Page 1

MOBILE REFRIGERATORS

MODELS: PHB7S & PHB12S

OWNER / OPERATOR’S MANUAL

MANUFACTURED BY:

CARTER-HOFFMANN

1551 McCormick Avenue

Mundelein, IL 60060 U.S.A.

Phone: 847-362-5500

Fax: 847-367-8981

Toll Free: 800-323-9793

Email: TechnicalService@Carter-Hoffmann.com

Before using, familiarize

yourself with the heater

controls. Read entire manual

before operating this cart.

PHB12S

CAUTION: EQUIPMENT ELECTRICAL DAMAGE

Do not plug in or use this appliance until all Installation Instructions are read and followed.

This manual is considered to be a permanent part of this appliance and must remain with the appliance if it is sold or

moved to another location

GENERAL INFORMATION

This appliance is intended for use in commercial establish-

ments, where all operators are familiar with the appliance

use, limitations and associated hazards.

Operating instructions and warnings must be read and un-

derstood by all operators and users.

This appliance is intended for use to holding perishable

foods for human consumption. No other use is recommended or authorized by the manufacturer or its agents.

Cleanliness of this appliance is essential to good sanitation.

Read and follow all included cleaning instructions and

schedules to ensure the safety of the food product.

All included trouble shooting guides, component views and

parts lists are included for general reference, and are intended for use by qualified service personnel.

Knowledge of proper installation, operation and maintenance

procedures is essential to ensure the safe operation of this

oven.

SERVICE / SAFETY

Always have dry hands prior to using the piece of equipment.

Turn OFF the unit (not all units have power switches) any-

time the cabinet is not in use.

If an electrical shock is felt when touching the cabinet, dis-

connect the power immediately and call Carter-Hoffmann

Technical Service for assistance.

If the power cord is frayed or the plug damaged, DO NOT

plug into the electrical power receptacle. If it is already

plugged in, turn off the main circuit breaker, usually located

in the building’s breaker box, then disconnect the plug.

Disconnect the power cord before attempting any repairs to

the cabinet.

Repairs to this unit must be by qualified personnel.

DO NOT SPRAY WITH WATER OR CLEANING SOLU-

TIONS, or submerge the appliance. Components and wiring

present a high shock hazard when wet.

Disconnect from power when cleaning cabinet.

NSF7

TABLE OF CONTENTS

UNPACKING AND INSTALLATION 2

CLEANING 3

CONTROLLER OPERATION 4

DAILY OPERATION 5

WIRING DIAGRAMS 6

MAINTENANCE & REPLACEMENT PARTS 7

SERVICE AND SHIPPING DAMAGE PROCEDURE 8

WARRANTY 9

Part Number: 18400-3237 Printed in the United States of America 092716KBA

Page 2

UNPACKING AND INSTALLATION

CAUTION: Electric Shock Hazard

All servicing requiring access to non-insulated components must be performed by qualified service personnel. Do

not open any access panels which require the use of tools. Failure to heed this warning can result in electrical

shock. Disconnect this appliance from electrical power before performing any maintenance or servicing.

WARNING: Injury Hazard

All installation procedures must be performed by qualified personnel with full knowledge of all applicable electrical

codes. Failure could result in property damage and personal injury.

WARNING Electric Shock Hazard

Appliance must be plugged into a properly grounded receptacle to prevent possible shock hazard. Electrical shock

will cause death or serious Injury.

WARNING:

Risk of personal injury

Installation procedures must

be performed by a qualified technician

with full knowledge of all applicable

electrical codes. Failure can result in

personal injury and property damage.

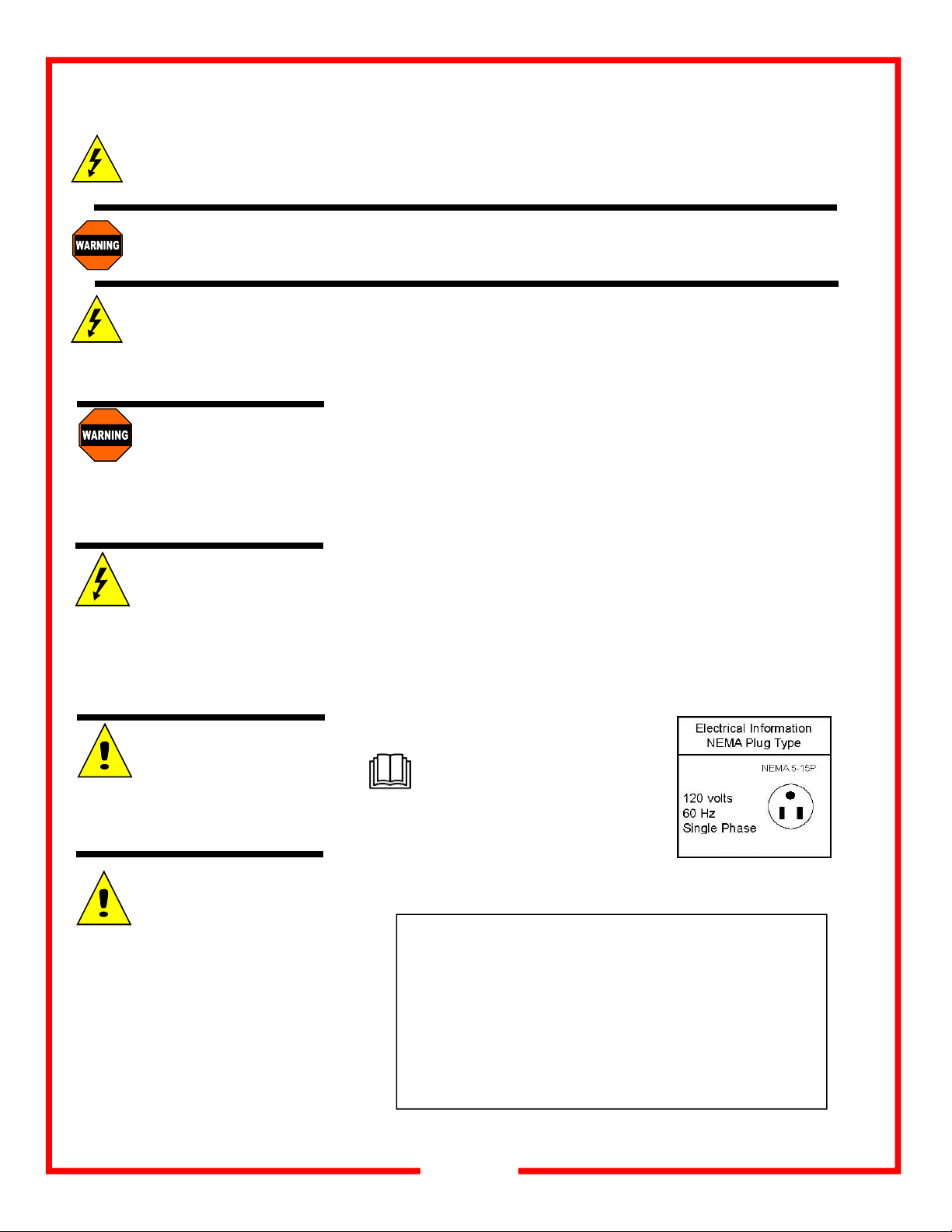

CAUTION:

Electrical Shock Hazard

The ground prong of the power cord is

part of a system designed to protect

you from electric shock in the event of

internal damage. DO NOT cut off the

large round ground prong or twist a

blade to fit an existing receptacle.

IMPORTANT:

Power cord is 10' long.

If necessary, contact a li-

censed electrician to install

an appropriate 15 amp electrical circuit with NEMA 5-15R receptacle. DO

NOT use an extension cord.

IMPORTANT:

Damage to unit due to being

connected to the wrong volt-

age or phase is NOT covered

by warranty.

Unpack the cart and any accessories included. Ensure that all packing materials and protective plastic has been removed from the unit. Inspect all components for completeness and condition.

NOTE: DO NOT discard the carton or other packing materials until you have

inspected the appliance for hidden damage and tested it for proper operation.

Refer to SHIPPING DAMAGE CLAIM PROCEDURE on PAGE 8 of this manual.

Appliance should be thoroughly cleaned before use. See CLEANING INSTRUCTIONS, page 3.

Plug the cabinet into a properly grounded NEMA 5-15R electrical receptacle.

DO NOT MODIFY CORD PLUG.

INSTALLATION CLEARANCES: Areas at the top and front of unit must remain

open and unobstructed. A clearance of 6” minimum must be maintained on the

left, right and back sides of the unit.

Before using, familiarize

yourself with the heater

controls. Read entire manual

before operating this cart.

5.5 running amps

GROUNDING INSTRUCTIONS

This appliance is equipped with a cord having a grounding wire

with a grounding plug which must be plugged into an outlet that is

properly installed and grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electrical current.

WARNING-Improper use of the grounding can result in a risk

of electric shock. Consult a qualified electrician or service agent if

the grounding instructions are not completely understood, or if

doubt exists as to whether the appliance is properly grounded.

2

Page 3

CLEANING

WARNING: ELECTRIC

SHOCK HAZARD

Unplug the unit from

electric po wer before

performing cleaning or maintenance.

WARNING: ELECTRIC

SHOCK HAZARD

DO NOT spray or splash

water on the control panel

or wiring.

CAUTION: CART

DAMAGE

Do not tip cart onto the

doors to drain excess

water. Permanent damage to the

doors and hinges will result. Use a

clean dry cloth to mop any excess

water inside cabinet after cleaning.

Turn the main power switch OFF and unplug the cabinet to before cleaning. DO

NOT spray or splash water on the electrical components, control panel, timer or

wiring.

1. Racks or shelves are easily removed without tools for cleaning, Simply lift up

and pull out. The tray racks may be hand washed or run through an automatic

washer.

2. To clean stainless steel surfaces use only cleansers, detergents, degreasers,

or sanitizers that are certified to be "chloride-free" and "phosphate-free," and

cleansers, degreasers, or sanitizers only in the recommended concentrations.

DO NOT exceed recommended concentrations or mixing ratios. After cleaning and sanitizing, rinse all exposed surfaces thoroughly with large amounts

of clean, clear water. Wipe off any standing liquid or residue from all surfaces,

corners and rear edges.

3. Vinyl trim should be washed with a chlorine-free detergent and water. Rinse

thoroughly with clear water and allow to dry. Never use abrasive clean ers,

waxes, car polish, or substances containing strong aromatic solvents or alcohol. Use of direct steam / hot water cleaning at temperatures above 190°F

may result in “bubbling” or loosening of vinyl adhesive.

4. After all parts are dry, reinstall them and then plug the cabinet back into electrical source.

IMPORTANT: Cleansers, detergents, degreasers, sanitizers or bleaching agents that contain chlorides or

phosphates will cause permanent damage to stainless steel products. This damage appears as pits,

eruptions, voids, small holes, cracks, severe discolorations or dulling of the metal finish. Water with a high

chlorine content can also damage stainless steel. If unsure of your water quality, we recommend you ha ve it

tested. THIS DAMAGE IS PERMANENT, COSTLY TO REPAIR, AND IS NOT COVERED BY WARRANTY.

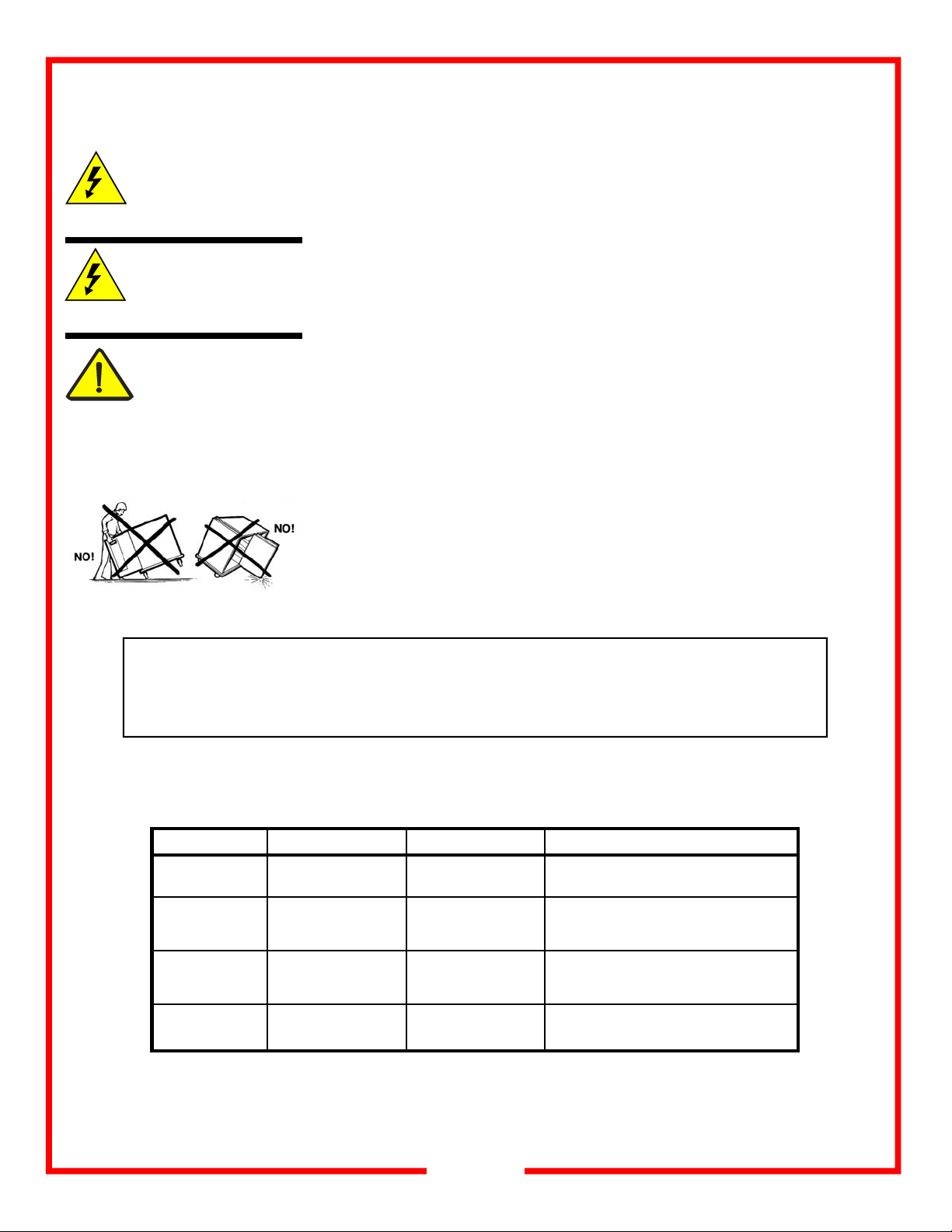

RECOMMENDED "TIPS" FOR CLEANING STAINLESS STEEL

PURPOSE FREQUENCY CLEANING AGENT METHOD OF APPLICATION

Routine

cleaning

Smears

and

fingerprints

Stubborn spots

and

stains

Hard

water spots

Daily Soap, ammonia,

detergent and water

As needed Stainless steel cleaner,

similar products

Daily or as needed Any chloride-free or

phosphate-free

cleanser

Daily or as needed Vinegar Swab with cloth.

Swab with cloth.

Rinse with clear water, wipe dry.

Rub with cloth as directed on package.

Rub in direction of grain of stainless steel.

Do not use on vinyl trim or control panel.

Apply with damp sponge or cloth.

Rub in direction of grain. Rinse thoroughly.

Do not use on vinyl trim or control panel.

Rinse with clear water, wipe dry.

3

Page 4

Controller

CONTROLLER OPERATION

TO CHANGE THE SET-POINT

1. Access the “Machine Status” menu by pressing the SET key

2. To display the set point value, press the Set key when “Set” is displayed. The set point v alue appe ars on the displ ay.

To change the set point value, press the UP and DOWN keys within 15 seconds. Press SET to confirm the change.

3. Return to the previous screen, press the STAND-BY key once, or do not press any keys for 15 seconds.

4

Page 5

PHB12S

DAILY OPERATION

PHB refrigerators are capable of cooling to a temperature of 32°F (O°C). Precooling time to 40°F (4°C) is approximately 40 minutes. Only product that has

been pre-chilled should be placed into the cabinet. Placing warm product will

elevate the cabinet air temperature above 40°F (4°C) . This will have a direct

effect on optimum serving temperatures.

Due to various conditions such as extremely high kitchen temperatures and/

or humidity, high frequency of tray activity and excessively long op erations,

the door may need to be closed so the unit can recover to proper op erating

temperature.

1. Pre-chill empty cabinet with the door closed for approximately 40

minutes. Always keep the door closed, except when actually loading or

unloading the cabinet. Do not load the cabinet until the proper operating

temperature has been reached (34°-40°F for refrigerators. Po wer switch

will illuminate when cabinet is “ON”.

2. Load the cabinet from the bottom to the top. After loading, close the

door and allow the inside air temperature to recover.

3. If necessary, unplug and move cabinet to serving area. Plug cabinet

back in immediately upon arrival.

4. Unload the cabinet from the top down.

5. Close the door during slow periods to extend the effective temperature

maintenance time.

Remember: the refrigerator must be at proper

temperature before the door is opened.

The cabinet will not lower food temperatures with the door open.

The cabinet is equipped with an automatic condensate ev aporator. To prevent water spills, leave the unit plugged in, with the door closed for at least 90

minutes after use.

5

Page 6

PHB7S & PHB12S Refrigerators

115-100v, 8.5 running amps, 50/60 Hz

Standard Electric

WIRING DIAGRAM

CF = Condenser Fan

C = Compressor

EF = Evaporator Fan

RW = Drainage Heater

PB1 = Cabinet Probe

PB2 = Defrost Probe

7

6

Page 7

GENERAL MAINTENANCE INSTRUCTIONS

WARNING

Never move cart unless

all doors are securely

closed. Serious damage

to hinges and doors may result if

bumped into walls, tables, or other

equipment when the doors are open.

DOORS

Never tip cart forward or open doors to drain water during or after washing. This can

cause serious damage to the hinges, doors and latches.

CASTERS

Some casters are equipped with Zerk grease fittings so that they may be easily lubricated with a grease gun. Recommended lubrication is at least once every six months.

Lubrication will be required more frequently if carts are cleaned with a hot water or

steam cleaning system. Casters with special bearings are recommended for frequent

cart wash or steam cleaning situations.

HINGES

Your cart doors and hinges have been factory aligned with nylon spacers to assure

positive latching and smooth action. Be sure to replace these washers if the are removed when cleaning doors and hinges. If doors are removed for cleaning, we recommend that they be put back on the same cart to assure the best possible alignment and

operation.

LATCHES

Check frequently to insure that all door latches are secure. Latches may become

“sticky” due to residue build-up from daily use and cleaning. Lubricate latches regularly

with WD-40, silicone spray, graphite or other commercial lubricants for stainless steel

products. Do not use oil.

PERIMETER BUMPERS

Vinyl which has been dislodged from the channel due to severe bumping or scraping

can be pried back into place with a common screwdriver.

WARNING

Use only (OEM) original

equipment manufacturer

unauthorized parts may cause serious

injury. Replacement parts should be

installed by a qualified technician.

replacement parts. Using

Part Numbers

REPLACEMENT PARTS

Contact factory with your model and serial number for replacement

components.

Factory Recommended Charge of Refrigerant:

PHB7S, PHB12S: 15.9 Oz. R404A

7

Page 8

SERVICE EXPECTATIONS

SERVICE PHILOSOPHY

For almost sixty years, Carter-Hoffmann has enjoyed a reputation for manufacturing rugged, dependable

foodservice equipment that permits foodservice professionals serve more food products to more

people, and thus, to grow their business.

Our goal is not only to provide the best food service equipment for the price, but also to back it up with after-sale

service that is responsive fast, efficient and professional. To ensure a clear understanding of our goals, expectations, and responsibilities, we have prepared this brief document.

Carter-Hoffmann products are innovative and efficient. They are easy to use, easy to clean and easy

to maintain. Although the products are quite reliable they are also designed for easy repair. We believe that a malfunction to a Carter-Hoffmann product should cause as little inconvenience to the customer as possible. Our aim is

to provide “same day”/first time fix” repair service on all of our products. We are dedicated to making every aspect

of our customer service the standard by which others are judged.

END-USER RESPONSIBILITIES

While we all strive to serve our mutual customers as well as possible that does not mean that

the end-user (including his employees) does not share some responsibilities.

1. All shipping damage must be noted on the freight bill when the shipment is received. Any freight

damages must be collected from the Freight Company, NOT Carter-Hoffmann.

2. The end-user should be advised beforehand to carefully unpack and inspect all products when they are received

BEFORE SIGNING THE SHIPPER'S RECEIPT OF DELIVERY.

3. The end-user must provide a safe, dry, level surface for the equipment to be placed upon.

4. The end-user must provide the proper electrical supply. All in-wall electrical modifications are to

be completed by a licensed electrician. All building modifications are the responsibility of the end-user.

5. The end-user must operate, clean and maintain the equipment in accordance with the

procedures described in the Operation Manual.

6. Carter-Hoffmann is NOT responsible for any loss of the customer’s income, loss of food product, extra labor

charges, or any other incidental or consequential costs as a result of the malfunction of our product.

7. The end-user shall allow for on-premises repair of the equipment to be completed at a mutually

convenient place and time.

WARRANTY SERVICE

1. Warranty service is to be initiated by authorized Carter-Hoffmann personnel only.

2. The service provider is NOT authorized to change or extend any of the terms or conditions of our warranty.

3. Initial freight damage is NOT covered by the product warranty.

CONFIDENTIALITY

1. The end user and all his employees and sub-agents shall protect and kee p confidential Carter-Hoffmann’s proprietary designs, information, and knowledge.

2. All literature and informational materials provided by Carter-Hoffmann are to be cons idered confidential; they

remain Carter-Hoffmann’s property; and are not to be reproduced without our prior written consent.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in this shipment was carefully inspected a nd packaged by skilled

personnel before leaving the factory. Upon acceptance of this shipment, the trans portation company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on the freight bill or express receipt,

and that the note of loss or damage is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY: Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is unnoticed until the merchandise is unpacked, notify the transportation

company or carrier immediately, and file “CONCEALED DAMAGE” claim with them. This should be done within ten (10)

days from the date the delivery was made to you. Be sure to retain the container for inspection.

4. Carter-Hoffmann cannot assume liability for damage or loss incurred in transit. We will, however, at your request, supply you with the necessary documents to support your claim.

8

Page 9

WARRANTY

Carter-Hoffmann Warranty:

Carter-Hoffmann (“CARTER-HOFFMANN”) warrants to the initial purchaser of its standard Carter

Line Products that CARTER-HOFFMANN will, at its option, repair or replace, during the warranty

period set forth below, any part of such products made necessary due to a defect in material or workmanship which is present when the product leaves its factory and which manifests itself d ur ing th e warranty period under normal use and service.

This warranty applies only to original equipmen t owned and possessed b y the in itial purchaser an d the

warranty period begins on the date of original shipment from the CARTER-HOFFMANN factory and

extends as follows: to component parts and labor for 12 months (36 months on hotLOGIX and

VAPORPRO holding cabinets and cook & hold cabinets); to refrigeration compressor unit for one

year (limited to replacement only - not to include labor for removal, repair or replacement).

Repair or replacements under this warranty will be performed, unless otherwise authorized in writing

by CARTER-HOFFMANN, at its factory. All parts or components to be repaired or replaced under this

warranty are to be shipped prepaid to CARTER-HOFFMANN, with reimbursement credit for such part

or component to be given if found by CARTER-HOFFMANN to be defective.

CARTER-HOFFMANN neither makes nor assumes and does not authorize any other person to make or

assume any obligation or liability in connection with its pro ducts other than that covered in this warranty. This warranty applies only within the continental United States and Canada. In Alaska and Hawaii, this warranty applies only to and is limited to the supply of replacement parts.

Warranty Exclusions and Limitations:

Any implied warranty of merchantability or fitness for a particular purpose is hereby specifically dis-

claimed by CARTER-HOFFMANN. There are no warranties, expressed or implied, which extend be-

yond the description on the face hereof. This warranty does not cover and CARTER-HOFFMANN shall

not under any circumstances be liable for any incidental, consequential or other damages (such as in-

jury to persons or property, loss of time, inconvenience, loss of business or profits, or other matters not

specifically covered) arising in connection with the use of, inability to use, or failure of these products.

Specifications subject to change through product improvement and innovation.

Carter-Hoffmann

1551 McCormick Ave.

Mundelein, Illinois, 60060 USA

Phone: 847-362-5500 Toll free: 800-323-9793 Fax: 847-367-8981

Sales and Marketing E-mail: sales@carter-hoffmann.com

Service E-mail: technicalservice@carter-hoffmann.com

Company Website: www.carter-hoffmann.com

9

Loading...

Loading...