CAS DH Owner's Manual

2

3

Technical Parameter

CONTENTS

............................................

4

Installation and Connection

1. Indicator Diagram

2. Loadcell Connection

...............................................

...........................................

.............................

3. Serial Communication interface and Scoreboard

Operation Instruction

1. Serial communication

2. Key Operation

......................................................

3. Weighing Operation

Calibration Description

User Function Setting

Error Indication

Maintenance and attention

...................................................

.........................................

.......................................

............................................

...................................

........................................

............................

* Dear users :

Please read the manual carefully before using this indicator.

....

5

5

6

7

9

9

9

9

11

14

17

17

4

1. Analog part

Class of Accuracy

Class III, n=3000

Input signal range

-19mV ~ 19mV

Conversion speed

10 times/sec

Gain drift

0.03%

Excitation voltage

DC 5V

Loadcell connection

Max. 4ea 350 Ω Loadcell

2. Display part

Display range

-99999 ~ 999999

(decimal point is not considered)

Scale division

1/2/5/10/20/50 optional

3. Serial communication interface

Signal

RS232 signal

Transmission distance

< 20m

4. Score board display interface

Adopts serial output method,

current loop signal, transmission distance

≤ 1000 M

5. Operation environment

Power supply

AC220V; 50, 60Hz (-2% ~ +2%)

Battery life time

Approx. 30 hours

Battery charging time

Approx. 15 hours

Operating temperature

0 ℃ ~ 40 ℃

Storage and transport temperature

- 25 ℃ ~ 55 ℃

Relative humidity

≤ 85%RH

Fuse

500mA

Weight

Approx. 2 kg

Technical Parameter

5

Installation and Connection

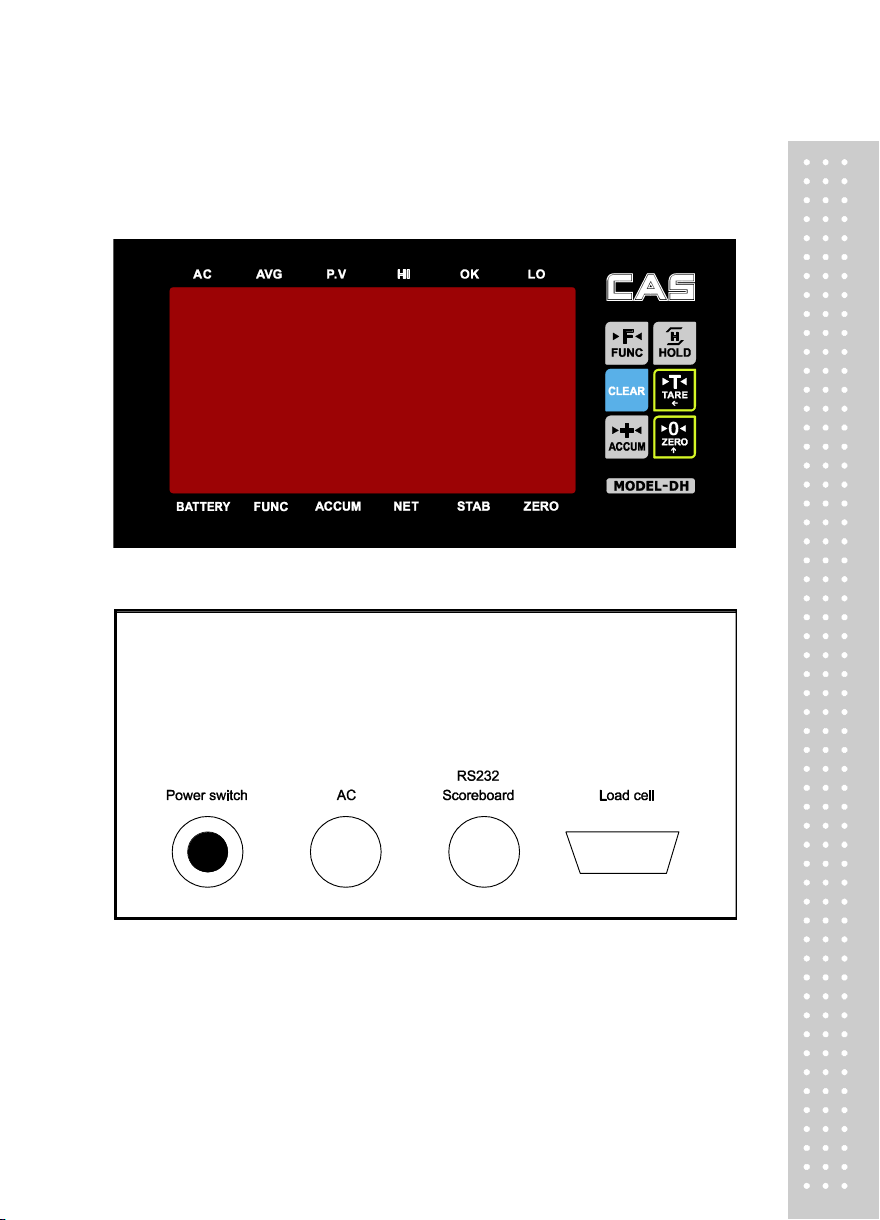

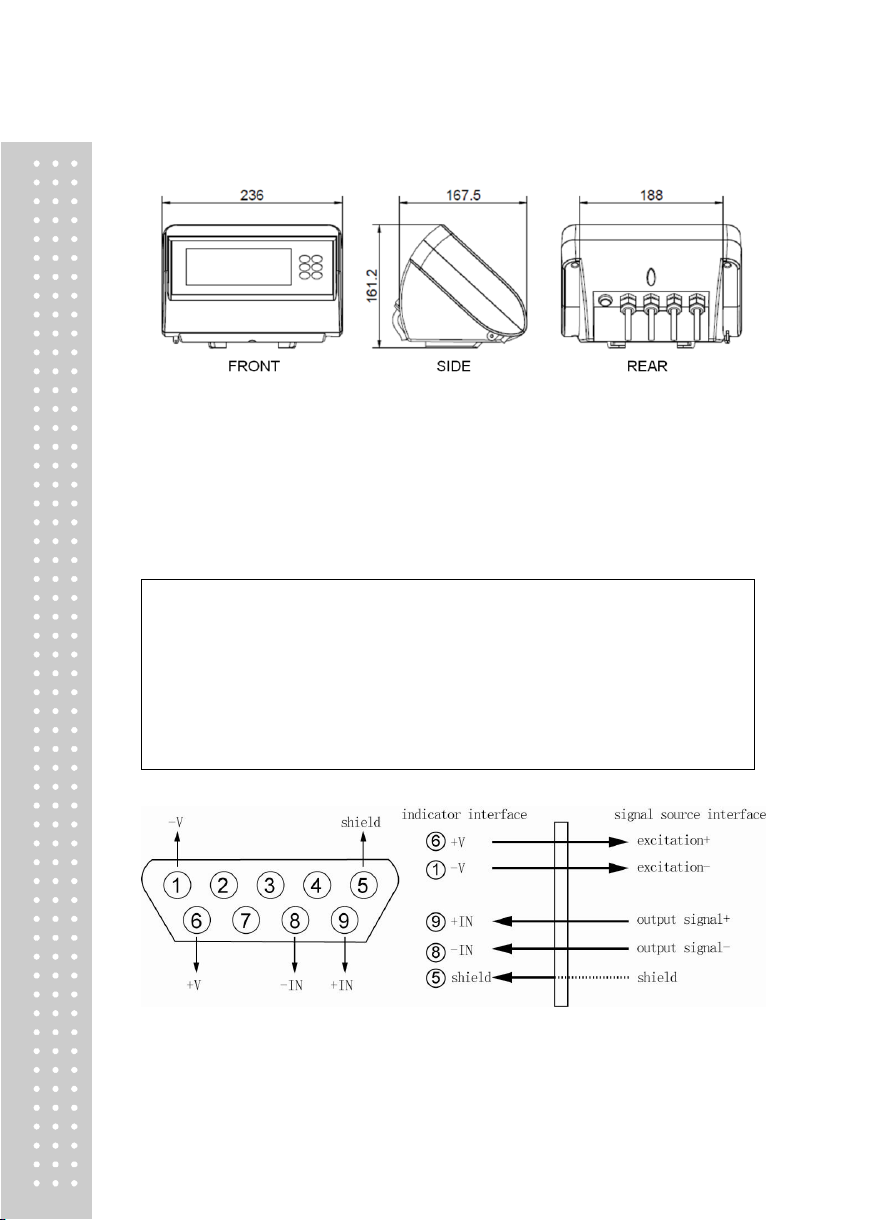

1. Indicator Diagram

Front cover

Back cover

6

▲!The connections of Loadcell and indicator must be reliable, and the shielded cable of

Loadcell must be reliably grounded. Connections wires shall not be plugged and pulled when the

indicator is in a Power-up State in order to prevent static electricity damaging to the indicator or

Load cell.

▲!Since both Load cell and indicator are static-sensitive device, anti-static measures must be

practically taken in the use, and welding or other strong-electric operations on weighing platform are

strictly prohibited. In the thunderstorm season, reliable lightning protection measures must be taken to

prevent lightning damaging the senor and instrument and to ensure the operator safety and the safe

operation of weighing equipment and related equipment.

Dimensions

2. Load cell Connection

■ The Load cell is connected through 9-pin plug socket (hole). Figure 2-3 shows the meaning

of each pin.

■ Please use 4-core shielded cable.

7

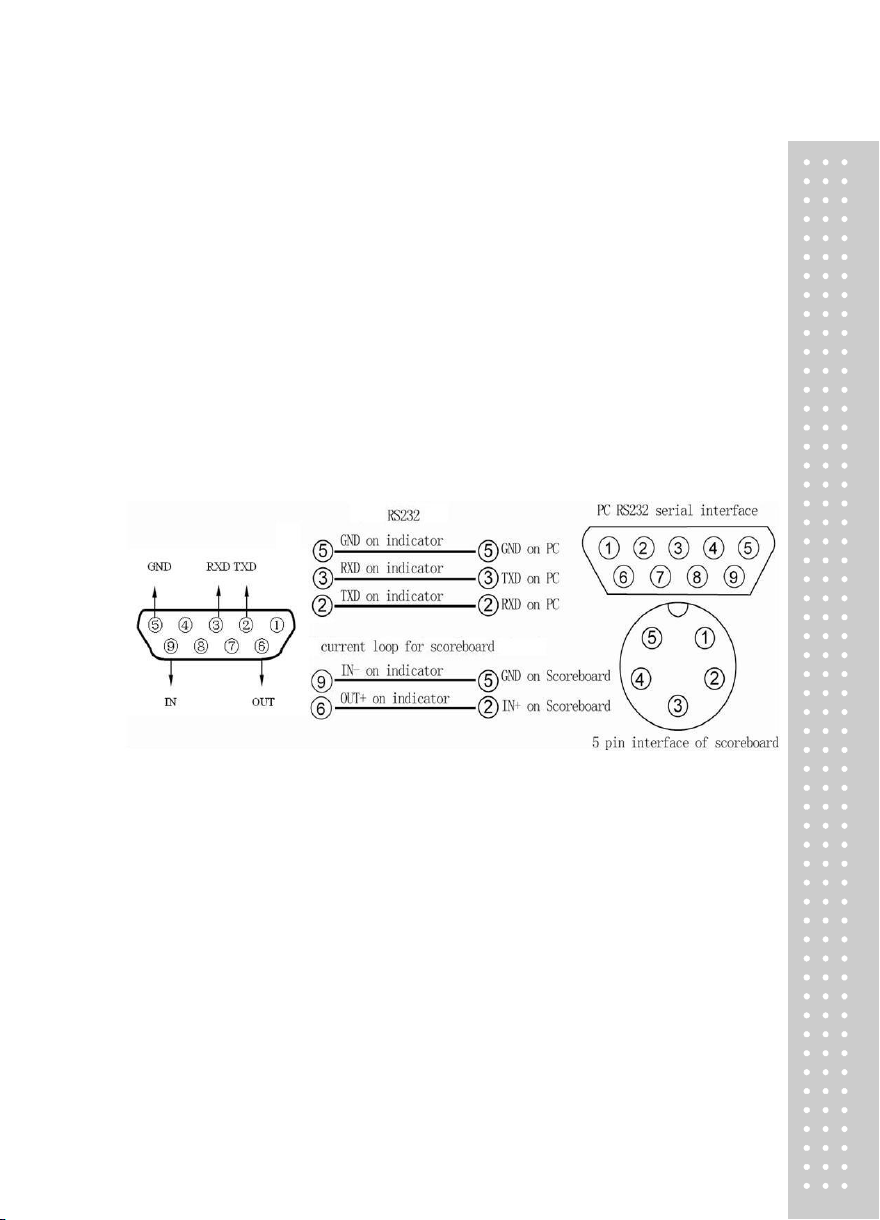

3. Serial Communication interface and Scoreboard

(Note : this function is optional)

Serial communication interface

Communication interface uses 5-pin socket (pin) and all the data is ASCII code, and there are 10 bits

in every data group, and the 1st bit is start bit and the 10th bit is stop bit, and there are 8 bits in the

middle and there is no parity bit.

1. Connection mode

CAS DH communication interface uses 9-pin socket (pin). Lead pin is defined as follows: pin 2 is for

TXD (serial communication data line) and pin 5 is for ground wire; shielded cable is recommended to

be used as connection line. See below Figure details.

Communication for scoreboard and RS232

2. Interface parameter

① Signal : RS232C

② Baud rate : 1200/2400/4800/9600

3. Communication method

Method 1 P5=2 continuous transmission

Transmitted data is weight. (gross weight, net weight or tare weight, decided by parameter P4).

Gross weight format is : ww000.000kg or ww000.000lb

Net weight format is : wn000.000kg or wn000.000lb

Tare weight format is : wt000.000kg or wt000.000lb

Note : Above decimal point position is determined by decimal point position setting of the indicator.

Loading...

Loading...