Page 1

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I. DESIGN AND FUNCTION

IOM-2100

01-14

Model 2100

Gauge Hatch

SECTION I

Models 2100 is primarily designed to provide easy

access into storage tanks for gauging and obtaining

samples. May also provide additional pressure relief

as a supplement for normal or emergency venting.

Available with either a non-locking or locking hatch.

LATCH DESIGNS

No Latch - (Non Locking)

Knob Latch - (Locking)

SECTION II

II. INSPECTION AND STORAGE:

The gauge hatch is carefully packaged to prevent damage or contamination during shipping. Inspect the

equipment when it is received and report any damage to the carrier immediately. The gauge hatch should be

stored with all protective covers in place.

SECTION III

III. INSTALLATION

WARNING

The gauge hatch must be installed in a horizontal

position. The tank nozzle on which the hatch is

mounted should have the same nominal diameter as

the gauge hatch. It is recommended that the tank

nozzle fl ange face be within 1 degree of horizontal.

Minimum clearance between tank roof and face of

the hatch fl ange must be at least equal to the valves’

nominal fl ange bore. Tank nozzle bore must be greater

than or equal to fl ange bore.

The Model 2100 Gauge Hatch is designed to mate with

a 150 lb ASME fl ange. Torque guidelines are provided

in Table 1.

Before installing the 2100 Gauge Hatch remove all

packing materials.

Inspect the gasket seating surface of the tank nozzle

fl ange. It must be clean, free of scratches, corrosion,

tool marks and fl at.

Gauge hatches are furnished with fl at faced fl anges. It

is recommended that they be installed on mating fl at

face fl anges with a full faced gasket. If the fl at face of

the hatch is sealing against a raised face steel fl ange,

a spacer or fi ller ring must be used to fi ll the annular

space of the raised face steel fl ange.

Make sure the gasket is suitable for the application

and is in good condition. For full face gaskets, we

recommend the use of a 1/8-inch Expanded PTFE

gasket.

Center the gasket within the bolt circle of the tank

fl ange and carefully set the gauge hatch on the fl ange

nozzle and align the bolt holes.

All stud threads must be lubricated to obtain proper

torque results. A washer should be used under each

stud nut.

Install the studs, washers and nuts and tighten nuts

hand tight. Check proper alignment of fl ange faces.

Misalignment of fl ange faces will cause bending

stresses at the fl ange and fl ange joint and damage

may result. Correct any misalignment prior to applying

torque to nuts.

Page 2

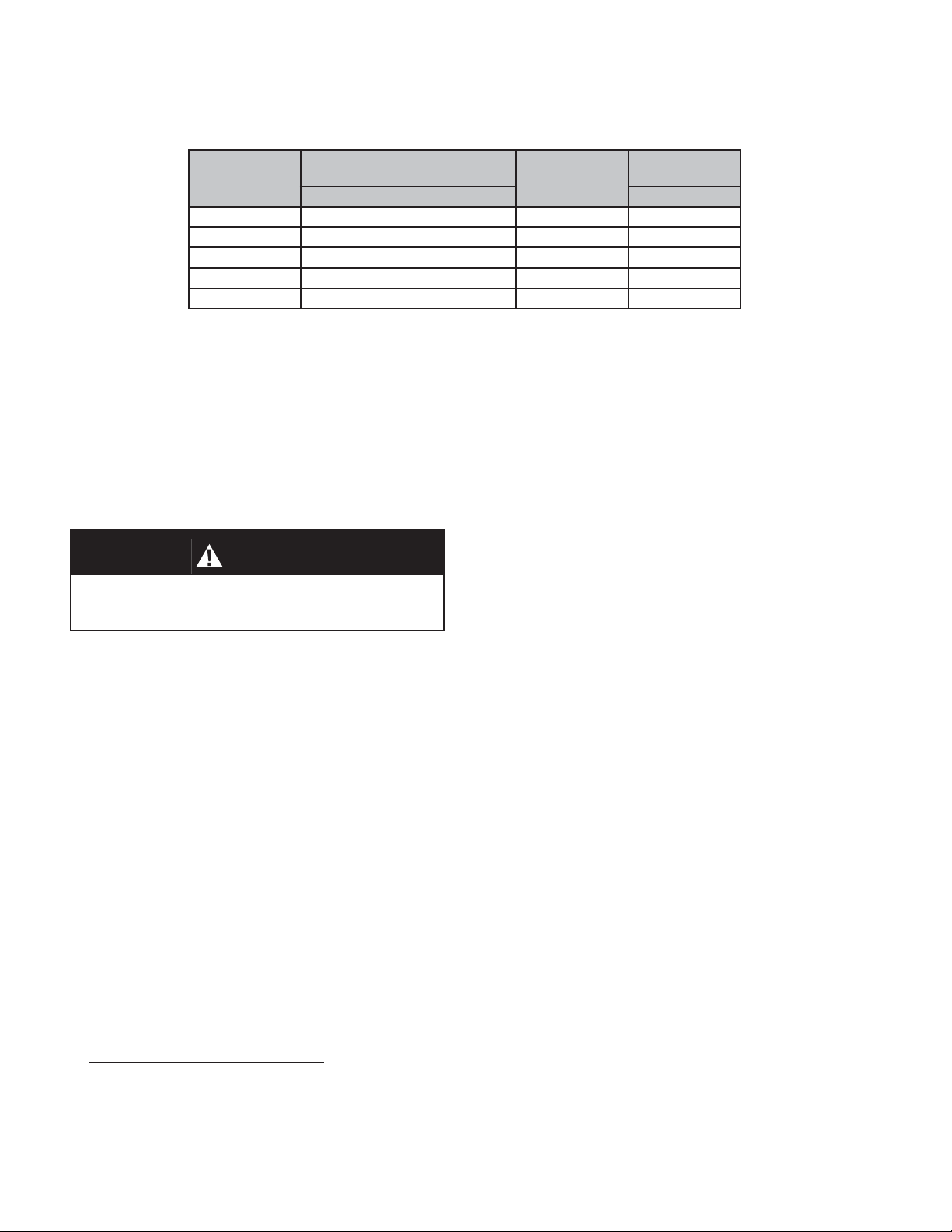

TABLE 1

All Torque Requirements Are Dependant On Gasket Materal

Bolt Torque Specifi cations - ASME #150 Flange Connections

MOUNTING

FLANGE

4” 78 8 5/8” - 11

6” 150 8 3/4” - 10

8” 228 8 3/4” - 10

10” 246 12 7/8” - 9

12” 348 12 7/8” - 9

BOLT TORQUE - ft. * lbs.

FLAT FACE THREAD UNC

NUMBER

BOLTS TOTAL

STUD SPECI-

FICATIONS

All nuts must be torqued in proper sequence and equal increments. Proceed through the tightening sequence until

the recommended torque is attained.

Recheck the torque on each bolt in the same sequence as bolts previously tightened may have relaxed through the

torque sequence.

SECTION IV

IV. MAINTENANCE - Replace Diaphragm

Maintenance procedures hereinafter are based upon removal of the gauge hatch from the tank fl ange.

CAUTION

DO NOT attempt to remove a locked gauge hatch from

a tank or process vessel without fi rst bleeding all pres-

sure from the system.

Hatch with Locking Feature:

Knob Latch: Rotate knob (19) CCW slowly

several revolutions to allow eye bolt (12) and washer

(17) to slide out and dis-engage from the hinge arm

assembly (2).

All Hatches:

Remove cotter pin and washer (35) from arm

pin (9). Slide arm pin (9) out of fl ange base (1).

Lift arm (2) and pallet (30) sub-assembly up to

remove and place on work surface.

Gauge Hatch without Weights: Flip arm/pallet

(2,3) sub-assembly over and secure center bolt (20)

in a vice. Remove the “S” hook (33) from center bolt

(20). Rotate pallet nut (24) CCW and remove nut,

lock washer (23), fl at washer (22) and diaphragm

retainer (5).

Remove diaphragm retainer plate (5) and diaphragm

(4).

Clean and inspect pallet (3) seating surface.

Apply TFE paste around the hole in the pallet (3).

Install new diaphragm (4) in recess of the pallet (3).

Re-install diaphragm retainer plate (5), fl at washer

(22), lock washer (23) and nut (24). Torque nut to

20 ft-lbs.

Re-insert “S” hook (33) into the hole in the center bolt

(20). Use pliers to close the end of the “S” hook and

secure it so it can not be easily removed from the

center bolt (20).

Flip arm/pallet (2,3) sub-assembly over and re-install

the whole pallet (3) /hinge arm assembly (2) on to the

fl ange base assembly (1). Align the pin holes and

insert the pivot pin (9), washer (35) and cotter pin

(15). Turn back the ends of the cotter pin to secure.

Raise and lower arm/pallet (2,3) assembly to confi rm

that diaphragm (4) rest evenly on the seating surface

of the fl ange base (1).

Gauge Hatch with Weights: Flip arm/pallet

(2,3) sub-assembly over and secure center bolt nut

(25) in a vice. Remove the “S” hook (33) from center

bolt (20). Rotate nut (24) CCW to remove nut (24),

lock washer (23) and fl at washer (22).

2

If hatch includes a locking feature, engage eye bolt

(12) and washer (17) over groove in the hinge arm (2)

and secure in place.

Return to Section III for Installation.

IOM-2100

Page 3

SECTION V

V. ORDERING INFORMATION

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was stamped

on the metal name plate and attached to the unit. This information can also be found on the Bill of Material

(“BOM”), a parts list that was provided when unit was originally shipped. (Serial Number typically 6 digits).

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number, Product code and the

pressure setting. With this information they can provide a quotation for a new unit including a complete

description, price and availability.

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory.

All purposed changes will require a new name plate with

appropriate ratings and new product code to accommodate the recommended part(s) changes.

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product

code. Identify the parts and the quantity required

to repair the unit from the “BOM” sheet that

was provided when unit was originally shipped.

NOTE: Those part numbers that have a quantity indi-

cated under "Spare Parts" in column "A” refl ect

minimum parts required for inspection and

rebuild, - "Soft Goods Kit". Those in column “B”

include minimum trim replacement parts needed

plus those "Soft Goods" parts from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for

part identifi cation and selection.

A Local Sales Representative will provide

quotation for appropriate Kit Number, Price

and Availability.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to

modify or improve the designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Cashco, Inc. product remains solely with the purchaser.

IOM-2100

3

Page 4

MODEL 2100

Knob Latch

Center Bolt

No Weights

No Latch

Center Bolt with Weights

PART LIST

ITEM NO. Description ITEM NO. Description ITEM NO. Description

1 Flange 10 Arm Stop 25 Weight Nut

2 Hinge Arm 11 Stop Nut 26 Weight Retainer

3 Pallet 12 Eye Bolt 27 Weight

4

Diaphragm

‡

17 Washer

33 S-Hook

5 Diaphragm Retainer 19 Knob 34 Swivel GrD Washer

6 Pallet Swivel 20 Center Bolt 35 Pivot Grd Washer

7 Latch Stop Pin 22 Flat Washer 36 Name Plate

8 Latch Pivot Pin 23 Lock Washer

9 Arm Pivot Pin 24 Pallet Nut

‡ Recommended replacement parts.

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax. # (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in U.S.A. 2100-IOM

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

email: brazil@cashco.com

Loading...

Loading...