Cashco DA5 User Manual

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM)

IOM-DA5

MODEL DA5

DA5 - DIRECT-ACTING, SPRING LOADED

BACK PRESSURE REGULATOR

SECTION I

I. DESCRIPTION AND SCOPE

The Model DA5 is a spring operated back pressure regulator used to control upstream (inlet or P1) pressure. Sizes

are 1/2" (DN15), 3/4" (DN20), 1" (DN25), 1 1/4" (DN32), 1 1/2" (DN40), 2" (DN50), 2 1/2" (DN65), 3" (DN80) and

4" (DN100). With proper trim uti li za tion, the unit is suitable for liquid, gaseous, or steam service. The Model DA5

is available in a more common “reverse” fl ow direction arrangement, that is balanced against outlet pressure varia-

tions, and a “standard” fl ow direction arrangement that is unbalanced. Refer to Technical Bulletin DA5-TB for design

conditions and selection rec om men da tions. (NOTE: This product was formerly iden ti fi ed as a Model D5 or Type V;

a Model DA5, D5 and Type V are one and the same product.)

SECTION II

11/13

II. REFERENCES

Refer to Technical Bulletin DA5-TB and DAG-TB for

tech ni cal specifi cations of a Model DA5 regulator.

SECTION III

III. INSTALLATION

CAUTION

For welded installations, all internal trim parts, seals and

diaphragm(s) must be removed from reg u la tor body prior to

welding into pipeline. The heat of fusion welding will dam age non-metallic parts if not re moved. NOTE: This does

not apply to units equipped with extended pipe nip ples.

1. Install per direction of fl ow arrow indicated on body,

or "IN" and "OUT" markings.

2. Regulator may be rotated around pipe axis 360

degrees. For ease of maintenance, the rec om mend ed position is with the spring chamber (4)

upwards. In liquid service it is recommended that

the spring cham ber be oriented down wards, and

that a cus tom er supplied and installed vent valve

be pro vid ed at the external sensing connection

to bleed-off trapped gas/air under the diaphragm

during initial startup.

3. Provide space below, above, and around reg u la tor

for removal of parts during maintenance.

ABBREVIATIONS

CCW – Counter Clockwise

CW – Clockwise

ITA – Inner Trim Assembly

4. Install block valves and pressure gauges to pro vide means for adjustment, operation, bypass,

or removal of the regulator. A pipeline strainer is

recommended upstream of inlet port to remove

typical pipe line debris from entering valve and

damaging internal “soft goods”, primarily the dynamic side seal and V-TFE seat when applied.

5. Upstream Sensing Installation Considerations

– Internal or External Sensing:

a. The regulator may be installed with internal

or external sensing. Unless otherwise spec i fi ed, the regulator is supplied by the factory

with internal sensing. The regulator may be

con vert ed in the fi eld to external sensing. (See

Section VII maintenance, Part H – Converting

Internal/External Sensing.

b. Reference DAG-TB, Table DAG-12 for rec-

om men da tions for applying external pressure

sensing.

c. For internal sensing, no external line is re-

quired. For external sensing, use an external

control line. The line is connected from the

port 1/4" (DN8) NPT on the side of the body

di a phragm fl ange (see following schematic)

to a pressure tap upstream of the regulator.

A tubing outside diameter of 0.25 inch is

adequate for short sensing lines (less than

4 feet). Use 3/8" tubing or 1/4" schedule 40

pipe for sensing lines of 5 to 50 feet.

d. For condensable vapors (i.e. steam) slope the

external sensing line downward 2 to 5 de grees

to inlet piping to prevent water pock ets, which

allows the diaphragm chamber to al ways be

self draining. The external sensing line may

be sloped upward for gas or liquid service;

i.e. non-condensibles.

CAUTION

DO NOT HYDROSTATIC TEST THROUGH AN IN STALLED

UNIT; ISOLATE REGULATOR FROM TEST. The upper

range spring pres sure level on the name plate is the

rec om mend ed “upper op er at ing limit” for the sens ing

di a phragm. Higher pres sures could cause internal dam age. See Table 2 in DA5-TB for pressure limits of different

diaphragm materials.

SECTION IV

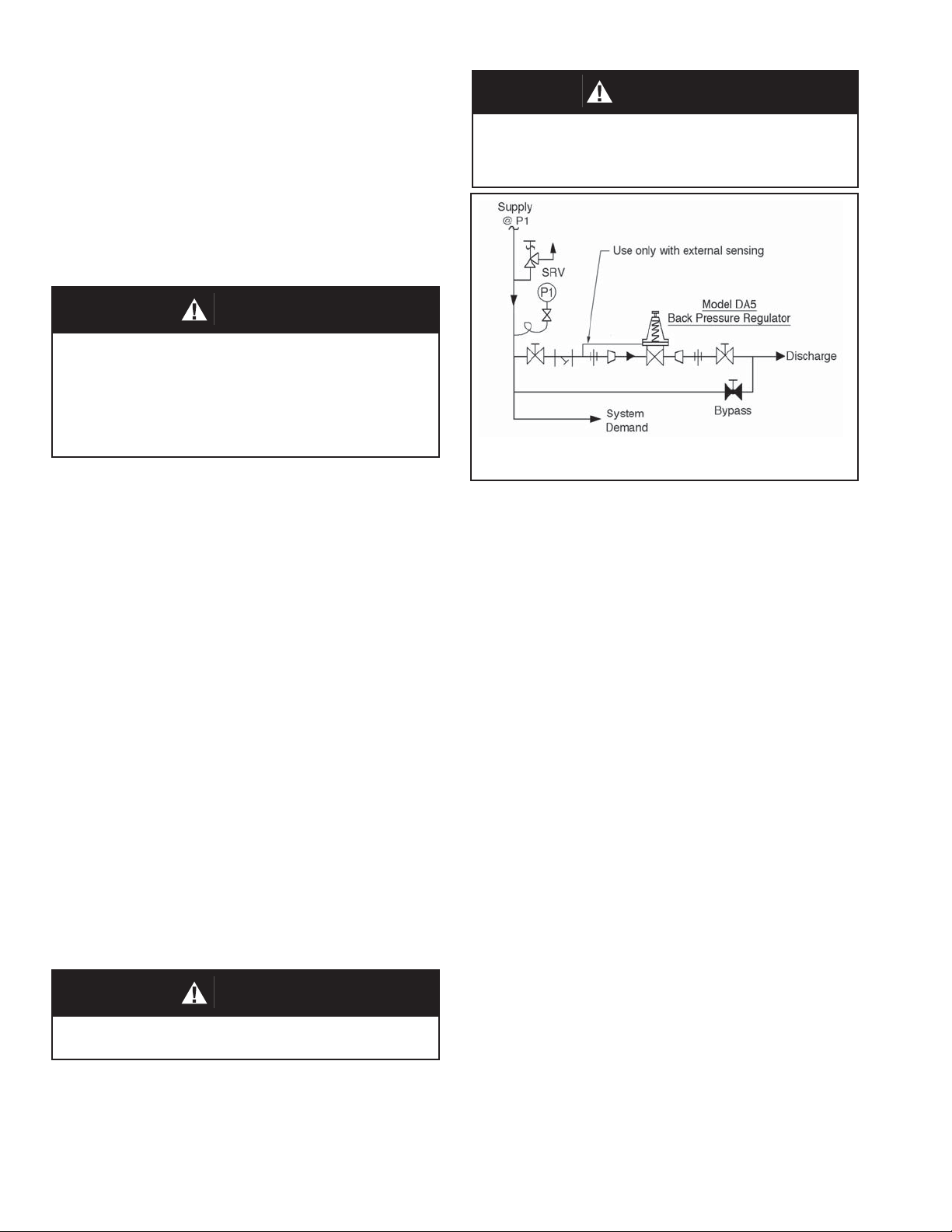

CAUTION

Installation of adequate overpressure pro tec tion is recommended to pro tect the reg u la tor from over pres sure and

all down stream equip ment from dam age in the event of

regulator failure.

Recommended Piping Schematic

For Back Pressure/Relief Station

IV. PRINCIPLE OF OPERATION

1. Movement occurs as pressure variations register

on the diaphragm. The registering pressure is the

inlet, P1, or upstream pressure. The range spring

op pos es di a phragm movement. As inlet pres sure

in creas es, the diaphragm pushes the range spring

V. STARTUP

1 Start with the block valves closed.

2. Relax the range spring by turning the ad just ing

screw CCW (viewed from above) a minimum of

three (3) full rev o lu tions. This reduces the inlet

(upstream) pres sure set point.

3. Crack open manual bypass valve. Initially pres sur ize system while simultaneously controlling

P1 pressure through manual actuation of bypass

valve.

up,lifting the valve plug further off the seat; as inlet

pres sure decreases, the range spring pushes the

di a phragm down closing the valve plug toward the

seat.

2. A complete diaphragm failure will cause the reg u la tor to fail closed and process fl uid will discharge

from the spring chamber vent hole.

SECTION V

trap op er a tion if in stalled. Close ly monitor inlet

(up stream) pres sure via gauge to ensure not

over-pres sur iz ing. NOTE: If no by pass valve is

in stalled, extra cau tion should be used in starting

up a cold system; (i.e., do ev ery thing slowly).

5. Open the outlet (downstream) block valve.

6. Slowly open the inlet (upstream) block valve to

about 25% open, observing the inlet (upstream)

pres sure gauge. Determine if the reg u la tor is

fl owing. If not, slowly rotate the regulator ad just ing screw CCW (viewed from above) until fl ow

be gins.

CAUTION

Do not walk away and leave a bypassed reg u la tor unattended!

4. If it is a “hot” piping system, and equipped with

a bypass valve, slowly open the bypass valve

to preheat the system piping and to allow slow

ex pan sion of the piping. Ensure proper steam

2

7. When fl ow is established steady enough that

the inlet (upstream) block valve can be fully

opened, begin to slowly close the bypass valve if

installed.

8. Develop system fl ow to a level near its expected

normal rate, and reset the regulator set point by

turning the adjusting screw CW to increase inlet

pressure, or CCW to reduce inlet pressure.

IOM-DA5

9. Reduce system fl ow to a minimum level and ob-

serve pressure set point. Inlet pressure will decrease from the set point of Step 8. The max i mum

SECTION VI

build in inlet pressure on increasing fl ow should not

exceed the stated upper limit of the range spring

by greater than 30%. If it does, consult factory.

VI. SHUTDOWN

1. Shutoff inlet block valve.

2. Remove range spring compression by turning the

adjusting screw CCW to reduce the inlet pressure.

VII. MAINTENANCE

A. General:

1. The regulator may be serviced without re mov ing the regulator from pipeline. The

regulator is designed with quick-change trim

to simplify maintenance.

2. Record the nameplate information to req ui si tion spare parts for the regulator. The

in for ma tion should include: size, KM Product

Code, Serial Number.

3. Refer to Section IX for selection of recommended spare parts. Only use original

equipment parts sup plied by Cashco/KM for

re build ing or re pair ing regulators.

4. Owner should refer to owner's procedures for

removal, handling, cleaning and disposal of

nonreuseable parts, i.e. gaskets, etc.

NOTE: On regulators originally supplied as

“oxygen clean” – Opt-55, maintenance must

include a level of cleanliness equal to Cashco

cleaning standard #S-1134.

5. The Inner Trim Assembly (ITA) is re moved and

re placed in the body (23) as an as sem blage

of parts. The ITA consists of the fol low ing

parts:

3. Shutoff the outlet block valve.

4. Relieve the trapped upstream and downstream

pres sure.

5. The regulator may now be removed from the

pipe line or disassembled for inspection and pre ven ta tive main te nance while in-line.

SECTION VII

Item Dynamic Side

No. Seal Type Part Description

7 ......................All ...........................Diaphragm Fastener

(Cap Screw or Locknut)

8 ......................All .......Upper Diaphragm Pressure Plate

9 ......................All ......................................Diaphragm(s)

10 .....................All ..........Lower Diaphragm Pusher Plate

13 .................... All......................... Piston/Guide Bearing√

14 .....................All ......................................... Stem Seals

14.1 ............... All ................................ Upper Stem Seal

14.2 ............... All ................................Middle Stem Seal

14.3 ............... All ..............................Lower Stem Seal√

14.4 ............... All ................Lower Pusher Plate Gasket

20 .....................All ...........................................Valve Plug

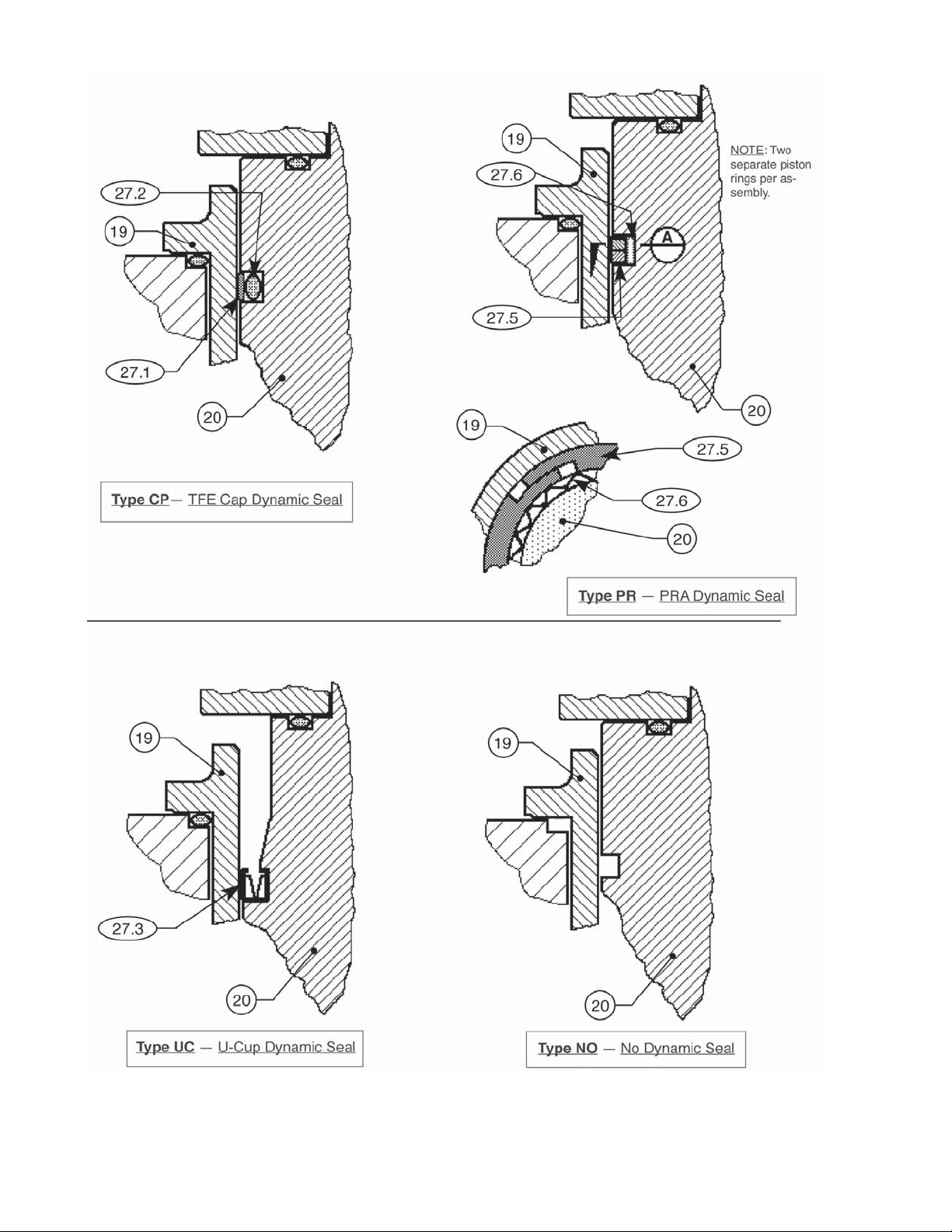

27 .....................All ...........................Dynamic Side Seal *

27.1 ...............CP ..................................... TFE Cap Seal

27.2 ...............CP ......................... O-ring Energizer/Seal

27.3 .............. UC .......... U-Cup Seal w/Metal Energizer

27.5 ...............PR ................................. Piston Ring Seal

27.6 ...............PR ................. Piston Ring SST Energizer

28 .....................All ............................................ Seat Disc

29 .....................All ...............................Seat Disc Washer

30 .....................All ......................................Seat Disc Nut

* The Dynamic Side Seal (27) and the Cage Seal (15) are

omitted for the FTC fl ow direction regulator. This is Type

NO. See Figure 1.

√ 2-1/2" thru 4" body sizes only.

A detailed view of the dynamic side seal parts is

shown in Figure 1 on the next page.

IOM-DA5 3

Figure 1: Dynamic Side Seals

(FTC Flow Direction Only)

4

IOM-DA5

B. Main Valve Disassembly:

NOTE: Valves with “Large Internal Sensing” will not

be equipped with any plug (32,33).

WARNING

SYSTEM UNDER PRESSURE. Prior to per form ing any

maintenance, isolate the reg u la tor from the sys tem and

relieve all pressure. Failure to do so could result in personal injury.*

* Includes external sensing connection if applicable.

1. Shut down the system in accordance with

15. For metal diaphragm constructions, remove

diaphragm gasket (37) from body (23) di a phragm fl ange.

16. Remove body (23) from vise. Solvent clean

all removed metal parts.

C. Disassembly of the ITA:

Section VI.

1. Body Sizes 1/2" – 2". (See Figures 3 and 4):

2. Disconnect the external sensing line, if in stalled.

a. Obtain two pieces of square-section

barstock with a 3/8"-7/16" dimension,

approximately 2 inches long.

3. Though it is possible to disassemble the regulator while installed in a pipe line, it is rec om mend ed that main te nance be done in a shop

when pos si ble. The de scrip tions here af ter will

assume shop dis as sem bly. Remove regulator

from pipe line.

b. Place plug (20) into a vise using the bars

of a. above, use "fl ats" located on plug

(20) to prevent vise jaw marks from direct

surface contact with the plug (20). Orient

with diaphragms on topside.

c. Sizes 1/2"-1": Remove diaphragm lock nut

(7) by rotating CCW.

4. Place the body (23) in a vise with the spring

chamber (4) oriented upwards.

Sizes 1-1/4"-2": Remove diaphragm cap-

screw (7) by rotating CCW.

d. Remove upper diaphragm pressure plate

5. Loosen adjusting screw lock nut (2) and relax

range spring (6) forces by turning adjusting

screw (1) CCW (viewed from above) until

removed from spring chamber (4).

(8).

e. Remove diaphragm(s) (9, 9.1, 9.2, 9.9).

Examine diaphragm(s) to determine

wheth er failed; determine if op er at ing

conditions are ex ceed ing pressure drop

6. Loosen the diaphragm fl ange bolts (11) and

nuts (12) uniformly.

or temperature lim its.

f. For composition diaphragm con struc tion,

remove upper stem seal (14.1).

7. Place matchmarks on body (23) and spring

chamber (4) fl anges. Com plete ly remove bolt-

ing (11,12) Re move the spring cham ber (4).

g. For metal diaphragm con struc tion, re move

lower pusher plate gasket (14.4).

h. Remove lower diaphragm pusher plate

(10).

8. Remove spring follower (5) and range spring

(6).

i. Remove middle stem seal (14.2).

j. Remove plug (20) from vise, ro tate end-

for-end, and resecure in vise using same

9. Grasp opposite edges of diaphragm (9) and

withdraw the ITA from within the cage (19).

Set the ITA aside.

metal bars above.

k. Loosen seat disc nut (30) CCW (viewed

from above) ap prox i mate ly two (2) rev o lu tions.

10. Evenly loosen the cage cap screws (18) in

single revolution increments until fully loos ened; remove cage cap screws (18).

l. Remove assembly (20, 27, 28, 29, 30)

from vise. Complete re mov al of seat disc

nut (30), seat disc washer (29), and seat

disc (28).

11. Pull cage (19) up and out of body.

2. Body Sizes 2-1/2" – 4". (See Figure 2):

12. Remove o-ring cage seal (15).

a. Place seat disc nut (30) into a vise with

the plug (20) oriented ver ti cal ly. DO NOT

13. Remove lower cage gasket (21).

over-tighten nut (30) in vise.

b. Place closed-end hex wrench onto di a-

14. If supplied, remove internal sensing drilled plug

(32) using 5/32" (4 mm) Allen key wrench for

1/2" - 2" size regulators. Use 3/16" Allen key

wrench for 2 1/2" - 4" size regulators.

phragm locknut (7). Place sock et wrench

on hex upper end of plug (20). Loos en

diaphragm lock nut (7) while holding plug

(20) from ro tat ing by socket wrench.

IOM-DA5 5

Loading...

Loading...