Page 1

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM)

IOM-31-N

05-14

MODEL 31-N

Pressure Reducing Service Regulator

SECTION I

I. DESCRIPTION AND SCOPE

The Model 31-N is a pressure reducing service regulator used to control downstream (outlet or P2) pressure to levels

between 2" – 16 “WC (50–400 mm H2O). Sizes are 1/2" 3/4”, 1", 1-1/2" and 2" (DN15, 20, 25, 40 and 50).

The unit is designed for gaseous service only.

Refer to Technical Bulletin 31-N-TB for sizing, application and selection recommendations.

WARNING

1. Model 31-N does not include an internal relief mech a nism. Overpressure protection requires use of a downstream

safety relief valve or rupture disc.

2. User to determine acceptance of non-relieving design by federal, state, and/or local codes.

3. IF GAS IS DETECTED BY SMELL, CONTACT YOUR GAS COMPANY IMMEDIATELY.

4.

User to comply with instructions, operating re quire ments and maintenance requirements located herein the “IOM-31-N”.

II. INSTALLATION

1. An inlet block valve should always be installed.

An outlet block valve is recommended.

2. If service application is continuous such that

shut down is not readily accomplished, it is

rec om mend ed that an outlet block valve and a

manual bypass valve be installed.

3. Pipe unions are recommended to be installed to

allow removal from piping. Trim can be changed

without removal from pipeline.

4. An outlet pressure gauge should be located

ap prox i mate ly 10 pipe diameters downstream,

and within sight.

5. All installations should include a downstream

re lief device if the inlet pressure could exceed the

pressure rating of any downstream equipment.

A downstream safety relief valve or a rupture

disc is absolutely required if the inlet P1

pres sure exceeds 100 psig (6.9 Barg) under

any normal or upset conditions.

SECTION II

CAUTION

Installation of adequate overpressure pro tec tion is recommended to pro tect the reg u la tor from overpressure and

all down stream equip ment from damage in the event of

regulator failure.

WARNING

The maximum outlet pressure listed on the name plate is

the “upper operative limit” for the sensing di a phragm.

Higher pressures could damage the internals. (Field hy dro stat ic or pneumatic pressure tests fre quent ly destroy

diaphragms. DO NOT HY DRO STAT IC OR PNEUMATIC

PRESSURE TEST THRU AN IN STALLED UNIT EX POS ING

THE OUTLET POR TION OF THE REGULATOR TO PRES SURES GREATER THAN 50 PSIG (3.45 BARG) FAIL URE

TO HEED MAY RESULT IN CAT A STROPH IC FAIL URE WITH

FLYING PARTS AND POSSIBILITY OF PER SON AL INJURY!

ISO LATE FROM TEST.)

CAUTION

For welded installations, all internal trim parts, seals and

diaphragm(s) must be removed from reg u la tor body prior to

welding into pipeline. The heat of fusion welding will dam age non-metallic parts if not re moved. NOTE: This does

not apply to units equipped with extended pipe nip ples.

Page 2

6. Clean the piping of all foreign material including

chips, welding scale, oil, grease and dirt before

in stall ing the regulator. Strainers are rec om mend ed.

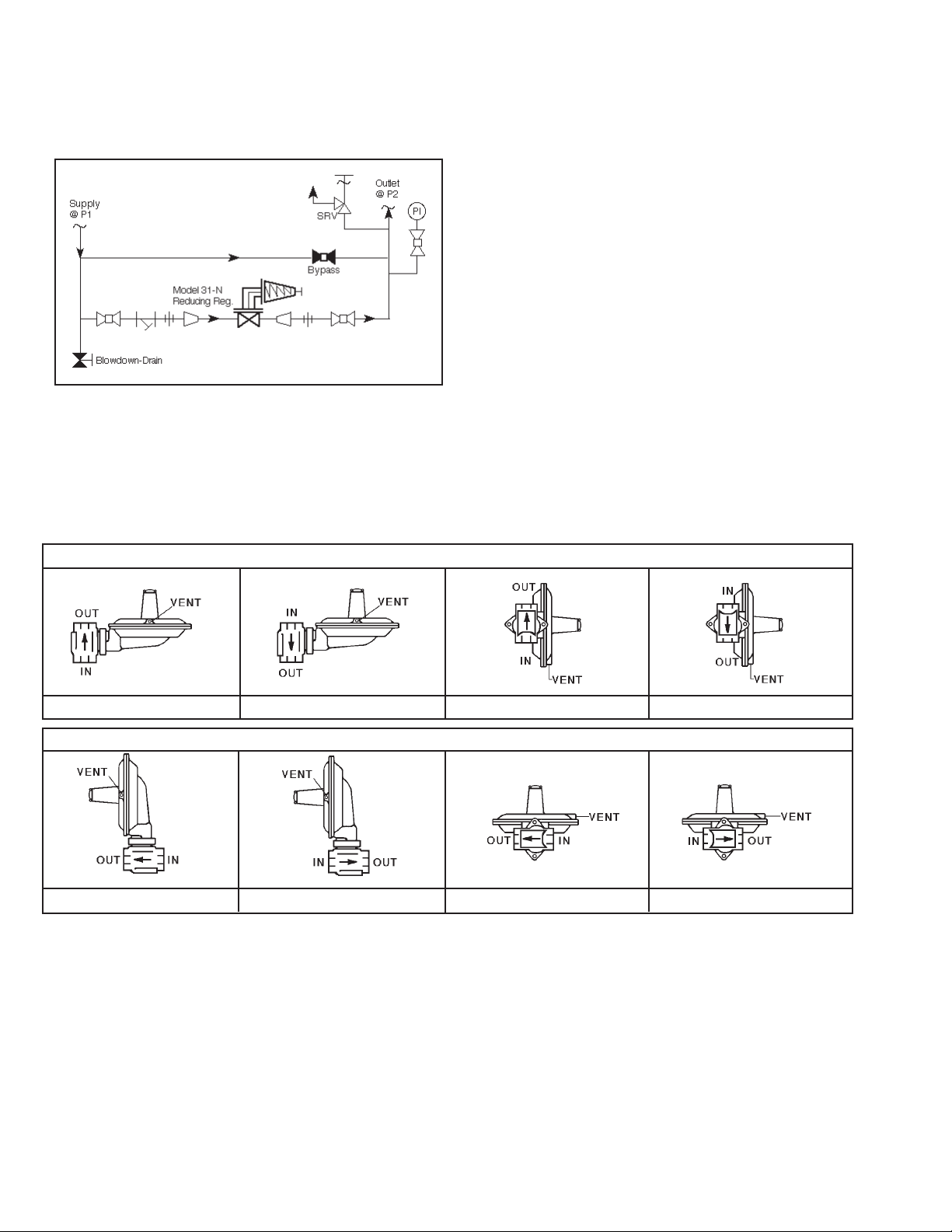

Figure 1

Recommended Piping Schematic For

Pressure Re duc ing Station

7. In placing thread sealant on pipe ends prior to

en gage ment, assure that excess material is

re moved and not allowed to enter the regulator

upon startup.

8. Flow Direction: Install so the fl ow direction match es

the arrow cast on the regulator body.

9. Refer to Figure 2. Regulator may be rotated

around the pipe axis 360°, and may be installed

in a horizontal or vertical pipeline. Four orientation/

arrangement assembly positions are standard. Orient to prevent the spring chamber vent hole from

collecting rainwater or debris. Reorient ac tu a tor

around the stem axis 360° if nec es sary.

10. Regulators are not to be direct buried un der ground.

11. For insulated piping systems, recommendation is

to not insulate regulator.

12. Cashco does not recommend fi eld welding on

the body of the regulator. If weld connections are

desired, specify Opt-32, extended plain end pipe

nipples.

FOR VERTICAL PIPING

Position 1

Position 1

Position 2

FOR HORIZONTAL PIPING

Position 2

III. PRINCIPLE OF OPERATION

1. Refer to internals drawings Figures 5 thru 8.

2. Internal trim movement occurs as pressure vari a tions register on the diaphragm. The registering

pressure is the controlled outlet pressure, P2, or

down stream pressure. The range spring opposes

Figure 2

SECTION III

Position 3

Position 3

up wards movement of the diaphragm due to the

P2 pressure. As outlet pressure drops, the range

spring pushes the diaphragm down, opening the

regulator’s port via the linkage lever travel. As

outlet pressure increases, the diaphragm pushes

up against the range spring and the port closes.

Position 4

Position 4

IOM-31-N2

Page 3

3. Model 31-N includes a linkage lever in its mech a nism. The linkage lever allows the regulator to

operate fl ow-to-open (FTO) and provides plug

travel multiplication thru the lever length ratio.

5. Aspiration (jet) effect is developed by properly

locating the “windows” of the loading ring. When

properly po si tioned, a high velocity path is in tro duced. This causes a corresponding decrease in

IV. STARTUP

static pressure to be de vel oped at a location that

allows this decreased pressure to register into the

lower case and beneath the diaphragm. The net

result is to pull the diaphragm down and open the

valve port, providing higher unit capacity.

6. A complete diaphragm failure will cause the reg u la tor to fail open.

SECTION IV

1. Assure that the proper range spring is indicated

to be within the regulator by inspection of the

unit’s name plate. Apply setpoint pressures that

are only within the stated range.

2. When stating direction of rotation of the ad just ment

screw, the view is with respect to looking down

towards the closing cap or its normal lo ca tion.

3. Start with the block valves closed. A bypass

valve may be used to maintain outlet pressure

in the down stream system without changing the

fol low ing steps.

4. Remove closing cap on top of spring chamber.

Relax the range spring by turning the adjustment

screw CCW a minimum of three (3) full rev o lu tions.

This reduces the outlet (downstream) pres sure

setpoint.

5.

Crack open the outlet (downstream) block valve.

6. Slowly open the inlet (upstream) block valve ob serv ing the outlet (downstream) pressure gauge.

Partially close off the bypass valve, if open. De ter mine if the regulator is fl owing. If not, slowly

rotate the regulator adjustment screw CW until

fl ow begins.

7. Continue to slowly open the inlet (upstream) block

valve until fully open.

8. Continue to slowly open the outlet (downstream)

block valve, especially when the downstream piping system isn’t pressurized. If the outlet (down stream) pres sure exceeds the desired pressure,

close the inlet (up stream) block valve fi rst, then

the outlet (downstream) block valve, and go to

Step 4, then return to Step 6.

9. When fl ow is established steady enough that the

outlet (downstream) block valve is fully open, begin

to slowly close the bypass valve if installed.

10. Develop system fl ow to a level near its expected

normal rate, and reset the regulator setpoint per

Section VII.

11. Reduce system fl ow to a minimum level and ob-

serve setpoint. Outlet pressure may rise from the

set point of Step 10. The maximum rise in outlet

pressure on decreasing fl ow should not exceed the

stated upper limit of the range spring by greater than

10%; i.e. 5.5–8.0 “WC (140–200 mmH2O) range

spring, at low fl ow the outlet pressure should not

exceed 8.8 “WC (224 mmH2O). If it does, consult

factory.

V. SHUTDOWN

1. On systems with a bypass valve, and where system pressure is to be maintained as the reg u la tor

is shut down, slowly open the bypass valve while

closing the inlet (up stream) block valve. Fully

close the inlet (up stream) block valve. (When on

bypass, the system pres sure must be con stant ly

observed and manually reg u lat ed.) Close the outlet

(downstream) block valve.

IOM-31-N

SECTION V

WARNING

Do not walk away and leave a bypassed reg u la tor

un at tend ed.

2. If the regulator and system are to both be shut down, slowly close the inlet (upstream) block

valve. Close the outlet (downstream) valve only

if regulator removal is required.

3

Page 4

SECTION VI

VI. MAINTENANCE

A. General:

WARNING

SYSTEM UNDER PRESSURE. Prior to performing any

maintenance, isolate the regulator from the system and

relieve all pressure. (Including the External Sensing

line when specifi ed.) Failure to do so could result in

personal injury.

1. Maintenance procedures hereinafter are based

upon removal of the regulator from the pipeline

where installed.

2. Owner should refer to owner’s procedures for

re mov al, handling and cleaning of re us able

parts, the dis pos al of non-reusable parts, i.e.

gaskets, suitable sol vents, etc.

3. If desired, gaskets may be oiled, or coated with

gasket sealant or thread sealing com pound,

provided the sealant is compatible with the fl u-

id. (See below for “oxygen cleaned” valves.)

4. Valves originally supplied as “special cleaned”

(Opt-56) are assembled using special seal ant,

Fluorolube GR-3621, or equivalent. Cash co,

Inc., rec om mends fol low ing factory cleaning

specifi cation #S-1542, or equiv a lent. Contact

factory for details.

5. When directions such as upwards, down wards,

leftwards or rightwards are given, they are with

respect to Figures 5 and 6.

When counter clockwise (CCW) or clock wise

(CW) ro ta tions are indicated, they are with

respect to:

a. Spring Chamber – as viewed from above

looking down towards the closing cap or

its normal location.

b. Body – as viewed looking into the body

cavity with the upper case assembly re moved.

B. Diaphragm Replacement:

WARNING

SPRING UNDER COMPRESSION. Prior to re mov ing upper case, relieve spring compression by removing the

ad just ing screw. Failure to do so may result in fl ying parts

that could cause personal injury

1. Install the body (1) in a vise with the spring

chamber (4) directed upwards.

2. Remove closing cap (5). Relax range spring

(17) by turning adjustment screw (18) CCW

until removed from spring cham ber (4); count

number of full revolutions and record below.

No. of revolutions to remove ad just ment

screw (18) ____________________ .

3. Paint or embed a match mark between lower

case (3) and spring chamber (4) at fl ange

O.D.

4. Remove all diaphragm fl ange nuts (10) and

screws (9).

5. Remove spring chamber (4) and range spring

(17).

6. Pry up the edges of the diaphragm (12) from

around the pe rim e ter of the lower case (3)

diaphragm fl ange to assure that the diaphragm

(12) is not “sticking” to the lower case.

7. Grasp stop post (19) and with hand carefully

lift up wards and to the right to disengage linkage lever (21) from cir cu lar opening of lower

di a phragm plate (20). Fully remove diaphragm

sub-assembly (DSA) from lower case.

8. Place the “ear” of the lower diaphragm plate

(20) into a soft jawed vise and fully secure,

with stop post (19) pointed upwards. Place a

wrench on the hex surface of stop post (19)

and loosen by rotating CCW (viewed from

above).

.

1

Product of Fisher Scientifi c Company

9. Grasp upper diaphragm plate (13) with fi n gers

and continue to loosen stop post (19) until removal. Finger remove washer (16), and nylon

bushing (15). Lift upper diaphragm plate (13),

together with stuck-on diaphragm (12) away

from lower diaphragm plate (20), and place

on bench top.

IOM-31-N4

Page 5

10. While holding upper diaphragm plate (13)

by palm of hand, hand-pull diaphragm (12)

away from upper di a phragm plate (13).

NOTE: The diaphragm (12) is adhered to the

upper di a phragm plate (13) with adhesive.

Rotate and repeat until the diaphragm (12)

is fully re moved. Discard used diaphragm

(12). Re move remaining ad he sive from

upper di a phragm plate (13).

11. Examine upper plate (13) for bending or

distortion. Re place if deformation is present.

12. Spread a thin layer of compatible adhesive (DuPont 732 or equal) onto the

cleaned upper pressure plate (13), staying away from the edges approximately

1/2" (12 mm). Place a new di a phragm (12)

down onto a fl at surface with the di a phragm’s

(12) fl ange edges up, forming a “bowl”

with a hole in the center. Carefully lift the

upper diaphragm plate (13), invert 180°,

and lower into the diaphragm (12) “bowl”

with the ad he sive meeting the diaphragm

(12); align the upper diaphragm plate (13)

as concentrically as able. Carefully lift the

adhered parts (12)(13) and invert 180°.

Align the diaphragm (12) hole and upper

diaphragm plate (13) hole con cen tri cal ly.

Work out any “bubbles” formed be tween the

diaphragm (12) and the upper di a phragm

plate (13) using a fl at tool as nec es sary.

Once aligned, set adhered parts (12)(13)

back down to allow adhesive approximately

30 minutes setting/drying time.

13. Place the adhered diaphragm (12) and the

upper diaphragm plate (13) back onto the

lower diaphragm plate (20) still resting in

the vise. Position/align the diaphragm (12)

with respect to the lower diaphragm plate

(20) as indicated in Figure 3; failure to align

properly may cause poor unit performance.

Figure 3

16. Position the diaphragm sub-assembly

(DSA) to wards the rightwards of center of

the lower case (3) with the opening of the

lower di a phragm plate (20) oriented per pen dic u lar to the linkage lever (21). Insert

the linkage lever (21) thru the opening of

the lower diaphragm plate (20). Align the

bolt holes of diaphragm (12) with the bolt

holes of the lower case (3).

17. Place range spring (17) over stop post

(19), and align properly by setting spring

(17) over washer (16) and nylon bushing

(15) so that the spring (17) rests on upper

diaphragm plate (13).

14. Set nylon bushing (15) into hole in the top

15. Insert stop post (19) thru the center opening

IOM-31-N

of the upper diaphragm plate (13). Place

washer (16) on top of nylon bush ing (15).

of stacked parts (16, 15, 13, 12) and engage

threaded end of stop post (19) into lower

diaphragm plate (20). Carefully tighten stop

post (19) to ensure concentricity of stacked

parts (16, 15, 13, 12). Tighten stop post

(19) to 18–20 in-# (2.0–2.3 N-M) torque.

This com pletes di a phragm sub-as sem bly

(DSA); re move from vise.

18. Clean threads of spring chamber (4) “barrel” thor ough ly using suitable solvent.

19. Set spring chamber (4) onto lower case (3)

align ing matchmarks of Step 3 previous.

20. Insert screws (9) into fl ange bolt holes.

En gage nuts (10). Align and push nuts

(10) up against the un der neath side of

the lower case (3) fl ange, ensuring that

the “tips” of the nuts are not improperly

positioned due to the small “lugs” on the

lower case fl ange. Hand-tighten all screws

(9) and nuts (10).

5

Page 6

21. In an alternating cross-pattern, tighten screws

(9) in one revolution increments. Repeat

pattern until torque reaches 25–30 in-#

(2.8–3.4 N-M).

22. Engage adjustment screw (18) the same

num ber of revolutions as recorded from Step

2 previous.

23. Remove and replace closing cap gasket (6).

Re place closing cap (5) and fi nger tighten

only.

C. Trim Replacement:

1. Place body (1) into a vise and secure. Paint

or embed a match mark between lower case

(3) and body (1).

2. Loosen both cap screws (11) bolting the ac tu a tor assembly (AA) to the body (1). Holding

the actuator assembly (AA) in hand, rotate cap

screws (11) to removal. NOTE: The ac tu a tor

assembly (AA) may be rotated around the

stem (24) axis during this procedure.

3. Place actuator assembly (AA) in a vise or on

a work bench to allow cleaning of the gasket

(8) surface of the lower case (3) with a fl at

tool. Use spray solvent as necessary (do not

im merse).

4. Remove “rubber” seat (27) from end of stem

(24); examine and discard. Place new seat

(27) onto end of stem (24). For sizes 1-1/2"

and 2" (DN40 & 50), a defl ector ring (32) is

included. Ensure the proper orientation of the

defl ector ring (32) when pushing the new seat

(27) into position. (See Figure 6.)

remove. When replacing orifi ce (26) use

pipe sealant PLS-2 or PST Loctite. Rotate

CW to tighten orifi ce (26); tighten to 35–40

ft-# (47.4–54.2 N-M). NOTE: Do not replace

orifi ce (26) without re plac ing seat (27).

8a. Examine glass-fi lled nylon loading ring (25) for

sizes 1/2" thru 1" (DN15 thru 25). This piece

may wear “notches” at the location where the

loading ring (25) touches the orifi ce (26) “hex

points”. It is necessary that the loading ring

(25) be “clamped snugly” to the orifi ce (26);

replace loading ring (25) if fi t is loose.

8b. Examine SST loading ring (33) for sizes

1-1/2" and 2" (DN40 & 50). Assure that the

three impression points (2 rectangular, 1

cir cu lar) are still present; if an impression

point is missing, replace loading ring (33). It

is nec es sary that the loading ring (33) “clamp

snugly” to the orifi ce (26) to prevent rotation;

replace loading ring (33) if fi t is loose.

9. Refer to Figure 4 for proper alignment of

load ing ring (25, 33) split. Using both thumbs,

push the interior walls of the loading ring (25,

33) apart and lower the loading ring (25, 33)

down into the body (1) cavity, and over the

orifi ce (26). Release thumbs. Assure loading

ring (25, 33) “clamps snuggly”. Re peat until

load ing ring (25, 33) is prop er ly located per

Figure 4. The “split” of the loading ring (25)

is factory as sem bled along the body (1) axial

centerline for body sizes 1/2" - 1" (DN15 -

25), and for loading ring (33) at the 21° mark

on the body (1) for body sizes 1-1/2" and 2"

(DN40 & 50). For all body sizes the “split” in

the loading ring (25, 33) is located opposite

the fl ow direction.

5. Return to the body (1) in vise. Observe po si tion

of “split” in loading ring (25, 33) with respect

to proper location as indicated in Figure 4.

Using both thumbs, push the interior walls to

pry apart the split of the loading ring (25, 33),

until the ring (25, 33) slips off the orifi ce (26).

Remove the loading ring (25, 33).

6. Remove the body (1) from the vise. Clean the

gasket (8) recess of the body (1) with a fl at

tool. Solvent clean body (1). Replace body

(1) into vise.

7. Examine orifi ce (26) for damage to the seat-

ing edge. Replace orifi ce (26) if damaged. To

remove orifi ce (26), place a socket over the

orifi ce (26) hex, and rotate CCW to loosen/

10. Place gasket (8) into body (1) recess.

11. Reposition actuator assembly (AA) into po si tion by hand, aligning body (1) bolt holes with

bolt holes in lower case (3). Insert two cap

screws (11) and fi nger tighten in an al ter nat ing

cross pattern.

12. Wrench tighten cap screws (11) in an al ter nat ing cross pattern to a torque of 8–10 ft.-#

(10.8–13.5N-M).

D. Linkage Lever and Stem Replacement:

1. Remove diaphragm sub-assembly (DSA) as

de scribed in Section VI.B., Steps 1 thru 7.

IOM-31-N6

Page 7

BODY SIZES 1/2', 3/4" & 1" (DN15, 20 & 25)

6. Insert linkage pivot pin (23) thru hole in link age lever (21). Simultaneously engage the

linkage lever (21) and the stem (24), and

place pin (23) ends back into the “cradles”

of the pedestal supports of the lower casing

(3), replace washer (37), engage and tighten

both machine screws (22).

7. Reinstall diaphragm sub-assembly (DSA)

and spring chamber (4) as described in

Section VI.B., Steps 16 thru 23.

8. Reinstall actuator assembly (AA) to body (1)

as de scribed in Section VI.C., Steps 11 and

12.

E. Range Spring Replacement:

1. Remove closing cap (5) from spring chamber

(4).

2. Rotate adjustment screw (18) CCW to re mov al.

3. Remove existing range spring (17).

BODY SIZES 1-1/2" & 2" (DN40 & 50)

Figure 4

2. Remove lower casing (3) from body (1) as

de scribed in Section VI.C., Steps 1 and 2.

3. Remove both machine screws (22), washers (37) and retaining link age pivot pin (23).

(See Figure 8.) Lift link age lever (21) from

its position of en gage ment with stem (24)

bringing linkage pivot pin (23) along. Remove

pin (23) and inspect for wear, bend ing, etc.

Replace pin (23) if re quired.

4. Inspect linkage lever (21) for bending, dis tor tion, etc. Replace lever (21) if required.

5. Withdraw stem (24) through the neck of the

lower case. Inspect stem to assure that there

is no bend ing in the "slot" area where the

stem and linkage lever (21) engage. Replace

stem if there are any signs of bending or

friction in the stem guide or engagement

zones. NOTE: If regulator has external

sensing - replace the o-ring (44). Re-insert

stem back into lower casing.

4. Install new range spring (17) (refer to Table

2).

5. Put thread locking compound on threads of

spring chamber (4) and on adjustment screw

(18).

6. Engage adjustment screw (18) into spring

cham ber (4) by rotating CW until the range

spring (17) begins to compress.

7. Shop calibrate the setpoint per Section VII.

8. Remove old nameplate (28) and drive screws

(29); install new nameplate with correct range

spring indicated.

IOM-31-N

7

Page 8

SECTION VII

VII. SETPOINT ADJUSTMENT/CAL I BRA TION

1. Establish fl ow thru the regulator, preferably a

relatively low fl ow rate, approximately 50 SCFH.

2. Remove closing cap (6) by rotating CCW.

3. If P2 outlet pressure is less than desired, rotate

ad just ment screw (18) CW; if higher than desired,

rotate ad just ment screw (18) CCW.

SECTION VIII

VIII. TROUBLE SHOOTING GUIDE

1. Variation in outlet P2 pressure.

Possible Cause Remedy

A. Oversized valve, insuffi cient rangeability. A1.

4. Reinstall closing cap (6) using pipe joint lubricant/

sealant on threads; fi nger tighten only.

5. Increase fl ow rate to near maximum. Check for

ad e quate P2. Repeat Steps 2 thru 4. as required.

NOTE: At higher fl ow rates, removal of the clos-

ing cap (6) can induce an instability. If this occurs,

make adjustment, and quickly replace closing cap

(6), then observe the new setpoint.

Check actual fl ow conditions; consider use of smaller

orifi ce.

A2.

Reduce P1 pressure if possible.

B. Undersized valve, insuffi cient rangeability. B1.

C. High Inlet P1 pressure. C. Reduce P1 pressure to 60 psig (4.14 Barg) or lower.

D. Loading ring is “loose”. D. Replace loading ring.

E. Variation of Inlet P1 pressure. E. P2 pressure setpoint will vary as P1 pressure varies;

F. Dirty service gas; unit becomes unresponsive. F1.

G. Downstream over-pressurization. G1.

H. Process pressure pulsations – inlet or outlet. H1.

J. Adjustment screw loosening, P2 outlet pressure

decreasing.

Check actual fl ow conditions; consider use of larger

orifi ce.

B2.

Increase P1 pressure if possible.

provide stable P1 inlet pressure.

Clean gas stream with liquid separators, strainers, etc.

F2.

Disassemble and clean buildup on a routine basis.

Install safety relief valve or rupture disc with a 50 psig

(3.45 Barg) setting or lower.

G2.

Disassemble actuator assembly and check for bent

upper diaphragm plate. Check for relief cap distortion.

G3.

Flow is tightly shutoff downstream of regulator;

relocate shutoff valve.

G4.

Seat leakage; replace seat.

G5.

Failure of orifi ce thread sealant; reinstall orifi ce.

G6.

Correct process conditions/controls that cause P

pressure to become greater than 50 psig (3.45 Barg).

Stabilize process pressures at source or end use.

H2.

Install volume tanks to reduce pulsation effects.

J1.

Place locking compound on threads of adjustment

J2.

screw.

Stabilize fl ow to reduce vibrations.

2

IOM-31-N8

Page 9

2. External leakage.

Possible Cause Remedy

A. Diaphragm failure. A. Replace diaphragm.

B. Downstream over-pressurization. B1.

Correct process conditions/controls that cause P

to become greater than 50 psig (3.45 Barg).

Install safety relief valve or rupture disc with a 50 psig

B2.

(3.45 Barg) setting or lower.

Disassemble actuator assembly and check for bent

B3.

upper diaphragm plate. Check for relief cap distortion.

Flow is tightly shutoff downstream of regulator;

B4.

relocate shutoff valve.

Seat leakage; replace seat.

B5.

C. Body gasket failure.

C1. Replace body gasket.

3. Unstable Operation.

Possible Cause Remedy

A. Closing cap removed. A. Reinstall gasketed closing cap.

B. Plug vent. B. Clean vent opening in spring chamber.

pressure

2

IOM-31-N

9

Page 10

SECTION IX

IX. ORDERING INFORMATION

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was stamped

on the metal name plate and attached to the unit. This information can also be found on the Bill of Material

("BOM"), a parts list that was provided when unit was originally shipped. (Serial Number typically 6 digits).

Product Code typical format as follows: (last digit is alpha character that refl ects revision level for the product).

–

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

With this information they can provide a quotation

for a new unit including a complete description,

price and availability.

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory. All

purposed changes will require a new name plate with appropriate ratings and new product code to accommodate

the recommended part(s) changes.

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

Identify the parts and the quantity required to repair

the unit from the "BOM" sheet that was provided

when unit was originally shipped.

–

7

Figure 6

1-1/2" & 2" Body Sizes

NOTE: Those part numbers that have a quantity indicated

under "Spare Parts" in column "A” refl ect minimum

parts required for inspection and rebuild, - "Soft

Goods Kit". Those in column “B” include minimum

trim replacement parts needed plus those "Soft

Goods" parts from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for part

identifi cation and selection.

A Local Sales Representative will provide quotation

for appropriate Kit Number, Price and Availability.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right

to modify or improve the designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Cashco, Inc. product remains solely with the purchaser.

Body Assembly (BA)-to-Actuator Assembly

Figure 7

Partial Section:

(AA) Con nec tion

IOM-31-N10

Page 11

Body Assembly (BA) Actuator Assembly (AA)

Figure 5

1/2", 3/4" & 1' Body Sizes

Pedestal

Internal Sensing Option

* Diaphragm Sub-Assembly (DSA) is made

up of Item Nos. 12, 13, 14, 15, 16 & 19.

Item

No. Description

1 Body

3 Lower Case

4 Spring Chamber

5 Closing Cap

6 Gasket (Closing

Cap)

8 Gasket (Body)

9 Machine Screw

10 Nut, Hex.

11 Cap Screw

12 Diaphragm

13 Upper Diaphragm

Plate

15 Nylon Bushing

16 Washer

17 Range Spring

18 Adjustment Screw

19 Stop Post

20 Lower Diaphragm

Plate

21 Linkage Lever

22 Machine Screw

23 Linkage Pivot Pin

24 Stem

25 Nylon Loading

Ring

26 Orifi ce

27 Seat

28 Nameplate

29 Drive Screw

30 Warning Plate

32 Defl ector Ring

33 SST Loading

Ring

34 Bug Proof Vent

Plug (not shown)

37 Washer (fl at)

44 O-ring (Stem)

(Ext'l Sensing)

* DSA Diaphragm

Sub-Assembly

IOM-31-N

External Sensing Option

44

Pedestals

Linkage Lever

(21) mounts between pedestals;

not shown for

clarity.

Figure 8

Partial Plan: Linkage Lever (21) Pedestals

11

Page 12

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax. # (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in U.S.A. IOM-31-N

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

email: brazil@cashco.com

Loading...

Loading...