Page 1

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM)

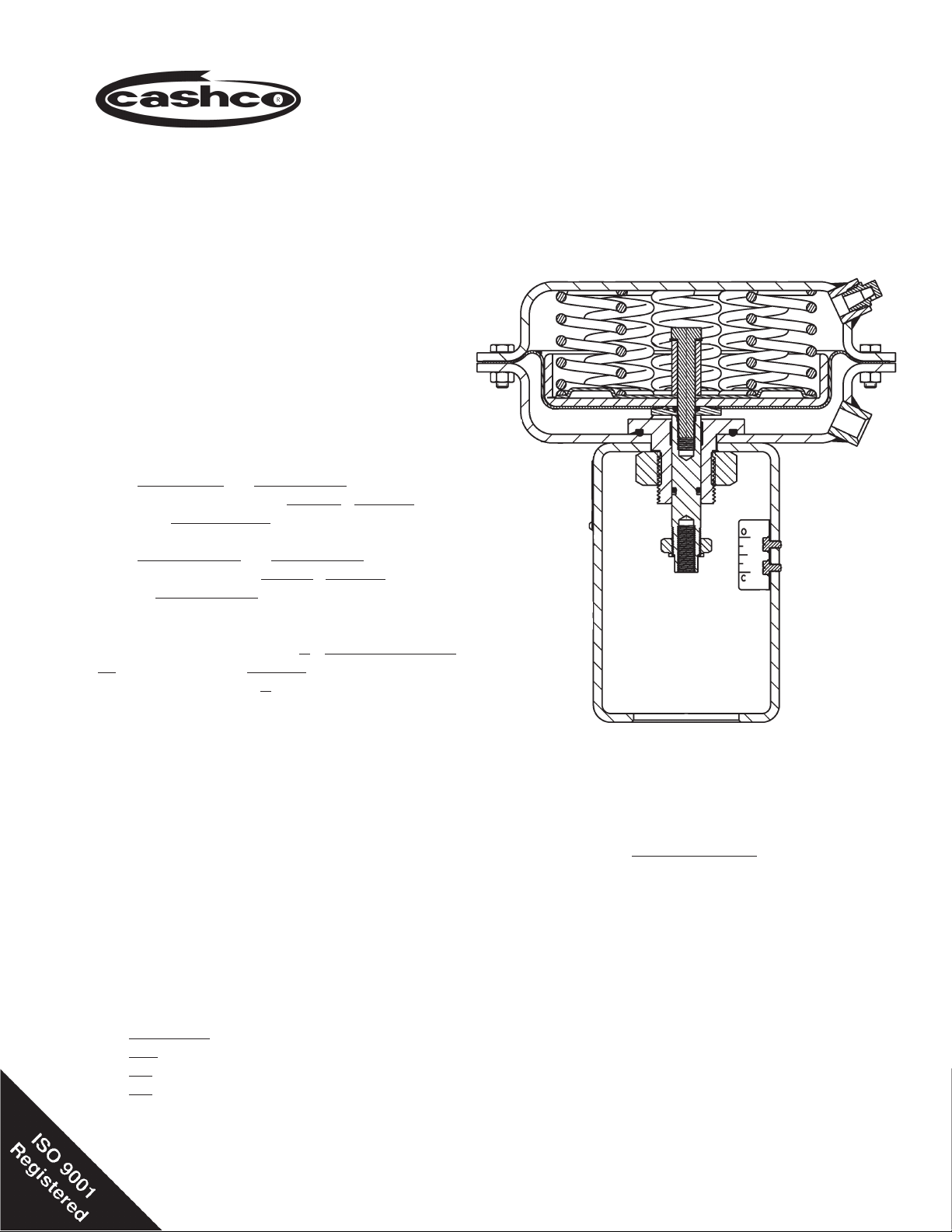

MODELS C27 - C53

SPRING/DIAPHRAGM LINEAR PNEUMATIC ACTUATORS

SECTION I

I. DESCRIPTION AND SCOPE

Actuator models C27 and C53 are multi-spring,

single acting, spring opposed, linear actuators used

with Cashco sliding stem (linear), globe-style control

valves. The “R” denotes“ reverse”acting arrangement;

the “D” denotes “direct” acting arrangement and are

reversible in the fi eld.

“D” = Direct action; on increasing air loading

pressure,the actuator stem extends. Fail-safe position

is with the stem retracted.

IOM-C27-C53

12-13

“R” = Reverse action; on increasing air loading pressure, the actuator stem retracts. Fail-safe position is

with the stem extended.

When coupled with a globe-style control valve with

pushdown to close action, a “D”- direct acting actuator will provide valve “fail open” action;“D” = ATC-FO.

When coupled with an “R” - reverse acting actuator,

will provide valve “fail closed” action; “R” = ATO-FC.

SECTION II

II. REFERENCES

Refer to the Control Valve Technical Bulletin this

actuator is unitized with for complete tech ni cal

specifi cations.

Refer to following Installation, Operation & Main te nance Manuals (IOM’s) for other devices that maybe

mounted to C27-C53 actuators:

Positioners:

P/P: www.cashco.com/techbulletins/9540l.pdf

I/P: www.cashco.com/techbulletins/srd991.pdf

I/P: www.cashco.com/iom/PS2iom.pdf

Shown w/ATO-FC Action

ABBREVIATIONS

ATO-FC ... Air-to-Open, Fail Close

ATC-FO ... Air-to-Close, Fail Open

CCW ........ Counter Clockwise

CW ........... Clockwise

D or DIR ... Direct Acting

R or REV.. Reverse Acting

IAS ........... Instrument Air Supply

IOM .......... Installation, Operation and Maintenance

Man u al

SIG .......... Output Signal from Instrument

LOAD ....... Positioner Output Air Pressure

V .............. Vent

Page 2

2

IOM-C27-C53

III. INSTALLATION

A. Orientation:

SECTION III

B. Air Supply:

1. Recommended actuator major axis orientation

with any model of Cashco control valve body,

is upwards in a horizontal pipe.

2. Actuator axis may be horizontal when valve

is in a vertical pipe.

3. Outdoors, all installations must be oriented

any angle from horizontal-to-vertical.

4. Models C27 and C53 actuators are not recommended for installation oriented downwards

in either “D” or “R” action.

5. In no case is additional weight to be applied

to the actuator when installed in an orientation

other than vertical; i.e. the valve is unsafe as

a “step” to support personnel.

IV. MAINTENANCE

A. General:

1. Hereafter, all maintenance, disassembly,

etc., is assumed to be done in an indoor

shop.

2. An actuator assembly (AA) is unitized with a

body assembly (BA). Reference should be

made to the body IOM for instructions about

the specifi ed body assembly (BA) utilized

with the actuator.

3. Where the body is not being removed from

the actuator, special care MUST be exhibited to prevent valve stem rotation during

any disassembly or reassemble for all valve

models. Following this procedure will ensure

not damaging seating surfaces.

4. Remove instrument tubing, airset, positioner,

and any other accessory that maybe mounted on the control valve unit (AA, BA).

5. All indicated Item Numbers that are with respect to body (BA) IOM will be in parenthesis

and underscored; i.e. (20); the same is true

for positioner parts. All Item Numbers that

are with respect to this manual are not underscored; i.e. (19).

1. Recommendation is that a desiccant dried,

instrument quality air supply be used.

Such a supply is recommended for outdoors installations, and is required in areas of freezing weather conditions.

2. If air supply contains moisture and/or lubricating oil, the air should be fi ltered with

a coalescing type of fi lter prior to use in

stroking the actuator.

3. Failure to remove moisture will cause corrosion to internals of casings (1,2).

4. Connections for the air supply are 1/4” female NPT. A suitable pipe thread sealant

is recommended to be used when installing the pipe or tube fi tting. Exhibit care to

prevent the sealant from getting inside the

tube/pipe.

SECTION IV

B. Diaphragm Removal/Replacement:

NOTE: Actuator (AA) must be separated from

the body (BA) in order to replace O-rings

(15, 16 &17) and diaphragm (7). Refer to

specifi ed body (BA) IOM for instructions to

remove actuator (AA).

NOTE: If actuator (AA) has Handwheel refer to

Step E and remove.

1. Secure the yoke (3) in a vise. Orient with

the (AA) upwards.

2. All air pressure must be released from the

actuator casings (1,2).

3. Take note of alignment of supply ports on

top and bottom cases (1,2); used to assist

with ori en ta tion when actuator is re- as sem bled.

WARNING

SPRINGS UNDER COMPRESSION! To relax spring com-

pression remove case bolting equally in an alternating

pattern. Ensure that all "short" bolting is removed

fi rst.

IOM-C27-C53

2

Page 3

IOM-C27-C53

3

4. Loosen all fl ange bolting (18,19,20,21) two

revolutions. Pry apart the casings (1,2) if

“stuck” together.

5. In one revolution increments loosen all op pos ing nuts (20, 21) until the short bolting

(18, 20) disengages and can be removed.

Con tin ue loosening long nuts (21) in the

alternating, one revolution pattern ensuring that the cas ings (1,2) are being “pushed

apart”, until the long bolting (19, 21) is disengaged and removed.

For Air-to-Close Construction:

6. Remove top case (1). Secure the fl ats on

the lower end of the actuator stem (6) with

a wrench. With a second wrench rotate

the upstop fl ex nut (52) CCW and remove.

Note: Item (52) not used if actuator has

handwheel.

7. Re-secure the fl ats on stem and with a 9/16”

socket wrench rotate bolt (12) CCW to remove.

For Air-to-Open Construction:

15. Remove top case (1). Place matchmarks

on spring plate (9) to mark location of the

springs (10). Remove springs (10).

16. Rotate upstop fl ex nut (52) CCW and remove.

Note: Item (52) not used if actuator has

handwheel assembly.

17. Secure the fl ats on stem (6) and with a 9/16”

socket wrench rotate bolt (12) CCW to remove.

18. Remove lock washer (22) and spacer (5).

19. Remove spring plate (9) diaphragm plate (8),

diaphragm (7), o-ring (15) and diaphragm

washer (14).

20. Grasp stem (6) with hand and pull down thru

the attachment hub (4). Remove o-ring (17)

from stem (6). Lubricate new o-ring (17) with

Lubri-plate or equivalent and install on stem

(6).

8. Lift out lock washer (22), diaphragm washer

(14) and O-ring (15). Remove diaphragm (7).

NOTE: To replace stem bushing (39) and o-ring

(17) refer to Step F.

9. Install new diaphragm (7) over the diaphragm

plate (8), convoluted side down. Align bolt

holes in diaphragm with holes in lower case.

10. Install new new o-ring (15) and reposition

washers (14 & 22) on top of diaphragm.

11. Apply Loc-tite #242 or equal to stem bolt (12)

threads, tighten stem bolt (12) to actuator

stem (6) with 35 ft-lbs. torque.

12. Place upper case on lower case align top and

bottom cases (1,2) per B.3 previous. Install

long bolting (19) and nuts (21) equally spaced

around the bolt circle - fi nger tighten.

13. Install remaining short bolts (18) and nuts

(20). Torque all bolting to 75 in-lbs.

14. Thread upstop fl ex nut (52) [coupling as-

sembly (33) for handwheel option] onto the

actuator stem (6) and engage until just past

stem fl ats. NOTE: Upstop position cannot

be set until actuator is mounted on the body

and the bench range is set.

21. From the top of the attachment hub (4) extract

the stem bushing (39). Install new bushing.

22. Grasp stem (6) with hand and from below

the lower case (2) push the stem up thru the

attachment hub (4) until the bottom end of

the stem aligns with the “C” close mark on

the indicator plate (23).

23. Reposition diaphragm washer (14) “o-ring

side up” and new o-ring (15) on top of attachment hub (4).

24. Place the diaphragm plate (8) inside the

diaphragm (7) and carefully place both on

the diaphragm washer (14). Align bolt holes

in diaphragm with holes in lower case.

25. Align the spring plate (9) and stem spacer (5)

over the center hole of the diaphragm plate

(8).

26. Apply Loc-tite #242 to stem bolt (12) threads

and insert down through stacked parts and

rotate CW to engage threaded end of stem

(6). Tighten stem bolt (12) to actuator stem

(6) with 35 ft-lbs. torque.

27. Place springs (10) equally spaced around

the spring plate (9). See Step 15 previous

for matchmarks.

IOM-C27-C53

3

Page 4

4

IOM-C27-C53

28. Refer to B.3 previous, align top and bottom

cases (1,2). Install long bolting (19) and nuts

(21) equally spaced around the bolt circle fi nger tight.

9. Place the diaphragm plate (8) inside the

diaphragm (7) and carefully center both on

the diaphragm washer (14). Align bolt holes

in diaphragm with holes in lower case.

29. Install remaining short bolts (18) and nuts

(20). Torque all bolting to 75 in-lbs.

30. Thread upstop fl ex nut (52) [coupling assem-

bly (33) for handwheel option] CW onto the

actuator stem (6) and engage until just past

stem fl ats. NOTE: Upstop position cannot

be set until actuator is mounted on the body

and the bench range is set.

C. Changing Action from Direct to Reverse; i.e.

From ATC to ATO.

NOTE: Not necessary to remove actuator assembly from body assembly, unless supplied

with Handwheel Assembly.

1. Follow steps from B.1 thru B.5 then continue

as follows.

NOTE: DO NOT rotate actuator stem (6) or body

stem.

2. Secure both stem jam nuts with wrenches

and rotate the lower nut fi rst down to thread

base of the stem, followed by the upper nut.

10. Align center holes in the spring plate (9) and

stem spacer (5) with the center hole of the

diaphragm plate (8).

11. Apply Loc-tite #242 to stem bolt (12) threads

and insert down through stacked parts.

Rotate CW to engage threaded end of stem

(6). Secure the fl ats on the lower end of the

actuator stem (6) with a wrench. Tighten

stem bolt (12) to actuator stem (6) with 35

ft-lbs. torque.

NOTE: DO NOT rotate actuator stem (6) or body

stem while plug is touching the seat surface.

12. Place springs (10) equally spaced around

the spring plate (9).

13. Refer to B.3 previous, align top and bottom

cases (1,2). Install long bolting (19) and

nuts (21) equally spaced around the bolt

circle - fi nger tight.

14. Install remaining short bolts (18) and nuts

(20). Torque all bolting to 75 in-lbs.

3. Secure the fl ats on the lower end of the actua-

tor stem (6) with a wrench. With a second

wrench rotate the upstop fl ex nut (52) CCW 5

revolutions. (Required to help release spring

preload when stem bolt (12) is removed.)

4. Remove top case (1). Re-secure the fl ats on

stem and with a 9/16” socket wrench rotate

bolt (12) CCW and remove.

5. Lift out lock washer (22), diaphragm washer

(14) and O-ring (15). Remove diaphragm (7).

6. Remove diaphragm plate (8), spring plate

(9), stem spacer (5) and springs (10).

7. With hand pressure - push stem (6) down to

where bottom of stem (6) aligns with the “C”

close mark on the indicator plate (23.

NOTE: DO NOT rotate actuator stem (6) or body

stem while plug is touching the seat surface.

8. Re-assemble by placing diaphragm washer

(14) “o-ring side up” and new o-ring (15) on

attachment hub (4).

Rotate upstop fl ex nut (52) CW up the

15.

actuator stem (6) until just past stem fl ats.

NOTE: Upstop position cannot be set until

the bench range is set.

16. Lift indicating washer up to bottom of stem

(6) and thread both jam nuts up secure

underneath the indicating washer.

D. Changing Action from Reverse to Direct; i.e.

From ATO to ATC.

NOTE: Not necessary to remove actuator assembly from body assembly, unless supplied

with Handwheel Assembly.

1. Follow steps from B.1 thru B.5, then continue

as follows.

2. Remove top case (1) and springs (10).

3. Secure the fl ats on stem (6) and with a

9/16” socket wrench rotate bolt (12) CCW

to remove.

NOTE: DO NOT rotate actuator stem(6) or body

stem while plug is touching the seat surface.

IOM-C27-C53

4

Page 5

IOM-C27-C53

5

4. Remove lock washer (22) and stem spacer

(5).

5. Remove spring plate (9) diaphragm plate (8),

diaphragm (7), o-ring (15) and diaphragm

washer (14).

E. To Remove Handwheel Assembly.

For Air to Close Construction:

1. Rotate locknut (36) CCW two revolutions.

Rotate handwheel (31.2) CCW until it spins

freely.

6. Grasp stem (6) with hand and push upwards

to where indicating washer aligns with the

“O” open mark on the indicator plate (23).

7. Place springs (10) equally spaced in bottom

case (2) around the attachment hub (4).

8. Place stem spacer (5) on top of stem (6).

Carefully position spring plate (9) over top

the tops of the springs and spacer. Ensure

the springs, spacer and spring plate are

properly engaged.

9. Carefully set the diaphragm plate (8) on top

of the spring plate (9).

10. Install diaphragm (7) over the diaphragm

plate (8) and align with bolt holes in case

(2). Insert new o-ring (15) into groove in the

diaphragm washer (14).

11. Position diaphragm washer (14) “o-ring

side down” and lock washer (22) on top of

diaphragm (7).

12. Apply Loc-tite #242 to stem bolt (12) threads

and insert down through stacked parts,

rotate CW to engage threaded end of stem

(6). Secure the fl ats on the lower end of the

actuator stem (6) with a wrench. Tighten

stem bolt (12) to actuator stem (6) with 35

ft-lbs. torque.

2. With hammer and pointed punch, tap the

spring pin (35) out of the handwheel and

remove handwheel.

3. Remove nuts (38) and lock washer (48) from

cap screws (37). DO NOT let bracket as-

sembly fall as cap screws are removed. Lift

bracket assembly up such that the opening

of the pivot brackets (26) slip over the posts

on the coupling assembly (33). Set bracket

assembly aside.

4. Provide a temporary air supply with an in-line

ad just able airset regulator to the actuator

con nec tion.

5. Pressurize the ac tu a tor to a pres sure level

2-3 psig (0.1-0.2 Barg) above the lower

pres sure lev el of the bench setting; i.e. for a

5-15 psig (.34 -1.0 Barg) range, set pressure

at 7-8 psig (0.48-0.55 Barg).

6. Rotate the coupling assembly (33) CCW to

remove and release all air pres sure from

ac tu a tor.

Return to Section IV. B. Step 1.

For Air to Open Construction:

1. Rotate locknut (36) CCW up to base of

handwheel. Rotate handwheel (31.2) CW

until it spins freely.

NOTE: DO NOT rotate actuator stem (6) or body

stem while plug is touching the seat surface.

13. Refer to B.3 previous, align top and bottom

cases (1,2). Install long bolting (19) and

nuts (21) equally spaced around the bolt

circle - fi nger tight.

14. Install remaining short bolts (18) and nuts

(20). Torque all bolting to 75 in-lbs.

Rotate upstop fl ex nut (52) to align just past

15.

the fl ats on the stem (6). NOTE: Upstop

position cannot be set until the bench range

is set.

IOM-C27-C53

2. With hammer and pointed punch, tap the

spring pin (35) out of the handwheel and

remove handwheel.

3. Remove nuts (38) and lock washer (48) from

cap screws (37). DO NOT let bracket assembly fall as cap screws are removed. Lift

bracket assembly up such that the opening

of the pivot brackets (26) slip over the posts

on the coupling assembly (33). Set bracket

assembly aside.

4. Rotate coupling assembly (33) CCW to

remove.

Return to Section IV. B. Step 1.

5

Page 6

6

IOM-C27-C53

F. Bushing & O-ring Replacement ATC only.

(Extension of IV. B. Steps 1 - 8.)

1. Remove diaphragm plate (8), spring plate

(9) and stem spacer (5).

2. Place matchmarks on lower case (2) to

mark location of the springs (10). Remove

springs (10).

6. Reset springs (10) equally spaced around

the lower case (2). See Step 2 previous for

matchmarks.

7. Place stem spacer (5) on top of stem (6).

Carefully position the spring plate (9) over

the tops of the springs and spacer. Make

sure the springs, spacer and spring plate are

properly engaged.

3. Grasp stem (6) with hand and pull down thru

attachment hub (4). Remove o-ring (17)

from stem (6). Lubricate new o-ring (17)

with Lubri-plate or equivalent and install on

stem (6).

4. From the top of the attachment hub (4)

extract the stem bushing (39). Install new

bushing.

5. Grasp stem (6) with hand and from below

the lower case (2) push the stem back up

thru the attachment hub (4) until the bottom

end of the stem aligns with the “O” open

mark on the indicator plate (23).

8. Carefully set the diaphragm plate (8) on top

of the spring plate (9).

9. Return to Section IV. B. Step 9.

IOM-C27-C53

6

Page 7

IOM-C27-C53

7

SECTION V

V. TROUBLE SHOOTING GUIDE

NOTE: Cashco, Inc. recommends that if the casings are unbolted, the diaphragm, o-ring and TFE tape guide bushing

should always be replaced.

1. Air Leakage; Reverse action units. Diaphragm removal/replacement per Section IV. MAINTENANCE in its entirety.

Symptom Cause-Remedy

A. Leakage at diaphragm-to-lower casing fl ange or thru vent

plug.

B. Leakage from around stem and attachment hub. B. Replace O-ring (17).

2. Air Leakage; Direct action units. Diaphragm removal/replacement per Section IV. MAINTENANCE in its entirety.

Symptom Cause-Remedy

Leakage at diaphragm-to-upper casing joint or thru vent

A.

plug.

A1.

Overpressure. Check source of air supply and determine

if pressure is greater than indicated in Technical Bulletin;

reset airset pressure as required.

A2.

Tighten fl ange bolting.

A3.

Faulty seal at stem-diaphragm-seal joint. Remove upper

case - diaphragm. Install new o-ring (15).

Overpressure. Check source of air supply and determine

A1.

if pressure is greater than indicated in Technical Bulletin;

reset airset pressure as required.

Tighten fl ange bolting.

A2.

Faulty seal at stem-diaphragm-seal joint. Remove upper

A3.

case - diaphragm washer. Install new o-ring (15).

3. Unstable stroking.

Symptom Cause-Remedy

A. Intermittent screaching noise, jumpy motion; positioner/

controller loading stable

B. Positioner output unstable; positioner input signal stable. B1.

C. Controller output signal unstable. C1.

A1.

Excessive valve packing friction. Maintain valve packing

per valve instructions.

A2.

Misalignment of valve stem-to-actuator stem; realign per

valve instructions.

A3.

Excessive valve guide wear. Maintain valve per valve

instructions.

A4.

Flow induced instability thru valve. Stabilize

A5.

Install high range spring in actuator; i.e. increase bench

setting level.

Refer to the positioner IOM

B2.

Reduce positioner gain.

B3.

Re-calibrate positioner.

Stabilize controller by increasing proportional band,

adding reset, adding rate, or combinations of all.

C2.

Unstable process. Snub process if able. Stabilize process.

IOM-C27-C53

7

Page 8

8

IOM-C27-C53

4. Actuator can not deliver full stroke.

Symptom Cause-Remedy

A. Valve can not fully close for “Direct Action-ATC-FO”

arrangement; or valve can not fully open for “Reverse

Action-ATO-FC” arrangement.

B. Valve can not fully open for “Direct Action-ATC-FO”

arrangement; or valve can not fully close for “Reverse

Action-ATO-FC” arrangement.

A1.

Insuffi cient air supply pressure. Check Technical Bulletin

for proper air supply pressure.

A2.

Manual handwheel out of “neutral” position.

A3.

If equipped with a pneumatic positioner, positioner maybe

in “bypass” mode.

A4.

Excessive pressure drop. Check technical bulletin of

control valve for maximum allowable ∆P.

A5.

Bench range not properly calibrated. Check calibration or

stem overall length and re-calibrate per valve instructions.

Restriction in air supply line limiting volume available

A6.

Restriction in valve. Gain access to the valve’s internals

A7.

for any debris.

B1.

Insuffi cient air supply pressure. Check Technical Bulletin

for proper air supply pressure.

B2.

Manual handwheel out of “neutral” position.

B3.

If equipped with a pneumatic positioner, positioner maybe

in “bypass” mode.

B4.

Excessive pressure drop. Check technical bulletin of

control valve for maximum allowable ∆P.

B5.

Bench range not properly calibrated. Check calibration or

stem overall length and re-calibrate per valve instructions.

Restriction in air supply line limiting volume available

B6.

Restriction in valve. Gain access to the valve’s internals

B7.

for any debris.

IOM-C27-C53

8

Page 9

IOM-C27-C53

9

SECTION VI

VI. ORDERING INFORMATION

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was stamped on

the metal name plate and attached to the unit. This information can also be found on the Bill of Material (“BOM”),

a parts list that was provided when unit was originally shipped. (Serial Number typically 6 digits). Product Code

typical format as follows: (last digit is alpha character that refl ects revision level for the product).

–

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

With this information they can provide a quotation

for a new unit including a complete description,

price and availability.

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory. All

purposed changes will require a new name plate with appropriate ratings and new product code to accommodate

the recommended part(s) changes.

–

7

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

Identify the parts and the quantity required to repair

the unit from the “BOM” sheet that was provided

when unit was originally shipped.

NOTE: Those part numbers that have a quantity indicated

under "Spare Parts" in column "A” refl ect minimum

parts required for inspection and rebuild, - "Soft

Goods Kit". Those in column “B” include minimum

trim replacement parts needed plus those "Soft

Goods" parts from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for part

identifi cation and selection.

A Local Sales Representative will provide quotation

for appropriate Kit Number, Price and Availability.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to

modify or improve the designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Cashco, Inc. product remains solely with the purchaser.

IOM-C27-C53

9

Page 10

10

IOM-C27-C53

C27 Actuator

ATC - FO Action

10

Item No. De scrip tion

1 Case - Top

2 Case - Bottom

3 Yoke

4 Attachment Hub

5 Stem Spacer

6 Stem

7 Diaphragm ‡

8 Diaphragm Plate

9 Spring Plate

10 Spring

11 Hub Nut

12 Stem Bolt

14 Diaphragm Washer

15 Diaphragm Washer O-ring ‡

16 Attachment Hub O-ring ‡

17 Stem O-ring ‡

Item No. De scrip tion

18 Case Bolts - Short

20 Case Nut - Short

22 Stem Lock Washer

23 Indicator Plate

24 Indicator Plate Screw

39 Stem Tefl on Bushing ‡

40 Name Plate

41 Drive Screw

47 Vent Plug

52 Stem Stop Nut

Not Shown

19 Case Bolts - Long

21 Case Nuts - Long

49 Warning Plate

(Item number for Indicating Washer

is unique to Model)

‡ Recommended replacement parts.

IOM-C27-C53

Page 11

IOM-C27-C53

11

C27 Actuator

ATO - FC Action

Item No. De scrip tion

1 Case - Top

2 Case - Bottom

3 Yoke

4 Attachment Hub

5 Stem Spacer

6 Stem

7 Diaphragm ‡

8 Diaphragm Plate

9 Spring Plate

10 Spring

11 Hub Nut

12 Stem Bolt

14 Diaphragm Washer

15 Diaphragm Washer O-ring ‡

16 Attachment Hub O-ring ‡

17 Stem )-ring ‡

IOM-C27-C53

Item No. De scrip tion

18 Case Bolts - Short

20 Case Nut - Short

22 Stem Lock Washer

23 Indicator Plate

24 Indicator Plate Screw

39 Stem Tefl on Bushing ‡

40 Name Plate

41 Drive Screw

47 Vent Plug

52 Stem Stop Nut

Not Shown

19 Case Bolts - Long

21 Case Nuts - Long

49 Warning Plate

‡ Recommended replacement parts.

11

Page 12

12

IOM-C27-C53

C53 Actuator

ATC - FO Action

12

Item No. De scrip tion

1 Case - Top

2 Case - Bottom

3 Yoke

4 Attachment Hub

5 Stem Spacer

6 Stem

7 Diaphragm ‡

8 Diaphragm Plate

9 Spring Plate

10 Spring

11 Hub Nut

12 Stem Bolt

14 Diaphragm Washer

15 Diaphragm Washer O-ring ‡

16 Attachment Hub O-ring ‡

17 Stem O-ring ‡

Item No. De scrip tion

18 Case Bolts - Short

19 Case Bolts - Long

20 Case Nut - Short

21 Case Nuts - Long

22 Stem Lock Washer

23 Indicator Plate

24 Indicator Plate Screw

39 Stem Tefl on Bushing ‡

40 Name Plate

41 Drive Screw

47 Vent Plug

52 Stem Stop Nut

Not shown

19 Case Bolts - Long

21 Case Nuts - Long

49 Warning Plate

‡ Recommended replacement parts.

IOM-C27-C53

Page 13

IOM-C27-C53

13

C53 Actuator

ATO - FC Action

IOM-C27-C53

Item No. De scrip tion

1 Case - Top

2 Case - Bottom

3 Yoke

4 Attachment Hub

5 Stem Spacer

6 Stem

7 Diaphragm ‡

8 Diaphragm Plate

9 Spring Plate

10 Spring

11 Hub Nut

12 Stem Bolt

14 Diaphragm Washer

15 Diaphragm Washer O-ring ‡

16 Attachment Hub O-ring ‡

17 Stem O-ring ‡

Item No. De scrip tion

18 Case Bolts - Short

19 Case Bolts - Long

20 Case Nut - Short

21 Case Nuts - Long

22 Stem Lock Washer

23 Indicator Plate

24 Indicator Plate Screw

39 Stem Tefl on Bushing ‡

40 Name Plate

41 Drive Screw

47 Vent Plug

52 Stem Stop Nut

Not shown

19 Case Bolts - Long

21 Case Nuts - Long

49 Warning Plate

‡ Recommended replacement parts.

13

Page 14

14

IOM-C27-C53

Handwheel Assembly

14

Item No. De scrip tion

25 Fixed Bracket

26 Pivot Bracket

27 Threaded Pin

28 Thrust Pin

29 Rocker Pin

30 Thrust Washer

31 Handwheel Assy

32 Retaining Ring

33 Coupling Assy

Item No. De scrip tion

34 Shoulder Bolt

35 Pin (Spring)

36 Lock Nut

37 Cap Screw

38 Nut

45 Handwheel Washer

48 Lock Washer

IOM-C27-C53

Page 15

IOM-C27-C53

15

NOTES

IOM-C27-C53

15

Page 16

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax. # (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in U.S.A. C27-C53-IOM

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

Email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

Email: brazil@cashco.com

Loading...

Loading...