Page 1

Single Package Gas Heating and Electric Cooling Units

with Direct Spark Ignition and COMFORTLINK™ Controls

Installation Instructions

WEATHERMASTER

48ZG,ZN030-105

48ZT,ZW,Z6,Z8075-105

®

CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . .1,2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

Jobsite Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unit Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Roof Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Slab Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Curb Gasketing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Field-Fabricated Ductwork . . . . . . . . . . . . . . . . . . . . . . . 2

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Condensate Drain Connections . . . . . . . . . . . . . . . . . 23

Install Outdoor Hoods

(48ZG,ZN,Z6,Z8 Units). . . . . . . . . . . . . . . . . . . . . . . . . 33

• UNIT SIZES 030-050

• UNIT SIZES 055-105

Install Economizer Hoods (48ZT,ZW Units) . . . . . . 35

• INSTALL SMALL HOODS

• INSTALL LARGE HOODS

Field Wire Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

• UNIT SIZES 030-050

• UNIT SIZES 055-105

Field Electrical Connections . . . . . . . . . . . . . . . . . . . . 36

•POWER WIRING

Air Pressure Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

• INLET GUIDE VANES

• VARIABLE FRQUENCY DRIVE

• MODULATING POWER EXHAUST

• RETURN/EXHAUST POWER EXHAUST

Supply-Fan Shipping Brackets . . . . . . . . . . . . . . . . . . 53

• UNIT SIZES 030-050

• UNIT SIZES 055-070

• UNIT SIZES 075-105

Return/Exhaust Fan Shipping Brackets

(48Z6,Z8 Units). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Remove TXV Shipping Blocks. . . . . . . . . . . . . . . . . . . 54

Compressor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . 55

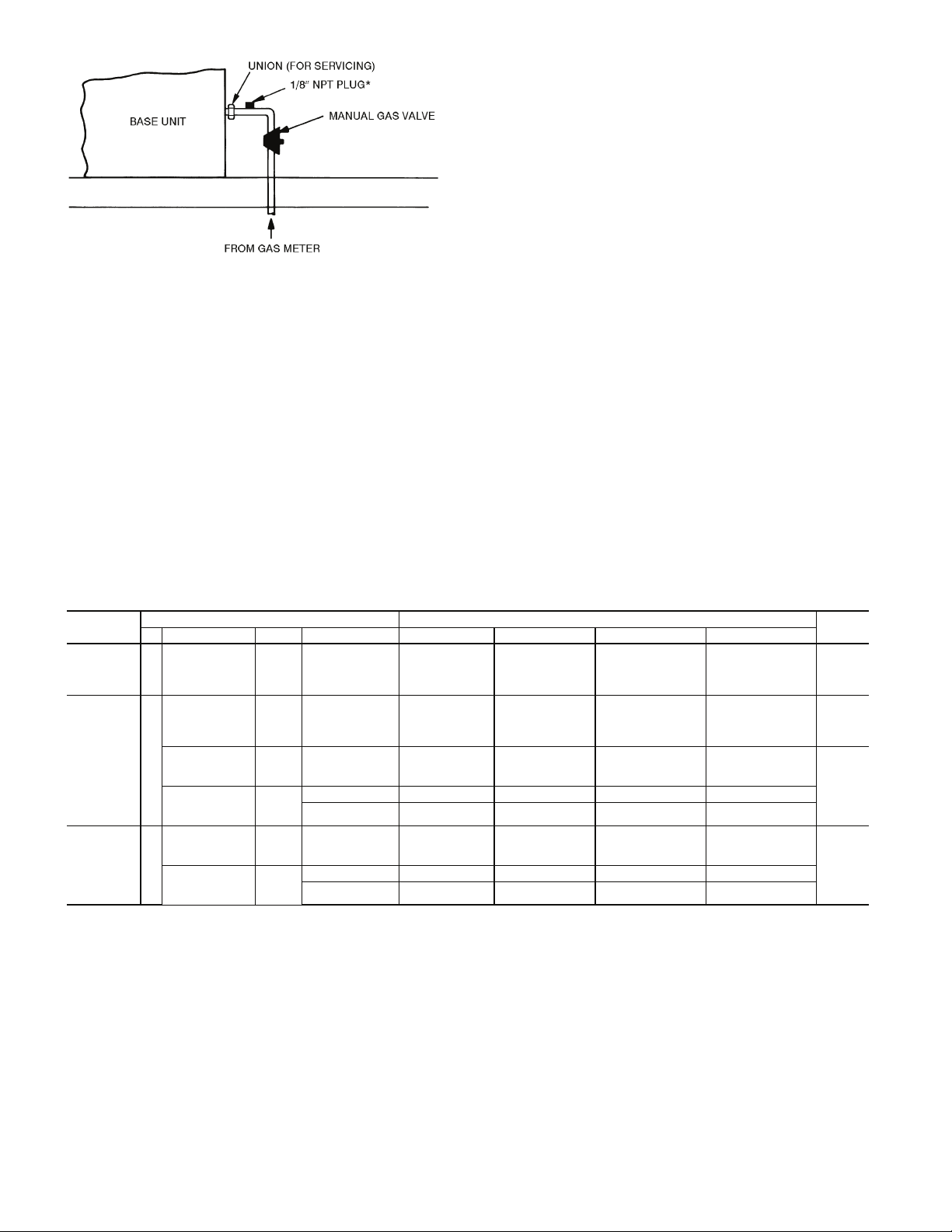

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Optional Staged Gas Control . . . . . . . . . . . . . . . . . . . . 55

Installing Flue/Inlet Hoods . . . . . . . . . . . . . . . . . . . . . . 56

Supply Air Thermistors

(Staged Gas Units Only) . . . . . . . . . . . . . . . . . . . . . . 56

Install Unit Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 59

CONTROLS INSTALLATION . . . . . . . . . . . . . . . . . . 59-66

Constant Volume Units. . . . . . . . . . . . . . . . . . . . . . . . . . 59

• CONTROL WIRING

Variable Air Volume Units . . . . . . . . . . . . . . . . . . . . . . . 59

Optional and Accessory Control Wiring . . . . . . . . . 60

Carrier Comfort Network

Smoke Control Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . 61

®

(CCN) Interface. . . . . . . 60

GENERAL

This installation instruction contains basic unit installation

information, including installation of thermostats and remote

temperature sensors.

For additional information and service instructions, refer to

the Controls and Troubleshooting literature also enclosed in

this literature packet.

The 48ZT,ZW units are equipped with standard integral

economizer and high-capacity power exhaust.

The 48Z6,Z8 units are equipped with factory-installed

return/exhaust fans.

The staged gas control (SGC) option adds the capability to

control the rooftop unit’s gas heating system to a specified supply air temperature set point for purposes of tempering a cool

mixed-air condition.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service personnel. When working on air-conditioning equipment, observe

precautions in the literature, tags and labels attached to the unit,

and other safety precautions that may apply.

Follow all safety codes, including ANSI (American National Standards Institute) Z223.1. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguisher available for all brazing operations.

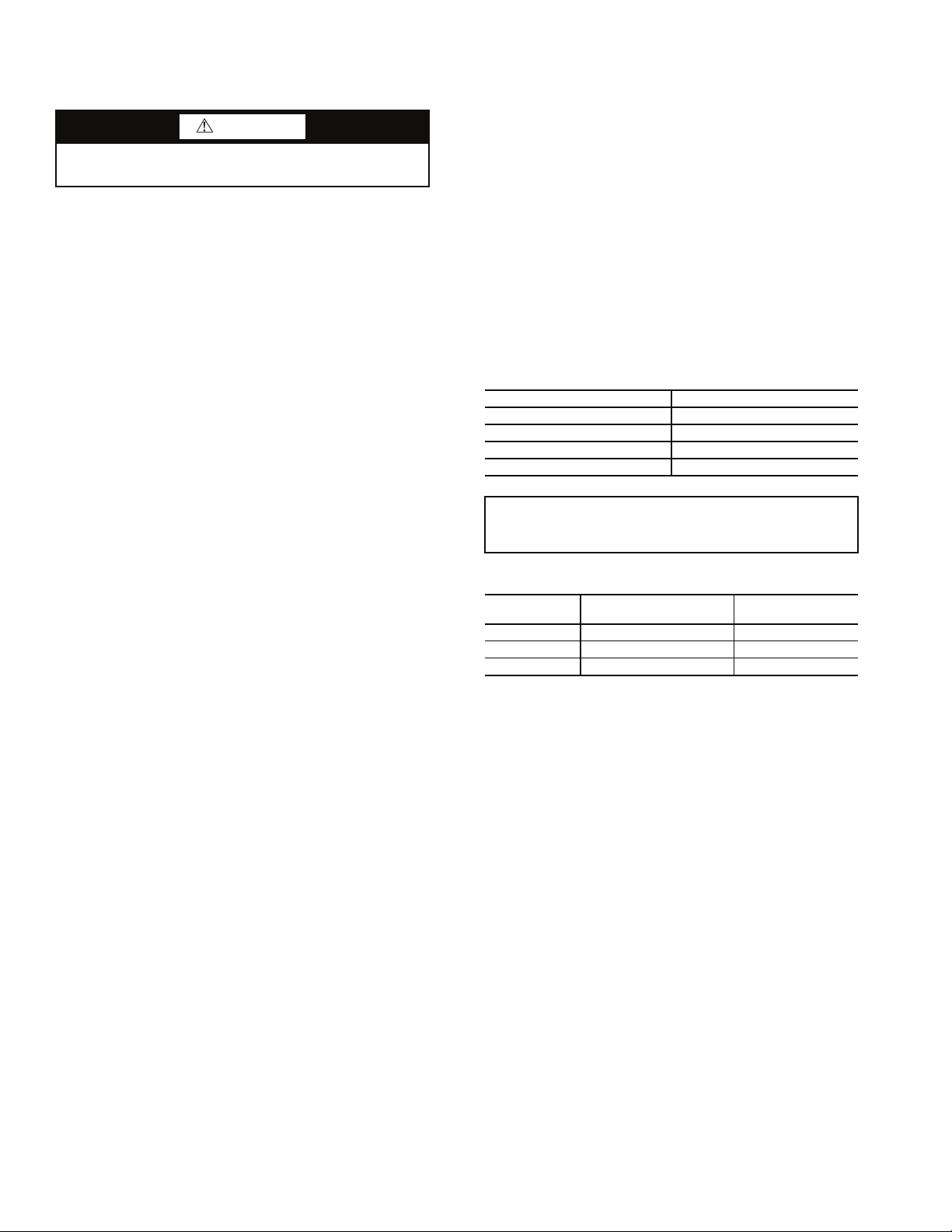

WARNING

Before performing service or maintenance operations on

unit, turn off main power switch to unit. Electrical shock

could cause personal injury.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance. Do not touch any electrical switch; do not use any phone in your building. Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions. If you cannot reach

your gas supplier, call the fire department.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service, or

maintenance can cause injury or property damage. Refer to

this manual. For assistance or additional information, consult a qualified installer, service agency, or the gas supplier.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53480060-01 Printed in U.S.A. Form 48Z-8SI Pg 1 4-09 Replaces: 48Z-7SI

Page 2

CAUTION

Disconnect gas piping from units when leak testing at pressures greater than 0.5 psig. Pressures greater than 0.5 psig

will cause gas valve damage resulting in a hazardous

condition. If gas valve is subjected to pressure greater than

0.5 psig, it must be replaced. When pressure testing fieldsupplied gas piping at pressures of 0.5 psig or less, the unit

connected to such piping must be isolated by manually

closing the gas valve.

INSTALLATION

Jobsite Survey —

installation.

1. Consult local building codes and the NEC (National

Electrical Code) (ANSI/NFPA [National Fire Protection

Association] 70) for special installation requirements.

2. Determine unit location (from project plans) or select unit

location.

3. Check for possible overhead obstructions which may interfere with unit lifting or rigging.

Complete the following checks before

CAUTION

Do not lift unit with forklift truck. Move unit with overhead rigging only.

Unit Placement — Inspect unit for transportation dam-

age. File claim with transportation agency.

Provide clearance around and above unit for airflow, safety,

and service access. Do not restrict top (area above condenser

fans) in any way. Allow at least 6 ft on all sides for rated performance, code compliance, and service.

Check unit dimensional drawings for unit arrangement and

minimum performance and service clearances.

Do not install unit in an indoor location. Do not locate air inlets near exhaust vents or other sources of contaminated air.

On units equipped with power exhaust option, high velocity

air is exhausted out the hood. Unit should be positioned with at

least 10 ft clearance between the exhaust hood and any obstruction. Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Level by using unit frame as a reference. Physical data is

shown in Tables 1A-6.

Roof Mount — Check building codes for weight distribu-

tion requirements. Unit weight is shown in Tables 1A-1E and

2. Unit may be mounted on class A, B, or C roofing material.

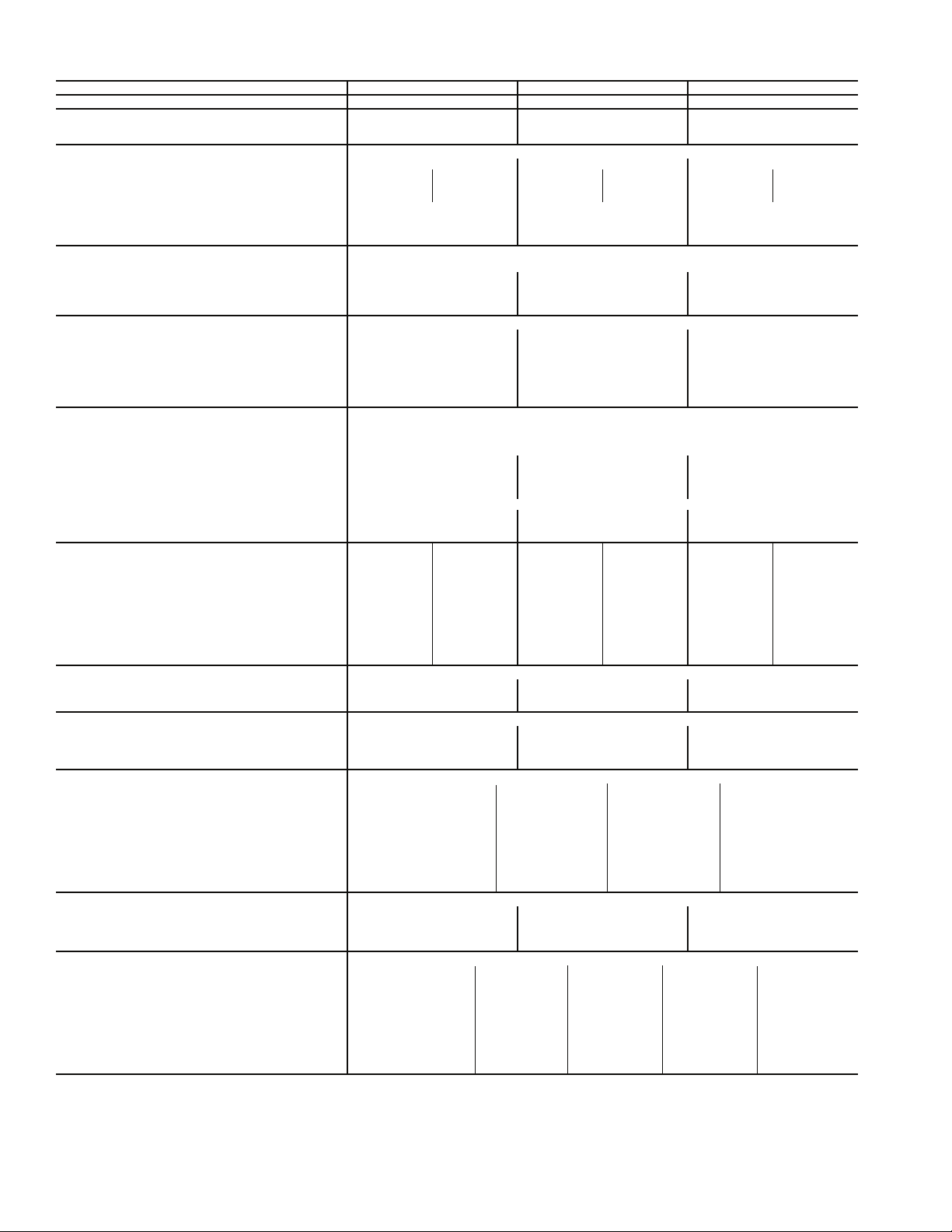

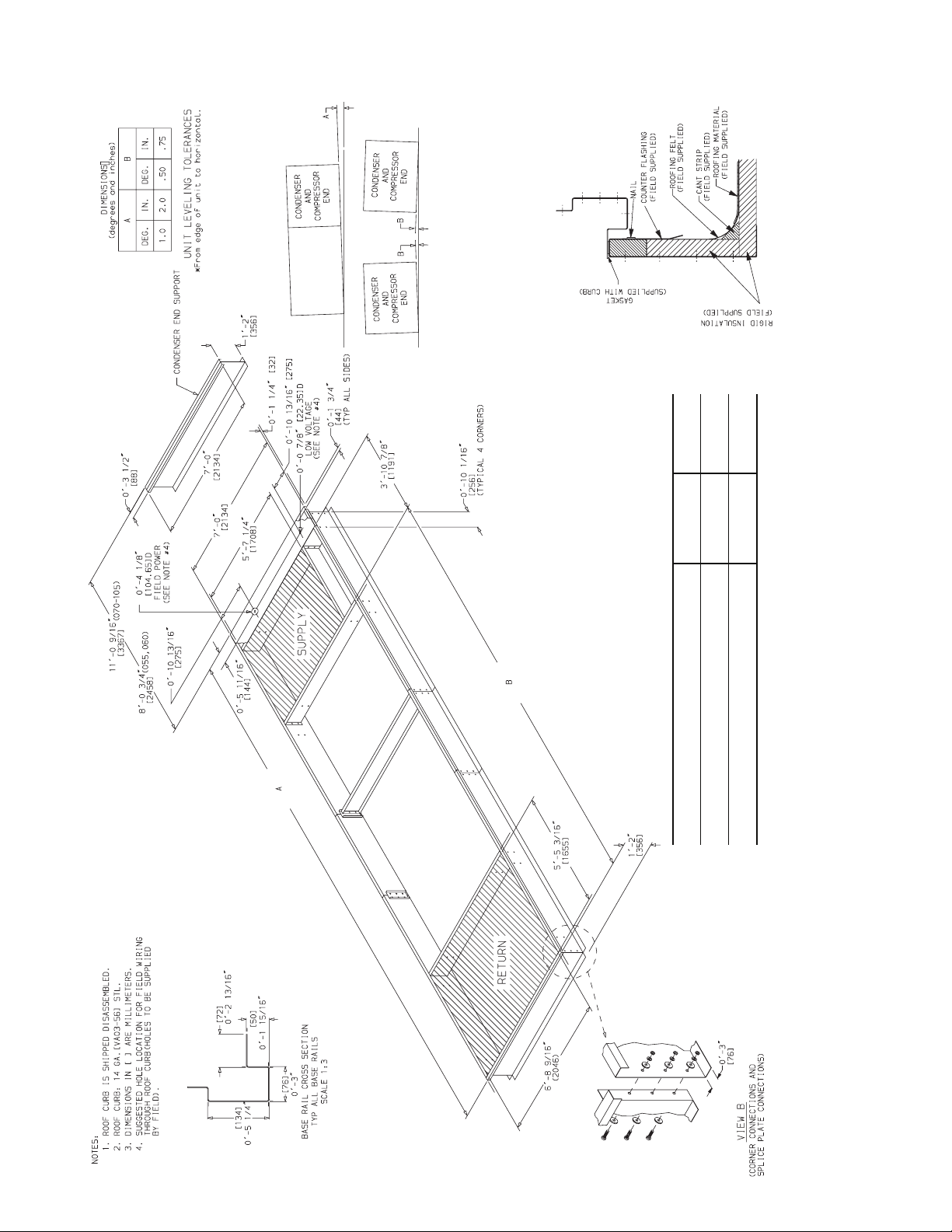

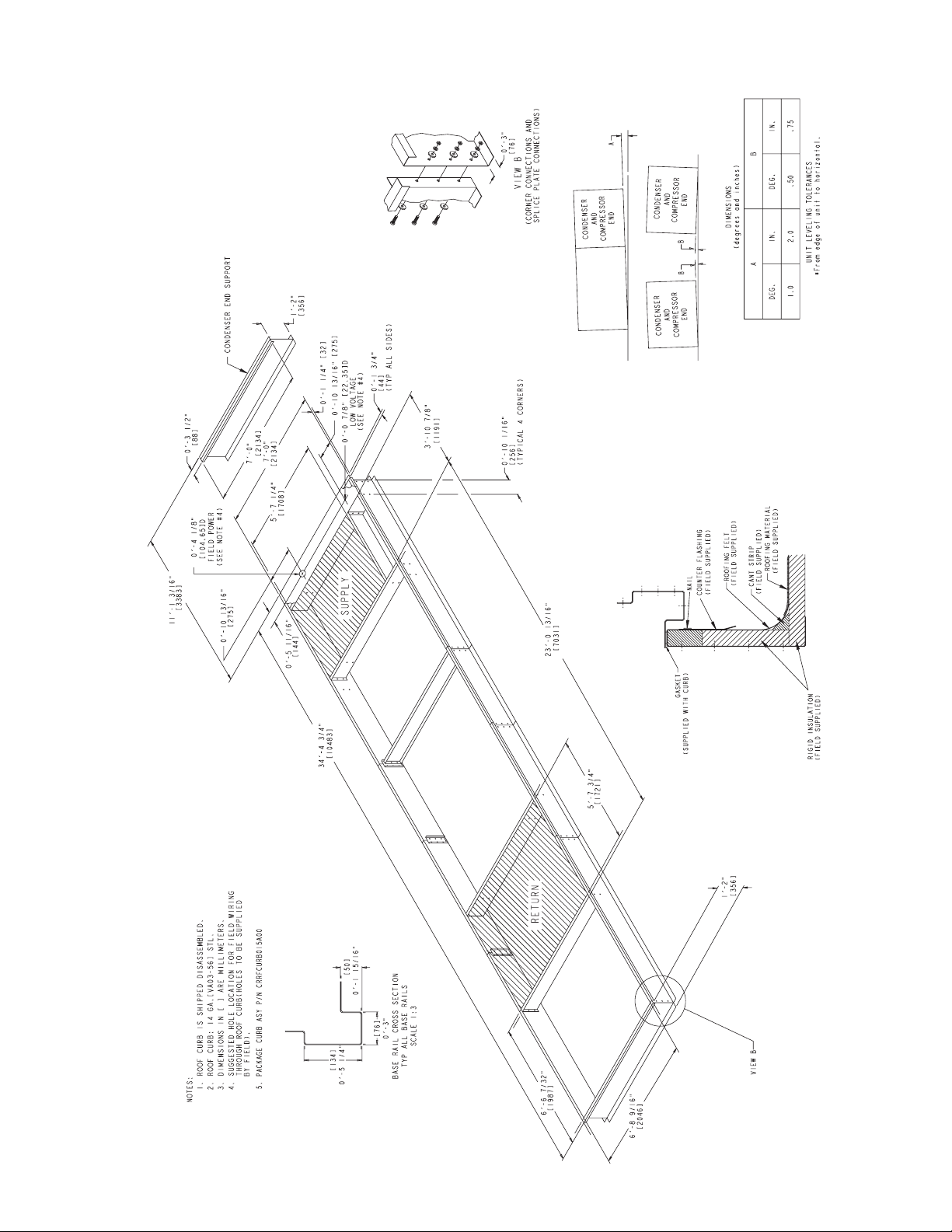

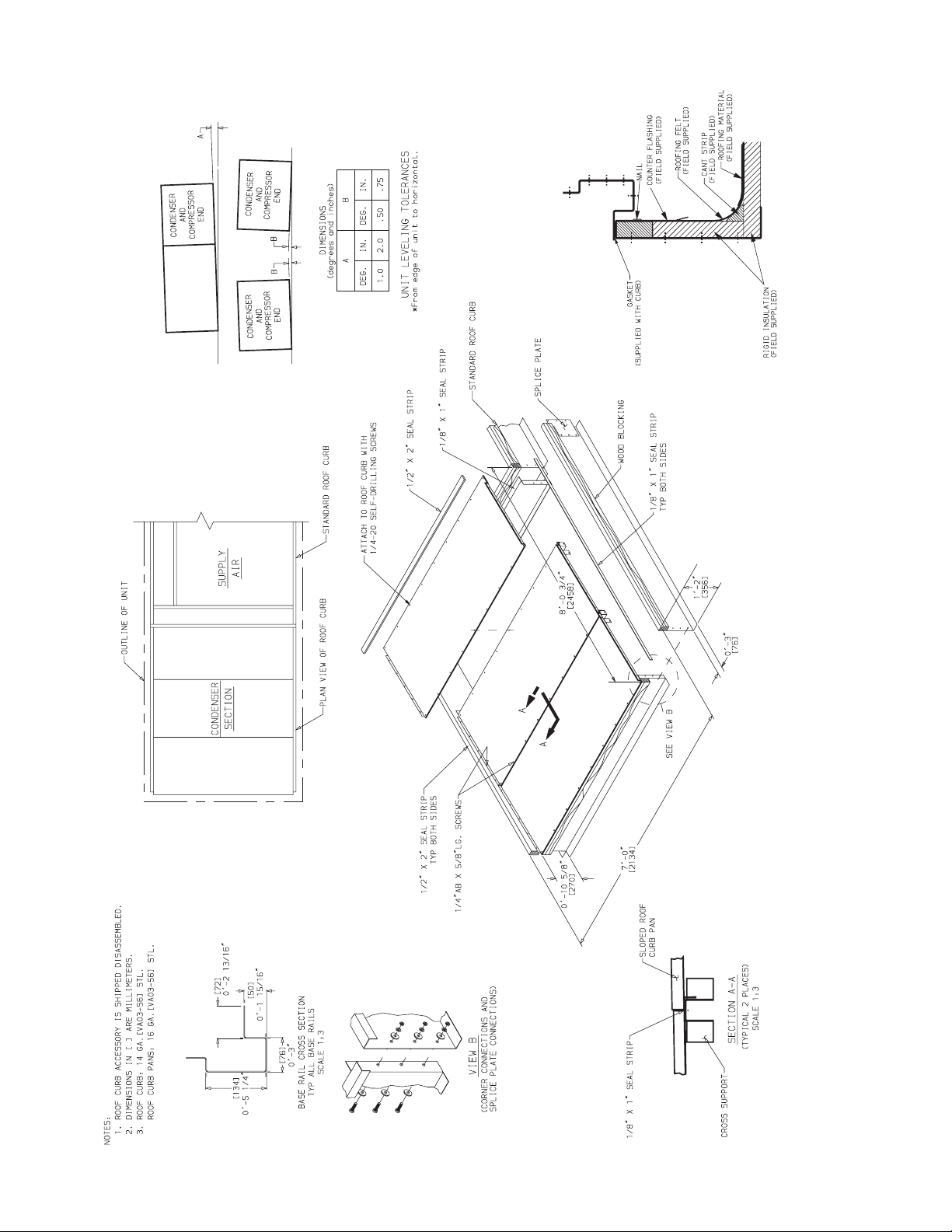

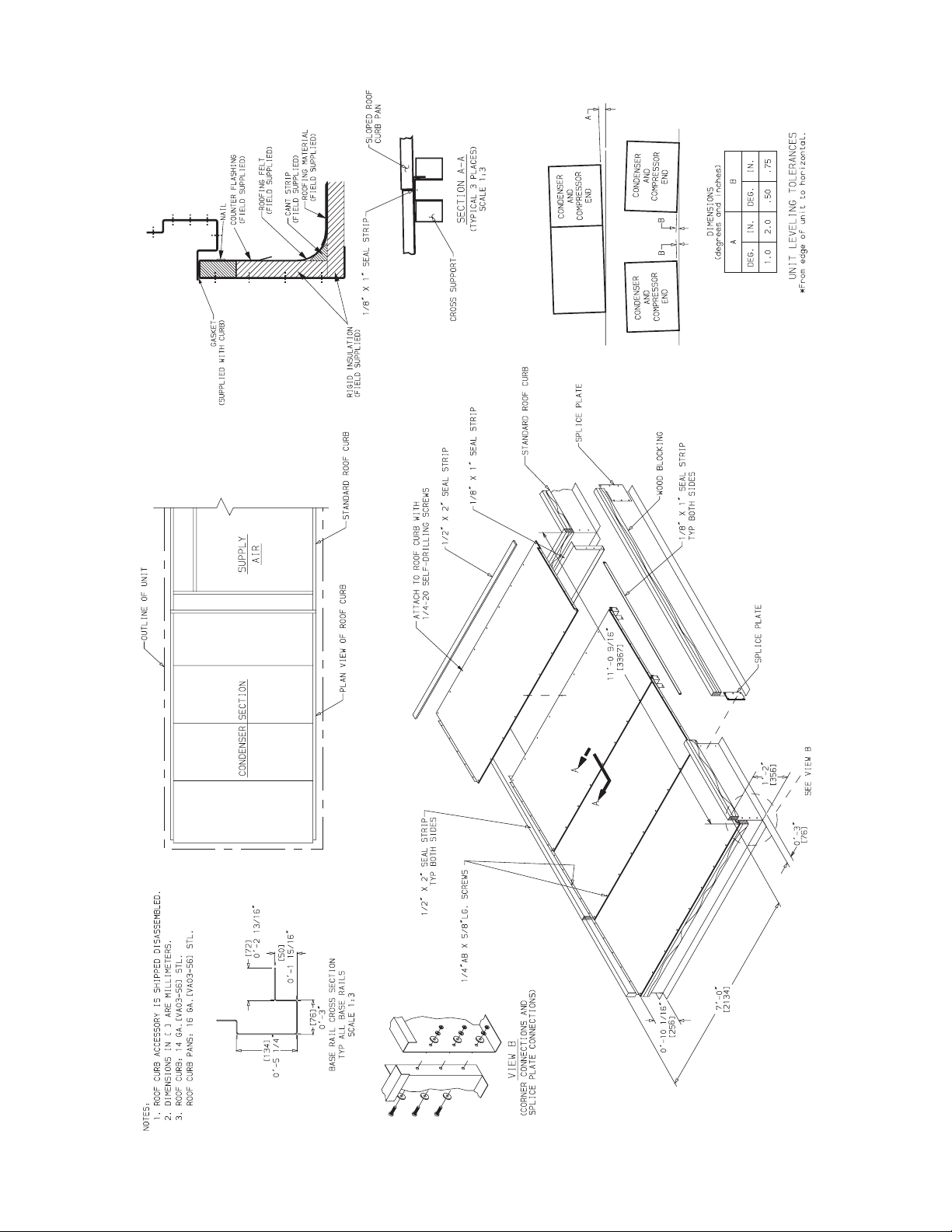

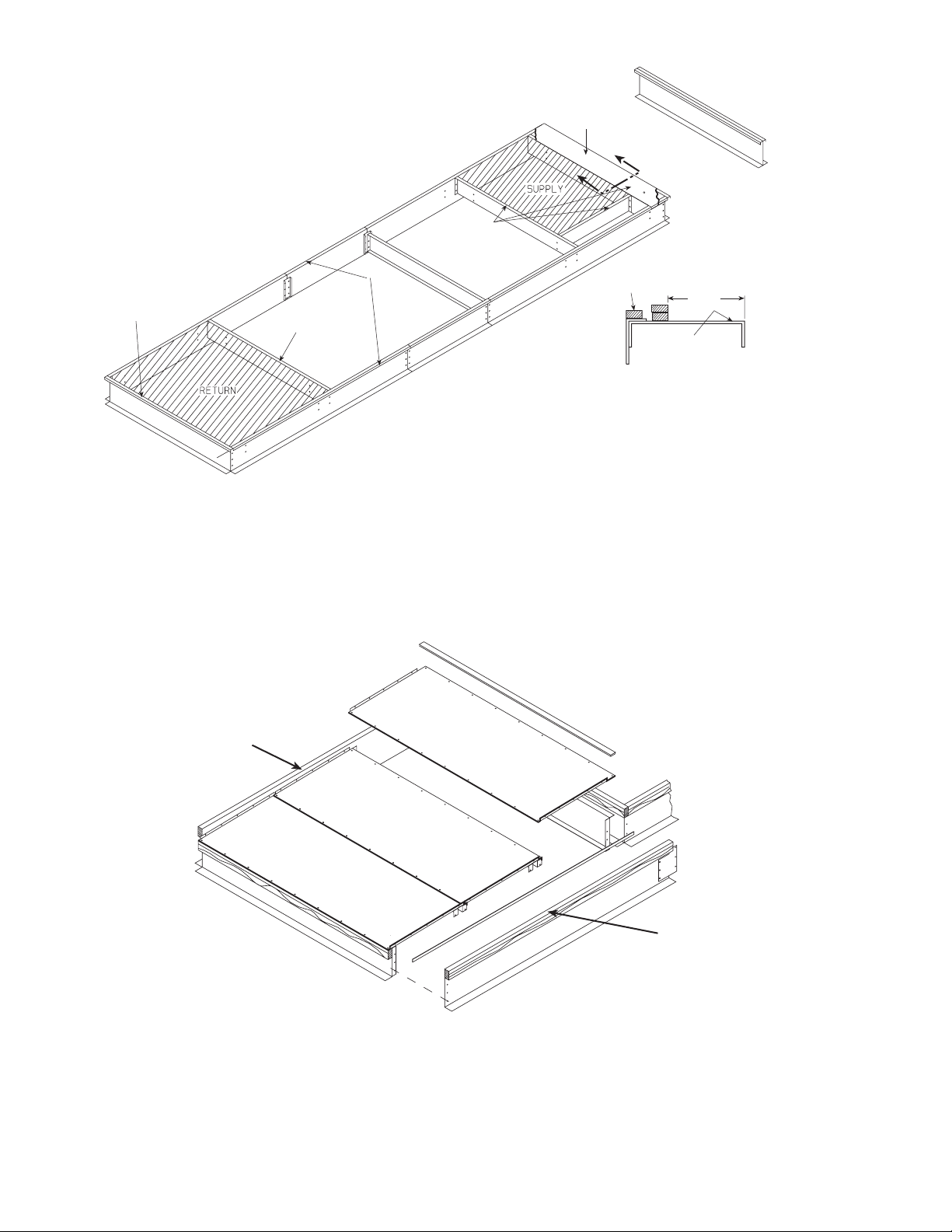

ROOF CURB — Assemble and install roof curb as described

in instructions shipped with the accessory. Accessory roof curb

and information required to field fabricate a roof curb is shown

in Fig. 1-5. Install insulation, cant strips, roofing and counter

flashing as required. For unit condensate drain to function

properly, curb must be level or within tolerances shown in

Fig. 1-5.

STEEL BEAMS — If roof curb is not used, support unit with

steel beams along its entire length and then support steel as required. As a minimum, unit must be supported across its width

at each lifting lug location.

Slab Mount — Provide a level concrete slab that extends

beyond unit cabinet at least 6 inches. Make a slab 8 in. thick

with 4 in. above grade. Use gravel apron in front of condenser

coil air inlet to prevent grass and foliage from obstructing

airflow. Ensure that slab is of sufficient height to allow for condensate trap of 4 in. on sizes 030-070 or 7 in. on sizes 075-105.

Curb Gasketing

SIZE 030-050 UNITS — After ductwork has been connected

to the roof curb, attach adhesive-backed gasketing on all end

rails, cross rails, and duct rails. Be sure all joints and corners of

gasket are square and flush to prevent possible water leaks.

Follow all applicable building codes.

SIZE 055-105 UNITS — After ductwork has been connected

to the roof curb, apply gasket material (

wide neoprene) where indicated.

Single-Thickness Gasketing (See Fig. 6-8 for Item Numbers) — Apply gasketing in the following places:

1. Along both side rails (1) — 2 places, full length

2. Along return air end rail (2) — 1 place

3. Around return air internal duct flange (3) — 1 or 2 places

4. Around supply air internal duct flanges (4) — 3 places

Double-Thickness Gasketing (See Fig. 6 and 8 and Detail

A-A) — Locate a line 93/4-in. from the supply air end of the

accessory curb. Apply a double-thickness of gasket material

along with line per detail A-A.

NOTE: Do not apply gasket material along the outside edge of

the curb (area “X”). This pan area of the curb extends out

beneath the end of the unit’s air handler section; applying gasket here develops a potential water trap area on top of the curb.

Condenser Section Roof Curb (See Fig. 7)

thickness gasket along both side rails (5).

1

/2-in. thick x 11/2-in.

— Apply single-

Field-Fabricated Ductwork

WARNING

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install a 90-degree

turn in the supply and return ductwork between the unit

and the conditioned space. If a 90-degree elbow cannot be

installed, then a grille of sufficient strength and density

should be installed to prevent objects from falling into the

conditioned space. Failure to follow these instructions

could result in personal injury or property damage due to

falling objects.

The 48ZG,ZN,ZT,ZW,Z6,Z8 units are designed for vertical

supply/return only. Field-fabricated ductwork must be attached

to the roof curb, on to the support steel, prior to the final rigging

and installation of the unit. Supply and return duct dimensions

are shown in Fig. 1-3.

To attach ductwork to roof curb, insert duct approximately 10

to 11 in. up into roof curb. Connect ductwork to 14-gage roof

curb material with sheet metal screws driven from inside the duct.

Secure all ducts to the building structure, using flexible duct

connectors between roof curbs and ducts as required. Ducts

passing through an unconditioned space must be insulated and

covered with a vapor barrier. Outlet grilles must not lie directly

below unit discharge. The return duct must have a 90-degree

elbow before opening into the building space if the unit is

equipped with power exhaust.

Design supply duct strong enough to handle expected static

pressures.

Rigging — Do not drop unit; keep upright. Use spreader

bars over unit to prevent sling or cable damage. Sheets of plywood placed along the condenser coils will provide additional

protection. All lifting lugs MUST be used when lifting unit.

Level by using unit frame as a reference. See Fig. 9-13 for information. Unit and accessory weights are shown in Tables 1A1E and 2. Weight distribution and center of gravity can be

found in Fig. 14.

2

Page 3

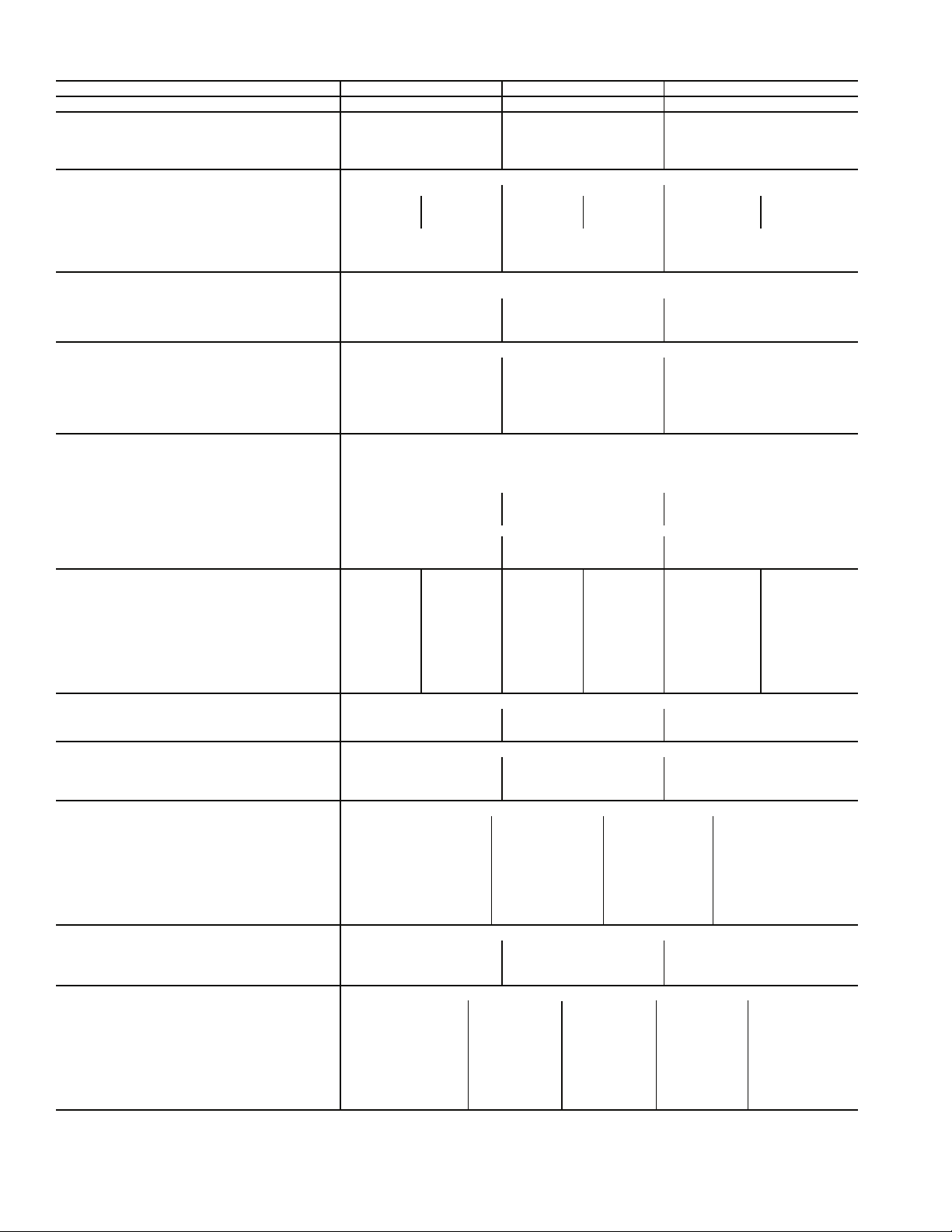

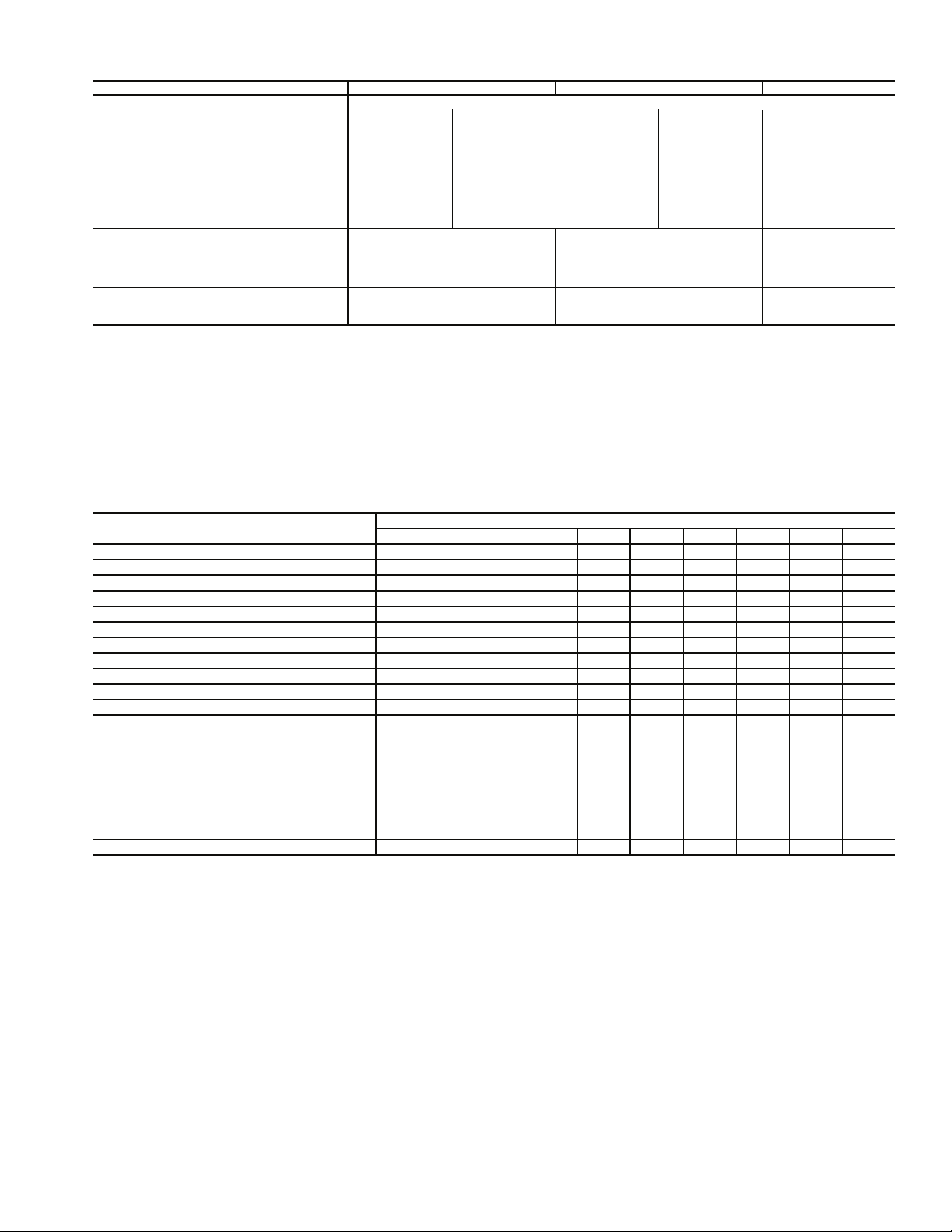

Table 1A — Physical Data (48ZG,ZN030-050)

BASE UNIT 48ZG,ZN030 48ZG,ZN035

NOMINAL CAPACITY (tons) 30 35

OPERATING WEIGHT (lb) Standard Chassis Extended Chassis Standard Chassis Extended Chassis

Base Unit

Low Heat 5640 6140 5766 6266

High Heat 5770 6270 5895 6395

With Economizer

Low Heat 5941 6441 6066 6566

High Heat 6070 6570 6195 6695

COMPRESSORS Semi-Hermetic

Quantity...Type 2...06D 1...06D, 1...06E

Oil Charge (pints) 88, 14

Capacity Steps (%)

CV 50,100 43,100

VAV 17,33,50,67,83,100 14,28,42,57,71,86,100

Number of Refrigerant Circuits 22

REFRIGERANT R-22

Operating Charge (lb), Ckt 1/Ckt 2

Standard Evaporator Coil 29.0/29.0 29.0/30.5

Standard Evaporator with HGBP 31.0/29.0 31.0/30.5

Alternate High-Capacity Evaporator Coil N/A N/A

Alternate High-Capacity Evaporator with HGBP N/A N/A

CONDENSER COILS

Quantity 22

Rows...Fins/in.

Aluminum 3...15.0 3...15.0

Copper (Optional) 3...13.7 3...13.7

Total Face Area (sq ft) 37.5 37.5

EVAPORATOR COILS

Quantity 1

Total Face Area (sq ft) 32.1

Refrigerant Feed Device...No. per Circuit TXV...1

Standard Evaporator Coils

Rows...Fins/in. 3...15.0 4...15.0

Fin Type Double Wavy Double Wavy

Tube Type Cross Hatched Cross Hatched

Alternate, High-Capacity Evaporator Coils N/A N/A

Rows...Fins/in. N/A N/A

Fin Type N/A N/A

Tube Type N/A N/A

HEATING SECTION Low Heat High Heat Low Heat High Heat

Number of Heat Exchangers 1212

Input (MBtuh) 325 650 325 650

Output (MBtuh) 263 527 263 527

Temperature Rise Range (F) 10-40 25-55 10-40 25-55

Efficiency (%) 81 81 81 81

Burner Orifice Diameter

Quantity (in. ...drill no.) 7 (.1285...30) 14 (.1285...30) 7 (.1258...30) 14 (.1258...30)

Manifold Pressure (in. wg) 3.3 3.3 3.3 3.3

Line Pressure (in. wg) (min...max) 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0

Firing Stages 2222

Number of Gas Valves 1212

CONDENSER FANS Propeller Type

Quantity...Diameter (in.) 2...30 2...30

Nominal Cfm 18,600 18,600

Motor Hp...Rpm 1.0...1140 1.0...1140

SUPPLY FAN Centrifugal 25 x 25 in.

Nominal Cfm 10,500 10,500

Maximum Allowable Cfm 15,000 15,000

Maximum Allowable Rpm 900 900

Shaft Diameter at Pulley (in.) 1

SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 7.510152025

Motor Frame Size 213T 215T 254T 256T 284T

Efficiency at Full Load (%)

High Efficiency 88.5 89.5 91.0 91.0 91.7

Premium Efficiency 91.7 91.7 93.0 93.6 93.6

Fan Pulley Pitch Diameter (in.) 13.7 13.7 13.7 13.7 13.7

Motor Pulley Pitch Diameter (in.) 3.4 4.3 4.9 5.5 6.5

Resulting Fan Speed (rpm) 438 549 626 703 830

Belts Quantity...Type 2...BX60 2...5VX630 2...5VX630 2...5VX630 2...5VX650

Center Distance Range (in.) 17.74-14.30 17.74-14.30 17.63-14.01 17.63-14.01 16.63-12.87

OPTIONAL POWER EXHAUST Centrifugal, 18 x 15 in. (Any motor available on any unit)

Quantity...Motor Hp 2...3.0 2...5.0 2...7.5 2...10

Motor Frame Size High Eff 56HZ 184T 213T 215T

Efficiency at Full Load (%) High/Premium 81.0/88.5 87.5/89.5 88.5/91.7 89.5/91.7

Fan Pulley Pitch Diameter (in.) High Eff 11 10.4 12 12

Motor Pulley Pitch Diameter Range (in.) High Eff 4.1-3.1 4.7-3.7 6.0-4.8 7.0-5.8

Motor Pulley Pitch Diameter Factory Setup (in.) 4.1 4.2 5.4 6.4

Blower Shaft Diameter at Pulley (in.) 1

Fan Rpm Range 500-656 621-785 717-882 854-1000

Factory Setup Fan Rpm 656 703 800 927

Maximum Allowable Rpm 1000 1000 1000 1000

Belts Quantity...No. High Eff 1...BX71 1...BX71 1...BX77 1...BX79

Center Distance Range (in.) 23.62-26.50 23.62-26.50 23.62-26.50 23.62-26.50

FILTERS

Standard Efficiency Throwaway (Standard) 8...20 x 25 x 2 8...20 x 25 x 2

Quantity...Size (in.) 8...20 x 20 x 2 8...20 x 20 x 2

Medium Efficiency (30%) Pleated (Optional) 8...20 x 25 x 2 8...20 x 25 x 2

Quantity...Size (in.) 8...20 x 20 x 2 8...20 x 20 x 2

High Efficiency (90%) Bag Filters

with High Velocity Prefilters (Optional)

Quantity...Size (in.)

Prem Eff 182T 184T 213T 215T

Prem Eff 11.0 10.4 12 12

Prem Eff 4.1-3.1 4.7-3.7 6.0-4.8 7.0-5.8

Prem Eff 1...BX71 1...BX71 1...BX77 1...BX79

Bag Filter

Prefilter

OUTSIDE AIR SCREENS

Standard Hood (25%) Quantity...Size (in.) None None

OPTIONAL ECONOMIZER FILTER Aluminum Frame, Permanent

Quantity...Size (in.)

7

/

16

1

/2 in. Tube Dia

11

/

16

6...20 x 24 x 22

6...20 x 20 x 22

12...16 x 20 x 2

3...20 x 24 x 2

5...20 x 20 x 2

2...20 x 25 x 1

LEGEND *460-3-60 only.

CV — Constant Volume

HGBP — Hot Gas Bypass

MBtuh — Btuh in Thousands

TXV — Thermostatic Expansion Valve

VAV — Var iabl e Ai r Volu me

17/

16

3

/8-in. Tube Diameter

17/

16

1

/2 in. Tube Dia

111/

16

6...20 x 24 x 22

6...20 x 20 x 22

12...16 x 20 x 2

3...20 x 24 x 2

5...20 x 20 x 1

2...20 x 25 x 1

17/

16

3

Page 4

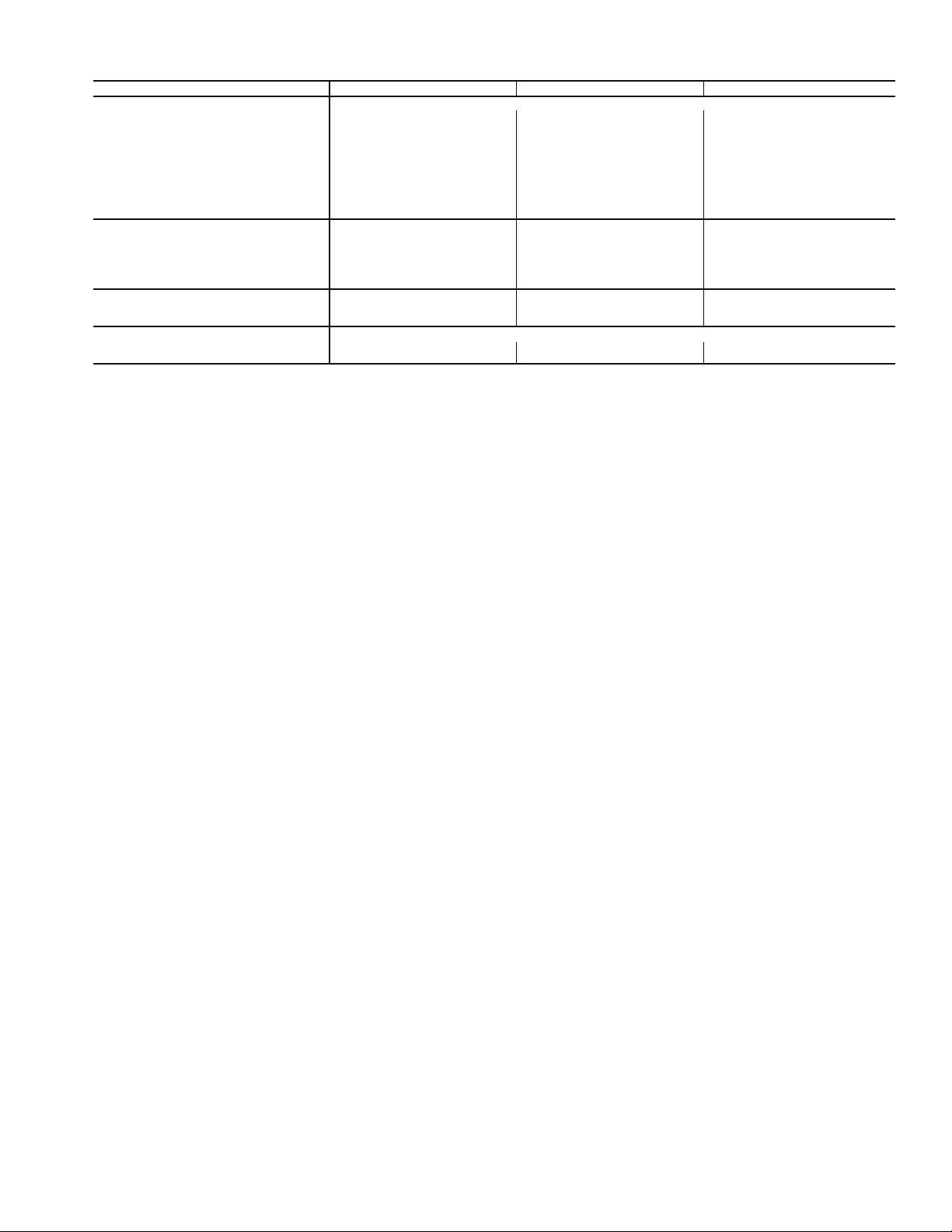

Table 1A — Physical Data (48ZG,ZN030-050) (cont)

BASE UNIT 48ZG,ZN040 48ZG,ZN050

NOMINAL CAPACITY (tons) 40 50

OPERATING WEIGHT (lb) Standard Chassis Extended Chassis Standard Chassis Extended Chassis

Base Unit

Low Heat 6540 7040 6581 7081

High Heat 6670 7170 6710 7210

With Economizer

Low Heat 6841 7341 6881 7381

High Heat 6970 7470 7010 7510

COMPRESSORS Semi-Hermetic

Quantity...Type 2...06E 2...06E

Oil Charge (pints) 14 19, 14

Capacity Steps (%)

CV 50,100 57,100

VAV 25,50,75,100 18,37,56,63,81,100

Number of Refrigerant Circuits 22

REFRIGERANT R-22

Operating Charge (lb), Ckt 1/Ckt 2

Standard Evaporator Coil 40.0/40.0 41.5/39.0

Standard Evaporator with HGBP 42.0/40.0 43.5/39.0

Alternate High-Capacity Evaporator Coil 50.0/51.0 49.0/49.0

Alternate High-Capacity Evaporator with HGBP 52.0/51.0 51.0/49.0

CONDENSER COILS

Quantity 22

Rows...Fins/in.

Aluminum 3...15.0 3...15.0

Copper (Optional) 3...13.7 3...13.7

Total Face Area (sq ft) 50.0 50.0

EVAPORATOR COILS

Quantity 2

Total Face Area (sq ft) 45.5

Refrigerant Feed Device...No. per Circuit TXV...2

Standard Evaporator Coils

Rows...Fins/in. 3...15.0 4...15.0

Fin Type Double Wavy Double Wavy

Tube Type Cross Hatched Cross Hatched

Alternate, High-Capacity Evaporator Coils

Rows...Fins/in. 6...16.0 6...16.0

Fin Type Double Wavy Double Wavy

Tube Type Cross Hatched Cross Hatched

HEATING SECTION Low Heat High Heat Low Heat High Heat

Number of Heat Exchangers 1212

Input (MBtuh) 325 650 325 650

Output (MBtuh) 263 527 263 527

Temperature Rise Range (F) 10-40 25-55 10-40 25-55

Efficiency (%) 81 81 81 81

Burner Orifice Diameter

Quantity (in. ...drill no.) 7 (.1285...30) 14 (.1285...30) 7 (.1285...30) 14 (.1285...30)

Manifold Pressure (in. wg) 3.3 3.3 3.3 3.3

Line Pressure (in. wg) (min...max) 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0

Firing Stages 2222

Number of Gas Valves 1212

CONDENSER FANS Propeller Type

Quantity...Diameter (in.) 3...30 3...30

Nominal Cfm 26,000 26,000

Motor Hp...Rpm 1.0...1140 1.0...1140

SUPPLY FAN Centrifugal 25 x 25 in.

Nominal Cfm 14,000 14,000

Maximum Allowable Cfm 20,000 20,000

Maximum Allowable Rpm 900 900

Shaft Diameter at Pulley (in.) 1

SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 7.51015202530*

Motor Frame Size 213T 215T 254T 256T 284T 286T

Efficiency at Full Load (%)

High Efficiency 88.5 89.5 91.0 91.0 91.7 92.4

Premium Efficiency 91.7 91.7 93.0 93.6 93.6 93.6

Fan Pulley Pitch Diameter (in.) 13.7 13.7 13.7 13.7 13.7 12.5

Motor Pulley Pitch Diameter (in.) 3.4 4.3 4.9 5.5 6.5 6.5

Resulting Fan Speed (rpm) 438 549 626 703 830 910

Belts Quantity...Type 2...BX60 2...5VX630 2...5VX630 2...5VX630 2...5VX650 3...5VX630

Center Distance Range (in.) 17.74-14.30 17.74-14.30 17.63-14.01 17.63-14.01 16.63-12.87 16.63-12.87

OPTIONAL POWER EXHAUST Centrifugal, 18 x 15 in. (Any motor available on any unit)

Quantity...Motor Hp 2...3.0 2...5.0 2...7.5 2...10

Motor Frame Size High Eff 56HZ 184T 213T 215T

Efficiency at Full Load (%) High/Premium 81.0/88.5 87.5/89.5 88.5/91.7 89.5/91.7

Fan Pulley Pitch Diameter (in.) High Eff 11 10.4 12 12

Motor Pulley Pitch Diameter Range (in.) High Eff 4.1-3.1 4.7-3.7 6.0-4.8 7.0-5.8

Motor Pulley Pitch Diameter Factory Setup (in.) 4.1 4.2 5.4 6.4

Blower Shaft Diameter at Pulley (in.) 1

Fan Rpm Range 500-656 621-785 717-882 854-1000

Factory Setup Fan Rpm 656 703 800 927

Maximum Allowable Rpm 1000 1000 1000 1000

Belts Quantity...No. High Eff 1...BX71 1...BX71 1...BX77 1...BX79

Center Distance Range (in.) 23.62-26.50 23.62-26.50 23.62-26.50 23.62-26.50

FILTERS

Standard Efficiency Throwaway (Standard) 8...20 x 25 x 2 8...20 x 25 x 2

Quantity...Size (in.) 8...20 x 20 x 2 8...20 x 20 x 2

Medium Efficiency (30%) Pleated (Optional) 8...20 x 25 x 2 8...20 x 25 x 2

Quantity...Size (in.) 8...20 x 20 x 2 8...20 x 20 x 2

High Efficiency (90%) Bag Filters

with High Velocity Prefilters (Optional)

Quantity...Size (in.)

Prem Eff 182T 184T 213T 215T

Prem Eff 11.0 10.4 12 12

Prem Eff 4.1-3.1 4.7-3.7 6.0-4.8 7.0-5.8

Prem Eff 1...BX71 1...BX71 1...BX77 1...BX79

Bag Filter

Prefilter

OUTSIDE AIR SCREENS

Standard Hood (25%) Quantity...Size (in.) None None

OPTIONAL ECONOMIZER FILTER Aluminum Frame, Permanent

Quantity...Size (in.)

7

/

16

1

/2 in. Tube Dia

1

/2 in. Tube Dia

11

/

16

6...20 x 24 x 22

6...20 x 20 x 22

12...16 x 20 x 2

3...20 x 24 x 2

5...20 x 20 x 2

2...20 x 25 x 1

LEGEND

CV — Constant Volume

HGBP — Hot Gas Bypass

MBtuh — Btuh in Thousands

TXV — Thermostatic Expansion Valve

VAV — Var iabl e Ai r Volu me

*460-3-60 only

.

17/

16

3

/8-in. Tube Diameter

17/

16

1

/2 in. Tube Dia

1

/2 in. Tube Dia

111/

16

6...20 x 24 x 22

6...20 x 20 x 22

12...16 x 20 x 2

3...20 x 24 x 2

5...20 x 20 x 1

2...20 x 25 x 1

17/

16

4

Page 5

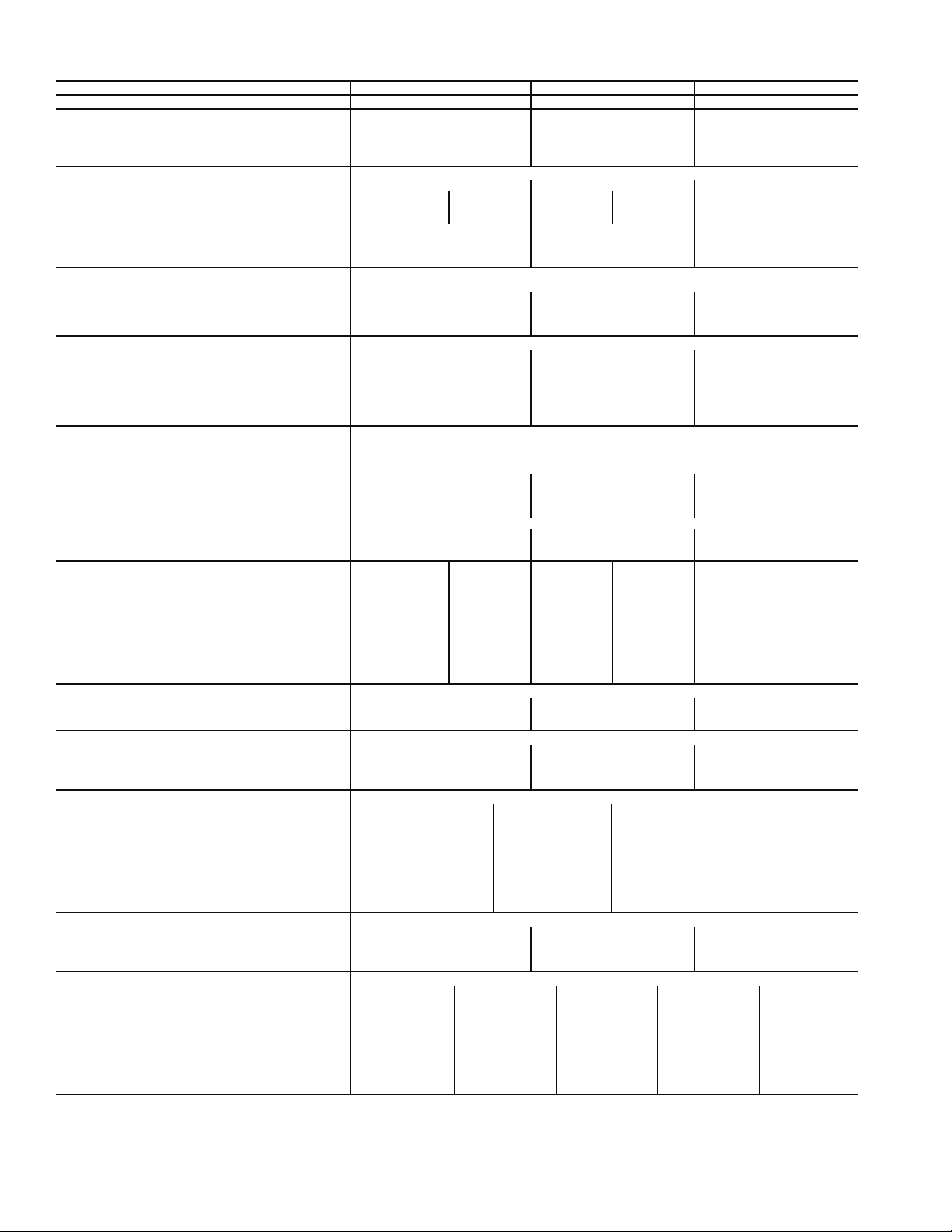

Table 1B — Physical Data (48ZG,ZN055-070)

BASE UNIT 48ZG,ZN055 48ZG,ZN060 48ZG,ZN070

NOMINAL CAPACITY (tons) 55 60 70

OPERATING WEIGHT (lb) Standard Chassis Extended Chassis Standard Chassis Extended Chassis Standard Chassis

Base Unit

Low Heat 8700 9248 9000 9,548 9,420

High Heat 8820 9368 9120 9,668 9,550

With Economizer

Low Heat 9230 9730 9530 10,030 9,950

High Heat 9350 9850 9650 10,450 10,080

COMPRESSORS Semi-Hermetic

Quantity...Type 2...06E 2...06E 2...06E

Oil Charge (Pints) 19, 14 19 19

Capacity Steps (%)

CV 60,100 50,100 45,100

VAV 20,40,60,80,100 17,33,50,67,83,100 14,29,43,51,66,71,85,100

Number of Refrigerant Circuits 222

REFRIGERANT R-22

Operating Charge (lb), Ckt 1/Ckt 2

Standard Evaporator Coil 59.0/44.5 61.0/61.0 70.5/64.5

Standard Evaporator with HGBP 62.0/44.5 64.0/61.0 73.5/64.5

Alternate High-Capacity Evaporator Coil 72.0/58.0 69.5/69.5 82.5/74.5

Alternate High-Capacity Evaporator

with HGBP

CONDENSER COILS

Quantity 444

Rows...Fins/in.

Aluminum 2...17.0, 3...17.0 3...17.0 3...17.0

Copper (Optional) 2...15.7, 3...15.7 3...15.7 3...15.7

Total Face Area (sq ft) 72.4 72.4 108.4

EVAPORATOR COILS

Quantity 2

Total Face Area (sq ft) 61.5

Refrigerant Feed Device...No. per Circuit TXV...2

Standard Evaporator Coils

Rows...Fins/in. 3...17.0 4...17.0 4...17.0

Fin Type Double Wavy Double Wavy Double Wavy

Tube Type Smooth Smooth Smooth

Alternate, High-Capacity Evaporator Coils

Rows...Fins/in. 6...16 6...16 6...16

Fin Type Double Wavy Double Wavy Double Wavy

Tube Type Cross Hatched Cross Hatched Cross Hatched

HEATING SECTION Low Heat High Heat Low Heat High Heat Low Heat High Heat

Number of Heat Exchangers 232323

Input (MBtuh) 650 975 650 975 650 975

Output (MBtuh) 527 790 527 790 527 790

Temperature Rise Range (F) 10-40 20-50 10-40 20-50 10-40 20-50

Efficiency (%) 81 81 81 81 81 81

Burner Orifice Diameter

Quantity (in. ...drill no.) 14 (.1285...30) 21 (.1285...30) 14 (.1285...30) 21 (.1285...30) 14 (.1285...30) 21 (.1285...30)

Manifold Pressure (in. wg) 3.3 3.3 3.3 3.3 3.3 3.3

Line Pressure (in. wg) (min...max) 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0

Firing Stages 222222

Number of Gas Valves 232323

CONDENSER FANS Propeller Type

Quantity...Diameter (in.) 4...30 4...30 5...30

Nominal Cfm 40,000 40,000 50,000

Motor Hp...Rpm 1.0...1140 1.0...1140 1.0...1140

SUPPLY FAN Centrifugal 25 x 25 in.

Nominal Cfm 17,500 21,000 24,500

Maximum Allowable Cfm 25,000 30,000 30,000

Maximum Allowable Rpm 800 800 800

Shaft Diameter at Pulley (in.) 111/

SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 15 20 25 30 40

Motor Frame Size 254T 256T 284T 286T S324T

Efficiency at Full Load (%)

High Efficiency 91.0 91.0 91.7 92.4 93.0

Premium Efficiency 93.0 93.6 93.6 93.6 94.5

Fan Pulley Pitch Diameter (in.) 13.7 13.7 13.7 15.5 16.1

Motor Pulley Pitch Diameter (in.) 4.5 5.1 5.5 5.9 6.7

Resulting Fan Speed (rpm) 575 651 703 711 740

Belts Quantity...Type 2...5VX1230 2...5VX1230 2...5VX1230 2...5VX1230 3...5VX1250

Center Distance Range (in.) 48.25-44.00 48.25-44.00 48.50-44.25 48.50-44.25 48.25-44.00

OPTIONAL POWER EXHAUST Centrifugal, 15 x 15 in. (Any motor available on any unit)

Quantity...Motor Hp 2...5 2...7.5 2...10

Motor Frame Size 184T 213T 215T

Efficiency at Full Load (%) High/Premium 87.5/89.5 88.5/91.7 89.5/91.7

Resulting Fan Rpm 740 820 920

Maximum Allowable Rpm 1000 1000 1000

FILTERS

Standard Efficiency Throwaway (Standard) 12...20 x 25 x 2 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 12...20 x 20 x 2 12...20 x 20 x 2 12...20 x 20 x 2

Medium Efficiency (30%) Pleated (Optional) 12...20 x 25 x 2 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 12...20 x 20 x 2 12...20 x 20 x 2 12...20 x 20 x 2

High Efficiency (90%) Bag Filters

with High Velocity Prefilters (Optional)

Quantity...Size (in.)

Bag Filter

Prefilter

OUTSIDE AIR SCREENS

Standard Hood (25%) Quantity...Size (in.)

OPTIONAL ECONOMIZER FILTER Aluminum Frame, Permanent

Quantity...Size (in.)

LEGEND

CV — Constant Volume

HGBP — Hot Gas Bypass

MBtuh — Btuh in Thousands

TXV — Thermostatic Expansion Valve

VAV — Variable Air Volume

75.0/58.0 72.5/69.5 85.5/74.5

3

/8-in. Tube Diameter

1

/2 in. Tube Dia

1

/2 in. Tube Dia

16

6...24 x 24 x 22

6...24 x 20 x 22

6...24 x 24 x 2

6...20 x 24 x 2

4...25 x 16 x 1

2...20 x 16 x 1

12...16 x 25 x 1

2...16 x 20 x 1

111/

16

6...24 x 24 x 22

6...24 x 20 x 22

6...24 x 24 x 2

6...20 x 24 x 2

4...25 x 16 x 1

2...20 x 16 x 1

12...16 x 25 x 1

2...16 x 20 x 1

6...24 x 24 x 22

6...24 x 20 x 22

6...24 x 24 x 2

6...20 x 24 x 2

4...25 x 16 x 1

2...20 x 16 x 1

12...16 x 25 x 1

2...16 x 20 x 1

111/

16

5

Page 6

Table 1C — Physical Data (48ZG,ZN075-105)

BASE UNIT 48ZG,ZN075 48ZG,ZN090 48ZG,ZN105

NOMINAL CAPACITY (tons) 75 90 105

OPERATING WEIGHT (lb)

Base Unit without Economizer

Low Heat/High Heat 10,270/10,445 10,480/10,655 11,210/11,385

With Economizer

Low Heat/High Heat 10,800/10,975 11,010/11,185 11,740/11,915

COMPRESSOR Semi-Hermetic

Number 22 4

Circuit (No. Cyl) A (6) B (6) A (6) B (6) A1 (6), A2 (4) B1 (6), B2 (4)

Model 06E -275 -299 -299 -299 -275, -250 -275, -250

Oil Charge (pints) 19 19 19 19 19, 14 19, 14

Capacity Steps (%)

CV 43,100 50,100 50,100

VAV 14,29,43,51,66,86,100 17,33,50,67,83,100 20,30,40,50,60,60,70,80,80,90,100

Number of Refrigerant Circuits 22 2

REFRIGERANT R-22

Operating Charge (lb), Ckt 1/Ckt 2

Standard Evaporator Coil 70.5/64.5 64.0/64.0 68.0/68.0

Standard Evaporator with HGBP 73.5/64.5 67.0/64.0 71.0/68.0

Alternate High-Capacity Evaporator Coil 83.0/75.0 76.0/76.0 79.5/79.5

Alternate High-Capacity Evaporator with HGBP 86.0/75.0 79.0/76.0 82.5/79.5

CONDENSER COILS

Quantity 44 4

Rows...Fins/in.

Aluminum 3...17.0 3...17.0 3...17.0

Copper (Optional) 3...15.7 3...15.7 3...15.7

Fin Type Double Wavy Lanced, Sine-wave Lanced, Sine-wave

Tube Type Smooth Cross-Hatched Cross-Hatched

Total Face Area (sq ft) 108.4 108.4 108.4

EVAPORATOR COILS

Quantity 2

Total Face Area (sq ft) 61.5

Refrigerant Feed Device...No. per Circuit TXV...2

Standard Evaporator Coils

Rows...Fins/in. 4...17.0 4...17.0 4...17.0

Fin Type Double Wavy Lanced, Sine Wave Lanced, Sine Wave

Tub e Ty p e Smooth Cross Hatched Cross Hatched

Alternate, High-Capacity Evaporator Coils

Rows...Fins/in. 6...16 6...16 6...16

Fin Type Double Wavy Double Wavy Double Wavy

Tub e Ty p e Cross Hatched Cross Hatched Cross Hatched

HEATING SECTION Low Heat High Heat Low Heat High Heat Low Heat High Heat

Number of Heat Exchangers 2323 2 3

Input (MBtuh) 650 975 650 975 650 975

Output (MBtuh) 527 790 527 790 527 790

Temperature Rise Range (F) 10-40 20-50 10-40 20-50 10-40 20-50

Efficiency (%) 81 81 81 81 81 81

Burner Orifice Diameter

Quantity (in. ...drill no.) 14 (.1285...30) 21 (.1285...30) 14 (.1285...30) 21 (.1285...30) 14 (.1285...30) 21 (.1285...30)

Manifold Pressure (in. wg) 3.3 3.3 3.3 3.3 3.3 3.3

Line Pressure (in. wg) (Min...Max) 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0

Number of Gas Valves 2323 2 3

CONDENSER FAN Propeller Type

Quantity...Diameter (in.) 5...30 6...30 6...30

Nominal Cfm 50,000 60,000 60,000

Motor Hp (ea)...rpm 1.0...1140 1.0...1140 1.0...1140

STANDARD SUPPLY FAN Forward Curved Centrifugal 36 x 30 in.

Nominal Cfm 24,500 29,750 35,000

Maximum Allowable Cfm 30,000 34,000 40,000

Maximum Allowable Rpm 670 670 670

Shaft Diameter at Pulley (in.) 1

STANDARD SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 30 40 50 60

Motor Frame Size S268T S324T S36T S364T

Efficiency at Full Load (%)

High Efficiency 92.4 93.0 93.0 93.6

Premium Efficiency 93.6 94.5 94.5 95.4

Fan Pulley Pitch Diameter (in.) 18.5 18.5 18.5 18.5

Motor Pulley Pitch Diameter (in.) 5.3 5.7 6.5 7.1

Resulting Fan Rpm 501 539 615 672

Belts Quantity...Type 3...5VX1320 4...5VX1320 4...5VX1320 4...5VX1320

Center Distance Range (in.) 47.88-45.01 47.64-44.76 47.42-44.52 47.42-44.52

ALTERNATE, AIRFOIL FAN Airfoil

Nominal Airflow (cfm) 24,500 29,750 35,000

Maximum Allowable Airflow (cfm) 30,000 34,000 40,000

Maximum Allowable Wheel Speed (rpm) 1846 1846 1846

Shaft Diameter at Pulley (in.) 2

ALTERNATE SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 30 40 50 60 75

Motor Frame Size S268T S324T S36T S364T 365T

Efficiency at Full Load (%)

High Efficiency 92.4 93.0 93.0 93.6 94.1

Premium Efficiency 93.6 94.5 94.5 95.4 95.4

Fan Pulley Pitch Diameter (in.) 9.7 10.2 8.9 8.9 10.8

Motor Pulley Pitch Diameter (in.) 7.5 8.7 8.1 8.7 11.1

Resulting Fan Rpm 1353 1493 1593 1711 1799

Belts Quantity...Type 2...5VX1150 2...5VX1180 3...5VX1150 3...5VX1150 3...5VX1230

Center Distance Range (in.) 42.96-45.82 42.96-45.57 42.96-45.57 42.45-45.35 42.45-45.35

1

/2 in. Tube Dia

11

/

16

11

/

16

3

/8-in. Tube Diameter

3

/8 in. Tube Dia

1

/2 in. Tube Dia

111/

16

211/

16

3

/8 in. Tube Dia

111/

16

211/

16

6

Page 7

Table 1C — Physical Data (48ZG,ZN075-105) (cont)

BASE UNIT 48ZG,ZN075 48ZG,ZN090 48ZG,ZN105

OPTIONAL POWER EXHAUST Centrifugal, 18 x 15 in. (Any motor available on any unit.)

Quantity...Motor Hp 2...5 2...7.5 2...10

Motor Frame Size 184T 213T 215T

Efficiency at Full Load (%)

High Efficiency 87.5 88.5 89.5

Premium Efficiency 89.5 91.7 91.7

Fan Pulley Pitch Diameter (in.) 10.6 10.6 10.6

Motor Pulley Pitch Diameter (in.) 4.5 5.0 5.6

Shaft Diameter at Pulley (in.) 1

Resulting Fan Rpm 740 820 920

Maximum Allowable Rpm 1000 1000 1000

FILTERS

Standard Efficiency Throwaway

(Standard)

Quantity...Size (in.) 12...20 x 20 x 2 12...20 x 20 x 2 12...20 x 20 x 2

30% and 65% Pleated (Optional) 12...20 x 25 x 2 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 12...20 x 20 x 2 12...20 x 20 x 2 12...20 x 20 x 2

OUTSIDE AIR SCREENS

Standard Hood (25%) Quantity...Size (in.)

OPTIONAL ECONOMIZER FILTER Aluminum Frame, Permanent

Quantity...Size (in.)

LEGEND

CV — Constant Volume

HGBP — Hot Gas Bypass

MBtuh— Btuh in Thousands

TXV — Thermostatic Expansion Valve

VAV — Va r ia b le A ir Vo lum e

7

/

16

17/

16

17/

16

12...20 x 25 x 2 12...20 x 25 x 2 12...20 x 25 x 2

4...25 x 16 x 1

2...20 x 16 x 1

12...16 x 25 x 1

2...16 x 20 x 1

4...25 x 16 x 1

2...20 x 16 x 1

12...16 x 25 x 1

2...16 x 20 x 1

4...25 x 16 x 1

2...20 x 16 x 1

12...16 x 25 x 1

2...16 x 20 x 1

7

Page 8

Table 1D — Physical Data (48Z6,Z8075-105)

BASE UNIT 48Z6,Z8075 48Z6,Z8090 48Z6,Z8105

NOMINAL CAPACITY (tons) 75 90 105

OPERATING WEIGHT (lb)

Base Unit without Economizer

Low Heat/High Heat 11,740/11,915 11,950/12,125 12,680/12,855

With Economizer

Low Heat/High Heat 12,270/12,445 12,480/12,655 13,210/13,385

COMPRESSOR Semi-Hermetic

Number 224

Circuit (No. Cyl) A (6) B (6) A (6) B (6) A1 (6), A2 (4) B1 (6), B2 (4)

Model 06E -275 -299 -299 -299 -275, -250 -275, -250

Oil Charge (pints) 19 19 19 19 19, 14 19, 14

Capacity Steps (%)

CV 43,100 50,100 50,100

VAV 14,29,43,51,66,71,86,100 17,33,50,67,83,100 20,30,40,50,60,70,80,90,100

Number of Refrigerant Circuits 222

REFRIGERANT R-22

Operating Charge (lb), Ckt 1/Ckt 2

Standard Evaporator Coil 70.5/64.5 64.0/64.0 68.0/68.0

Standard Evaporator with HGBP 73.5/64.5 67.0/64.0 71.0/68.0

Alternate High-Capacity Evaporator Coil 83.0/75.0 76.0/76.0 79.5/79.5

Alternate High-Capacity Evaporator with HGBP 86.0/75.0 79.0/76.0 82.5/79.5

CONDENSER COILS

Quantity 444

Rows...Fins/in.

Aluminum 3...17.0 3...17.0 3...17.0

Copper (Optional) 3...15.7 3...15.7 3...15.7

Fin Type Double Wavy Lanced, Sine-wave Lanced, Sine-wave

Tube Type Smooth Cross-Hatched Cross-Hatched

Total Face Area (sq ft) 108.4 108.4 108.4

EVAPORATOR COILS

Quantity 2

Total Face Area (sq ft) 61.5

Refrigerant Feed Device...No. per Circuit TXV...2

Standard Evaporator Coils

Rows...Fins/in. 4...17.0 4...17.0 4...17.0

Fin Type Double Wavy Lanced, Sine Wave Lanced, Sine Wave

Tub e Ty p e Smooth Cross Hatched Cross Hatched

Alternate, High-Capacity Evaporator Coils

Rows...Fins/in. 6...16 6...16 6...16

Fin Type Double Wavy Double Wavy Double Wavy

Tub e Ty p e Cross Hatched Cross Hatched Cross Hatched

HEATING SECTION Low Heat High Heat Low Heat High Heat Low Heat High Heat

Number of Heat Exchangers 2 32323

Input (MBtuh) 650 975 650 975 650 975

Output (MBtuh) 527 790 527 790 527 790

Temperature Rise Range (F) 10-40 20-50 10-40 20-50 10-40 20-50

Efficiency (%) 81 81 81 81 81 81

Burner Orifice Diameter

Quantity (in. ...drill no.) 14 (.1285...30) 21 (.1285...30) 14 (.1285...30) 21 (.1285...30) 14 (.1285...30) 21 (.1285...30)

Manifold Pressure (in. wg) 3.3 3.3 3.3 3.3 3.3 3.3

Line Pressure (in. wg) (Min...Max) 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0

Number of Gas Valves 2 32323

CONDENSER FAN Propeller Type

Quantity...Diameter (in.) 5...30 6...30 6...30

Nominal Cfm 50,000 60,000 60,000

Motor Hp (ea)...rpm 1.0...1140 1.0...1140 1.0...1140

STANDARD SUPPLY FAN Forward Curved Centrifugal 36 x 30 in.

Nominal Cfm 24,500 29,750 35,000

Maximum Allowable Cfm 30,000 34,000 40,000

Maximum Allowable Rpm 670 670 670

Shaft Diameter at Pulley (in.) 1

STANDARD SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit.)

Motor Hp 30 40 50 60

Motor Frame Size S268T S324T S36T S364T

Efficiency at Full Load (%)

High Efficiency 92.4 93.0 93.0 93.6

Premium Efficiency 93.6 94.5 94.5 95.4

Fan Pulley Pitch Diameter (in.) 18.5 18.5 18.5 18.5

Motor Pulley Pitch Diameter (in.) 5.3 5.7 6.5 7.1

Resulting Fan Rpm 501 539 615 672

Belts Quantity...Type 3...5VX1320 4...5VX1320 4...5VX1320 4...5VX1320

Center Distance Range (in.) 47.88-45.01 47.64-44.76 47.42-44.52 47.42-44.52

ALTERNATE, AIRFOIL FAN Airfoil

Nominal Airflow (cfm) 24,500 29,750 35,000

Maximum Allowable Airflow (cfm) 30,000 34,000 40,000

Maximum Allowable Wheel Speed (rpm) 1846 1846 1846

Shaft Diameter at Pulley (in.) 2

ALTERNATE SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit.)

Motor Hp

Motor Frame Size

Efficiency at Full Load (%)

High Efficiency

Premium Efficiency

Fan Pulley Pitch Diameter (in.)

Motor Pulley Pitch Diameter (in.)

Resulting Fan Rpm

Belts Quantity...Type

Center Distance Range (in.)

1

/2 in. Tube Dia

11

/

16

11

/

16

30 40 50 60 75

S268T S324T S36T S364T 365T

92.4 93.0 93.0 93.6 94.1

93.6 94.5 94.5 95.4 95.4

9.7 10.2 8.9 8.9 10.8

7.5 8.7 8.1 8.7 11.1

1353 1493 1593 1711 1799

2...5VX1150 2...5VX1180 3...5VX1150 3...5VX1150 3...5VX1230

42.96-45.82 42.69-45.57 42.69-45.57 42.45-45.35 42.45-45.35

3

/8-in. Tube Diameter

3

/8 in. Tube Dia

1

/2 in. Tube Dia

111/

16

211/

16

3

/8 in. Tube Dia

111/

16

211/

16

8

Page 9

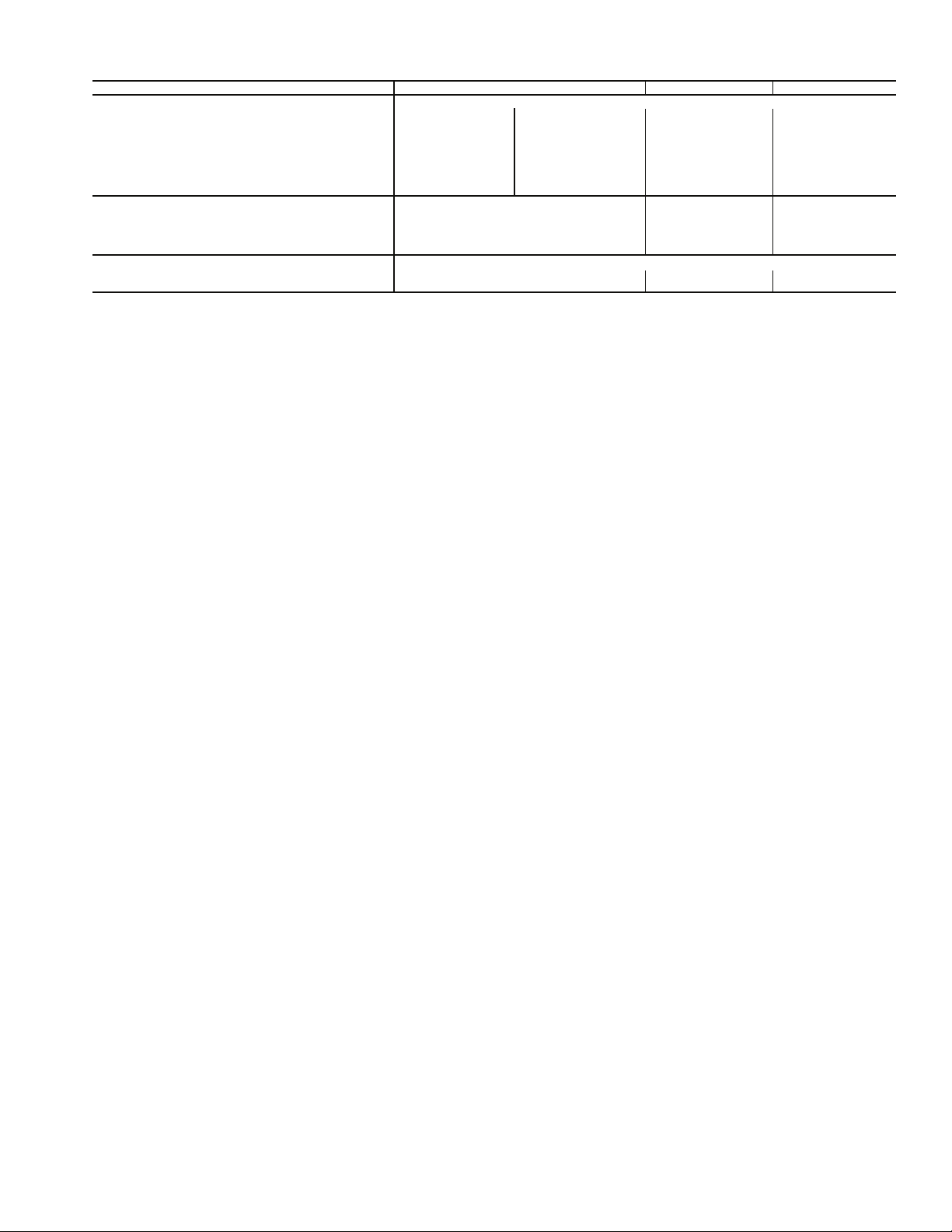

Table 1D — Physical Data (48Z6,Z8075-105) (cont)

BASE UNIT 48Z6,Z8075 48Z6,Z8090 48Z6,Z8105

RETURN/EXHAUST FAN Plenum Fan, 47.13 in. (Any motor available on any unit.)

Quantity...Motor Hp 1...20 1...25 1...30 1...40

Motor Frame Size 256T 284T 286T 324T

Efficiency at Full Load (%) High/Premium 91/93.6 91.7/93.6 92.4/93.6 93/93.8

Fan Pulley Pitch Diameter (in.) 8.5 9.8 8.5 8.5

Motor Pulley Pitch Diameter (in.) 5.3 6.7 6.1 6.7

Shaft Diameter at Pulley (in.) 2

Resulting Fan Rpm 1104 1209 1271 1396

Maximum Allowable Rpm 1447 1447 1447 1447

FILTERS

Standard Efficiency Throwaway (Standard) 12...20 x 25 x 2 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 12...20 x 20 x 2 12...20 x 20 x 2 12...20 x 20 x 2

30% and 65% Pleated (Optional) 12...20 x 25 x 2 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 12...20 x 20 x 2 12...20 x 20 x 2 12...20 x 20 x 2

OPTIONAL ECONOMIZER FILTER Aluminum Frame, Permanent

Quantity...Size (in.)

LEGEND

CV — Constant Volume

HGBP — Hot Gas Bypass

MBtuh— Btuh in Thousands

TXV — Thermostatic Expansion Valve

VAV — Va r ia b le A ir Vo lum e

15

/

16

12...16 x 25 x 1

2...16 x 20 x 1

215/

16

215/

16

12...16 x 25 x 1

2...16 x 20 x 1

215/

12...16 x 25 x 1

2...16 x 20 x 1

16

9

Page 10

Table 1E — Physical Data (48ZT,ZW075-105)

BASE UNIT 48ZT,ZW075 48ZT,ZW090 48ZT,ZW105

NOMINAL CAPACITY (tons) 75 80 100

OPERATING WEIGHT (lb)

Base Unit without Economizer

Low Heat/High Heat 13,205/13,380 13,415/13,590 14,145/14,320

COMPRESSOR Semi-Hermetic

Number 224

Circuit (No. Cyl) A (6) B (6) A (6) B (6) A1 (6), A2 (4) B1 (6), B2 (4)

Model 06E -275 -299 -299 -299 -275, -250 -275, -250

Oil Charge (pints) 19 19 19 19 19, 14 19, 14

Capacity Steps (%)

CV 43,100 50,100 50,100

VAV 14,29,43,51,66,71,86,100 17,33,50,67,83,100 20,30,40,50,60,70,80,90,100

Number of Refrigerant Circuits 222

REFRIGERANT

Operating Charge (lb), Ckt 1/Ckt 2

Standard Evaporator Coil 70.5/64.5 64.0/64.0 68.0/68.0

Standard Evaporator with HGBP 73.5/64.5 67.0/64.0 71.0/68.0

Alternate High-Capacity Evaporator Coil 83.0/75.0 76.0/76.0 79.5/79.5

Alternate High-Capacity Evaporator with HGBP 86.0/75.0 79.0/76.0 82.5/79.5

CONDENSER COILS

Quantity 444

Rows...Fins/in.

Aluminum 3...17.0 3...17.0 3...17.0

Copper (Optional) 3...15.7 3...15.7 3...15.7

Fin Type Double Wavy Lanced, Sine-wave Lanced, Sine-wave

Tube Type Smooth Cross-Hatched Cross-Hatched

Total Face Area (sq ft) 108.4 108.4 108.4

EVAPORATOR COILS

Quantity 2

Total Face Area (sq ft) 61.5

Refrigerant Feed Device...No. per Circuit TXV...2

Standard Evaporator Coils

Rows...Fins/in. 4...17.0 4...17.0 4...17.0

Fin Type Double Wavy Lanced, Sine Wave Lanced, Sine Wave

Tube Type Smooth Cross Hatched Cross Hatched

Alternate, High-Capacity Evaporator Coils

Rows...Fins/in. 6...16 6...16 6...16

Fin Type Double Wavy Double Wavy Double Wavy

Tube Type Cross Hatched Cross Hatched Cross Hatched

HEATING SECTION Low Heat High Heat Low Heat High Heat Low Heat High Heat

Number of Heat Exchangers 232323

Input (MBtuh) 650 975 650 975 650 975

Output (MBtuh) 527 790 527 790 527 790

Temperature Rise Range (F) 10-40 20-50 10-40 20-50 10-40 20-50

Efficiency (%) 81 81 81 81 81 81

Burner Orifice Diameter

Quantity (in. ...drill no.) 14 (.1285...30) 21 (.1285...30) 14 (.1285...30) 21 (.1285...30) 14 (.1285...30) 21 (.1285...30)

Manifold Pressure (in. wg) 3.33.33.33.33.33.3

Line Pressure (in. wg) (Min...Max) 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0 5.0...13.0

Number of Gas Valves 232323

CONDENSER FAN Propeller Type

Quantity...Diameter (in.) 5...30 6...30 6...30

Nominal Cfm 50,000 60,000 60,000

Motor Hp (ea)...rpm 1.0...1140 1.0...1140 1.0...1140

STANDARD SUPPLY FAN Forward Curved Centrifugal 36 x 30 in.

Nominal Cfm 24,500 29,750 35,000

Maximum Allowable Cfm 30,000 34,000 40,000

Maximum Allowable Rpm 670 670 670

Shaft Diameter at Pulley (in.) 1

STANDARD SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 30 40 50 60

Motor Frame Size S268T S324T S36T S364T

Efficiency at Full Load (%)

High Efficiency 92.4 93.0 93.0 93.6

Premium Efficiency 93.6 94.5 94.5 95.4

Fan Pulley Pitch Diameter (in.) 18.5 18.5 18.5 18.5

Motor Pulley Pitch Diameter (in.) 5.3 5.7 6.5 7.1

Resulting Fan Rpm 501 539 615 672

Belts Quantity...Type 3...5VX1320 4...5VX1320 4...5VX1320 4...5VX1320

Center Distance Range (in.) 47.88-45.01 47.64-44.76 47.42-44.52 47.42-44.52

ALTERNATE, AIRFOIL FAN Airfoil

Nominal Airflow (cfm) 24,500 29,750 35,000

Maximum Allowable Airflow (cfm) 30,000 34,000 40,000

Maximum Allowable Wheel Speed (rpm) 1846 1846 1846

Shaft Diameter at Pulley (in.) 2

ALTERNATE SUPPLY-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 30 40 50 60 75

Motor Frame Size S268T S324T S36T S364T 365T

Efficiency at Full Load (%)

High Efficiency 92.4 93.0 93.0 93.6 94.1

Premium Efficiency 93.6 94.5 94.5 95.4 95.4

Fan Pulley Pitch Diameter (in.) 9.7 10.2 8.9 8.9 10.8

Motor Pulley Pitch Diameter (in.) 7.5 8.7 8.1 8.7 11.1

Resulting Fan Rpm 1353 1493 1593 1711 1799

Belts Quantity...Type 2...5VX1150 2...5VX1180 3...5VX1150 3...5VX1150 3...5VX1230

Center Distance Range (in.) 42.96-45.82 42.96-45.57 42.96-45.57 42.45-45.35 42.45-45.35

1

/2 in. Tube Dia

11

/

16

11

/

16

R-22

3

/8-in. Tube Diameter

3

/8 in. Tube Dia

1

/2 in. Tube Dia

111/

16

211/

16

3

/8 in. Tube Dia

111/

16

211/

16

10

Page 11

Table 1E — Physical Data (48ZT,ZW075-105) (cont)

BASE UNIT 48ZT,ZW075 48ZT,ZW090 48ZT,ZW105

POWER EXHAUST Centrifugal, 22 x 20 in., 1

Tot a l Hp 20 30 40 50 60

Quantity...Motor Hp 2...10 2...15 2...20 2...25 2...30

Motor Frame Size S215T D254T S256T S284T S286T

Efficiency at Full Load (%)

High Efficiency 89.5 91 91 91.7 92.4

Premium Efficiency 91.7 93 93.6 93.6 93.6

Fan Sheave Pitch Diameter (in.) 12.4 12.4 11.1 11.1 11.1

Motor Sheave Pitch Diameter (in.) 4.8 5.8 5.9 6.5 6.9

Resulting Fan Rpm 714 841 928 1020 1094

Maximum Allowable Rpm 1175 1175 1175 1175 1175

Belts — Quantity...Type 2...BX93 2...BX93 2...5VX950 2...5VX950 2...5VX950

FILTERS

Standard Efficiency Throwaway (Standard) 12...20 x 25 x 2 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 12...20 x 20 x 2 12...20 x 20 x 2 12...20 x 20 x 2

30% and 65% Pleated (Optional) 12...20 x 25 x 2 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 12...20 x 20 x 2 12...20 x 20 x 2 12...20 x 20 x 2

OUTSIDE AIR SCREENS

Standard Hood (25%) Quantity...Size (in.)

LEGEND

CV — Constant Volume

HGBP — Hot Gas Bypass

MBtuh— Btuh in Thousands

TXV — Thermostatic Expansion Valve

VAV — Va r ia b le A ir Vo lum e

8...25 x 16 x 1

2...20 x 16 x 1

11

/16 in. shaft diameter (Any motor available on any unit)

8...25 x 16 x 1

2...20 x 16 x 1

8...25 x 16 x 1

2...20 x 16 x 1

Table 2 — Operating Weights of Options and Accessories (lb)

OPTION OR ACCESSORY

Roof Curb 450 480 515 515 515 560 560 560

Condenser Section Roof Curb — — 540 540 625 625 625 625

Economizer* 300 300 530 530 530 530 530 530

Power Exhaust* 600 600 710 710 710 710 710 710

Barometric Relief 200 200 200 200 200 200 200 200

Return Exhaust Fan* — — — — — 1470 1470 1470

High-Efficiency Filters 20 20 20 20 20 — — —

Bag Filters 35 35 40 40 40 — — —

Hail Guard 120 150 145 145 210 210 210 210

Copper Condenser Coil Fins 180 235 235 235 420 420 420 420

Inlet Guide Vanes 95 95 115 115 115 115 115 115

Variable Frequency Drive

7.5 hp

10 hp

15 hp

20 hp

25 hp

30 hp

40 hp

50 hp

60 hp

75 hp

High-Capacity Evaporator Coil — 300 300 300 300 300 300 300

030,035 040,050 055 060 070 075 090 105

65

65

110

111

190

—

—

—

—

—

65

65

110

111

190

190

—

—

—

—

UNIT SIZE

—

—

110

111

190

190

190

—

—

—

—

—

110

111

190

190

190

—

—

—

—

—

110

111

190

190

190

—

—

—

—

—

—

—

—

152

155

263

266

266

—

—

—

—

—

152

155

263

266

266

*Includes hood.

—

—

—

—

—

152

155

263

266

266

11

Page 12

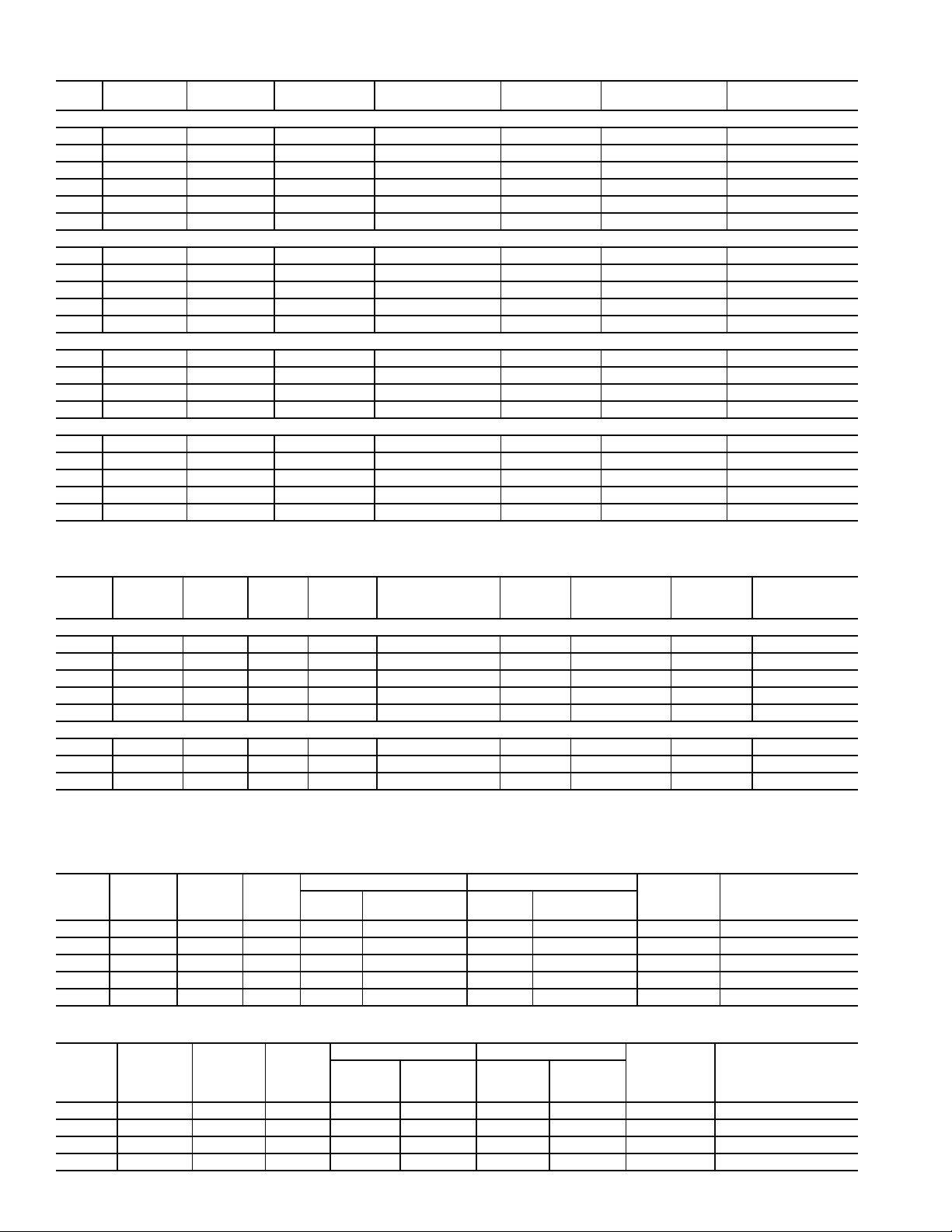

Table 3 — Supply Fan Drive Data

HP

SHAFT

DIA (in.)

SPEED

(rpm)

MOTOR

SHEAVE

MOTOR

PITCH DIA (in.)

WHEEL

SHEAVE

WHEEL

PITCH DIA (in.).

QUANTITY

...BELT

Sizes 030-050

7.5 1

10 1

15 1

20 1

25 1

30* 1

3

/

8

3

/

8

5

/

8

5

/

8

7

/

8

7

/

8

438 2BK36 3.4 2B5V136 13.7 2...BX60

549 2B5V42 4.3 2B5V136 13.7 2...5VX630

626 2B5V48 4.9 2B5V136 13.7 2...5VX630

703 2B5V54 5.5 2B5V136 13.7 2...5VX630

830 2B5V64 6.5 2B5V136 13.7 2...5VX650

910 3B5V64 6.5 3B5V124 12.5 3...5VX630

Sizes 055-070

15 1

20 1

25 1

30 1

40 2

5

/

8

5

/

8

7

/

8

7

/

8

1

/

8

575 2B5V44 4.5 2B5V136 13.7 2...5VX1230

651 2B5V50 5.1 2B5V136 13.7 2...5VX1230

703 2B5V54 5.5 2B5V136 13.7 2...5VX1230

711 2B5V62 6.3 2B5V154 15.5 2...5VX1230

740 3B5V66 6.7 3B5V160 16.1 3...5VX1250

Sizes 075-105 (Forward Curved Fan)

30 1

40 2

50 2

60 2

7

/

8

1

/

8

1

/

8

3

/

8

501 3B5V52 5.33 B5V184 18.5 3...5VX1320

539 4B5V56 5.74 B5V184 18.5 4...5VX1320

615 4B5V64 6.54 B5V184 18.5 4...5VX1320

672 4B5V70 7.14 B5V184 18.5 4...5VX1320

Sizes 075-105 (Airfoil Fan)

30 1

40 2

50 2

60 2

75 2

7

/

8

1

/

8

1

/

8

3

/

8

3

/

8

1353 2B5V74 7.5 2Q5V97 9.7 2...5VX1150

1493 2B5V86 8.7 2Q5V103 10.2 2...5VX1180

1593 3B5V80 8.1 3R5V90 8.9 3...5VX1150

1711 3B5V86 8.7 3R5V90 8.9 3...5VX1150

1799 3B5V110 11.1 3R5V109 10.8 3...5VX1230

*Sizes 040,050 only. NOTE: Part numbers are Browning Manufacturing Corp. reference.

Table 4 — Power Exhaust Fan Drive Data

TOTALHPMOTOR

QTY...HP

MOTOR

SHAFT

DIA (in.)

FAN

SPEED

RPM

MOTOR

SHEAVE

P/N

MOTOR SHEAVE

PITCH

DIA (in.)

FAN

SHEAVE

P/N

FAN SHEAVE

PITCH

DIA (in.)

BELTS

QTY...P/N

CENTER DIST

Sizes 030-050

6* 2...3

6† 2...3 1

10** 2...5 1

15** 2...7.5 1

20** 2...10 1

7

/

8

1

/

8

1

/

8

3

/

8

3

/

8

656 1VL44 4.1 BK115 11 1...BX71 23.62-26.50

656 1VP44L 4.1 BK115 11 1...BX71 23.62-26.50

785 1VP50L 4.7 BK110 10.4 1...BX71 23.62-26.50

882 1VP65 6.0 BK130 12 1...BX77 23.62-26.50

1000 1VP75 7.0 BK130 12 1...BX79 23.62-26.50

Sizes 055-105

1

10 2...5 1

15 2...7.5 1

20 2...10 1

*High-Efficiency Motor Option.

†Premium-Efficiency Motor Option.

**Applies to both motor options.

/

8

3

/

8

3

/

8

740 2P3V45 4.5 2Q3V106 10.6 2...3VX800 26.8-28.5

820 2P3V50 5.0 2Q3V106 10.6 2...3VX800 26.8-28.5

920 2P3V56 5.6 2Q3V106 10.6 2...3VX800 26.8-28.5

NOTE: Part numbers are Browning Manufacturing Corp. reference.

Table 5 — High-Capacity Power Exhaust Fan Drive Data (48ZT,ZW Units)

TOTALHPMOTOR

QTY...HP

MOTOR

SHAFT

DIA. (in.)

SPEED

RPM

20 2...10 1.375 714 2B5V48 4.8 2B5V124 12.4 2...BX93 32.8 to 36.7

30 2...15 1.625 841 2B5V58 5.8 2B5V124 12.4 2...BX93 32.6 to 36.5

40 2...20 1.625 928 2B5V58 5.9 2B5V110 11.1 2...5VX950 32.6 to 36.5

50 2...25 1.875 1020 2B5V64 6.5 2B5V110 11.1 2...5VX950 32.5 to 36.3

60 2...30 1.875 1094 2B5V68 6.9 2B5V110 11.1 2...5VX950 32.5 to 36.3

MOTOR SHEAVE BLOWER SHEAVE

Part

Number

Pitch Diameter

(in.)

Part

Number

Pitch Diameter

(in.)

QTY...BELT

CENTER DISTANCE

RANGE (in.)

Table 6 — Return/Exhaust Fan Drive Data (48Z6,Z8 Units)

RANGE (in.)

TOTALHPMOTOR

QTY...HP

MOTOR

SHAFT

DIA. (in.)

SPEED

RPM

MOTOR SHEAVE BLOWER SHEAVE

Part

Number

Pitch

Diameter

(in.)

Part

Number

Diameter

Pitch

(in.)

QTY...BELT

CENTER DISTANCE

RANGE (in.)

20 1...20 1.625 1104 3B5V52 5.3 3R5V85 8.5 3...5VX1000 38.1 to 41.0

25 1...25 1.875 1209 3B5V66 6.7 3R5V97 9.8 3...5VX1060 38.9 to 41.8

30 1...30 1.875 1271 3B5V60 6.1 3R5V85 8.5 3...5VX1030 38.9 to 41.8

40 1...40 2.125 1396 3B5V66 6.7 3R5V85 8.5 3...5VX1060 39.9 to 42.8

12

Page 13

*

″

″

″

″

16

8

8

16

/

/

/

/

5

7

5

11

16′-0

18′-1

27′-9

040,050

25′-8

UNIT SIZE

″

″

″

″

16

4

16

16

/

/

/

/

1

1

7

11

23′-9

21′-8

030,035

UNIT SIZE

15′-4

13′-3

A

B

A

B

UNIT TYPE DIMENSION

WITH GAS HEAT

VERTICAL SUPPLY AND RETURN

VERTICAL SUPPLY AND RETURN WITH

Fig. 1 — Roof Curb; Sizes 030-050

GAS HEAT AND EXTENDED CHASSIS

13

Page 14

*

″

″

″

″

8

8

16

16

/

/

/

/

7

3

3

11

055-105

UNIT SIZE

24′-11

29′-10

27′-9

22′-10

A

B

A

B

UNIT TYPE DIMENSION

WITH GAS HEAT

VERTICAL SUPPLY AND RETURN

VERTICAL SUPPLY AND RETURN WITH

GAS HEAT AND EXTENDED CHASSIS

Fig. 2 — Roof Curb; Sizes 055-070 and Sizes 075-105 without High-Capacity Power Exhaust

14

Page 15

15

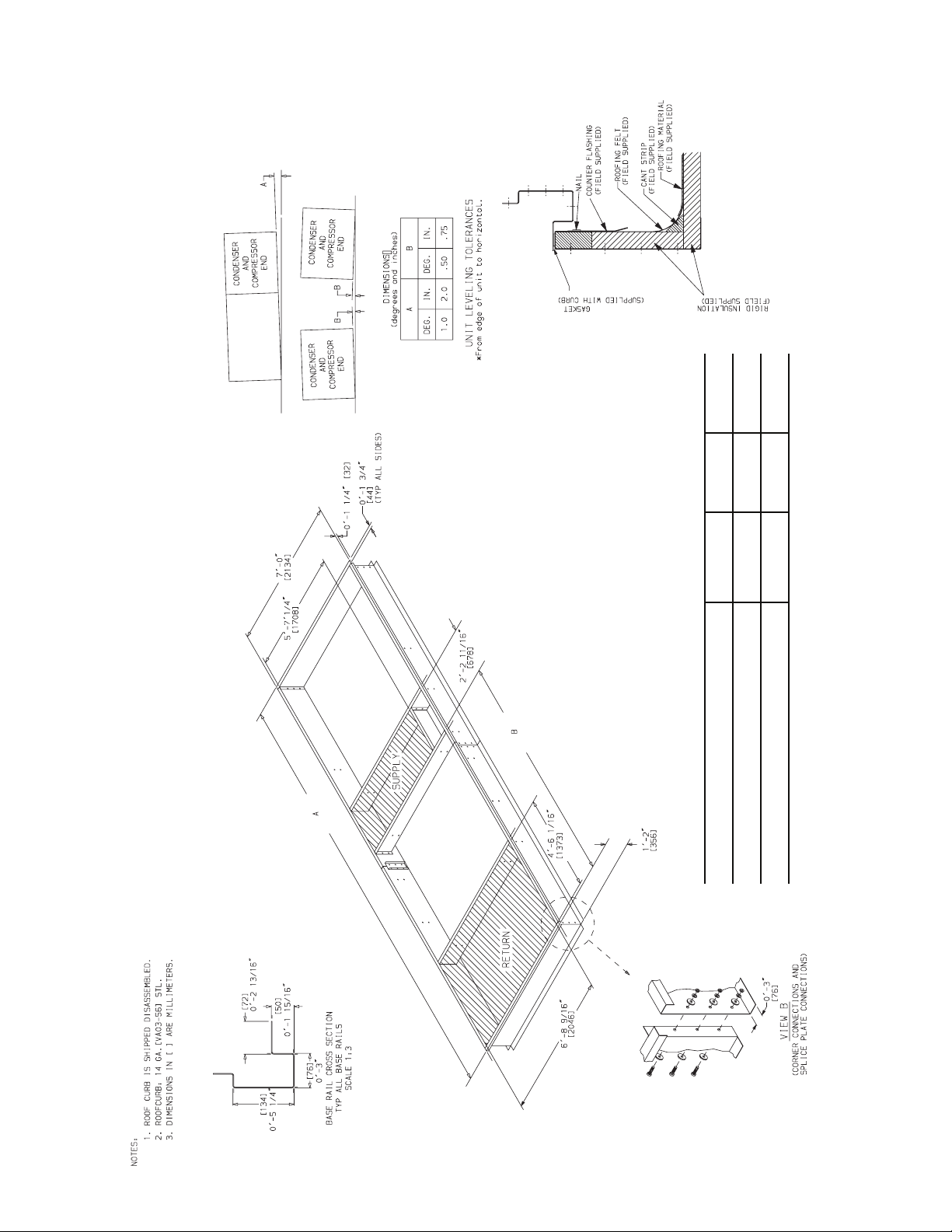

Fig. 3 — Roof Curb; Sizes 075-105 with High-Capacity Power Exhaust

Page 16

*

16

Fig. 4 — Condenser Section Roof Curb (Size 055 and 060 Only)

Page 17

*

17

Fig. 5 — Condenser Section Roof Curb (Size 070-105 Only)

Page 18

"X"

A

A

CONDENSER

END SUPPORT

4

1

4 REF.

9 3/4"

2

3

"X"-

NO GASKET

DETAIL A-A

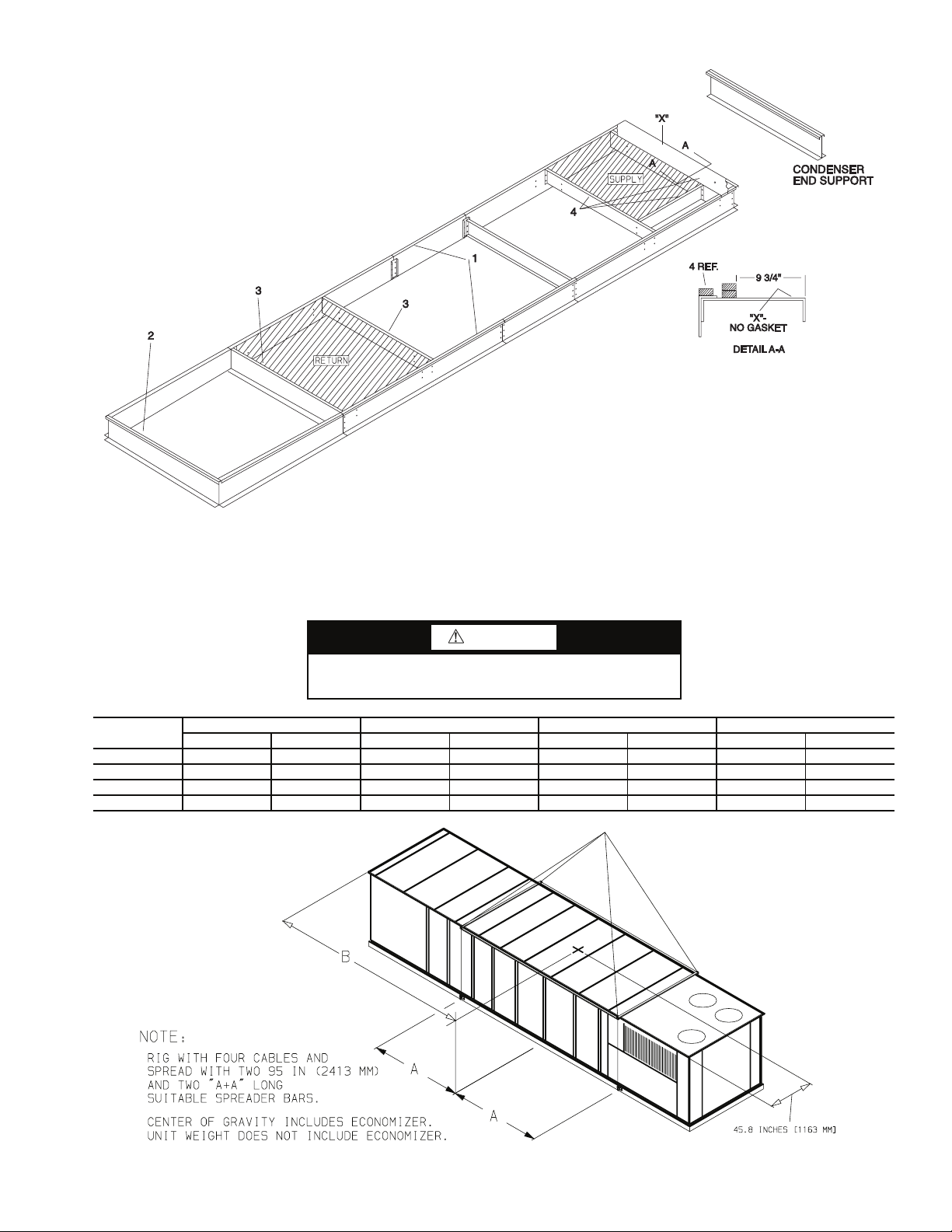

Fig. 6 — Gasket Location on Roof Curb (48ZG,ZN055-105 and 48Z6,Z8075-105 Units)

5

5

Fig. 7 — Gasket Location — Condenser Section Roof Curb (Size 055-105 Units)

18

Page 19

Fig. 8 — Gasket Location on Roof Curb (48ZT,ZW075-105 Units)

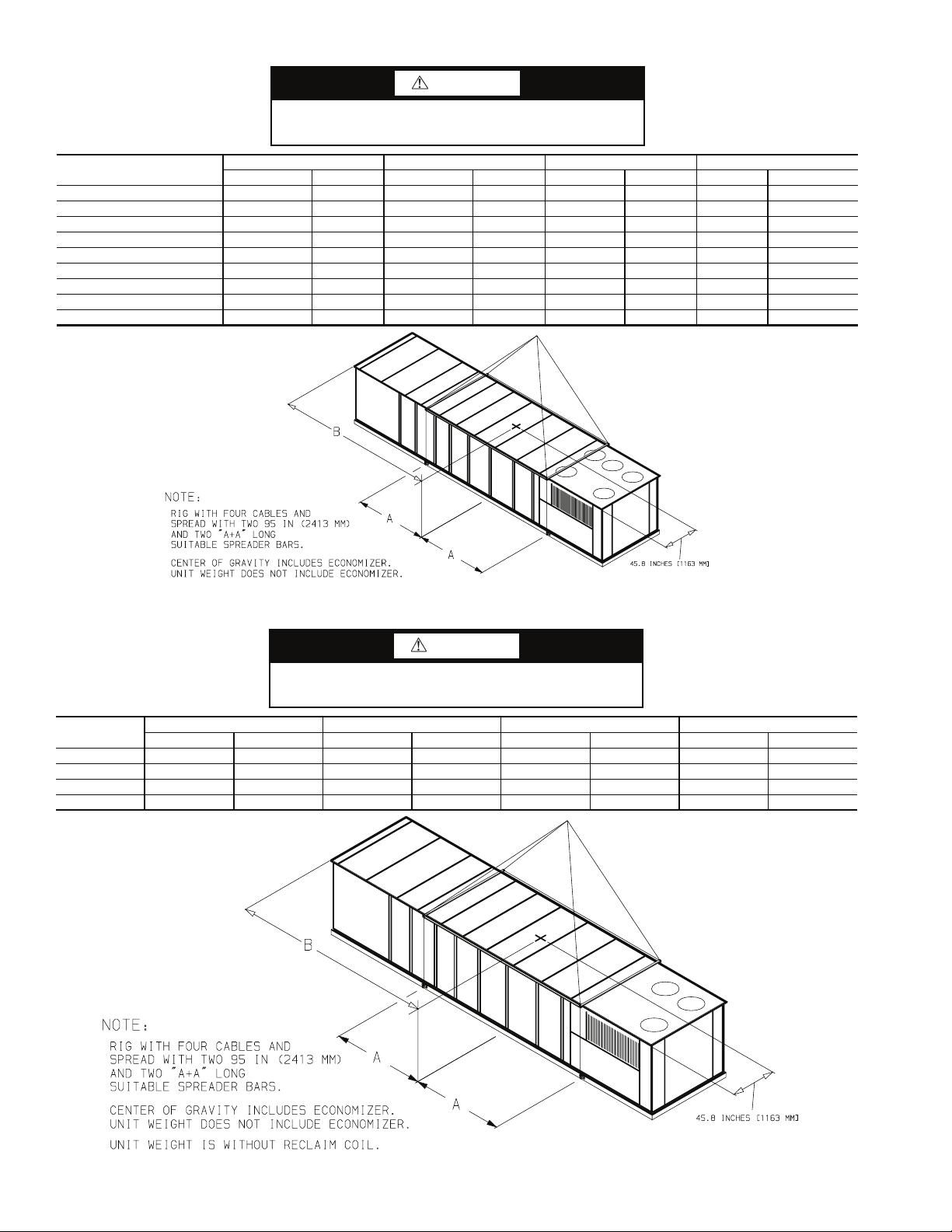

CAUTION

1. ALL PANELS MUST BE IN PLACE WHEN RIGGING.

2. DO NOT ATTEMPT TO FORK THESE UNITS.

NOTICE TO RIGGERS

UNIT

48Z030 5770 2623 83.23 2114 176.14 4474 300 136

48Z035 5895 2679 83.23 2114 177.99 4521 300 136

48Z040 6670 3032 92.64 2353 205.87 5229 300 136

48Z050 6710 3050 92.64 2353 207.01 5258 300 136

WEIGHT A B ECONOMIZER

lb kg in. mm in. mm lb kg

Fig. 9 — Rigging Label — Size 030-050 Units (Standard Chassis)

19

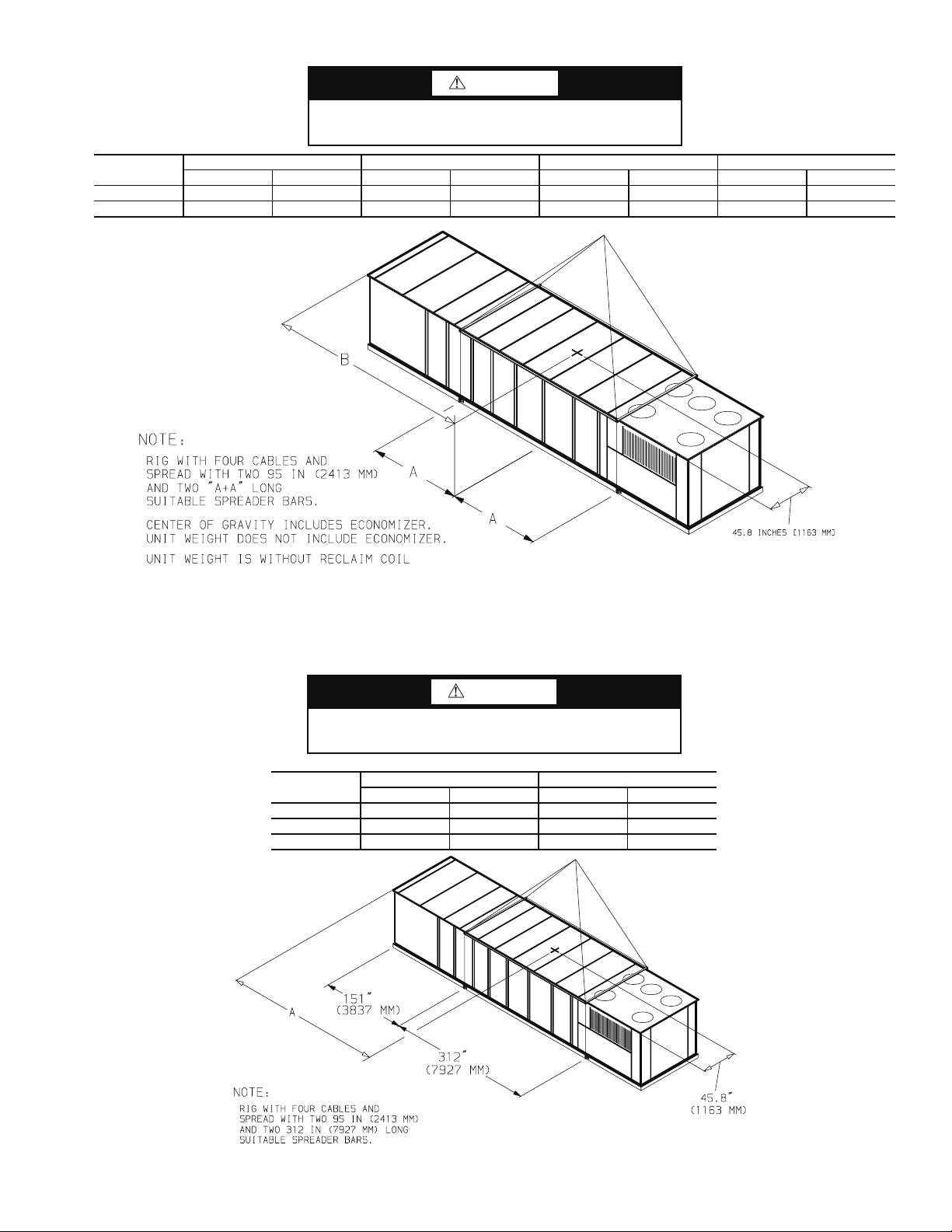

Page 20

CAUTION

1. ALL PANELS MUST BE IN PLACE WHEN RIGGING.

2. DO NOT ATTEMPT TO FORK THESE UNITS.

NOTICE TO RIGGERS

UNIT

48Z055 8,820 4009 128.75 3270 235.0 5969 530 240.9

48Z060 9,120 4145 128.75 3270 235.0 5969 530 240.9

48Z070 9,550 4341 112.50 2858 252.0 6401 530 240.9

48ZG,ZN075 10,445 4738 127.80 3247 260.6 6618 530 240.9

48ZG,ZN090 10,655 4833 127.80 3247 262.4 6666 530 240.9

48ZG,ZN105 11,385 5164 127.80 3247 271.0 6883 530 240.9

48Z6,Z8075 11,915 5405 127.80 3247 260.6 6618 530 240.9

48Z6,Z8090 12,125 5500 127.80 3247 262.4 6666 530 240.9

48Z6,Z8105 12,855 5831 127.80 3247 271.0 6883 530 240.9

WEIGHT A B ECONOMIZER

lb kg in. mm in. mm lb kg

Fig. 10 — Rigging Label — Size 055-105 Units (Standard Chassis)

CAUTION

1. ALL PANELS MUST BE IN PLACE WHEN RIGGING.

2. DO NOT ATTEMPT TO FORK THESE UNITS.

UNIT

48Z030 6270 2844 95.83 2434 192.56 4891 300 136

48Z035 6395 2900 95.83 2434 194.72 4946 300 136

48Z040 7170 3252 105.24 2673 222.44 5650 300 136

48Z050 7210 3270 105.24 2673 223.50 5677 300 136

WEIGHT A B ECONOMIZER

lb kg in. mm in. mm lb kg

NOTICE TO RIGGERS

Fig. 11 — Rigging Label — Size 030-050 Units (Extended Chassis)

20

Page 21

CAUTION

1. ALL PANELS MUST BE IN PLACE WHEN RIGGING.

2. DO NOT ATTEMPT TO FORK THESE UNITS.

NOTICE TO RIGGERS

UNIT

48Z055 9548 4330 121.50 3085.5 248.50 6312 530 240.9

48Z060 9668 4385 121.50 3085.5 248.50 6312 530 240.9

WEIGHT A B ECONOMIZER

lb kg in. mm in. mm lb kg

Fig. 12 — Rigging Label — Size 055,060 Units (Extended Chassis)

CAUTION

1. ALL PANELS MUST BE IN PLACE WHEN RIGGING.

2. DO NOT ATTEMPT TO FORK THESE UNITS.

UNIT

48Z075 13,380 6069 298.9 7591

48Z090 13,590 6164 300.7 7637

48Z105 14,320 6495 309.9 7873

NOTICE TO RIGGERS

WEIGHT A

lb kg in. mm

Fig. 13 — Rigging Label — 48ZT,ZW075-105 Units (High-Capacity Power Exhaust Units)

21

Page 22

3

B

4

UNITS 48ZG,ZN SIZE

VERTICAL SUPPLY AND RETURN/

LOW GAS HEAT

VERTICAL SUPPLY AND RETURN/

HIGH GAS HEAT

VERTICAL SUPPLY AND RETURN/

EXTENDED CHASSIS/LOW GAS HEAT

VERTICAL SUPPLY AND RETURN/

EXTENDED CHASSIS/HIGH GAS HEAT

2

A

CORNER WEIGHTS (lb)

1 2 3 4 ft-in. ft-in.

030 1968 1004 1005 1964 5,941 14- 9

035 1851 1184 1142 1889 6,066 14-11 3-913/

040 2246 1177 1179 2239 6,841 17- 27/

050 2264 1182 1179 2256 6,881 17- 4 3-913/

055 2478 2140 2144 2468 9,230 19- 7 3-913/

060 2557 2211 2212 2549 9,530 19- 7 3-913/

070 2648 2330 2334 2638 9,950 21- 0 3-913/

075 2955 2447 2445 2953 10,800 21- 71/

090 3035 2471 2471 3033 11,010 21- 97/

105 3342 2529 2529 3340 11,740 22- 6 3-913/

030 2000 1037 1038 1995 6,070 14- 81/

035 2061 1038 1037 2059 6,195 14-10 3-913/

040 2277 1210 1213 2270 6,970 17- 17/

050 2301 1206 1205 2297 7,010 17- 3 3-913/

055 2510 2168 2172 2500 9,350 19- 7 3-913/

060 2587 2242 2237 2584 9,650 19- 7 3-913/

070 2683 2361 2365 2672 10,080 21- 0 3-913/

075 3015 2474 2472 3013 10,974 21- 89/

090 3095 2499 2498 3092 11,184 21-107/

105 3405 2554 2554 3401 11,914 22- 7 3-913/

030 2133 1089 1091 2127 6,441 16- 111/

035 2198 1087 1087 2194 6,566 16- 37/

040 2411 1262 1264 2404 7,341 18- 71/

050 2434 1259 1256 2432 7,381 18- 85/

055 2617 2251 2255 2607 9,730 20- 9 3-913/

060 2698 2320 2325 2687 10,030 20- 9 3-913/

030 2188 1100 1101 2182 6,570 16- 23/

035 2187 1163 1161 2184 6,695 18- 67/

040 2454 1284 1287 2446 7,470 18- 71/

050 2017 1740 1738 2014 7,510 20- 9 3-913/

055 2649 2279 2283 2639 9,850 20- 9 3-913/

060 3442 1787 1791 3431 10,450 16- 09/

1

TOTAL

(lb)

AB

1

/

8

8

2

16

8

8

16

16

16

8

2

8

4

16

2

16

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

3-913/

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

WITH HIGH-CAPACITY POWER EXHAUST

UNITS 48ZT,ZW

VERTICAL SUPPLY AND RETURN/

LOW GAS HEAT, HIGH-CAPACITY

POWER EXHAUST

VERTICAL SUPPLY AND RETURN/

HIGH GAS HEAT, HIGH-CAPACITY

POWER EXHAUST

UNITS 48Z6,Z8

WITH RETURN/EXHAUST FAN

VERTICAL SUPPLY AND RETURN

LOW GAS HEAT,

RETURN/EXHAUST FAN

VERTICAL SUPPLY AND RETURN

HIGH GAS HEAT,

RETURN/EXHAUST FAN

Fig. 14 — Weight Distribution and Center of Gravity

SIZE

CORNER WEIGHTS (lb)

1 2 3 4 ft-in. ft-in.

TOTAL

(lb)

075 3551 3053 3049 3551 13,204 24- 9

090 3629 3080 3075 3630 13,414 24- 15/

105 3948 3126 3121 3948 14,144 25- 91/

075 3611 3081 3076 3611 13,380 24-107/

090 3691 3106 3102 3691 13,590 25- 03/

105 4008 3155 3150 4008 14,320 25- 915/

SIZE

075 2802 3002 3008 2868 11,740 19-4 3-9

090 2940 3029 3035 2946 11,950 19-6 3-913/

CORNER WEIGHTS (lb)

1 2 3 4 ft-in. ft-in.

TOTAL

(lb)

105 3242 3091 3098 3249 12,680

075 2921 3029 3036 2928 11,914 19-6 3-913/

090 2999 3056 3063 3006 12,124 19-7 3-913/

105 3304 3116 3123 3311 12,854

AB

13

/

8

8

8

4

3-913/

16

3-913/

3-913/

3-913/

3-913/

3-913/

16

AB

20-2

20-4

3-913/

3-913/

16

16

16

16

16

16

13

/

16

16

16

16

16

16

22

Page 23

Condensate Drain Connections — There are a to-

tal of five drain connections required on each unit: one primary

drain (on right-hand side of the unit) and four secondary drains

(two on each side of unit).

PRIMARY DRAIN — The primary drain is a 2-in. NPT pipe

connection located on the right-hand side of the unit looking at

the unit from the return air end. See Fig. 15-24.

With field-supplied fittings and pipe sections, plumb the primary condensate drain to the 2-in. FPT connector on the base

rail. Use a trap height of at least 4-in. for size 030-070 units

and 7-in. for size 075-105 units. See Fig. 24 and 25. Install with

a height dimension of at least 2-in. from the top of the exit pipe

from the trap section to the bottom of the connector. Apply a

bead of RTV or similar sealant around the pipe joint at the connector in the base rail.

SECONDARY DRAINS (Units Installed on

Curb) — There are two secondary drain connections on each

side of the unit. See Fig. 26. There are secondary drains on

each side of the unit in the filter section and one on each side of

the unit in the supply fan section. There are labels marking

each location on the unit base rail. See Fig. 15-23.

Locate the four 1

mounting screws (shipped in a bag taped to the basepan in the

supply fan section, located behind the access panel marked

FAN SECTION). The drain couplings are a 10-gage plate with

1

a 1

/4 in. half coupling welded to the plate.

At each secondary drain hole location, there is a 1

hole pre-drilled in the bottom of the base rail, surrounded by

four 0.20-in. engagement holes. Install a drain coupling assembly using screws provided at each secondary drain hole location. See Fig. 27. Do not attach any drain coupling assemblies

in the condenser section base rail.

Using field-supplied fittings and pipe sections, assemble Utraps at each secondary drain fitting. See Fig. 28. Provide a

minimum size of ½-in. pipe for secondary drains. Use a trap at

least 4-in. deep for size 030-070 units and 7-in. deep for size

075-105 units. Apply a bead of RTV or similar sealant around

the drain assemblies.

Consult local plumbing codes for direction on joining multiple drain lines. Total size of any combined line does not need

to exceed nominal 2-in. size of primary drain connection.

1

/4-in. drain coupling assemblies and

3

/8-in.

Fill the U-traps at the secondary drain locations prior to unit

start-up. Also check the U-traps before each cooling season to

ensure the traps are filled and functioning properly.

SECONDARY DRAINS (Units Installed on Steel Beam or

Slab) — There are two secondary drain connections required

on each side of the unit. See Fig. 26. There are secondary

drains on each side of the unit in the filter section and one on

each side of the unit in the supply fan section. There are labels

marking each location on the unit base rail. See Fig. 15-23. Prior to final positioning of the unit, apply a bead of RTV or similar sealant around each secondary drain hole in the bottom of

the unit base rail. Then position the unit into final location.

Locate the four 1

1

/4-in. drain coupling assemblies and

mounting screws (shipped in a bag taped to the basepan in the

supply fan section, located behind the access panel marked

FAN SECTION). The drain couplings are a 10-gage plate with

1

a 1

/4 in. half coupling welded to the plate.

After final positioning of the unit, perform the following

procedure:

1. At each of the four secondary drain locations (marked

with labels on the unit base rail), position the drain coupling assembly in the side of the base rail. Mark the

screw holes and the drain hole locations on the base rail.

2. Drill holes for drain outlet (use 1

the mounting screws (use

3

3

/8-in. hole saw) and for

/16-in. drill bit).

3. Install a drain coupling assembly using screws provided

at each secondary drain hole location.

4. Using field-supplied fittings and pipe sections, assemble

U-traps at each secondary drain fitting. See Fig. 28. Provide minimum size of ½-in. pipe for secondary drains.

Use a trap at least 4-in. deep for size 030-070 units and

7-in. deep for size 075-105 units.

5. Apply a bead of RTV or similar sealant around the drain

assemblies.

Consult local plumbing codes for direction on joining multiple drain lines. Total size of any combined line does not need

to exceed nominal 2-in. size of primary drain connection.

Fill the U-traps at the secondary drain locations prior to unit

start-up. Also check the U-traps before each cooling season to

ensure the traps are filled and functioning properly.

23

Page 24

→

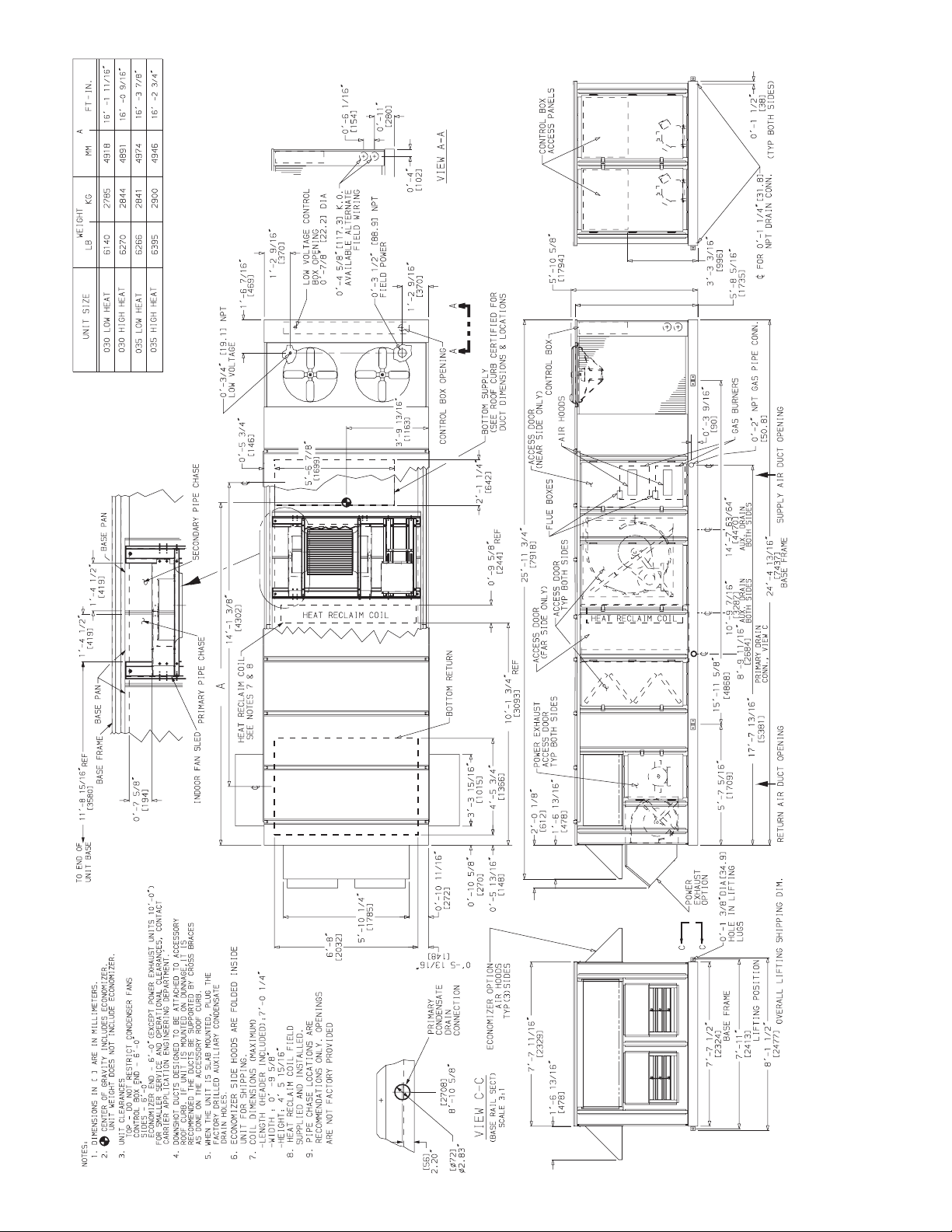

Fig. 15 — Base Unit Dimensional Drawing — 48ZG,ZN030,035 (Standard Chassis)

24

Page 25

25

Fig. 16 — Base Unit Dimensional Drawing — 48ZG,ZN040,050 (Standard Chassis)

Page 26

26

Fig. 17 — Base Unit Dimensional Drawing — 48ZG,ZN055-070 (Standard Chassis)

Page 27

a48-8451

27

Fig. 18 — Base Unit Dimensional Drawing — 48ZG,ZN075-105 (Standard Chassis)

Page 28

28

Fig. 19 — Base Unit Dimensional Drawing — 48ZG,ZN030,035 (Extended Chassis)

Page 29

29

Fig. 20 — Base Unit Dimensional Drawing — 48ZG,ZN040,050 (Extended Chassis)

Page 30

a48-8452

30

Fig. 21 — Base Unit Dimensional Drawing — 48ZG,ZN055,060 (Extended Chassis)

Page 31

a48-8453

4.65]

[10

[352]

1'-1 3/4"

POWER

[1933]

6'-4 1/8"

Fig. 22 — Base Unit Dimensional Drawing — 48ZT,ZW075-105 (Units with High-Capacity Power Exhaust)

CONTROL

[22.35] 0'-0 7/8" D LOW VOLTAGE

31

Page 32

a48-8454

32

Fig. 23 — Base Unit Dimensional Drawing — 48Z6,Z8075-105 (Units with Return/Exhaust Fan)

Page 33

Fig. 24 — Primary Drain Connection

A = 4-in. (102 mm) min — Sizes 030-070

7-in. (178 mm) min — Sizes 075-105

Fig. 25 — Slab-Mounted Condensate

Drain Piping Details

Fig. 26 — Secondary Condensate Drain Location

Fig. 27 — Secondary Drain Seal Plate Location

A = 4-in. (102 mm) min — sizes 030-070

7-in. (178 mm) min — sizes 075-105

Fig. 28 — Curb-Mounted Condensate

Drain Pipe Details

Install Outdoor Hoods (48ZG,ZN,Z6,Z8 Units)

UNIT SIZES 030-050

25% Outdoor-Air Hoods (Units without Economizer

Option) (Fig. 29)

1. Outdoor-air hoods are shipped bolted to the unit in a shipping position. Remove the 6 screws holding each 25%

outdoor air hood shipping cover in place.

2. Remove the holddown screw from each upper corner of

each hood.

3. Pivot hoods outward (2 hoods).

4. Install 17 screws around outside of each hood. (Screws

are in the fastener package taped to the basepan inside the

fan section.)

5. Apply a bead of RTV or similar sealant to corner of each

hood at pivot point to prevent water leaks. See Fig. 30.

Economizer Hoods (Units with Economizer Option)

(Fig. 31 and 32)

1. Remove the 4 screws holding each of the 2 economizer

side hoods in place.

2. Pivot hoods outwards (2 hoods).

3. Apply seal strip to vertical flange of hood sides.

4. Install hood sides of hood top using 19 screws (7 each

side, 5 top). Screws are in fastener package located with

the hood sides and seal strip which is taped inside the

unit.

5. Apply a bead of RTV or similar sealant to corners of

economizer hoods to prevent water leaks.

UNIT SIZES 055-105

25% Outdoor-Air Hoods (Fig. 33)

are factory installed on the 055-105 units.

Economizer Hoods (Units with Economizer Option) (Fig. 34-36)

1. Remove the 6 screws holding each of the 4 economizer

shipping covers in place.

2. Remove the holddown screw from each upper corner of

each economizer hood.

3. Pivot hoods outward (4 hoods).

4. Apply seal strip to vertical flange of hood sides.

5. Install 18 screws (5 each side, 6 top, and 2 bottom)

around the outside of each hood. (Screws are in the fastener package taped to the basepan inside the fan section.)

6. Apply a bead of RTV or similar sealant to corner of economizer hood at pivot point to prevent water leaks. (See

Fig. 30.)

— The outdoor-air hoods

33

Page 34

OUTDOOR

AIR HOOD

OUTDOOR

AIR HOOD

OUTDOOR

AIR HOODS

(FIXED)

Fig. 29 — Outdoor Air Hood Installation

(Sizes 030-050)

OUTDOOR-AIR HOOD

RTV

(ALL HOODS)

Fig. 30 — Outdoor-Air and Economizer Hood

SIDE HOOD

(ROTATE

OPEN)

Fig. 33 — 25% Outdoor-Air Hood Location

SIDE HOODS

(ROTATE OPEN)

END HOODS

4”

(FIXED)

SIDE HOODS

(ROTATE

OPEN)

Fig. 34 — Economizer Outdoor-Air Hood

Installation (Sizes 055-105)

SIDE HOODS

(ROTATE OPEN)

SIDE HOOD

(ROTATE

END HOOD

(FIXED)

OPEN)

Fig. 31 — Economizer Outdoor-Air Hood

Installation (Sizes 030-050)

SIDE HOOD

(ROTATE

OPEN)

END HOOD

(FIXED)

SIDE HOOD

(ROTATE

OPEN)

POWER EXHAUST (FIXED)

Fig. 32 — Economizer with Power Exhaust

Outdoor-Air Hood Installation (Sizes 030-050)

34

END HOODS

(FIXED)

POWER

EXHAUST (FIXED)

SIDE HOODS

(ROTATE

OPEN)

Fig. 35 — Economizer with Power Exhaust

Outdoor-Air Hood Installation (Sizes 055-105)

SIDE HOODS

(ROTATE OPEN)

END HOODS

(FIXED)

RETURN/

EXHAUST (FIXED)

SIDE HOODS

(ROTATE

OPEN)

Fig. 36 — Economizer with Return/Exhaust

Fan Outdoor-Air Hood Installation

(48Z6,Z8075-105 Units)

Page 35

Install Economizer Hoods (48ZT,ZW Units) —

The economizer uses a total of 4 outdoor intake hoods, 2 on

each side of the unit. See Fig. 37. Two small hoods (one per

side) are factory-installed and are pivoted inside the unit chassis for shipment. Two large hoods are shipped in packages

located inside the unit. The large hoods (1 on each side) require

field assembly and mounting.

INSTALL SMALL HOODS — To install the small economizer hoods, perform the following procedure:

1. Remove the 10 screws holding each of the small economizer hood shipping covers in place.

2. Pivot hoods outward. (There are a total of 2 hoods.)

3. Apply seal strip to vertical flange of hood sides.

4. Install 15 screws (4 each side, 7 across top) around the

outside of each hood. Screws are in the fastener package

taped to the basepan inside the fan section.

5. Apply a bead of RTV or similar sealant to corner of economizer hood at pivot point to prevent water leaks. (See

Fig. 30.)

INSTALL LARGE HOODS — Large hoods are shipped disassembled in the economizer section of the unit behind the

large economizer hood shipping cover. See Fig. 38 for assembly details for large economizer hoods. To install the large

economizer hoods, perform the following procedure:

1. Remove the 17 screws holding each of the large economizer hood shipping covers in place.

2. Remove the packages containing the disassembled large

economizer hoods (total of 2 packages). Each package

contains the following: left hood side, right hood side,

hood top, hood front, top filter flange, side filter flanges

(4), bottom support, front support, filters (6), filter clips

(9), seal strip, fasteners.

3. Place seal strip on backside of bottom support along entire length of support, covering 6 clearance holes.

4. Attach bottom support piece to unit. Be sure seal strip is

between bottom support and panel on unit.

5. Place seal strip on

3

/4-in. flange on both the left and right

hood side.

6. Attach the side filter flanges to the left and right hood

sides, 2 on each hood side.

7. Attach left and right hood sides to unit. Be sure seal strip

is between hood side and unit.

8. Place seal strip on

3

/4-in. flange on hood top.

9. Attach top filter flange to hood top.

10. Attach top hood to unit and to hood sides. Be sure seal

strip is between hood top and unit.

11. Attach front support between left and right hood sides.

12. Place seal strip on all filter flanges.

13. Attach filter clips to front and bottom supports.

14. Install filters and filter clips. Filters are held in place with

filter clips.

15. Attach hood front to hood top and sides.

16. Apply RTV or similar sealant to 6 places shown in

Fig. 38.

EXHAUST

AIR

PE VFD

POWER EXHAUST

ACCESS DOOR

AUXILIARY

CONTROL BOX

LARGE ECONOMIZER

HOOD LOCATION

ACCESS DOOR

LEGEND

PE VFD — Power Exhaust Variable Frequency Drive

Fig. 37 — Economizer Hood Location — 48ZT,ZW Units

SMALL ECONOMIZER

HOOD LOCATION

35

Page 36

DETAIL Z

SCALE 3:4

SEE DETAIL Z

AND BOTH ENDS OF

BOTTOM FILTER ROW

APPLY RTV IN THE

INDICATED AREAS

Fig. 38 — Large Economizer Hood Assembly

Field Wire Routing

UNIT SIZES 030-050 — Field wiring can be brought into the

unit through the basepan and roof curb or through the corner

post in the side of the unit next to the control box.

1

A 3

coupling for 24 v control wiring are provided in the basepan.

There are two 4

power wiring.

wiring out through one of the 4

supplied disconnect and then back into the unit through the other knockout. See Fig. 39 for recommended disconnect location.

wiring from field-supplied disconnect through top 4

knockouts into unit.

unit, a

next to the control box.

UNIT SIZES 055-105 — Field wiring is brought into the unit

through the bottom of the control box. Wiring can be brought

through the roof curb through field-supplied watertight connections. See Fig. 40 and 41.

24 v control wiring are provided in the bottom of the control

box. Field-supplied couplings must be used when routing wiring into the control box.

/2-in. NPT coupling for field power and a 3/4-in. NPT

5