32))

unless required.

5. Using a 7/16" allen key wrench, remove the

four sockethead cap screws (34) that secure

the cover plate ((13)) (13) to the arm housing

(4). Remove the cover plate ((13)) (13) by

pulling outwards.

6. Remove ball bearing (18) over shaft-end

(Rang er (7)), (Premier (3.2)).

7. Remove lock nut (46) that secures shoulder

bolt pin (40) through lever arms (5). Remove

shoulder bolt pin (40).

8. Units with Model 73N-B P/P Positioner or No

Positioner. Remove indicator spacer (17) by

sliding over end of shaft (Ranger (7)), (Pre mier

(3.2)).

9. Grasp lever arms and rotate stem (Ranger

(7)), (Pre mier (3.2)) as required to pull down

and away from the lower rod end-L.H. (9) to

allow clearance to remove arms (5). Slide

subassembly consisting of both arms (5),

spacer (12) or characterization cam (Model

73N-B (12)), and two spring pins (50) out wards

and away from the arm housing (4) and over

shaft-end (Ranger (7)), (Premier (3.2)).

10. While securely holding the actuator assembly

(AA) with an overhead sling support, and the

body assembly (BA) to prevent movement,

remove the four bolts (24) that secure the

body yoke (12) to the actuator arm housing

(4). Slide the actuator assembly (AA) over the

stem-end (Ranger (7)), (Pre mier (3.2)). Lay

body assembly (BA) aside.

C. Changing Actuator Mounting Position (With

No Change in Failsafe Action).

1. Determine the desired mounting position of

actuator assembly (AA) with respect to valve

body assembly (BA) from Figures 6-9, fol low ing pages.

6

2. The valve body/bonnet (1) to valve body

yoke (12) can be rotated in four 90° increments around the centerline of the valve shaft

(Rang er (7)) (Premier (3.2)).

3. Separate the actuator assembly (AA) from

the body assembly (BA) as described in this

Sec tion, V.B.1. through V.B.10.

4. Determine if it is necessary to interchange

packing studs (21) on Ranger or Premier

Un lined, and yoke (12) attachment studs (20)

on Ranger or Premier Unlined per fol low ing:

Rotary Valve

Ranger 90˚, 270˚ Required

Premier Unlined 180˚ Not Required

Premier EZO 90˚, 180˚, 270˚ Not Required

Degrees

Rotation

Position Change

Packing Studs

Yoke Attach Studs

Switch of Position

5. If required, remove both packing stud nuts

(22) on Ranger or Premier Unlined, and any

external live-loaded packing com po nents

(Rang er (27) (28) (29)), and set both aside

carefully to prevent an “inadvertent mix ing”

of the component’s “stack-up”.

6. Place matchmarks between yoke (12) and

valve bon net/body (1). While holding yoke

(12) with hand, remove yoke attachment stud

nuts (22)(Ranger and Premier Unlined qty =

2) (Premier EZO qty = 4). Move loose yoke

(12) over end of stem (Ranger (7)) (Premier

(3.2)) and set aside.

7. If necessary, remove all studs (20) (21) from

Ranger or Premier Unlined body assembly

(BA) and re lo cate/in ter change as re quired.

8. Reposition yoke (12) back onto body bonnet

(1), shifted/rotated the number of degrees

re quired (i.e. 90°, 180° or 270°), using the

matchmarks to guide to correct position. Se cure yoke (12) to body bonnet (1) by engaging

two yoke at tach ment nuts (22) on Ranger and

Premier Unlined, and four nuts (22) on Pre mier

EZO. Torque per following:

3" & 4" Rangers — 35-40 ft-lbs (47-54 N-m)

All Others — 75-80 ft-lbs (101-108 N-m).

9. Reposition packing fl ange (Ranger (14))

(Pre mier Unlined (5)) over packing studs (21)

for Ranger and Premier Unlined. Reinstall

live-loaded packing components (Rang er (27)

(28) (29) 2 sets). Reengage both pack ing stud

nuts (22) for Ranger and Premier Un lined. Set

torque level on pack ing stud nuts as indicated

in IOM-Ranger QCT, IOM-Pre mier EZO, or

IOM-Premier Unlined body as sem bly (BA)

instructions.

IOM-148

Page 7

FIGURE 6:

ORIENTATION – RANGER QCT ACTUATOR MOUNTING POSITIONS

WITH MODEL 73 P/P POSITIONER

REVERSE ACTION DIRECT ACTION

IOM-148

NOTES: 1. Flangeless valve design indicated; integral fl anged units follow same orientation.

2. Dimension tables are included in the Ranger-TB.

7

Page 8

FIGURE 7:

ORIENTATION – RANGER QCT/PREMIER ACTUATOR MOUNTING POSITIONS

WITH MODELS 9540R P/P or 991 or PS2 I/P POSITIONERS

REVERSE ACTION DIRECT ACTION

NOTES: 1. Flangeless valve design indicated; integral fl anged units follow same orientation.

2. Dimension tables are printed in the Ranger-TB.

8

IOM-148

Page 9

FIGURE 8

PREMIER ACTUATOR MOUNTING POSITIONS – 73

Position "A" is standard for fail closed action. Position "B" is stan dard for fail open action.

Po si tion "C" and "D" covers ver ti cal piping.

FIGURE 9

PREMIER ACTUATOR MOUNTING POSITIONS – 9540R/991/PS2

Position "A" is standard for fail closed action. Position "B" is stan dard for fail open action.

Po si tion "C" and "D" covers ver ti cal piping.

IOM-148

Note: All basic valve dimensions are printed in the Premier-TB

9

Page 10

10. Reorient body assembly (BA) with respect to

the actuator assembly (AA). Rejoin the body

assembly (BA) to the actuator assembly (AA)

as described in this section, V.I. Ensure prop er

plug (Ranger (6)) or disc (Premier (3.1)) po si tion

prior to reinstalling lever arms (5). Ensure that

the lever arms (5) are “centered” within the arm

housing (4), and with respect to the actuator

stem linkage (8) (9) (10) (43) (44).

NOTE: Valve stem always goes CW to

“close”, viewed from stem-end.

4. Separate the actuator assembly (AA) from

the body assembly (BA) as described in this

Sec tion, V.B.1. through V.B.10.

5. Rotate plug (Ranger (6)) or disc (Premier (3.1))

position 90° to new failsafe position.

11. Recalibrate the unit (AA) (BA) and its positioner

((PA)).

D. Changing Failsafe Action:

1. Model 148 actuator (AA) is fi eld-reversible for

failsafe action with no additional parts required.

2. It is possible that both of the following can occur

together for the degree of disassembly undertaken:

a. Failsafe action reversed.

b. Change in actuator mounting position.

NOTE: This section will be limited to the pro ce dures

for 2.a. above. If 2.b. is also desired, then it will be

necessary to reference Sub sec tion C. here in for the

added procedural steps as required.

This subsection will thus be limited as in di cat ed as

follows (reference Figures 10– 11 herein for be gin ning and end graphic orientations).

Product

Ranger QCT

Premier EZO

or

Premier

Unlined

Begin End

Position Action Position Action

“A” ATO-FC “B” ATC-FO

“C” ATO-FC “D” ATC-FO

“E” ATO-FC “F” ATC-FO

“G” ATO-FC “H” ATC-FO

“B” ATC-FO “A” ATO-FC

“D” ATC-FO “C” ATO-FC

“F” ATC-FO “E” ATO-FC

“H” ATC-FO “G” ATO-FC

“A” ATO-FC “B” ATC-FO

“C” ATO-FC “D” ATC-FO

“B” ATC-FO “A” ATO-FC

“D” ATC-FO “C” ATO-FC

3. To reverse actuator (AA) failsafe action ba si cal ly

requires:

a. Moving lever arms (5) from left side of valve’s

stem (Ranger (7)) (Premier (3.2)) to right

side, or vice versa. This is ac com plished by

removing actuator assembly (AA) from body

assembly (BA) and ro tat ing actuator (AA)

180° about the ac tu a tor’s stem linkage (8)

(9) (10) (43) (44).

b. Rotating plug (Ranger (6)) or disc (Pre mier

(3.1)) by 90°; ie. from “closed” po si tion to

“open” position, or vice versa.

c. Reconnecting actuator (AA) to body (BA)

with lever arms (5) also rotated 180°.

10

6. Slide actuator assembly (AA) that has been

rotated 180° back over the stem-end (Ranger

(7)) (Premier (3.2)). Align bolt holes between

arm housing (4) and valve yoke (12).

7. Reengage bolting (24) securing arm housing

(4) to yoke (12). Torque bolting (24) to 30-35

ft-lbs (40-47 N-m).

8. Ensure that the reinstalled lever arms (5) are

also rotated 180° in the same reference as the

actuator as sem bly (AA) was rotated. (NOTE:

The repositioned arms (5) will appear to have

only changed relative position by 90° in an oth er

plane.) Ensure the lever arms assembly (5)

is “centered” within the arm housing (4), and

with respect to the actuator stem (8) (9) (10)

(43) (44).

9. Rejoin the body assembly (BA) to the actuator

as sem bly (AA) as described in this Section,

V.I.

E. Diaphragm Replacement:

1. Place unit assembly (AA) (BA) onto a fl at work

bench with actuator upper casing (1) on top

side; i.e. handwheel (58), if supplied, on top

side. Place a matchmark between actuator

casings (1) (2).

2. Ensure that all air pressure is released from

actuator assembly (AA) casing (1).

3. Ensure that manual handwheel (58) operator

is fully rotated upwards by loosening locking

lever (59) and ro tat ing CCW (viewed from top

side) as far as possible.

WARNING

SPRING UNDER COMPRESSION. Prior to re mov ing

fl ange bolting (27, 28, 41, 42) re lieve range spring

(11) compression by rotating the handwheel or

adjusting screw assembly (58) CCW (viewed from

above handwheel (58) until all spring com pres sion

is re lieved. Fail ure to do so may result in fl ying

parts that could cause personal injury.

IOM-148

Page 11

LOAD

VENT

CLOSE

OPEN

Rotati on

VENT

LOAD

OPEN

Rotati on

CLOSE

CCW-TO-OPEN

ATC-FO

(DIRECT)

Push Down-to-Close

NOTE: To switch “action” requires locating actuator stem

to opposite side of valve stem.

CCW-TO-OPEN

ATO-FC

(REVERSE)

Push Down-to-Open

Figure 10

Ranger Plug vs. Lever Arm vs. Actuator Ori en ta tion

7. Remove pivot screw (25) by rotating CCW

(viewed from above), and seal (56).

8. Pry diaphragm washer (52) loose. Clean

wash er (52) of any rubberized sealant.

9. Prior to diaphragm (6) removal, inspect to see

where a diaphragm (6) leak may have been

caused by wearing against the upper case (1)

at any point. Inspect the upper case (1). NOTE:

The diaphragm (6) is a rolling di a phragm and

should NOT touch the upper case (1) at any

point of the piston’s (3) up wards/downwards

travel. If there is side move ment of the piston

(3), further dis as sem bly for inspection of range

springs (11) is man da to ry. If there is topside

wear, uptravel stop washer (54) is not prop er ly

adjusted.

10. Remove diaphragm (6) and discard.

11. Clean surface of piston (3) of any foreign ma-

terial that could cause a premature failure of

diaphragm (6) if cov ered. Turn diaphragm (6)

“inside-out”. Place diaphragm (6) onto piston

(3) centered over the center bolt hole in piston

(3); ensure that the smooth black sur face of

di a phragm (6) is on the “pressurized air-side”.

CCW-TO-OPEN

ATC-FO

(DIRECT)

Push Down-to-Close

NOTE: To switch “action” requires locating actuator stem

to opposite side of valve stem.

CCW-TO-OPEN

ATO-FC

(REVERSE)

Push Down-to-Open

Figure 11

Premier Plug vs. Lever Arm vs. Actuator Ori en ta tion

4. Loosen all casing (1,2) fl ange bolting (27, 28,

41, 42) two revolutions. Pry apart the casings

(1,2) if “stuck” together.

5. In one revolution increments loosen all op pos ing nuts (41, 42) until the short bolting

(27, 41) disengages and can be removed.

Con tin ue loosening extension nuts (42) in

the alternating, one revolution pattern ensuring that the cas ings (1, 2) are being “pushed

apart”, until the extension bolting (28, 42) is

disengaged and removed.

6. Lift the upper casing (1) upwards and away

from the lower casing (2) and set upper case

(1) aside.

IOM-148

12. Place silicone sealant, Dow-Corning “Silastic”

#732 RTV or equal, around the diaphragm’s

(6) center bolt hole opening. Lay diaphragm

washer (52) onto sealant and centered over

bolt hole. Replace seal (56) on top of washer

(52).

13. Place a tool around the skirt circumference

of the piston (3) to secure during tightening;

use tape or similar material to prevent this tool

from leaving sharp edges that could damage

the new diaphragm (6). Place Locktite #242,

or equal, thread sealant onto the threads of

pivot screw (25); engage and tighten screw

(25) to 15-20 ft-lbs (21-27 N-m) torque. NOTE:

Piston (3) must be held from rotating to pre vent

the multiple nested range springs (11) from

tilting away from a common vertical centerline

be tween hubs of lower case (2), piston (3) and

range spring (11).

14. Fold the diaphragm (6) skirt from its insideout ori en ta tion, down and around the piston’s

(3) skirt. Using a rounded-end tool, push the

diaphragm (6) down between the lower cas ing

(2) sidewall and the piston’s (3) skirt, forming

a “valley”. Work diaphragm (6) to ensure that

all folds or “puckers” are taken away. Press

the di a phragm’s (6) lower/outer beaded edge

into the groove. Again, smooth out all folds or

puckers in diaphragm (6).

11

Page 12

15. Place a light coating of graphite powder lu bri cant, Dow-Corning “Molycote” (dry mo lyb de num disulfi de) or equal, on the skirted areas

of diaphragm (6), and into the “valley”. This

lubricant will prevent the diaphragm (6) from

“sticking together” or abrading itself during

piston (3) travel.

16. If actuator (AA) is supplied with a manual handwheel operator (MHWO), place a heavy-duty

wheel bearing grease, Lubriplate No. 130-AA,

or equal, into the v-notch in the head of the

pivot screw (25).

17. Inspect working of manual handwheel op er a tor (MHWO) located within the upper casing

(1) for signs of wear. Go to Subsection F. for

maintenance of manual handwheel operator

(MHWO).

18. Place properly oriented upper casing (1) down

onto the lower casing (2) with matchmarks

aligned and all casing fl ange bolt holes cen-

tered. NOTE: The casing fl anges (1) (2) will

not touch together.

Place one short bolt (27) through a bolt hole

of upper fl ange (1) to serve as an indicator. In

one-rev o lu tion increments and an al ter nat ing

cross-pattern, draw the casing (1) (2) fl anges

to wards each other. When there is at least

one-half of the indicator short bolt (27) threads

exposed through the lower casing (2) fl ange,

engage nut (41) until the short bolting (27)

(41) is fi nger-tight.

21. Place all short bolts (27) through the re main ing

upper casing (1) fl ange bolt holes, and engage

each ones nut (41) until the short bolting (27)

(41) is fi nger-tight.

22. In an alternating cross-pattern, tighten all

fl ange bolt ing (27) (28) (41) (42) in onerev o lu tion increments. When all bolting (27)

(28) (41) (42) is hand-wrench tight, torque to

levels indicated below:

Item Nos. Description

27, 41 Short Bolting 15-18 20-24

28, 42 Extension Bolting 8-12 11-16

Torque Req’d

ft-lbs. N-m

WARNING

1. Elongated extension bolting (28) (42) is a safe ty

feature to allow relaxation of range springs (11)

to the piston’s (3) mechanical uptravel stop at

dis as sem bly.

2. Extension bolting (28) (42) should ONLY be

re placed with factory replacements; DO NOT

sub sti tute con ven tion al bolting.

3. Extension bolting (28) (42) MUST be located 180°

opposite of each other in the fl ange bolt ing array.

Failure to heed could cause per son al injury at a

later dis as sem bly.

19. Insert both extension bolts (28) through two

upper casing (1) bolt holes that are located

180° across from each other; these bolts

should extend through the lower casing (2)

fl ange enough to engage its companion ex ten sion nut (42). Place a friction-reducing thread

lubricant on the lower exposed threads of the

extension bolts (28).

20. Place the same friction-reducing thread lu bri cant into the threaded portion of both ex ten sion

nuts (42). NOTE: Only one end of ex ten sion

nut (42) is threaded. It is not possible to engage the extension bolting (28) (42) with the

extension nut (42) upside down; the threads

of the nut (42) will not engage. Engage both

extension nuts (42) until they draw tight to the

lower casing (2) fl ange’s underneath side.

12

23. Connect a temporary instrument air source

di rect ly to the 1/4" FPT connection in the upper casing (1). Pres sur ize to the “Air Supply

Pressure” level as indicated in Table 2-4 of

Section IV.A.4. for the corresponding actual

benchset range of the actuator being ser viced,

and test for leakage at upper casing (1) to

lower casing (2) joint. Also test for leakage at

manual handwheel operator (MHWO), rotating handwheel (58) in and out several times

during the test.

24. Release all air pressure into actuator upper

casing (1); remove air source from 1/4" FPT

connection.

F. Manual Handwheel Operator:

1. Reference Item Number drawing at end of IOM

for de tails of the man u al handwheel op er a tor

(MHWO) sub-assembly.

2. Place unit (AA) (BA) on a fl at work surface

with the handwheel (58) on topside.

3. Ensure all air pressure has been released from

ac tu a tor casing (1). Ensure handwheel (58)

is fully “backed-out” by rotating CCW (viewed

from above); i.e. is as “high” as pos si ble.

4. Remove slotted-head screw (65) securing

handwheel gland (67) to upper casing (1).

5. Place a smooth-jawed wrench onto handwheel

IOM-148

Page 13

gland (67) and rotate CCW (viewed from

above) to removal of the manual handwheel

operator sub-assembly (MHWO).

6. Place the sub-assembly (MHWO) into a vise,

grasping with leaded jaws on the coarsescrewed handwheel stem (58.2) near the

base of the handwheel (58.1), oriented to

allow driving-out the rolled pin (66) securing

the handwheel (58.1) to the handwheel stem

(58.2).

7. Drive pin (66) out using a suitable punch and

locking pliers. Set pin (66) aside for reuse.

Remove handwheel (58.1) from stem (58.2).

8. Rotate locking lever (59) CCW (viewed from

handwheel-end) to removal.

9. Slide washer (60) and threadseal washer

(61) off handwheel stem-end (58.2). Discard

threadseal washer (61).

10. Remove remaining engaged parts (67) (58.2)

from vise. Reorient horizontally in vise along

fl ats of handwheel gland (67).

11. Place stick punch in drive-pin hole and rotate

handwheel stem (58.2) CW (viewed from handwheel (58.1) end) back into the handwheel

gland (67). When stem (58.2) protrudes far

enough through gland (67), re lo cate locking

pliers to opposite end and ro tate stem (58.2)

until stem (58.2) fully dis en gag es.

12. Remove O-ring (62) from handwheel gland

(67).

13. Remove O-ring (63) from handwheel stem

(58.2).

14. Place parts (58.2) (59) (60) (64) (67) into a

suitable solvent and clean as much as pos si ble, remove parts and allow to dry.

15. Inspect handwheel stem (58.2) with em bed ded

ball (64) for wear on ball (64). If ball (64) is

worn, or threads of stem (58.2) are dam aged,

replace handwheel sub-assembly (58); i.e.

parts (58.1) (58.2) and (64).

16. If handwheel gland (67) shows signs of wear

in female threads (i.e. loose gauging), replace

handwheel gland (67) and self-tapping slot ted-head screw (65). NOTE: A re place ment

handwheel gland (67) will require drilling a

new 5/32" x 1-1/16" (4mm x 25.5mm) deep

hole into the lip of the upper casing (1).

17. Install new O-ring (63) onto handwheel stem

(58.2) and new O-ring (62) onto handwheel

gland (67).

IOM-148

18. Place a thin coat of lithium grease on the

handwheel stem O-ring (63) and the im me di ate surrounding area of the handwheel stem

(58.2).

19. Engage the handwheel stem (58.2) into the

gland’s (67) underneath side. When the handwheel (58.1) end of the stem (58.2) pro trudes

through the gland’s (67) upper side, place a

new threadseal washer (61) over the stem’s

(58.2) upper end. Continue engaging stem

(58.2) until the O-ring (63) is pulled into the

gland (67).

20. Install washer (60) and locking lever (59) onto

stem (58.2).

21. Place handwheel stem (58.2) into a soft-jawed

vise. Position handwheel (58.1) onto stem

(58.2) with holes for pin (66) aligned. Insert

pin (66) and drive through stem (58.2) and

handwheel (58.1) far side. Remove handwheel

assembly (MHWO) from vise.

22. Place heavy duty wheel bearing grease as

specifi ed previously onto the stem-end ball

(64). Engage the gland (67) into the upper

casing (1) female opening. Align tapped open ing for self-tapping slotted-head screw (65).

23. Install slotted-head screw (65) fully.

G. Adjusting Screw Assembly and Actuator Plug

Maintenance:

1. Reference Item Number drawing at end of the

IOM.

2. Determine the portion of the text of Sub sec tion F. above that would apply to the adjusting screw assembly (ASA) counterpart of

the manual handwheel operator (MHWO)

as sem bly, and complete maintenance in a

sim i lar procedure. NOTE: Adjusting screw

assembly (ASA) is ONLY applied to reverseaction, ATO-FC Ranger QCT units (AA) (BA).

3. Determine the portions of the text of Sub sec tion F. previous that would apply to the

ac tu a tor plug (67) coun ter part of the manual

handwheel operator (MHWO) as sem bly, and

complete maintenance in a similar procedure.

NOTE: Actuator plug (67) may be applied on

all Premier units (AA) (BA) and ONLY directaction, ATC-FO Ranger QCT units (AA) (BA).

H. Replacement of Range Springs:

1. Replacement of actuator assembly (AA)

range springs (11) requires what is essen-

13

Page 14

tially a complete actuator (AA) disassembly.

It is rec om mend ed that the range spring (11)

re place ment should include:

a. diaphragm (6) replacement

b. O-ring(s) (62) (63) replacement

c. threadseal (61) replacement.

2. Separate the actuator assembly (AA) from

the body assembly (BA) as described in this

Sec tion, V.B.1 through V.B.10.

3. Push piston (3) downwards by:

a. manual handwheel operator (MHWO)

being rotated CW (viewed from above

handwheel (58.1)) approximately one-half

of full travel.

b. pressurize actuator to approximately one-

half of the stated benchset range; i.e. for

6-26 psig (0.41-1.79 Barg) pressurize to

approximately 16 psig (1.1 Barg).

8. Remove all range springs (11) and set in a row

side-by-side. Inspect for any difference in the

spring (11) height or verticality. Replace any

abnormal spring(s) (11). Re place any springs

(11) that show cracks, nicks, damaged epoxy

coating, corrosion, etc. Inspect springs (11)

using data in table below as the “normal”:

Part Number

psig (Barg)

5-13 (0.34-0.90) 4

830-H2-5-R9066-95

10-26 (0.69-1.79) 8

* Acceptable ± 1/8” (±3 mm)

9. Inspect clevis (7), upper R.H. rod end (8), clevis

pin (48) and retaining ring (49) for signs of looseness and/or wear; replace any worn parts. Check

bolting (26) (47) for loose ness; tighten as necessary to 15-18 ft-lbs (20-23 N-m).

Benchset

Range

Qty. of

Springs

Free

Height*

in.

7.75 Black7.5-19.5 (0.52-1.34) 6

Coating

Color

WARNING

Do NOT stick hand or fi ngers into the arm housing (4)

when the actuator is pressurized. ONLY USE TOOLS

WITHIN ARM HOUSING (4).

4. Place a wrench on the hex surface of the

ac tu a tor’s stem/pushrod (10). Rotate the push

rod (10) CCW (viewed from lower L.H. rod

end (9)); keep track of number of revolutions

to disengage from upper R.H. rod end (8) in

box below.

Number of revolutions of push

rod (10) required to disengage

from upper R.H. rod end (8). ______________

5. Allow piston (3) to travel upwards by:

a. manual handwheel operator (MHWO)

being rotated CCW (viewed from above

handwheel (58.1)) fully out/up.

b. releasing air pressure as applied per

3.b. above; remove the air supply from

ac tu a tor upper casing (1).

6. Orient actuator assembly (AA) with upper

casing (1) on top side. Disassemble the ac tu a tor assembly (AA) to the point of di a phragm

(6) replacement as described in this Section

V.E.1 through V.E.10.

1

52

3

7

8

10

25

56

48

49

Figure 12

Piston & Clevis Close-up

10. Place range springs (11) back onto hubs of

lower casing (2) per following table:

NOTE: Every spring (11) has another spring (11) 180°

across/opposite.

14

7. Place a matchmark at fl ange of lower casing

(2) and correspondingly on piston (3). Lift

off piston (3) in a vertical direction to prevent

tipping range springs (11) over. Set piston

(3) on work surface upside down.

IOM-148

Page 15

Benchset Range

psig (Barg)

5-13 (0.34-0.90) 4

7.5-19.5 (0.52-1.34) 6

Quantity

of Springs

Array

Hub w/NO

Spring (11)

Hub With

Spring (11)

Hub w/NO

Spring (11)

Hub With

Spring (11)

I. Joining of Body Assembly (BA) to Actuator

As sem bly (AA):

1. Determine proper orientation of actuator (AA)to-body (BA) for the following considerations:

• failsafe action

• installed piping orientation.

Reference Sub-sections V.C. and V.D. to see

sche mat ics of orientations available.

10-26 (0.69-1.79)

8

11. Aligning matchmarks of Article 7. above,

re po si tion piston (3) back onto top side of

range spring (11) array. Using a mirror tool

and fl ashlight, look through the rect an gu lar

open ing in the lower casing (2) from within the

arm housing (4) to ensure that the piston (3)

hubs are centered within the ID of the range

spring (11) coil. It may be necessary to use

a tool to move the upper end of the range

spring (11) as necessary to be “captured” by

a piston (3) hub. Each spring (11) MUST be

captured by a hub on top and bottom ends.

12. Reinstall a new diaphragm (6) and re as sem ble

the upper casing (1) as described in this Section, V.E.11 through V.E.23.

13. Using air pressure of V.E.23., pressurize the

actuator upper casing (1) to the upper value

of the stated benchset range plus 2 psi (0.14

Bar); i.e. for 10-26 psig (0.69-1.79 Barg)

benchset range, pressurize to 26+2 = 28 psig

(1.79+0.14 = 1.93 Barg). This pressure level

should cause the piston’s (3) lower skirt-edge

to bottom out on the lower casing (2).

14. Using only tools (i.e. no fi ngers within arm

housing (4)) to grasp the actuator stem/push

rod (10), insert push rod (10) with in ter con nect ed parts (9) (43) (43) (44) (54) into arm

housing (4) and engage into dangling upper

R.H. rod end (8) by rotating CW (viewed from

lower L.H. rod end (9)). Count number of

revolutions of push rod (10) en gage ment to

match those recorded in Article 4., previous,

at removal.

15. Release all air pressure into actuator upper

casing (1); remove air source from 1/4" FPT

connection.

16. Join the actuator assembly (AA) to the body

assembly (BA) as described in this Section,

V.I.

IOM-148

Spring (11)

on ALL eight

hubs

2. Position body assembly (BA) on a fl at work

surface. Orient such that the actuator as sem bly

(AA) can be ori ent ed with the top of the actuator upper casing (1) on topside; i.e. man u al

handwheel operator sub-assembly (MHWO)

stem (58.2) vertically oriented, if supplied.

3. Place stem spacer ring (24) with its set screw

(39) located to not be protruding into the

spacer ring’s (24) internal diameter, over the

end of the valve’s stem (Ranger (7), Premier

(3.2)) and beyond the circumferential groove

of the upper round portion of the valve’s stem

(Ranger (7), Premier (3.2)).

4. Place round dust cover plate (23) over valve

stem’s (Ranger (7), Premier (3.2)) end and

onto the round part of the stem (Ranger (7),

Premier (3.2).

5. Place “C-type” snap retainer ring (57) into a

tool designed to use with snap rings. Spread

ring (57) apart and locate over valve’s stem

(Ranger (7), Premier (3.2)) end and move to

circumferential groove in round portion of stem

(Ranger (7), Premier (3.2)) and release ring

(57) into groove.

6. Push dust cover plate (23) up against the

retainer ring (57) and hold. Push stem spacer

(24) up against dust cover plate (23) and hold.

Using a 3/32" allen key wrench, tighten set

screw (39) fi rmly to secure plate (23) and

spacer (24) to stem (Ranger (7), Premier

(3.2)).

7. Using an overhead hoist, lift the actuator as sem bly (AA) (with position indicator ap pa ra tus

(13,14,15,16,17,31,31,34), lever arm ap pa ra tus (5,5,12,40,46,50,50), end-of-shaft bearing

(18) and cover plate (20) removed) properly

oriented and shift laterally over the protruding

stem (Ranger (7), Premier (3.2)) and the attached dust cover plate (23). Bring the round

opening of the arm housing (4) into position

against the mounting yoke (12). Raise/lower/

tip/rotate the actuator assembly (AA) to align

15

Page 16

at least one bolt hole of the yoke (12) with one

bolt hole in the arm housing (4). Insert one cap

screw (24) from behind the yoke’s (12) bolt

hole and engage with the tapped opening in

the arm housing (4); fi nger tighten cap screw

(24).

8. Reposition actuator assembly (AA) as re quired

to align the three remaining bolt holes securing yoke (12) with arm housing (4). In sert the

three cap screws (24) and fi nger-tighten.

9. Use cardboard, or some tool that can pro vide

ap prox i mate ly 1/32" (0.80 mm) thick ness,

and wedge three such spacers be tween the

cir cum fer en tial edge of dust cover plate (23)

and the round opening in the arm housing (4).

10. Wrench-tighten in one-half revolution in cre ments and alternating cross-pattern the four

cap screws (24) securing actuator as sem bly

(AA) to body assembly (BA). Final tightening

should be by torque wrench to 30-35 ft-lbs

(40-47 N-m).

11A. For units (AA, BA) with Model 73N-B P/P

positioner:

a. Secure characterization cam (12) prop er ly

oriented over the two rolled spring pins

(50) stuck into the inner lever arm (5).

b. Place the outer lever arm (5) over the

two spring pins (50) with the bolt holes

align ing. Press the apparatus (5,50,50,5)

to geth er.

11B. For Units (AA, BA) with no positioner, Model

9540R P/P positioner or 991 or PS2 I/P positioner:

a. Similar to 11A. above, except a spacer

wash er (12) replaces the cam (12) of a

Model 73N-B P/P positioner.

12. Position valve plug (Ranger (6)) / disc (Pre mier

(3.1) in the proper “Full Closed” or “Full Open”

position. NOT FOLLOWING THIS ARTICLE

WILL CAUSE ME CHAN I CAL DAMAGE TO

THE UNIT’S (AA, BA) MECH A NISM! See

Figure 13.

13. Place properly oriented lever arm ap pa ra tus

(5,50,12,50,5) over shaft’s (Ranger (7), Pre mier (3.2)) square end and push into place

while holding lower L.H. rod end (9) “swung”

aside so as to not interfere. NOTE: For units

(AA, BA) with 73N-B P/P positioner, it will be

nec es sary to “swing” the feedback linkage

subassembly ((72)) out of the way as the

lever arm apparatus (5,50,12,50,5) is pushed

into place. Center-align lever arm apparatus

(5,50,12,50,5) transversely within the arm

housing (4), directly over stop screw (35).

14A. For units (AA, BA) with Model 73N-B P/P po-

sitioner: Place indicator spacer (17) over end

of shaft (Ranger (7), Premier (3.2)) prop er ly

oriented for travel indicator (16) to be “located”

by spring pin (51). See Fig. 13.

14B. For units (AA, BA) with Model 9540R P/P

positioner or 991 oR PS2 I/P positioner:

Reference the IOM-9540R or 991 or PS2 for

proper instructions on reinstallation of in di ca tor

spacer (17) and drive coupling ((32)).

15. Align the bolt holes in lever arms (5) and lower

L.H. rod end (9). NOTE: For units (AA, BA)

with ATO-FC action it will be necessary to

offset “stem windup” by –

a. Rotating manual handwheel operator

(MHWO) handwheel (58.1) ap prox i mate ly

1-3 rev o lu tions CW (viewed from above

handwheel) until the bolt holes of lever

arms (5) and lower L.H. rod end (9) are

aligned.

b. Pressurize actuator casing (1) only until

the bolt holes of the lever arms (5) and

the lower L.H. rod end (9) align.

16. Insert shoulder bolt (40) through the round

opening of the arm housing (4) and into the

bolt holes of lever arms (5) and lower L.H. rod

end (9).

17. Ensure that lever arm apparatus (5,50,12,50,5)

is transversely centered within the arm hous ing (4). Engage lock nut (46) together with

shoulder bolt. Wrench-tighten to a torque of

15-20 ft-lbs (20-27 N-m).

18. Place ball bearing (18) into cover plate (13).

Place cover plate (13) into arm housing (4) in

correct orientation. There should be a prob lem

with the cover plate (13) not aligning properly.

Slowly remove the “stem windup” in tro duced

in Article 15 above by reversing the loading

forces from the manual handwheel operator

(MHWO) or the air pressure to ac tu a tor upper

casing (1). Removal of the forces will allow

the cover plate (13) bolt holes to align with

those of the arm housing (4), and allow the

cover plate (13) to properly shoulder into the

arm housing (4).

19. Secure cover plate (13) to arm housing by

engaging the four cap screws (34) into the

arm housing (4); fi nger-tighten. In a crossing

pattern wrench-tighten the four cap screws (34)

in 1/4 revolution increments using a 7/32" allen

16

IOM-148

Page 17

LOAD

CLOSED

LOAD

VENT

OPEN

CLOSED

CLOSED

ATO-FC (Reverse) Action

Figure 13:

key wrench until fi rmly tight. NOTE: Ensure

that cover plate (13) is shouldered properly

into position on back side.

20A. Units (AA, BA) with Model 73N-B or without

positioner:

a. Insert rolled spring pin (51) into indicator

spacer (17). Pin (51) will protrude ap prox i mate ly 1/16" (1.5 mm).

b. Position travel indicator (16) onto end of

shaft (Ranger (7), Premier (3.2)) impaling

over pro trud ing spring pin (51) and align ing

with shaft-end tapped opening with hole

in travel in di ca tor (16). Align lock-tooth

washer (55) on spacer (17) and secure

trav el in di ca tor (16) to shaft (Rang er (7),

Pre mier (3.2)) with cap screw (32) using

a 7/32" allen key wrench until fi rmly tight.

VENT

OPEN

OPEN

CLOSED

ATC-FO (Direct) Action

c. Position travel indicator dial (15) onto

cover plate (13) properly oriented.

d. Position clear plastic dial lens (14) over

in di ca tor dial (15), aligning bolt holes of

lens (14), dial (15) and cover plate (13).

e. Secure lens (14) and dial (15) to cover

plate (13) by engaging the two socket

head cap screws (31) using a 3/16" allen key wrench and tighten fi rmly; do not

over-tighten and crack plastic lens (14).

20B. Units (AA, BA) with Models 9540R or 991 or

PS2 positioners: Reference the IOM-9540R

or 991 or PS2 for proper instructions on re in stal la tion of positioner ((PA)) assembly to

shaft-end.

IOM-148

17

Page 18

VI. CALIBRATION

A. General:

SECTION VI

1. This section covers calibration of the actuator

as sem bly (AA) to a Ranger QCT, Premier EZO,

or Premier Unlined body assembly (BA).

2. Positioner, if installed, requires ref er ence to

the spe cifi c positioner model IOM for proper

calibration pro ce dure.

3. All indicated Item Numbers that are with re spect to this Model 148 actuator as sem bly (AA)

are in pa ren the sis but are not un der scored;

i.e. (20). Item Numbers that relate to the body

assemblies (BA) are in parenthesis and are

underscored; i.e. (7). Item Num bers that relate

to the positioners ((PA)) are in a double set of

parenthesis and are un der scored; i.e. ((3)).

4. This Section assumes that the actuator as sem bly (AA) and body assembly (BA) have

been interconnected to geth er as recorded in

Section V.

5. This Section assumes that the cal i bra tion is

performed with the valve unit re moved from

its normal pipeline location, and is in a repair

shop located on a suitable work bench. Ac tu a tor stem/push rod sub as sem bly (8, 9,10, 43,

43, 43, 44, 54) should be oriented ver ti cal ly.

6. Premier EZO (lined) body assembly (BA)

MUST be properly clamped between two ANSI

150# RF weld neck fl anges. NOTE: Flanges

MUST be of weld neck type! Clamping of liner

(Premier (10)) will prevent false move ment of

liner (Premier (10)) within body (1).

7. In this Section reference will be made to three

phrases –

a. “lower value of benchset range”,

b. “higher” value of benchset range”,

c. benchset range.

The meaning of these phrases is sum ma rized in

the following table.

Lower Value

Benchset Range*

psig (Barg) psig (Barg) psig (Barg)

5-13 (.34-.90) 5 (0.34) 13 (0.90)

7.5-19.5 (.52-1.34) 7.5 (0.52) 19.5 (1.34)

10-26 (.69-1.79) 10 (0.69) 26 (1.79)

*Identifi ed on namelate (21) as “Bench” or “Input Range”.

of Benchset

Range

Higher Value

of Benchset

Range

WARNING

Do not pressurize actuator assembly (AA) be yond the

“MAX ACTUATOR PRESSURE” level/value in di cat ed

on the unit’s nameplate (21). Fail ure to heed may

cause catastrophic failure of upper cas ing (1) lead ing

to fl ying parts.

B. Actuator Stem/Push Rod Adjustment:

1. Actuator stem/push rod linkage (8, 9, 10, 43,

43, 43, 44, 54) when properly ad just ed will –

a. Provide the proper benchset range.

b. Provide 90° rotation.

c. Provide proper valve stem (Ranger (7),

Premier (3.2)) “windup”.

2. Ensure that manual handwheel operator

(MHWO) has handwheel (58.1) backed fully

out by rotating CCW (viewed from above

handwheel (58.1)).

3. Remove cover plate (20) by removing four

screws (36).

4. Remove travel indicator dial (15) and dial

lens (14) by removing the two socket head

cap screws (31) securing to cover plate (13)

using a 3/16" allen key wrench.

5. Units with ATO-FC (Reverse) Action:

a. Disconnect the lower L.H. rod end (9) from

en gage ment with the lever arms (5) by

removing shoulder bolt (40) and lock nut

(46). It will be necessary to re move stem

(Ranger (7), Premier (3.2)) “wind up” as

described in Sec tion V.B.4.

b. Swing the lever arms (5) down against

the travel stop screw (35); this “opens”

valve plug (6)/disc (3.1).

c. Loosen lower upstop jam nut (43) from

securing upstop washer (54); back nut

(43) to the root of its threads on push rod

(10).

d. The upper R.H. rod end (8), lower L.H. rod

end (9), and push rod (10) act to geth er as

a turnbuckle; the upper end is standard

right-hand threaded while the lower end is

left-hand thread ed. To en sure max i mum

and equal en gage ment of rod ends (8,9) to

the push rod (10), it is rec om mend ed that

the link age (8,9,10) be fully en gaged and

then re ad just ed as a safety pre cau tion.

18

IOM-148

Page 19

CAUTION

Unequal engagement adjustment of rod ends (8,9)

and push rod (10) can cause failure of a rod end

(8,9)-to-push rod (10) connection.

a. If this occurs during bench main te nance, the

parts (8,9,10) could snap apart and cause

per son al injury.

b. If this occurs during installed operation, con trol

func tion would be lost.

e. Loosen lower L.H. rod end (9) jam nut (44)

by rotating CW (viewed from above); this

nut (44) is “left-handed”. Back nut (44) to

the root of its threads on push rod (10).

f. Using a suitable tool to prevent lower L.H.

rod end (9) from rotating, rotate push rod

(10) CCW (viewed from above) until up per

end of push rod (10) is fully engaged with

upper R.H. rod end (8). NOTE: If lower L.H.

rod end (9) reaches full en gage ment with

lower push rod (10) end fi rst, remove tool

securing against ro ta tion, and allow lower

L.H. rod end (9) to rotate with push rod

(10). Once upper end of push rod (10) is

fully engaged with upper R.H. rod end (8),

rotate lower L.H. rod end (9) CW (viewed

from above) until it is fully engaged.

g. Provide a temporary air supply with an

inline ad just able airset to the actuator

upper cas ing (1) connection.

h. Reference the name plate (21) attached

to the cover plate (20) that is fas tened to

the arm hous ing (4). De ter mine the bench

set ting from the name plate (21).

i. Pres sur ize the ac tu a tor (AA) to the lower

val ue of the benchset range pres sure

in di cat ed on the name plate (21).

j. While holding low er L.H. rod end (9) out

of way, lift lever arms (5) up as far as pos si ble (this will close plug (Ranger (5))/disc

(Pre mier (3.1)).

k. Rotate lower L.H. rod end (9) as required

to orient the holes of the rod end (9) and

the lever arms (5) in the same plane. Swing

low er L.H. rod end (9) be tween the lever

arms (5).

l. Rotate the push rod (10) CW (viewed

from above) lowering the lower L.H. rod

end (9) until it’s hole is centered with the

lever arm (5) holes. Center lever arms (5)

with in arm housing’s (4) transverse axis;

i.e. center over travel stop screw (35).

m. Reinstall the shoulder bolt (40) through

the lever arm (5) and lower L.H. rod end

(9) holes. Finger-tighten lock nut (46) onto

shoul der bolt (40). Using a 1/4" allen key

wrench to secure the head of shoul der

bolt (40), torque wrench-tighten nut (46)

to 15-20 ft-lbs (20-27 N-m).

n. Tighten lower L.H. jam nut (44) down until

locked against lower L.H. rod end (9); nut

(44) is “left-handed”.

o. Add approximately 6 psig (0.4 Barg) to the

actuator’s (AA) lower value of benchset

range. This will extend the actuator stem/

push rod sub-assembly (8, 9, 10, 43, 43,

43, 44, 54) downwards to al low loos en ing double jam nuts (43) on top side of

uptravel stop washer (54).

RANGER QCT®

SERIAL NO.

BODY SIZE

BODY RATING CLASS

END CON NEC TION

MAX ALLOWABLE WORKING PRESSURE

MAX.

MAX. WORKING ∆P PSIG

SEAT MATERIAL

PACKING

INHERENT FLOW CHAR.

RATED TRAVEL

FLOW TOWARD

FAILURE POSITION

MAX ACTUATOR PRESSURE

INPUT RANGE

OPTIONS

PRODUCT CODE

TAG NO.

WARNING: REFER TO IOM PRIOR TO MAIN TE NANCE

PSIG @ 100°F

90°

CASHCO, INC.

ELLSWORTH, KS.

p. Release air pressure down to the lower

value of benchset range.

q. Rotate lower jam nut (43) to raise uptravel

stop wash ers (54) until the gap clearance

between the lower casing (2) and the

top side of the washer (54) is 1/8"±1/16"

(3mm±1.5mm).

r. Repressurize actuator (AA) to level as

indicated in Article 5.o. above. Tighten

the lower of the two upper jam nuts (43)

until it is tight, and secures the uptravel

stop washer (54). Tighten the upper of

the two upper jam nuts (43) down to

secure the double jam nut (43) locking

effect. Retighten lower jam nut (43) on

un der neath side of washer (54).

s. Release all air pressure from actuator

upper casing (1). Repressurize slowly to

confi rm that as the pressure reaches the

lower valve of the benchset range (see

Article 5.i. previous), the actuator stem/

push rod sub-assembly (8, 9, 10, 43, 43,

43, 44, 54) begins to move. If move ment

is prematurely occurring (i.e. move ment

at less than the lower benchset range

MATERIAL

PLUGSTEM

RATED Cv

RATED Kv

TRIM NUMBER

OF PLUG

MTG. POSITION

PSIG

U.S.A.

@ 38°C

PSIG

IOM-148

19

Page 20

val ue), the length of the actuator stem

sub-as sem bly (8, 9, 10, 43, 43, 43, 44,

54) must be short ened. Re peat pro ce dure

from Article 5.a. through to this Ar ti cle. If

move ment is late (i.e. move ment at more

than the lower benchset range value), the

length of the actuator stem sub-assembly

(8,9,10,43,43,43,44,54) must be length ened (i.e. increased). Re peat procedure

from Article 5.a. through to this Article. It

is recommended that ad just ment of ac tu a tor stem sub-assembly (8, 9, 10, 43,

43, 43, 44, 54) be made in one rev o lu tion

of push rod (10) increments. Re peat as

nec es sary.

t. Slowly increase air pressure in upper cas-

ing (1) until reaching the higher value of

the benchset range; i.e. pres sur ize only

until plug (Ranger (5))/disc (Premier (3.1))

is in the full open position.

u. Release all air pressure in actuator upper

casing (1). Repeat Article 5.t above and

this article, cycling valve unit (AA, BA)

closed-open-closed-open-closed sev er al

times.

v. With valve plug (Ranger (5)) / disc (Pre mier

(3.1)) in “full closed” position, re in stall

travel indicator dial (15) and dial lens (14),

securing with two socket head screws

(31). Position dial (15) such that travel

indicator (16) shows “0°” travel before

fully tightening screws (31).

w. Completion to this point completes the

benchset range adjustment. Proceed to

Subsection VI.C. to adjust 90° travel stop.

6. Units with ATC-FO (Direct) Action:

a. Disconnect the lower L.H. rod end (9)

from en gage ment with the lever arms (5)

by removing shoulder bolt (40) and lock

nut (46).

b. Swing the lever arms (5) down and as

close as possible to the travel stop screw

(35); this “closes” valve plug (6) / disc

(3.1). Ensure that the “closed” position

is reached by observing actual plug (6) /

disc (3.1) position.

c. Loosen lower upstop jam nut (43) from

securing upstop washer (54); back nut

(43) to the root of its threads on push rod

(10).

d. The upper R.H. rod end (8), lower L.H. rod

end (9), and push rod (10) act to geth er as

a turnbuckle; the upper end is stan dard

right-hand thread ed while the low er end is

left-hand thread ed. To ensure max i mum

and equal en gage ment of rod ends (8,9) to

the push rod (10), it is rec om mend ed that

the link age (8,9,10) be fully en gaged and

then re ad just ed as a safety pre cau tion.

CAUTION

Unequal engagement adjustment of rod ends (8,9) and

push rod (10) can cause failure of a rod end (8,9)-topush rod (10) connection.

a. If this occurs during bench maintenance, the

parts (8,9,10) could snap apart and cause

per son al injury.

b. If this occurs during installed operation, con trol

func tion would be lost.

e. Loosen lower L.H. rod end (9) jam nut (44)

by rotating CW (viewed from above); this

nut (44) is “left-handed”. Back nut (44) to

the root of its threads on push rod (10).

f. Using a suitable tool to prevent lower L.H.

rod end (9) from rotating, rotate push rod

(10) CCW (viewed from above) until up per

end of push rod (10) is fully engaged with

upper R.H. rod end (8). NOTE: If lower L.H.

rod end (9) reaches full en gage ment with

low er push rod (10) end fi rst, remove tool

se cur ing against ro ta tion, and allow lower

L.H. rod end (9) to rotate with push rod

(10). Once upper end of push rod (10) is

fully engaged with upper R.H. rod end (8),

rotate lower L.H. rod end (9) CW (viewed

from above) until it is fully engaged.

g. Provide a temporary air supply with an

inline ad just able airset to the actuator

upper casing (1) connection.

h. Reference the nameplate (21) attached

to the cover plate (20) that is fastened to

the arm housing (4). De ter mine the bench

setting from the nameplate (21).

i. Rotate lower L.H. rod end (9) until the rod

end (9) and the lever arm’s (5) holes are

in the same plane.

j. Loosen jam nut (45) and rotate downtra-

vel stop screw (35) out by rotating CCW

(viewed from below screw’s (35) head)

until just barely engaged in arm housing

(4).

k. Pressurize actuator (AA) to the higher

value of the benchset range pressure

indicated on the nameplate (21), while

“guiding” the lower L.H. rod end (9) hub

to its proper position between the lever

arms (5).

l. Pressurize actuator (AA) to a level as

indicated by “C” pressure in table below

according to the formula: “A” + “B” = “C”.

20

IOM-148

Page 21

Benchset

Range

_ psig _ psig 2 psig _ psig

_ Barg _ Barg .14 Barg _Barg

Higher Value

of Benchset

Range - “A”

m. Adjust the push rod (10) by rotating CW

(viewed from above) until the holes of

the lever arms (5) and the lower L.H.

rod end (9) are centered and the valve

is in the “closed” position.

n. Reinstall the shoulder bolt (40) through

the lever arm (5) and lower L.H. rod end

(9) holes. Finger-tighten lock nut (46)

onto shoulder bolt (40). Using a 1/4"

allen key wrench to secure the head

of shoul der bolt (40), torque wrenchtighten nut (46) to 15-20 ft-lbs (20-27

N-m).

o. Loosen double jam nuts (43,43) on top

side of uptravel stop washer (54).

p. With valve in “closed” position, reinstall

travel indicator dial (15) and dial lens

(14), securing with two socket head

screws (31). Position dial (15) such

that travel indicator (16) shows “0°”

travel (no “bright orange” showing from

indicator (16)) be fore fully tightening

screws (31).

q. Fully release air pressure in actuator

(AA). Observe position of valve on

travel in di ca tor (16). Travel should be

short of “full open”; i.e. 90° rotation.

1. Travel short of 90°. Adjust the push

rod (10) by rotating CCW (viewed

from above) until the travel reaches

90° as shown by travel indicator

(16).

2. Travel beyond 90°. Adjust the push

rod (10) by rotating CW (viewed

from above) until the travel is

reduced to 90° as shown by the

travel indicator (16).

r. Rotate lower jam nut (43) to raise up-

travel stop wash ers (54) until the gap

clearance between the lower casing (2)

and the top side of the washer (54) is

1/8"±1/16" (3mm±1.5mm).

s. Repressurize actuator (AA) to upper

val ue of benchset range. Tighten the

lower of the two upper jam nuts (43)

until it is tight, and secure the uptravel

stop washer (54). Tighten the upper of

the two upper jam nuts (43) down to

secure the double jam nut (43) locking

effect. Retighten lower jam nut (43) on

underneath side of wash er (54).

t. Tighten lower L.H. jam nut (44) down

until locked against lower L.H. rod end

Adder

Value -

“B”

Loading

Pressure

- “C”

(9); nut (44) is “left-handed”.

u. For Premier EZO and Premier Unlined

ONLY. Ref er ence VI.C.2. for procedure

to adjust downtravel stop screw (35).

v. Release all air pressure in actuator up-

per casing (1). Repeat loading-unloading

to cycle the valve unit (AA, BA). Repeat

adjustments as necessary.

w. Completion to this point completes the

benchset range adjustment. Proceed to

the next subsection (VI.C.) to adjust 90°

travel stop, if necessary.

C. 90° Rotation Adjustment:

1. Units with ATO-FC (Reverse) Action:

a. Pressurize actuator (AA) to the higher

value of benchset range. This pressure

should cause 90° rotation as shown by

travel indicator (16).

1. Travel short of 90°. Hub of lower

L.H. rod end (9) may be touching on

downtravel stop screw’s (35) upper

end.

a. Loosen jam nut (45).

b. Rotate downtravel stop screw

(35) CCW (viewed from below

screw (35)) until 90° rotation is

reached on the travel indicator

(16).

c. Retighten jam nut (45).

2. Travel beyond 90°. Hub of lower L.H.

rod end (9) may or may not be touch ing on downtravel stop screw’s (35)

upper end.

a. Loosen jam nut (45) about four

revolutions.

b. Very slowly release air pressure

into actuator (AA) until travel

in di ca tor (16) is showing at 90°.

c. Rotate downtravel stop screw

(35) CW (viewed from below

screw (35)) until the screw’s (35)

upper edge touch es the hub of

lower L.H. rod end (9).

d. Retighten jam nut (45).

2. Units with ATC-FO (Direct) Action:

a. Loosen jam nut (45).

b. Rotate downtravel stop screw (35) CW

(viewed from below screw (35)).

c. Pressurize actuator (AA) slowly until the

travel in di ca tor (16) indicates that travel

is at 0°; the valve should be in the “fully

closed” position.

d. Adjust gap between downtravel stop screw

(35) and hub of lower L.H. rod end (9) as

indicated in following table.

e. Retighten jam nut (45).

IOM-148

21

Page 22

Product

Model

Ranger QCT 1/8” ± 1/16” (3.0 mm ± 1.5 mm)

Premier EZO 1/16” ± 1/16” (1.5 mm ± 1.5 mm)

Premier Unlined No gap; i.e. touching

Gap Between L.H. Rod End (9)

and Downtravel Stop Screw (35)

SECTION VII

VII. TROUBLE SHOOTING GUIDE

Reference the IOM of the valve body which this actuator is unitized with for additional information on Trouble Shooting.

1. Air leakage.

Possible Causes Remedies

A. Leakage at diaphragm-to-upper casing fl ange. A1. Overpressure. Check source of air supply and determine

if pressure is greater than indicated in Table 1; reset airset

pressure as required.

A2. Tighten casing fl ange bolting (27, 28, 41 & 42).

B. Leakage at handwheel gland-to-upper case. B. Faulty O-ring (62); replace O-ring.

C. Leakage at manual handwheel threads. C. Faulty thread seal (61); replace thread seal.

D. Leakage around stem on side where yoke bolts to arm housing. D1. Failure of diaphragm (6); replace diaphragm.

D2. Faulty seal (56); replace seal.

SECTION VIII

VIII. ORDERING INFORMATION

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was stamped on

the metal name plate and attached to the unit. This information can also be found on the Bill of Material (“BOM”),

a parts list that was provided when unit was originally shipped. (Serial Number typically 6 digits). Product Code

typical format as follows: (last digit is alpha character that refl ects revision level for the product).

PARTS "KIT" for FIELD REPAIR:

–

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

With this information they can provide a quotation

for a new unit including a complete description,

price and availability.

–

7

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

Identify the parts and the quantity required to repair

the unit from the “BOM” sheet that was provided

when unit was originally shipped.

NOTE: Those part numbers that have a quantity indicated

under "Spare Parts" in column "A” refl ect minimum

parts required for inspection and rebuild, - "Soft

Goods Kit". Those in column “B” include minimum

trim replacement parts needed plus those "Soft

Goods" parts from column "A".

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory. All

purposed changes will require a new name plate with appropriate ratings and new product code to accommodate

the recommended part(s) changes.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the

designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Cashco,

Inc. product remains solely with the purchaser.

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for part

identifi cation and selection.

A Local Sales Representative will provide quotation

for appropriate Kit Number, Price and Availability.

22

IOM-148

Page 23

42

28

58.1

63

58.2

25

66

47

62

26

58.2

59

65

1

3

48

49

1/4" (DN8) NPT

27

41

11

ADJUSTING SCREW ASSEMBLY

Not availabe on Air to Close-Fail Open Rangers

60

61

67

62

60

61

67

56

6

7

8

52

59

65

64

R.H. THREAD

A

43

10

L.H. THREAD

44

9

21

20

2

54

4

22

67

62

ACTUATOR PLUG

36

38

5

45

12

35

33

50

A

148 ACTUATOR

Shown Air to Open

Available on Premier Butterfl y

Valves ONLY

ITEM NO. DESCRIPTION ITEM NO. DESCRIPTION

1. Upper Case 38. Drive Screw

2. Lower Case 39. Set Screw

3. Piston 40. Bolt Shoulder

4. Arm Housing 41. Nut

5. Arm 42. Extension Nut

6. Diaphragm 43. Jam Nut

7. Clevis 44. Jam Nut (L.H.)

8. Rod End (R.H.) 45. Jam Nut

9. Rod End (L.H.) 46. Lock Nut

10. Push Rod 47. Nut

11. Spring 48. Clevis Pin

12. Cam 49. Retaining Ring

13. Cover Plate 50. Spring Pin

14. Dial Lens 51. Spring Pin

15. Travel Indicator Dial 52. Diaphragm Washer

16. Travel Indicator 54. Stop Washer

17. Indicator Spacer 55. Internal Lock Tooth Washer

18. Ball Bearing 56. Seal

20. Cover Plate 57. Retaining Ring

21. Name Plate 58. Handwheel Subassembly

22. Housing Cover or Adjusting Screw

23. Dust Cover Plate 59. Locking Lever or Nut

24. Stem Spacer 60. Washer

25. Pivot Screw 61. Thread Seal

26. Hex. Head Cap Screw 62. O-Ring (Gland to Upper Case)

27. Hex. Head Cap Screw 63. O-Ring (Handwheel to Gland)

28. Hex. Head Cap Screw 64. Ball

29. Hex. Head Cap Screw 65. Self-Tapping Screw

31. Button Head Cap Screw 66. Pin (Spring)

32. Button Head Cap Screw 67. Handwheel Gland or

33. Socket Head Cap Screw Actuator Plug

34. Button Head Cap Screw

35. Socket Head Stop Screw

36. Fillister Head Machine Screw

37. Fillister Head Machine Screw

40

34

55

17

14

15

51

32

37

29

31

18

16

13

SECTION “A-A”

23

46

57

39

24

5

12

IOM-148

23

Page 24

106

107

72

12

A

VENT

POSITIONER

Air-To-Open

AC TU A TOR

A

102

129

1/4" NPT

Supply

106

72

1/4" NPT

Signal

101

108

1/4" NPT

Supply

128

SEC TION A-A

OUTPUT

35

35

131

1/4" NPT

Inlet

35

130

VENT

STOP SCREW

106

132

73N-B POSITIONER

ITEM NO. DESCRIPTION

72 Feedback Linkage Subassembly

73 Feedback Linkage Spacer

74 Feedback Linkage Pivot Shaft

101 Positioner

102 Range Spring

106 Tube Fitting (Elbow)

107 Output Tube

108 Name Plate

SOLENOID VALVE

ITEM NO. DESCRIPTION

128 Solenoid Valve

129 Nipple

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax. # (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in U.S.A. 148-IOM

SOLENOID VALVE

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

Email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

Email: brazil@cashco.com

AIR SUPPLY REGULATOR

AIR SUPPLY REGULATOR

ITEM NO. DESCRIPTION

130 Air Supply Regulator

131 Mounting Bracket

132 Supply Tube

GAUGES (Not Shown)

ITEM NO. DESCRIPTION

135 Signal Gauge

137 Output Gauge

138 Branch Tee

139 Reducing Bushing

Loading...

Loading...