cashco 1000HP, 1000HP-1PLUS6, 1000HP-1PLUS8 Installation, Operation & Maintenance Manual

INSTALLATION, OPERATION & MAINTENANCE MANUAL

ISO Registered Company

IOM-1000HP-

Differential

MODEL 1000HP - DIFFERENTIAL

PRESSURE REDUCING REGULATOR

SECTION I

I. DESCRIPTION AND SCOPE

The Model 1000HP-1+6 and 1000HP-1+8 are dif fer en tial pressure reducing regulators used to control dif fer en tial

pressure between downstream (outlet or P2) pressure and a loading (P

are 1/2" , 3/4", 1", 1-1/4", 1-1/2" and 2" (DN15, 20, 25, 32, 40 and 50). With proper trim uti li za tion and jet selection,

this unit is suitable for liquid, gaseous, or steam service. Refer to Technical Bulletin 1000HP-DIFF-TB for sizing,

application and selection rec om men da tions.

SECTION II

II. INSTALLATION

1. An inlet block valve should always be installed.

An outlet block valve is desirable.

) pressure to the spring chamber. Sizes

Load

01-17

2. A manual bypass valve is recommended for “hot

piping” systems to assist in piping warm-up at

startup.

3. An isolation valve on the loading line is not

rec om mend ed. The annular body ring of the

1000HP-1+8 may be piped to a safe drainage

point, but no valve should be installed in the drain

line.

4. Pipe unions must be installed to allow removal from

piping. Trim can only be changed by unit removal

from pipeline. If flanges are utilized, a lap joint

flange is required on the inlet end of the regulator

to help align bolt holes as the cylinder screws into

place. NOTE: Cashco does not rec om mend field

welding on the cylinder (inlet) end of the valve due

to the possibility of warpage.

CAUTION

DO NOT HYDROSTATIC TEST THROUGH AN

IN STALLED UNIT; ISOLATE FROM TEST. DO NOT

HY DRO STAT IC TEST THE LOADING PRESSURE

WITH OUT PRESSURE IN THE MAIN REGULATOR.

The name plate indicated outlet pressure rating, if

reached, may cause internal damage. Refer to Tech ni cal

Bulletin Model 1000HP-DIFF-TB, Table 3 for “emer gen cy

overpressure level” that will not do irreparable internals

damage. In addition, note on the name plate that the

Inlet and Outlet pressure and tem per a ture ratings are

at different levels.

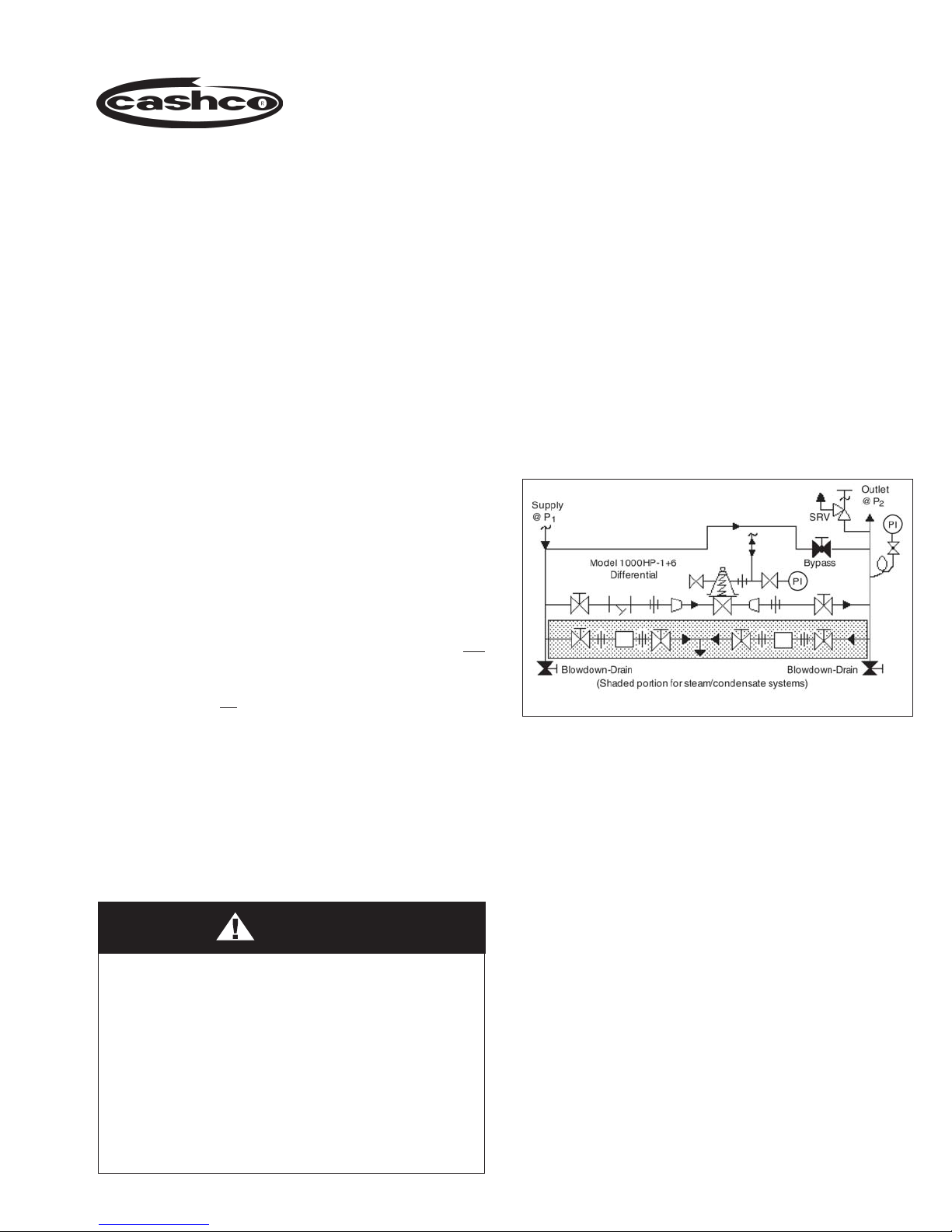

Recommended Piping Schematic for

Differential Pressure Reducing Station

5. An outlet pressure gauge should be located

ap prox i mate ly ten pipe diameters downstream,

and within sight. A loading pressure (or differential

pressure) gauge is rec om mend ed.

6. All installations should include a downstream

re lief device if the inlet pressure could exceed the

pressure rating of any downstream equipment or

the maximum outlet pressure rating of the unit.

7. Clean the piping of all foreign material including

chips, welding scale, oil, grease and dirt

before in stall ing the regulator. Strainers are

rec om mend ed.

8. In placing thread sealant on pipe ends prior to

en gage ment, ensure that excess material is

re moved and not allowed to enter the regulator

upon startup.

9. Flow Direction: Install so the flow direction match es

the arrow cast on the body.

10. For best performance, install in well drained

hor i zon tal pipe, properly trapped if a steam ser vice

ap pli ca tion.

diaphragm design): Regulator may be rotated

around the pipe axis 360° and may be installed

in a horizontal or vertical pipeline.

11. Differential Regulator – (Refer to Dwg. Opt-1+6

for single diaphragm or Dwg. Opt-1+8 for double

III. PRINCIPLE OF OPERATION

1. The differential Model 1000HP is also available

in two options: 1000HP-1+6 is single diaphragm

con struc tion; 1000HP-1+8 is double diaphragm

con struc tion. The dou ble diaphragm construction

prevents the loading fluid from direct mixing with

the system fluid in case of di a phragm failure.

2. Movement occurs as pressure variations register

on the diaphragm. One pressure is the outlet (p

or down stream pressure, which registers on the

“un der neath” side of the diaphragm. The second

pressure reg is tered is the loading (P

in the spring chamber “above” the di a phragm.

The range spring determines the differential

pres sure level (P

). As outlet (P2) pressure

Set

drops, the range spring pushes the diaphragm

down, open ing the port; as outlet (P

in creas es, the diaphragm pushes up and the port

closes. As the loading (P

) pressure varies, the

Load

outlet (P2) pressure tends to follow. An increase

in P

Load

(∆P

) will increase outlet P2 pressure

Load

by near ly an equal amount (∆P

decrease in P

outlet P

pres sure.

2

will have a similar effect on

Load

) pres sure

Load

) pressure

2

= ∆P2); a

Load

12. Regulators are not to be direct buried un der ground.

SECTION III

)

2

∆P

P2 > P

P2 = P

∆P

5. The Model 1000 includes an aspiration jet effect,

due to the clearance of the piston from the body

near the outlet. These clearances vary as to

whether the fluid is a gas (including steam), a liquid,

or a viscous liquid (required Opt-27). Jets must

be selected to match one of these three general

fluids. An improper jet will reduce per for mance.

NOTE: The regulator requires minimum output

pressure level or the regulator will not close.

= P1 - P

Sizing

Load

Load

Differential

2

+ P

Set

= P2 - P

Load

1000HP-1+6

DIFFERENTIAL SCHEMATIC

RANGE SPRING:

SETTING @ P

Set

LOADING

FLUID @ P

Diaphragm

Load

OUTLET

@ P

2

& T

2

3. The Model 1000 includes a rocker arm in its

operation mechanism. The rocker arm allows the

regulator to op er ate flow-to-open (FTO), rather

than conventional flow-to-close (FTC), which

in creas es rangeability.

4. Due to the FTO design, there is a limit as to how

low of a downstream (P

or outlet) pressure level

2

setting is capable for a given inlet P1 pressure.

This is a function of the ratio of the port area to the

diaphragm area. It is possible for there to be too

high of an inlet pressure for the regulator to close

off against. (Refer to 1000HP-DIFF-TB, Ta bles 9,

10, 11 and 12 for limits.) Reduced port, Opt-12,

allows lower down stream (P

2

settings for a given upstream (P1 or inlet) pressure

level.

2

or outlet) pres sure

6. For a 1000HP-1+6 (single diaphragm) design, a

com plete diaphragm failure will cause the fluids

to mix in the spring chamber or loading pressure

piping system.

7. For a 1000HP-1+8 (double diaphragm) design, a

complete diaphragm failure will cause the reg u la tor

to fail open, leaking fluid through the annular ring

vent hole.

NOTE: Composition (soft) diaphragms may be

utilized only on -1+6 single diaphragm con struc tion.

8. For viscous fluids normally heated (heavy fuel

oil), it may be desirable to include a flow-through

spring cham ber, the -65 Option.

IOM-1000HP-Dif fer en tial

IV. STARTUP

SECTION IV

1. Start with the block valves closed. A by pass valve

may be used to maintain outlet pressure in the

down stream system without changing the fol low ing

steps.

2. Remove closing cap and relax the range spring

by turning the adjusting screw counterclockwise

(CCW) a minimum of three (3) full revolutions.

This reduces the outlet (downstream) pressure

set point.

3. If it is a “hot” piping system, and equipped with

a bypass valve, slowly open the bypass valve

to pre-heat the system piping and to allow slow

expansion of the piping. Ensure proper steam

trap operation if installed. Closely monitor outlet

(down stream) pressure, via gauge, to en sure not

over-pressurizing. NOTE: If no bypass valve is

in stalled, extra caution should be used in starting

up a cold system; i.e. do everything slow ly.

CAUTION

Do not walk away and leave a bypassed reg u la tor

unattended!

4. Crack open the outlet (downstream) block valve.

5. Slowly open the inlet (upstream) block valve

ob serv ing the outlet (downstream) pressure gauge.

De ter mine if the regulator is flowing. If not, slowly

rotate the regulator adjusting screw clockwise

(CW) until flow be gins.

6. Continue to slowly open the inlet (upstream) block

valve until fully open.

7. Continue to slowly open the outlet (downstream)

block valve, especially when the downstream

piping sys tem isn’t pressurized. If the outlet

(down stream) pressure exceeds the desired

pressure, close the block valve and go to Step 2,

then return to Step 4.

8. When flow is established steady enough that the

outlet (downstream) block valve is fully open, begin

to slowly close the bypass valve if installed.

9. Set the regulator set point (P

ad just ing screw clockwise (CW) to increase outlet

pres sure or CCW to reduce outlet pressure. The

outlet (P2) pressure under these conditions will

approximate the desired dif fer en tial pressure when

loaded with P

10. Pressurize the source of loading (P

and allow to fill the spring chamber cavity. Slightly

open the bleeder valve to vent any air as the spring

chamber is filling.

11. Develop system flow and pressure and readjust

set point as required to obtain desired response.

Per for mance should be analyzed at minimum and

maximum flow levels.

12. Install closing cap.

Load

.

) by turning the

set

) pres sure

Load

V. SHUTDOWN

CAUTION

Loading Pressure must be shut off before shut ting

down the system pressure.

1. To prevent force imbalances and possible

di a phragm failure, the loading pressure (P

should always be shutdown first from its source of

pres sure. Systems se quenc ing must ensure this

oc curs.

3

SECTION V

)

Load

2. It is recommended that manual operation not be

attempted by a bypass valve during a shutdown.

3. When the loading pressure (P

shut down, the regulator outlet pressure (P2) should

decrease substantially. When this is observed, the

inlet (upstream) block valve may be closed.

IOM-1000HP-Dif fer en tial

) has been

Load

VI. MAINTENANCE

SECTION VI

(19) is not used with a composition (soft)

diaphragm.)

WARNING

SYSTEM UNDER PRESSURE. Prior to per form ing

any maintenance, isolate the regulator from the

system and relieve all pressure. Failure to do so

could result in personal injury.

A. General:

1. Maintenance procedures hereinafter are based

upon removal of the unit from the pipeline

where installed.

2. Owner should refer to owner’s procedures for

re mov al, handling and cleaning of reusable

parts, and dis pos al of non-reusable parts, i.e.

gaskets.

3. If desired, the gaskets may be lubricated with

a light oil provided it is com pat i ble with the

fluid.

B. Diaphragm Replacement:

1. Securely install the body (1) in a vice with the

spring chamber (2) directed upwards.

NOTE: The text hereafter will refer to:

a. The -1+8 double di a phragm op tion al

con struc tion (-1+6 single di a phragm

con struc tion is sim i lar. Text regarding

com po si tion diaphragm(s) (20)

applies only to -1+6 op tion). Text

portions deal ing with body spacer (42),

diaphragm spacer (41) and sep a ra tion

of total di a phragm (20) quantity into two

“stacks” applies only to -1+8 option.

b. The “pusher plate and stud” (13) as a

single part for 1/2" – 1-1/4" sizes and

as two separate parts, a “pusher plate”

(5) and a “pusher stud” (13) , for 1-1/2"

and 2" sizes.

7. Pry up the diaphragm(s) (20) and diaphragm

gas ket (19) around the perimeter of the body (1)

di a phragm flange to ensure the diaphragm(s)

(20) are not “stick ing”. (Di a phragm gasket

(19) is not used with a com po si tion (soft)

diaphragm.)

WARNING

SPRING UNDER COMPRESSION. Prior to

re mov ing flange bolts, relieve spring compression

by back ing out the adjusting screw. Failure to

do so may result in flying parts that could cause

personal injury.

2. Remove closing cap (31). Relax range spring

(27) by turning adjusting screw (6) CCW until

re moved from spring chamber (2).

3. Paint or embed a match mark between body

casting (1), spring chamber casting (2), and

body spacer (42) along flanged area.

4. Remove all diaphragm flange nuts (9) and

bolts (8). Remove nameplate (28).

5. Remove spring chamber (2), spring button (4)

and range spring (27).

6. Pry up the diaphragm(s) (20) and diaphragm

gasket (19) around the perimeter of the spring

chamber (2) flange to ensure the diaphragm(s)

(20) are not “sticking”. (Di a phragm gasket

8. Remove diaphragm subassembly by sliding

the push er plate and stud (13), body spacer

(42) and nut (11) in the direction of the reg u la tor

inlet, approximately 1/2"–3/4" (15-20 mm)

The pusher plate and stud (13), stud nut

(10), and stud collar (16) should dis en gage

with the rocker arm (14) slot. Lift ver ti cal ly for

di a phragm subassembly re mov al, carefully

hold ing the assembly at its outer edge to

prevent the body spacer (42) from falling from

be tween the diaphragm(s) (20).

4

IOM-1000HP-Dif fer en tial

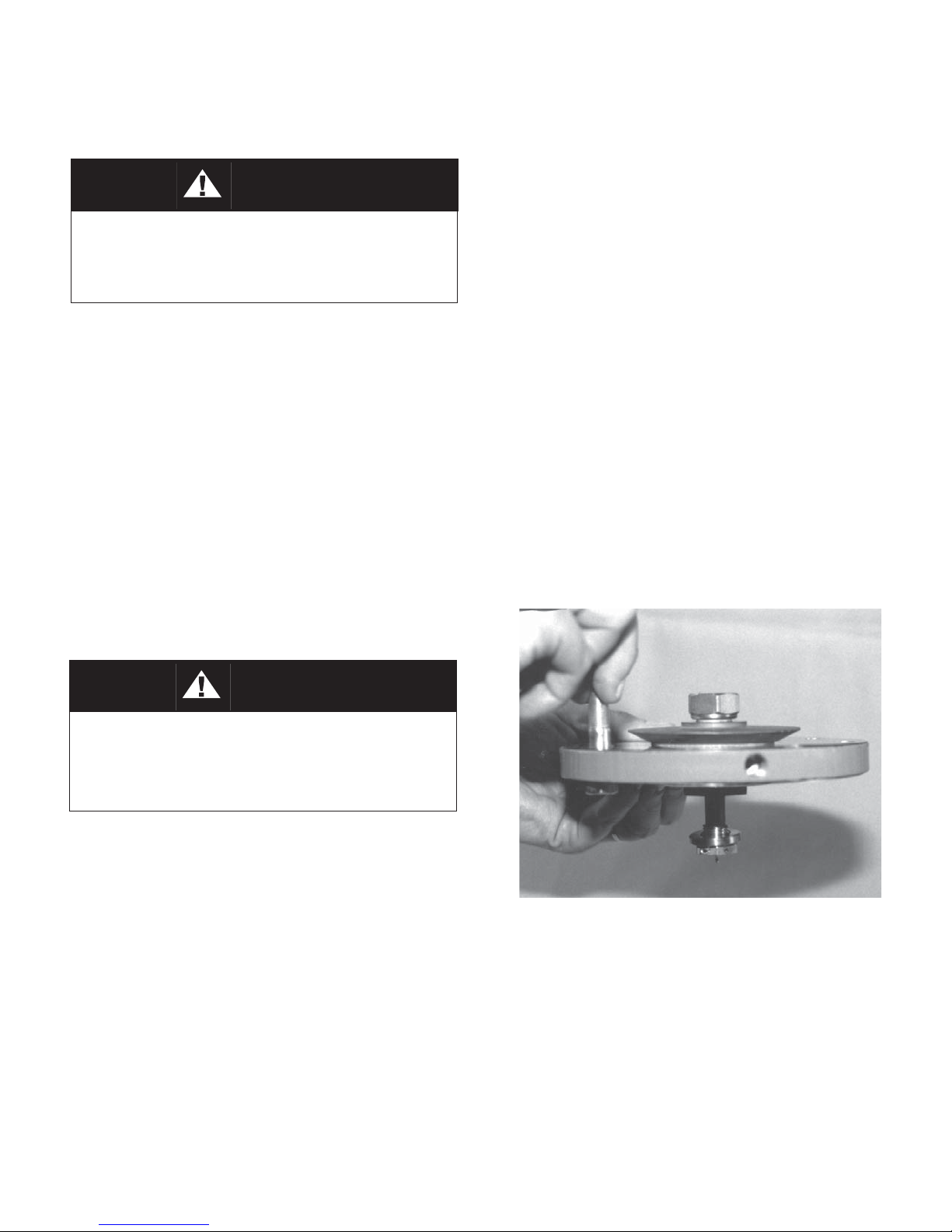

9. Place the pusher plate stud (13) in a separate

vise, gripping the stud (13) on the hexagonal

cast-in-place edges located on the un der neath

side of the pusher plate stud. NOTE: Do not

remove the stud nut (10), stud collar (16), and

the location locking cotter pin (15).

10. Loosen and remove nut (11).

plate (3) over the pusher plate and stud (13).

Place nut (11) onto the stud (13) and tighten.

Recommended torques are as follows:

Body Size Metal Diaphragm Comp. Diaphragm

3/8" – 1/2" 45–50 ft. lbs. 25–30 ft. lbs.

3/4" – 1" 45–50 ft. lbs. 30–45 ft. lbs.

1-1/4" – 2" 80–90 ft. lbs. 50–60 ft. lbs.

11. Lift and remove pressure plate (3) and O-ring

(50).

12. Remove upper diaphragm(s) (20), diaphragm

spacer (41) and body spacer (42).

13. Pry loose pusher plate and stud (13) from lower

diaphragm(s) (20) or from lower pusher plate

gasket (12). (Pusher plate gasket (12) is not

utilized with composition (soft) di a phragm.)

Remove the diaphragm(s) (20).

14. Remove pusher plate gasket (12) from push er

plate and stud (13).

15. Clean gasket sealing surfaces of pusher plate

and stud (13), spring chamber (2), body (1),

and pres sure plate (3) thoroughly.

16. Install new pusher plate gasket (12) over

pusher plate and stud (13).

17. Install one-half of total quantity of new

diaphragm(s) (20) over pusher plate and stud

(13). NOTE: Refer to quantity of diaphragms

(20) incorporated in the bill of materials

listing. Depending on outlet pressure level,

var i ous quantities of metal diaphragms will be

“stacked”. They should always be in multiples

of two for -1+8 option.

Use two flange bolts (8) to keep mul ti ple

di a phragms’ (20) bolt holes prop er ly aligned

while tight en ing the nut (11).

CAUTION

Do not use your fingers to hold diaphragms (20)

during tightening of nut (11)!

23. Remove cotter pin (15) securing stud nut (10)

to lower end of pusher plate and stud (13),

and replace with a new pin (15). (Do not allow

the stud nut (10) to move when the cotter pin

(15) is removed.)

24. Remove rocker arm shaft (17) and rock er

arm (14). Measure inside of rocker arm (14)

“prongs” as in di cat ed in the following di a gram.

If either of the below di men sions are exceeded

by 1/8" (3mm), re place rocker arm (14).

18. Place diaphragm spacer (41) over pusher

plate and stud. Place body spacer (42) over

outer perimeter of diaphragm(s) (20).

19. Install remaining quan ti ty of diaphragm(s) (20)

over pusher plate and stud (13).

20. Place O-ring (50) over push er plate and stud

(13).

21. Inspect pressure plate (3) to ensure no

de for ma tion due to over-pressurization.

If de formed, bent, or otherwise distorted,

replace.

22. Ensuring that the curved outer rim side of the

pressure plate (3) is down, place the pressure

5

Valve Size

DIM MAT'L 1/2" (DN15) 3/4" (DN20) 1" (DN25)

A BRZ 7/8" 22 mm 1-5/32" 29 mm 1-7/16" 37 mm

B BRZ 5/8" 16 mm 25/32" 20 mm 3/4" 20 mm

A SST 13/16" 21 mm 1-1/16" 27 mm 1-7/16" 37 mm

B SST 9/16" 14 mm 23/32" 18 mm 3/4" 20 mm

DIM MAT'L 1-1/4" (DN32) 1-1/2" (DN40) 2" (DN 50)

A BRZ 1-13/16" 46 mm 1-25/32" 45 mm 2-3/16" 56 mm

B BRZ 29/32" 23 mm 7/8" 22 mm 29/32" 23 mm

A SST 1-1/2" 38 mm 1-25/32" 45 mm 2-5/32' 55 mm

B SST 11/16" 17 mm 7/8" 22 mm 29/32" 23 mm

IOM-1000HP-Dif fer en tial

25. Check rocker arm shaft (17) for wear and

straightness. Replace if damaged. Reinstall

in body (1) through rocker arm (14). Apply

thread sealant to the rocker arm shaft (17)

threads prior to tightening. Make sure that the

rocker arm shaft (17) enters the support slot

opposite the threaded opening, and does not

align crook ed and re strained from full thread

engagement of the rocker arm shaft (17).

Make sure that the rocker arm (14) prongs

that straddle the piston (24) hold the piston

collar (23) against the piston (24); do not allow

the rocker arm (14) prongs to push directly on

the piston (24).

26. Install a new di a phragm gas ket (19).

Com po si tion (soft) diaphragms require no

di a phragm gasket. NOTE: Use only gaskets

man u fac tured by Cashco, Inc., that are of the

same material as those originally supplied.

Sub sti tu tion may cause im prop er gas ket

com pres sion. It may also adversely change

the di a phragm setting, which will affect the

unit’s per for mance, i.e. Option 1000-45, nonas bes tos construction utilizes special gaskets.

30. Aligning the matchmarks, place spring

cham ber (2) over the above stacked parts.

Install all bolts (8), nuts (9) and nameplate (28)

by hand tightening. Tighten bolting (8 and 9)

in a cross pattern that allows spring chamber

(2) to be pulled down evenly. Recommended

torques are as follows.

Body Size Bolt Size Metal Diaph 1 Comp Diaph

1/2" 3/8"-24 25 ft-lb 25 ft-lb

3/4" 7/16"-20 30 ft-lb 30 ft-lb

1"–1-1/4" 1/2"-20 35 ft-lb 35 ft-lb

1-1/2" 9/16"-18 45 ft-lb 45 ft-lb

2" 5/8"-18 45 ft-lb 45 ft-lb

1

Minimum recommended torque regardless of gasket

ma te ri als. Some gasket materials may re quire higher

bolt torques to obtain adequate seal.

2

Gasket material may “set” with time; a recheck of

torques should be made if the unit has been stored

on the shelf for over 30 days.

NOTE: Never replace bolting (8 and 9) with just

any bolting. Bolt heads and nuts are marked

with spec i fi ca tion identification mark ings. Use

only proper grades as re place ments.

2

27. Using small gauge wire approximately 18"

(457 mm) long, form a hook and place the

hook over one prong of the rocker arm (14),

and rotate the rocker arm (14) up until slack

is removed in the mechanism. Secure the

wire through a body (1) flange bolt hole on

the outlet side of the regulator.

28. Firmly holding the outer perimeter, take the

di a phragm subassembly (Step 8) and lower

it down into the body (1) cavity off-center

ap prox i mate ly 3/4"–1" (20–25 mm) and

towards the inlet side of the regulator. When

fully low ered, slide the diaphragm subassembly

hor i zon tal ly towards the regulator outlet. The

wire of Step 27. should hold the rocker (14) up

to allow en gag ing of the pusher plate and stud

(13) (with stud nut (10) and stud collar (16)),

so the rocker arm (14) prongs rest directly

on the stud collar. NOTE: DO NOT ALLOW

THE ROCKER ARM (14) PRONGS TO GET

BE TWEEN THE STUD NUT (10) AND THE

STUD COL LAR (16). Pull firmly to remove

wire holding rocker arm (14) up.

29. Align diaphragm(s) (20) bolt holes with body (1)

flange bolt holes. Install new diaphragm gasket

(19) on top of diaphragm(s) (20). Vi su al ly

center range spring (27) on to pressure plate

(3), place spring button (4) on top of range

spring (27).

31. Reinstall adjusting screw (6) with sealing

lock nut (7); install new closing cap gasket

(32); install closing cap (31).

32. Pressurizing the body (1) and spring chamber

(2) to the same level, soap solution test around

bolting (8 and 9), body (1), spring chamber

(2) flanges, closing cap (31) and cylinder

(21) - to body (1) joint for leakage. Use 100

psig min i mum inlet pressure to leak test.

Actual service con di tions should be used if

in excess of the minimum condition. (NOTE:

Do not pres sur ize spring chamber without

equal or greater pressure in body registering

on diaphragm(s) (20) underneath side.)

C. Diaphragm Setting Adjustment:

1. In the previous “Sub-Section B., Diaphragm

Re place ment”, care was taken to prevent

removal of the stud collar (16) and stud nut

(10). Location of the stud nut (10) is a critical

adjustment for a Model 1000 regulator.

2. Not removing the stud nut (10) will provide

per for mance equal to original factory

per for mance when diaphragm(s) (20)

is replaced with like diaphragm(s) (20);

however, if the stud nut (10) is removed, or

a switch is made from metal to composition

(soft) diaphragm(s) (20), or vice versa, the

diaphragm setting should be checked.

6

IOM-1000HP-Dif fer en tial

Loading...

Loading...