Page 1

NEW

Zone Manager

INST ALLA TION MANUAL

•

L

L

O

Y

D

'

S

R

E

G

I

S

T

E

R

Q

U

A

L

I

T

Y

A

S

S

U

R

A

N

C

E

I

S

O

9

0

0

1

40KMC---N

42HMC---N

42VMC---N

40SMC---N

Page 2

Zone Manager

ENGLISH

GB - 1

This control system only operates with indoor units of the following models:

42HMC---N Hi-Wall, 42VMC---N Console & Underceiling, 40SMC---N Satellite and 40KMC---N Cassette.

For installation instructions of this unit, refer to the relevant manuals.

Contents

Page

General information.................................................................................... 2

Characteristics............................................................................................ 2

Choosing the installation site...................................................................... 3

Installation .................................................................................................. 4

Electrical connections................................................................................. 5/6

Configuration .............................................................................................. 7/12

Unit zone addressing.................................................................................. 13

Test System ................................................................................................ 13

Smart Start function.................................................................................... 14

Trouble Shooting ........................................................................................ 15

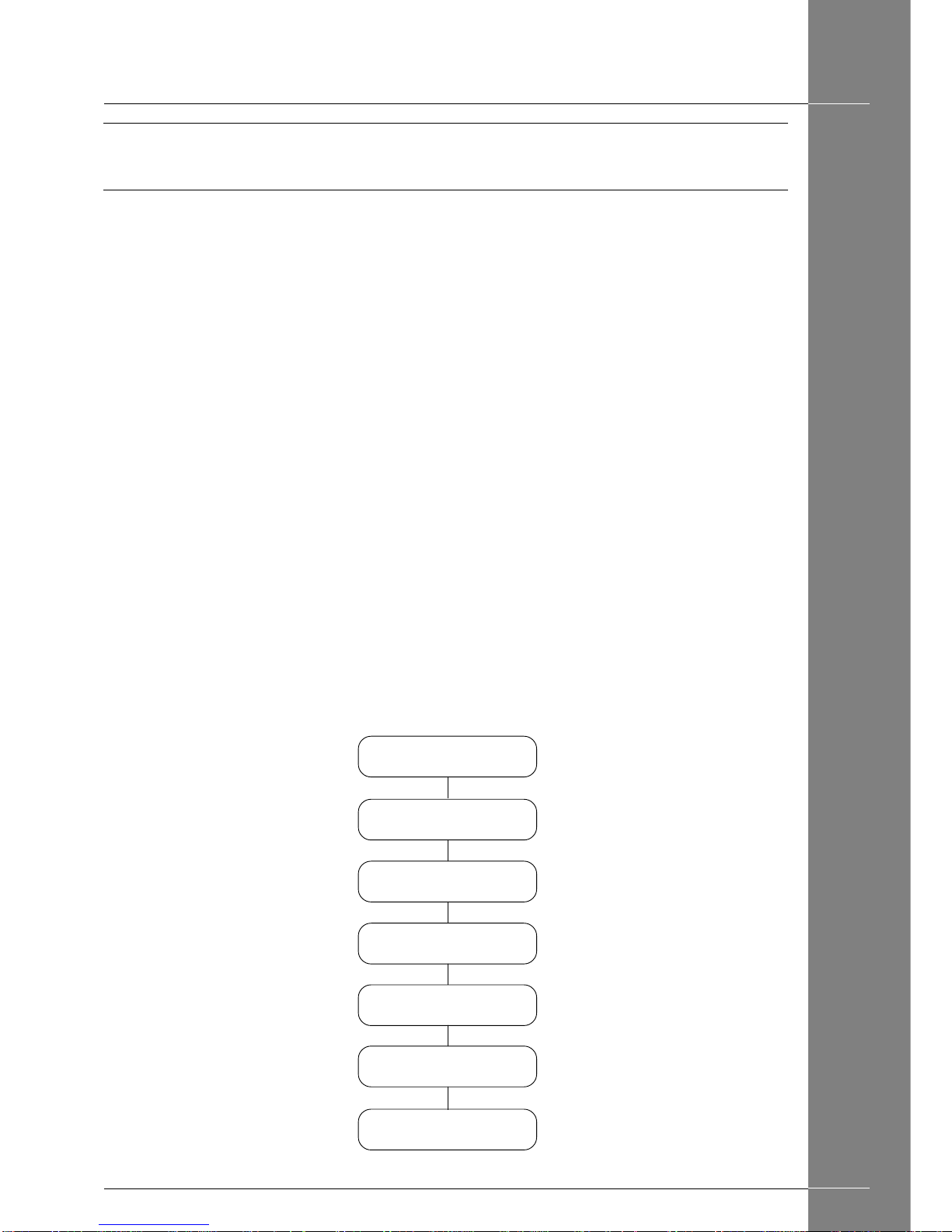

Installation Flow Chart

Read manual

Install

Zone Manager

Wire Zone Manager

and unit network

Configure

Zone Manager

Address unit by zone

Test System

Operate

Zone Manager

Installation manual

Page 3

GB - 2

Zone Manager

General information and characteristics

IMPORTANT:

Read this instruction manual thoroughly before starting

the installation.

• For trouble-free installation, which should be carried out by a

qualified installer, follow the installation chart sequence.

• Follow all current national safety code requirements. In particular

ensure that a properly sized and connected ground wire is in place.

• After installation thoroughly test the system operation and

explain all system functions to the owner.

• Leave this manual with the owner for consultation during

future periodic maintenance.

• Dispose of packaging material in accordance with local

requirements.

• The manufacturer denies any responsibility and warranty shall

be void if these installation instructions are not observed.

• Inspect equipment for damage due to improper transportation

or handling: file an immediate claim with the shipping company.

Do not install or use damaged units.

• In case of any malfunctioning turn the unit off, disconnect the

mains power supply and contact a qualified service engineer.

Models

There is only 1 model, which is easily configurable for all installations.

Products that the Zone Manager can Interface

40 KMC---N CASSETTE

42 HMC---N HI-WALL

42 VMC---N CONSOLE

40 SMC---N SATELLITE

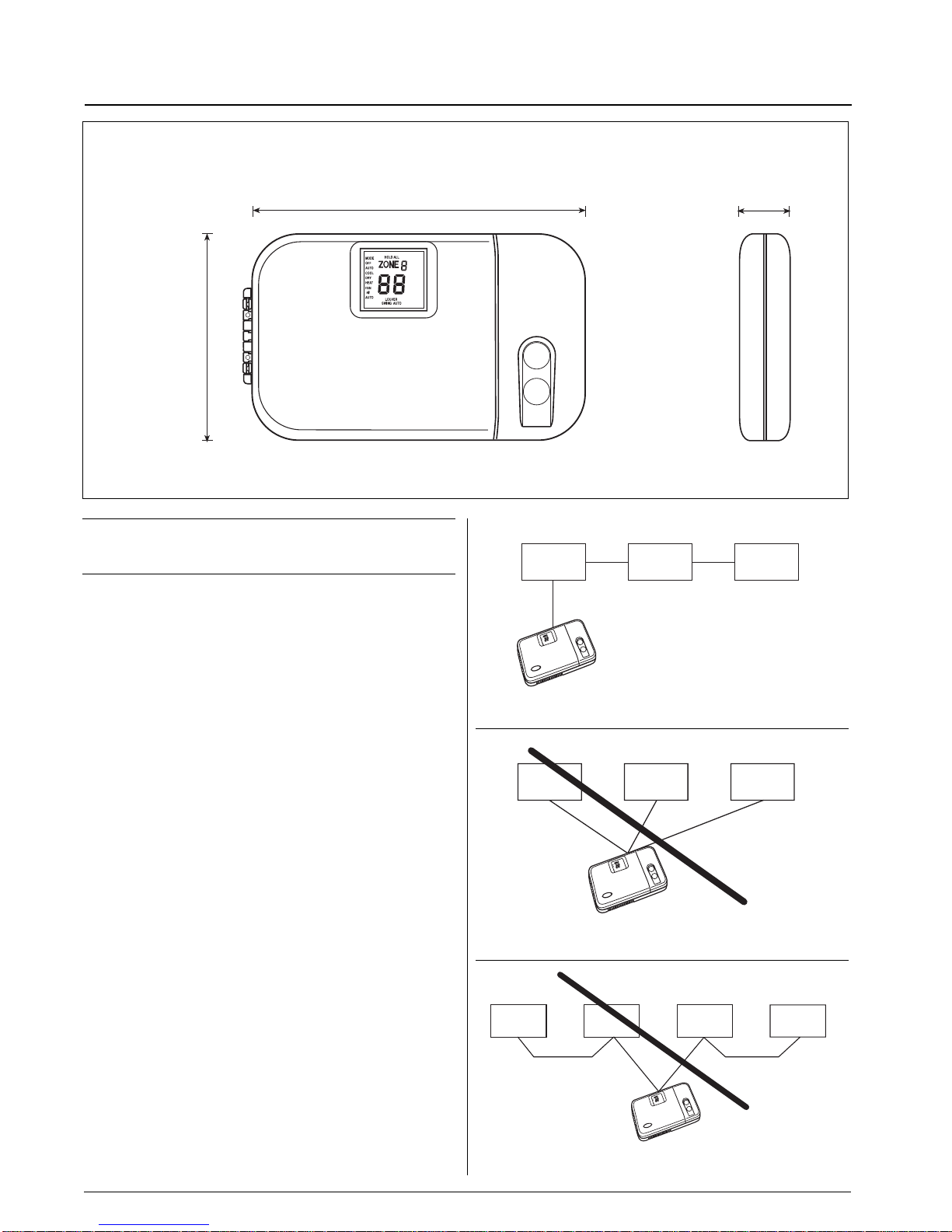

Wiring

• The Zone Manager can be connected to one unit (that is the

first in the network).

• Each unit must be connected one after the other (daisy chain).

• If the Zone Manager is to use its room sensor the controller has to

be located in the same area as the addressed unit(s) number 1.

Power

Note that the Zone Manager requires no batteries and is not

"power stealing". It requires 12 VDC to be connected for proper

operation, which is easily obtained from any of the unit by

means of an auxiliary board.

The Zone Manager will not operate without this connection.

Dimensions (mm)

Unit 1

Unit 2

Unit 3

Zone Manager

Unit 1

Unit 2

Unit 3

Zone Manager

Unit 1

Unit 2

Unit 3

Zone Manager

Unit 4

Not recommended TEE connection

Incorrect layout must not be used Start Layout

Correct layout Daisy chain

107,9

190,5

39

Page 4

GB - 3

Zone Manager

ENGLISH

Choosing the installation site

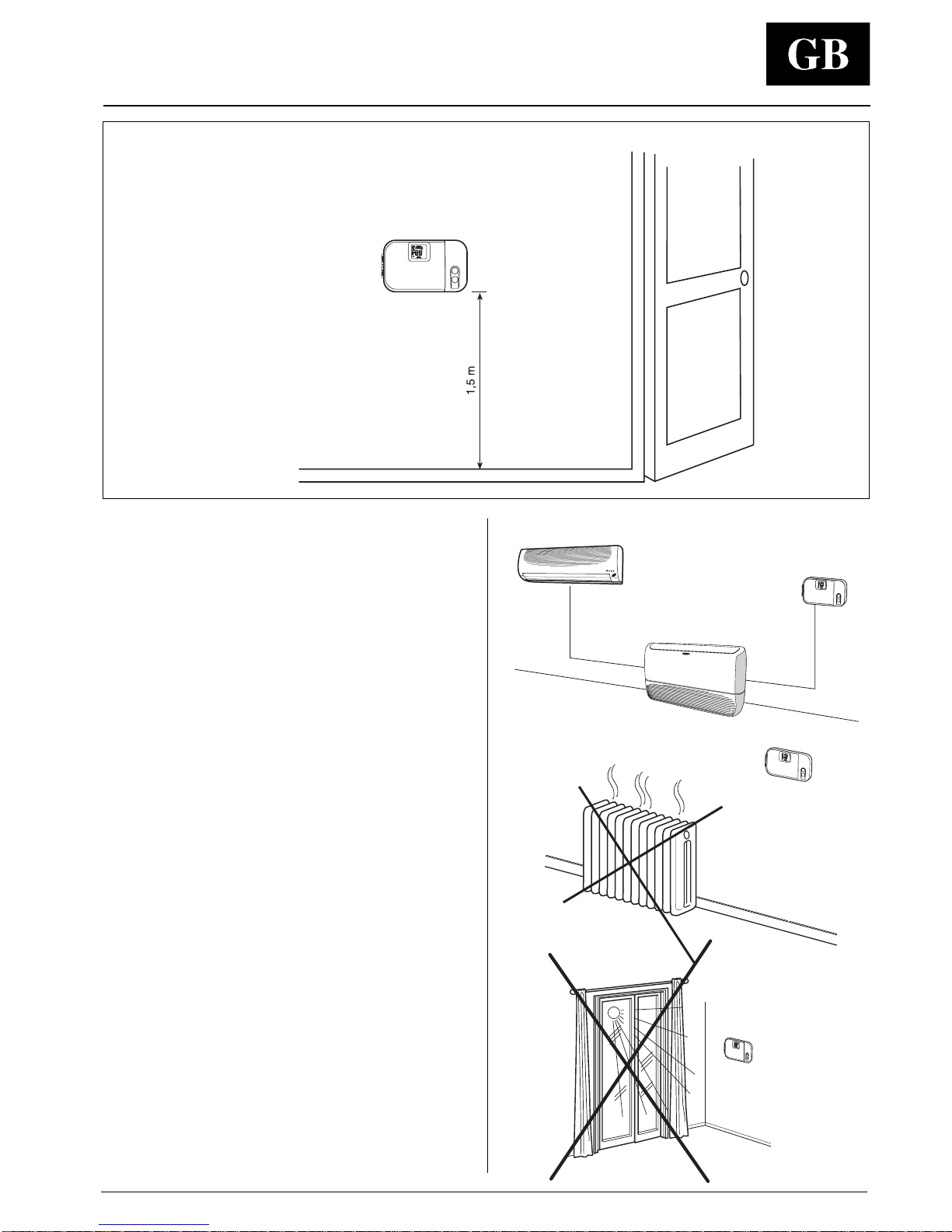

The Zone Manager Location

The Zone Manager can be located anywhere.

However, if the installation requires the systems in the location

in zone 1 to use the Air Sensor on the Zone Manager; then, the

controller should be mounted:

• Approximately 1.5 m from floor.

• In the same area where the units from group are located,

preferably on an inside partitioning wall.

• On a section of wall without pipes or duct work.

If the air sensor on the Zone Manager has been selected, it

should NOT be mounted:

• Close to a window, on an outside wall, or next to a door

leading to the outside.

• Exposed to direct light or heat from a lamp, sun, fireplace, or

other temperature-radiating object which may cause a false

reading.

• Close to or in direct airflow of a heating or cooling supply.

• In areas with poor air circulation, such as behind a door or in

an alcove.

Minimum clearances

Page 5

GB - 4

Zone Manager

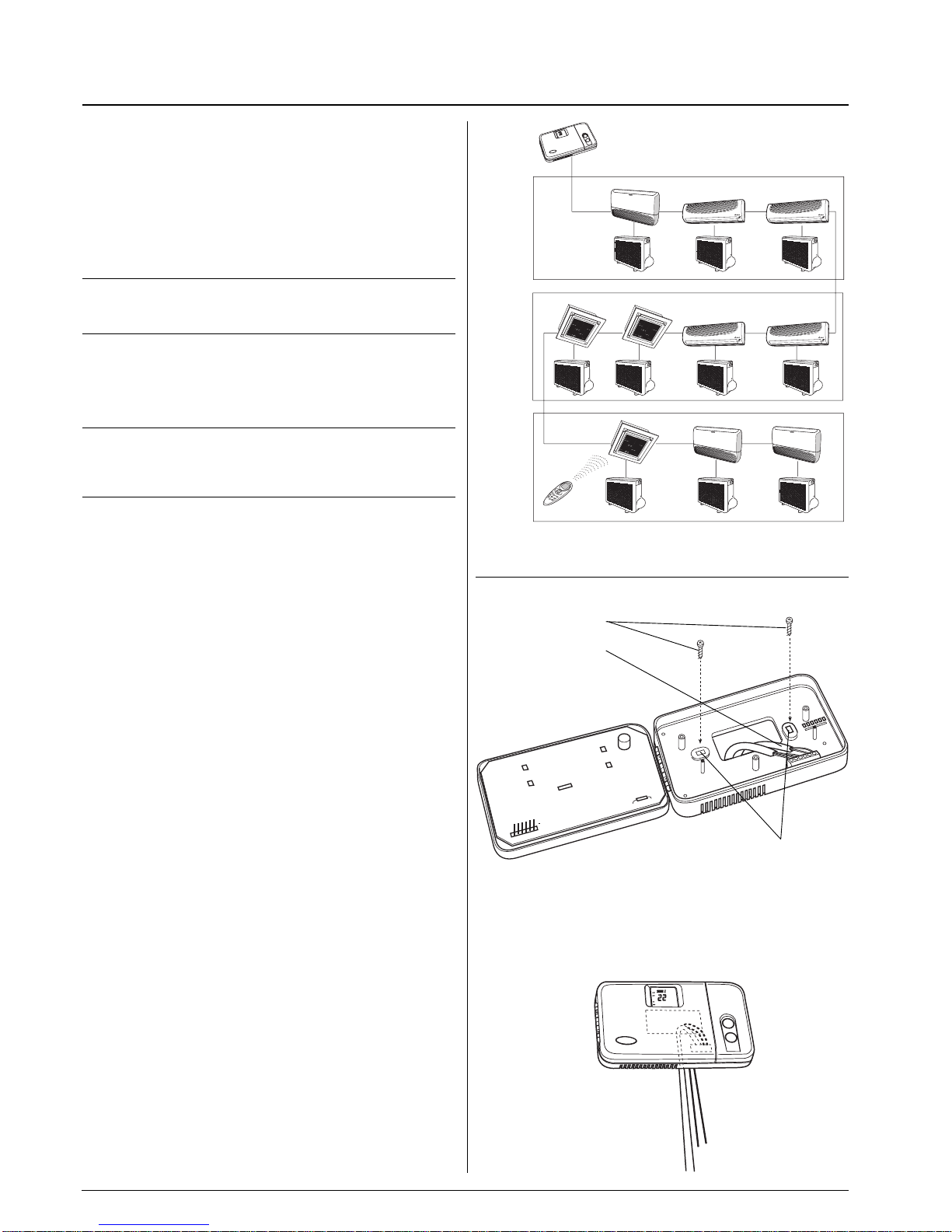

Considerations

• Maximum of 500 m of total network wiring.

• Maximum of 32 units allowed on a system.

• Maximum number of zones 8.

• Only zone 1 can use the room sensor located on the Zone

Manager.

Network wiring must be daisy chained.

CAUTION:

Star configuration can cause improper operation of the

Zone Manager.

Mounting

WARNING:

Before installing the Zone Manager, turn off all power to

the unit that will supply power to the Zone Manager.

Electrical shock can cause personal injury or death.

• Turn OFF all power to unit.

• Open the front door and unscrew the fixing screw placed

near the “FAN” and “LOUVER” keys.

• Open the Zone Manager rear door (mounting base) to expose

mounting holes.

The base can be removed to simplify mounting (snap apart

carefully at hinge to separate mounting base from remainder

of the Zone Manager).

• Route the Zone Manager wires through the large hole in the

mounting base.

Level mounting base against wall (for aesthetic value only the

Zone Manager need not be level for proper operation) and

mark the wall through the 2 mounting holes.

• Drill two 5 mm mounting holes in wall where marked.

• Secure mounting base to wall with 2 screws and anchors

provided, (additional anchoring holes available for more

secure mounting if needed) making sure all wires extend

through hole in mounting base.

• Adjust length and routing of each wire to reach the proper

terminal in the connector block on the mounting base, with 6

mm of extra wire (strip only 6 mm of insulation from each wire

to prevent adjacent wires from shorting together when

connected).

• Match and connect equipment wires to proper terminals in the

connector block (See section "Electrical connections").

Both power and communication wires must be connected

correctly for proper Zone Manager operation.

• Push any excess wire into the wall and against mounting

base.

If the air sensor is being used on the Zone Manager, seal

hole in wall to prevent air leaks.

Leaks can affect sensor operation.

• Snap hinge back together.

• Close the Zone Manager assembly making sure pins on back

of circuit board align with sockets in connector.

• Tighten the fixing screw placed on the unit keyboard.

Zone Manager

ZONE ..

ZONE 1

ZONE 8

Installation

Mounting

a Mounting screws

b Connection cables

c Holes

a

b

c

Page 6

GB - 5

Zone Manager

ENGLISH

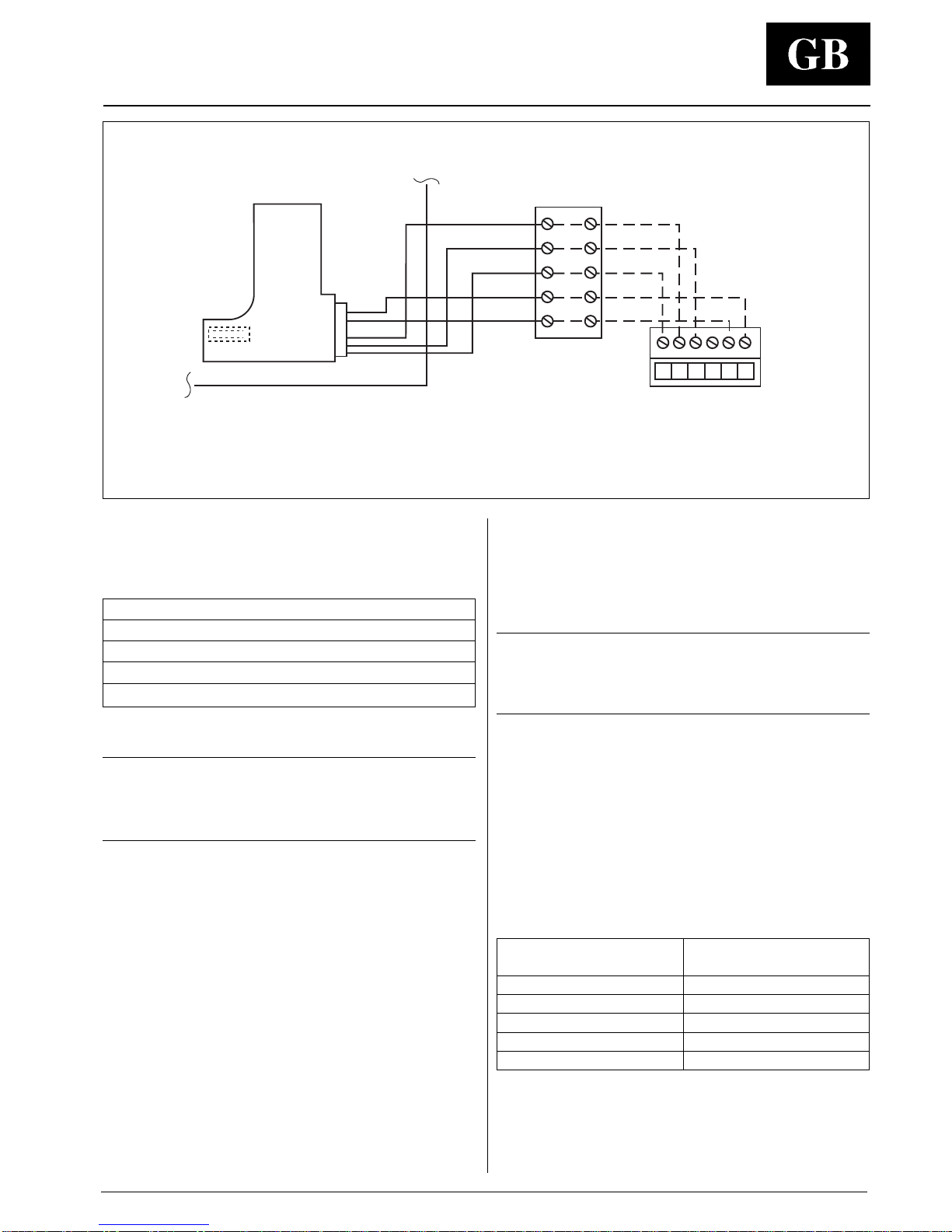

Electrical connections

a

b

c

d

e

f

+12V

GND

C

+RS485A

-RS485B

1

6

a Main board

b Communication board (supplied with the kit)

c 5-cable wiring

d Auxiliary terminal board (supplied with the kit)

e Wiring by the installer

f Zone Manager terminal board (supplied with the kit)

Installation of the kit into the unit

Skip this paragraph if the unit does not need the installation of

a kit.

Kit part number Unit type

40 KMC---N 33MC9001

40 SMC---N 33MC9001

42 HMC---N 33MC9001

42 VMC---N 33MC9001

CAUTION:

Improper wiring or installation may damage the Zone

Manager.

Check to make sure wiring is correct before proceeding

with turning on unit.

A communication board is required for all products that are

networked to a Zone Manager system.

Reference the table on products that the Zone Manager can

be networked with, it identifies whether an installation kit is

required or not.

If required:

• The kit includes a communication board, a pre-assembled 5cable wiring connected to a 6-way connector, 2 auxiliary

terminal boards and one user’s installation manual.

• The auxiliary terminal board (5 poles) must be secured to the

main terminal board, which is installed in the control panel

board of each indoor unit, by means of a fixing screw.

• By means of the J8 connector, connect the communication

board to the main board.

In the case of troubles during installation, remove the main

board from the control panel board.

Wiring Zone Manager to master unit

The Zone Manager has the ability to control up to 32 units.

To insure the correct operation of this system the wiring must

be installed using the following guidelines.

WARNING:

Before connecting any wiring to the Zone Manager , turn

off all power to the unit that will supply power to the Zone

Manager. Electrical shock can cause personal injury or

death.

The Zone Manager is connected to the master unit using the

following instructions. Reference Diagram 1 when making

these connections.

AUXILIARY BOARD AND ZONE MANAGER CONNECTION

• Unloose the screws of the auxiliary terminal board.

• Connect the auxiliary terminal board to the Zone Manager

terminal board as follows:

Auxiliary terminal Zone Manager

board terminals terminal board

+12V* Red +12V

GND* Black GND

A** White +R5485A

C** Grey C

B** Blue -R5485B

* use a 2x0,5 mm

2

double-insulated multiple cable.

** use a 3x0,5 mm

2

double-insulated multiple cable.

• Tighten the terminal board screws.

Diagram 1: wiring for Zone manager

WHITE

GREY

BLUE

RED

BLACK

A

C

B

12V

GND

Page 7

GB - 6

Zone Manager

Wiring for networking multiple units

Materials required for wiring multiple units into a network.

Reference Diagram 2 when doing this installation.

• Loosen the screws on terminals A, C , B, 12V and GND from

the auxiliary terminal board in all units.

• Connect the first terminal board to the other terminal boards:

1

st

Auxiliary 2nd Auxiliary 3rd Auxiliary _

terminal board terminal board terminal board _

AAA_

CCC_

BBB_

• Tighten all the screws.

CAUTION:

• The Zone Manager must only be connected to one single

auxiliary terminal board.

• Do not tie the shield to a GND post at more than 1

location.

Diagram 3: networking of multiple units

Electrical connections

a First indoor unit

b Second indoor unit

c Third indoor unit

d Zone Manager terminal board

1 Communication board

2 To the other main terminal boards

NOTE:

The shield for the communications cable is not connected at

the Zone Manager.

Terminate the shield in such a manner that it will not short with

anything in the Zone Manager.

Wiring Materials required

(supplied by installer)

• 1 small screwdriver

• 3 x 0,5 and 2 x 0,5 mm

2

multiple cables, double insulated.

Suggested type: H03VV-F.

Networking multiple units

Multiple units can be connected together and controlled by a

single Zone Manager.

Diagram 3 is a block diagram of multiple units networked into

a system controlled by 1 Zone Manager.

To accomplish this the communication boards from the networked

units must be wired together in a daisy chain configuration.

The following section describes how to do the wire installation

for a networked system.

Zone Manager

a

a Power connection

b Communication connections

b

UNIT 1 UNIT 2 UNIT 3 UNIT ....

a b c

+12V

GND

C

+RS485A

-RS485B

A

C

B

12V

GND

A

C

B

12V

GND

A

C

B

12V

GND

d

Diagram 2: multiple units in a network configuration

1

1

1

2

a Zone Manager

b Unit

WHITE

GREY

BLUE

RED

BLACK

Page 8

GB - 7

Zone Manager

ENGLISH

Configuration options are intended to be selected at installation

and normally are not modified by the end user.

These options are not discussed in the end user’s manual and

therefore must be made as part of the installation.

A special procedure allows entry into the configuration mode.

The Zone Manager will automatically exit this mode if no button

is pressed within 20 seconds.

While in configuration mode, 9 choices can be made:

• Fahrenheit (F) or Celsius (C) (Default: Celsius).

• Room Air Override ON or OFF (Default: OFF).

• Cooling only (C) or Heat Pump (H)

(Default: Heat Pump).

• Auto Mode Setback Deadband (Default 16): Value

Adjustment.

• Number of Zone Installed (Default 1): Value Adjustment.

• Smart Start ON or OFF (Default: ON).

• Military Time (ON) or Standard Time (OFF)

(Default: Standard Time).

• Local unit override ON or OFF (Default: OFF).

• Ability to not allow mode or schedule changes: Lock

(Default : UL, Unlocked)

In configuration mode ON is represented by the display "On"

and OFF is represented by the display "OF."

An explanation for each of these and how to enter the

configuration mode follows.

T o enter configuration mode

Press and hold the "FAN" button for approximately 5 seconds

until the normal display disappears and reads "1-" and either

"C" or "F". You are now in the configuration mode.

NOTE:

If no button is pressed for 20 seconds, the Zone Manager will

exit configuration mode and resume normal operation.

To re-enter configuration mode, "FAN" button must be pressed

and held again.

Configuration

up

down

1-

up

down

F

C

"SET TIME"

"SET TIME"

2-

On

OF

"SET TIME"

3-

"SET TIME"

"SET TIME"

"SET TIME"

"SET TIME"

"SET TIME"

up

down

up

down

H

C

up

down

up

down

4-

5....16

up

down

up

down

5- 1....8

up

down

up

down

6-

On

OF

up

down

7-

up

down

On

OF

up

down

up

down

8-

On

OF

up

down

up

down

"SET TIME"

9-

Lo

UL

up

down

Page 9

GB - 8

Zone Manager

T o change multiple configuration parameters:

To make another modification to configuration, depress the

"

SET TIME/TEMP" button. This will toggle between selecting the

Configuration Option and the Configuration Value.

To change the selection, press the "up" and "down" arrows

until the desired configuration selection is displayed.

1- FAHRENHEIT OR CELSIUS

Select between Fahrenheit (F) or Celsius (C) operation.

Factory default is Celsius.

To select while in configuration mode:

• The Configuration Option ("1-") and the current selection

should be displayed.

• Depress the "

SET TIME/TEMP" button to alter the current

selection (current selection will now blink).

• Use either the "up" or "down" button to change between "F" or "C".

• To end configuration, either depress the "

END PROGRAM" button

or do not press any buttons for 20 seconds.

2- ROOM THERMISTOR OVERRIDE

Select whether the units in zone 1 will use room temperature

sensor in the Zone Manager "

ON"or whether they will use the air

sensor at the units "

OF". Factory default is OFF.

If the chosen option is "

ON" the room air temperature will be

displayed.

CAUTION:

If the room air sensor on the Zone Manager is selected,

installation of the Zone Manager is critical.

To select while in configuration mode:

• Press the "up" or "down" button until "2-" is displayed.

• Depress the "

SET TIME/TEMP" button to alter the current

selection (current selection will now blink).

up

down

up

down

Configuration

Page 10

GB - 9

Zone Manager

ENGLISH

• Use either the "up" or "down" button to change between "OF"

(OFF) and "On" (ON).

• To end configuration, either depress the "

END PROGRAM" button

or do not push any buttons for 20 seconds.

3- COOLING ONLY OR HEA TPUMP: SELECTION

Select whether the system is a cooling only or Heat Pump system.

If there is a combination of cooling only and heatpump units on

the system, then Heat Pump must be selected.

Factory default is Heat Pump.

To select when in configuration mode:

• Press the "up" or "down" button until "3-" is displayed.

• Depress the "

SET TIME/TEMP" button to change the current

selection (current selection will now blink).

• Use either the "up" or "down" button to change between "H"

(Heat Pump) and "C" (Cooling only).

• To end configuration, either depress the "

END PROGRAM" button

do not push any buttons for 20 seconds.

4 -

AUTO MODE SETBACK DEADBAND: ADJUSTMENT

Select the number of degrees to setback the heating and cooling

setpoints while a unit is in auto mode during a setback period.

Factory default is 9°C (or 18°F).

To select when in configuration mode:

• Press the "up" or "down" button until "4-" is displayed.

• Depress the "

SET TIME/TEMP" button to change the current

selection (current selection will now blink).

up

down

up

down

up

down

up

down

Configuration

Page 11

GB - 10

Zone Manager

• Use either the "up" or "down" button to change the current

number of degrees to setback.

(Allowable selections are 4 at 18°C or 8 at 36°F).

NOTE:

The scale of the temperature is dependent up on the currently

configured scale. If the configuration item "1-" is set to "F" and

configuration item "4-" has a value of 16, then an Auto Mode

Setback Deadband of 16°F will be used. If the configuration

item "1-" is set to "C" and configuration item "4-" has a value of

16, then an Auto Mode Setback Deadband of 16°C will be

used.

• To end configuration, either depress the "END PROGRAM" button

or do not push any buttons for 20 seconds.

5- ZONE CONFIGURA TION

This adjustment controls the number of zones on the system.

Factory default is 1 zone.

To adjust when in configuration mode:

• Press the "up" or "down" button until "5-" is displayed.

• Depress the "

SET TIME/TEMP" button to change the current

selection (current selection will now blink).

• Use either the "up" or "down" button to change the number of

zones installed, allowable selection are 1- 8 zones.

• To end configuration, either depress the "

END PROGRAM" button

or do not push any buttons for 20 seconds.

up

down

up

down

up

down

Configuration

Page 12

GB - 11

Zone Manager

ENGLISH

6- SMART ST AR T ACTIVE

This selection allows you to select whether Smart Start is

active or not. Factory default is "On".

See Algorithm Descriptions for an explanation of Smart Start.

To adjust when in configuration mode:

• Press the "up" or "down" button until "6-" is displayed.

• Depress the "

SET TIME/TEMP" button to change the current

selection (current selection will now blink).

• Use either the "up" or "down" button to change your selection

to "On" (ON) or "OF" (OFF).

• To end configuration, either depress the "

END PROGRAM" button

or do not push any buttons for 20 seconds.

7- MILITAR Y OR ST ANDARD TIME

This adjustment controls whether time is displayed in military

(24-hour clock) or standard format (12-hour AM/PM clock).

Factory default is "On" for military time.

• Press the "up" or "down" button until "7-" is displayed.

• Depress the "

SET TIME/TEMP" button to change the current

selection (current selection will now blink).

• Use either the "up" or "down" button to change to "On"

(military time) or "OF" (standard time).

• To end configuration, either depress the "

END PROGRAM" button

or do not push any buttons for 20 seconds.

up

down

up

down

up

down

up

down

Configuration

Page 13

GB - 12

Zone Manager

8- LOCAL UNIT OVERRIDE

If Local Unit Override is active, certain information (operating

mode, desired temperature, fanspeed, louver setting) from the

Zone Manager will be ignored by a unit that has recently been

locally controlled. The unit will control to the local settings for

at least one hour. Factory default is "OF".

To adjust when in configuration mode:

• Press the "up" or "down" button until "8-" is displayed.

• Depress the "

SET TIME/TEMP" button to change the current

selection (current selection will now blink).

• Use either the "up" or "down" button to change to "On" for active

Local Unit Override or "OF" for disabled local Unit override.

• To end configuration, either depress the " END PROGRAM" button

or do not push any buttons for 20 seconds.

9- LOCK MODE

If this option is active (Lo) after 4 minutes the installer exits

installation mode the operator will not be able to change mode

or program schedule.

If the operator press the "MODE" or "PROGRAM" button "Lo:c" will

be displayed. Default is unlocked (U

L).

To adjust when in configuration mode:

• Press the "up" or "down" button until "9-" is displayed.

• Depress the "

SET TIME/TEMP" button to change the current

selection (current selection will now blink).

• Use either the "up" or "down" button to change to "L

O" to

Lock mode and program schedule or "U

L" to allow the end

user modify these parameters.

• To end configuration, either depress the "

END PROGRAM" button

or do not push any buttons for 20 seconds.

up

down

up

down

up

down

up

down

Configuration

Page 14

GB - 13

Zone Manager

ENGLISH

Unit zone addressing

The units must have their communications address changed to

the zone number in which they will occupy. Figure shows an

example using 9 units and 4 zones. For this example, the

values shown in Table 1 should be used. For this example,

units B, C, E, H, and I will occupy Zone 4. Therefore their

communications addresses should be configured to address 4.

The numbering of the zones must begin with Zone 1. Any

further zones must be added in a sequential order.

For example, configuring the zones 1, 2, 3, and 5 will result in

improper operation. (Fault code C4 would be seen).

Configuring the communications address using the

IR remote

The instructions below refer to the unit configuration shown in the

drawing.

• Each unit must have its own address ("UAdr" in the IR remote

control menu) which will be different from the others. The

example shows 9 units, so 9 different addresses will have to

be configured.

• Suppose you want to configure units A and D in room (zone)

1. Keeping the IR remote control OFF, press the keys mode

and louver simultaneously for at least 5 seconds to

access to the 12 configuration menus.

Use "

MODE" button to select item "UAdr" and then use and

buttons to select address "1". Now press louver button to

send a message to unit "A". A "beep" confirms the address

reception.

Make sure one same address is not sent to the other units.

• Press

button to select address "2" and by means of louver

button send the message to unit "D".

Press mode

button again to select item "ZONE". Use

and buttons to select zone "1". Press louver button to

send the message to unit "A" and "D".

Configuration of unit "F" is made as follows:

• If "

ZONE" menu is still active, press button to select zone

"2". Press louver

button to send the message to unit

"F".

A "beep"

confirms message reception

.

If more than 30 seconds have passed from configuration of unit

"D" , the IR remote control exits from the configuration menu

automatically.

If so, go back to the menu as previously described.

• By means of mode

button scroll all menus and select

item "UAdr". Use

button to select address "3". Press

louver

button to send the message to unit "F.

A "beep"

confirms message reception

.

Remote control

Unit zone addressing and control system

A

AM

PM

A

B

1

2

F

T est System Installation

To assist with installation wiring and unit zone addressing

issues, an installation test mode exists, that allows the installer

to easily verify that all units, by zone, are communicating

properly with the Zone Manager.

• To enter installation test mode on the Zone Manager, depress

and hold the "

LOUVER" button down for 5 seconds. When test

mode is entered, the display will show zone number and

"

CONF" in place of the system clock.

• The only buttons that are active at this time are "

NEXT ZONE"

and "

END PROGRAM".

The Zone Manager will continuously send out messages to the

units in the displayed zone, telling them to flash theirprotect

LED (RED) at a rate of 1 sec on and 1 sec off.

The installer can now visually verify that the units in the zone

are communicating properly with the Zone Manager.

The "

NEXT ZONE" button can be depressed to select a new zone

to test. Once the zone is changed, all units in the new zone will

start blinking their protect LEDs, assuming addressing and

wiring is correct. The previous zone will time out and stop

blinking their protect LEDs (RED), after 10 seconds of not

receiving a message from the Zone Manager.

The installer should run this test on all zones in the system, verifying

that every unit is addressed and wired properly. When complete, the

installer can depress the "

END PROGRAM" button to disable Installation

Test Mode and have the Zone Manager operate normal again.

Once complete, the installer can be confident that the Zone

Manager will control all of the zones, based upon each zones’o

programming information.

T able 1: CCN addresses for units

Unit A B C D E F G H I

Zone 14414 2344

Unit

address (UAdr)

156273498

Example unit configuration

Unit H

Unit D

Unit F

Unit B

Unit C

Unit G

Unit A

Unit I

Unit E

U=1

U=2

U=3

Z=2

U=4

Z=3

U=5

Z=4

U=6

UAdr=1/2

ZONE=1

U=7

U=8

U=9

Page 15

GB - 14

Zone Manager

OFF to ON period if the operating mode is Auto

1.5 hours before the "ON" period starts, the unit will turn on in

Auto mode.

The unit will control the room air temperature to the "ON"

periods setpoint plus or minus the Auto Mode Deadband

divided by two.

The controlling setpoints will then ramp towards the "ON"

periods setpoint plus or minus two degrees.

EXAMPLE OF SMART START FOR AUTO MODE:

Auto Mode Deadband = 10

TIME SETPOINT TYPE OF PERIOD

12:00 am OFF

8:00 am 25° CON

• The unit is off from 12:00 am to 6:30 pm.

• The Heat setpoint ramps from 30

°

C to 27° C from 6:30 am

until 8:00 am.

• The Cool setpoint ramps from 30

°

C to 27° C from 6:30 am

until 8:00 am.

Setback to ON period

If the Zone Manager is currently operating in a Setback period

and the next period is an "ON" period and the setpoint in the

Setback period is the same as the setpoint in the "ON" period,

the unit will ramp the same as going from an "OFF" period to

an "ON" period.

EXAMPLE OF SMART START FOR AUTO MODE:

Auto Mode Deadband = 10

TIME SETPOINT TYPE OF PERIOD

12:00 am 25° C SETBACK

8:00 am 25° CON

• The Heat setpoint is 20° C and the Cool setpoint is 30° C

from 12:00 am to 6:30 pm.

• The Heat setpoint ramps from 20

°

C to 23° C from 6:30 am

until 8:00 am.

• The Cool setpoint ramps from 30

°

C to 27° C from 6:30 am

until 8:00 am.

If the Zone Manager is currently operating in a Setback period and

the next period is an "ON" period with a different setpoint, the

following will occur 1.5 hours before the next period is entered.

1.5 hours before the "ON" period starts Smart Start is

activated. The unit will control the room air temperature to the

Setback periods setpoint plus of minus the Auto Mode

Deadband divided by two and ramp towards the "ON" periods

setpoint plus or minus two degrees.

The purpose of Smart Start is so that the room temperature is

at the desired temperature by the time the "ON" period starts.

Smart Start is only valid if the period transition is from " OFF"

to "ON" in "

HEAT", "COOL", or "AUTO" modes; or a "Setback" to

"ON" period in "

AUTO".

If the Zone Manager has been configured for Smart Start then

the following applies, otherwise period transitions will occur on

time boundaries.

If the Zone Manager is currently operating in an "OFF" period

and the next period is an "ON" period, the following will occur

1.5 hours before the next period is entered.

"OFF" to "ON" period if the operating mode is Heat

If the operating mode is "HEAT", 1.5 hours before the "ON" period

starts, the unit will turn on in Heat mode.

The unit will control the room air temperature to the "ON" periods set

point minus 5 degrees.

The controlling set point will then ramp to the "ON" periods set point.

EXAMPLE OF SMART START FOR HEATING MODE:

TIME SETPOINT TYPE OF PERIOD

12:00 am OFF

8:00 am 25° CON

• Unit is off from 12:00 am until 6:30 am.

• The setpoint ramps from 20

°

C to 25° C from 6:30 am until 8:00 am

• The setpoint remains at 25

°

C until the next period or the user

modifies the setpoint.

OFF to ON period if the operating mode is Cool

If the operating mode is "COOL", 1.5 hours before the "ON" period

starts, the unit will turn on in "

COOL" mode.

The unit will control the room air temperature to the "ON" periods

setpoint plus 5 degrees.

The controlling setpoint will then ramp to the "ON" periods setpoint.

EXAMPLE OF SMART START FOR COOLING MODE:

TIME SETPOINT TYPE OF PERIOD

12:00 am OFF

8:00 am 25° CON

• Unit is off from 12:00 am until 6:30 am.

• The setpoint ramps from 30

°

C to 25° C from 6:30 am until 8:00 am

• The setpoint remains at 25

°

C until the next period or the user

modifies the setpoint.

Smart Start function

12:00 AM 6:30 AM 8:00 AM 4:00 PM

30

25

20

15

12:00 AM 6:30 AM 8:00 AM 4:00 PM

12:00 AM 6:30 AM 8:00 AM 4:00 PM

12:00 AM 6:30 AM 8:00 AM 4:00 PM

Page 16

GB - 15

Zone Manager

ENGLISH

T rouble Shooting

Diagnostic erros

Displayed error "A2" Temperature sensor error!

Check temperature sensor for damage.

If recycling power does not clear display, replace the Zone Manager.

Displayed error "Cx" Communication error with unit(s) in zone (x)!

Where x is a number identifying a zone. 1) Put the zone manager into "Installation Test" mode and check unit(s) LED to blink rapidly.

If the units LED does not blink:

1) Configure unit for the proper zone and re-try "COMM" mode.

2) Check communication wiring

3) Check prime board installation.

Displayed error "Fx" Unit(s) in zone (x) has recorded a failure! 1) go to the unit(s) in zone (x) and determine the cause

Where x is a number identifying a zone. of the failure.

System errors

System does not Heat/Cool 1) If diagnostic code is displayed, check diagnostic trouble shooting table.

2) Put the zone manager into "Installation Test" mode and check unit’s LED to blink rapidly.

If the unit’s LED does not blink:

1) Configure unit for the proper zone and re-try "Installation Test".

2) Check communication wiring.

3) Check prime board installation.

3) Select Heat/Cool mode. Adjust the set point so that there is a real heating or cooling request.

Wait for unit’s time guard to expire. If unit does not operate, check unit for errors.

If unit does operate, Check the Zone Managers programming for scheduling errors.

Symptom Possible Cause Things to check Solution

No LCD display 1) mis-wiring of the 12 volt

power to Zone Manager control.

2) Power not online

3) No 12 volts on +12

and GND of terminal block.. .

1) Make sure the cable

connections are correct

2) The Zone Manager control

is damaged.

1) Verify that +12 v and Gnd are connected to the

proper terrminals of the Zone Manager control and

the COM board. Reference Installlation wiring section

for correct connections

2) Check pin connections of Zone Manager to base

plate terminal block while closing the plastic.

1) Check that the units main power is connected. The

main control board should be operating normally

1) Check the installation of the COM board. Check to

see that the 9 pin connection of the COM board to

main board is correct.

After disconnecting the power,

correct the wiring problem and

re-cycle power.

After verifing the wiring to the

Zone Manager control, re-cycle

the unit power.

After disconnecting the power,

correct the wiring problem and

re-cycle power.

Verify wiring did not damage

the Zone Manager.

Change the Zone Manager

control and re-cycle power.

+12 volts applied

to CZM at the

correct terminals

and still does not

operate

Page 17

L010125H80 - 0503

Via R. Sanzio, 9 - 20058 Villasanta (MI) Italy - Tel. 039/3636.1

The manufacturer reserves the right to change any product specifications without notice.

Order No. 18191-74, May 2003. Supersedes Order No. 8191-74, Novemberber 2002 Printed in Italy

Loading...

Loading...