Page 1

CARVIN ENGINEERING DA T A OPERATING MANUAL

Pristine sound, brute power and no-fault reliability make the DCM amps the power

amp of choice for pro audio. Massive Toroid power supplies with huge capacitors deliver the bass that kick drums demand. Designed for continuous operation, overheating is not a problem especially down at minimum impedances where

other amps simply turn off.

Each DCM is hand built at our San Diego factory featuring all steel construction,

recessed controls and heavy-duty power components. The rock-solid, efficient

design with its superb testimonial-proven sound makes the USA built DCM an

amp you'll own for years.

PURE—TRANSPARENT SOUND

Carvin considers the sound of an amp equally important as to its reliability. To

insure pure, uncolored sound, we build one of the fastest power stages on the

market today. High slew rates of 50v/µs deliver superb transient response. High

frequencies are transparent and open—even at extreme levels. Linear feedback

circuits reduce distortion to near the theoretical zero limit preventing harshness

which would lead to ear fatigue. The DCM deliver transparent, unaltered sound—

especially important to the studio user. Drive any type of reactive loads, including 70V transformer distribution systems.

ULTRA RUGGED FOR TOURING

Every chassis is made from heavy-duty 16 gauge steel that is plated before painted

to prevent rust. All internal cabling is neatly tied and harnessed. Every circuit

card is FR-4 MILITARY SPEC, double-sided, fire retardant glass epoxy. Plated

through-holes insure that the solder flows on the top, bottom and through each

hole of every component preventing components from shaking loose. Speakon™

connectors, heavy-duty power switches, recessed knobs, all give the DCM amps

a “tank-like” ruggedness.

TOROID POWER SUPPLY

Toroids deliver massive amounts of “on demand” current for continuous 2 ohm

operation. This gives the power supply a solid foundation, yielding more headroom for large subwoofer applications. Not only do toroids deliver high current,

but they are known for reducing stray magnetic fields eliminating hum & noise.

This is especially important to the recording industry.

MODULAR CONSTRUCTION

With the DCM Series, Carvin brings you totally modular construction. If you

ever need an I/O (input/output) connector card because a connector wore-out,

just unplug and re-install the replacement card. This applies to every aspect of

the DCM Series amps including the power supply, power cards, heat sinks and

fans. Everything is connected by heavy-duty AMP™ and MOLEX™ type connectors

for easy replacement—even the Toroid transformer is a plug-in.

DISTORTION-FREE LIMITERS

The purpose of a limiter is to hold down peaks so the amp won’t distort with

extra hot input signals (helps protect speakers). In addition, a well designed limiter can increase your amp’s average output as much as 3 dB allowing levels to

be turned up without peak distortion. Part of Carvin’s design uses the more expensive, distortion-free linear “opto isolators”. Unlike amps that use FET controlled

limiters, which inject small amounts of distortion, the DCM Series limiters keep

your sound pure and uncolored!

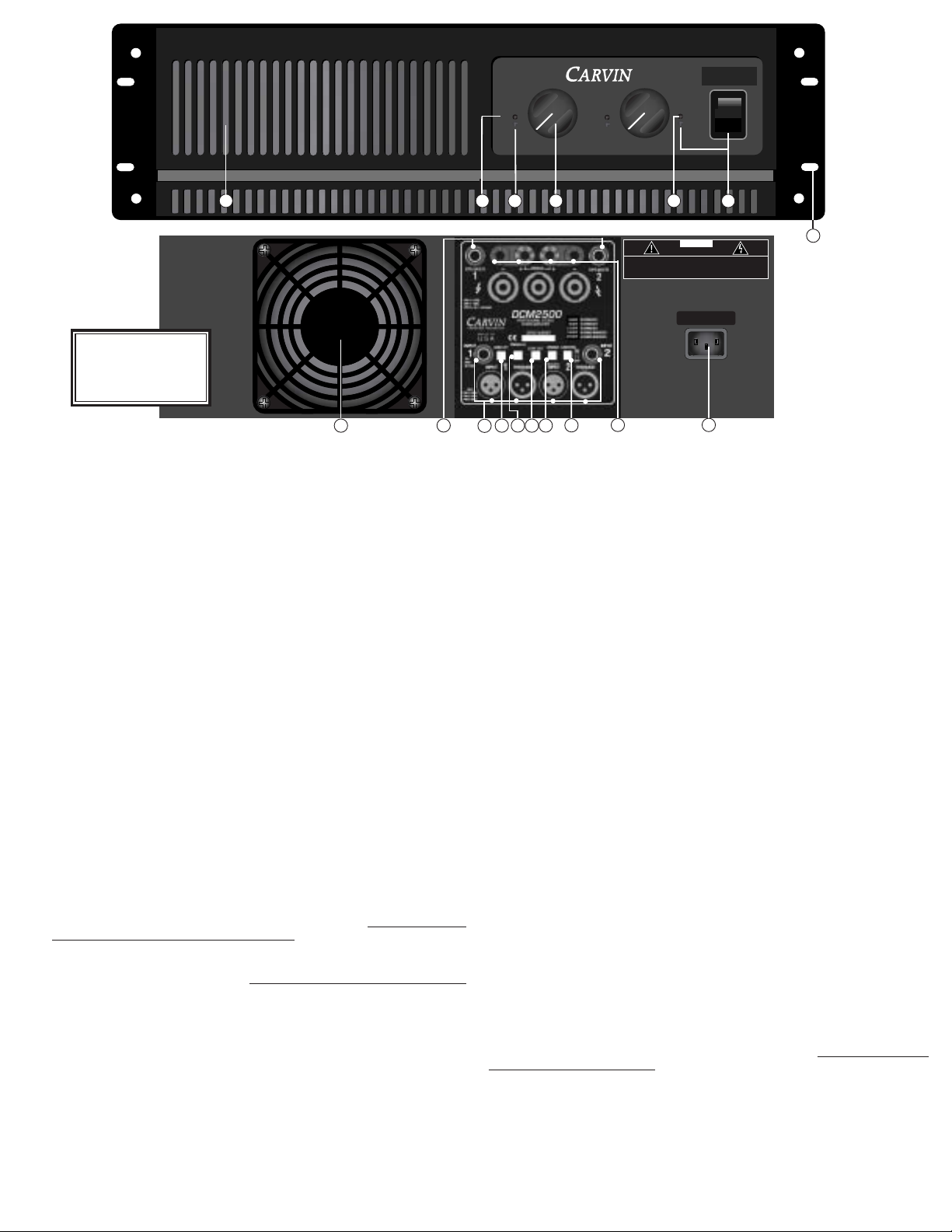

FRONT PANELS & CONNECTING UP

DCM POWER AMP SPECIFICATIONS:

MODEL DCM2000 DCM2500 DCM2570

Bridged RMS Continuous

4Ω, (20-20k Hz, <1.0%) 2000w 2500w

8Ω, (20-20k Hz, <1.0%) 1400w 1700w 2400

Both Channels RMS Continuous

2Ω (20-20k Hz, <1.0%) 1000/1000w 1250/1250w

4Ω (20-20k Hz, <1.0%) 700/700w 850/850w 1200/1200

8Ω (20-20k Hz, <1.0%) 425/425w 500/500w 700/700

THD (20-20k Hz 50% power) 0.03% 0.03% 0.03%

THD (20-20k Hz 90% power) 0.1% 0.1% 0.1%

Damping Factor: >500 >500 >500

Slew Rate: bridged mode >50v/µs >50v/µs >50v/µs

Sensitivity: (4Ω, Vms) 1.0 V 1.0 V 1.0 V

Signal to Noise Ratio: Above 100dB

Frequency Response: ±0.5 dB, 20 Hz to 20kHz

(±1.5 dB, 10 Hz & 40 kHz)

Input Impedance: >20K Ω, balanced

Protection Circuits: Short Circuit • No Load Protection • SpeakerGuard™ • Thermal Shut-Off • Mute On/Off

Control and Indicators:

Front: Power switch • Recessed detente attenuators • Signal LED • Clip LED • Protect LED • Power Indicator

Rear: Ground Lift (each channel) • Parallel Input Switch • Speaker Output Bridge Switch • Limiters

IN/OUT Switch • Input Connectors: Two each; Balanced XLR & 1/4” • Speaker Output Connectors:

Dual heavy duty binding posts, three Speakon™ & four 1/4”

Internal Fuse SLOW BLOW- DCM2000, DCM2500,DCM2700: 25A, 240V/15A

Dimensions: 5 1/4" High x 19" Wide x 10" Depth (3-space); 13.3 x 48.3 x 25.3 cm

Net Weight: DCM2000: 34 lbs. (16.4Kgs), DCM2500: 39 lbs. (16.6Kgs), DCM2570: 39 lbs. (16.7Kgs)

76-02000E 011404

For your records, you may wish to record the following information.

Serial No._____________________ Invoice Date_______________

RECEIVING INSPECTION—read before getting started

INSPECT YOUR UNIT FOR ANY DAMAGE which may have occurred during shipping. If

any damage is found, please notify the shipping company and CARVIN immediately.

SAVE THE CARTON & ALL P ACKING MA TERIALS. In the event you have to re-ship your unit,

always use the original carton and packing material. This will provide the best possible protection during shipment. CARVIN and the shipping company are not liable for any damage

caused by improper packing.

SAVE YOUR INVOICE. It will be required for warranty service if needed in the future.

SHIPMENT SHORTAGE. If you find items missing, they may have been shipped separately .

Please allow several days for the rest of your order to arrive before inquiring.

RECORD THE SERIAL NUMBER on the enclosed warranty card or below on this manual

for your records. Keep your portion of the card and return the portion with your name and

comments to us.

USA customers register online at: www.carvin.com/registration

All other countries register online at: www.carvinworld.com/registration

The DCM Series feature front panel signal, peak and protect LEDs which let you

monitor the status of the amp. Both channels use detente level controls allowing you to see your settings at a glance. Balanced TRS & XLR input connectors

are used to eliminate hum & noise. Speaker outputs feature heavy-duty binding

posts, Speakon™ connectors and 1/4” jacks.

The rear professional accessory group offers a GROUND switch to remove the

chassis ground from the XLR input. A PARALLELinput switch connects the inputs

together eliminating Y cables for patching multiple amp systems. The accessory

group also features a BRIDGE MODEswitch to deliver twice the power into a “mono”

load or full power into a 70V distribution system, and a LIMITER ON/OFF switch

gives the choice of using the internal limiter circuitry.

12340 World Trade Drive, San Diego, CA 92128

800.854.2235 www.carvin.com

DCM2000, DCM2500 & DCM2570 POWER AMPS

DCM2000, DCM2500, DCM2570

Page 2

∞

50

30

22

19

17

15

13

12

11

10

9

8

7

6

5

4

3

2

1

0 dB

∞

50

30

22

19

17

15

13

12

11

10

9

8

7

6

5

4

3

2

1

0 dB

50

30

22

19

17

15

13

12

11

10

0 dB

50

30

22

19

17

15

13

12

11

10

0 dB

FRONT PANEL

1. MOUNTING

Sturdy one piece 12 gauge steel face plate accomodates standard 19” rack installation. The rack mounting holes are designed on ISO standard spacing. Four 10-32 x .5” phillip machine screws are normally

used to secure the amp. Rear support brackets are not required.

2. POWER SWITCH

Check the power amp connections and verify the AC line power source before engaging the POWER

switch. The yellow LED unmistakably indicates that all circuits are properly powered up. Yellow is used

so the operator can see the red indicators (clipping or protect) from a distance.

3. CHANNEL LEVEL CONTROL

A precision input LEVEL attenuator is used to adjust the volume levels. To deliver the amps maximum power

without reducing the headroom of the signal source, the level controls should be turned full on.

4. CHANNEL SIGNAL INDICATOR

The green SIGNAL LED indicators will start to flash when there is a signal passing to your speakers (-30dBµ).

This lets you know when the amp is passing a signal to your speaker connectors.

5. CHANNEL CLIP INDICATOR

The red CLIP LED indicators will start to flash when each channel has reached its maximum output. Occasional

flashing caused by lower bass frequencies is OK. However, consistent flashing caused from higher frequencies

may damage high frequency drivers (excessive distortion). This does not cause damage to the amp.

6. COOLING VENTS/FAN

Upon rack installation, the rear of the amp must be fully exposed to room temperature air. The surrounding air should not be warmer than 120°F or the thermal protection could activate the PROTECT LED.

The front cooling vents are not to be restricted from exhausting the warm air.

7. PROTECT LED INDICATOR

The red PROTECT LED provides the operator with information about the status of the amplifier. The

PROTECT LED can come on under 3 different conditions (when this happens both channels are muted

by disconnecting the output speaker relays protecting your speakers);

1) During power-up, the amplifier stays in a muted state for approx. 3 sec until it determines that

everything is functioning normally (no output shorts or over temp conditions).

2) When the output load draws excessive current or a direct short is detected caused by a shorted

speaker cable or speaker system, the RED PROTECT LED will illuminate. Reset this condition by

turning the amp off for two seconds and then on again.

Check for shorted cables and the total

speaker system impedance connected to each channel.

3) Overheating is usually determined when the amp stops in the middle of a performance and the

PROTECT LED comes on. If this is the cause, leave the amp on for the fan to cool the amp down.

The amp will automatically reset within 1 to 3 minutes. The PROTECT LED will turn off when ready.

Check for the following conditions; a) The rear intake air is restricted, b) The intake air is extremely

warm, c) The front exhaust vents are restricted, or d) Excessive speaker load (try other speakers

or remove speakers if you have more than one connected to each channel). The minimum impedance is 2 ohms per ch or 4 ohms BRIDGED. DCM2570 minimum load is 4 ohms per ch or 8 ohms

BRIDGED.

REAR PANEL

8. CHANNEL INPUTS AND THROUGH

Balanced or Unbalanced 1/4” TRS inputs can be used along with the balanced XLR’s. The male “THROUGH”

XLR connector carries the same signal as the female XLR to daisy chain channels or additional amps. XLR

pin configuration: Pin 1: Grounded through the GROUND LIFT switch, Pin 2: positive Bal. signal and Pin

3: negative Bal. signal.

9. PARALLEL OR “Y” INPUTS

The rear PARALLEL switch “IN” allows you to drive both channels from either input in which a signal

entering any input will be available on both channels eliminating Y adapters.

10. INPUT GROUND LIFT

Many times sound systems are connected in such a manner to cause a grounded loop with the inputs

which result in audible hum. The input GND LIFT (1/4” & XLR) switch on the rear panel will help eliminate

this problem. If not, another way to eliminate ground loops is to install Carvin’s MTF55 “Ground Lifter”

between the amplifier input and the signal source. This isolates the input ground from the AC power ground.

11. LO CUT

(DCM2500, DCM2570)

The LO CUT switch inserts a 40Hz, 3rd order, high pass filter. This will remove sub audio frequencies

from damaging speakers and wasting inaudible power. It is active when the switch is pushed “IN”.

12. LIMITERS

To activate the LIMITERS, engage the rear limiter switch to the “IN” position. The built-in “optio” limiters

are recommended to hold down peaks that could cause early distortion. This will help to raise the average

power so that you can get more output from each channel. To check the effectiveness of the limiters when

the channel starts to distort (under full output), engage the limiters and hear the reduction of the distortion.

If the distortion stops, you can try to turn the channel up for more power. The lower bass frequencies are

most affected. WARNING: Do not check in an environment where the sound level could damage your ears!

13. SPEAKER 1/4” AND SPEAKON™ OUTPUTS

The standard 1/4” SPEAKER jacks are offered for low power applications. Speakon™ connectors are provided for high power application. Secure the Speakon™ connection by turning to the right. The center Speakon™

is for Bridge only. Turn the amp off before connecting your speakers. DCM 2570 minimum load 4 ohms

14. BINDING POST OUTPUTS

For other high power speaker connections, use the rear BINDING POSTS to connect your speakers. Wire

sizes up to 7 gauge (50 amps) can be inserted into the binding post “side holes”. Larger cable can be used

with “banana” plugs which plug into the end of the binding posts (remove colored caps from the top of the

binding post). Binding posts are spaced on ISO standards. Use the two center RED binding posts to BRIDGE

both power amps (see 15 BRIDGE MODE).

15. BRIDGE MODE—25V/70V DISTRIBUTION SYSTEMS

The “DCM” Series can be operated in bridge mode if you require a 25V / 70V distribution speaker system

or a high powered mono (single channel) amp, which can double your power into a single load. With your

amp off, push “IN” the rear (recessed) BRIDGE switch after you have made your connections to either the

center bridge Speakon™ or the rear center RED binding posts (ch 1 is + and ch 2 is -). Select carefully or

damage may result to your speakers. This is why the switch has been recessed. No other speaker connectors or binding posts can to be used at the same time! The INPUT and LEVEL is handled by channel 1. Channel

2 is non-operational. The minimum speaker impedance is 4 ohms. CAUTION: The power developed by

bridging your amp can destroy most speaker systems! DCM2570 minimum load is 8 ohms in BRIDGE

16. AC POWER

Your amp is designed to run on either 120V 60 Hz or 240V 50Hz depending on the model purchased.

The voltage range for 120V model is 95V to 132V and for 230V model it is 195V to 255V. The rear heavyduty AC receptacle will accept a standard grounded AC cord that is designed for your country. Be sure

to check your power source before plugging into a grounded (3 prong) outlet. Never defeat the grounded

connection or electrocution may result! Firmly push the power cord all the way into its recepticle. In the

case of a blown fuse; unplug the amp, remove the lid and replace the fuse located in the back corner

above where the AC cord connects to the circuit board.

FUSE: The fuse is located within the main chassis above the AC connector mounted on the rear, inside

the PC card. Normaly if the fuse fails, the amp will require service. See spec. chart for fuse values.

NOTE: Each amp will require a dedicated circuit if you are driving the amp to its full output. There will

be a sustained loss of power if the AC voltage falls below the rated 120V or 230/240V. Use a heavy gauge

power cable and power source.

6

FRONT & REAR PANEL CONTROLS

WARNING

This product produces high

sound pressure levels that

could damage your hearing.

Use with caution.

1

5

15

12

10

16

4

3

7

2

6

13

8

14

9

11

10

11

9

8

12

13

15

17

19

CLIP

22

SIGNAL

30

50

0 dB

∞

CHANNEL ONE CHANNEL TWO

DCM2500

10

11

9

12

7

1

13

15

6

17

5

19

4

CLIP

22

3

SIGNAL

30

2

50

0 dB

∞

2500 Watt Power Amp

8

7

6

5

4

PROTECT

3

POWER

2

1

SPEAKER

1

GND LIFT PARALLEL BRIDGE LIMITERS

XLR

PIN 1 GND

PIN 2 POS

PIN 3 NEG

+ ––BRIDGE–– +

PROFESSIONAL STEREO

POWER AMPLIFIER

SERIAL NUMBER

CH1

IN

––

SPEAKER

2

RISK OF ELECTRIC SHOCK

CAUTION - TO PREVENT ELECTRICAL SHOCK DO NOT DEFEAT THE SAFETY

GROUND ON THE POWER CORD - DO NOT REMOVE COVER .

WARNING - TO PREVENT FIRE OR SHOCK HAZARD DO NOT EXPOSE TO RAIN

OR MOISTURE. REFER SERVICING TO QUALIFED PERSONNEL.

CAUTION

DO NOT OPEN

120V~60Hz Slow Blow

FUSE 8AG 700VA

Page 3

SHIELD

-NEG.

3

1

2

GND

+ SIGNAL (BAL.)

Speakon™

Twist-Lok

Housing

Contact

Insert

Cable

Clamp

Securing

Hub

• Connection Configuration:

Black (1+) / positive

White (1-) / negative

Red (2+) / positive

Green (2-) / negative

• Solder wires in contacts or use hex screws provided.

• Slip "Securing Hub" then "Cable Clamp" over cable before attaching wires.

1+

1-

2+

2-

Solder tinned wires 1/4"

Strip cable insulation back 3/4"

Sleeve

Ring

Neg.

Tip

Pos.

TRS 1/4” Balanced

Tip-Ring-Sleeve

TS 1/4” Unbalanced

Tip-Sleeve

TipSleeve

Ring

Tip

XLR

Tip

Ground

Ground

Ring

HELPFUL HINTS

1) NO SOUND FROM CH 2: The rear (recessed) BRIDGE

switch has been inadvertently pushed in.

2) STEREO CHANNELS SOUND THE SAME: The rear

PARALLEL switch has been inadvertently pushed in.

3) NO HIGH FREQUENCIES: Tweeters or midrange drivers have

been damaged or blown from feedback or to much power.

4) SYSTEM HUM: Switch the rear GND LIFT switch IN or OUT. If

the hum is not eliminated, then install Carvin’s MTF55 “Ground

Lifter” between the amplifier input and signal source. This isolates the input ground from the AC power ground.

5) POOR SOUND (BASS): The speaker systems are wired out

of phase to each other. To correct, reverse the wires on one

speaker connector only and your sound, especially the bass

response will improve.

- SIGNAL (BAL.)

TYPICAL STEREO SETUP

MONO MAINS & MONITORS

STEREO BIAMPING

CHANNEL TWO

HIGH

PHASE

MID

PHASE

LOW

PHASE

XC3000

Electronic Crossover

1-800-854-2235

www.carvin.com

INTERNAL FUSE

90-250 VAC

10 VA ~50-60HZ

GND

LIFT

CHANNEL ONE

HIGH

PHASE

MID

PHASE

LOW

PHASE

MONO

[ LOW 1+2 ]

SWITCHABLE

TO MONO

[ LOW 1+2]

PROFESSIONAL STEREO

POWER AMPLIFIER

SERIAL NUMBER

120V~60Hz Slow Blow

FUSE 8AG 700VA

+ ––BRIDGE–– +

––

SPEAKER

2

SPEAKER

1

GND LIFT PARALLEL BRIDGELIMITERS

CH1

IN

XLR

PIN 1 GND

PIN 2 POS

PIN 3 NEG

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION - TO PREVENT ELECTRICAL SHOCK DO NOT DEFEAT THE SAFETY

GROUND ON THE POWER CORD - DO NOT REMOVE COVER .

WARNING - TO PREVENT FIRE OR SHOCK HAZARD DO NOT EXPOSE TO RAIN

OR MOISTURE. REFER SERVICING TO QUALIFED PERSONNEL.

PROFESSIONAL STEREO

POWER AMPLIFIER

SERIAL NUMBER

120V~60Hz Slow Blow

FUSE 8AG 700VA

+ ––BRIDGE–– +

––

SPEAKER

2

SPEAKER

1

GND LIFT PARALLEL BRIDGELIMITERS

CH1

IN

XLR

PIN 1 GND

PIN 2 POS

PIN 3 NEG

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION - TO PREVENT ELECTRICAL SHOCK DO NOT DEFEAT THE SAFETY

GROUND ON THE POWER CORD - DO NOT REMOVE COVER .

WARNING - TO PREVENT FIRE OR SHOCK HAZARD DO NOT EXPOSE TO RAIN

OR MOISTURE. REFER SERVICING TO QUALIFED PERSONNEL.

Left Input

Left Low Out

Left High Out

Right High Out

Right Low Out

Right Input

STEREO

CROSSOVER

Suggested settings

Low Frequency Amp

High Frequency

Left Lows

Right

Lows

Right Highs

Left Highs

PROFESSIONAL STEREO

POWER AMPLIFIER

SERIAL NUMBER

120V~60Hz Slow Blow

FUSE 8AG 700VA

+ ––BRIDGE–– +

––

SPEAKER

2

SPEAKER

1

GND LIFT PARALLEL BRIDGE LIMITERS

CH1

IN

XLR

PIN 1 GND

PIN 2 POS

PIN 3 NEG

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION - TO PREVENT ELECTRICAL SHOCK DO NOT DEFEAT THE SAFETY

GROUND ON THE POWER CORD - DO NOT REMOVE COVER .

WARNING - TO PREVENT FIRE OR SHOCK HAZARD DO NOT EXPOSE TO RAIN

OR MOISTURE. REFER SERVICING TO QUALIFED PERSONNEL.

For (stereo) the PARALLEL

switch must be OFF (OUT).

Ch 1 Left

Ch 2 Right

BRIDGE switch

must be OFF (OUT).

Right Full Range

Left Full Range

PROFESSIONAL STEREO

POWER AMPLIFIER

SERIAL NUMBER

120V~60Hz Slow Blow

FUSE 8AG 700VA

+ ––BRIDGE–– +

––

SPEAKER

2

SPEAKER

1

GND LIFT PARALLEL BRIDGE LIMITERS

CH1

IN

XLR

PIN 1 GND

PIN 2 POS

PIN 3 NEG

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION - TO PREVENT ELECTRICAL SHOCK DO NOT DEFEAT THE SAFETY

GROUND ON THE POWER CORD - DO NOT REMOVE COVER .

WARNING - TO PREVENT FIRE OR SHOCK HAZARD DO NOT EXPOSE TO RAIN

OR MOISTURE. REFER SERVICING TO QUALIFED PERSONNEL.

Mains

Monitors

Mains

Ch 1 Main Mix

Ch 2 Monitor Mix

BRIDGE switch

must be OFF (OUT).

The PARALLEL switch

must be OFF (OUT).

25V OR 70V DISTRIBUTION SYSTEM

BRIDGED MONO

PROFESSIONAL STEREO

POWER AMPLIFIER

SERIAL NUMBER

120V~60Hz Slow Blow

FUSE 8AG 700VA

+ ––BRIDGE–– +

––

SPEAKER

2

SPEAKER

1

GND LIFT PARALLEL BRIDGE LIMITERS

CH1

IN

XLR

PIN 1 GND

PIN 2 POS

PIN 3 NEG

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION - TO PREVENT ELECTRICAL SHOCK DO NOT DEFEAT THE SAFETY

GROUND ON THE POWER CORD - DO NOT REMOVE COVER .

WARNING - TO PREVENT FIRE OR SHOCK HAZARD DO NOT EXPOSE TO RAIN

OR MOISTURE. REFER SERVICING TO QUALIFED PERSONNEL.

PARALLEL switch OFF (OUT).

To signal socket XLR or 1/4" 2 or 3 cond. shielded

Activate the BRIDGE switch

(IN). Control the level by Ch 1

(Ch 2 does not function.)

Ch 1 Input

Single speaker or

system connected

in BRIDGE mode.

Minimum imp. 4Ω

Use either the Bridged

Speakon™ connector or the

binding posts. No other

connections can be used while

in Bridged mode.

PROFESSIONAL STEREO

POWER AMPLIFIER

SERIAL NUMBER

+ ––BRIDGE–– +

––

SPEAKER

2

SPEAKER

1

GND LIFT PARALLEL BRIDGE LIMITERS

CH1

IN

XLR

PIN 1 GND

PIN 2 POS

PIN 3 NEG

25V or 70V

Distribution System:

Wattage of transformer (TAP)

divided by total wattage

of Amp = Number of

transformer/speaker(s)

that can be hooked up.

+

16

8

4

C

15w

7w

3w

1w

C

+

16

8

4

C

15w

7w

3w

1w

C

6) DEDICATED CIRCUIT BREAKER: Each amp will require a

dedicated circuit breaker for its full output. There will be a

sustained loss of power if the AC voltage falls below the rated

120V or 230/240V input.

Page 4

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

SAFETY INSTRUCTIONS (EUROPEAN)

The conductors in the AC power cord are colored in accordance with the following code.

GREEN & YELLOW—Earth BLUE—Neutral BROWN—Live

U.K. MAIN PLUG WARNING: Amolded main plug that has been cut off from the cord is

unsafe. NEVER UNDER ANYCIRCUMST ANCES SHOULD YOU INSER TADAMAGED

OR CUT MAIN PLUG INTO APOWER SOCKET.

IMPORTANT! FOR YOUR PROTECTION, PLEASE READ THE FOLLOWING:

WATER AND MOISTURE: Appliance should not be used near water (near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a swimming pool, etc). Care should be taken

so that objects do not fall and liquids are not spilled into the enclosure through openings.

POWER SOURCES: The product should be connected to a power supply only of the type described

in the operating instructions or as marked on the appliance.

GROUNDING OR POLARIZATION: Precautions should be taken so that the grounding or polarization is not defeated.

POWER CORD PROTECTION: Power supply cords should be routed so that they are not likely

to be walked on or pinched by items placed upon or against them, paying particular attention

to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

SERVICING: The user should not attempt to service the appliance beyond that described in the

operating instructions. All other servicing should be referred to qualified service personnel.

FUSING: If your unit is equipped with a fuse receptacle, replace only with the same type fuse.

Refer to replacement text on the unit for correct fuse type.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL! THIS UNIT CONTAINS HIGH VOLTAGE INSIDE!

CAUTION

RISK OF ELECTRIC SHOCK

REPLACEMENT P ARTS LIST FOR DCM AMPS

This symbol is intended to

alert the user to the presence of uninsulated “dan-

gerous voltage” within the

product’s enclosure that may be of sufficient magnitude to constitute a risk of

electric shock to persons.

This symbol is

intended to alert the

user to the presence of

important operating

and maintenance (servicing) instructions in the literature accompanying

the appliance.

LIMITED WARRANTY

Your Carvin product is guaranteed against failure for 3 YEARS unless otherwise stated.

Carvin will service and supply all parts at no charge to the customer providing the unit

is under warranty. Shipping costs are the responsibility of the customer . CARVIN DOES

NOT PA Y FOR P ARTS OR SERVICING OTHER THAN OUR OWN. A COPY OF THE ORIGINAL INVOICE IS REQUIRED TO VERIFY YOUR WARRANTY . Carvin assumes no responsibility for horn drivers or speakers damaged by this unit. This warranty does not cover,

and no liability is assumed, for damage due to: natural disasters, accidents, abuse, loss

of parts, lack of reasonable care, incorrect use, or failure to follow instructions. This warranty is in lieu of all other warranties, expressed or implied. No representative or person

is authorized to represent or assume for Carvin any liability in connection with the sale

or servicing of Carvin products.

CARVIN SHALL NOT BE LIABLE FOR INCIDENTAL OR CON-

SEQUENTIAL DAMAGES.

When RETURNING merchandise to the factory, you may call for a return authorization number. Describe in writing each problem. If your unit is out of warranty, you

will be charged the current FLAT RATE for parts and labor to bring your unit up to factory specifications.

MAINTAINING YOUR EQUIPMENT

Avoid spilling liquids or allowing any other foreign matter inside the unit. The panel of

your unit can be wiped from time to time with a dry or slightly damp cloth in order to

remove dust and bring back the new look.

As with all pro gear, avoid prolonged use in

caustic environments (salt air). When used in such an environment, be sure the amplifier is adequately protected by rack, covers, etc..

03-00220 2 EACH INSLTR MICA .0030".450"X .65"

03-00223 2 EACH INSLTR MICA .0030"1.37"X .65"

03-00450 1 EACH INSLTR 9.125x1.5x.01" SGL ADHV

03-00475 1 EACH SPACER PAD .1X .4X .75 W/ADHSV

03-00503 8 EACH INSULATOR .36X .36X .20" 85deg

03-82061 1 EACH CABLE TIE 14.5Lx .19Wx 2" BNDL

03-92521 6 EACH STANDOFF LED .925 x .215 T1

USE ON D2,D3,D181,D180,D31,D32

05-85622 1 EACH CABLE ASSY, 5C 220MM

06-10028 24 EACH MS PPH 4-40X .500 ZINC TYPE F

06-40050 7 EACH TERMINAL VERT MALE PC MTG .250

QC1,QC2,QC3,QC4,QC5,QC6,QC7

07-01602 1 EACH KNOB "6" 6x6x9.7mm GREY CAP S3

07-01603 3 EACH KNOB "6L" 6x6x17.4mm GREY CAP

S1,S2,S4

12-00880 1 EACH HEATSINK 8"L 1pc FAN MOUNTED

15-00105 2 EACH COIL AIR 1.5uH 14AWG L100,L200

21-31100 1 EACH RECEPTACLE AC W/FAST-ON CHASS PL1

21-40000 2 EACH XLR FEMALE CONNECTOR W/O GRND

J100,J200

21-40001 2 EACH XLR MALE CONNECTOR J1,J2

21-45000 3 EACH SPEAKON 4-POLE PCMTG #NL4MD-V

J3,J103,J203

21-52345 2 EACH JACK .250 PHONE MONO STEEL

J105,J205

23-03529 2 EACH FUSEHOLDER CLIPS 3AG VERT MTG

F1

23-08604 3 EACH CONNECT HEADER .086" 4 PIN H6B H1 H6A

23-08605 1 EACH CONNECT HEADER .086" 5 PIN H5

23-08612 1 EACH CONNECT HEADER .086" 12 PIN H7

23-10002 3 EACH CONNECT HEADER .100" 2 PIN H4,H8,H9

23-11010 6 EACH CONNECT HEADER 10 PIN STRAIGHT

H1A,H1B,H2A,H2B,H3A,H3B

25-02201 4 EACH SWITCH DPDT PUSH PC MTG LOCKNG

S1,S2,S3,S4 3002000K 1 EACH PCB CARD MAIN DCM1500/2000

41-47322 3 EACH CAP MYLR .0470UF 250VAC BOX

C19,C20,C21

42-10312 4 EACH CAP ELEC 10,000 MFD 100V 20%

C115,C116,C215,C216

44-13520 2 EACH JUMPER PCB 20AWG .350" X .175" B1,B3

45-25152 4 EACH CAP CERM 250PF 500VOLT 5%

C106,C107,C206,C207

46-10412 2 EACH CAP POLY .1000UF 100VOLT 10%

C117,C217

46-47312-1 2 EACH CAP POLY .0470UF 100V 10%PREP

C127,C227

47-10235 4 EACH CAP ELEC 1,000 MFD 35V 20%

C1,C2,C8,C12

47-22151 1 EACH CAP ELEC 220 MFD 50VOLT 10% C18

47-47125 1 EACH CAP ELEC 470 MFD 25VOLT 20% C7

49-10412 2 EACH 0.1UF SMT 5% CERAMIC 0805 C10,C13

49-22035 13 EACH SMT CAP 22uF 35v ELECTROLITIC

C15,C16,C17,C102,C120,C124,C126,

C181,C202,C220,C224,C226,C281

49-22212 1 EACH 0.0022UF SMT 10% FILM 0805 50V C14

49-27052 9 EACH 27 PF SMT 5% CERAMIC 0805

C100,C101,C103,C104,C200,C201,

C203,C204,C280

49-39052 2 EACH 39PF SMT 5% CERAMIC 0805 C123,C223

49-47312 6 EACH 0.047UF SMT 10% FILM 0805 50V

C3,C4,C9,C11,C105,C205

49-82052 2 EACH 82PF SMT 5% CERAMIC 0805 C121,C221

52-10015 1 EACH RES 10.00 OHM .50W 5% CARBON R27

55-03300 24 EACH RES .33 OHM 5W 5% SB VERT R142,R143,

R144,R145,R146,R147,R148,R149,R150,

R151, R152,R153,R242,R243,R244,R245,

R246,R247,R248,R249, R250,R251,

R252,R253

55-05025 4 EACH RES 5.00 OHM 5W 5% SB VERT

R120,R121,R220,R221

55-30035 2 EACH RES 3.00KOHM 5W 5% SB WIRE R42,R43

56-35010 2 EACH RES 350.00 OHM 10W 10% SB SDOF

R44,R45

58-00035 2 EACH 0.0 SMT JUMPER 1206 R181,R282

58-10025 2 EACH 100.5 SMT .25W 1206 1% R128,R228

58-10035 9 EACH 1K SMT .25W 1206 1% R8,R15,R22,R34,

R111,R129,R211,R229,R187

58-10045 24 EACH 10K SMT .25W 1206 1% R5,R13,R19,R28,

R30,R35,R100,R101,R113,R154,R156,

R200,R201,R213,R254,R256,R183,

R185,R190 R283,R285,R290,R189,R289

58-10055 7 EACH 100K SMT .25W 1206 1%

R21,R114,R157,R214,R257,R184,R284

58-10065 2 EACH 1M SMT .25W 1206 1% R115,R215

58-15025 2 EACH 150ohm SMT .50W 1206 1% R141,R241

58-15035 1 EACH 1.5K SMT .25W 1206 1% R18

58-15045 9 EACH 15K SMT .25W 1206 1% R23,R102,R103,

R202, R203, R112, R212,R155,R255

58-15055 3 EACH 150K SMT .25W 1206 1% R11,R12,R260

58-22035 5 EACH 2.2K SMT .25W 1206 1% R1,R137,R237,

R191,R291

58-22045 9 EACH 22K SMT .25W 1206 1% R26,R29,R106,

R107, R125,R130,R206,R230,R225

58-22055 6 EACH 220K SMT .25W 1206 1% R31,R119,

R140,R219,R240,R186

58-27025 6 EACH 270.5 SMT .25W 1206 1% R108,R131,

R132,R208,R231,R232

58-47025 2 EACH 470.5 SMT .25W 1206 1% R24,R32

58-47035 9 EACH 4.7K SMT .25W 1206 1% R2,R7,R10,

R14,R188,R288,R135,R235,R20

58-47045 6 EACH 47K SMT .25W 1206 1% R33,R126,

R226,R180,R280,R281

58-47055 6 EACH 470K SMT .25W 1206 1% R16,R25,

R109,R209, R110, R210

58-68035 2 EACH 6.8K SMT .25W 1206 1% R104,R204

58-68045 1 EACH 68K SMT .25W 1206 1% R17

58-92201 8 EACH 22 SMT 1W 2512 20% R38,R39,R40,

R41,R133,R134,R233,R234

58-95102 8 EACH 510 SMT 1W 2512 5% R6,R9,R36,

R37,R127,R136,R227,R236

60-00014 1 EACH TRANS MPSA14 DRLNGTN NPN T0-92 Q1

60-15032 2 EACH TRANS MJE15032 NPN T0-220

Q107,Q207

60-15033 2 EACH TRANS MJE15033 PNP T0-220 Q108,Q208

60-21193-1 *STD 12 EACH TRNS BIPOLAR MJL21193-PREPPED

Q109,Q110,Q111,Q112,Q113,

Q114,Q209,Q210,Q211,Q212, Q213,Q214

60-21194-1 *STD 12 EACH TRNS BIPOLAR MJL21194-PREPPED

Q115,Q116,Q117,Q118,Q119,Q120,

Q215,Q216,Q217,Q218, Q219,Q220

60-31000 3 EACH BIPOLAR PWR TIP31C NPN 3A 100V

Q4,Q106,Q206

60-35041 2 EACH RECTIFIER BRIDGE 35AMP/400V PC

BR100,BR200

60-50200 4 EACH DIODE GEN REC 1N5402 3A 200V

D107,D108,D207,D208

60-50253 2 EACH OPTO ISOLATOR VACTROL AXIAL

OP100,OP200

60-75320 3 EACH LED RED DIFFUSED 3MM T-1.00

D2,D31,D181

60-75330 2 EACH LED GREEN DIFFUSED 3MM T-1.00

D32,D180

60-75340 1 EACH LED YELLOW DIFFUSED 3MM T-1.00

D3

60-78150 1 EACH REGULATOR VOLTAGE 15 +V 1 AMP

VR1

60-79120 1 EACH REGULATOR VOLTAGE 12 -V 500mA

Q7

60-79150 1 EACH REGULATOR VOLTAGE 15 -V 1 AMP

VR2

61-04733 1 EACH DIODE ZENER 1N4733A 5.1V 1W

Z1

61-40030 1 EACH DIODE RECT GEN 1N4003 200V 1A

D24

62-00014 2 EACH MMBTA14 SOT-23 SMT Q100,Q200

62-06001 7 EACH DIODE ULTRA FAST 600V 1A SMA

D11,D12,D4,D5,D6,D7,D9

62-19140 24 EACH 1N914 HI SPD SMT 250mW DIODE

D1,D8,D10,D13,D14,D19,D20,

D21,D22,D23,D100,D104,D106,

D200,D204,D206,D15,D16,D25,

D26,D27,D28,D29, D30

62-20430 4 EACH NJM2043SMT(TESTED) DUAL HFREQ

A1,A5,A100,A200

62-29010 1 EACH NJM2901SMT SNGLE SUPPLY A3

62-45650 3 EACH NJM4565 SMT DUAL HI FREQ A6,A7,A2

62-54001 5 EACH MMBT5401LT1 PNP SOT-23 SMT

Q2,Q3,Q6,Q101,Q201

62-55500 5 EACH MMBT5550 NPN SOT-23

Q5,Q102,Q202,Q8,Q9

70-05712 4 EACH RELAY SPDT 12A@120VAC/24V COIL

K100,K200,K1,K2

70-22125 1 EACH FUSE MDA 25.00A SLOW 6.35X32MM

71-09251 2 EACH POT 9 D-P 25F B10K THREAD BSH

P100,P200

71-24450 2 EACH POT VERT TRIMMER 500ohm

P101,P102

Loading...

Loading...