Page 1

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

IOM-C-CS

12-13

MODEL C-CS

“CLEAN STEAM”

PRESSURE REDUCING REGULATOR

SECTION l

I. DESCRIPTION AND SCOPE

Model C-CS is a pressure reducing regulator used to control down stream (outlet or P2) pressure. Inlet and outlet sizes

are 3/4" (DN20), 1" (DN25), 1-1/2" (DN40), 2" (DN50) and 3" (DN80) with Tri-Clamp® fi tting connections. This regula-

tor is primarily designed for steam service at tem per a tures equal to or less than 366°F (185°C); this cor re sponds to

150 psig (10.3 Barg) sat u rat ed steam; however the unit may also be used for clean gaseous or liquid applications.

CAUTION

The Model C-CS should never be used as a shut-off device.

SECTION II

II. INSTALLATION

Outlet

@ P2

1. An inlet block valve should always be in stalled.

2. If service application is continuous such that

shutdown is not readily accomplished, it is

recommended that inlet and outlet block valves

and a manual bypass valve be in stalled.

3. An outlet pressure gauge should be lo cat ed

ap prox i mate ly ten pipe diameters down stream

and within sight.

Inlet

@ P1

Blowdown Drain

SRV

Bypass

Model C-CS

Reducing Regulator

Blowdown Drain

4. All installations should include a down stream

re lief device if the inlet pressure could exceed

the pressure rating of any down stream equip ment.

5. Flow Direction: Install so the fl ow enters

through the bottom connection and exits the

side connection.

6. Install in a well drained pipe, properly trapped,

with spring chamber (2) in the vertical position

to allow for proper drain ing.

III. PRINCIPLE OF OPERATION

1. Movement occurs as pressure variations reg is ter on the diaphragm. The registering pres sure is the outlet, P2 or down stream pressure.

The range spring opposes di a phragm move ment. As the outlet pressure drops, the range

spring pushes the diaphragm down, opening

(Recommended Piping Schematic for Pressure Reducing Station)

7. For insulated piping systems, the regulator

should not be insulated.

CAUTION

Installation of adequate overpressure protection is

recommended to protect the regulator from overpressure and all downstream equipment from damage in

the event of regulator failure.

SECTION III

CAUTION

Do not apply spring load or operate regulator with

hitch pin (21) removed from top of guide post (27 ).

Pre ma ture di a phragm failure will re sult.

Page 2

the port; as outlet pressure in creas es, the

diaphragm pushes up and the port closes.

IV. START-UP

NOTE: The regulator set point must be set

under normal fl owing conditions.

1. CCW = Counter Clockwise,

CW = Clockwise.

2. Inspect the unit's nameplate to confi rm that

the proper range spring is installed in the

reg u la tor. Apply setpoint pres sures that are

only within the stated range.

2. A complete diaphragm failure will cause the

reg u la tor to fail open.

SECTION IV

7. Slowly open the inlet (upstream) block valve

ob serv ing the outlet (downstream) pressure

gauge. De ter mine if the regulator is fl owing

(see NOTE above step 1). If no fl ow, rotate the

reg u la tor handle (6) CW (viewed from above)

until fl ow begins. De ter mine if downstream

equip ment is in operation.

8. Continue to slowly open the inlet (upstream)

block valve until fully open.

3. Start with the block valves closed. A bypass

valve may be used to maintain outlet pressure

in the down stream system while performing

the following steps.

4. Relax compression of range spring (7) by

turning handle (6) counter-clockwise (CCW)

until rotation stops. Rotate handle (6) clockwise (CW) three (3) full revolutions to maintain

spring (7) to di a phragm(17) contact. This

reduces the outlet pres sure setpoint.

5. If piping system includes a bypass valve,

slowly open the bypass valve to preheat the

system piping and to allow slow expansion of

the piping. Ensure proper steam trap op er a tion, if installed. To prevent overpressurization,

closely mon i tor out let (down stream) pressure

with a gauge. NOTE: If no bypass valve is

installed, extra caution should be used in

starting up a cold system; i.e. do everything

slowly.

6. Crack open the outlet (downstream) block

valve.

9. Continue to slowly open the outlet (down stream) block valve. When fl ow is es tab lished

steady enough that the outlet (down stream)

block valve is fully open, begin to slowly

close the bypass valve, if installed, until fully

closed.

10. Develop system fl ow to a level near its ex-

pect ed normal rate and reset the regulator

setpoint by turning the handle (6) CW (viewed

from above) to increase outlet pres sure or

CCW to reduce outlet pressure.

11. Reduce system fl ow to a minimum level and

observe setpoint. Outlet pressure will rise from

the setpoint of Step 10. The max i mum rise

in outlet pressure on de creas ing fl ow should

not exceed the stated upper limit of the range

spring by greater than 30%; i.e. 10-30 psig

(.69-2.1 Barg) range spring – at low fl ow the

outlet pres sure should not ex ceed 39 psig (2.7

Barg). If it does, consult factory.

SECTION V

V. SHUTDOWN

1. On systems with a bypass valve, and where

system pressure is to be main tained as the

reg u la tor is shutdown, slow ly open the by pass

valve while closing the inlet block valve. Fully

close the inlet block valve. When on bypass,

the system pres sure must be con stant ly ob served and man u al ly reg u lat ed.

2 IOM-C-CS

2. If the regulator and system are to both be

shut down, slowly close the inlet block valve.

Close the outlet valve only if reg u la tor re mov al

is required.

CAUTION

DO NOT DEAD-END FLOW DOWN STREAM of the

Mod el C-CS as overpressurizing reg u la tor may

damage internals.

Page 3

SECTION VI

VI. MAINTENANCE

WARNING

SYSTEM UNDER PRES SURE. Prior to per form ing

any maintenance, isolate the reg u la tor from the

sys tem and relieve all pressure. Failure to do so

could result in personal injury.

A. General:

1. Maintenance procedures here in af ter are

based upon removal of the regulator unit from

the pipeline where installed.

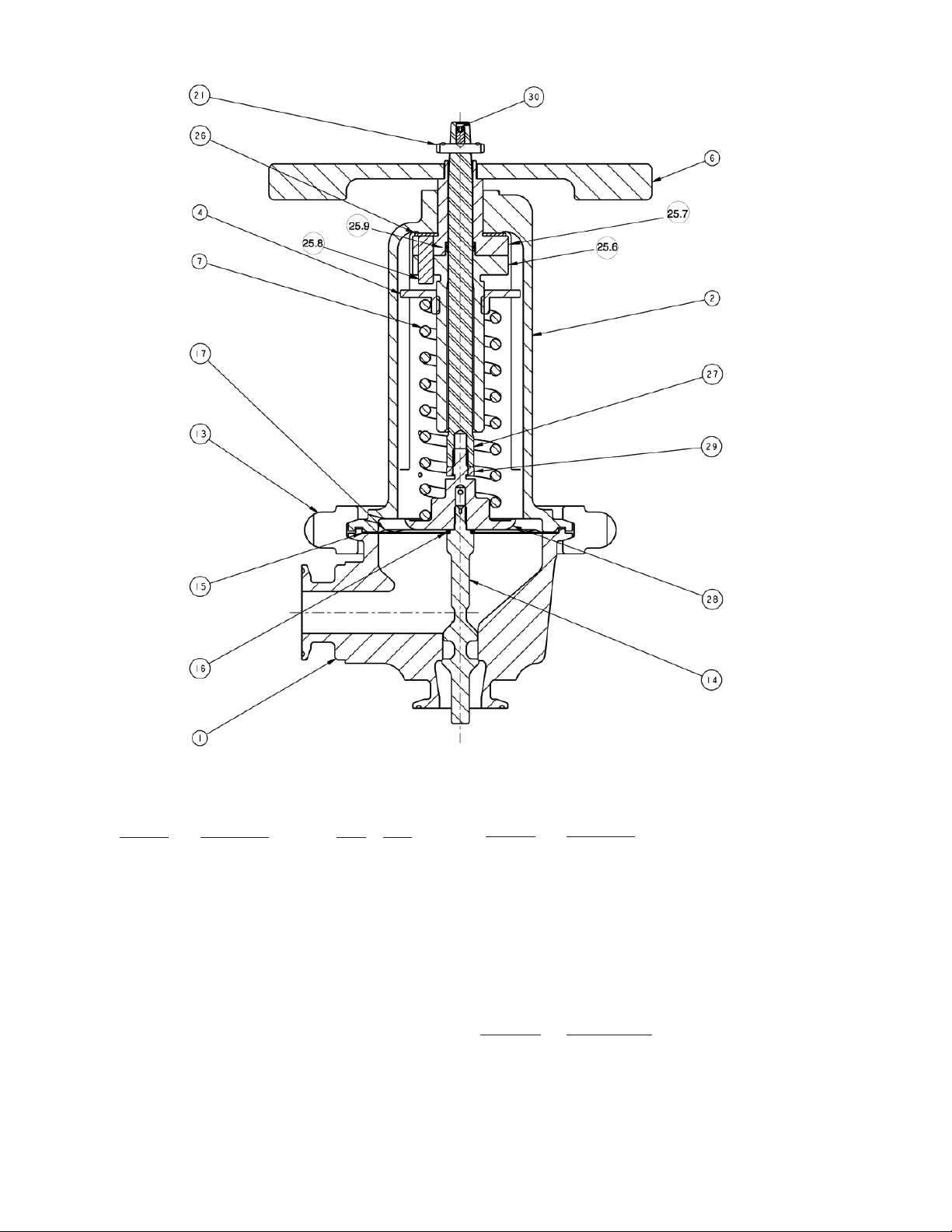

2. Refer to Figure 2 for basic regulator item

num ber reference ( ) and description.

B. Diaphragm – Trim Replacement:

1. Securely install the regulator in a soft-jawed

vise with the spring chamber (2) di rect ed upwards. Ensure that the body (1) is not held in

the vise by the Tri-clamp® fi tting con nec tions.

The regulator may be held in the vise with

fl ats on the plug (14). If this method is used,

ensure that the plug (14) is in contact with the

seating area of the body (1) and the face of

the inlet fl ange of the body (1) is resting on

the vise.

WARNING

SPRING UNDER COMPRESSION. Relieve all

spring (7) compression prior to removing clamp

(13). Failure to do so may result in fl ying parts that

could result in personal injury.

2. Relax range spring (7) by turning handle (6)

CCW (viewed from above) until rotation stops.

Count and record the number of rev o lu tions

in the box below:

Number of revolutions required to relax

range spring: ________

4. Pull hitch pin (21) and lift up on handle (6) to

remove.

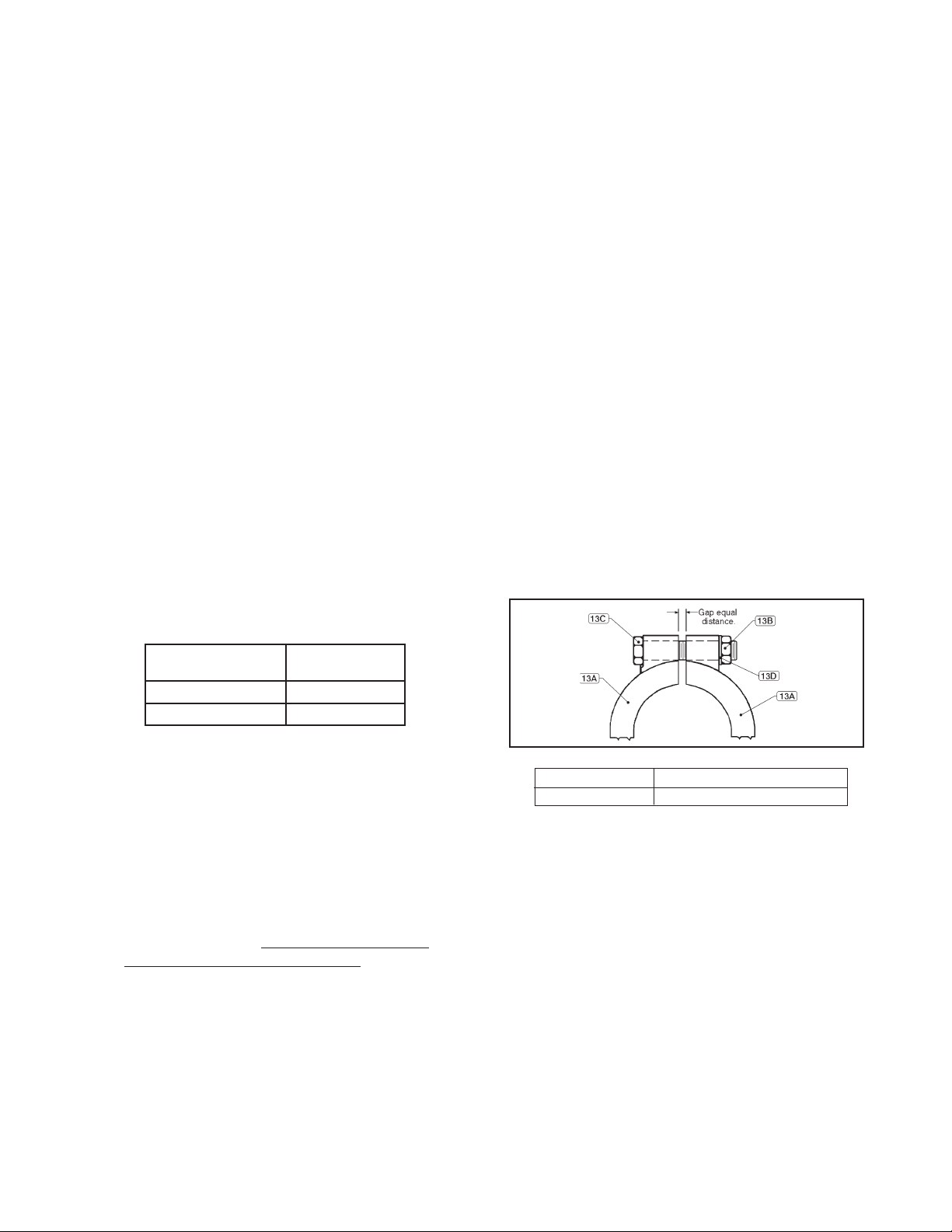

5. Loosen and remove clamp nuts (13B), wash ers (13D), bolts (13C) and clamps (13A). See

Figure 1.

6. Place matchmarks between body (1) and

spring chamber (2) to assist in fi nal ori en ta-

tion when re as sem bled. Lift spring chamber

(2) vertically up and off of body (1) and above

guide post (27) to remove. Note alignment of

spring button (4) tabs (ears) with respect to

slot guides inside spring chamber (2).

7. Remove bearing (26). Lift up and remove ad just ing screw cap (25.7) and dowel pin (25.8)

as sem bly. NOTE: May need to tap lightly on

O.D. of adjusting screw (25.6) to free Dowel

pin (25.8) from adjusting screw (25.6).

NOTE: The two guide seals (25.9) may/may

not be extracted with as sem bly (25.7,25.8).

Re move guide seals (25.9).

8. Lift up to remove the ad just ing screw (25.6 )

and spring but ton (4) as an as sem bly. NOTE:

Do not rotate or re move spring button (4) from

ad just ing screw (25.6). Re move spring (7) and

lay aside.

9. Secure the pres sure plate assembly (27,28

and 29) at the “fl ats” near the base of pressure

plate (28). Grasp the lower portion of the plug

(14) by the “fl ats”, which protrudes from the

body (1) inlet, with soft-jawed pliers or softjawed vice and pro ceed to turn CCW (viewed

from above) for dis as sem bly. NOTE: Main tain

fi rm grasp of plug (14). After dis en gage ment,

plug (14) could fall out of body (1) and damage

seating surface area. Remove plug (14).

10. Remove pressure plate assembly (27,28 and

29) and lay aside. NOTE: The travel of the

guide post (27) has been factory set. Do not

loosen or adjust the hex nut (29) on pres sure

plate assembly (27,28,29).

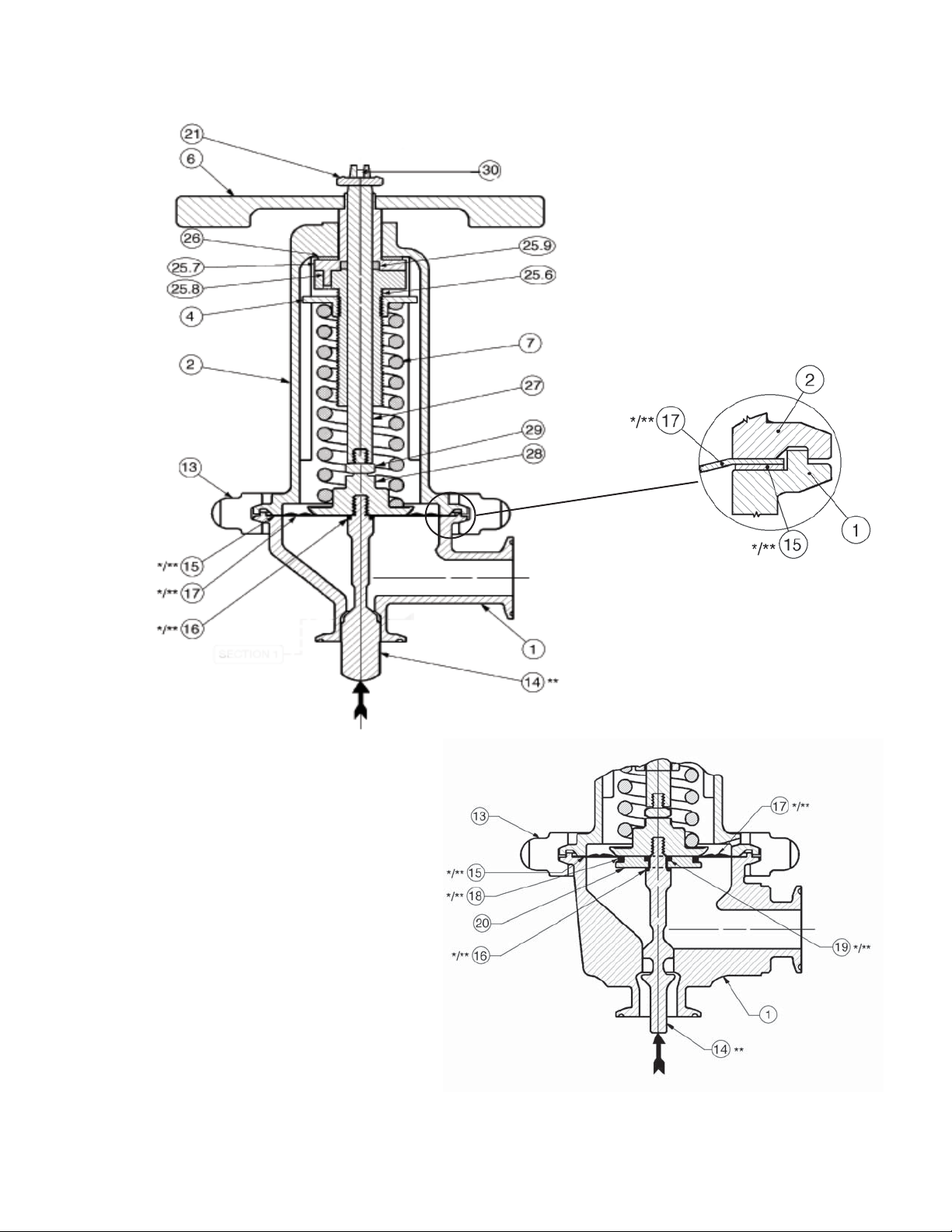

11a. For Model C-CS :

Remove diaphragm (17), O-ring (16), dia-

phragm gas ket (15) and body (1).

11b. For Model C-CS with Opt.-11:

CAUTION

Do not apply spring load or operate regulator with

hitch pin (21) removed from top of guide post (27 ).

Pre ma ture di a phragm failure will re sult.

3. Remove socket head set screw (30) CCW

from top end of guide post (27).

IOM-C-CS 3

Remove diaphragm (17), diaphragm gaskets

(15), O-ring (18), seal (19), push er plate (20),

O-ring (16) and body (1).

12. Inspect plug (14) and seating surface of body

(1) for excessive wear. Replace all worn

parts.

Page 4

13. Clean gasket (15) and O-ring (16) retaining

surfaces of body (1) and spring chamber (2).

14. Clean all parts in accordance with Own er’s

cleaning procedures. Reposition plug (14)

back into vise with body (1). Ensure that the

plug (14) is in contact with the seating area of

the body (1) and the face of the inlet fl ange of

the body (1) is resting on the vise.

15. Place new diaphragm gasket (15) on body (1)

fl ange.

16. Install O-ring (16). NOTE: For Opt.-11 re po si-

tion push er plate (20) on threaded end of plug

(14) and install O-ring (18) and seal (19). Refer

to Figure 4.

17. Place diaphragm (17) over threaded end of

plug (14). NOTE: The word ‘TOP’ is etched on

one side of the diaphragm and should be visible when looking down on the diaphragm.

18. Place a small amount of medium strength

threadlocker equal to "Blue 242 Loctite" on

threaded end of plug (14). Reassemble pressure plate assembly (27,28 and 29) to plug

(14). Refer to NOTE: in Step 10. Grasp the

parts and rotate pres sure plate assembly

(27,28,29) CW until wrench tight (met al-tometal con tact); Torque values not to ex ceed

the following:

together by hand. NOTE: Top of dowel

pin (25.8) should be fl ush with top surface

of adjusting screw cap (25.7).

22. Install new bearing (26) on top of upper

guide assembly (25).

23. Align slot guides inside spring chamber

(2) with spring button (4) tabs (ears) and

position on to body (1). Align with match

marks of step 6. previous.

24. Place handle (6) over end of guide post

(27) coming to rest on adjusting screw cap

(25.7). Insert hitch pin (21) into hole through

end of guide post (27). Apply Loctite 242

or equalivent to threads of set screw (30)

install into top of guide post (27) and tighten

securely.

25. Reposition clamps (13A) around body (1)

and spring chamber (2) fl anges. Insert clamp

bolts (13C), washers (13D) and tighten

clamp nuts (13B) in alternating pattern.

NOTE: Gap be tween clamp (13A) halves

should be equal in size. Gap and torque

re quire ments are as follows:

Body Size

in (DN)

3/4"-1 1/2" (20-40)

2" - 3" (50-80)

Torque

in-lbs (N-m)

100 (11)

270 (31)

19. Center/align the above pressure plate/

diaphragm assembly on the di a phragm (17)

fl ange sur face in the body (1).

20. Position spring (7) on to hub of pressure plate

(28). Place adjusting screw (25.6) - with spring

button (4) - over end of guide post (27) and

into spring (7) cav i ty. NOTE: Apply a small

amount of Emhart Bostik White Food Grade

“Never-Seez” or equiv a lent to threads of ad just ing screw (25.6) Do Not rotate adjusting

screw (25.6) or spring button (4).

21. Install new guide seals (25.9) in adjusting

screw cap (25.7). NOTE: There are two sizes

of u-cup seals - install the seal with the bigger diameter spring fi rst, open face into the

cap recess. Install the second u-cap seal,

open face exposed to face of adjusting screw

(25.6). Slide adjusting screw cap (25.7) over

end of guide post (27). Align dowel pin (25.8)

with hole in adjusting screw (25.6) and press

Figure 1: Clamp Arrangement.

Gap Torque

Equal Distance 225-250 in-lbs (25-28 N-m)

26. Reapply compression to the range spring

(7) by rotating handle (6) CW as per the

num ber of revolutions re cord ed in VI.B.2.

27. Return to Section II for Installation and

Sec tion IV for Start-up.

4 IOM-C-CS

Page 5

SECTION VII

VII. ORDERING INFORMATION

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was

stamped on the metal name plate and attached to the unit. This information can also be found on the

Bill of Material ("BOM"), a parts list that was provided when unit was originally shipped. (Serial Number

typically 6 digits). Product Code typical format as follows: (last digit is alpha character that refl ects revi-

sion level for the product).

–

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

With this information they can provide a quotation

for a new unit including a complete description,

price and availability.

CAUTION

Do not attempt to alter the original construction

of any unit without assistance and approval from

the factory. All purposed changes will require a

new name plate with appropriate ratings and new

product code to accommodate the recommended

part(s) changes.

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

Identify the parts and the quantity required to repair

the unit from the "BOM" sheet that was provided

when unit was originally shipped.

–

7

NOTE: Those part numbers that have a quantity indicated

under "Spare Parts" in column "A” refl ect minimum

parts required for inspection and rebuild, - "Soft

Goods Kit". Those in column “B” include minimum

trim replacement parts needed plus those "Soft

Goods" parts from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for part

identifi cation and selection.

A Local Sales Representative will provide quotation

for appropriate Kit Number, Price and Availability.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to

modify or improve the designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Cashco, Inc. product remains solely with the purchaser.

IOM-C-CS 5

Page 6

Figure 2

Forged body.

Repair Parts

Item No. Description Kit A Kit B

1 Body

2 Spring Chamber

4 Spring Button

6 Handle

7 Range Spring

13 Clamp (2 Req'd)

14 Plug

15 Gasket (Diaphragm)

16 O-ring (Plug)

17 Diaphragm

18 O-ring

19 Seal

20 Pusher Plate

21 Hitch Pin

25 Upper Guide Assembly

25.6 Adjusting Screw

25.7 Adjusting Screw Cap

25.8 Dowel Pin

25.9 Guide Seals (2 Req'd) * **

1

**

* **

* **

* **

* **

* **

Item No. Description

26 Bearing

27 Guide Post

28 Pressure Plate

29 Nut Hex Jam

30 Set Screw

1

Refer to Figure 1 for Clamp and related item

numbers.

Not Shown:

Item No. Description

11 Name Plate

12 Drive Screw

6 IOM-C-CS

Page 7

See the previous page for Item Number Descriptions.

Figure 3

Investment Cast body.

Figure 4: Option-11, Diaphragm Restraint

(Forged Body Shown)

IOM-C-CS 7

Page 8

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax. # (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in U.S.A. IOM-C-CS

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

Email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

Email: brazil@cashco.com

Loading...

Loading...