Page 1

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM)

IOM-PGR-1

MODEL PGR-1

DIRECT-ACTING, PRESSURE LOADED

PRESSURE REDUCING REGULATOR

SECTION I

I. DESCRIPTION AND SCOPE

Model PGR-1 is a pressure reducing regulator used to control downstream (outlet or P2) pressure. Sizes are

1/2" (DN15), 3/4" (DN20), 1" (DN25), 1-1/2" (DN40), 2" (DN50), 3" (DN80) and 4" (DN100). This model is applied

primarily in gaseous service.

SECTION II

03-14

II. REFERENCES

Refer to Technical Bulletin PGR-1-TB for tech ni cal

specifi cations for this reg u la tor.

SECTION III

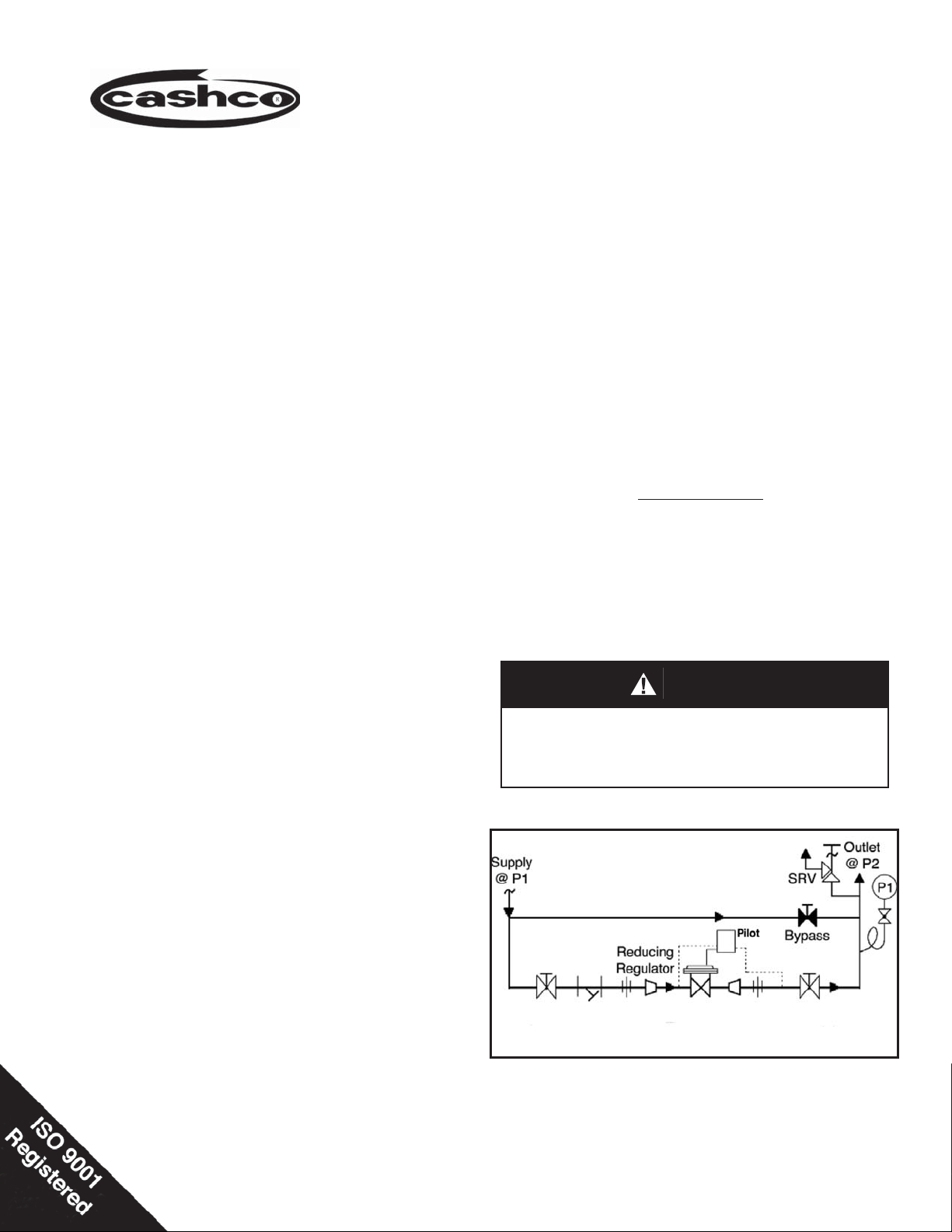

III. INSTALLATION

1. Regulator may be rotated around pipe axis 360

degrees. For ease of maintenance, the rec om mend ed position is with the cover dome (2)

up wards.

2. Provide space below, above, and around reg u la tor for removal of parts during maintenance.

3. Install block valves and pressure gauges to pro vide means for adjustment, operation, bypass,

or removal of the regulator. A pipeline strainer

is recommended before inlet to remove typical

pipe line debris from entering valve and damaging

internal “soft goods”, primarily the dynamic seal.

ABBREVIATIONS

CW – Clockwise

CCW – Counter Clockwise

ITA – Inner Trim Assembly

CAUTION

Installation of adequate overpressure pro tec tion is recommended to pro tect the reg u la tor from overpressure and

all down stream equip ment from damage in the event of

regulator failure.

Model PGR-1

Page 2

SECTION IV

CAUTION

DO NOT HYDROSTATIC TEST THROUGH AN IN STALLED

UNIT; ISOLATE REGULATOR FROM TEST. The "OUTLET

RATING" as printed on the name plate is the rec om mend ed

“upper op er at ing limit” for the sens ing di a phragm. Higher

pres sures could cause internal dam age. In ad di tion, note

on the nameplate that the Inlet and Outlet pres sure and

temperature ratings are at different levels.

IV. PRINCIPLE OF OPERATION

1. When a loading pressure – P

the top side of a diaphragm, the outlet controlled

pressure – P

– will balance at approximately

2

.90 – .98 of the loading pressure - PL.

– is applied to

Load

SECTION V

V. STARTUP

1 Start with the block valves closed.

2. Movement occurs as pressure variations register

on the diaphragm. The registering pressure is the

outlet, P

, or downstream pressure. The loading

2

pressure fl uid op pos es di a phragm move ment.

As outlet pres sure drops, the loading pressure

push es the di a phragm down, opening the port; as

outlet pres sure increases, the diaphragm pushes

up and the port opening closes.

3. A diaphragm failure will tend to cause the reg u la tor

to fall below setpoint. A loss of loading pres sure

while inlet pressure is imposed will cause the

regulator to fail close.

pressure upwards until the main valve is fl owing.

Observe the outlet pressure gauge to ensure not

overpressurizing.

CAUTION

Do not walk away and leave a bypassed reg u la tor unattended!

2. Rotate the adjusting screw (47) on the pilot valve

CCW so that main regulator is trying to be con trolled

at 0 psig pressure. DO NOT rotate the adjusting

screw on the stabilizer, stabilizer was preset and

calibrated at the factory.

3. DO NOT rotate knob on metering valve, it was

preset at the factory at 2.5 to 3 full revolutions from

closed position. DO NOT close metering valve.

4. If it is a “hot” piping system, and equipped with

a bypass valve, slowly open the bypass valve

to preheat the system piping and to allow slow

ex pan sion of the piping. Closely monitor outlet

(down stream) pressure via gauge to ensure not

over-pressurizing. NOTE: If no bypass valve is

in stalled, extra caution should be used in starting

up a cold system; i.e. do everything slowly.

5. Crack open the outlet (downstream) block valve

to approximately 10% full open.

6. Slowly open the inlet (upstream) block valve to

about 25% open. Rotate the adjusting screw

(47) on the pilot valve CW to increase setpoint

7. Continue to slowly open the inlet (upstream) block

valve until fully open.

8. Continue to slowly open the outlet (downstream)

block valve, especially when the downstream piping system isn’t pressurized. If the outlet (down stream) pressure exceeds the desired pres sure,

close the inlet block valve and go to Step 2. Close

bypass valve approximately 25%, and re peat

pro ce dure.

9. When fl ow is established steady enough that the

outlet (downstream) block valve is fully open, begin

to slowly close the bypass valve if installed.

10. Develop system fl ow to a level near its expected

normal rate, and reset the regulator set point by

rotating the adjusting screw (47) on the pilot valve

CW to change the setpoint to the desired outlet

pressure level. If system pressure is unstable

rotate knob on metering valve in quarter turn increments CW or CCW to combat instability. DO

NOT rotate knob more than 6 full revolutions from

the closed position.

11. Reduce system fl ow to a minimum level and

observe pressure set point. Outlet pressure will

rise from the set point of Step. The max i mum rise

in outlet pres sure on de creas ing fl ow should not

exceed the 10%. If it does, consult factory.

2

IOM-PGR-1

Page 3

VI. SHUTDOWN

1. Shutoff inlet block valve.

SECTION VI

4. Relieve any trapped upstream and downstream

pressure and loading pres sure from PGR-1.

2. Allow suffi cient time for the line pressure down-

stream of the inlet block valve to bleed down.

3. Shutoff the outlet block valve.

SECTION VII

VII. MAINTENANCE

WARNING

SYSTEM UNDER PRESSURE. Prior to per form ing any

maintenance, isolate the reg u la tor from the system and

relieve all pressure. Failure to do so could result in personal injury.

A. General:

1. The main regulator body may be serviced

without re mov ing the regulator from pipeline.

The reg u la tor is designed with quick-change

trim to simplify maintenance.

2. Record the name plate information to req-

ui si tion repair parts for the regulator. This

in for ma tion should include: Serial Number

and Product Code.

5. The regulator may now be removed from the

pipe line or disassembled for inspection and pre ven ta tive main te nance while in-line.

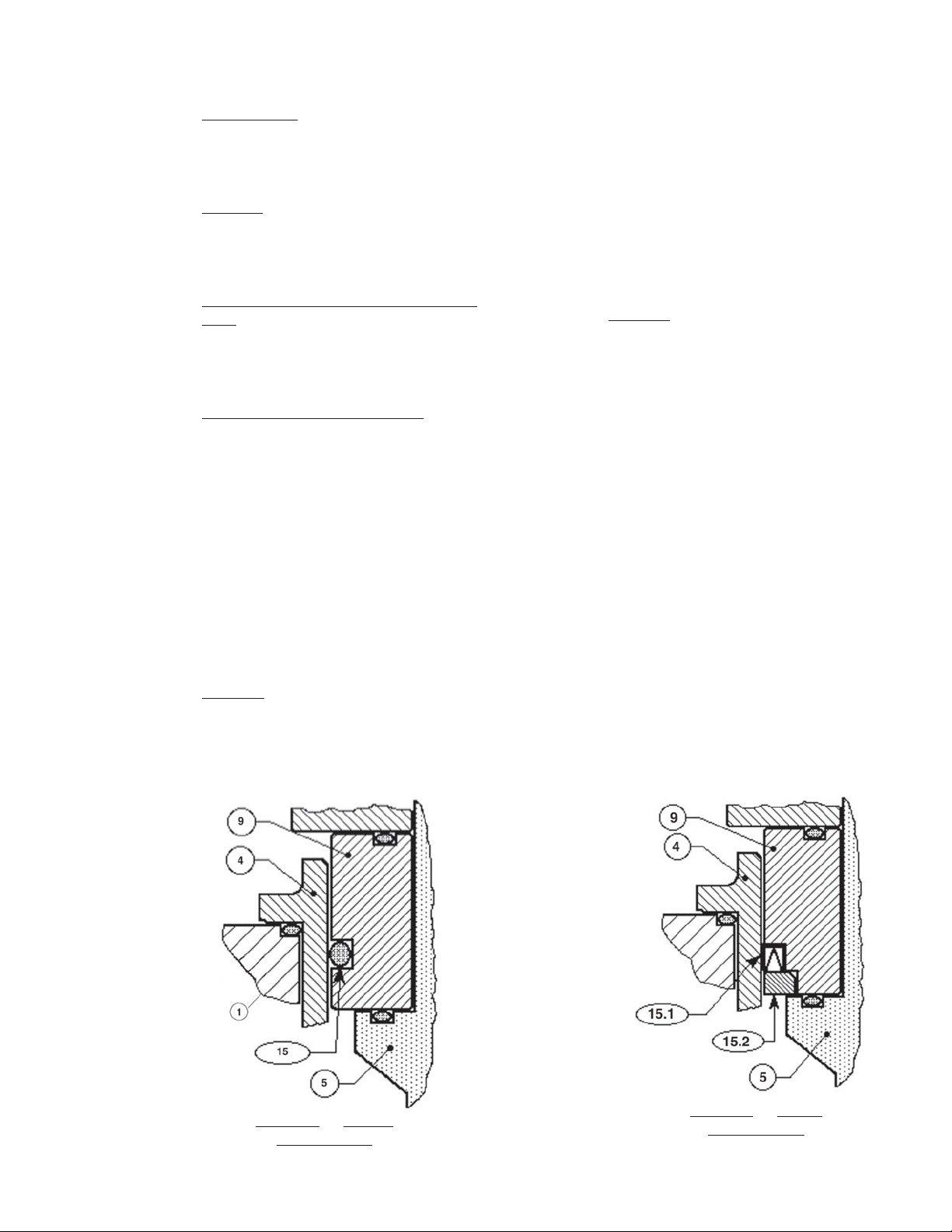

Item Dynamic

No. Seal Type Part Description

4 .......................All....................................................Cage

5........................All......................................................Plug

9 ......................All .....................................Guide Bearing

10......................All......................................................Seat

13 .....................All ................................. Static Stem Seal

13.1 ............... All ...................... Upper Static Stem Seal

13.2 ............... All ......................Middle Static Stem Seal

13.3 ............... All ...................... Lower Static Stem Seal

14 ......................All..................................Cage O-ring Seal

15......................OR...........................Dynamic O-ring Seal

15.1...............UC............................Dynamic U-cup Seal

15.2............... UC.......................................Seal Retainer

B. Main Valve Disassembly:

1. Shut down system in accordance Section

VI.

2. Disconnect the external sensing line from

the pilot valve sensing port.

3. Refer to Section IX for recommended repair

parts. Only use original equipment parts

sup plied by Cashco for re build ing or re pair ing reg u la tors.

4. Owner should refer to owner's procedures

for removal, handling, cleaning and disposal

of nonreuseable parts, i.e. gaskets, etc.

NOTE: On regulators originally supplied as

“special clean” – Opt-56, maintenance must

include a level of cleanliness equal to Cashco

cleaning standard #S-1542.

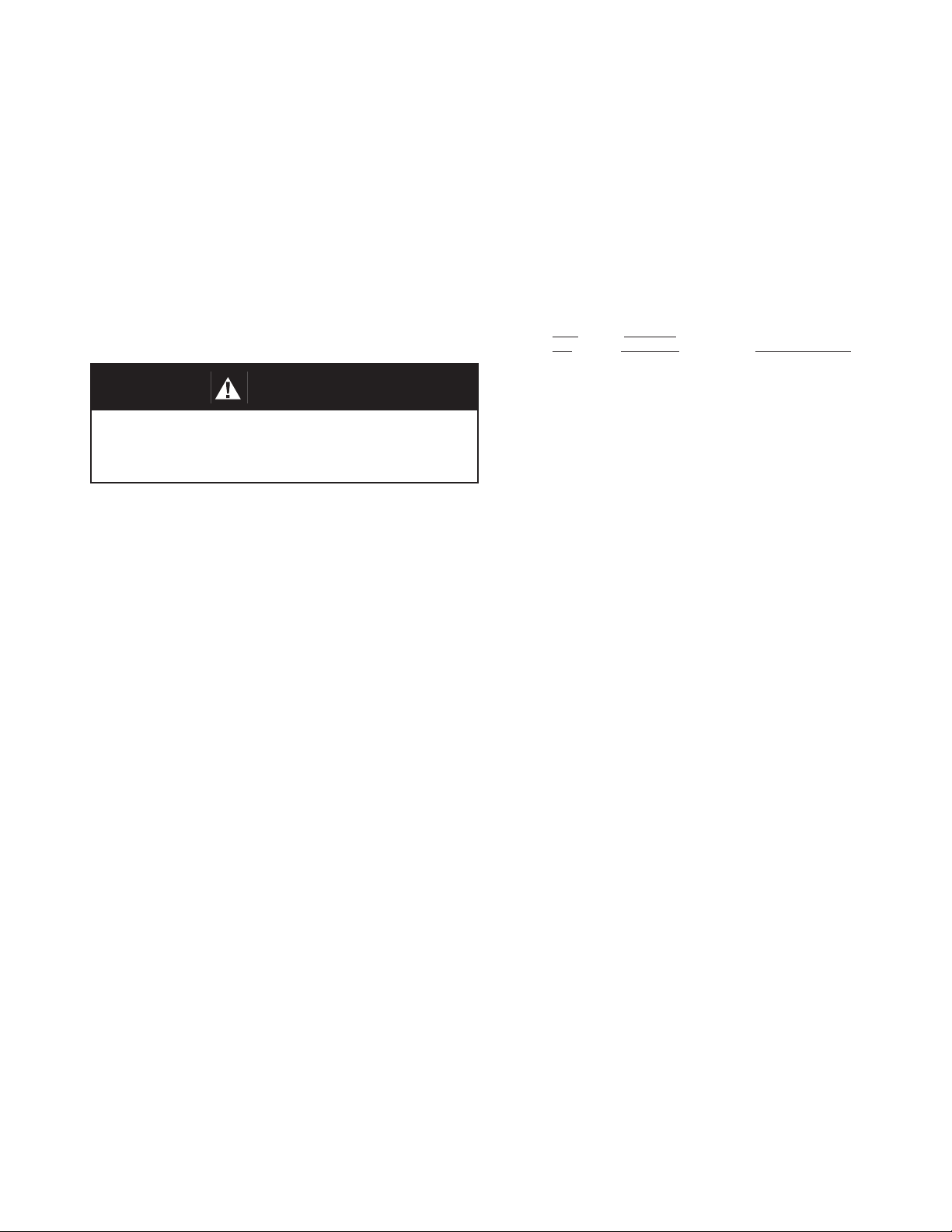

5. The Inner Trim is re moved and replaced back

in the body (1) as an assemblage of parts.

The Inner Trim Assembly, here in af ter called

ITA, consists of following parts: (See Figure

1)

A detailed view of the dynamic side seal

parts is shown on page 5.

3. Though it is possible to disassemble the

valve unit while installed in a pipeline, it is

rec om mend ed that all maintenance be done

in a shop. The instructions hereafter will assume in shop disassembly. Remove valve

from pipeline.

4. Place the main valve unit in a vise with the

cover dome (2) upwards.

5. Loosen all fi tings and remove tubing that

connect the inlet fi lter to the stablizer, the

cover dome to the metering valve and the

outlet of the metering valve to the outlet of

the body.

6. Loosen and remove the two nuts (24) that

secure the mounting bracket (3) and pilot to

the cover dome (2). Set pilot assembly aside.

Place match marks on the cover dome fl ange

to mark the location for the mounting bracket

and two longer bolts (23).

IOM-PGR-1

3

Page 4

7. Loosen the diaphragm fl ange bolts (23) and

nuts (24) uniformly and remove.

8. Place matchmarks on body (1) and cover

dome (2) fl anges. Remove cover dome.

9. With wrench grasp and hold the milled “fl ats”

on top of the valve plug (5) stationary. Rotate

di a phragm nut (11) CCW and remove .

10. Remove upper diaphragm plate (7).

11. Remove diaphragm (6) and o-ring upper stem

seal (13). Examine diaphragm to determine

whether failed; determine if op er at ing conditions are ex ceed ing pressure, pressure drop

or temperature limits.

12. Re move lower diaphragm pusher plate (8).

13. Rotate the cage bolts (22) CCW evenly in single

revolution increments. Regulator con tains a

lower return spring (18); the ITA should rise

up as the cage cap screws are evenly backed

out. A down wards holding force should be

ap plied to the top of the guide bearing (9) to

pre vent the ITA from pop ping up as the last

threads of the cage bolts are backed out.

14. Remove the ITA by pulling up on the valve

plug (5). Set ITA aside.

d. Examine the com po nent(s) (15 or 15.1,

15.2) of the dy nam ic side seal to de ter mine if sig nifi cant leakage was oc cur ring.

If the dy nam ic side seal shows signs of

sig nifi cant leakage, de ter mine if op er at-

ing con di tions are ex ceed ing pres sure,

pres sure drop, or tem per a ture limits.

Remove dynamic side seal com po nents.

Special care should be taken when using “tools” to remove the components to

ensure that no scratches are imparted

to any portion of the guide bearing (9)

groove.

e. Remove o-ring lower stem seal (13) from

plug (5).

f. Remove seat (10); examine for signs of

leakage. If seat ring shows signs of signifi cant leakage, determine if op er at ing

con di tions of pressure, pressure drop, or

temperature are ex ceed ing limits.

913

15

14

4

15. Remove the lower return spring (18) from

within the body (1) cavity.

16. Remove cage o-ring seal (14). It may have

been removed when the ITA was lifted out of

the body.

17. Remove internal sensing drilled plug (19) using 5/32" (4 mm) allen wrench.

18. Remove body (1) from vise. Clean all re us able

metal parts according to owner's pro ce dures.

C. Disassembly of the ITA:

1. See Figure 1 for details:

a. While holding the cage (4) pull the valve

plug (5) down wards and thru of the guide

bear ing (9) and out the bottom of the cage.

b. Remove the guide bearing (9) from the

upper end of the cage (4).

c. Remove o-ring middle stem seal (13) from

guide bearing (9).

5

10

Figure 1: Assembled ITA,

D. Inspection of Parts:

1. After inspection remove from the work area

and dis card the old “soft goods” parts (i.e. orings, di a phragms, seals, gaskets, etc.) after

in spec tion. These parts MUST be re placed

with fac to ry supplied new parts.

2. Inspect the metal parts that will be reused. The

parts should be free of surface con tam i nants,

burrs, oxides, and scale. Rework and clean

parts as necessary. Surface con di tions that

affect the regulator performance are stated

below; replace parts that can not be re worked

or cleaned.

4

IOM-PGR-1

Page 5

3. QC Requirements:

a. Valve plug (5);

1. 16 rms fi nish on its seating surface

for tight shutoff.

2. No major defects on bottom guide

spin dle.

b. Cage (4);

1. 16 rms fi nish on cylinder bore. No

“ledges” formed due to wear from

moving dynamic side seal (27) or

wiper seal (16).

c. Lower guide bushing (24) (non-re place-

able):

1. 16 rms fi nish on bore.

2. Max 0.015 inch (0.38 mm) clearance

be tween valve plug (20) spindle and

lower guide bushing (24).

d. Internal sensing drilled plug (32);

1. Ensure that bore is minimum 0.125

inch (3.20 mm). Drill out as required.

4. Staging Material for Reassembly.

a. Inspect and clean parts, as necessary,

from the spare parts kit. (See Article VII

A.4. comments concerning special cleaning.

b. Lay out all the regulator parts and check

against the bill of material.

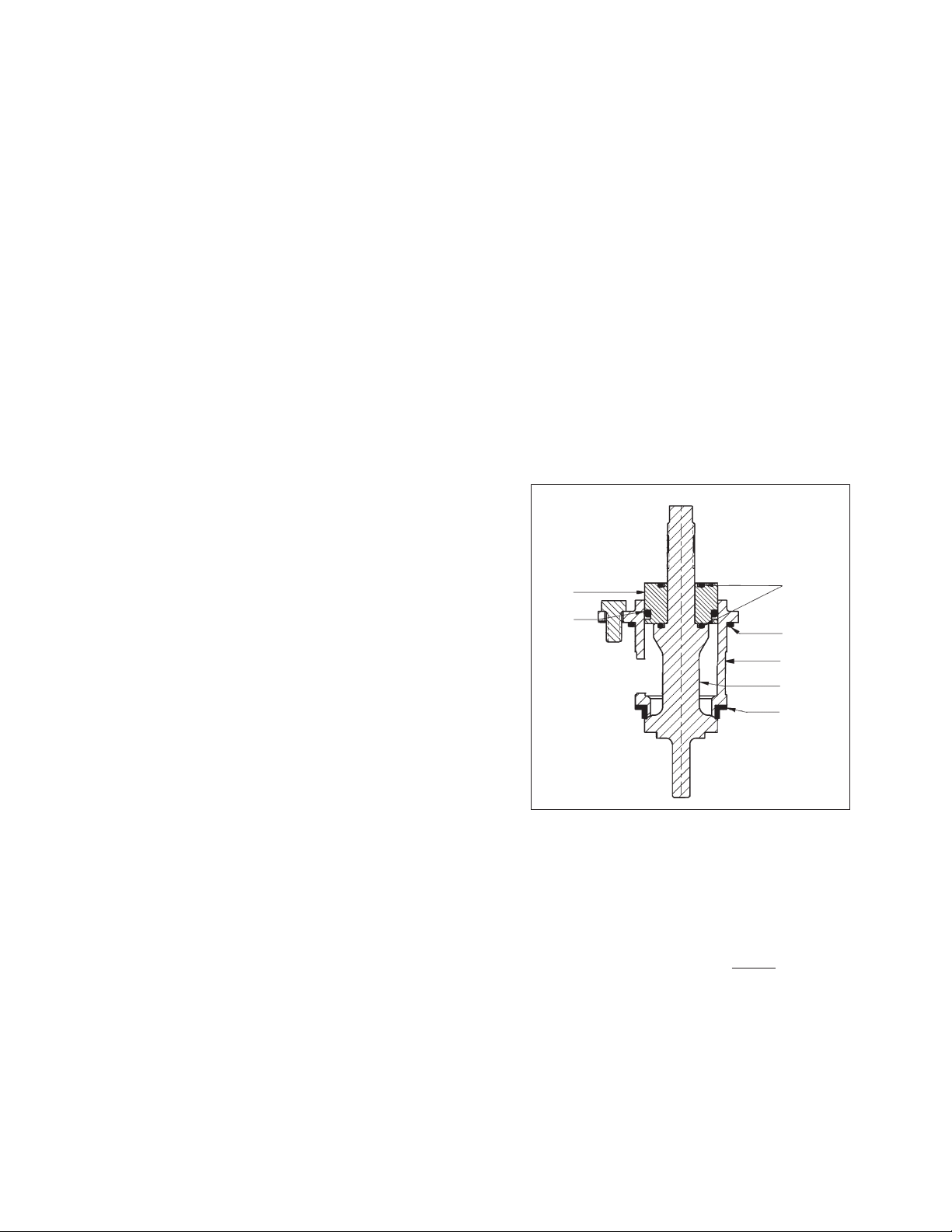

E. Reassembly of the ITA:

1. Installation of dynamic side seal (15).

a. Type OR:

1. Stretch o-ring seal (15) over lower

cir cum fer ence of guide bear ing (9),

tak ing care not to “cut” o-ring seal.

Using thumbs, work the o-ring seal

up and into the groove of the guide

bearing. NOTE: A very slight amount

of fl uid and elas tomer compatible

lu bri cant is rec om mend ed as an

in stal la tion aid.

2. Position guide bearing (9) over top

of the upper end of cage (4) properly

oriented. Using thumbs, evenly press

guide bearing into the cage, ensuring not to “cut” o-ring seal. Continue

pressing guide bearing into cage until

in ap prox i mate fi nal position.

b. Type UC:

1. Stretch u-cup seal (15.1) over lower

circumference of guide bear ing (9),

taking care not to “cut” u-cup seal on

the protruding shelf that is part of the

guide bear ing's groove. Ensure that

the u-cup seal is oriented with the

center-open-downwards as shown

in image below, as the u-cup seal

depends upon the P1-Inlet Pres sure

to pressure activate the seal for proper

sealing action.

2. Position guide bearing (9) over top

of the upper end of cage (4) properly oriented, until the cup seal edge

touches the upper lip of the cage

(4). While gently applying force to

press the guide bearing (9) into the

cage, simultaneously use fi ngers to

lightly press the edges of the u-cup

seal inwards into the groove of the

guide bearing until the u-cup seal

(15.1) “slips into” the cage (19). DO

NOT USE TOOLS, LUBRICANT, OR

HEAVY FORCE TO ENGAGE THE

U-CUP SEAL INTO THE CAGE .

IOM-PGR-1

Type OR — O-Ring

Dynamic Seal

Type UC — U-Cup

Dynamic Seal

5

Page 6

2. Place properly oriented seat (10) onto its

shoul der at the lower end of cage (4).

3. Place new o-ring lower stem seal (13) into

groove of valve plug (5).

4. Insert valve plug (5) upwards through lower

end of cage (4) and through the center hole

in guide bearing (9). Hold plug and cage

together in the closed position.

5. Place an oversized nut or stack of wash ers,

the same approximate height of the up per

diaphragm plate (7) and the lower diaphragm

plate (8), over the upper end of valve plug

(5) and temporarily secure with diaphragm

nut (11), manually tightened. Do NOT al low

valve plug to rotate against seat (10) during

tightening.

6. This completes ITA preliminary/partial reassembly.

F. Main Valve Reassembly:

1. Place body (1) in a vise fl ange face up.

2. Reinstall internal sensing drilled plug (19) with

compatible thread sealant.

3. Insert the lower return spring (18) into the

body (1).

4. Fit the cage o-ring seal (14) into the body

groove.

5. With the ITA held manually in the closed po si tion, insert ITA into body (1).

6. Properly align bolt holes in the cage with

the holes in the body, as there is only one

circumferential location pos si ble for this align ment. Apply downward force to the top of the

cage (4) until the ITA is lowered suf fi cient ly

to engage the cage bolts (22) into the body

(1). Engage all of the cage bolts, Rotate the

cage bolts in one-half revolution increments

to pull down the ITA evenly, taking care NOT

TO “AN GLE” the ITA in the body. Torque the

cage bolts to 13-15 ft-lbs. (17.6-20.3 N-m).

9. Position lower diaphragm plate (8) over upper end of plug (5) with tongue and groove

“groove” side up.

10. Place new o-ring upper stem seal (13) over

upper end of valve plug (5).

11. Place diaphragm (6) over end of valve plug

(5).

12. Place upper diaphragm plate (7) over upper

end of plug (5) with tongue and groove “ridge”

side down.

13. Place lubricant on valve plug (5) thread ed end.

Engage diaphragm nut (11) with upper end

of valve stem (5) as far as possible manually.

Place a wrench on diaphragm nut and a torque

wrench on the upper end of valve plug . Hold

torque wrench sta tion ary and rotate diaphragm

nut (7) to the following torque values:

Body Size

in (DN)

1/2" - 1" (15 - 25) 60 - 70 (81 - 95)

2" (50) 120 - 130 (163 - 176)

3" - 4" (80 - 100) 180 - 200 (244 - 271)

Torque Value

Ft-lbs (N-m)

DO NOT allow valve plug (20) to rotate

against seat ring (21) during tightening.

14. Aligning matchmarks and bolt holes, place

cover dome (2) onto body (1).

15. Reinstall all fl ange bolts (23) and nuts (24)

with nameplate (26) located under one bolt

head. Hand-tighten nuts. Make sure to install

the two longer bolts for the pilot bracket in the

correct location.

16. Evenly tighten the boltin in an alternating

cross pattern in one revolution increments to

the following torque values:

Body Size

in (Dn)

1/2" - 2" (15 - 50) 30 - 35 (41 - 47)

3" - 4" (80 - 100) 45 - 50 (61 - 69)

Torque Value

Ft-lbs (N-m)

G. Pilot Valve Disassembly:

7. Remove temporarily installed diaphragm nut

(11) and spacers of previous Step E.5. this

WARNING

section.

SYSTEM UNDER PRESSURE. Prior to per form ing any

8. Place new o-ring middle stem seal (13) into

groove of guide bearing (9) upper surface.

6

maintenance, isolate the reg u la tor from the system and

relieve all pressure. Failure to do so could result in personal injury.

IOM-PGR-1

Page 7

1. Shut down system in accordance Section VI.

2. Disconnect the external sensing line, from the

pilot valve sensing port.

3. Loosen all fi tings and remove tubing that con-

nect the inlet fi lter to the stablizer, the cover

dome to the metering valve and the outlet of

the metering valve to the outlet of the body.

4. Loosen and remove the two nuts (24) that

secure the mounting bracket (3) and pilot to

the cover dome (2).

5. Remove pilot assembly from main valve.

6. Place the pilot valve body (31) in a vise with

the spring chamber (32) upwards.

16. Remove return spring (41), ball holder (39),

and ball (52).

17. Place socket wrench over seat (37) and rotate

CCW to remove from body.

18. Remove body (1) from vise. Clean all re us able

metal parts according to owner's pro ce dures

H. Pilot Valve Reassembly:

1. Place body (31) in a vise fl ange face down.

2. Apply "Gasoila" or equivalent, thread sealant

to the threads of the seat (37). Engage the

seat threads into the body and apply 20 - 25

ft-lbs. torque. Place the ball (52), ball holder

(39) and return spring (41) onto seat.

7. Loosen adjusting screw nut (48) one revolution CCW. Relax range spring (34) forces

by rotating adjusting screw (47) CCW until

removed from spring chamber (32).

8. Loosen the diaphragm fl ange bolts (49) and

nuts (51) uniformly and remove bolting.

9. Place match marks on body (31) spring chamber (32) fl anges. Remove spring chamber.

10. Remove spring button (35), range spring (34)

and pressure plate (36).

11. Remove diaphragm (43).Examine diaphragm

to determine whether failed; determine if op er at ing conditions are exceeding pressure,

pressure drop or temperature limits. If just

replacing the diaphragm, proceed to Step H.9

and skip the following instructions.

12. Grasp pusher post (42) and lift up to remove.

Place socket wrench over retainer (40) and

rotate CCW to remove from body.

13. Remove seal gasket (45), piston seal (44) and

a second seal gasket (45) from bore inside

the body.

14. To remove the stem (38), remove the body

from the vise and slowly turn upside down.

Stem will slide out of the body, Do Not let the

stem fall and hit the fl oor.

15. Place body (31) in a vise with the body cap

(33) upwards. Rotate cap bolts (5) CCW to

remove bracket and body cap. Remove cap

seal (46).

3. Place the o-ring (46) into the groove in the

body cap (33) and place onto the body.

Position the bracket on the body cap and reinstall cap bolts (50). Make sure the return

spring (41) fi ts inside the bore of the body

cap. Tighten nuts evenly in a star crossing

pattern. Apply 15 - 18 ft-lbs. torque to tighten

the cap bolts.

4. Remove body from the vise. Reinstall body

again in vise with the bolt fl ange facing up.

5. Insert the stem (38) into the center hole of

the body and the seat (37), square end fi rst.

6. Place one seal gasket (45), one piston seal

(44) and one seal gasket (45) into the center

bore on top of the stem ((38). See Detail "A".

Ensure to align the seal and gaskets so they

are centered inside the threaded bore hole.

7. Engage the retainer (40) threads into the

center bore hole to hold the piston seal and

gaskets in place and apply 75 in-lbs. torque.

to tighten.

8. Insert pusher post (42) into retainer (40).

9. Place diaphragm (43) on bolt fl ange, centered

between bolt holes. Center the pressure

plate (36) on top of the diaphragm.

10. Place range spring (34) in center of the pressure plate (36) cup. Apply Mobile XHP 222

grease or equivalent into recessed area of

the spring button (35) and place on top of the

range spring. (Also lubricate the threads of

the adjusting screw lightly).

IOM-PGR-1

7

Page 8

11. Engage threads of the adjusting screw (47)

into the spring chamber (32) three or four

revolutions and place the spring chamber

over the spring button and spring.

12. Align the match marks on the body and spring

chamber fl anges. NOTE: Vent hole in the

spring chamber should be directly above the

"sense port in the body.

13. Place fl ange bolts through holes in spring

chamber and body and engage nuts (51).

Tighten nuts evenly in a star crossing pattern.

Apply 15 - 18 ft-lbs. torque to fi nsih tightening.

Ensure to secure the name plate (53) under

one of the fl ange bolts (49) above the "inlet"

of the pilot.

14. Rotate adjusting screw (47) CW into the spring

chamber (32) to where the nut (48) comes in

contact with the top of the spring chamber.

Pilot valve set pressure should approach

the set point prior to removal from the piping

installation. Retighten nut (48).

BODY

(INSIDE)

ELEMENT

COVER

Inlet Filter

K. Disassembly of the Stabilizer:

I. Mounting Pilot Valve to Main Valve:

1. Place the bolt holes for the mounting bracket

over the the two longer bolts (23) installed

throught the top of the cover dome (2). Engage

the fi nal two nuts (24) and secure tight.

2, Re-install tubing and fi ttings that previously

connected the inlet fi lter to the stablizer, the

cover dome to the metering valve and the

outlet of the metering valve to the outlet of

the body.

3. Re-connect the external sensing line to the

pilot valve sensing port.

WARNING

SYSTEM UNDER PRESSURE. Prior to per form ing any

maintenance, isolate the reg u la tor from the system and

relieve all pressure. Failure to do so could result in personal injury.

J. Changing the fi lter element:

1. Maintenance procedures hereinafter are

based upon re mov al of the stabilizer from

the pilot. Shut down system in accordance

Section VI.

2. Owner should refer to owner's procedures for

removal, handling, cleaning and disposal of

non reuseable parts, i.e. gaskets, etc.

3. Loosen fi ting and remove tubing that con-

nect the inlet fi lter to the stablizer, Remove

stabilizer from fi ttings that run between the

stabilizer and the pilot.

4. Securely stabilizer body (61) in a vise with

the spring chamber (62) oriented upwards

CAUTION

To prevent damage to body, use soft jaws when securng

the body in a vise. Position so that vise closes over the

inlet and the outlet connections.

DIAPHRAGM REPLACEMENT -

1. See Section IV.

2. Unscrew the fi lter cover from the body. Re-

move old element and replace with new element.

SPRING UNDER COMPRESSION. Prior to re mov ing the

spring chamber, relieve spring com pres sion by back ing

out the adjusting screw. Fail ure to so so may result in

fl ying parts that could cause personal injury.

WARNING

3. Screw cover on fi lter body and secure tight.

8

IOM-PGR-1

Page 9

1. Loosen adjusting screw nut (71) one revolution CCW. Relax range spring (75) forces

by rotating adjusting screw (68) CCW until

removed from spring chamber (62).

2. Loosen spring chamber (62) by placing

wrench on “fl ats” and rotating CCW making

sure not to use the fl at where the vent hole

is located.

3. Remove spring chamber (62), spring (75)

and spring button (65).

12. Reinstall ad just ing screw (68) with nut (71)

into the spring chamber (62).

13. Pressurize with air and spray liquid leak

de tec tor to test around body and spring

cham ber for leakage. En sure that an outlet

pressure is main tained during this leak test

of at least mid-range spring level; i.e. 20-80

psig (1.4-5.5 Barg) range spring, 50 psig

(3.4 Barg) test pres sure min i mum.

TRIM REPLACEMENT -

4. Remove the diaphragm subassembly

con sist ing of the pressure plate nut (70),

lock wash er (69), pres sure plate (63), diaphragm (72), push er plate seal (73) and

pusher plate (64).

5. Loosen pusher plate nut (70) and separate

all parts (63, 64, 69, 72 & 73) of the diaphragm subassembly.

6. Inspect pressure plate (63) to ensure no

de for ma tion due to over-pressurization. If

de formed, replace.

7. Clean all re us able metal parts according to

owner's pro ce dures.

8. Reassemble diaphragm subassembly

by plac ing pusher plate seal (73) over

thread ed post of pusher plate (64), placing diaphragm (72) and pressure plate

(63) over the threaded post. Assure the

pressure plate (63) is placed with curved

outer rim down next to the diaphragm (72)

surface. Place a thread sealant compound

on the threads of the push er plate post (64).

Apply 15 in-lbs torque to tighten the nut.

9. Place spring (75) over the pusher plate

nut (70) of the diaphragm subassembly.

10. Place multipurpose, high temperature

grease into de pres sion of spring button

(65) where ad just ing screw (68) makes

contact. Set spring but ton (65) onto range

spring (75); en sure spring button is laying

fl at on top of spring.

11. Rotate the spring chamber (62) CW by

hand into the threaded portion of the body

(61) ensuring not to cross thread. Continue

ro tat ing CW until fi rmly seated against the

upper di a phragm. Tighten to 30-35 ft-lbs

(41-47 N-m) torque value.

1. Secure stabilizer body (61) in a vise with

the body cap (66) oriented up and the

spring chamber (62) down wards.

CAUTION

To prevent damage to the body, use soft jaws when securing body in a vise. Position body so that vise closes over

the inlet and the outlet connections.

2. Loosen and remove body cap.

3. Remove piston spring (67), and piston

(74). Note that the seat and piston guide

are in te gral parts of the body (61) cast ing.

Inspect integral seat and guide for ex ces sive

wear, espe cially at seat sur fac es. Replace if

worn, nicked or de pressed. If integral seat

is nicked, use seat lapping com pound to

remove.

NOTE: Pis ton (74) assembly is a com po si-

tion seat, Cashco, Inc. does not recom mend

at tempt ing to remove the com po si tion seat.

If composition seat is damaged, re place

entire piston assembly.

4. Clean fl at mating surfaces of body (61) to

body cap (66) shoulder. Be careful not to

scratch either surface.

5. Clean debris from within the body (61) cavity. Parts to be reused should be cleaned

ac cord ing to own er's pro ce dures.

6. Slide the post end of the piston (74), slowly

into the body cavity.

7. Place piston spring (67) over spring hub of

the piston (74).

8. Apply pipe thread sealant to the body cap

(66) threads. Thread body cap into body.

When body cap is fully down against body

at the body cap shoulder, impact the body

cap into the body tight. NOTE: When unit is

put into service and pressurized, these two

parts seal metal-to-metal with no gasket.

IOM-PGR-1

9

Page 10

9. Bench test unit for suitable operation.

NOTE: Regulators are not tight shutoff devices. Even if pressure builds up beyond set

point, a reg u la tor may or may not develop

bubble tight shutoff. In general, tighter

shutoff can be expected with composition

seat.

10. Pressurize with air and spray liquid leak

de tec tor to test around body cap (66) and

body (61) for leak age. Test pres sure should

be a mini mum of 100 psig (6.9 Barg) at the

inlet.

11. Remove body from vise, rotate down side

up and secure body in vise with body cap

down.

12. Reassemble diaphragm subassembly by

plac ing pusher plate seal (73) over thread ed

post of pusher plate (64), placing diaphragm

(72) and pressure plate (63) over the

threaded post. Assure the pressure plate

(63) is placed with curved outer rim down

next to the diaphragm (72) surface. Place

a thread sealant compound on the threads

of push er plate post (64). Apply 15 in-lbs.

torque to tighten the nut.

pressure is main tained during this leak test

of at least mid-range spring level; i.e. 20-80

psig (1.4-5.5 Barg) range spring, 50 psig

(3.4 Barg) test pres sure min i mum.

13. Place spring (75) over the pusher plate

nut (70) of the diaphragm subassembly.

14. Place multipurpose, high temperature

grease into de pres sion of spring button (65)

where ad just ing screw (68) makes contact.

(Also lubricate the threads of the adjusting

screw lightly).

15. Set spring but ton (65) onto range spring

(75); en sure spring button is laying fl at on

top of spring.

16. Rotate the spring chamber (62) CW by

hand into the threaded portion of the body

(61) ensuring not to cross thread. Continue

ro tat ing CW until fi rmly seated against the

upper di a phragm. Tighten to 30-35 ft-lbs

(41-47 N-m) torque value.

17. Rotate adjusting screw (68) CW into the

spring chamber (62) to where the nut (71)

comes in contact with the top of the spring

chamber. Stabilizer set pressure should

approach the set point prior to removal from

the piping installation.Retighten nut (71).

10

18. Pressurize with air and spray liquid leak

de tec tor to test around body and spring

cham ber for leakage. En sure that an outlet

IOM-PGR-1

Page 11

SECTION VIII

VIII. TROUBLE SHOOTING GUIDE

When trouble shooting this regulator there are many possibilities as to what may be causing problems. Many times, the regulator itself is not defective, but one or more of the accessories may be. Sometimes the pro cess may be causing diffi culties.

The key to effi cient trouble shooting is information and communication. The customer should try to be as precise as possible

in their explanation of the problem, as well as their understanding of the application and operating con di tions.

It is imperative the following information be provided by the customer:

• Type of Service (with fl uid properties) • Range of outlet pressure

• Range of fl ow rate • Range of temperature

• Range of inlet pressure • Range of ambient temperature

Pressure readings should be taken at every location where pressure plays a role - i.e., regulator inlet (as close as possible to

inlet port), regulator outlet (as close as possible to outlet port), etc.

Following are some of the more common complaints along with possible causes and remedies.

1. Erratic regulation, instability or hunting.

Possible Causes Remedies

A. Sticking of internal parts. A. Remove internals, clean, and if necessary, replace.

B. Oversized regulator.

C. Metering Valve may not be adjusted correctly.

B. Check actual fl ow conditions; resize regulator for min i mum and maxi-

mum fl ow; if necessary, replace with smaller regulator.

C1. Rotate knob on metering valve in 1/4 turn increments to be more or

less sensitive to changes in P2 pressure. DO NOT fully close the

metering valve.

2. Downstream pressure will not reach desired setting.

Possible Causes Remedies

A. Supply pressure is down (confi rm on pressure

gauge.

B. Undersized regulator. B. Check actual fl ow conditions; resize regulator for min i mum and maxi-

C. Pressure loading system pressure restricted. C1. Clean fi lter.

D. Faulty loading pressure control device. D. Replace/repair loading pressure control device.

A. Increase supply pressure.

mum fl ow; if necessary, replace with larger regulator.

C2. Clean pilot valve.

3. Diaphragm continually breaks.

Possible Causes Remedies

A. Stem seals (13) which protect fl uorocarbon

elastomer in diaphragm assembly may have

deteriorated.

B. Diaphragm nut (11) may not be torqued to

correct value.

A. Replace with new stem seals (13).

B. Confi rm torque value in accordance with Section VII, F-13.

IOM-PGR-1

11

Page 12

4. Diaphragm continually breaks (all regulators).

Possible Causes Remedies

A. Differential pressure across diaphragm may

have exceeded limits.

A1. Be aware of limits as well as where the various pressures are acting.

Install pressure safety equipment as necessary.

5. Leakage at diaphragm fl ange.

Possible Causes Remedies

A. Body bolts not torqued properly. A. Torque to proper value (see Section VII, F-16).

B. Pressures at diaphragm may be too high. B. Consult factory.

6. Leakage across seat.

Possible Causes Remedies

A. Contamination (debris) in regulator. A. Remove internals, clean, and if necessary, replace sealing and

seating elements. *

B. Oversized regulator; valve plug operates

directly next to seat.

* Seat leakage may be diagnosed when a failure of the dynamic side seal has occurred. Inspect both potential internal leak paths.

B. Check actual fl ow conditions; resize regulator for minimum and maxi-

mum fl ow; if necessary, replace with smaller regulator.

SECTION IX

IX. ORDERING INFORMATION

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was stamped on

the metal name plate and attached to the unit. This information can also be found on the Bill of Material ("BOM").

a parts list that was provided when unit was originally shipped. (Serial Number typically 6 digits). Product Code

typical format as follows: (last digit is alpha character that refl ects revision level for the product).

–

–

7

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen-

NEW REPLACEMENT UNIT:

ta tive with the Serial Number and Product code.

Identify the parts and the quantity required to repair

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

the unit from the "BOM" sheet that was provided

when unit was originally shipped.

With this information they can provide a quotation

for a new unit including a complete description,

price and availability.

NOTE: Those part numbers that have a quantity indicated

under "Spare Parts" in column "A” refl ect minimum

parts required for inspection and rebuild, - "Soft

Goods Kit". Those in column “B” include minimum

trim replacement parts needed plus those "Soft

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory. All

purposed changes will require a new name plate with appropriate ratings and new product code to accommodate

the recommended part(s) changes.

Goods" parts from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for part

identifi cation and selection.

A Local Sales Representative will provide quotation

for appropriate Kit Number, Price and Availability.

12

IOM-PGR-1

Page 13

Assembled View

METERING VALVE

IOM-PGR-1

13

Page 14

Main Body Assembly with

Dynamic O-ring Seal

Item No. Description

1 Body

2 Cover Dome

4 Cage

5 Plug

6 Diaphragm *

7 Upper Diaphragm Plate

8 Lower Diaphragm Plate

9 Guide Bearing

10 Seat *

11 Nut

12 Guide Bushing

13 Static Seal (Plug) *

14 Static Seal (Cage) *

14

Item No. Description

15 Dynamic Seal (Guide Bearing) *

18 Return Spring

19 Internal Sensing Plug

20 Pipe Plug (Dome)

22 Cage Bolts

23 Flange Bolts

24 Flange Nuts

* Recommended Spare Parts.

Items not shown

3 Mounting Bracket

15.2 Seal Retainer

16 Seal Retainer (Dynamic)

21 Pipe Plug (Body)

26 Name Plate

IOM-PGR-1

Page 15

Sense Port

Vent to Atmosphere

Pilot Inlet

Detail A

Pilot Assembly

Item No. Description

31 Body

32 Spring Chamber

33 Body Cap

34 Range Spring

35 Spring Button

36 Pressure Plate

37 Seat

38 Stem

39 Ball Holder

40 Retainer

41 Return Spring

42 Pusher Post

Item No. Description

43 Diaphragm *

44 Piston Seal *

45 Seal Gasket *

46 Seal (Body Cap) *

47 Adjusting Screw

48 Jam Nut

49 Flange Bolts

50 Body Cap Bolts

51 Flange Nuts

52 Ball *

53 Name Plate

* Recommended Spare Parts

IOM-PGR-1

15

Page 16

Inlet

Stabilizer

Item No. Description

61 Body

62 Spring Chamber

63 Pressure Plate

64 Pusher Plate

65 Spring Button

66 Body Cap

67 Piston Spring

68 Adjusting Screw

69 Lock Washer

70 Nut (Pressure Plate)

71 Nut

72 Diaphragm *

73 O-ring *

74 Piston *

75 Range Spring

Vent

Outlet

* Recommended Spare Parts

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify

or improve the designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Cashco, Inc. product remains solely with the purchaser.

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in USA IOM-PGR-1

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

email: brazil@cashco.com

Loading...

Loading...