Page 1

Installation and Start-Up Instructions

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

PAGE

Safety Consideration......................................................................1

Installation Considerations..........................................................1-2

Introduction ....................................................................................2

Installation.................................................................................2-18

Check Equipment and Jobsite..................................................2

Wiring........................................................................................2

Shielded Cable.....................................................................2

Install Comfort Zone Center ....................................................3

Install Zone Dampers............................................................3-5

Round Metal Duct Work.....................................................4

Rectangular Metal Duct Work............................................4

Round Flexible Duct Work..............................................4-5

Rectangular Fibrous Glass Duct Work...............................5

Install Barometric Bypass Dampers.........................................5

Install Duct Temperature Sensor ..........................................5-6

Install Dx Coil Sensor..............................................................6

Install Four Zone Controller.....................................................6

Install Remote Room Sensor or Smart Sensors ......................6

Comfort Zone System Wiring Diagram...................................7

Sequence Of Operation.............................................................6-12

Temperature Setpoints.........................................................6

Heating and Cooling Comfort Setpoints.....................6 & 8

Sequence of Events For a Normal Heating

or Cooling Cycle............................................................8

Selection of a Reference Zone In The System ..................8

Pre-positioning Dampers And Starting

The System Fan................................................................8-9

Controlling The Zone Dampers..........................................9

Operating The Heating And Cooling Equipment...............9

Control Strategy For Heating/Cooling Stages...............9-10

Configuration Options For Equipment Operation............10

Relay Pack To HVAC Equipment Connections ..............10

Starting The HVAC Equipment ..................................10-11

Stage Control During Equipment Operation...............11-12

Configuring Four Zone Controller....................................12-13

Programmable Options Settings ..................................12-13

Programmable Options Toggles........................................13

Wiring Diagram Reference Tables.........................................13

Start Up..............................................................................13-14

Programming Schedules....................................................14-16

System Switches...........................................................14-15

Controller Display .............................................................15

Zone Selector Dial .......................................................15-16

Accessories ........................................................................16-17

Troubleshooting ......................................................................17

Care And Maintenance ................................................................17

Toggle Summary Table................................................................18

Operating Problem Table.............................................................19

Storage Failure Error Table.........................................................20

ZONEKIT4ZCAR

Comfort Zone

72

COOL HEAT

68

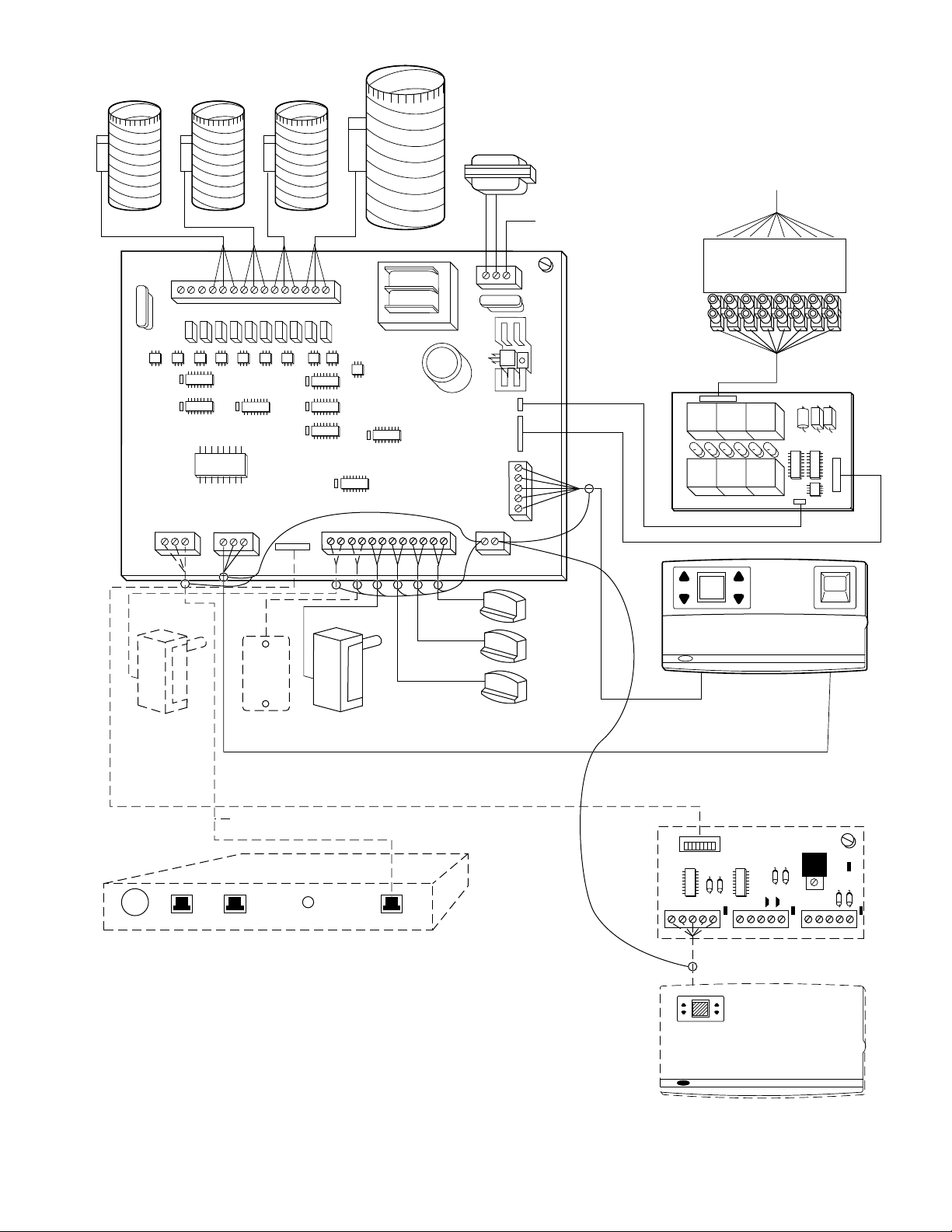

Fig. 1−Comfort Zone System

Hardware Failure Error Table......................................................21

Wiring Diagrams.....................................................................22-31

Configuration Table .....................................................................32

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause fire, electrical shock, or other conditions which

may cause personal injury or property damage. Consult a qualified

installer, service agency or your distributor or branch for information or assistance. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this product. Refer to the individual instructions packaged with the kits or

accessories when installing.

Follow all safety codes and wear safety glasses. Have fire

extinguisher available. Read these instructions thoroughly and

follow all warnings or cautions attached to the unit. Consult local

and state building codes and Sheet Metal and Air Conditioning

National Association (SMACNA) for special installation requirements.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the unit or in instructions and

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

INSTALLATION CONSIDERATIONS

1. Install in a non-condensing area with ambients between 32°F

and 120°F.

2:45

A93208

.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1144

Tab 3a 5a 2a 5a

PC 101 Catalog No. 809-568 Printed in U.S.A. Form ZONEKIT4-1SI Pg 1 7-95 Replaces: 920415-3SI

Page 2

2. Use vibration isolators (flex connectors) on zone dampers and

duct work to minimize noise.

3. Place dampers away from areas that may be noise sensitive.

4. TXV is required in air conditioning and heat pump applications.

5. Use separate isolated transformer to supply power to Comfort

Zone System (50 va minimum, class 2, field supplied).

6. Load calculations must be performed to determine equipment

size. Equipment selection is matched to block load. It is

imperative equipment is not oversized.

7. Duct work must be designed based off the sum of peaks plus

25 percent oversize. It is imperative duct work is not undersized.

INTRODUCTION

This installation guide pertains to revision 1.6 or greater. The

Comfort Zone System allows air conditioning and heating equipment to control temperatures in up to 4 distinct spaces or Zones

within a building. Each zone has independent temperature settings.

The comfort temperature settings can change automatically

through the use of schedules. This allows Comfort Zone to change

temperature settings in zones to reflect occupancy or usage. For

example, you can condition the bedrooms in a home from 5:00 PM

through 7:00 AM or the kitchen from 3:00 PM through 6:00 PM.

The Comfort Zone System uses motorized air volume control

dampers (also called zone dampers) to regulate flow of conditioned air into zones. In this manner Comfort Zone can selectively

heat or cool certain portions of a building depending upon space

temperature requirements.

INSTALLATION

Step 1—Check Equipment and Jobsite

INSPECT EQUIPMENT — File claim with shipping company,

prior to installation, if shipment is damaged or incomplete.

Step 2—Wiring

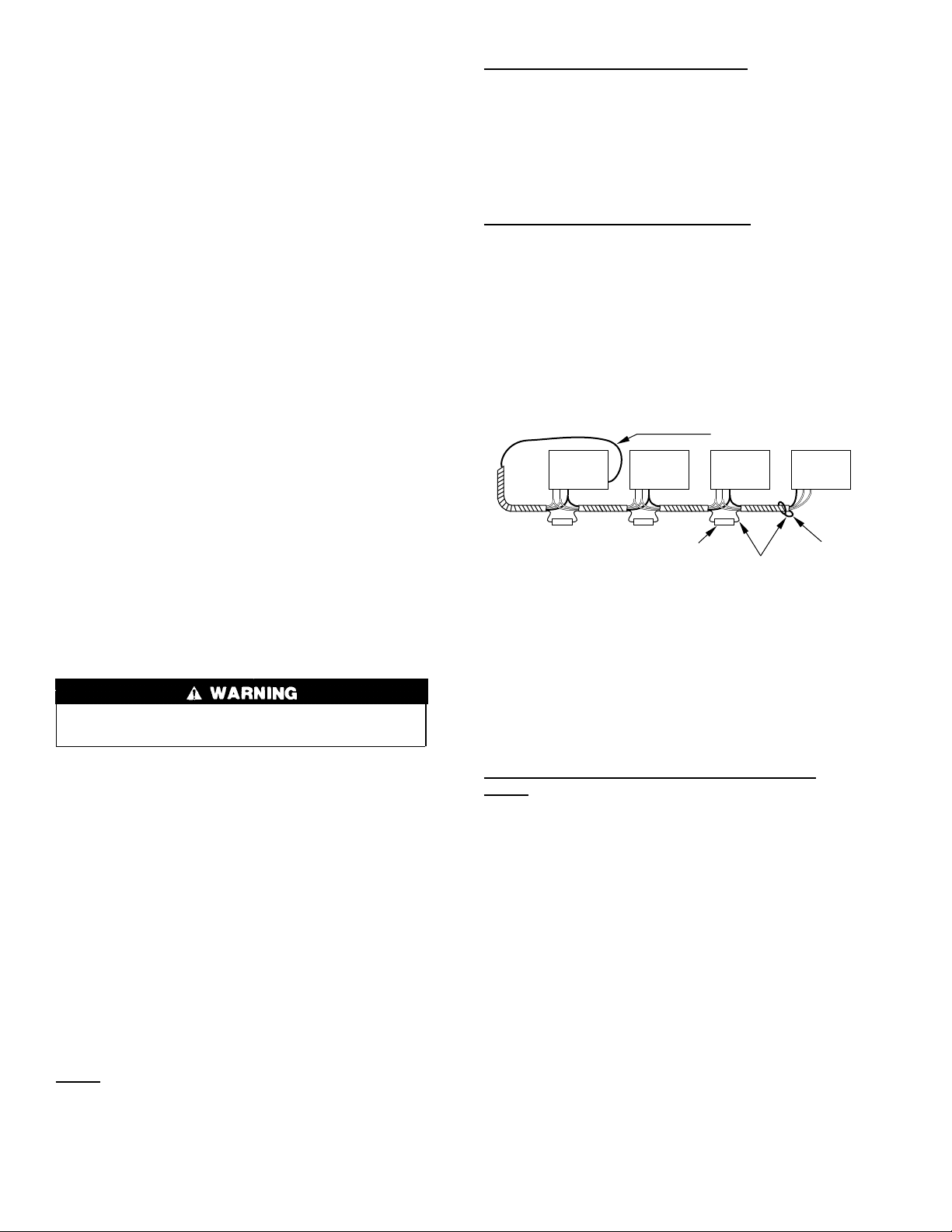

Shielding For A Single Comfort Zone System

1. Fig. 16 Shows a Comfort Zone System with all possible

options. The shield from all devices should be tied together at

I/O board and terminated at shield ground at lower right hand

corner of board. Be sure shielding does not touch any other

wiring on board.

NOTE: Do not connect shield wire at device end. Cut end and

tape up to avoid shorting.

Shielding For Multiple Comfort Zone Systems

1. If more than 1 Comfort Zone System resides on 1 job, they

may be tied together for communication purposes. If no

communication is required, then Comfort Zone System should

be wired separate and shielded as previously stated.

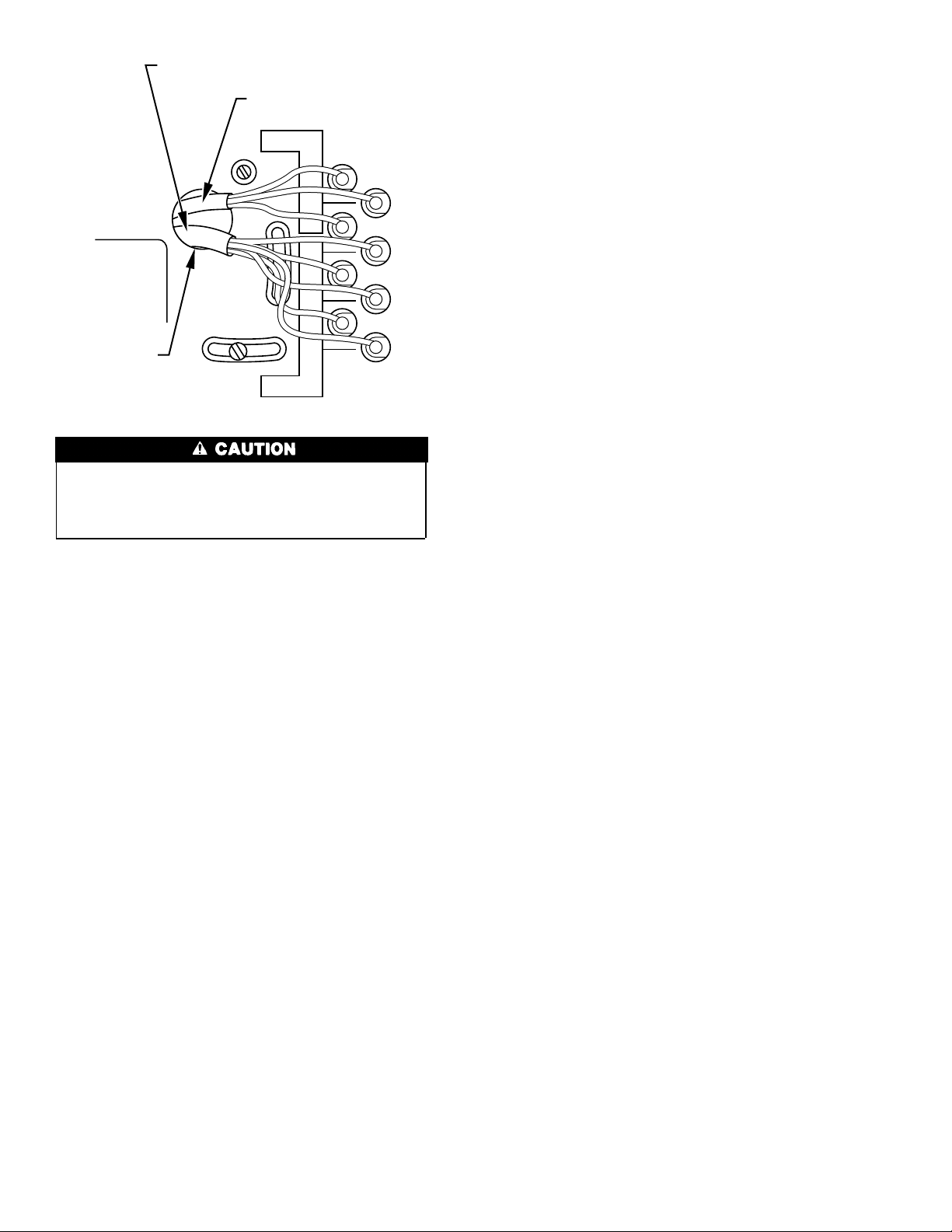

2. When 2 to 4 systems are on 1 job and require communication,

they should be daisy chained together through 3-wire communication bus at COM BUS HAM terminal.The shielding

should only be grounded at 1 point on end of communication

bus as shown in Fig. 2.

SHIELD DRAIN WIRE

Comfort

Zone

I/O

NOTES:

1. Use butt splices, or solder, for shield connections. Then tape up shield.

2. Do not connect the shield drain wire at the end of Communication Bus.

Cut and tape up to avoid shorting.

Comfort

Zone

I/O

Comfort

Zone

I/O

SHIELD DRAIN WIRE

Comfort

Zone

I/O

NOTE 2NOTE 1

A93251

Fig. 2—Daisy-Chained Comfort Zone Systems

To prevent personal injury or possible equipment damage

disconnect power supply before routing wire.

All wiring must comply with local and state codes.

NOTE: A remote room sensor requires a 2-wire cable, however,

it is recommended that a 5-wire cable be installed to allow for a

possible smart sensor upgrade. Connect white wire to terminal

labeled B- if a 5-wire cable is used. Connect red wire to R+.

Shielded cable is recommended to reduce noise interference.

NOTE: Use No. 22 AWG color-coded, insulated (35°C min)

wire. If thermostats are to be located more than 100 ft from

Comfort Zone Center as measured along control voltage wires, use

18 AWG colored-coded wires to avoid excessive voltage drop.

All wiring is run back to Comfort Zone Center. Keep wires a

minimum of 12 in. from any AC voltage. Do not tie-wrap wires

together. When wiring to COM BUS, a 3-wire cable must be

separate from the 5-wire cable. The thermostats should be located

approximately 5 ft above floor and must be located within 200 ft

of Comfort Zone Center.

SHIELDED CABLE

General

1. All wiring should be shielded (except damper wiring) with 18

or 22 gage. The 3-wire, 5-wire, and Remote Sensor wire must

be in separate jacketed cable.

2. All system wiring must be within 1 building. Never connect

devices between 2 or more buildings.

3. If more than 4 systems are used on 1 job, multiple device

buses must be used. Each device bus must be separated by an

ISOSAT-01. A typical arrangement is shown in Fig. 3.

Communication Bus Guidelines for Maximum Number of

Devices

1. The maximum number of Comfort Zone Systems allowed on

1 device bus is 4.

2. Four Zone Controllers must be addressed 4 addresses apart,

example 4, 8, 12, 16 for a device bus with 4 Comfort Zone

Systems.

3. Home Access Module (optional) will scan a maximum of 4

Comfort Zone Systems.

4. Multiple device buses can be tied together for communication

via ISOSAT-01. An ISOSAT-02 is required for remote or

direct communications via personal computer or modem. (See

Fig. 4.)

5. Comfort Zone Systems may reside on a bus with VVT system

devices. They may receive or broadcast time to these devices

accordingly by toggling T5 enable broadcast on or off.

NOTE: If multiple 4-zone controllers are on 1 bus, only 1 can

broadcast time. Turn all others off (T5).

2

Page 3

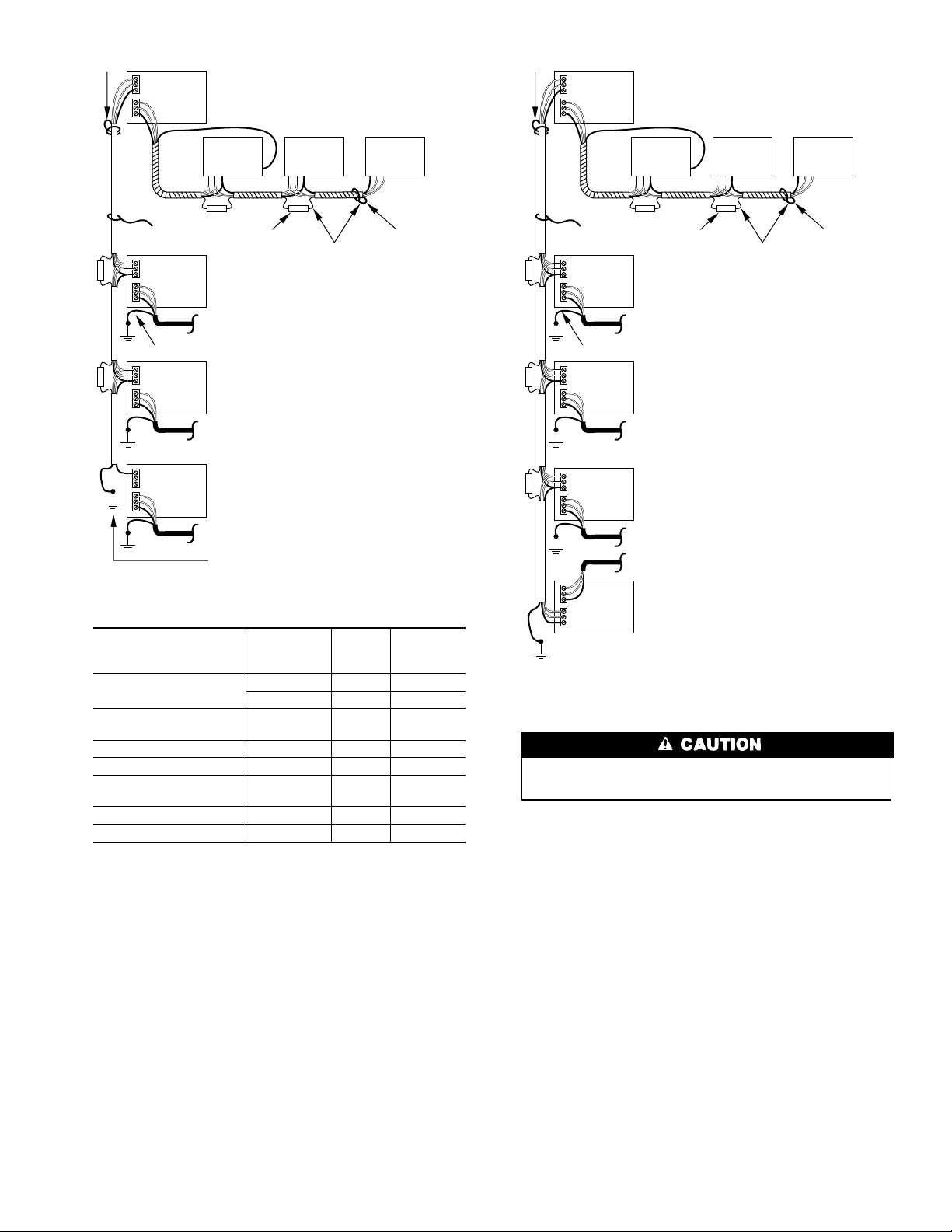

NOTE 2

PORT #1

PORT #2

ISOSAT-01

NOTE 2

PORT #1

PORT #2

ISOSAT-01

Comfort

Zone

I/O

ISOSAT BUS

PORT #1

PORT #2

SHIELD DRAIN WIRE (TYP)

PORT #1

PORT #2

PORT #1

PORT #2

ISOSAT-01

DEVICE BUS (TYP)

ISOSAT-01

ISOSAT-01

BUILDING GROUND

Fig. 3—Typical Communications Network

Comfort

Zone

I/O

SHIELD DRAIN WIRE (TYP)

NOTES:

1.Use butt splices, or solder,

for shield connections. Then

tape up shield.

2.Do not connect the shield

drain wire at the end of

Communication Bus. Cut

and tape up to avoid shorting.

Comfort

Zone

I/O

NOTE 2NOTE 1

A93249

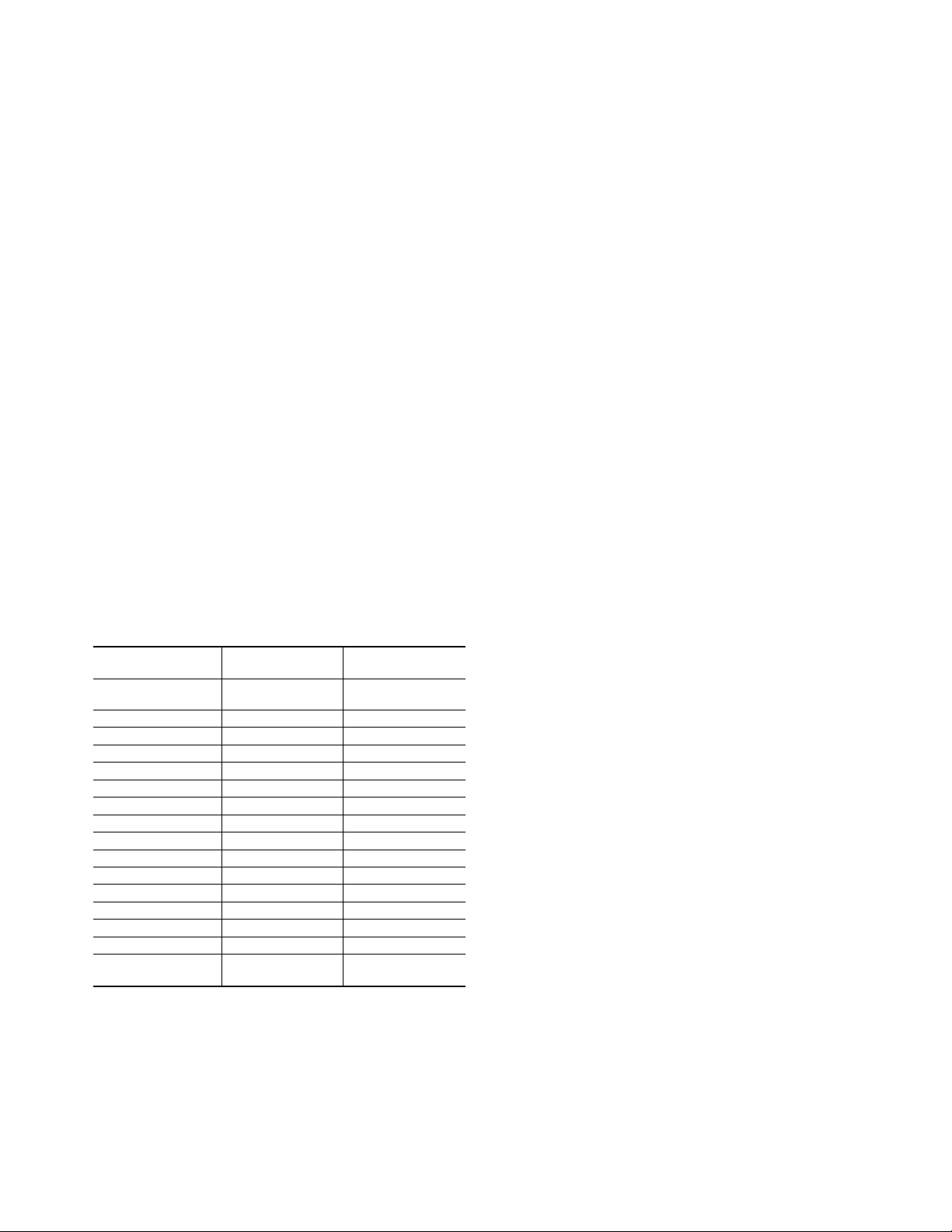

Table 1—Wiring Requirements

FROM

COMFORT ZONE

CENTER TO

Four Zone Controller

Remote Room Sen-

sors

NO.

OF WIRES

GAGE

3‡ 18/22 200/100

5‡ 18/22 200/100

2‡ 18/22 200/100

Remote Duct Sensors 2‡ 18/22 200/100

Dx Coil Sensor 2‡ 18/22 200/100

Home Access

Module

3‡ 18/22 1000/100

ISOSAT* 3‡ 18/22 1000/100

Transformer† 21875

* When using ISOSATS in interfacing multiple buses together, the length of

wiring between ISOSATS cannot exceed 4000 ft with 18 gage.

† 24 vac, 50-75 va

‡ Shielded cable recommended to reduce noise interference.

Step 3—Install Comfort Zone Center

NOTE: The Comfort Zone System is approved for indoor use

only and should never be installed with any of its components

exposed to the elements. The enclosure must be installed with

center cover to help prevent damage from other sources. Do not

mount Comfort Zone Center where it will be accessible to

children. Do not locate center in areas of the home that are noise

sensitive since relays are energized and de-energized during

operation and may be an annoyance. Install Comfort Zone in an

area with a temperature range between 32°F and 120° F.

Install Comfort Zone Center in either a vertical or horizontal

position. Locate in an area that is easily accessible in case

servicing should be required.

NOTE: Four vent plugs and 2 bushings have been supplied. Snap

bushings in the 1-in. diameter holes that are to be used for wiring

and place plugs in remaining holes.

MAX.

LENGTH

(FT)

Comfort

Zone

I/O

ISOSAT BUS

PORT #1

PORT #2

SHIELD DRAIN WIRE (TYP)

PORT #1

PORT #2

PORT #1

PORT #2

PORT #1

PORT #2

BUILDING GROUND

ISOSAT-01

DEVICE BUS (TYP)

ISOSAT-01

ISOSAT-01

TO PERSONAL COMPUTER OR MODEM

ISOSAT-02

Fig. 4—Communication Network With

Comfort

Zone

I/O

SHIELD DRAIN WIRE (TYP)

NOTES:

1.Use butt splices, or solder,

for shield connections. Then

tape up shield.

2.Do not connect the shield

drain wire at the end of

Communication Bus. Cut

and tape up to avoid shorting.

Comfort

Zone

I/O

NOTE 2NOTE 1

A93250

An ISOSAT-02

To prevent possible damage to Comfort Zone Center, do not

mount on plenum, duct work, or flush against furnace.

1. Separate Comfort Zone Center cover. (See Fig. 5)

2. Mount back plate of center cover to wall using screws and

wall anchors provided.

3. Level back plate and tighten screws.

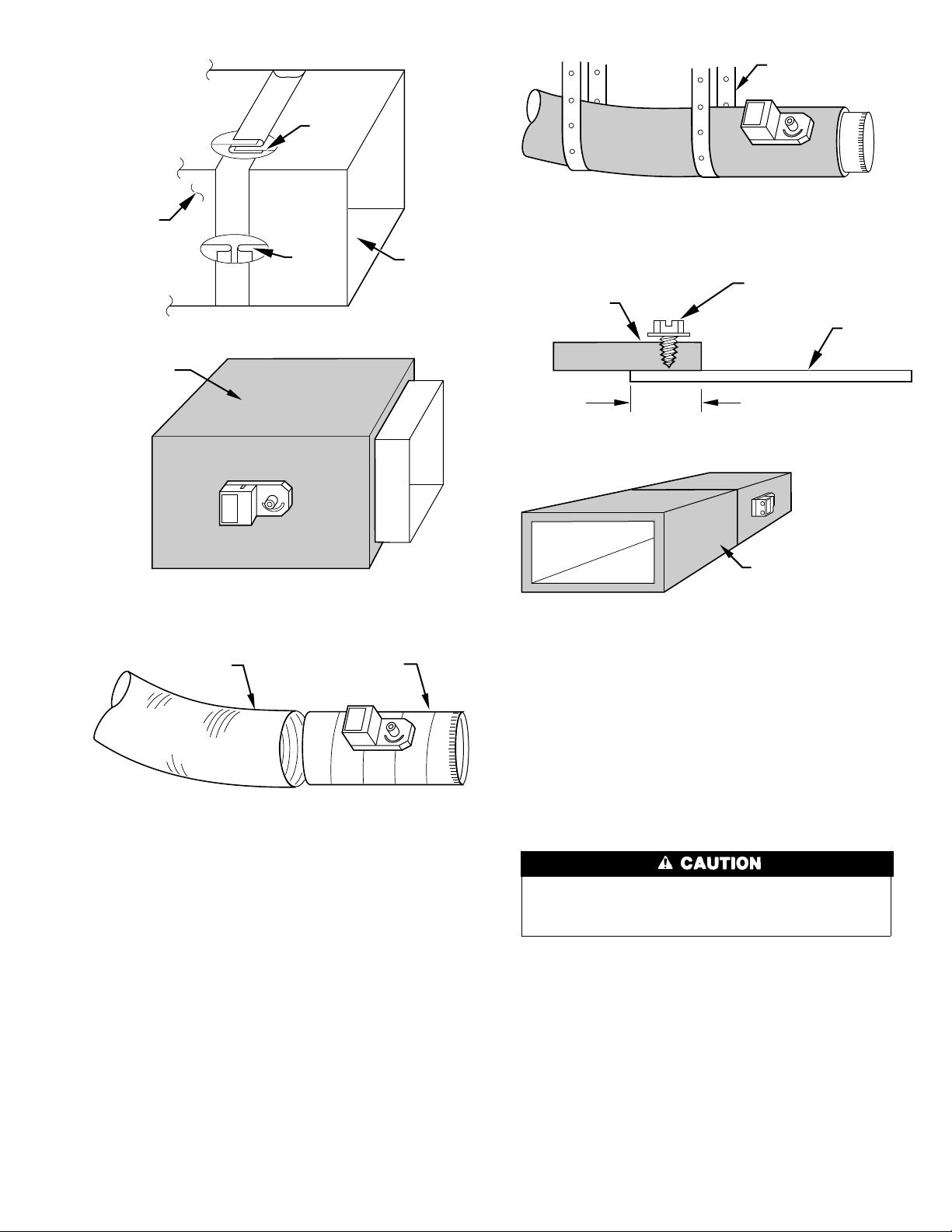

Step 4—Install Zone Dampers

IMPORTANT: If conditions exist for possible condensing, motor

must be positioned for adequate draining. (See Fig. 6.)

NOTE: If a multi-damper enabler is used to link dampers

together, add 5va per damper to the transformer power supply

rating. Reference multi-damper enabler Installation Instructions.

Zone dampers may be installed in any direction.

Install dampers so that actuator is visible for inspection and

accessible in the event it would ever need to be serviced. The black

mark on the end of damper shaft represents the position of damper

blade.

NOTE: Insulate damper using 1-1/2 in. insulation (check local

codes). In areas where excessive condensing may occur, carefully

insulate over the actuator assembly. Make sure insulation does not

interfere with operation of actuator.

3

Page 4

COMFORT ZONE CENTER

BACK PLATE

INTERCHANGEABLE

HOLE PLUGS AND

BUSHINGS

MOUNTING

HUB

AIRFLOW

AIRFLOW

POSITION

INDICATOR

COMFORT ZONE

CENTER COVER

Fig. 5—Comfort Zone Center

Comfort Zone

Center

DAMPER MOUNTING

BRACKET

A93247

ACTUATOR

HOUSING

QUICK BLADE

RELEASE

BUTTON

(RED)

FIELD

INSTALLED

POWER WIRING

Fig. 7—Damper 24-vac Connections

SUPPLY

Fig. 8—Round Metal Duct Work

CLS

FLEX

CONNECTOR

COM

OPN

90

45

0

ZONE DAMPER

ANGULAR

ROTATION

STOPS

MOUNTING

BRACKET

A95096

A95129

1

/ ″ STEEL STRAP

2

ACTUATOR

Fig. 6—Damper Motor Positioning

A95128

Before insulating the duct work, check for proper damper operation. Apply the 24vac between COM and OPN to open the damper

and COM and CLS to close the damper. (See Fig. 7.) The damper

will modulate counter-clockwise to open and clockwise to close.

If in an emergency it becomes necessary to force a damper open,

manually press in the red quick blade release button with one hand

and turn the mounting hub to reposition the damper shaft. Release

the button to hold the damper shaft in the new position.

To avoid noise and vibration, do not hard mount dampers to any

solid structure such as joists.

ROUND METAL DUCT WORK

IMPORTANT: If application exists with all metal duct work

without insulation, flex connectors must be used on each end of

zone dampers to avoid noise and vibration.

1. Crimp end of branch duct.

2. Slip end of zone damper over end of duct work. Use

self-tapping sheet metal screw to secure. (See Fig. 8.)

3. Properly seal joint using duct tape, mastic, or other approved

method. Do not allow mastic to come in contact with actuator.

4. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.)

Fig. 9—Insulated Round Metal Duct Work

NOTE: All zone dampers and duct work must be properly

supported according to local codes or SMACNA standards.

RECTANGULAR METAL DUCT WORK

1. Make connections using S-lock and drives. (See Fig. 10.)

2. Properly seal joint using duct tape, mastic, or other approved

method. Do not allow mastic to come in contact with actuator.

3. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.)

NOTE: All zone dampers and duct work must be properly

supported according to local codes or SMACNA standards.

NOTE: There should be a minimum of 4 ft between zone damper

and first branch duct if more than 1 branch duct is downstream of

zone damper.

ROUND FLEXIBLE DUCT WORK

1. Slip 1 end of flexible duct work over 1 end of zone damper.

(See Fig. 12.)

4

A95130

Page 5

S-LOCK

1

2

/ ″ STEEL STRAP

SUPPLY

AIR DUCT

DRIVE

Fig. 10—Rectangular Metal Duct Work

1

2

1 / " TO 2"

INSULATION

ZONE

DAMPER

A92478

A95131

Fig. 11—Insulated Rectangular Metal Duct Work

FLEXIBLE

DUCT

Fig 12—Round Flexible Duct Work

ZONE

DAMPER

A95132

A95133

Fig. 13—Insulated Round Flexible Duct Work

FIBROUS

GLASS

DUCTWORK

2″ TO 3″

FIELD

SUPPLIED

SCREWS

ZONE

DAMPER

A92480

Fig. 14—Rectangular Fibrous Glass Duct Work

1

2

1 / ″ TO 2″

INSULATION

A95134

Fig. 15—Insulated Rectangular Fibrous Glass Duct

Work

Step 5—Install Barometric Bypass Damper

NOTE: The barometric bypass damper is a critical part of

Comfort Zone System for control of minimum airflow and noise

reduction. It is recommended that the bypass be installed.

The bypass should be installed according to local codes and

SMACNA standards. Be sure bypass is properly supported.

For proper installation, refer to Installation Instructions packaged

with barometric bypass.

2. Secure flexible duct to zone damper using SMACNA or other

approved method.

3. Properly seal joint using duct tape, mastic, or other approved

method. Do not allow mastic to come in contact with actuator.

4. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.)

NOTE: All zone dampers and duct work must be properly

supported according to local codes or SMACNA standards.

RECTANGULAR FIBROUS GLASS DUCT WORK

1. Insert 1 end of zone damper into 1 end of fibrous glass duct

work approximately 2- to 3-in. (See Fig. 14.)

2. Screw field-supplied screws and tabs into zone damper.

3. Properly seal joint using duct tape, mastic, or other approved

method. Do not allow mastic to come in contact with actuator.

4. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.)

Failure to properly install bypass damper can cause permanent damage to the HVAC equipment. For single speed

furnace applications bypass air must never exceed 25 percent.

Step 6—Install Duct Temperature Sensor

Locate duct temperature sensor in main supply trunk after heating

and cooling coil and before bypass damper and first branch. The

duct temperature sensor must be radiant shielded to prevent heat

from affecting correct air temperature.

1. Drill a 7/8-in. hole at location in unit where sensor will be

installed.

2. Remove cover and insert sensor probe through 7/8-in. hole.

3. Drill two 1/16-in. holes to accept No. 6 screws through

pre-drilled holes in duct temperature sensor back plate.

4. Use two No. 6 sheet metal screws included with sensor to

mount duct temperature sensor back plate to unit.

5

Page 6

5. Insert 2-conductor wiring through 1 of pre-drilled holes in side

of back plate.

6. Connect sensor to 2-wire conductor using provided wire nuts.

(See Fig. 16 for connection to Comfort Zone Center.)

Step 7—Install Dx Coil Sensor

The Dx coil temperature sensor is recommended for use in heat

pump with fan coil applications only. The sensor should be

installed between Dx coil and electric heaters. It measures Dx coil

temperature and adds extra protection for high/low temperature

limits. The range is from 30°F to 180°F. The Dx coil sensor

interfaces to Comfort Zone Center on terminal TB-1. (See Fig. 16.)

To activate Dx coil temperature sensor turn T-27 on. When

activated, the Dx coil sensor has built-in LAT setpoints of 50°F

and 45°F in the cooling mode, and 105°F and 110°F in the heating

mode. This is non-adjustable.

Step 8—Install Four Zone Controller

The Four Zone Controller is the zone 1 thermostat. It is recommended to locate this in the zone occupied as the living room or

family room for maximum comfort.

DO NOT locate controller where supply air can blow directly on

it. Avoid locating controller where heat from any lamps, appliances, or direct sunlight will affect temperature sensor on controller. Do not locate on an outside wall or next to a return air grill.

1. Separate base plate from main body of controller.

2. Pull 3-wire cable for communication bus and 5-wire cable for

controller through 3/4-in. round hole on base plate. Three-wire

cable and 5-wire cable must be separate jacketed wiring. Do

not use one 8-wire cable. (See Fig. 17.)

NOTE: Insulate or seal field wiring feed through hole to reduce

draft.

3. Mount base plate using provided screws, starting screw in

round hole first then second screw in slotted hole. On drywall

it is recommended to use provided plastic wall anchors.

NOTE: If mounting controller using an electrical box, mount base

plate using pair of horizontal holes.

4. Level base plate and tighten screw in slotted hole first, then

the screw in round hole.

5. Connect the 3 wires for communication bus and the 5 wires for

controller to base plate terminal screws. (See Fig. 16.) Ensure

that there are no excess or bare wires exposed.

6. Plug base plate connector into back of main body and ensure

it is secure into connector located on back of 4 zone

controller’s main body. Ensure connectors and main body are

secure.

7. Align main body with base plate and snap into place.

Step 9—Install Remote Room Sensors or

Smart Sensors (Optional)

Comfort Zone may have up to 4 zones. The 4 zone controller

controls zone 1. Remote room sensors or smart sensors control the

other 3 zones. If using a smart sensor, a smart sensor power pack

must be used. The remote sensors should be located 5 ft above the

floor and must be less than 200 ft away from Comfort Zone Center.

DO NOT locate sensors where supply air can blow directly on

them. Avoid locating sensors where heat from any lamps, appliances, or direct sunlight will affect temperature sensor on room

sensors. Do not locate on an outside wall or next to a return air

grill.

1. Separate the 2 parts of sensor and mount back plate with

provided flat-head screw.

2. Pull a 2-wire conductor through hole on right-hand side.

3. Connect black or white wire to terminal labeled B- and

connect red wire to terminal labeled R+.

4. Align sensor case with base plate then press firmly until cover

snaps into place.

Step 10—Sequence of Operation

TEMPERATURE SETPOINTS

The Comfort Zone System uses 2 temperature setpoints. The

setpoints are displayed in the left-hand window on the 4 zone

controller. (See Fig. 18.)

In display window, cooling setpoint is shown on upper left and

heating setpoint is shown on lower right.

The temperature setpoints for any of the 4 zones can be displayed

by the 4 zone controller. When the 4 zone controller rotary switch

points to zone 1, setpoints for zone 1 at the 4 zone controller are

displayed. Selecting zone 2, zone 3, or zone 4 will display

setpoints for each of these zones which use either remote room

sensors or smart sensors. The system is not required to have all 4

zones installed.

HEATING AND COOLING COMFORT SETPOINTS

If space temperature is between heating and cooling setpoints for

the zone, then the zone is said to be "satisfied" with respect to

temperatures. When a zone is "satisfied" no heating or cooling

equipment will turn on to condition the space. For example, if

cooling setpoint is 76°F and heating setpoint is 72°F, then a space

temperature of 73°F is assumed to be satisfactory and no heating

or cooling of zone is required.

If space temperature in a zone falls below heating setpoint, then

that zone needs to have heat added to zone which will raise space

temperature back to heating setpoint. For example, if heating

setpoint is 72°F and space temperature is 70°F, then space

temperature must be raised 2 degrees in order for zone to be

satisfied. In this case, temperature "heating demand" for zone is

2°F. (72°F minus 70°F.)

Otherwise, if space temperature in a zone rises above cooling

setpoint, then that zone needs to have heat removed from zone

which will lower space temperature back to cooling setpoint. For

example, if cooling setpoint is 76°F and space temperature is 77°F,

space temperature must be lowered 1° in order for zone to be

satisfied. In this case, "cooling demand" for zone is 1°F. (77°F

minus 76°F.)

Comfort Zone allows owner or installer to set ranges for comfort

setpoints along with maximum and minimum temperatures which

can be used by system.

Comfort Zone allows both heating and cooling comfort setpoints

to operate in a 14° span. The heating and cooling temperature

"spans" can be set to allow for a selected range of operation.

Rotary switch position 9 sets base temperatures for both heating

and cooling spans.

When switch is set to 9, both heating and cooling base temperatures are displayed and each can be modified by using up/down

setpoint buttons. The base temperatures are the same for all 4

zones.

If cooling base temperature is set to 68°F, then cooling comfort

range will be 68°F to 82°F. If heating base temperature is set to

54°F, then heating comfort range will be 54°F to 68°F.

6

Page 7

Zone Dampers

ZN4

BYPASS

CL OP COM CL OP COM CL OP COM CL OP COM CL OP COM

COMFORT ZONE I/O

COMM

BUS HAM

ZN3 ZN2 ZN1

COMM BUS

CONTROLLER

G

R

W

WR

G

RWRWRWRWRWR

DX

OAT

LAT

ZT4

ZT3

ZT2

W

PWR. 24VAC

SHIELD

GROUND

24 VAC Transformer

(Field Supplied)

50 VAC req. for basic

4 damper system. Please

see Page 1, Electrical

Rating for details.

#16 AWG to

Grounded to Water Pipe

or Solid Electrical Ground

PWR

CHR06

RELAY

CHR06

R

Y

B

WG

SYSTEM CONTROLLER

Zone 2*

Zone 3*

Power

To

HVAC

System

FAN (G)

RV COOL (0)

RV HEAT (B)

72

68

HEAT 2 (W2)

OR

4-Zone Controller

COOL 2 (Y2)

HEAT 1 (W1)

COOL 1 (Y1)

UNIT 24 VAC (R)

CHR-06

2:45

Dx Coil

Sensor

(optional)

Outside Air

(optional)

Custom Cable

CALLOUT TO PHONE COMM BUSPOWER PHONE LINE

Home Access Module

(optional)

Sensor

Duct

Sensor

Remote Room

Sensors

* It is recommended that a 5 wire cable be used to install

Remote Room Sensors to allow

for future upgrade to Smart Sensors.

Fig. 16—Comfort Zone System Wiring Diagram

Zone 4*

Zone 1

Communication Bus

B Y G W RB Y G W RB Y G W R

Smart Sensor Power Pack

(optional)

Smart Sensor

(optional)

A94311

7

Page 8

5 WIRE CONDUCTOR

(INTERFACE BOARD)

3 WIRE CONDUCTOR

(COMM BUS)

COMM BUS

FIELD WIRING

(FEED THRU)

I/O BOARD

Fig. 17—Wiring Four Zone Controller

GRN

RED

WHT

RED

YEL

BLU

GRN

WHT

GREEN

RED

WHITE

RED

YELLOW

BLUE

GREEN

WHITE

A93231

Changing the base temperatures will change the Comfort

Temperature Setpoints used in the system schedules. Always

set the Base Temperatures prior to programming the system

schedules.

Comfort Zone also uses a minimum temperature and a maximum

temperature for comfort setpoints. The minimum and maximum

temperatures are the same for all 4 zones.

The Maximum Temperature is only used for cooling. It is set by

selecting Rotary Switch Position S-2. The Maximum Temperature

setting is used when a temperature above the 14° span is selected.

If Cooling Base Temperature is set to 68°F and cooling setpoint is

82°F, any attempt to raise cooling setpoint will select Maximum

Temperature.

The Minimum Temperature is only used for heating. It is set by

selecting Rotary Switch Position S-3. The Minimum Temperature

setting is used when a temperature below the 14 ° span is selected.

If Heating Base Temperature is set to 54°F, any attempt to lower

heating setpoint below 54°F will select Minimum Temperature.

Both Maximum and Minimum Temperatures are intended for use

with schedules or setpoints which are extreme compared to normal

building temperatures.

Comfort Zone also has one additional set of temperature settings.

These are Vacation Setpoints. The Vacation Setpoints are heating

and cooling setpoints to be used in all 4 zones whenever 4 zone

controller rotary switch is turned to "Vacation." The Vacation

option is used to place entire building in setback during long

unoccupied periods without danger of freezing or extreme

heat/humidity.

SEQUENCE OF EVENTS FOR A NORMAL HEATING OR

COOLING CYCLE

Given Comfort Setpoints and space temperature for zones within

system, Comfort Zone will determine if active heating or cooling

is required. If so, Comfort Zone will perform the following:

1. Select a reference zone.

2. Make sure all zone dampers are fully open.

3. Energize HVAC equipment fan.

4. Energize heating or cooling equipment. The equipment may

be a compressor, furnace, strip heater, etc.

5. Set the zone damper positions based upon zone demand.

6. Energize additional stages of heating or cooling if demand

warrants.

7. Continue to adjust zone dampers as conditions within zones

change.

8. Turn off heating or cooling equipment when all zones are

within 0.5°F of desired comfort setpoint.

9. Open all zone dampers when equipment is turned off.

This is the basic Sequence of Operation for the Comfort Zone

system. The actual control of dampers, HVAC equipment, and

system fan will change with configuration of system. Depending

upon configuration, Comfort Zone can control heat pumps, furnaces, and dual fuel applications.

SELECTION OF A REFERENCE ZONE IN THE SYSTEM

The first step in any heating or cooling cycle requires Comfort

Zone to evaluate zones, determine if heating or cooling is needed,

and select a Reference Zone.

The Comfort Zone system actively looks at Comfort Setpoints and

space temperature in all zones. If any zone in system has a demand

of 1.5°F or more, then Comfort Zone will prepare to operate

heating or cooling equipment to reduce demand.

First, Comfort Zone will select a reference zone in the system. The

reference zone will be zone with greatest demand. The zone

damper serving reference zone will be forced fully open and will

remain fully open as long as that zone is used as reference.

As long as any zone in system has a demand greater than or equal

to 1.5°F, then Reference Zone will be selected by zone with

greatest demand. Once all zones have a demand less than 1.5

Reference Zone selection will not change until demand in that

zone is below 0.5°F. At this point Comfort Zone will re-select

Reference Zone and position that particular zone damper fully

open.

The objective of Reference Zone is to ensure that zone with

greatest demand is receiving as much conditioned air as system

will allow. It also gives Comfort Zone system a point of reference

in observing response of zones to equipment operation.

PRE-POSITIONING DAMPERS AND STARTING

THE SYSTEM FAN

In order to minimize noise and enhance system operation, Comfort

Zone maintains all zone dampers full open prior to starting system

fan or heating or cooling equipment. The intent is to provide

HVAC equipment with unrestricted duct work and reduce pressure

surges. Comfort Zone also fully opens dampers whenever a

heating or cooling cycle is completed and system fan is shutting

down. If Fan Switch on 4 zone controller is set to Auto, then all

zone dampers will remain fully open until next heating or cooling

cycle.

The other reason for opening dampers is to provide unrestricted

duct work to other equipment which is not directly controlled by

Comfort Zone. One example may be Heat Recovery Ventilator. If

Comfort Zone is not actively controlling HVAC system, then it

must not impose any control influences (i.e., closed zone dampers)

on system and prevent proper operation of other devices.

For Fan operation, switch settings on 4 zone controller and system

configuration can change actual operation.

If Auto Fan Off For Heating option (Rotary switch position

number T-9) is ON, then Comfort Zone will only energize fan for

cooling cycles. This option is intended for furnaces which will

control their own fan internally.

8

o

F,

Page 9

If Fan Switch on 4 zone controller is set to ON instead of Auto,

then system fan will run continuously. Any time Comfort Zone is

operating fan, it will be in active control of system.

NOTE: If Auto Fan Off For Heating option (rotary switch

position T-9) is ON, and Fan Switch on the 4 zone controller is

ON, Comfort Zone will operate fan full time.

Operating fan continuously will place Comfort Zone in a Float

Mode any time no active heating or cooling is taking place. During

Float Mode, Comfort Zone will position zone dampers based upon

demand in each zone. Comfort Zone will check air temperature in

duct work and allow air into zones if it will help zones reduce their

individual demands. For example, if temperature of air in duct

work is 65°F, cooling comfort setpoint for a zone is 72°F, and

space temperature is 73°F, then Comfort Zone will open damper

servicing that zone and allow cooler air into space.

Ventilation Mode is only in effect when temperature of supply air

is between 65°F and 80°F. Ventilation Mode establishes minimum

position of zone dampers and is intended to help air movement

throughout zones and reduce chance of having areas which are

stagnant or have high humidities with respect to rest of system.

The changes to dampers are detailed in the next section "Controlling the Zone Dampers."

CONTROLLING THE ZONE DAMPERS

The zone dampers have a total of 16 possible positions or

increments which are numbered 0 (zero) through 15. Position

number 0 is fully closed and position number 15 is fully open.

While damper servicing reference zone remains fully open, all

other zone dampers are positioned by selecting a position equal to

demand of space in tenths of a degree. (See Table 2.)

Table 2—Zone Damper Positions

Damper Position Versus Zone Demand

DAMPER

POSITION

0

Fully Closed

10.1 0.06

2 0.2 0.11

3 0.3 0.17

4 0.4 0.22

5 0.5 0.28

6 0.6 0.33

7 0.7 0.39

8 0.8 0.44

9 0.9 0.50

10 1.0 0.55

11 1.1 0.61

12 1.2 0.67

13 1.3 0.72

14 1.4 0.78

15

Fully Opened

For example, a zone which has a 1.0°F demand will have damper

set to position number 10 while a zone which has a demand of

0.5°F will have damper set to position number 5. A demand of 0

(zero) will fully close zone damper. Any zone which has a demand

greater than 1.5°F will remain fully open.

Notice that positions are based upon tenths of a degree Fahrenheit.

If Comfort Zone has Celsius Temperature Display option (rotary

position T-2) turned on, the damper control is still based upon

Fahrenheit scale.

DEMAND °F DEMAND °C

00

1.5 0.83

The damper positions in table are also used during a Float Mode.

A zone with a demand of 0.5°F will be set to position number 5.

The actual control of zone dampers by Comfort Zone system can

be modified using 3 configurable options. These are Maximum

Damper Position, Minimum Damper Position, and Ventilation

Mode.

These options apply to all zone dampers simultaneously. Any

dampers servicing Zone 1 cannot be configured differently than

those servicing Zone 2. The options are as follows:

1. The Maximum Damper Position (rotary position number

S-4) sets maximum open damper position for all 4 zones. The

allowable range for this option is damper positions number 8

through number 15 (fully open). The factory default is 15. The

only time zone dampers will exceed this position is if system

fan is off or zone dampers are being calibrated.

2. The Minimum Damper Position (rotary position number

S-5) sets minimum open damper position for all 4 zones. The

allowable range for this option is damper positions number 0

through number 7. The factory default is number 0 (fully

closed). If Ventilation Mode (rotary position T-25) is turned

OFF, then minimum damper position will be an absolute

minimum regardless of operating mode. If Ventilation Mode

is turned ON, then minimum damper position will be minimum position during a Ventilation Mode only and dampers

will be allowed to fully close at any other time.

3. Ventilation Mode (rotary position T-25). If Ventilation Mode

is turned ON, then any time air inside supply air duct work is

between 65°F and 80°F, system will be in a "Ventilation

Mode". During a Ventilation Mode all zone dampers will have

a minimum position which is set by Minimum Damper

Position (rotary position S-5). The zone dampers are not

allowed to fully close as long as supply air temperature

remains within the 65°F-80°F range. If supply air temperature

falls outside the 65°F-80°F range, then zone dampers may

fully close.

NOTE: If Ventilation Mode option (rotary position T-25) is

turned ON, and Minimum Damper Position (rotary position S-5) is

set to position 0, there is no difference between Float Mode and

Ventilation Mode. In other words, Ventilation Mode option has

no effect on system.

OPERATING THE HEATING AND COOLING EQUIPMENT

Before any heating or cooling equipment is started, Comfort Zone

must first choose between heating or cooling. For most of the year

there is little question as to the need for heat or cooling. But for

portions of the year, particularly during mid-season, a building

may have simultaneous needs for both heating and cooling.

The first step in selecting heating or cooling is the determination of

a Reference Zone. If there is a single zone which has greatest

demand, then it will become the Reference Zone and Comfort

Zone will start equipment based upon needs of that zone. If 2 zones

have same "greatest demand" but in different modes (1 needs

heating and the other needs cooling), then Comfort Zone will

select mode which has greatest number of zones which require

same mode.

CONTROL STRATEGY FOR HEATING / COOLING STAGES

The Comfort Zone system will attempt to minimize use of

additional stages of heating or cooling equipment. In an ideal case,

building conditioning needs can be supplied by first stage cooling

or first stage heating alone.

For most heat pump applications, there may be only 2 or 3 stages

of heat depending upon type of emergency heater present. For a

heat pump, secondary heat source will generally be an electric strip

9

Page 10

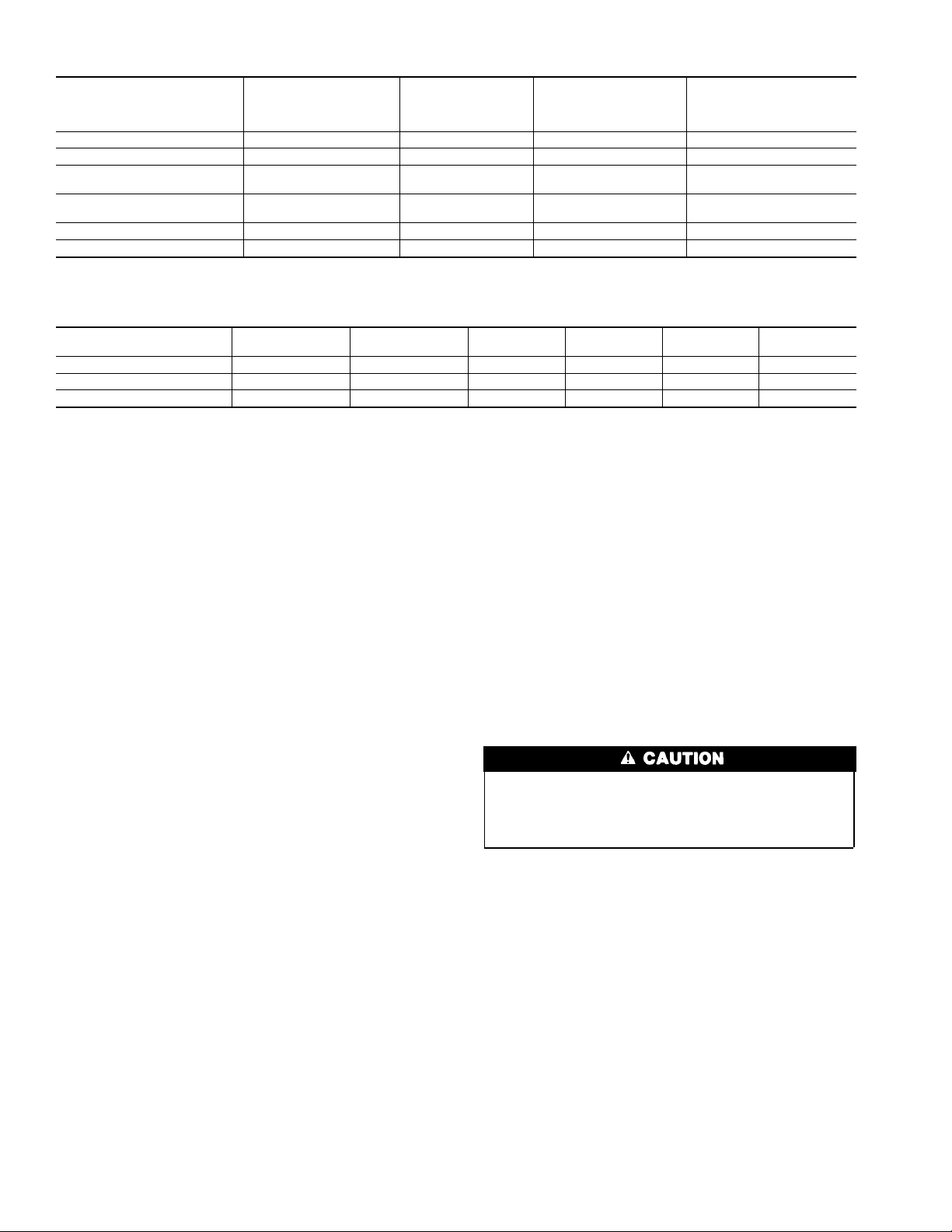

Table 3—Heating System Option Vs. Type of Heater Used

HEATER TYPE USED

IN SYSTEM

Single-Stage Heat Pump On Off 0

Two-Stage Heat Pump On On 0

Heat Pump/Furnace Dual

Two-Stage Heat Pump,

* Refer to 2-speed heat pump Installation and Start-Up Instructions for details regarding 2-speed heat pump operation. It is recommended that heat pump control board

controls operation of this equipment and not Comfort Zone.

Fuel

Furnace Dual Fuel*

Furnace Heat Only Off Off 0

Strip Heater Only Off Off 0

HEAT PUMP

SYSTEM TOGGLE:

T-6

On Off 10 to 60

On On 0°F Off

TWO STAGE

HEAT PUMP

TOGGLE: T-26

DUAL FUEL

SYSTEM SWITCH:

S-7

o

F (off) Off

o

F (off) Off

o

F Off

o

F (off) On or Off

o

F (off) Off

FAN ON

FOR COOLING ONLY

TOGGLE:

T-9

Table 4—Available Heating and Cooling Stages Vs. System Type

TYPE OF HVAC

EQUIPMENT USED

Cooling Only, any Heater Type Y1 Y2 W1 W2 -- --

Single-Stage Heat Pump Y1 -- Y1 W1 W2 --

Two-Stage Heat Pump Y1 Y2 Y1 Y2 W1 W2

For cooling applications, the second stage of an air conditioner is not necessarily more expensive to operate than first stage. But additional cooling can drive down the

efficiency of a 2-speed air conditioner and longer use of first stage alone tends to deliver better humidity control in moist climates. Again, because of these advantages,

Comfort Zone will attempt to minimize use of second stage cooling. This is not as great of a concern for a heating application, because the majority of small air

conditioning systems sold today (5 tons and below) are single-stage cooling only.

COOLING STAGE 1 COOLING STAGE 2 HEAT STAGE 1 HEAT STAGE 2 HEAT STAGE 3 HEAT STAGE 4

heater. The electric strip heat is much more expensive to operate

when comparing cost per unit of heat. Because auxiliary stages of

heating tend to be more expensive to operate, Comfort Zone

attempts to keep number of stages at a minimum.

CONFIGURATION OPTIONS FOR EQUIPMENT

OPERATION

Comfort Zone has several configurable options which allow it to

control different types of HVAC equipment and change the

manner in which the equipment is controlled. This first group must

be set given the type of HVAC equipment installed. These include:

1. Heat Pump Operation (Rotary Position T-6).

2. Two-Stage Heat Pump (Rotary Position T-26).

3. Dual Fuel trip temperature (Rotary Position S-7).

4. Auto Fan Off For Heat (Rotary Position T-9).

The second group modifies the way the HVAC equipment is

controlled. These include:

1. Comfort Trend Staging (Rotary Position T-8).

2. System Mode Reselect (Rotary Position T-22).

3. High/Low Temperature Limits Enabled (Rotary Position

T-10).

4. High Temperature Trip Limit (Rotary Position S-6).

5. Dx Sensor (Rotary Position T-27).

6. Smart Start (Heat Pump Strip Heat Economy Feature)

The first options which must be set are based upon the type heater

or heaters used. These are shown in Table 3. The only option

which appears to impact cooling operation is Two-Stage Heat

Pump which implies the availability of 2 stages of cooling. In

reality there are no changes to cooling control scheme.

Comfort Zone assumes that there are always 2 stages of cooling

present. These are connected to the Comfort Zone Relay Pack on

the Y1 and Y2 contacts.

RELAY PACK TO HVAC EQUIPMENT CONNECTIONS

Given system configuration, Comfort Zone can determine number

of heating stages that it will actually control and which relay

outputs will be used to control each stage of heat. Comfort Zone

can control up to 4 stages of heat depending upon system

configuration.

For cooling only applications with any type of heater, Comfort

Zone will only control 2 stages of heat. If system uses a heat pump,

then Comfort Zone will control 3 stages of heat. The additional

stage is heat pump compressor contact. The auxiliary heat is still

2 stages. If system uses a 2 stage heat pump, then Comfort Zone

will control 4 stages of heat, 2 stages for heat pump and 2 stages

for auxiliary heat.

The Comfort Zone Relay Pack outputs are shown in Table 4. The

Y1 and Y2 contacts are used for compressor contacts only.

Comfort Zone operates heat pumps by energizing compressor

contacts and controlling reversing valve through Reversing Valve

(RV) relay output. The W1 and W2 contacts are always used for

heat sources. These are heating only units such as furnaces, strip

heaters, etc. The relay outputs for Comfort Zone 1.4 are shown in

Table 4.

Under no circumstances may the W1 and Y1 contacts on the

relay pack be jumpered together. This is a common practice

for many heat pump installations but will cause improper

operation of the Comfort Zone (1.4 or greater) system.

STARTING THE HVAC EQUIPMENT

Once Comfort Zone selects a mode, controller will use configu-

ration options to modify control of HVAC equipment. The

controller first selects number of stages of heating and cooling that

may be applied to building load. The "available" stages are

determined by Reference Zone temperature demand and are shown

in Table 5.

Using Table 5, if Reference Zone has a 2.3°F demand, then

Comfort Zone may use 2 stages of cooling or 2 stages of heating.

The HVAC equipment may not have 3 stages of heat or even 2

stages of cooling. The table is only used to determine what

equipment Comfort Zone is allowed to turn on at any given time

during a heating or cooling cycle. Actual operation of stages

depends on other variables as well.

Normally Comfort Zone will start equipment operation when it has

a demand of 1.5°F or greater. In some cases, Comfort Zone will be

facing a demand greater than 1.5°F when a mode is starting. This

can occur when user changes setpoints in a zone or if a schedule

change has reset the Comfort Setpoints.

10

Page 11

Table 5—HVAC Equipment Stages

Vs. Zone Demand

HEATING & COOLING

EQUIPMENT STAGES

First-Stage Cooling 1.5 0.83

Second-Stage Cooling 2.0 1.11

First-Stage Heating 1.5 0.83

Second-Stage Heating 2.0 1.11

Third-Stage Heating 2.5 1.39

Fourth-Stage Heating 3.0 1.67

NOTE: Comfort Zone uses a 3-minute timer to delay start of

second-stage (heating or cooling). This timer is started whenever

first-stage heating or cooling is energized. This delay cannot be

overridden or disabled.

STAGE CONTROL DURING EQUIPMENT OPERATION

As shown earlier, Comfort Zone has 6 configurable options which

help govern equipment operation. They are:

1. Comfort Trend Staging (Rotary Position T-8).

2. System Mode Reselect (Rotary Position T-22).

3. High/Low Temperature Limits Enabled (Rotary Position

T-10).

4. High Temperature Trip Limit (Rotary Position S-6).

5. Dx Sensor (Rotary Position T-27).

6. Smart Start (Heat Pump Strip Heat Economy Feature)

Comfort Trend Staging and High/Low Temperature Limits

control the use of extra stages of heating and cooling. Both can be

turned off by the installer but the use of these options is highly

recommended.

Comfort Trend Staging is used by Comfort Zone as an aid to

decide if second-stage (heating or cooling) is needed. The system

must have at least 1 zone with a demand equal to or greater than

o

2.0

F to allow use of second stage. Comfort Trend looks at

temperature inside zone and watches trend over time. If zone

demand is being lowered by first-stage operation, second stage is

not energized. Stage 1 would remain ON and Stage 2 would

remain OFF as long as temperature and trend continued to

improve.

Comfort Trend Staging uses a 6-minute timer and a record of the

Reference Zone demand to control second stage. When Comfort

Trend Staging starts, demand in Reference Zone is recorded and

temperature in zone is continuously monitored. If demand in

Reference Zone is reduced (temperature is approaching comfort

setpoints), then 6-minute timer is restarted and new demand is

recorded. If 6-minute timer expires and demand is the same or has

grown greater, Comfort Zone will start second stage.

Comfort Trend works for all stages of heating and cooling

operation.

Comfort Trend staging will be used if rotary Position T-8 is turned

ON. If T-8 is turned OFF, then second stage will be energized

whenever Reference Zone demand meets or exceeds 2.0°F and

after 3-minute delay.

System Mode Reselect allows Comfort Zone to switch between

heating and cooling even if current system demand has not been

satisfied. For example, if Comfort Zone is providing heat, System

Mode Reselect allows Comfort Zone to look at any cooling needs

which may also exist in the building. If cooling demand exceeds

heating demand for 20 minutes, Comfort Zone will stop providing

DEMAND °F DEMAND °C

heat and switch into a cooling mode. Once cooling demand is

satisfied (or System Mode Reselect dictates a switch), Comfort

Zone will revert to a heating mode in order to try and satisfy that

demand.

The need for System Mode Reselect usually indicates some type of

system problem. Common use of System Mode Reselect may be

caused by poor or improper duct work, open windows or doors,

HVAC equipment failure, improper equipment sizing, etc. The

need for System Mode Reselect usually occurs in larger installations where zone use or occupancy may vary widely. For residential application, the need for System Mode Reselect is normally not

frequent unless the building has unusual architectural features or

problems with HVAC system.

High/Low Temperature Limits is an option that allows Comfort

Zone to control equipment stages and position dampers based upon

temperature of supply air leaving HVAC equipment. As the

Comfort Zone system operates through a heating or cooling cycle,

zone demands and damper positions will change. This changes

actual tonnage or BTUH that is applied to HVAC equipment. The

tonnage generated by HVAC equipment must equal tonnage

placed into zones. If zone’s airflow decreases, cooling equipment

will tend to drive down supply air temperatures. Conversely,

heating equipment will tend to drive up supply air temperatures.

With High/Low Temperature Limits turned ON, Comfort Zone

will detect this condition and take corrective action. The first step

taken by Comfort Zone will be to start turning off extra stages of

equipment. this will continue until either the Leaving Air Temperature problem is corrected or system is operating on first-stage

heating or cooling only.

If system is operating on first-stage heating or cooling, Comfort

Zone will begin to gradually open zone dampers. This can continue

until system has become a fully-open constant-volume system if

needed. The objective is to provide required heating or cooling as

best as possible prior to shutting off equipment. In practice the

control tends to match equipment capacity to zone demands and

will seldom revert back to a fully-open system.

The Leaving Air Temperature control can also indicate problem

zones within a system which are not receiving sufficient airflow. If

1 area (or zone) within a building has difficulty becoming satisfied

then there may be a sizing problem or an obstruction in duct work

supplying that zone.

To use the Leaving Air Temperature Control, 3 options must be

setup properly. They are:

1. High/Low Temperature Limits Enabled (Rotary Position

T-10).

2. High Temperature Trip Limit (Rotary Position S-6).

3. Dx Coil Sensor For Leaving Air Temperature Checking

(Rotary Position T-27).

First, High/Low Temperature Limits Enabled must be turned

ON. This is the ON-OFF switch for the control option. The

temperature used for this control is measured by Remote Duct

Sensor and (optionally) the Dx Coil Sensor.

The High Temperature Trip Limit (Rotary Position S-6) is

supply air temperature for heating that the Leaving Air Temperature control uses to detect a problem during heating modes only.

The Comfort Zone thermostat will display a number between 05

and 55°F. The actual temperature is 100°F greater, such that the

actual range is 105°F to 155°F. Comfort Zone cannot display the

100’s digit.

Selecting the Offset Temperature picks the temperature when

Comfort Zone will start taking action to correct the Leaving Air

Temperature. If limit temperature is between 105°F and 109°F,

11

Page 12

then temperature at which first stage will be shut down will be

offset 5°F above limit value (110°F to 114°F). If limit temperature

is between 110°F and 155°F, then temperature at which first stage

will shut down will be offset 20°F above limit value (130°F to

175°F). For Cooling modes the temperature is fixed at 50°F (10°C)

for starting the control and 45°F (7.2°C) for turning off first-stage

cooling.

The heating value must be set given the type of heater used in the

system. This is for the final heat source. So a heat pump with

strip heat would use a temperature appropriate for strip heaters. A

furnace application may have a setting in the 130°F to 155°F

range. Strip heaters may fall into a 115°F to 130°F range. Heat

pump only systems may use 105°F to 115°F. Check equipment

manufacturer recommendations and verify setting is in accordance

with UL, NFPA, or any applicable Local or State Building Codes.

If there is any question about what may be an appropriate

temperature setting, use conservative (low) temperatures.

Dx Coil Sensor For Leaving Air Temperature (Rotary Position

T-27) allows Comfort Zone to use a Dx Coil Sensor in addition to

Remote Duct Sensor for Leaving Air Temperature Checking. The

Dx Coil Sensor is used in heat pumps with fan coil applications

and will be located after the Dx coil and before any strip heaters.

This sensor is only active during heat pump operation. The

temperature setting for this sensor is fixed at 105°F for initiating

the control option and 110°F for shutting down first stage.

Heat Pump-Strip Heat Economy Feature (Smart Start). This is

an automatic control within Comfort Zone and not a selectable

option. The Smart Start feature is used whenever primary source of

heat is a heat pump. As such, the Heat Pump toggle (Rotary

Position T-6) must be turned ON. Smart Start is designed to help

minimize use of strip heat or emergency heat whenever a large

heating demand occurs due to a scheduled setpoint change. Smart

Start looks at scheduled comfort setpoints for the next hour. If

scheduled setpoints will make system provide heat, Smart Start

will start heat pump an hour early. Smart Start will operate until

zone demand is brought within 0.5°F (0.28°C) of the next hour’s

heat setpoint or setpoints change due to the schedule (the hour

expires).

Smart Start assumes auxiliary heat is more expensive to operate

when compared to heat pump and it assumes that heat pump is a

relatively "slow" source of heat. Smart Start allows a zone to

recover from a setback or unoccupied period and use the most

economic source of heat in doing so. The idea of using a setback

or unoccupied schedule is to save money in operating costs. There

is little incentive to use schedules if zone is heated with most

expensive source of heat available.

Step 11—Configuring Four Zone Controller

PROGRAMMABLE OPTIONS-SETTINGS

Turn zone selector dial to position S. (See Fig. 18.) The controller

display shows setting number and its value.

The upper 2 digits show the setting’s number and the lower 2 digits

show the value of setting.

Press the COOL up or down setpoint buttons to change setting

number and the HEAT up or down setpoint buttons to change

value. Refer to Table 6 for settings and their definitions.

1. Zone Controller Bus Address (S-1)

This setting establishes the identity of the 4 zone controller on

the Carrier communication bus.

NOTE: Remote room sensors do not require addressing.

If using optional Smart Sensors, they must be addressed as

follows:

Table 6—Programmable Options-Settings

SETTING

NO.

S-1 4 Zone Controller Bus Address 4-64 4

S-2 Maximum Cooling Setpoint 80-95 85

S-3 Minimum Heating Setpoint 34-64 65

S-4 Maximum Damper Position 8-15 15

S-5 Ventilation/Minimum Damper Position 0-7 0

S-6 High Temperature Trip Limit 105-155 105

S-7 Dual Fuel Setpoint 0 or 10-60 0

ZONE 1 Address of 4 zone controller

ZONE 2 Address must be 1 less than zone 1

ZONE 3 Address must be 2 less than zone 1

ZONE 4 Address must be 3 less than zone 1

To set address of a Smart Sensor, rotary switch position 1 on

Smart Sensor must be selected first.

2. Maximum Cooling Setpoint (S-2)

This is the highest temperature value to which cooling setpoint

can be adjusted. All zones will use same value. The maximum

cooling setpoint can be programmed from 80°F to 95°F. This

allows cooling setpoints to be programmed above normal

range.

Example: Maximum cooling setpoint is programmed at 92°

F. The temperature range for cooling setpoint is 70° F to 84°F.

When the COOL setpoint up button is pressed to adjust

cooling setpoint above 84°F, setpoint will jump to 92°F.

3. Minimum Heating Setpoint (S-3)

This is the lowest temperature value to which heating setpoint

can be adjusted. All zones will use same value. The minimum

heating setpoint can be programmed from 34°F to 64°F. This

allows heating setpoints to be programmed below normal

range.

Example: Minimum heating setpoint is programmed at 56°

F. The temperature range for heating setpoint is 66° F to 80°F.

When the HEAT setpoint down button is pressed to adjust

heating setpoint below 66°F, setpoint will jump to 56°F.

4. Maximum Damper Position (S-4)

This is the highest open position to which a damper will

change. Full open is designated as position 15. Maximum

open damper position can be programmed between 8 (half

open) and 15, in increments of 1. All zone dampers will use

the same programmed maximum value.

5. Ventilation/Minimum Damper Position (S-5)

When there is no demand for cooling or heating, this is the

minimum position that every zone damper will maintain as

long as air temperature in duct work is between 65°F and

80°F. Full closed is designated as position 00. Minimum open

damper position can be programmed between 7 (half-open)

and 00, in increments of 1. All zone dampers will use the same

programmed ventilation value.

6. High Temperature Trip Limit (S-6)

The trip temperatures limits are duct temperatures used to turn

HVAC equipment off to prevent damage to equipment.

Temperature values are measured by duct temperature sensors.

The low temperature trip limits are 50°F (turn off second-stage

cooling) and 45°F (turn off first-stage cooling) and cannot be

changed.

The second-stage high temperature trip limit can be programmed from 105°F to 155°F.

SETTING NAME VALUE

12

FACTORY

DEFAULT

Page 13

If a value of 105 to 110 is selected (second-stage heating is

turned off at this value) then the first-stage high temperature

trip limit is the programmed value plus 5°F (first-stage is

turned off).

If a value of 111 to 155 is selected (second-stage heating is

turned off) then the first-stage high temperature trip limit is the

programmed value plus 20°F (first stage is turned off).

Example 1:

High temperature trip limit selected is 105°F. (Shown as 05 in

controller display.)

Second-stage heat will turn off when duct temperature sensor

measures a temperature greater than 105°F.

First-stage heat will turn off when duct temperature sensor

measures a temperature greater than 110°F.

Example 2: High temperature trip limit selected is 140°F.

(Shown as 40 in controller display.)

Second-stage heat will turn off when duct temperature sensor

measures a temperature greater than 140°F.

First-stage heat will turn off when duct temperature sensor

measures a temperature greater than 160°F.

7. Dual Fuel Setpoint (S-7)

This option is used with a system that has a heat pump and

another heat source (possibly gas) that should not run at the

same time as heat pump. When any heat pump is on, all

auxiliary heat will be off, and vice versa.

NOTE: The auxiliary heat must always have greater heating

ability than the heat pump at low outdoor temperatures for this

option to have any value.

NOTE: If Dual Fuel setpoint is set to 0, then this option is

disabled. If Dual Fuel option is used, an outside air temperature

sensor or refrigerated air sensor must be used.

When dual fuel setpoint variable is set to outdoor temperature

(10°F to 60°F) that is the crossover point between running

heat pump or using auxiliary heat as the preferred method of

heating.

The setpoint is used only when the first stage of heating is

brought on. If outdoor temperature is above setpoint, heat

pump (Y1) is energized. If outdoor temperature is below

setpoint, auxiliary heat (W1) is used. If heat pump is started

and outdoor temperature goes below setpoint, dual fuel option

is not used for that heating cycle.

PROGRAMMABLE OPTIONS-TOGGLES

Turn zone selector dial to position T. (See Fig. 18.) The controller

display shows setting number and its value.

The upper left 2 digits show setting number while the right side

shows the value of ON or OFF.

Press the COOL up or down setpoint buttons to change toggle

number and the HEAT up or down setpoint buttons to change

status of toggle. (See Table 11.)

Step 12—Wiring Diagrams

Refer to Tables 7 and 8 for wiring diagram reference information.

Step 13—Start-Up

1. Verify that zone number for remote room sensors and corresponding zone damper wire connections are the same in the

Comfort Zone Center.

2. Check that AC power wires (dampers and transformer) are

kept away from DC wires (remote room sensors, 4 zone

controller, communication bus) leading up to, and in the

Comfort Zone Center.

3. Check location of 4 zone controller and remote room sensors

to make sure that they are not near heat producing devices

such as lamps, sunlight, and appliances.

Table 7—Wiring Diagram Reference

For Fig. 19 and 20

FAN COIL WITH AIR CONDITIONER

INDOOR UNIT (FIG. 19)

OUTDOOR UNIT

Single-Stage

Air Conditioner

Two-Speed

Air Conditioner

OUTDOOR UNIT

Single-Speed

Air Conditioner

Two-Speed

Air Conditioner

* KGATT0101VSP (Optional) Two-stage relay kit— may help to control over

conditioning.

† Latent capacity control—Required, field supplied. See 2-speed Installation

Instructions.

FA4A

FB4A

FC4B

AA B

C† D E

FURNACE WITH AIR CONDITIONER

58VUA/VCA

A* B B B C C

DE* F† G† H HI†

FK4A FK4B

INDOOR UNIT (FIG. 20)

58PAP

58RAP

58GFA

58DFA

58EFA

58SXA

58DXA

58WAV

58ZAV

58PAV

58RAV

58SXC

58DXC

58EJA

58MXA

58MCA

58MVP

Table 8—Wiring Diagram Reference

For Fig. 21 and 22

FAN COIL WITH HEAT PUMP

INDOOR UNIT (FIG. 21)

OUTDOOR UNIT

Single-Stage

Heat Pump

Two-Speed

Heat Pump

OUTDOOR UNIT

Single-Speed

Heat Pump

Two-Speed

Heat Pump

* KGATT0101VSP (Optional) Two-stage relay kit—may help to control over

conditioning.

† Latent capacity control—Required, field supplied. See 2-speed Installation

Instructions.

** Field-supplied isolation relay.

FA4A

FB4A

FC4B

AA B

C† D E

FURNACE WITH HEAT PUMP

58VUA/VCA

A** B* ** C C D D

E** F* ** G† H† I I

FK4A FK4B

INDOOR UNIT (FIG. 22)

58PAP

58RAP

58GFA

58DFA

58EFA

58SXA

58DXA

58WAV

58ZAV

58PAV

58RAV

58SXC

58DXC

58EJA

58MXA

58MCA

58MVP

4. Make sure that the 3 wire communication bus cable for the 4

zone controller is not run in same conduit, or use same cable

jacket, as the 5 wire conductor of the 4 zone controller.

5. On a remote room sensor follow wire guide stamped on base

by terminal screws in order to keep polarity and voltages

correct. Otherwise sensor will not work properly.

6. Make sure duct temperature sensor is placed in supply air duct

work, downstream of furnace and evaporator coil, and upstream of bypass damper.

13

58TUA

58TMA

58TUA

58TMA

Page 14

7. Write down on a piece of paper AND GIVE TO THE

OWNER a list showing what rooms are controlled by what

dampers, and their corresponding zone numbers. Keep list for

your future use.

8. Instruct owner to turn cool switch OFF in the fall, and turn it

ON in the spring.

9. Make sure emergency heat switch is in the OFF position. If a

gas furnace is used this switch should never be turned on. It is

for heat pumps only.

10. Be sure and set clock to correct time of day. You only need to

do this when you first power up system, or after a power

outage lasting longer than 8 hours.

11. Go to rotary switch setting 2 on the 4 zone controller. Check

calibration of room sensor. Do same for zones 2, 3, and 4

(rotary switch 3-4-5). Sensors must be calibrated.

12. Instruct owner in operation of Comfort Zone System

13. Instruct owner to call 800 number supplied with Comfort Zone

Center to receive free "How to use Comfort Zone" video tape.

14. For toggle settings for configuration see Programmable

Toggles and Options and Table 9.

Step 14—Programming Schedules

The 4 zone controller is the program center for the Comfort Zone

System. The 4 zone controller provides the ability to program

system for unique demands of each zone at different times during

the day and week. See Fig. 18 to become familiar with various

parts of the 4 zone controller.

SYSTEM SWITCHES

System switches select desired equipment operation.

Heat Switch

OFF—Heat will not come on.

AUTO—Heat will come on when any zone is more than 1.5°F

below desired heat setpoint.

INDICATES ZONE SETPOINTS, ZONE TEMPERATURES,

AND PROGRAMMING INFORMATION AND

ALLOWS SETPOINT ADJUSTMENT.

FOUR

CONTROLLER DISPLAY

ZONE

CONTROLLER

OPTIONS

T89

ZONE 1

8

7

6

5

4

ZONE 2

ZONE 3

ZONE 4

1

VACATION

3

2

SET

TIME/TEMP

SCHEDULES

HOLD

TEMPERATURES

OFF AUTO AUTO OFF AUTO ON ONOFF

HEAT COOL FAN EMERGENCY HEAT

SELECT

MIN/HR/DAY

ADVANCE

TIME/DAY

INDICATES THE CURRENT TIME AND DAY

AND THE START TIMES/WEEKLY PERIODS

DURING PROGRAMMING.

AM

AM

SET

TIME/TEMP

SCHEDULES

HOLD

TEMPERATURES

SELECT

MIN/HR/DAY

ADVANCE

TIME/DAY

PROGRAMMING ADJUSTMENT BUTTTONS

ALLOWS FOR PROGRAMMING WEEKLY PERIODS, START TIMES

FOR EACH ZONE AND SETS THE CLOCK FOR DAY AND TIME.

CLOCK DISPLAY

OPTIONS

8

7

6

5

4

S

9

3

T

ZONE 1

ZONE 2

ZONE 3

ZONE 4

1

2

VACATION

ZONE SELECTOR DIAL

PROVIDES ACCESS TO INFORMATION AND PROGRAMMING

FOR EACH ZONE AND SELECTION OF VACATION MODE.

OPTION AREA IS FOR USE BY INSTALLATION/SERVICE.

Fig. 18—Four Zone Controller

14

OFF AUTO AUTO OFF AUTO ON ONOFF

HEAT COOL FAN EMERGENCY HEAT

!

SYSTEM SWITCHES

PROVIDES FOR SELECTION OF HEAT, COOL,

FAN AND EMERGENCY HEAT OPERATION.

A93232

Page 15

Cool Switch

OFF—Cooling will not come on.

AUTO—Cooling will come on when any zone is more than 1.5°F

above desired cool setpoint.

Fan Switch

ON—Fan will stay on continuously (recommended).

AUTO—Fan will come on only when heating or cooling is

required.

Emergency Heat Switch (Heat Pump Systems only)

OFF—Electric strip heat will not come on unless there is a zone

more than 2°F below desired heat setpoint and comfort trend

demand has been satisfied.

ON—When any zone requires heat, electric strip heat will turn on.

The compressor will remain off.

CONTROLLER DISPLAY

When set for normal operation, the 4 zone controller display shows

current zone temperature setpoints and allows adjustment of these

setpoints using setpoint buttons. By pressing both heating or

cooling setpoint buttons simultaneously, controller will lock in and

display temperatures for that zone. To release, push both buttons

simultaneously again. This will only work when T-20 is off.

ZONE SELECTOR DIAL

To view setpoints for each zone, turn zone selector dial to zone

number you wish to view.

The setpoints for selected zone will be displayed in controller

display.

Program Schedules

Each zone has 3 different weekly periods, (Weekdays, Saturday,

and Sunday) and up to 4 different possible combinations of heating

and cooling setpoints that can be programmed to provide automatic climate control depending upon day of week and time of

each day. Each zone can be programmed independently. (See

Table 9.)

NOTE: All zones must be programmed.

Table 9—Example Weekly Schedule

WEEKDAYS SATURDAY SUNDAY

6AM 72/70 7 AM 72/68 8 AM 72/70

8AM 85/65 10 AM 85/65 10 AM 85/65

5PM 70/68 2 PM 70/68 7 PM 70/68

10 PM 85/65 11 PM 85/65 10 PM 85/65

WEEKLY PERIOD

Start Time Cooling Setpoint/Heating Setpoint

Vacation Mode

Vacation mode displays current vacation temperature setpoints and

allows adjustment of these setpoints using setpoint buttons. These

setpoints are used by all zones until selector dial is returned to 1 of

the zone selection positions. At all times, the setpoints displayed

will be the temperature range that the system will maintain.

This mode can also be used to maintain entire home at 1 constant

temperature-typically when unoccupied.

NOTE: If Fan Switch is set to ON, fan will continue to run in

vacation mode.

To enter vacation mode, turn selector dial to VACATION. The

word "VACATION" will appear on controller display whenever

system is in this mode. Set vacation mode setpoints.

Setting The Clock

The clock display will normally show hour, minutes, AM or PM,

and day.

1. Set minutes.

Press SELECT MIN/HR/DAY button once.

Press ADVANCE TIME/DAY button to scroll to proper

minutes.

2. Set hour.

Press SELECT MIN/HR/DAY button once again.

Press ADVANCE TIME/DAY button to scroll to proper hour,

AM or PM.

3. Set day.

Press SELECT MIN/HR/DAY button once again.

Press ADVANCE TIME/DAY button to scroll to proper day.

4. Return to normal operation.

Press SELECT MIN/HR/DAY button once again. The newly

programmed time will be displayed.

Programming Schedules

1. Enter Program Mode

Press SET TIME/TEMP SCHEDULES button to enter pro-

gram mode. The program mode and current zone will be

shown on controller display.

2. Select a zone.

Turn rotary switch to the zone to be programmed.

3. Select a weekly period.

The clock display will show MTWTHF.

Pressing ADVANCE TIME/DAY button selects weekly pe-

riod to be programmed.

Pressing button 1 time will change clock display to SA.

A second press will change display to SU.

A third press returns display to MTWTHF.

4. Program time periods.

There are 4 start times that can be programmed in each weekly

period.

Press SELECT MIN/HR/DAY button to program start times

for selected weekly period.

Pressing SELECT MIN/DAY/HR button once shows first

program start time on clock display and setpoints, with the

word PROGRAM for this start time on controller display.

Additional presses display start times 2, 3, 4, and then back to

weekly period display.

NOTE: While in program mode, if a period of 4-1/2 minutes

passes without a change to some value, the controller will return to

normal operation.

5. Program start time

NOTE: Start times must be programmed in chronological order

and must be in the same day. Any times before previous time

period will be ignored. In the WRONG example below, periods 2

and 4 will be ignored.