Page 1

CARVIN ENGINEERING DATA CG200 Optical Compressor/Gate INSTRUCTIONS

76-00120 0403

12340 World Trade Drive, San Diego, CA 92128

(800) 854-2235 www.carvin.com

RECEIVING INSPECTION

INSPECT YOUR ITEM FOR ANY DAMAGE which may have occurred during shipping.

If any damage is found, please notify the shipping company & CARVIN.

SAVE THE CARTON & ALL PACKING MATERIALS. In the event you have to re-ship

your unit, always use the original carton and packing material. This will provide the

best possible protection during shipment. CARVIN and the shipping company are not

liable for any damage caused by improper packing.

SAVE YOUR INVOICE. It will be required for warranty service if needed in the future.

SHIPMENT SHORTAGE. If you find items missing, they may have been shipped

separately. Please allow several days for the rest of your order to arrive before

inquiring.

RECORD THE SERIAL NUMBER on the enclosed warranty card or below on this

manual for your records. Keep your portion of the card and return the portion with

your name and comments to us.

For your records, you may wish to record the following information.

Serial No._____________________ Invoice Date_______________

Congratulations on your purchase of the CARVIN CG200 two

channel Optical Compressor/Gate. The CG200 was designed with

the professional in mind. Your unit has been engineered and

assembled in the U.S.A., using only high quality electronic

components and uncompromising workmanship. The CG200 was

designed around hand matched analog optoisolators. Unlike many

compressor/gates which use higher noise VCA’s, the CG200 is

based on classic optical compressors from the 60’s that had that

warmth and softness that cannot be recreated with VCA’s.

Optoisolators are also known for their extremely low distortion.

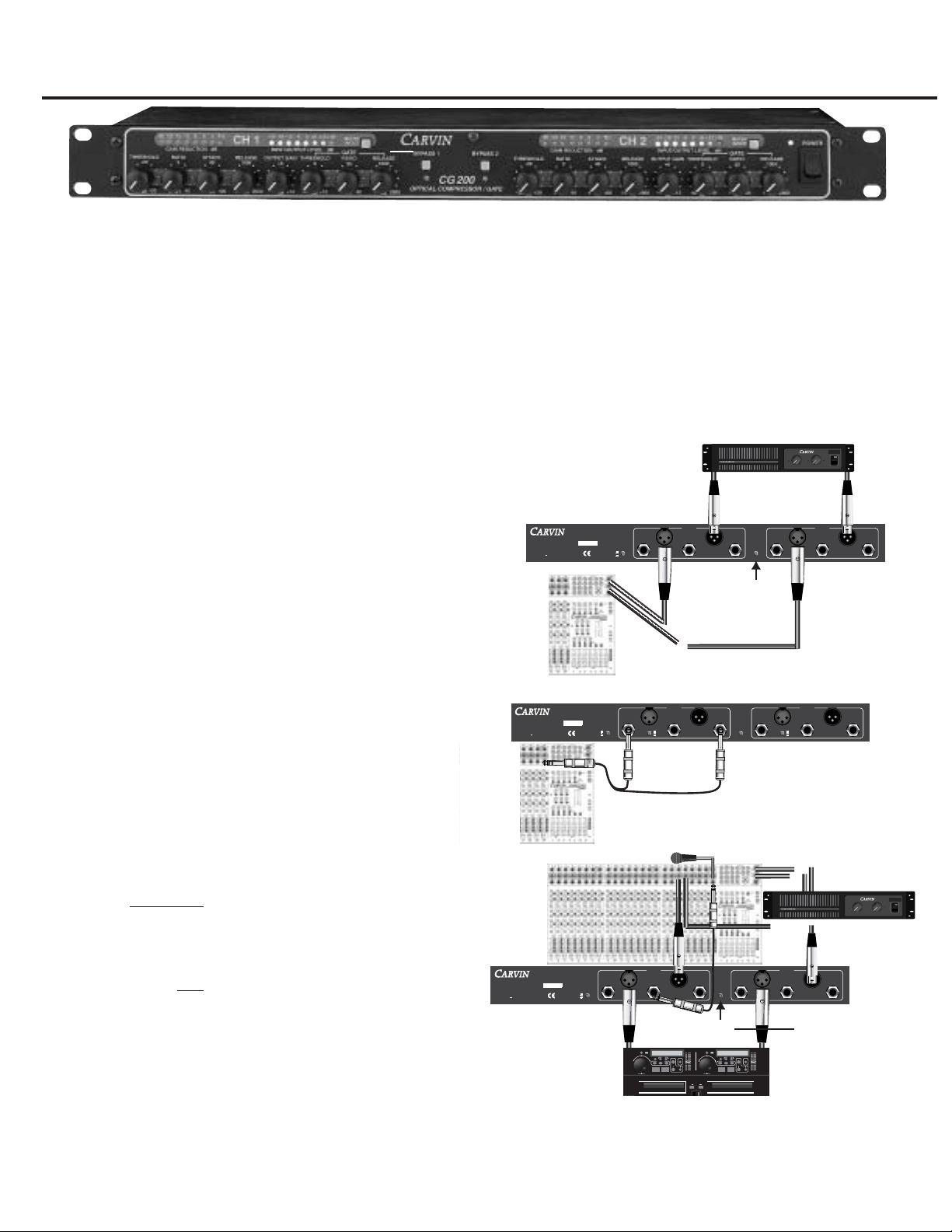

CONNECTING UP

The CG200 can be used in various applications that require different

configuration within a sound system. Fig. 1 shows the CG200

connected between the stereo output of a mixer and the inputs of a

power amp. This is best for compressing or gating an entire main

mix of program material. Fig. 2 depicts a channel insert

connection. This is done with a TRS (tip send, ring return) Y-cable.

The signal is sent out of the channel, compressed/gated and

returned into the channel. This is a typical set-up on most vocal or

drum microphone channels. Fig. 3 depicts a mic channel direct out

to the SIDE CHAIN INPUT. The mic signal triggers the

compressor/gate .

GND

LIFT

1-800-854-2235

www.carvin.com

MADE

AUS

IN THE

CG200

OPTICAL COMPRESSOR/GATE

SERIAL NUMBER

90-250 VAC

INTERNAL FUSE

10 VA 50-60Hz

STEREO

LINK

INPUTS OUTPUTS

SIDE CHAIN

INPUT

0 dBu

+6 dBu

0 dBu

+6 dBu

UNBAL UNBAL

UNBAL

CH1

INPUTS OUTPUTS

SIDE CHAIN

INPUT

UNBAL UNBAL

CH2

PROTECT

∞

5050

3030

2222

1919

1717

1515

1313

1212

1111

1010

9

8

7

6

5

4

3

2

1

0 dB0 dB

DCM1000

1000 Watt Power Amp

CLIP

SIGNAL

∞

5050

3030

2222

1919

1717

1515

1313

1212

1111

1010

9

8

7

6

5

4

3

2

1

0 dB0 dB

POWER

CHANNEL ONE CHANNEL TWO

CLIP

SIGNAL

POWER AMP

L-R OUTPUT

GND

LIFT

1-800-854-2235

www.carvin.com

MADE

AUS

IN THE

CG200

OPTICAL COMPRESSOR/GATE

SERIAL NUMBER

90-250 VAC

INTERNAL FUSE

10 VA 50-60Hz

STEREO

LINK

INPUTS OUTPUTS

SIDE CHAIN

INPUT

0 dBu

+6 dBu

0 dBu

+6 dBu

UNBAL UNBAL

UNBAL

CH1

INPUTS OUTPUTS

SIDE CHAIN

INPUT

UNBAL UNBAL

CH2

∞

50

30

22

19

17

15

13

12

11

10

9

8

7

6

5

4

3

2

1

0 dB

∞

50

30

22

19

17

15

13

12

11

10

9

8

7

6

5

4

3

2

1

0 dB

∞

50

30

22

19

17

15

13

12

11

10

9

8

7

6

5

4

3

2

1

0 dB

∞

50

30

22

19

17

15

13

12

11

10

9

8

7

6

5

4

3

2

1

0 dB

GND

LIFT

1-800-854-2235

www.carvin.com

MADE

AUS

IN THE

CG200

OPTICAL COMPRESSOR/GATE

SERIAL NUMBER

90-250 VAC

INTERNAL FUSE

10 VA 50-60Hz

STEREO

LINK

INPUTS OUTPUTS

SIDE CHAIN

INPUT

0 dBu

+6 dBu

0 dBu

+6 dBu

UNBAL UNBAL

UNBAL

CH1

INPUTS OUTPUTS

SIDE CHAIN

INPUT

UNBAL UNBAL

CH2

PROTECT

∞

5050

3030

2222

1919

1717

1515

1313

1212

1111

1010

9

8

7

6

5

4

3

2

1

0 dB0 dB

DCM1000

1000 Watt Power Amp

CLIP

SIGNAL

∞

5050

3030

2222

1919

1717

1515

1313

1212

1111

1010

9

8

7

6

5

4

3

2

1

0 dB0 dB

POWER

CHANNEL ONE CHANNEL TWO

CLIP

SIGNAL

POWER AMP

L-R OUTPUT

OPEN/CLOSE

CD 1

DUAL CD PLAYER

OPEN/CLOSE

REV FWD

PITCH CONTROL

8%,12%,16%

-SEAMLESS LOOP-

PLAY/PAUSE

TRACK SKIP

RELAY

SHUTTLEJOG

CD1

0

+

-

CD 2

OPEN/CLOSE

REV FWD

PITCH CONTROL

8%,12%,16%

-SEAMLESS LOOP-

PLAY/PAUSE

TRACK SKIP

RELAY

SHUTTLEJOG

CD1

0

+

-

CD Player

Enable the STEREO

LINK switch so both

channels are controlled

by the settings on

Channel 1.

FIG. 1

FIG. 2

FIG. 3

Enable the STEREO

LINK switch so both

channels are controlled

by the settings on

Channel 1.

Connect the CG200 between the CD

player and the mixer. Use a

standard unbalanced 1/4” cable and

“half insert” into the INSERT jack on

the mixer and connect the other end

to the SIDE CHAIN INPUT on the

CG200. Connect a vocal mic to the

same channel as the insert cable on

the mixer. The CG200 will

compress the CD audio whenever

someone speaks into the mic.

c

FREQUENCY RESPONSE: 20Hz TO 20kHz +/- 1dB

DYNAMIC RANGE: 115dB

MAX INPUT LEVEL: +20dBu

THD+N: LESS THAN 0.002% 20Hz TO 20kHz,

NO COMPRESSION/GATING, 0dB INPUT

LESS THAN 0.05%, ANY AMOUNT OF

COMPRESSION, 0dB INPUT

ATTACK AND RELEASE TIMES NOMINAL

INPUT IMPEDANCE: 20K BALANCED XLR

CROSSTALK: <-90dB 20Hz TO 20kHz

OUTPUT GAIN: -∞ TO +12dB

COMPRESSOR

THRESHOLD RANGE: -30bB to +20dB

RATIO: 2:1 TO 20:1

ATTACK TIME: 4mS TO 400mS

RELEASE TIME: 10mS TO 2 SEC

GATE

THRESHOLD RANGE: OFF(OPEN GATE) TO +10dB

RATIO: 1:1(OFF) TO 30:1

RELEASE TIME: 1mS TO 2 SEC

INPUTS AND OUTPUTS: XLR BALANCED AND 1/4” UNBALANCED

SIDECHAIN INPUT: 1/4” UNBALANCED

INPUT LEVEL SELECTION: 0dBu or +6dBu

POWER REQUIREMENTS: 4VA 90-250VAC, 50/60Hz SWITCHING SUPPLY

FUSE: INTERNAL 1.5A FAST BLOW

DIMENSIONS: 1 3/4”H x 19”W x 6”D

SHIPPING WEIGHT: 7 LBS

CG200 SPECIFICATIONS

Page 2

1. GAIN REDUCTION LED METER

Shows how much gain reduction (in dB) that is taking place

whether compression, gating or both.

2. INPUT/OUTPUT LED METER

Shows the incoming signal or output signal level (in dB) depending

on the position of the meter in/out switch.

3. METER IN/OUT SWITCH

When this switch is “IN”, the input/output meter shows the input

signal level. When “OUT”, the meter shows output level.

4. BYPASS SWITCH

With this switch “IN”, the signal passes with no processing. Note:

The OUTPUT GAIN knob will still control the output level even when

the CG200 is set to bypass.

5. BYPASS INDICATOR

This LED illuminates when the unit is bypassed.

6. POWER INDICATOR

This LED illuminates when power to the unit is on.

7. POWER SWITCH

Push this switch to the "ON" position to apply power to the unit. The

power indicator LED will light to show the CG200 is on.

8. THRESHOLD

The THRESHOLD is the signal level where compression begins. All

incoming signals above this threshold will be compressed

according to the RATIO control. If no compression is desired, and

use of the gate is desired by itself, turn the THRESHOLD control

clockwise to "OFF"

9. RATIO:

The RATIOis the amount of compression applied to the signal above

the threshold setting. The numbers 2 through 20 are the dB of input

signal required to achieve a 1 dB output increase. 2:1 is the most

subtle. 20:1 is the most extreme and will produce a more

"squashed" sound. High ratio settings can be used for limiting.

10. ATTACK:

Delay (in milliseconds) is “before compression takes place.” A

short attack time will respond much faster to signal dynamics than

a longer setting. Increase this setting if you want the initial hit

from a snare or punch from a bass to get through before

compressing the signal.

11. RELEASE:

Time (in milliseconds) in which compression is held after the

initial attack. The shorter the release time, the closer the

compressor follows the signal dynamics. Longer release times will

tend to make the sound more "squashed".

12. OUTPUT GAIN:

Output signal level. Use this after setting the compressor to make

up the over all signal level lost due to compression.

13. GATE THRESHOLD:

Signal level where “gating begins.” All incoming signals below this

threshold will be attenuated according to the GATE RATIO control.

Any signals above this threshold will be passed unaffected (unless

compression is on). If no gating is desired, turn this control fully

counter clockwise to the "OFF" position.

14. GATE RATIO:

Amount of attenuation applied to the signal below the gate

threshold level. Setting the GATE RATIO to 1:1 will effectively turn

gating off. A setting of 30:1 will attenuate all incoming signals

below the gate threshold by 30dB.

15. GATE RELEASE:

Amount of time after signal reaches the Gate Threshold before

gating turns on. The shorter the setting, the more "choppy" and

tighter the effect. The longer the time, the smoother the effect but

the more un-wanted noise will pass.

1

3

2

4

5

7

6

FRONT PANEL:

8

9

10

11

12

13

14

15

COMPRESS A STEREO MIX

CONNECTION METHOD: STEREO L-R MIX (see fig. 1)

To compress a stereo mix, depress the STEREO LINK button. Start with a

low RATIO setting. Set the THRESHOLD for a bit of Gain Reduction and

set the ATTACK on a slow setting. Raise the RATIOfor more compression

if needed.

EVEN OUT VARIOUS VOCAL MICS

CONNECTION METHOD: CHANNEL INSERT (see fig. 2)

In a situation where there are various vocalists with different dynamics, it

is best to compress each mic channel before adding each mic to the mix.

Start with a medium ATTACK setting on each mic. Set the RELEASE time

to a slow setting. Set the compression RATIO to 4:1. Set the

THRESHOLD so the GAIN REDUCTION meters show 9dB of gain

reduction. Increase the compression RATIO as needed. Soft vocal signals

may require a higher RATIO setting.

BASS GUITAR, ELECTRIC GUITAR COMPRESSION

CONNECTION METHOD: CHANNEL INSERT (see fig. 2)

To increase Bass sustain and reduce transient spikes, set the

compression RATIO around 4:1, set the THRESHOLD at 9dB of gain

reduction. Use a higher RATIO setting (5:1 or higher) to add sustain to

Guitar signals. Set the THRESHOLD as needed.

Compressor/Gate Applications

Page 3

16. LINE CORD:

The exclusive built-in auto switching power supply allows you to

connect any voltage from 90 to 255v 50-60Hx. Use a 3-conductor

line cord for maximum safety. If the CG200 is to be plugged into a

2-prong outlet, use a quality 3-to-2 prong grounded adapter. Do

not defeat the grounding pin of your AC line cord.

17. GROUND LIFT SWITCH:

This switch lifts the grounds on the inputs and outputs when

depressed. Useful in getting rid of ground loops.

18. UNBALANCED 1/4" INPUT:

This input will accept an unbalanced input from insert patch

cables, amplifier effects sends, etc. The tip is signal, the ring is

shield.

19. LEVEL SWITCH:

Depressing this switch “OUT” gives a 6 dBu boost to the input

signal if a low level signal is to be used.

20. BALANCED XLR INPUT:

This input will increase the gain by 3dB because it is balanced and

that will be most resistant to any induced noise. The connector

wiring is: Pin 1 – ground, Pin 2 – Positive Balance, Pin 3 –

Negative Balance.

21. SIDE CHAIN INPUT:

Use this if an external source is desired to control the compressor

or gate (ducking, de-essing, etc.). For example, if a lower music

level were desired when someone is talking on a microphone, the

microphone signal would be split, and sent into the side-chain

input. The music would be run into the input and back out of the

output of the processor. The music would automatically be turned

down when ever some one spoke into the mic, according to the

compressor settings. The Tip is signal, Ring is shield.

22. BALANCED XLR OUTPUT:

The balanced output is also 3dB hotter out the 1/4” output

because thats what “active balancing” does to the signal. for the

processor. The connector wiring is the same as for the balanced

XLR input.

23. UNBALANCED 1/4" OUTPUT:

This is the unbalanced output for the processor. Use this to return

the processed signal to insert patch cables, or the return on an

amplifier effects loop. The tip is signal, ring is shield.

24. STEREO LINK:

Depressing this switch links channel 2 to channel 1 for stereo

operation. The controls for channel 1 become the master controls

for both channels, with the exception of the Output Level controls

and Level switch, which remain independent. The signals are

effectively processed identically in this mode to give proper stereo

imaging.

REAR PANEL:

16

17

18

19

20

21

22

23

24

COMPRESSING DRUMS

CONNECTION METHOD: CHANNEL INSERT (see fig. 2)

To tighten the sound of a kick drum start with a RATIO around 6:1. Turn

up the THRESHOLD until the GAIN REDUCTION LED’s light up around

12dB. Increase the compression RATIO if needed. These suggested

settings can also be a starting point for snare and tom-toms. Experiment

for the best results.

To gate a drum mic signal so adjacent sounds don’t “false trigger” the

gate, set a fast RELEASE time so the gate closes fairly quick after the

signal falls under the THRESHOLD. This will help tighten up the sound of

a drum kit by eliminating sustained “ring”.

DISTORTION PREVENTION-SPEAKER PROTECTION

CONNECTION METHOD: STEREO L-R MIX (see fig. 1)

A compressor can be used to control audio levels from distorting power

amps and speakers. If the audio mix being sent to the power amps is

loud, a 10:1 or more RATIO setting with the THRESHOLD provide 15dB or

more of compression, which will protect against surprise signal spikes.

For best results in this application, position the compressor before any

EQ’s in the system.

INPUT

OUTPUT

THRESHOLD

RATIO 20:1

RATIO 2:1

CG200 COMPRESSION CURVE

Page 4

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

SAFETY INSTRUCTIONS (EUROPEAN)

The conductors in the AC power cord are colored in accordance with the following code.

GREEN & YELLOW—Earth BLUE—Neutral BROWN—Live

U.K. MAIN PLUG WARNING: A molded main plug that has been cut off from the cord is unsafe. NEVER

UNDER ANY CIRCUMSTANCES SHOULD YOU INSERT A DAMAGED OR CUT MAIN PLUG INTO A POWER SOCKET.

IMPORTANT! FOR YOUR PROTECTION, PLEASE READ THE FOLLOWING:

WATER AND MOISTURE: Appliance should not be used near water (near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a swimming pool, etc). Care should be taken

so that objects do not fall and liquids are not spilled into the enclosure through openings.

POWER SOURCES: The appliance should be connected to a power supply only of the type

described in the operating instructions or as marked on the appliance.

GROUNDING OR POLARIZATION: Precautions should be taken so that the grounding or

polarization means of an appliance is not defeated.

POWER CORD PROTECTION: Power supply cords should be routed so that they are not likely to

be walked on or pinched by items placed upon or against them, paying particular attention to

cords at plugs, convenience receptacles, and the point where they exit from the appliance.

SERVICING: The user should not attempt to service the appliance beyond that described in the

operating instructions. All other servicing should be referred to qualified service personnel.

FUSING: If your unit is equipped with a fuse receptacle, replace only with the same type fuse.

Refer to replacement text on the unit for correct fuse type.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL!

This symbol is intended to alert the user to

the presence of uninsulated “dangerous

voltage” within the product’s enclosure that

may be of sufficient magnitude to

constitute a risk of electric shock to persons.

This symbol is intended to alert the

user to the presence of important

operating and maintenance

(servicing) instructions in the

literature accompanying the appliance.

LIMITED WARRANTY

Your Carvin product is guaranteed against failure for 1 YEAR unless otherwise stated. Carvin

will service and supply all parts at no charge to the customer providing the unit is under

warranty. Shipping costs are the responsibility of the customer. CARVIN DOES NOT PAY FOR

PARTS OR SERVICING OTHER THAN OUR OWN. A COPY OF THE ORIGINAL INVOICE IS

REQUIRED TO VERIFY YOUR WARRANTY. Carvin assumes no responsibility for horn drivers or

speakers damaged by this unit. This warranty does not cover, and no liability is assumed, for

damage due to: natural disasters, accidents, abuse, loss of parts, lack of reasonable care,

incorrect use, or failure to follow instructions. This warranty is in lieu of all other warranties,

expressed or implied. No representative or person is authorized to represent or assume for

Carvin any liability in connection with the sale or servicing of Carvin products.

CARVIN SHALL

NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

When RETURNING merchandise to the factory, you may call for a return authorization

number. Describe in writing each problem. If your unit is out of warranty, you will be charged

the current FLAT RATE for parts and labor to bring your unit up to factory specifications.

MAINTAINING YOUR EQUIPMENT

Avoid spilling liquids or allowing any other foreign matter inside the unit. The panel of

your unit can be wiped from time to time with a dry or slightly damp cloth in order to

remove dust and bring back the new look.

As with all pro gear, avoid prolonged use in

caustic environments (salt air). When used in such an environment, be sure the mixer is

adequately protected by a cover.

CG200 PARTS LIST

03-50250 3 EACH STANDOFF LED .250 X .135 T1

“FOR D3, D17, D217”

03-92521 32 EACH STANDOFF LED .925 x .215 T1

“FOR D1, D2, D4, D6, D7, D8, D9,”

“D10, D12, D13, D14, D15, D18,”

“D21, D5, D22, D201, D202, D204,”

“D205, D206, D207, D208, D209, D210,”

“D212, D213, D214, D215, D218, D221,”

D222

06-40040 2 EACH TERMINAL VERT FEML PC MTG .250

S10

07-01603 4 EACH “KNOB “”6L”” 6x6x17.4mm GREY CAP”

“FOR S3, S4, S5, S205”

15-00300 2 EACH INDUCTOR .3 mH DRUM CORE

“L8, L10”

15-05002 2 EACH LINE FILTER 5mh ASE-1303F B

L3

15-10110 2 EACH INDUCTOR CHOKE 100uH 1.13Amp

“L1, L2”

15-86020G 1 EACH XFORM SWITCHING 20W .3/.6AMP

T1

21-40000 2 EACH XLR FEMALE CONNECTOR W/O GRND

“J5, J205”

21-40001 2 EACH XLR MALE CONNECTOR

“J4, J204”

21-31100 1 EACH RECEPTACLE AC W/FAST-ON CHASS

PL1

21-51345 6 EACH JACK .250 PHONE MONO PLASTIC

“J1, J2, J3, J201, J202, J203”

23-05601 2 EACH FUSE HOLDER BRASS .5 mm

F1

23-10308B 1 EACH “HEADER 8 PIN SIP 1.015”””

H2B

23-11004 6 EACH CONNECT HEADER 4 PIN STRAIGHT

“H3A, H4A, H4B, H5A, H5B, H201A”

23-11008 1 EACH CONNECT HEADER 8 PIN STRAIGHT

H1A

23-12004 2 EACH CONNECT HEADER 4 PIN RT/ANGLE

“H3B, H201B”

23-12008 1 EACH CONNECT HEADER 8 PIN RT/ANGLE

H1B

23-13008 1 EACH CONNECTOR HEADER 8PIN SIP

H2A

25-02201 3 EACH SWITCH DPDT PUSH PC MTG LOCKNG

“S4, S5, S205”

25-02200- 4 EACH ASSEMBLED SWITCH W/5MM CAP

“S1, S2, S201, S202”

25-04201 1 EACH SWITCH 4PDT PUSH PC MTG LOCKNG

S3

30-02200D 1 EACH PCB C200

REV D

42-33042 1 EACH CAP ELEC 33uF 400VOLT

C106

46-10242 1 EACH CAP POLY .0010UF 400VOLT 10%

C171

41-27322 3 EACH CAP POLY FILM .027uF 250VAC 10

“C338, C339, C341”

41-47422 1 EACH CAP MYLR .47uF 250VAC BOX

C282

41-10342 1 EACH CAP POLY .0100UF 400VOLT 10%

C11

46-47412 2 EACH CAP MYLR .4700UF 63VOLT 10%

“C43, C243”

47-10225 4 EACH “CAP ELEC 1,000 MFD 25V 20%”

“C159, C160, C161, C162”

49-10050 10 EACH CAP SMT 1UF 50V ELECTROLITIC

“C28, C29, C39, C40, C42, C228,”

“C229, C239, C240, C242”

49-10312 3 EACH 0.01UF SMT 10% FILM 080550V

“C47, C167, C168”

49-10412 4 EACH 0.1UF SMT +80-20% CERAMIC 0805

“C25, C26, C225, C226”

49-18152 10 EACH 180PF SMT 5% CERAMIC 0805

“C15, C18, C27, C33, C212, C215, C218”

“C227, C233, C12”

49-22035 21 EACH SMT CAP 22uF 35v ELECTROLITIC

“C3, C8, C10, C13, C16, C19, C20, C22”

“C23, C24, C32, C166, C203, C208, C210,”

“C213, C216, C219, C220, C224, C232”

49-27052 4 EACH 27 PF SMT 5% CERAMIC 0805

“C30, C31, C230, C231”

49-39052 22 EACH 39PF SMT 5% CERAMIC 0805

“C1, C2, C4, C5, C6, C7, C9, C14, C34,”

“C36, C37, C201, C202, C204, C205, C206,”

“C207, C209, C214, C234, C236, C237”

49-47212 1 EACH 0.0047uF SMT FILM 0805 50V

C158

58-00035 13 EACH 0.0 SMT JUMPER 1206

“R8, R26, R63, R72, R76, R95, R98,”

“R208, R226, R272, R276, R295, R298”

58-10025 17 EACH 100.5 SMT .25W 1206 1%

“R5, R7, R16, R25, R64, R87, R108,”

“R109, R118, R205, R207, R216, R225,”

“R287, R2108, R2109, R2118”

58-10035 8 EACH 1K SMT .25W 1206 1%

“R55, R57, R100, R103, R255, R257,

R2100, R2103”

58-10045 47 EACH 10K SMT .25W 1206 1%

“R1, R3, R4, R15, R18, R20, R34, R46, R47,”

“R59, R60, R61, R62, R66, R67, R71, R73,”

“R77, R78, R79, R111, R112, R114,”

“R116, R201, R203, R204, R215, R218,”

“R220, R234, R246, R247, R259, R261,”

“R262, R266, R267, R271, R273, R277,”

“R278, R279, R2111, R2112, R2114, R2116”

58-10055 10 EACH 100K SMT .25W 1206 1%

“R10, R14, R28, R93, R113, R210, R214,”

“R228, R293, R2113”

58-10065 2 EACH 1M SMT .25W 1206 1%

“R88, R288”

58-15035 2 EACH 1.5K SMT .25W 1206 1%

“R80, R280”

58-15045 6 EACH 15K SMT .25W 1206 1%

“R27, R32, R58, R227, R232, R258”

58-15055 2 EACH 150K SMT .25W 1206 1%

“R102, R2102”

58-18035 4 EACH 1.8K SMT .25W 1206 1%

“R45, R50, R245, R250”

58-22015 2 EACH 22.1 SMT .25W 1206 1%

“R86, R286”

58-22025 2 EACH 220.5 SMT .25W 1206 1%

“R9, R209”

58-22035 13 EACH 2.2K SMT .25W 1206 1%

“R11, R21, R43, R44, R99, R101, R107, R211,”

“R221, R243, R244, R299, R2101”

58-22045 16 EACH 22K SMT .25W 1206 1%

“R2, R12, R19, R30, R56, R68, R69,”

“R74, R94, R202, R219, R256, R268,

R269,”

“R274, R294”

58-22055 2 EACH 220K SMT .25W 1206 1%

“R65, R265”

58-27045 2 EACH 27K SMT .25W 1206 1%

“R38, R238”

58-33035 8 EACH 3.3K SMT .25W 1206 1%

“R24, R41, R42, R49, R224, R241, R242 , R249”

58-39035 1 EACH 3.9K SMT .25W 1206 1%

R83

58-43045 2 EACH 43K SMT .25W 1206 1%

“R35, R235”

58-47025 4 EACH 470.5 SMT .25W 1206 1%

“R53, R54, R253, R254”

58-47035 7 EACH 4.7K SMT .25W 1206 1%

“R17, R22, R40, R106, R240, R217, R216”

58-47045 12 EACH 47K SMT .25W 1206 1%

“R6, R48, R81, R104, R105, R206, R115,

R248, R281,”

“R2104, R2105, R2115”

58-47055 4 EACH 470K SMT .25W 1206 1%

“R70, R117, R270, R2117”

58-56035 1 EACH 5.6K SMT .25W 1206 1%

R85

58-68015 9 EACH 68.5 SMT .25W 1206 1%

“R23, R33, R51, R84, R97, R223,”

“R233, R251, R297”

58-68035 4 EACH 6.8K SMT .25W 1206 1%

“R36, R82, R236, R282”

58-68045 6 EACH 68K SMT .25W 1206 1%

“R29, R37, R39, R229, R237, R239”

58-91025 2 EACH 910.5 SMT .25W 1206 1%

“R52, R252”

60-20060 1 EACH TRANSIENT VOLT SUPP 200V 600W

Z1

60-22020 1 EACH IC PRIMARY VIPER 20 8P DIP

VP1

60-25011 1 EACH IC OPTO COUPLER ISOLATOR

OP3

60-40002 1 EACH THERMISTOR 40ohm 2amp 20%

TR1

60-50253-1 6 EACH OPTO ISOLATOR VACTROL AXL TEST

“OP1, OP2, OP3, OP201, OP202, OP203”

60-75320 22 EACH LED RED DIFFUSED 3MM T-1.00

“D1, D4, D6, D7, D8, D9, D10,”

“D17, D18, D21, D23, D201, D204, D206,”

“D207, D208, D209, D210, D217,”

“D218, D221, D223”

60-75330 11 EACH LED GREEN DIFFUSED 3MM T-1.00

“D3, D5, D12, D13, D14, D15, D205,”

“D212, D213, D214, D215”

60-75340 4 EACH LED YELLOW DIFFUSED 3MM T-1.00

“D2, D22, D202, D222”

61-47450 1 EACH DIODE ZNR REG 1N4745A 16V 1W

Z2

62-06001 7 EACH DIODE ULTRA FAST 600V 1A SMA

“D25, D26, D27, D31, D32, D33, D34”

62-19140 9 EACH 1N914 HI SPD SMT 250mW DIODE

“D11, D16, D19, D20, D24, D28, D219, D220,

D224”

62-20430 6 EACH NJM2043SMT(TESTED) DUAL HFREQ

“A1, A2, A11, A201, A202, A211”

62-29010 12 EACH NJM2901SMT QUAD COMP

“A5, A6, A7, A8, A10, A12, A204,”

“A205, A206, A207, A208, A212”

62-45650 8 EACH NJM4565 SMT DUAL HI FREQ

“A3, A4, A9, A13, A17, A203, A209, A213”

62-54001 10 EACH MMBT5401LT1 PNP SOT-23 SMT

“Q1, Q2, Q4, Q5, Q7, Q201, Q202, Q204,”

“Q205, Q207”

62-55500 2 EACH MMBT5550 NPN SOT-23

“Q3, Q203”

70-12015 1 EACH FUSE 320 1.50A SLOW 5X 20MM

F1

71-09012 2 EACH POT 9 D-P 25F 10K THREAD

“P2, P202”

71-09210B 2 EACH “POT 9 “”D-P”” 25F 10C10K BLACK”

“P4, P204”

71-09250 2 EACH POT 9 D-P 25F B50K THREAD BLK

“P7, P207”

71-09251A 2 EACH POT 9 D-P 25F B10K THREAD LTGR

“P1, P201”

71-09500 8 EACH POT 9 D-P 25F 500K THREAD

“P3, P5, P8, P9, P203, P205, P208, P209”

71-24450 2 EACH POT VERT TRIMMER 500ohm

“P11, P211”

Loading...

Loading...