Page 1

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

SAFETY INSTRUCTIONS (EUROPEAN)

The conductors in the AC power cord are colored in accordance with the following code.

GREEN & YELLOW—Earth BLUE—Neutral BROWN—Live

U.K. MAIN PLUG WARNING: Amolded main plug that has been cut off from the cord is

unsafe. NEVER UNDER ANY CIRCUMSTANCES SHOULD YOU INSERT A DAMAGED OR CUT MAIN PLUG INTO APOWER SOCKET.

IMPORTANT! FOR YOUR PROTECTION, PLEASE READ THE FOLLOWING:

WATER AND MOISTURE: Appliance should not be used near water (near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a swimming pool, etc). Care should be taken

so that objects do not fall and liquids are not spilled into the enclosure through openings.

POWER SOURCES: The appliance should be connected to a power supply only of the type

described in the operating instructions or as marked on the appliance.

GROUNDING OR POLARIZATION: Precautions should be taken so that the grounding or polarization means of an appliance is not defeated.

POWER CORD PROTECTION: Power supply cords should be routed so that they are not likely to

be walked on or pinched by items placed upon or against them, paying particular attention to

cords at plugs, convenience receptacles, and the point where they exit from the appliance.

SERVICING: The user should not attempt to service the appliance beyond that described in the

operating instructions. All other servicing should be referred to qualified service personnel.

FUSING: If your unit is equipped with a fuse receptacle, replace only with the same type fuse.

Refer to replacement text on the unit for correct fuse type.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL! THIS UNIT CONTAINS HIGH

VOLTAGE INSIDE!

CAUTION

RISK OF ELECTRIC SHOCK

D6 03-50135 1 EACH STANDOFF LED .500 X .135 T1

D7 03-50135 1 EACH STANDOFF LED .500 X .135 T1

S1 06-40040 4 EACH TERMINAL VERT FEML PC MTG .250

QC5 06-40050 1 EACH TERMINAL VERT MALE PC MTG .250

QC1 06-40060 2 EACH TERMINAL 90dg MALE PC MTG .250

QC2 06-40060 2 EACH TERMINAL 90dg MALE PC MTG .250

J11 21-40000 6 EACH XLR FEML CON NEUTRIK #NC3FAV-0

J21 21-40000 6 EACH XLR FEML CON NEUTRIK #NC3FAV-0

J31 21-40000 6 EACH XLR FEML CON NEUTRIK #NC3FAV-0

J41 21-40000 6 EACH XLR FEML CON NEUTRIK #NC3FAV-0

J51 21-40000 6 EACH XLR FEML CON NEUTRIK #NC3FAV-0

J61 21-40000 6 EACH XLR FEML CON NEUTRIK #NC3FAV-0

J5 21-40022 1 EACH JACK RCA QUAD PC VERTICAL MTG

J1 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J2 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J3 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J4 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J6 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J12 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J22 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J32 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J42 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J52 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

J62 21-50345 “11 EACH JACK .250”” PHONE MONO PCB MTG”

F1 23-03529 2 EACH FUSEHOLDER CLIPS 3AG VERT MTG

“H2, H4, H5, H6, H7, H8”

23-11004 6 EACH CONNECT HEADER 4 PIN STRAIGHT

“H1, H10, H11, H12”

23-11008 4 EACH CONNECT HEADER 8 PIN STRAIGHT

“H13, H14” 23-11010

2 EACH CONNECT HEADER 10 PIN STRAIGHT

H9 23-15605 “1 EACH CONNECT HEADER .156”” 5 PIN”

H3 23-40008 1 EACH CONNECT HEADER .400 IN 8 PIN

H3 middle pins 23-92995

2 EACH SHUNT JUMPER UNPLATED

“S4, S11, S21, S31, S41, S51, S61”

25-02201- 1 * STD 7 EACH ASSEMBLED

SWITCH AND CAP

AA 30-62004 1 EACH PCB CARD SYS MSTR PA620/410

“C58, C98” 42-47251“1 * STD 2 EACH CAP ELEC 4,700 MFD 50V 20%”

C150 or C250 46-22461

1 EACH CAP MYLR .2200UF 63VOLT 10%

“C14, C15, C61, C70, C84, C85, C94”

47-10225 “7 EACH CAP ELEC 1,000 MFD 25V 20%”

“C49, C51, C53, C71, C111, C117, C123, C211, C223, C311, C323,

C411, C423, C511, C523, C611, C623”

49-10212 17 EACH 0.001UF SMT 10% FILM 0805 50V

“C27, C40, C43, C57, C95”

49-10312 5 EACH 0.01UF SMT 10% FILM 080550V

“C3, C4, C7, C10, C11, C12,”

49-10412 23 EACH 0.1UF SMT 5% CERAMIC 0805

“C13, C24, C35, C39, C60, C65,”

49-10412 23 EACH 0.1UF SMT 5% CERAMIC 0805

“C74, C75, C76, C77, C78, C79,”

49-10412 23 EACH 0.1UF SMT 5% CERAMIC 0805

“C80, C142, C151, C152, C155”

49-10412 23 EACH 0.1UF SMT 5% CERAMIC 0805

“C42, C44, C99” 49-10451

3 EACH 0.1 uF SMT 10% FILM 1206 50V

“C2, C5, C16, C19, C20, C21,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C22, C26, C29, C31, C34, C56,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C59, C62, C63, C64, C66, C67,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C68, C93, C103, C104, C105, C108,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C110, C114, C153, C154,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C203, C204, C205, C208, C210, C214,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C303, C304, C305, C308, C310, C314,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C403, C404, C405, C408, C410, C414,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C503, C504, C505, C508, C510, C514,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C603, C604, C605, C608, C610, C614,”

49-22035 58 EACH SMT CAP 22uF 35v ELECTROLITIC

“C72, C122, C124, C135”

49-22212 4 EACH 0.0022UF SMT 10% FILM 0805 50V

“C50, C112, C134, C212, C312, C412, C512, C612”

49-22312 8 EACH 0.022UF SMT 10% FILM 0805 50V

“C8, C9” 49-25152

2 EACH 220PF SMT 5% CERAMIC 0805

“C8, C9”

“C1, C36, C37, C106, C107,”

49-27052 16 EACH 27 PF SMT 5% CERAMIC 0805

“C206, C207, C209, C306, C307,”

49-27052 16 EACH 27 PF SMT 5% CERAMIC 0805

“C406, C407, C506, C507, C606, C607”

49-27052 16 EACH 27 PF SMT 5% CERAMIC 0805

C55 49-33152 1 EACH 330PF SMT 5% CERAMIC 0805

C47 49-33212 1 EACH 0.0033UF SMT 10% FILM 0805 50

“C38, C48” 49-33312

2 EACH 0.033UF SMT 10% FILM 0805 50V

“C17, C18, C23, C25, C28, C33,”

49-39052 24 EACH 39PF SMT 5% CERAMIC 0805

“C69, C82, C87, C90, C100, C109,”

49-39052 24 EACH 39PF SMT 5% CERAMIC 0805

“C113, C118, C119, C213, C309, C313,”

49-39052 24 EACH 39PF SMT 5% CERAMIC 0805

“C409, C413, C509, C513, C609, C613”

49-39052 24 EACH 39PF SMT 5% CERAMIC 0805

“C45, C52, C54” 49-47212

3 EACH 0.0047uF SMT FILM 0805 50V

“C32, C46, C73” 49-47312

2 EACH 0.047UF SMT 10% FILM 0805 50V

“C30, C41, C101, C102, C201, C202, C301,”

49-82052 14 EACH 82PF SMT 5% CERAMIC 0805

“C302, C401, C402, C501, C502, C601, C602”

49-82052 14 EACH 82PF SMT 5% CERAMIC 0805

“R222, R224” 58-92201

2 EACH 22 SMT 1W 2512 20%

“R59, R60, R89, R128”

55-03300 4 EACH RES .33 OHM 5W 5% SB VERT

R196 58-00035 1 EACH 0.0 SMT JUMPER 1206

“R85, R91, R165, R171, R172, R188, R189”

58-10015 7 EACH 10.5 SMT .25W 1206 1%

R40 58-10025 1 EACH 100.5 SMT .25W 1206 1%

“R48, R66, R78, R81, R86, R99,”

58-10035 15 EACH 1K SMT .25W 1206 1%

“R111, R131, R133, R136, R150, R158,”

58-10035 15 EACH 1K SMT .25W 1206 1%

“R187, R190, R191”

58-10035 15 EACH 1K SMT .25W 1206 1%

“R1, R4, R28, R29, R30,”

58-10045 39 EACH 10K SMT .25W 1206 1%

“R31, R35, R36, R37, R39,”

58-10045 39 EACH 10K SMT .25W 1206 1%

“R83, R116,” 58-10045

39 EACH 10K SMT .25W 1206 1%

“R120, R121, R123, R139,”

58-10045 39 EACH 10K SMT .25W 1206 1%

“R152, R153, R154, R156, R159, R160,”

58-10045 39 EACH 10K SMT .25W 1206 1%

“R167, R170, R175, R176, R193,”

58-10045 39 EACH 10K SMT .25W 1206 1%

“R198, R199, R216, R223, R316,”

58-10045 39 EACH 10K SMT .25W 1206 1%

“R323, R416, R423,”

58-10045 39 EACH 10K SMT .25W 1206 1%

“R516, R523, R616, R623”

58-10045 39 EACH 10K SMT .25W 1206 1%

“R52, R61, R71, R100, R134, R135, R138”

58-10055 7 EACH 100K SMT .25W 1206 1%

“R92, R94, R144” 58-10065

3 EACH 1M SMT .25W 1206 1%

“R112, R115, R212, R215, R312, R315,”

58-15035 12 EACH 1.5K SMT .25W 1206 1%

“R412, R415, R512, R515, R612, R615”

58-15035 12 EACH 1.5K SMT .25W 1206 1%

“R38, R105, R125, R205,”

58-15045 8 EACH 15K SMT .25W 1206 1%

“R305, R405, R505, R605”

58-15045 8 EACH 15K SMT .25W 1206 1%

“R2, R8, R41, R44,”

58-15055 8 EACH 150K SMT .25W 1206 1%

“R54, R65, R67, R79”

58-15055 8 EACH 150K SMT .25W 1206 1%

“R76, R130, R137”58-22025

3 EACH 220.5 SMT .25W 1206 1%

“R21, R27, R32, R47, R53, R55, R56,”

58-22035 36 EACH 2.2K SMT .25W 1206 1%

“R62, R64, R68, R72, R74, R95, R97,”

58-22035 36 EACH 2.2K SMT .25W 1206 1%

“R103, R104, R124, R142, R155, R157,”

58-22035 36 EACH 2.2K SMT .25W 1206 1%

“R169, R203, R204, R303, R304,”

58-22035 36 EACH 2.2K SMT .25W 1206 1%

“R403, R404, R503, R504, R603, R604,”

58-22035 36 EACH 2.2K SMT .25W 1206 1%

“R117, R217, R317, R417, R517, R617”

58-22035 36 EACH 2.2K SMT .25W 1206 1%

“R5, R10, R11, R12, R14,”

58-22045 41 EACH 22K SMT .25W 1206 1%

“R15, R16, R18, R19, R23,”

58-22045 41 EACH 22K SMT .25W 1206 1%

“R24, R25, R26, R33,”

58-22045 41 EACH 22K SMT .25W 1206 1%

“R108, R109, R113, R126, R127, R129,”

58-22045 41 EACH 22K SMT .25W 1206 1%

“R132, R137, R140, R141, R148, R149, R163,”

58-22045 41 EACH 22K SMT .25W 1206 1%

“R208, R209, R213, R308, R309, R313,”

58-22045 41 EACH 22K SMT .25W 1206 1%

“R408, R409, R413, R508, R509, R513,”

58-22045 41 EACH 22K SMT .25W 1206 1%

“R608, R609, R613”

58-22045 41 EACH 22K SMT .25W 1206 1%

“R20, R22, R63, R69, R73, R75”

58-22055 6 EACH 220K SMT .25W 1206 1%

“R50, R90” 58-27025

2 EACH 270.5 SMT .25W 1206 1%

“R77, R82, R161, R162, R177, R178, R233”

58-33025 7 EACH 330.5 SMT .25W 1206 1%

“R70, R106, R107, R168, R206,”

58-33035 14 EACH 3.3K SMT .25W 1206 1%

“R207, R306, R307, R406, R407,”

58-33035 14 EACH 3.3K SMT .25W 1206 1%

“R506, R507, R606, R607”

58-33035 14 EACH 3.3K SMT .25W 1206 1%

“R3, R9, R34, R145”

58-33045 * STD 4 EACH 33K SMT .25W 1206 1%

“R48, R58, R88, R200”

58-47015 4 EACH 47.5 SMT .25W 1206 1%

“R42, R43, R45, R80, R93, R98, R146”

58-47025 7 EACH 470.5 SMT .25W 1206 1%

“R6, R13, R17, R84,”

58-47035 22 EACH 4.7K SMT .25W 1206 1%

“R110, R118, R119, R210, R218, R219,”

58-47035 22 EACH 4.7K SMT .25W 1206 1%

“R310, R318, R319, R410, R418, R419,”

58-47035 22 EACH 4.7K SMT .25W 1206 1%

“R510, R518, R519, R610, R618, R619”

58-47035 22 EACH 4.7K SMT .25W 1206 1%

“R46, R57, R87, R96, R114,”

58-47045 13 EACH 47K SMT .25W 1206 1%

“R147, R164, R166, R214”

58-47045 13 EACH 47K SMT .25W 1206 1%

“R314, R414, R514, R614”

58-47045 13 EACH 47K SMT .25W 1206 1%

R92 58-47055 1 EACH 470K SMT .25W 1206 1%

R7 58-56025 1 EACH 560.5 SMT .25W 1206 1%

“R101, R102, R201, R202, R301, R302,”

58-56035 12 EACH 5.6K SMT .25W 1206 1%

“R401, R402, R501, R502, R601, R602”

58-56035 12 EACH 5.6K SMT .25W 1206 1%

“R173, R174, R192, R193, R194, R195”

58-68015 6 EACH 68.5 SMT .25W 1206 1%

“R49, R51, R151” 58-68025

3 EACH 680 SMT .25W 1206 1%

R122 58-68035 1 EACH 6.8K SMT .25W 1206 1%

“R142, R143” 58-91025

2 EACH 910.5 SMT .25W 1206 1%

“Q32, Q34” 60-00142

2 EACH TRANS NPN TIP142 TO-218

“Q31, Q33” 60-00147

2 EACH TRANS PNP TIP147 TO-218

“D31, D32, D33, D34”

60-50200 4 EACH DIODE GEN REC 1N5402 3A 200V

“Q2, Q11, Q23, Q25”

60-55500- 1 * STD 4 EACH TRANS 2N5550

HV NPN 250V T0-92

U3 60-71024 1 EACH CMOS STATIC RAM 1MEG 20NS

D6 60-75320 1 EACH LED RED DIFFUSED 3MM T-1.00

D1 60-75330 1 EACH LED GREEN DIFFUSED 3MM T-1.00

D2 60-75340 1 EACH LED YELLOW DIFFUSED 3MM T-1.00

Q27 60-78050 1 EACH REGULATOR VOLTAGE 5 +V 1 AMP

Q14 62-04391 1 EACH TRANSISTOR SMT MMBF4391LT1

“Z1, Z2, Z3, Z4, Z11, Z12, Z13”

62-04739 7 EACH SMT DIODE ZENER 4739

“D15, D16, D17, D18, D35, D36”

62-06001 6 EACH DIODE ULTRA FAST 600V 1A SMA

U1 62-07712 1 EACH IC DSP W/CODEC AKM7712

Y1 62-16400 1 EACH CRYSTAL CERAMIC SMT 16.4mHz

“D3, D4, D5, D7, D8, D9,”

62-19140 11 EACH 1N914 HI SPD SMT 250mW DIODE

“D10, D11, D12, D13, D14”

62-19140 11 EACH 1N914 HI SPD SMT 250mW DIODE

“A10, A11, A21, A31, A41, A51, A61”

62-20430 7 EACH NJM2043SMT(TESTED) DUAL HFREQ

“A1, A2, A3, A4, A5, A7,”

62-45650 16 EACH NJM4565 SMT DUAL HI FREQ

“A8, A9, A12, A15, A16,”

62-45650 16 EACH NJM4565 SMT DUAL HI FREQ

“A22, A32, A42, A52, A62”

62-45650 16 EACH NJM4565 SMT DUAL HI FREQ

“Q3, Q4, Q5, Q6, Q9, Q10, Q13, Q16, Q17, Q18, Q21, Q24”

62-54001 12 EACH MMBT5401LTI PNP SOT-23 SMT

“Q7, Q8, Q19, Q20”

62-55500 4 EACH MMBT5550 NPN SOT-23

U2 62-87764 1 EACH MICRO CONTROLLER SOIC PACKAGE

“K1, K2” 70-05713

2 EACH RELAY SPDT 12A@120VAC/24V COIL

F1 70-21050 1 EACH FUSE ABC 5.00A FAST 6.35X32MM

“P11, P13, P21, P23, P31, P33,”

71-09252 “12 EACH POT 9 “”D-P”” 25F B50K-CC”

“P41, P43, P51, P53, P61, P63”

71-09252 “12 EACH POT 9 “”D-P”” 25F B50K-CC”

“P1, P2, P3, P8, P9, P10,”

71-09253 “24 EACH POT 9 “”D-P”” 25F B50K-”

“P14, P16, P17, P24, P26, P27,”

71-09253 “24 EACH POT 9 “”D-P”” 25F B50K-”

“P34, P36, P37, P44, P46, P47,”

71-09253 “24 EACH POT 9 “”D-P”” 25F B50K-”

“P54, P56, P57, P64, P66, P67”

71-09253 “24 EACH POT 9 “”D-P”” 25F B50K-”

“P72, P73, P74, P75, P76, P77, P78”

71-10320 7 EACH FADER 20MM SL20V3-B10K-L15D(G)

REPLACEMENT PARTS LIST (for circuit cards)

This symbol is intended to

alert the user to the presence of uninsulated “dan-

gerous voltage” within the

product’s enclosure that may be of sufficient magnitude to constitute a risk of

electric shock to persons.

This symbol is intended to alert the user to

the presence of important operating and

maintenance (servicing) instructions

in the literature accompanying the

appliance.

LIMITED WARRANTY

Your Carvin product is guaranteed against failure for 1 YEAR unless otherwise stated.

Carvin will service and supply all parts at no charge to the customer providing the unit is

under warranty. Shipping costs are the responsibility of the customer. CARVIN DOES NOT

PAY FOR PARTS OR SERVICING OTHER THAN OUR OWN. A COPY OF THE ORIGINAL

INVOICE IS REQUIRED TO VERIFY YOUR WARRANTY. Carvin assumes no responsibility

for horn drivers or speakers damaged by this unit. This warranty does not cover, and no

liability is assumed, for damage due to: natural disasters, accidents, abuse, loss of parts,

lack of reasonable care, incorrect use, or failure to follow instructions. This warranty is in

lieu of all other warranties, expressed or implied. No representative or person is authorized

to represent or assume for Carvin any liability in connection with the sale or servicing of

Carvin products.

CARVIN SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

When RETURNING merchandise to the factory, you may call for a return authorization

number. Describe in writing each problem. If your unit is out of warranty, you will be

charged the current FLAT RATE for parts and labor to bring your unit up to factory specifications.

MAINTAINING YOUR EQUIPMENT

Avoid spilling liquids or allowing any other foreign matter inside the unit. The panel of

your unit can be wiped from time to time with a dry or slightly damp cloth in order to

remove dust and bring back the new look.

As with all pro gear, avoid prolonged use in

caustic environments (salt air). When used in such an environment, be sure the mixer

is adequately protected by a cover.

Page 2

12340 World Trade Drive, San Diego, CA 92128

800.854.2235 www.carvin.com

Congratulations on your purchase of the PA410 or PA620 mixer! These mixers are

the culmination of Carvin’s 50 years of knowledge and experience in the pro sound

arena. The quality and features included in these powerful little units make them revolutionary and unheard of in their price range! Please take the time to review this

manual so that you may fully enjoy all the benefits your mixer has to offer.

PRO FEATURES

The PA series mixers give you pro XLR mic preamps, along with 1/4" line inputs on every

channel. Phantom power is provided on the XLR inputs for compatibility with high quality

condenser mics. Each channel also provides a MONITOR send, a GAIN switch for accommodating low and high input signals, EFFECTS send and LEVEL control.

ACTIVE EQ

Each channel of the PA series provides a HI and LOW shelving EQ with ±12dB of adjustment range featuring an internally optimized midrange circuit, for easy, effective tone

adjustments that sound great for vocals.

BUILT-IN POWER AMPS

The amplifiers in the PA series mixers are powerful enough to easily drive your speakers

for excellent coverage and clean, punchy sound. The PA410 delivers 100 Watts RMS,

while the more powerful PA620 delivers 200 Watts RMS! (Note: Each model is designed

to be used with 8Ω speakers (not 4 Ω). If the relay protection engages after 20 minutes

of heavy use (no output from the mixer while the power LED is on), you are using 4Ω

speakers. If the mixer goes into protect, let the mixer cool down and it will reset).

24-BIT DIGITAL PROCESSOR

Perhaps the most incredible feature of the PA series mixer is the "Full-Featured" 24-Bit Digital

Processor. You get awesome lush Reverbs, rich Chorus, crisp Delay and Echo, and thick,

layered Flanging – all with full band-width and pristine clarity. And with the PARAMETER

control, you can continuously modify each effect for up to 64 different sounds for a total of

256 effects! Nobody else has offered these features in a mixer in this price range!

MASTER SECTION

The master section of the PA series provides a MAIN volume for controlling your over-all

mix volume. A master MONITOR knob lets you control the over-all volume of an external monitor amp. The TAPE IN control is for varying the level of the signal being received

at the RCA TAPE IN jacks. A PHANTOM POWER switch is provided for engaging or disengaging power to condenser mics. Three controls EFFECT, SELECT, and PARAMETER,

are for setting up the full-featured Digital Effects. Finally, there is a master 7-Band

GRAPHIC EQ for fine tuning your over-all mix. It’s so easy to get a great sound!

CONNECTIVITY

The PA series mixers allow easy connections to most related equipment. There is a 1/4"

MAIN LINE OUT for sending the main signal to an external power amp or for plugging in

headphones. The MONITOR OUT is a 1/4" jack for feeding an external monitor amplifier.

RCA TAPE IN and OUT are provided for easy connection to keyboards, tape decks, CD

players, MiniDisc, computers, etc. The EFFECTS FOOT SW jack allows the connection of

the optional FS22 or equivalent footswitch for turning on or off your effects during performances. Two 1/4" SPEAKER jacks provide quick, easy connection for two 8 Ohm

speakers.

CONSTRUCTION

Solid plywood construction, space-age aluminum chassis and a modern power supply all add

up to make the PA series the best-built and most lightweight, compact pro mixers available.

Technical advances like SMT (surface mount components) and incredible 24-Bit DSP ensure

that they are the best sounding and most reliable compact mixers as well.

RECEIVING INSPECTION—read before getting started

INSPECT YOUR MIXER FOR ANY DAMAGE which may have occurred during shipping.

If any damage is found, please notify the shipping company and CARVIN immediately.

SAVE THE CARTON & ALL PACKING MATERIALS. In the event you have to re-ship your

unit, always use the original carton and packing material. This will provide the best possible protection during shipment. CARVIN and the shipping company are not liable for

any damage caused by improper packing.

SAVE YOUR INVOICE. It will be required for warranty service if needed in the future.

SHIPMENT SHORTAGE. If you find items missing, they may have been shipped sepa-

rately. Please allow several days for the rest of your order to arrive before inquiring.

RECORD THE SERIAL NUMBER on the enclosed warranty card or below on this manual for your records. Keep your portion of the card and return the portion with your

name and comments to us or register online at www.carvin.com/registration

For your records, you may wish to record the following information.

Serial No._____________________ Invoice Date_______________

PA620

76-41620A 0101

PA410 / PA620 SPECIFICATIONS:

Frequency Response: 20Hz-20KHz ±1dB

Total Harmonic Distortion: Less than 1%

Equivalent Input Noise: 150 ohm source: -110dBu

Output Noise: -90dBu Master Line Out

(all levels minimum)

Output Power: PA410 4Ω: 100 watts RMS

PA620 4Ω: 200 watts RMS

Output Headroom: +20dB 1/4” unbalanced

Maximum Gain: Mic in to Master Line Out: 65dB

Crosstalk: Adjacent ch’s: -60db at 1KHz

Common Mode Rejection: -75db at 1KHz

Phantom Power: All XLR Mic in channels

Channel EQ.: HI: 12KHz ±15dB

LOW: 85Hz ±15dB

Graphic EQ.: 7 Band Oct. Intervals ±12dB

100, 250, 1k, 2.5k, 5k, 10k

Mic Input: Balanced XLR input

Line Input: Unbalanced 1/4” Phone Jack

Power Requirements: PA410 120 or 240 VAC - 110VA

PA620 120 or 240 VAC - 220VA

Size: 16”W x8”D x 8.25”H

Weight: PA410: 15lbs., PA620: 18lbs

Options: FS22 Footswitch, CV620 cover

PA410 / PA620

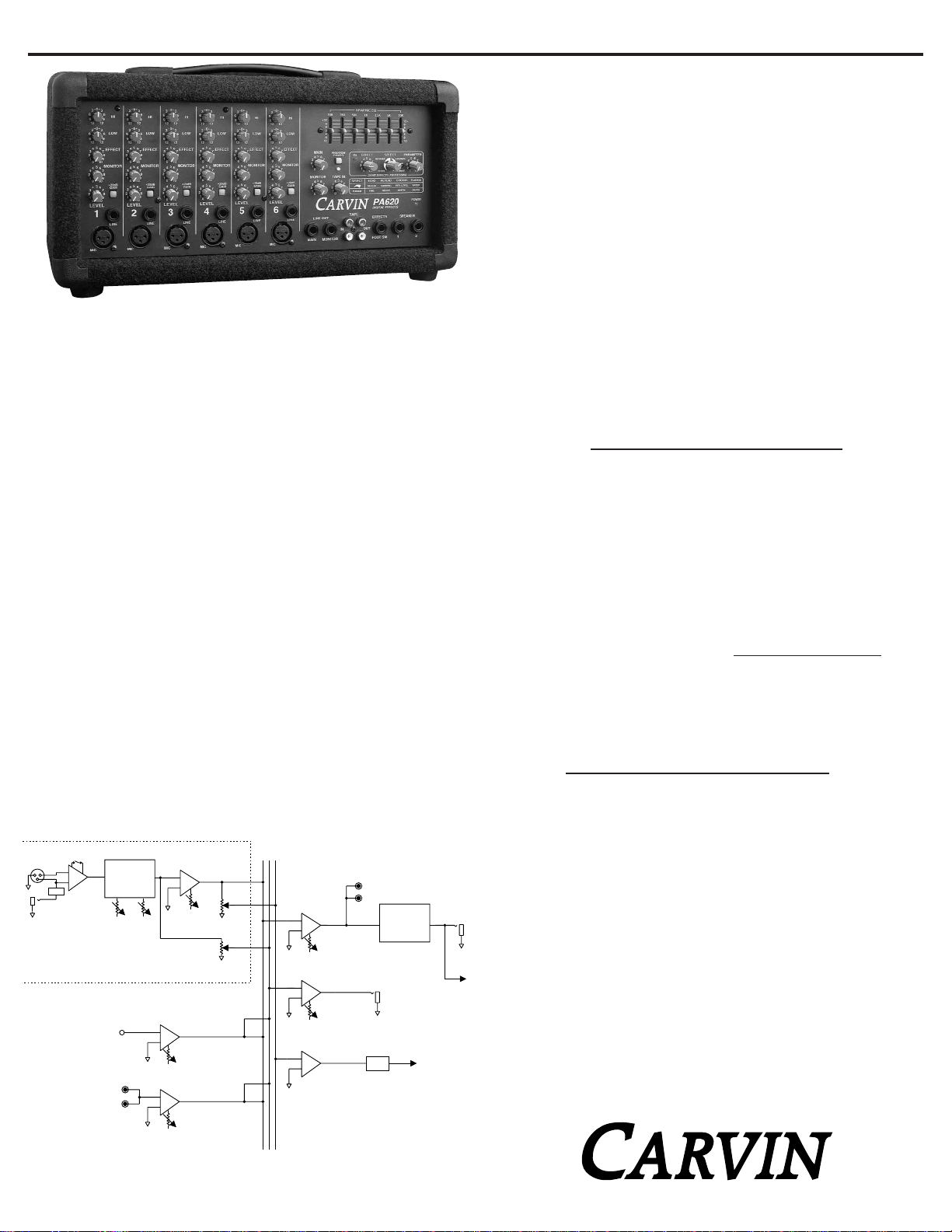

BLOCK DIAGRAM

CARVIN ENGINEERING DATA

OPERATING MANUAL

PA410/PA620 POWERED MIXERS

20dB

GAIN SWITCH

MIC

PRE

PAD

line pad

(-26dB)

CHANNEL

TAPE INPUT

TWO BAND

CHANNEL TONE

CONTROLS

HI LOW

RETURN FOR

INTERNAL DSP

CHANNEL

LEVEL

CHANNEL

MONITOR

LEVEL

DSP RETURN

LEVEL

TAPE INPUT

LEVEL

CHANNEL

EFF SND

DSP TO

MONITOR

TAPE TO

MONITOR

MAIN

MON

EFF

TAPE OUT

SEVEN BAND

GRAPHIC

EQUALIZER

MAIN

SUMMING AMP

AND LEVEL

MONITOR

LINE OUT

MONITOR

SUMMING AMP

AND LEVEL

GAIN

REDUCTION

FOR DSP

INTERNAL

EFFECTS

SUMMING AMP

DSP SEND

MAIN

LINE OUT

TO INTERNAL

POWER AMP

Page 3

LIVE SOUND SYSTEM

In a live sound reinforcement or a public address system (P.A.

System), the input signals to the mixer will come from the microphones and instruments on the stage. Each microphone or instrument to be amplified by the P.A. system must be connected to one

of the mixer’s inputs. If you have enough channels, try to mic each

stage instrument. This allows for the best overall sound control of

the instruments as they are mixed together and then amplified by

the P.A. system. This will also provide the ability to record your

performace with all instruments in the mix via the TAPE OUT RCA

jacks.

THE SOUND CHECK

The sound check takes some skill, but mostly patience from the

performers and especially you the system operator. If you get frustrated during the sound check the performers can lose confidence

and the sound may suffer due to things missed in the sound check.

The basic sound check follows this format: First test all micro-

phones and other input devices (direct boxes, etc.) before the performers are included in the sound check. A good thing to also

check here is feedback in the monitors from the microphones.

Good positioning of the monitors and the use of the graphic equalizer solves most major monitor feedback problems. Now for a

sound check with the performers. First set the level of each performer individually and in cases where a performer has multiple

microphones, such as with a drummer, set each drum mic individually then the drum set as a whole. This is also a good time to

make some channel tone control adjustments to tailor the sound of

the individual performers and instruments. Next after setting each

individual, have the performers run through a song or a portion of

the show. Don’t hesitate to stop the performers if something needs

to be adjusted or if an individual performer or microphone needs to

be heard solo again. Remember the sound check is not a rehearsal, but a system check, a time to work the bugs out of the system

so the show can go smoothly.

0

1

2

3

456

7

8

9

10

0

1

2

3

4

5

6

7

8

9

10 0

1

2

3

4

5

6

7

8

9

10

MONITOR TAPE IN

MAIN

PHANTOM

FOOT SW

PA620

PK

0

1

2

3

456

7

8

9

10

PARAMETER

110

2

3

4567

8

9

SELECTEFFECT

LINE OUT

1

SPEAKER

2

EFFECTS

MONITORMAIN

POWER

OUT

TAPE

IN

DIGITAL EFFECTS

24-BIT EFFECTS PROCESSING

FLANGE

REVERB

ECHO

CHORUS

PARAM

ECHO

REGEN

TIME

REVERB

DAMPING

DECAY

FLANGE

SPEED

DEPTH

CHORUS

REV LEVEL

DEPTH

SELECT

TWO-TRACK

RECORDER

R/L

TAPE

OUT

R/L

TAPE

IN

TAPE AND CD IN - OUT

DSP EFFECTS FOOTSWITCH

The hook up is simple,

using four (or two

stereo) RCA cables.

Plug the TAPE OUT on

the mixer into the tape

deck’s inputs and the

mixer’s TAPE RTN’s

into the tape deck’s

outputs. This can provide the means to

record a performance

or play pre-recorded

music through the

mixer.

DSP EFFECTS SELECTOR

Use Carvin’s FS22 footswitch to remotely turn effects on and off.

The PA410 and PA620 effects offer a wide

array of effect possibilities. Use the SELECT

control to dail in your desired effect. Use the

PARAMETER control to change characteristics

about that effect. For a detailed description of

each EFFECT and PARAMETER please see

11. DSP EFFECTS SELECTOR

.

FS22

MAIN

PHANTOM

PK

POWER

456

3

7

2

8

9

1

10

0

MONITOR TAPE IN

5

5

6

4

4

7

3

3

2

8

2

1

9

1

0

10 0

LINE OUT

MONITORMAIN

6

7

8

9

10

TAPE

IN

456

3

2

1

0

10

24-BIT EFFECTS PROCESSING

ECHO

SELECT

REGEN

PARAM

TIME

OUT

REVERB

7

8

9

PA620

DIGITAL EFFECTS

EFFECTS

FOOT SW

ECHO

REVERB

DAMPING

DECAY

PARAMETER

SELECTEFFECT

CHORUS

4567

3

8

2

9

110

FLANGE

FLANGE

CHORUS

SPEED

REV LEVEL

DEPTH

DEPTH

SPEAKER

1

2

MAIN

456

3

2

1

0

MONITOR TAPE IN

5

4

3

2

1

0

PHANTOM

POWER

7

8

9

10

6

7

8

9

10 0

5

4

3

2

1

6

10

7

8

9

SELECT

PK

PARAM

SELECTEFFECT

REVERB

456

7

3

2

8

1

9

0

10

ECHO

24-BIT EFFECTS PROCESSING

ECHO

REVERB

REGEN

DAMPING

TIME

DECAY

PARAMETER

CHORUS

FLANGE

CHORUS

REV LEVEL

DEPTH

4567

3

2

110

FLANGE

SPEED

DEPTH

8

9

Page 4

MIC CHANNEL FEATURES

1. XLR MICROPHONE INPUT

The XLR MIC input is designed for balanced low impedance

(microphone) input signals. The differential balanced input

amplifier reduces the common noise picked up on the

microphone cables. The XLR connector is wired as per the

industry standard, pin 1 is ground, pin 2 is non-inverting

(positive), and pin 3 is inverting (negative). Phantom power

is available on every XLR input jack when the phantom

power switch in the master section is pressed. This feature

allows condenser microphones to be run directly from the

mixer. Note: When using phantom power, make sure the

phantom power is switched off before connecting or disconnecting microphones to the mixer. It is recommended

to allow 5 seconds for the phantom power to discharge

before making any microphone connections. Also, to avoid

hearing a pop, turn down the master volume when turning

on the phantom power.

2. LINE INPUT JACK

The LINE input is a 1/4” phone jack designed for unbalanced

line and instrument level inputs. Examples to use in these

inputs are guitars, keyboards, mics, or a CD or tape player.

The line inputs can be used at the same time the XLR inputs.

3. +20DB GAIN SWITCH

The GAIN switch increases the input sensitivity on both the

LINE and MIC input jacks by 20dB. After determining the

input is too low for mixing with the level control, turn down

the level control, press in the gain switch and adjust the

level again. If distortion is heard regardless of the channel

LEVEL control’s setting, disengage this switch to eliminate

over-driving of the input stage.

4. CHANNEL LEVEL CONTROL

The LEVEL control adjusts the volume of the channel before

going to the MAIN master LEVEL. Here is where the individual channel volumes are adjusted to make up the desired

mix heard at the main outputs. A general rule to prevent

interstage distortion is to always keep the MAIN master

LEVEL the same or higher than the channel LEVEL.

5. MONITOR LEVEL CONTROL

The MONITOR level control adjusts the volume of the channel going to the monitor mix. The monitor level control is

pre-channel level and pre-channel tone controls. This

means it is unaffected by adjustments in channel level and

tone controls. The purpose for this is so the main mix

adjustments for tone and level can be made without disturbing the monitor mix.

6. CHANNEL EFFECTS LEVEL CONTROL

The EFFECT control adjusts the volume of the channel going

to the internal effects. Make sure the effects level is not set

too high, if the master effect PK (Peak) LED flashes red, turn

down the Channel Effect until it stops flashing. See # 11 for

more details.

7. CHANNEL TONE CONTROLS

Each channel features active tone controls LOW and HI. Both

function as boost (clockwise) & cut (counter-clockwise) controls where the center 0 position is neutral. Both LOW and HI

are shelving type tone controls with corner frequencies at

80Hz and 11.5k Hz respectively. It is suggested the channel

tone controls start out in their center 0 positions. A good setting for added dynamics is to set the LOW & HI at +6.

8. THE GRAPHIC EQUALIZER

The 7 band graphic EQ is an excellent tool to fine tune the

overall mix. Set all sliders to their center detent position.

When the sliders are in this position, they do not effect the

audio signal. When a slider is raised or lowered it boosts and

cuts the listed frequency respectively. One setting that can be

used to enhance your sound is to cut the mid range (set the

1KHz slider to -8) and raise the high and low frequencies as

shown. This is a common “smile” curve that gives a tight

punchy sound with

plenty of highs to

cut through a

crowd. The

Graphic EQ can

also help to reduce

feedback.

9. MAIN MASTER LEVEL CONTROL

The MAIN control is the master volume control for the mixer. The

MAIN will control the volume of the LINE OUT jack, the TAPE OUT

RCA jack and the internal power amplifier (speaker volume).

10. PHANTOM POWER

SWITCH AND LED

The PHANTOM power switch turns on the microphone

phantom power in the channel XLR jacks. This power is

used for supplying a bias voltage to condenser microphones. The LED indicates the phantom power is turned

on. The phantom power will not damage dynamic microphones.

PA410 / PA620 CONTROLS

1

PA620

4

5

6

7

3

2

QUICK START UP

If you’re like most new owners, you’re probably in a

hurry to plug your mixer in and use it. Here are some

brief instructions to get you going quickly. With the

mixer unplugged and the unit turned off, complete the

following procedures:

1. CONNECTING AC POWER TO YOUR MIXER

• Be sure to use the correct power cable for your country.

(120VAC or 240 VAC)

• Use only a grounded (3 prong) power outlet to prevent

a shock hazard and reduce hum and noise.

2. CONNECTING SPEAKERS

• Use the 1/4” SPEAKER jacks on the front panel to connect up to two 8Ω speakers. The speaker cables are to

be non-shielded with a minimum size of 16 gauge.

NOTE: Do not run your speakers through microphone

wire, guitar cables, or multi-conductor microphone

junction boxes or “snakes” as they are sometimes

referred to. This wire is normally shielded and of a very

light gauge causing a substantial loss of power.

3. CONNECTING INPUTS TO YOUR MIXER

• For low level balanced devices such as microphones, plug

into the balanced MIC inputs using a shielded XLR cable.

• For high level unbalanced devices such as instruments

& Keyboards plug into the LINE input jacks using a

shielded 1/4” phone cable. Set the GAIN switch so the

LEVEL control is not overly sensitive.

4. TURNING YOUR MIXER ON

• Turn all channel and master LEVEL controls to their off

positions

• Adjust all “EQ” tone controls— the channel’s HI and LOW

and the 7 Band Graphic EQ’s to their center position.

• Turn the mixer on by the rear panel POWER SWITCH and

watch for the POWER LED to light. Your mixer is now

ready to operate.

MASTER SECTION FEATURES

GRAPHIC EQ

250 500100

+

12

8

4

0

4

8

12

-

1K 2.5K

5K 10K

+

12

8

4

0

4

8

12

-

Page 5

11. DSP EFFECTS SELECTOR

The 24bit processor will provide a host of awesome sounding effects that include: Flange, Reverb, Echo, & Chorus. The

EFFECT control will adjust the volume level of the selected

effect. Remember each channel has its own EFFECT send

that will adjust the amount of signal sent to the effects

processor. The red PK LED will indicate when the effects signal from the channel is clipping. Lowering the channel

EFFECT control until the PK LED stops flashing is a good rule

of thumb when setting up your effects. (Note: An audible

note can be heard when adjusting the effects).

EFFECT PARAMETERS

Each of the four effects has a variable parameter that can be

easily adjusted.

ECHO: When the SELECT control is at the “7 O-clock” posi-

tion, it is selected to the first ECHO setting where you get a

single repeat echo (minimal regeneration). Turning the

PARAMETER control to 1 will provide the shortest delay time

between the original signal and the echo. Increasing the

PARAMETER

control to the

right will

increase the

time delay

between the

original signal

and the echo.

You can get a maximum of .5 second delay. To increase the

number of echoes, turn the SELECT control clockwise to “9

O-clock” (maximum regeneration).

REVERB: When the SELECT control is at the “10 O-clock”

position, it is selected to the first REVERB setting. Turning

the SELECT control clockwise will increase the amount of

high frequencies in the reverb. Turning the PARAMETER con-

trol to 1 will provide minimal decay time of the reverb.

Increasing the PARAMETER to the right will increase the

reverb decay time.

CHORUS: When the SELECT control is at the “1 O-clock”

position it is selected to the first CHORUS setting. Turning

the SELECT control clockwise will increase the amount

reverb in the chorus. Turning the PARAMETER control to 1

will provide a minimal chorus depth setting. Increasing the

PARAMETER to the right will increase the chorus depth.

FLANGE: When the SELECT control is at the “4 O-clock”

position it is selected to the first FLANGE setting. Turning the

SELECT control clockwise will increase the flanger’s speed.

Turning the PARAMETER control to 1 will provide minimal

flanging depth. Increasing the PARAMETER to the right will

increase the flanger’s depth.

12. MONITOR MASTER LEVEL CONTROL

The MONITOR master level control is the master volume

for the monitor mix which is sent to the monitor output.

This control receives its signals from the channel monitor

level controls.

13. TAPE IN

The TAPE IN control sets the level coming from the RCA

TAPE IN jacks. Just like the channel LEVEL control, the

TAPE IN will add this signal to your overall mix with your

MAIN control adjusting the entire mixer volume output.

14. MONITOR OUTPUT JACK

The MONITOR line out jack is the monitor mix from the

MONITOR master level control. This is a line level output to

drive an external power amplifier like our HT100M for separate floor monitors. This output will include any effects

mixed at the individual channels allowing you to hear your

effects in your monitors!

15. MAIN OUTPUT JACK

The MAIN line out jack is a line level post graphic EQ output

of the main mix. Use this to drive an external power amp.

This same signal is also being fed to the internal power

amplifier.

16. TAPE IN-OUT RCA JACKS

The RCA IN jacks are Ideal for pluggng in keyboard, cassette deck or CD player. The LEFT/RIGHT TAPE OUT RCA

jacks deliver the main mix for recording (pre graphic EQ).

17. EFFECTS/FOOTSWITCH

Plug the optional FS22 footswitch into this jack to remotely turn the effects ON or OFF.

18. SPEAKER OUTPUT JACKS

Connect the main speakers to these two 1/4” phone jacks.

A total of two 8Ω speakers can be connected (one per

jack). Connecting 4Ω speakers or more than two 8Ω

speakers will cause the mixer to go into “protect mode”

and mute the audio. The output relay will engage after 20

minutes of heavy use when using 4Ω speakers.

19. POWER LED

The Power LED indicates when the mixer is powered up.

HELPFUL HINTS

1) FEEDBACK: To reduce feedback, the placement of the

speakers with respect to the microphones may need to be

reconsidered. As much as possible, try to have the main

speaker facing away from and in front of the microphones

not on stage behind them. The graphic EQ may be used to

reduce feedback from microphones.

2) NO HIGH FREQUENCIES: Check the channel tone controls and EQ settings. The tweeters or midrange drivers may

have been damaged or blown from feedback or overpowering.

1612

9

12

14

17

18

13

15

11

19

8

10

Page 6

SYSTEM WITH MONITORS

8Ω

8Ω

Min. impedance: 8Ω per speaker

-

+

08448

12

12

12+

GRAPHIC EQ

100 250 500 1K 2.5K 5K 10K

+12

08448

08448

8

9

7

SPEED

DEPTH

FLANGE

56

110

4

2

3

12-

PARAMETER

CHORUS

SELECTEFFECT

REVERB

7

6

5

4

PK

POWER

PHANTOM

789

±12

6

5

4

MAIN

DEPTH

CHORUS

FLANGE

REV LEVEL

DECAY

DAMPING

REVERB

ECHO

8

9

10

24-BIT EFFECTS PROCESSING

0

123

10

0

123

ECHO

SELECT

6

5

6

5

MONITOR TAPE IN

PA620

DIGITAL EFFECTS

TIME

REGEN

PARAM

789

10

4

123

789

10 0

0

4

123

SPEAKER

EFFECTS

TAPE

LINE OUT

2

1

FOOT SW

OUT

IN

MONITORMAIN

5K 10K 10K 10K

CHANNEL 1

1K 2.5K

dcm

250 500100

08448

12

12

+

-

345

2

6

1

7

8

0 dB

9

10

11

CHANNEL

12

13

50

15

30

171922

345

2

6

1

7

8

0 dB

9

12

10

11

CHANNEL

12

13

50

15

30

17

22

19

-

+

08448

12

12

5K 10K 10K 10K

CHANNEL 1

1K 2.5K

250 500100

08448

12

12

+

-

HI

6

3

0

3

6

HI

6

3

0

3

6

HI

6

3

0

3

6

HI

6

3

0

3

6

HI

6

3

0

3

6

HI

6

3

0

3

6

LOW

6

3

12

0

3

12

99

6

LOW

6

3

12

0

3

12

99

6

LOW

6

3

12

0

3

12

99

6

LOW

6

3

12

0

3

12

99

6

LOW

6

3

12

0

3

12

99

6

LOW

6

3

12

0

3

12

99

6

EFFECT

12

6

5

4

12

321

99

EFFECT

12

6

5

4

12

321

99

EFFECT

12

6

5

4

12

99

321

EFFECT

12

6

5

4

12

321

99

EFFECT

12

6

5

4

12

321

99

EFFECT

12

6

5

4

12

321

99

20dB

GAIN

MONITOR

987

987

987

6

6

5

5

4

321

321

321

321

321

321

010

010

321

20dB

GAIN

987

987

6

5

4

010

010

321

20dB

GAIN

987

987

6

5

4

010

010

LEVEL LEVEL LEVEL

321

20dB

GAIN

987

987

6

5

4

010

010

321

20dB

GAIN

987

987

6

5

4

010

010

321

20dB

GAIN

987

987

6

5

4

010

010

LEVEL LEVEL LEVEL

321

4

010

MONITOR

987

6

5

4

010

MONITOR

987

6

5

4

010

MONITOR

987

6

5

4

010

MONITOR

987

6

5

4

010

MONITOR

987

6

5

4

010

LINE

654

MIC

LINE

MIC

LINE

4

MIC

LINE

3

MIC

LINE

2

MIC

LINE

1

MIC

Loading...

Loading...