Carrier Transicold Supra 550, Transicold Supra 850, Transicold Supra 950, Transicold Supra 650, Transicold Supra 750 Operator's Manual

MANUAL

OPERATOR’S

Supra 550, 650,

750, 850 & 950

TRUCK

REFRIGERATION

UNITS

CONTENTS

Page

Unit Identification 2..........................

Safety 3....................................

Pre-Trip Inspection 4.........................

Unit Operation 6............................

Starting the Unit -- Road Operation 6...........

Starting the Unit -- Standby Operation 7........

Starting the Unit -- Manual Operation 8.........

Pretrip Check 9.............................

Changing Setpoint 10........................

Start/Stop Operation 12......................

Continuous Run Operation 14.................

Manual Defrost 15...........................

City Speed 16...............................

Function Change 17.........................

Unit Data 19................................

Alarm Display and Reset 21..................

Stopping Unit 23............................

Product Loading 24..........................

Recommended Transport Temperatures 26.....

Problems 27................................

Troubleshooting 28..........................

Relay Board 30.............................

Unit Maintenance 32.........................

Unit Maintenance Schedule 34................

Standby Operation Guidelines 39..............

Emergency Road Service 40..................

1

SUPRA OPERATOR’S MANUAL

This guide has been prepared for the operator of Carrier Transicold

diesel truck refrigeration units. It contains basic instructions for the

daily operation of the refrigeration unit as well as safety information,

troubleshooting tips, and other information that will help you to deliver the load in the best possible condition. Please take the time to

read the information contained in this booklet and refer to it whenever you have a question about the operation of your Carrier Transicold Supra unit.

Your refrigeration unit has been engineered to provide long,

trouble-free performance when it is properly operated and maintained. The checks outlined in this guide will help to minimize overthe-road problems. In addition, a comprehensive maintenance program will help to insure that the unit continues to operate reliably.

Such a maintenance program will also help to control operating

costs, increase the unit’s working life, and improve performance.

This guide is intended as an introduction to your unit and to provide

general assistance when needed. More comprehensive information can be found in the Operation and Service Manual for your unit.

This manual can be obtained from your local Carrier Transicold

dealer.

When having your unit serviced, be sure to specify genuine Carrier

Transicold replacement parts for the highest quality and best reliability.

At Carrier Transicold, we are continually working to improve the

products that we build for our customers. As a result, unit specifications may change without notice.

2

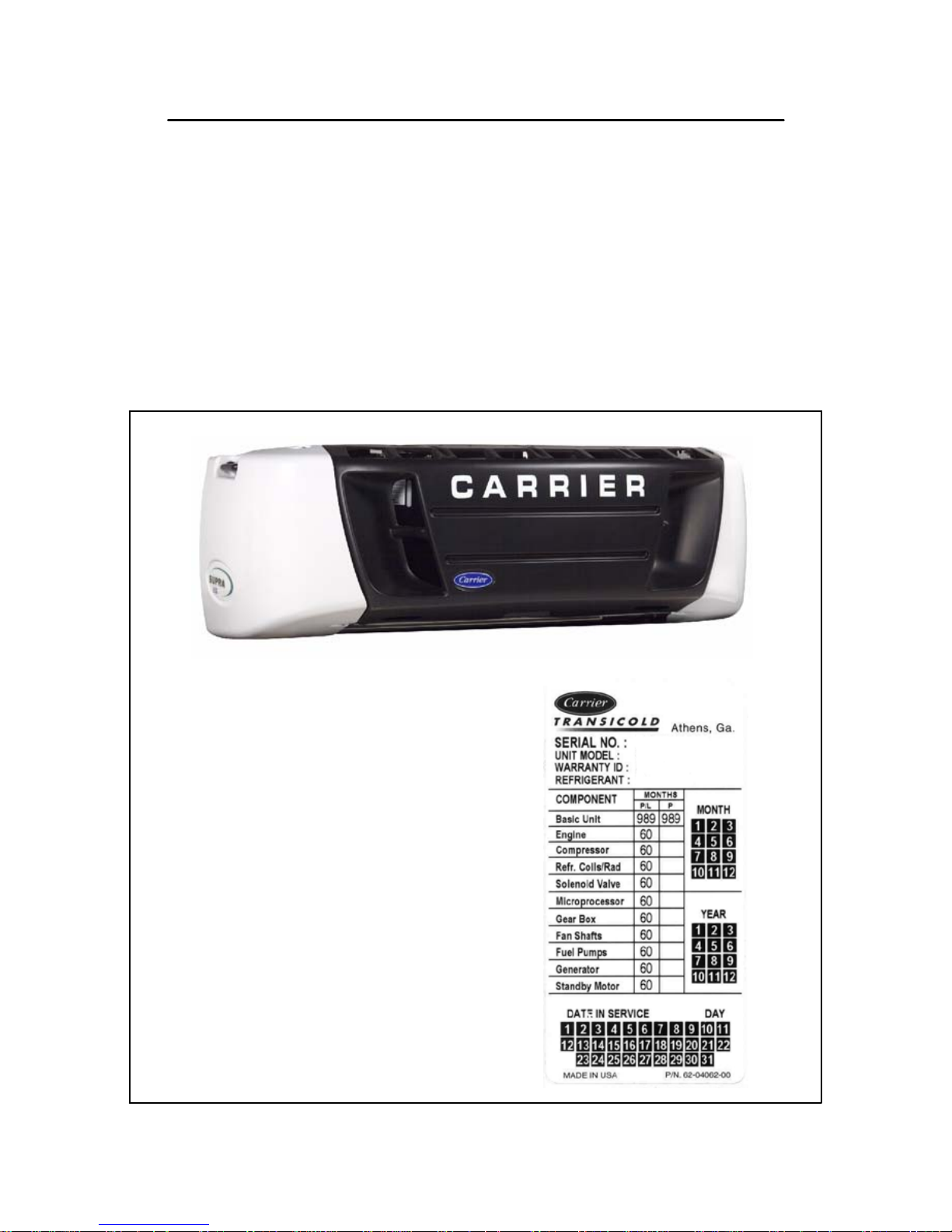

UNIT IDENTIFICATION

Each Supra 50 Series unit is identified by a nameplate attached to

the frame near the accumulator. This nameplate identifies the

complete model number of the unit, the serial number, the

refrigerant charge and quantity, and the date the unit was placed

in service.

If a problem occurs, please refer to the information on this plate,

and make a note of the model and serial number before calling for

assistance. This information will be needed when you contact a

technician or Carrier Transicold Service Engineer so that he or she

may properly assist you.

NAMEPLATE

3

SAFETY

Your Carrier Transicold refrigeration unit has been designed with

the safety of the operator in mind. During normal operation, all

moving parts are fully guarded to help prevent injury. During all

pre-trip inspections, daily inspections, and problem

troubleshooting, you may be exposed to moving parts; please stay

clear of all moving parts when the unit is in operation and when the

unit main power switch is in the RUN position.

AUTO-START/STOP

Your refrigeration unit is equipped with Auto-Start/Stop, a valuable

fuel saving feature. When the unit is set for Auto-Start/Stop

operation it may start at any time and without warning. When

performing any check of the refrigeration unit (e.g., checking the

belts, checking the oil), make certain that the main power switch is

in the OFF position.

ENGINE COOLANT

The engine is equipped with a pressurized cooling system. Under

normal operating conditions, the coolant in the engine and radiator

is under high pressure and is very hot. Contact with hot coolant can

cause severe burns. Do not remove the cap from a hot radiator. If

the cap must be removed, do so very slowly in order to release the

pressure without spray.

REFRIGERANTS

The refrigerant contained in the refrigeration system of your unit

can cause frostbite, severe burns, or blindness when in direct

contact with the skin or eyes. For this reason, and because of

legislation regarding the handling of refrigerants during system

service, we recommend that whenever your unit requires service

of the refrigeration system, you contact your nearest Carrier

Transicold authorized repair facility for service.

BATTERY

This unit utilizes a lead-acid type battery. The battery normally

vents small amounts of flammable hydrogen gas. Do not smoke

when checking the battery. A battery explosion can cause serious

physical harm and/or blindness.

4

PRE-TRIP INSPECTION

The pre-trip inspection should be performed before picking up any

load. This inspection is essential to anticipate and help minimize the

possibility of “over-the-road” problems. These checks take only a

few minutes.

1. Place the unit’s main switch in the STOP (0) position.

2. Fuel -- drain any water and impurities from the sump of the

refrigeration unit fuel tank by opening the drain-cock located on

the bottom of the tank (if so equipped). Close the valve when

only pure fuel emerges. Check the fuel level in the tank,

ensuring that the fuel supply is adequate for unit operation.

Refuel if necessary.

3. Belts -- Check the belt tension by depressing the belt with your

thumb, near the center of the longest free run of each belt.

Under moderate pressure each belt should deflect

approximately 6 mm to 13mm (1/4 inch to 1/2 inch). If the belts

deflect more than this they should be tightened (loose belts

may slip, generating heat and reducing belt life). If the belts are

too tight they should be loosened; tight belts can reduce

bearing life.

3. Battery -- on units equipped with serviceable batteries, the level

of the electrolyte in each of the cells should be checked. If the

level is low, distilled water should be added to the correct level.

Most units, however, are equipped with low or no--maintenance

batteries. These should be inspected to ensure that the

connections are clean and tight, and the battery hold--down

should be checked for tightness.

MARKS ONLY

NO WORDING

5

5. Engine Oil -- the engine oil should

be checked last since it is

necessary for oil to drain from the

block and into the oil pan to obtain

a correct reading. Remove the

dipstick, wipe it off and re-insert it

fully into the engine block. Once

again, remove the dip-stick and

observe the oil level; it should be

somewhere between the full and

add marks. If it is below the add

mark, add oil until the level is

correct.

6. Over-all Unit -- visually inspect the entire unit for leaks, loose

bolts, frayed, loose, or broken wires, etc. The radiator and

condenser coils of the unit should be free of dirt, bugs,

cardboard, or any other debris that may obstruct airflow across

the coils. The evaporator (located inside the body) should be

free of debris also, especially stretch-wrap, which is often used

during transport to prevent cargo shifting.

7. Truck body -- The body should be inspected prior to loading.

Check the door and vent seals for damage and wear. Inspect

the entire interior and exterior of the body for damage; check

for damage to the inner and outer skins of the body. Damage

to the insulation may compromise the unit’s ability to maintain

the product temperature by increasing the amount of heat gain

across the truck body.

6

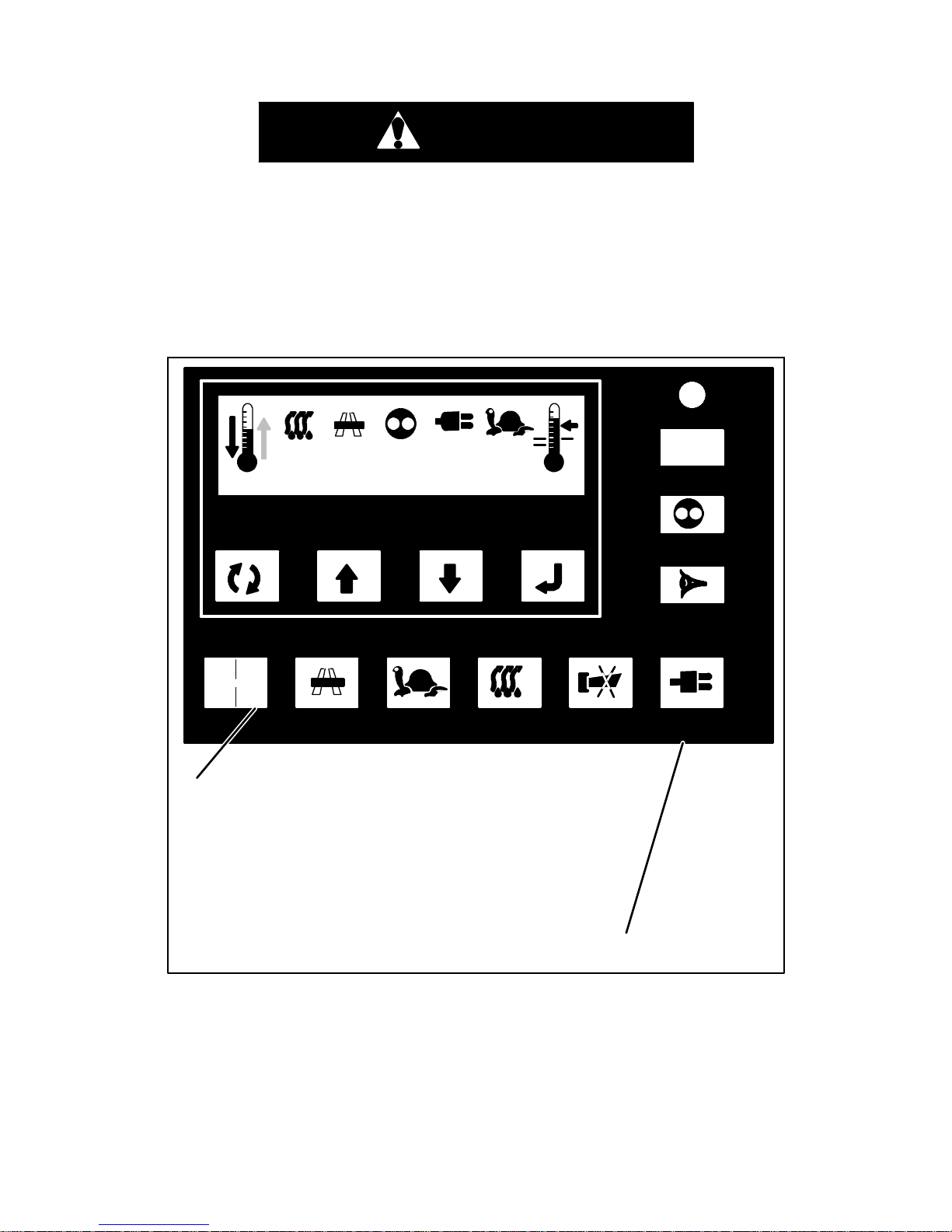

UNIT OPERATION

STARTING THE UNIT -- ROAD OPERATION

WARNING

Under no circumstances should ether or any other

starting aids be used to start engine.

BOX TEMPERATURE

AUTO START/STOP

I

UNIT DATA

PRETRIP

ALARM/FAULT

STANDBYBUZZER OFF

MAN

DEFROST

CITY

SPEED

ROAD

FUNCTION

ENTER

SETPOINT

O

i

-20 35° F

1. Place the I/O switch in the “I” position.

2. If unit was previously used in Standby

Mode, press the ROAD key.

Under normal circumstances this is all that is required to start the

unit. The unit will then perform a complete diagnostic check on the

microprocessor controller, pre-heat for the required amount of time

based on the engine temperature and start automatically.

Complete the Pre-Trip Inspection described in the previous section.

7

STARTING THE UNIT -- STANDBY OPERATION

WARNING

Make sure the power plug is clean and dry before connecting to any power source.

Do not attempt to connect or remove power plug or

perform service and/or maintenance before ensuring

the unit RUN/STOP Switch is in the STOP position and

the I/O switch is in the “O” position.

BOX TEMPERATURE

AUTO START/STOP

I

UNIT DATA

PRETRIP

ALARM/FAULT

STANDBYBUZZER OFF

MAN

DEFROST

CITY

SPEED

ROAD

FUNCTION

ENTER

SETPOINT

O

i

-20 35° F

2. Connect unit to appropriate power source.

(See table on page 39)

4. Press Standby key.

1. Place the unit RUN/STOP switch in the

“STOP” position and the I/O switch in the “O”

position.

3. Place the unit RUN/STOP switch in the

“RUN” position and the I/O switch in the “I”

position.

Under normal circumstances this is all that is required to run the unit

in standby power. The unit will then perform a complete diagnostic

check on the microprocessor controller and start automatically.

Complete the Pre-Trip Inspection described in the previous section.

8

STARTING THE UNIT -- MANUAL OPERATION

BOX TEMPERATURE

AUTO START/STOP

I

UNIT DATA

PRETRIP

ALARM/FAULT

STANDBYBUZZER OFF

MAN

DEFROST

CITY

SPEED

ROAD

FUNCTION

ENTER

SETPOINT

O

i

MAN OP

1. Place unit RUN/STOP switch in RUN and I/O switch in “I”

position. (Manual Operation will only function if unit is in

Continuous Mode. If AUTO START/STOP indictor is

illuminated, press AUTO START/STOP toggle key to

place unit in Continuous Mode.)

2. Press FUNCTION key until AUTO OP or MAN OP is

displayed. If MAN OP appears, unit is already in Manual

Start Mode.

3. If AUTO OP appears, first press

ENTER key,

then UP or DOWN arrow key until MAN OP

appears.

Press ENTER key to lock in Manual Mode.

4. Place manual GLOW/CRANK switch in

GLOW and hold for 5 to 15 seconds. Then

place switch in CRANK position to

crank and start.

Control Box

9

PRETRIP CHECK

BOX TEMPERATURE

AUTO START/STOP

I

UNIT DATA

PRETRIP

ALARM/FAULT

STANDBYBUZZER OFF

MAN

DEFROST

CITY

SPEED

ROAD

FUNCTION

ENTER

SETPOINT

O

i

PPPP

1. Start and run unit until box temperature is

40_±5°F(4.4_±2.8°C).

2. Press PRETRIP CHECK key.

The PRETRIP key initiates a check of all normal operating modes.

Upon initiation, the unit will cycle through all operating modes at 30

second intervals. The display will show “PPPP” at the beginning

and will show various unit data during the pre-trip cycle. The final

PRETRIP mode is Defrost. When Defrost ends, PRETRIP will be

complete.

This is not a self-diagnosing pretrip test. No specific pretrip alarms

will be generated. Pretrip must be monitored by the user to verify

that the unit operates through all cycles.

10

CHANGING SETPOINT

BOX TEMPERATURE

AUTO START/STOP

I

UNIT DATA

PRETRIP

ALARM/FAULT

STANDBYBUZZER OFF

MAN

DEFROST

CITY

SPEED

ROAD

FUNCTION

ENTER

SETPOINT

O

i

Press ENTER key when desired setpoint is

displayed to lock in new setpoint.

New setpoint will flash and then return to original

setpoint if ENTER key is not pressed within 5

seconds.

Press UP or DOWN arrow key to increase or

decrease displayed setpoint.

-20 35° F

11

Setpoints of -22°Fto+89°F (-30°Cto+32°C) may be entered via

the keypad. The controller always retains the last entered setpoint

in memory. If no setpoint is in memory (i.e. on initial startup), the

controller will lock out the run relay and flash “SP” on the left hand

display until a valid setpoint is entered. The setpoint may be

changed up or down in 1° increments by pressing and releasing

either the UP ARROW or DOWN ARROW key .

You cannot change setpoint when unit is in Pretrip or when viewing

Unit Data or Functional Parameters.

Loading...

Loading...