Page 1

MAINTENANCE & ASSEMBLY INSTRUCTIONS

IOM-FL

11-13

FUSIBLE LINK

Inline Thermal Check Valve

MODEL FL-200

REFERENCE DATA:

FL-200 Series Assembly Drawing No. A88-60200-00.

INSTALLATION:

1. Clean the piping of all foreign material including chips, welding scale, oil, grease and dirt before installing the thermal

trip valve.

2. In placing thread sealant on pipe ends prior to engagement, ensure that excess material is removed and not allowed

to enter the thermal trip valve upon startup.

3. Flow Direction: Install so the fl ow direction matches the fl ow arrow on the body of the thermal trip valve.

PRINCIPLE OF OPERATION:

1. When the valve is installed it is open.

2. This valve will stay open until it is actuated by the fusible link.

3. This will cause the valve to close.

MAINTENANCE:

1. All valves are leak tested at the factory at 200 PSIG and should be externally leak tight after installation. If after pro longed ser vice the valve should leak externally, it is recommended that the valve be replaced or sent to the factory

for rebuilding.

Page 2

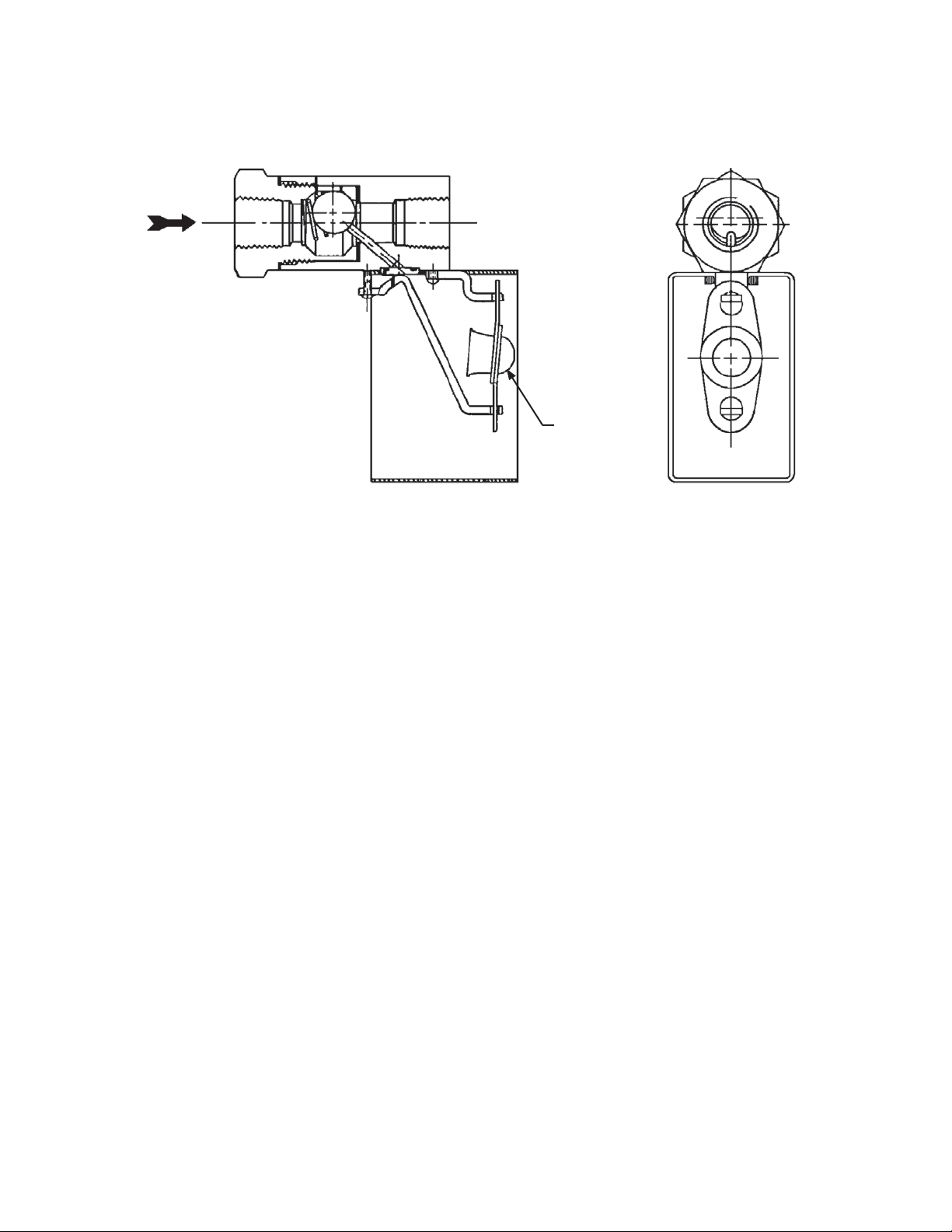

THERMAL CHECK VALVE

FL-200 SERIES

Fusible

Link

NOTES:

1. Maximum pressure rating 130 psig (896 kPa) WOG.

2. No changes shall be made to parts, material or manufacturing process without

prior ap prov al by Factory Mutual Research Corporation.

3. All valves to be assembled, inspected and test ed in strict accordance with

Cashco Standard S-1549.

4. Link shown 17° out of position.

2

IOM-FL

Page 3

FUSIBLE LINK

Barstock Thermal Shutoff Valves

MODEL FL-800 S and V

REFERENCE DATA:

FL-800 Series Assembly Drawing No. A66-60800-00, A66-60800-01, A66-60800-02 & A66-60800-03.

INSTALLATION:

1. Clean the piping of all foreign material including chips, welding scale, oil, grease and dirt before installing the thermal

trip valve.

2. In placing thread sealant on pipe ends prior to engagement, ensure that excess material is removed and not allowed

to enter the thermal trip valve upon startup.

3. Flow Direction: Install so the fl ow direction matches the fl ow arrow on the body of the thermal trip valve.

PRINCIPLE OF OPERATION:

1. When the valve is installed it is open.

2. This valve will stay open until it is actuated by the fusible link.

3. This will cause the valve to close.

MAINTENANCE:

1. All valves are leak tested at the factory at 450 psig and should be externally leak tight after installation. If after prolonged ser vice the valve should leak externally, it is recommended the valve be replaced or sent to the factory for

rebuilding.

IOM-FL

3

Page 4

Fusible

Link

BARSTOCK THERMAL SHUT-OFF

VALVES FL-800 SERIES

Fusible

Link

Type S (Standard)

View 2

View 1

Type V (Vented)

View 3

NOTES:

1. Maximum pressure rating 300 psig (2069 kPa) WOG.

2. Type S (Standard) Shut-off valve will not allow venting of downstream line after valve has ac tu at ed.

3. Type V (Vent) Shut-off valve will allow venting of downstream line.

4. No changes shall be made to parts, materials or manufacturing process without prior approval by Factory Mutual Research Corporation.

5. All valves to be assembled, inspected and test ed in strict accordance with Cashco standard S-1668.

4

IOM-FL

Page 5

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify

or improve the designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Cashco, Inc. product remains solely with the purchaser.

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax. # (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in U.S.A. FL-IOM

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

Email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

Email: brazil@cashco.com

Loading...

Loading...