Page 1

INSTALLATION, OPERATION AND MAINTENANCE MANUAL (IOM)

Vacu-Gard Pilot Operated Blanketing Valve

I. DESCRIPTION AND SCOPE

IOM-1078

09-10

Model 1078

SECTION I

The Model 1078 Vacu-Gard is a pilot operated

blanketing valve intended for installation on top of

medium to large storage tanks. The standard valve

comes with either FNPT or Weldneck connections.

SECTION II

II. PRIOR TO INSTALLATION

Clean out blanket gas supply lines prior to valve

installation to get rid of dirt, sand, loose scales and

other foreign particles trapped in the piping. This is

particularly true for new tanks and/or new piping. One

way to accomplish this is to blow out the lines from the

supply side up to the connection to the Vacu-Gard inlet.

SECTION III

III. INSTALLATION

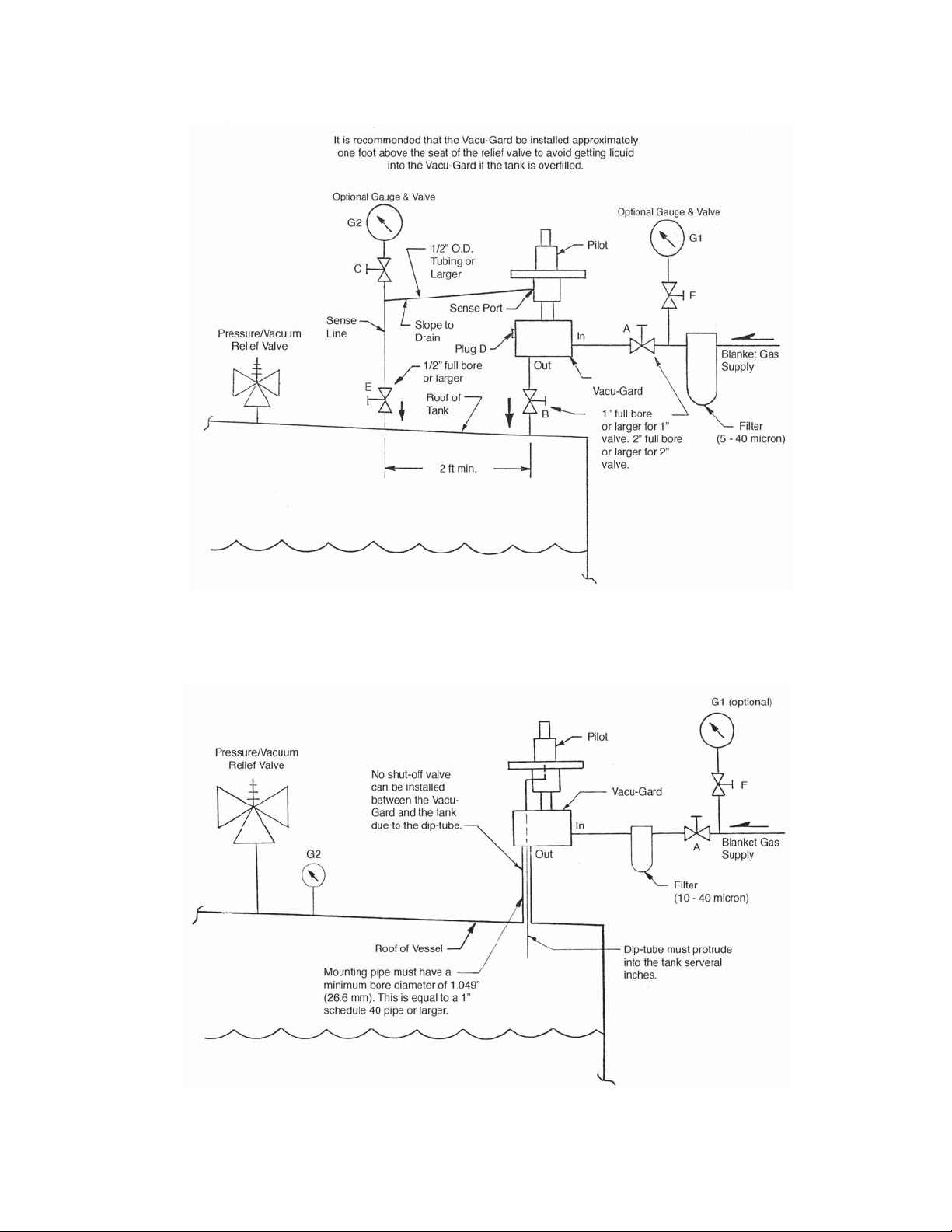

It is always good practice to install a main line fi lter

upstream of any tank blanketing valve. The element

should be approximately 5-40 microns with a fl ow ca-

pacity at least equal to or greater than that of the VacuGard.

The valve should be installed in the normal upright

position. The inlet is horizontal and the outlet is vertical downward. There is an optional horizontal outlet

available only for the remote sensing design. All outlet

piping from the valve body to the vessel must be at

least as large or larger than the outlet port in the body.

Keep piping as short as possible for best valve performance.

All standard 1” size valve bodies are cast 316 stainless

steel (CF3M). Standard 2” size valve bodies are

available in cast carbon steel (WCB) or stainless steel

(CF3M). All sizes have 316 SST Trim.

CAUTION

Follow your company’s safety procedures to avoid

injury to personnel or damage to equipment.

For Remote Sensing:

The sense line should be a 1/2” O.D. tube (or larger)

and the length should not exceed fi fteen feet. Longer

lengths may be used with larger diameter sense lines.

The sense line should slope downward from the pilot to

the tank to allow condensate, if any, to drain back into

the tank. (The sense port is the port on the side of the

pilot body marked with an “S”. A “tee” may be added to

the sense port for gauging pressure in the vessel.)

For Dip-Tube Sensing:

The integral dip-tube line must protrude into the tank at

least 6” below the roof.

NOTE: The port at the end of the main valve body opposite the inlet is not a sense port. This port is an optional horizontal outlet for remote sensing valve. This

port should not be used for pressure gauging since the

pressure at this point may be higher than the maximum

tank pressure and may cause damage to the gauge.

Page 2

NOTE: The sense chamber is not a dead-ended cham-

ber. In addition to the main fl ow and pilot fl ow when the

valve is open, there is also a very small fl ow from the

pilot valve into the vessel through the sense connec-

tion. Therefore the sense tube must be large enough

so that the fl ow will not be restricted. Premature closing

of the valve may occur if excess pressure builds up in

the sense chamber due to a sense line that is too small.

CAUTION

A pressure/vacuum relieving device large enough to

vent excess pressure and to serve as an emergency

vacuum breaker must be installed to protect the tank.

SECTION IV

IV. START-UP

Operation of the Model 1078 is automatic once the set

pressure has been established. (The set pressure is

usually bench-set at the factory prior to shipment.) The

set pressure may be approximated on the bench or set

after the valve has been installed. If the set pressure is

to be made after valve installation, the adjusting screw

should be backed off before applying inlet pressure to

the valve. NOTE: The set pressure is defi ned as the

pressure at which the valve should be fully closed on

increasing tank pressure.

Refer to applicable drawing dependent on sensing

style. Temporarily keep valve A closed. Use an

appropriate pressure indicating instrument for G2

to measure the pressure in the vessel. (For external

sensing open valves C and E, then valve B.) Now very

slowly open valve A while watching gauge G2. NEVER

SLAM OPEN VALVE A! The Vacu-Gard should close

when the tank pressure reaches the set pressure of the

pilot. To adjust the set pressure, remove the hex cap

at the top of the valve and loosen the jam nut around

the adjusting screw. Clockwise rotation of the adjusting

CAUTION

DO NOT overtighten threaded connections since damage or breakage may result. Wrap all NPT threads with

TFE tape. Apply anti-seize compound on bolt threads.

screw will increase the set pressure. Counter clockwise

will decrease the pressure provided there is a manual

valve to vent the excess pressure. Do not set the set

pressure beyond the nameplate range. Tighten the jam

nut after adjustments are made and replace the hex

cap.

CAUTION

DO NOT exceed the maximum inlet pressure on the

nameplate, as the valve may not open in time. Likewise, the minimum nameplate pressure must be maintained, otherwise the valve may not open.

In the event that the adjusting screw is backed out

eliminating the spring compression, intentionally or

unintentionally, the valve will begin to open when the

tank pressure reaches about 1” w.c. vacuum.

VACUUM SET VALVES: For valves that are set to

open and close on vacuum - a clockwise rotation of

the adjusting screw will set the valve to open closer

towards atmospheric pressure (less vacuum).

SECTION V

V. SHUT-DOWN

To shutdown the Vacu-Gard, reverse start-up procedure and bleed off trapped pressure before disassembly.

2 IOM-1078

Page 3

Normal Installation - Remote Sensing

Model 1078 Pilot Operated Vacu-Gard

Installation - with Integral Dip-Tube Sensing

Model 1078 Pilot Operated Vacu-Gard

3IOM-1078

Page 4

SECTION VI

VI. MAINTENANCE

The Model 1078 should be periodically actuated and

all sliding surfaces and seals lubricated to ensure

smoothness of operation. The frequency required

depends on the severity of the service conditions. At

least once a year is recommended.

CAUTION

If the valve must be disassembled for any reason,

fi rst make sure all pressure to the blanketing valve is

blocked and any pressure trapped in the valve is vented safely out. Refer to your company procedure for

any special precautions when handling toxic or other

hazardous materials.

Refer to the appropriate drawings for disassembly.

Pilot Internals: NOTE: The working components and

o-rings within the pilot body may be inspected and

replaced without the need to take apart the diaphragm

case. To remove the body internals, simply remove the

tubings (115) and unscrew the pilot body (038) from

the pilot mount (037)(on 1” valve) or from the pilot

connector (047)(on 2” valve). NOTE: Be careful not

to drop internal components. The return spring (025)

could dislodge the spindle (020) as the body and pilot

mount separate.

CAUTION

If the piston (107) does not remain in the main body

cavity, it may slowly slide out from the housing. Make

sure the piston does not fall out of the housing while

retracting the housing from the main body.

mount (037) upwards to remove from the main body.

The piston (107) and other internal parts should come

out with the pilot mount. To access the o-rings (105,

106), pull the piston (107) out of the pilot mount and

remove the screw (111) and lock washer (112). The

fl ow plug (109) will come out with a straight pull.

2” SIZE VALVES: Remove the six cap screw (129)

and lock washers (130) holding the piston housing (124)

to the main body. Carefully lift the pilot housing (124)

upwards to remove from the main body. To access

the o-rings (105,106), pull the piston (107) out of the

piston housing or remove it from the main body cavity.

Remove cap screw (011) and lock washer (012). The

fl ow plug (109) will come out with a straight pull.

To access seat ring seal (132), remove cap screws

(011) and lock washers (012) from seat ring (131).

Remove the seat ring from the main body. If the seat

ring is diffi cult to remove, thread two cap screws into

the threaded holes and remove the seat ring by lifting

upwards on the cap screws.

To Disassemble the Diaphragm Case Assembly:

Relax the compression on spring (007) by fi rst

unscrewing the cap (001). Rotate the jam nut (003)

CCW two rotations and then back out the adjusting

screw (002). Remove nuts (015), lock washers (012),

fl at washers (041) and cap screws (011) from around

the diaphragm case (009). Lift up to remove upper case

assembly, ring gasket (014) and diaphragm assembly.

Remove cap screws (011) and lock washers (012) from

the upper and lower cases to replace gaskets (008).

At re-assembly torque cap screws 13-15 ft-lbs.

To Disassemble Pilot Diaphragm Assembly:

Secure head of center bolt (017) in soft jawed vise.

Rotate nut (015) CCW. Remove nut, fl at washers (033)

and lock washer (012). Lift up to remove upper support

plate (016), gasket (018) and diaphragm (013). Lift up

to remove lower support plate (016) and gasket (018).

To Disassemble the Main Valve Assembly:

1” SIZE VALVES: Remove the four cap screws

(011) and washers (012, 041) holding the mounting

plate (036) to the main body. Carefully lift the pilot

Replace all parts that show signs of damage or excessive

wear. Make sure the material for new parts is suitable

for the service, especially elastomeric components.

If an o-ring needs to be replaced, be sure to use the

correct size and material. Prior to reassembly, make

sure all parts are clean and free of contamination and

seating surface is free of scratches.

CAUTION

DO NOT overtighten threaded connections since damage or breakage may result. Wrap all NPT threads with

TFE tape. Apply anti-seize compound on bolt threads.

Very lightly lubricate all o-rings with a lubricant that is

compatible with the service, sealing surfaces of gaskets and diaphragms also.

Reassemble in reverse order - utilize specifi c

instructions as follows for:

DIAPHRAGM CASE ASSEMBLY: Ensure center

bolt (017) is installed with the threaded end up. Install

one bolt gasket (018) between the center bolt and the

lower support plate (016) as shown on the drawing. An

identical gasket is used between the upper surface of

the sense diaphragm (013) and the bottom side of the

upper support plate. This is to ensure a tight squeeze

4 IOM-1078

Page 5

on both sides of the sense diaphragm to effect a tight

seal. Position ring gasket (014) on the top side of the

sense diaphragm. Install washers (033), lockwasher

(012) and nut (015). Torque nut 13-15 ft-lbs. Washers

are used to center the lower end of the spring. It may

sometimes be necessary to “thread” the spring onto

the washer or onto spring button (006). NOTE: You will

fi nd that turning the end of the spring in one direction

against the spring button or washers will tend to close

the coils and make installation more diffi cult. However,

turning the spring in the opposite direction will tend to

open the coils for easier installation.

PILOT INTERNALS: Before installation, ensure

o-ring (035) is placed around the groove adjacent to

the threads on pilot mount (037)(on 1” valve) or on

pilot connector (047)(on 2” valve). Install o-ring (021)

around the outside groove of the spindle (020). Install

o-ring (022) in the internal groove at the lower end of

the spindle. NOTE: O-RINGS (021,022) MUST BE

ORDERED FROM THE FACTORY.

To install the internals, turn the pilot body upside down

and insert the spindle (020) into the body with the small

diameter tip fi rst. Insert the spacer (026) and press it

down to the bottom of the body cavity. Insert return

spring (025) into the spindle cavity. Insert guide pin

(024) into the spring. Place the mounting plate (036)

around the pilot mount (037)(1” valve only). Place the

center cavity of the pilot mount (037)(1” valve) or pilot

connector (047)(2” valve) over the spring. Slowly and

carefully push against the spring to engage the threads

on the pilot mount or connector. Tighten until snug.

MAIN VALVE: Lightly lubricate all o-rings as mentioned

above. Prior to installing the fl ow plug, place o-ring

(106) on the piston (107). Install o-ring (105) in the

recess at the upper end of the fl ow plug (109). Grasp

the fl ow plug and push it into the shallow cavity of the

piston. Making sure to use the lock washer (item 112

for the 1” valve, item 012 for the 2” valve), install the

screw(111)(1” valve) or the bolt (011)(2” valve). For 1”

size torque the screw to 8-10 ft-lbs. For 2” size torque

the bolt to 13-15 ft-lbs. NOTE: The size of the fl ow plug

is stamped on the fl at end. See TABLE 1.

For 1” valves. Install o-ring (135) in the groove

inside the pilot mount (037). Next install o-ring (103)

around the groove on the piston (107). Lightly grease

the O.D. of the piston and the I.D. of the pilot mount.

Be sure that o-ring (104) is placed under the fl ange of

the pilot mount. Insert the spring (102), followed by the

piston, into the pilot mount. Push the piston in against

the spring several times to ensure there is no undue

binding. Guide the pilot mount, with the piston inside,

straight into the main body cavity. Install the four fl at

washers (041), lock washers (012) and cap screws

(011). Before the fi nal tightening of the bolts, it is a

good idea to check the tightness of the pilot mount in

the pilot body. To do so, tighten the bolts enough to

hold the pilot mount against the main body to prevent

the mount from turning. Then grasp the O.D. of the

pilot case by hand and turn it clockwise to tighten. After

tightening the mount into the pilot body, loosen the

bolts and turn the mount to orient the pilot ports in the

proper direction. Tighten the cap screws to 13-15 ft-lbs.

and reinstall all tubing. Make sure all tubing is clean

and unobstructed.

For 2” valves. Install the seat o-ring (132) in the

groove in the main body cavity. Place seat ring (131)

over the o-ring and use the four lock washers (012) and

cap screws (011). Be sure the fl at side of the seat ring

is up. Torque cap screws to 13-15 ft-lbs.

Grease the O.D. of the piston (107) and I.D. of the

piston housing (124). Install o-ring (135) in the groove

in the piston housing. Next install o-ring (103) around

the groove in the piston (107). Before placing the piston

into the main body cavity, ensure the o-ring (135) seats

properly into the piston housing and the piston can

slide smoothly in the housing. To check this, insert

the spring (102), followed by the piston, into the piston

housing. Push the piston in against the spring several

times to ensure there is no undue binding. If there is

no binding, the piston can then be removed from the

housing and placed in the main body.

Place the piston on the seat ring in the main body

cavity. Then place the spring (102) into the cavity of

the piston (107). Be sure that o-ring (104) is placed

under the fl ange of the piston housing. Carefully guide

the piston housing straight into the main body cavity,

making sure the piston slides properly into the housing.

Align the ports, and use the six lock washers (130) and

cap screws (129) to secure the housing.

Before the fi nal tightening of the bolts, it is a good idea

to check the tightness of the pilot connector to the pilot

body, the pilot connector to the piston housing, and the

alignment of the pilot ports. To do so, grasp the O.D.

of the pilot case by hand and turn it clockwise to tighten

while holding the pilot connector (047) in place. If the

pilot ports need re-positioning, use a combination of

tightening the pilot connector onto the piston housing

and/or rotating the piston housing one bolt hole.

Tighten the cap screws to 15-18 ft-lbs. Reinstall all

tubing, ensure it is clean and unobstructed.

After the valve has been completely reassembled, it

should be checked for set point pressure and any signs

of leakage. If the valve will not shut off tight, check for

dirt or other foreign particles on the o-rings or seating

surfaces. Also check to make sure the body internals

have not been damaged.

5IOM-1078

Page 6

TABLE 1

Identifi cation Grooves for reduced fl ow plugs for verifi cation when the valve is fully assembled.

1” and 2” Vacu-Gards

Flow plugs are steel stamped with their size on the fl at tip as follows:

1” Valve 2” Valve

100 100

75 80

50 60

25 40

10 20

This number represents the percentage of maximum fl ow that is allowed through the valve. The number is marked

on the fl at tip of the plug and is not visible when the valve is assembled. Therefore all fl ow plugs (except the 100%

plug) are marked with circumferential grooves that are visible from the inlet port of a fully assembled valve. The

identifying grooves are as follows:

FLOW PLUG SIZE

No. of Grooves 1” Valves 2” Valves

None 100% (barely visible) 100% (not visible)

1 75% 80%

2 50% 60%

3 25% 40%

4 10% 20%

SECTION VII

VII. ORDERING INFORMATION:

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was

stamped on the metal name plate and attached to the unit. This information can also be found on the Bill of

Material (parts list) that was provided when unit was originally shipped.) (Serial Number typically 6 digits).

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number, Product code and the

pressure/vacuum settings. With this information they

can provide a quotation for a new unit including a

complete description, price and availability.

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory.

All purposed changes will require a new name plate with

appropriate ratings and new product code to accomodate the recommended part(s) changes.

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product

code. Identify the parts and the quantity

required to repair the unit from the Bill of Materials sheet that was provided when unit was

originally shipped.

NOTE: Those part numbers that have a quantity

indicated under "Spare Parts" in column "A”

refl ect minimum parts required for inspection

and rebuild, - "Soft Goods Kit". Those in column “B” include minimum trim replacement

parts needed plus those "Soft Goods" parts

from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for

part identifi cation and selection.

Local Sales Representative will provide quotation for appropriate Kit Number, Price and

Availability.

6 IOM-1078

Page 7

SECTION VIII

VIII. TROUBLE SHOOTING GUIDE

1. Vacu-Gard will not open.

Possible Cause Remedy

A. Incorrect sense line connection. A1.

B. Sense line is clogged. B1. Check sense line and sense port for blockage.

C. Improper inlet and/or outlet connection. C1. Check and be sure supply line is connected to inlet of Vacu-

D. Loss of supply pressure. D1. Check supply pressure and see that it is within the range

2. Vacu-Gard will not close.

Possible Cause Remedy

A. Sense line not installed. A1. Check that the sense line is properly connected.

Check sense line and be sure it is connected from the sense

port on the Vacu-Gard to the tank.

A2.

Check sense line and shut-off valve for size and confi guration

to prevent pressure drops and trapped condensate.

Gard and outlet of Vacu-Gard is connected to tank, making

sure it is not reversed.

stated on nameplate.

B. Vacu-Gard set pressure is higher than or too close to

the set pressure of the pressure relieving devices.

C. Blanket gas is escaping from opening in tank. C1. Be sure all openings such as pressure relieving devices,

D. Malfunction of pressure relieving devices. D1. Check operation of pressure relieving devices.

E. Blanket gas is escaping from faulty piping or con-

nections.

F. Foreign particles trapped in Vacu-Gard. F1. Check Vacu-Gard for dirt and debris. (See Maintenance

G. Pilot inlet port is clogged. G1. Check pilot inlet port, fi lter and tubing.

H. Vacu-Gard has loose connections. H1. Check and make sure all Vacu-Gard connections are

B1. Check settings of valves and adjust if needed. The pressure

relieving devices must be set higher than the Vacu-Gard

setting. The greater the spread the better.

gauge hatches, etc., are closed and working properly.

E1. Check all piping and connections for tightness.

Section for disassembly and reassembly.)

tight.

3. Vacu-Gard cycles rapidly.

Possible Cause Remedy

A. Shut-off valve at outlet is restricting fl ow. A1. Be sure shut-off valve at outlet is full bore or larger.

B. Vacu-Gard set pressure too close to the set pressure

of the pressure relieving devices.

C. Sense or fl ow line pipe is undersized. C1. Check all piping connected to Vacu-Gard for size and confi gu-

B1. Check settings of valves and adjust if needed. The pressure

relieving devices must be set higher than the Vacu-Gard.

ration to prevent pressure drops and trapped condensate.

4. Vacu-Gard closes but will not shut-off tight.

Possible Cause Remedy

A. Worn o-rings or seat surfaces. A1. Replace worn parts. (See Maintenance Section for disas-

sembly and reassembly.)

B. Foreign particles on o-rings or seat surfaces. B1. Clean and lubricate parts. (See Maintenance Section for

disassembly and reassembly.)

C. Loose connections on Vacu-Gard. C1. Check all connections for tightness.

7IOM-1078

Page 8

Pilot Assembly for 1” Model 1078

ITEM NO. QUANTITY PART NAME

001 1 Cap

002 1 Adjusting Screw

003 1 Jam Nut

004 1 Vent

005 1 Spring Bonnet

006 1 Spring Button

007 1 Set Pressure Spring

008 2 Gasket ‡

009 2 Diaphragm Case

011 24

012 25 Lockwasher

013 1 Sense Diaphragm ‡

014 1 Ring Gasket ‡

015 17 Nut

016 2 Support Plate

017 1 Center Bolt

018 2 Bolt Gasket

020 1 Spindle

021 1 O-Ring ‡

022 1 O-Ring ‡

024 1 Guide Pin

025 1 Return Spring

026 1 Spacer

033 2 Washer

035 1 O-Ring ‡

036 1 Mounting Plate

037 1 Pilot Mount

038 1 Pilot Body

041 32 Washer-fl at

‡ Typical Parts required for inspection and rebuild.

Cap Screw

8 IOM-1078

Page 9

Main Valve Assembly for 1” Model 1078

ITEM NO. QUANTITY PART NAME

011 4 Cap Screw

012 4 Lockwasher

041 4 Washer-Flat

101 1 Pilot Valve Assy.

102 1 Spring

103 1 O-Ring ‡

104 1 O-Ring ‡

105 1 O-Ring ‡

106 1 O-Ring ‡

107 1 Piston

108 1 Main Body

109 1 Flow Plug

110 1 Strainer

111 1 Screw

112 1 Lockwasher

113 1 Tube Fitting - Elbow

ITEM QUANTY DESCRIPTION

114 2 Tube Fitting

115 2 Tubing

116 1 Pipe Plug

117 1 Pipe Plug

118 1 Thermocouple Fitting

119 1 Nameplate

120 2 Drive Screw

135 1 O-Ring ‡

201 1 Nipple

202 1 Filter Assy.

‡ Typical Parts required for inspection and rebuild.

9IOM-1078

Page 10

Pilot Assembly for 2” Model 1078

ITEM NO. QUANTITY PART NAME

001 1 Cap

002 1 Adjusting Screw

003 1 Jam Nut

004 1 Vent

005 1 Spring Bonnet

006 1 Spring Button

007 1 Set Pressure Spring

008 2 Gasket ‡

009 2 Diaphragm Case

011 24 Cap Screw

012 25 Lockwasher

013 1 Sense Diaphragm ‡

014 1 Ring Gasket ‡

015 17 Nut

016 2 Support Plate

017 1 Center Bolt

018 2 Bolt Gasket ‡

020 1 Spindle

021 1 O-Ring ‡

022 1 O-Ring ‡

024 1 Guide Pin

025 1 Return Spring

026 1 Spacer

033 2 Washer

035 1 O-Ring ‡

038 1 Pilot Body

041 32 Washer-fl at

047 1 Pilot Connector

‡ Typical Parts required for inspection and rebuild.

10 IOM-1078

Page 11

Main Valve Assembly for 2” Model 1078

ITEM NO. QUANTITY PART NAME

011 5 Cap Screw

012 5 Lockwasher

101 1 Pilot Valve Assembly

102 1 Spring

103 1 O-Ring ‡

104 1 O-Ring ‡

105 1 O-Ring ‡

106 1 O-Ring ‡

107 1 Piston

108 1 Main Body

109 1 Flow Plug

110 1 Stainer

114 2 Tube Fitting

ITEM QUANTY DESCRIPTION

115 2 Tubing

116 1 Pipe Plug

117 1 Pipe Plug

118 1 Thermocouple Fitting

119 1 Nameplate

120 2 Drive Screw

124 1 Piston Housing

129 6 Cap Screw

130 6 Lockwasher

131 1 Seat Ring

132

135 1 O-Ring ‡

201 2 Nipple

202 1 Filter Assembly

308 1 Tube Fitting-Female Elbow

‡ Typical Parts required for inspection and rebuild.

1 Seat Ring Seal ‡

11IOM-1078

Page 12

Valve Concepts, Inc./ Cashco, Inc.

607 W. 15th Street

Ellsworth, KS 67439

PH (785) 472-4461

FAX (785) 472-3539

www.cashco.com

email: vcisales@cashco.com

Printed in U.S.A. Model 1078-IOM

Loading...

Loading...