Page 1

Minimum Load Control Accessory

Installation Instructions

Part No. 30GX-900---048,

(60 Hz — 115-v Control)

Part No. 30GX-900---049

(50 or 60 Hz — 230-v Control)

30GXN,R080-528

30HX076-271

50/60 Hz

CONTENTS

Page

SAFETY CONSIDERATIONS

INTRODUCTION

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Step 1 — Examine Package Contents

Step 2 — Install Piping

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

• REMOVE MINIMUM LOAD PORT PLUGS

AND INSTALL FITTINGS

• INSTALL PIPING

• INSTALL BALL AND SOLENOID VALVES

• CONNECT PIPING

• 30GXN,R UNITS ONLY

Step 3 — Dehydrate and Recharge Circuit

Step 4 — Install Control Wiring

. . . . . . . . . . . . . . . . . . . 3

. . . . . . . . 3

• 30HX UNITS

• 30GXN,R UNITS

• ALL UNITS

Step 5 — Configure Unit for Minimum

Load Control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 6 —Test Minimum Load Relay

Outputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 7 — Adjust Setting of Minimum

Load Ball Valve

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equip-

ment can be hazardous due to system pressures, electrical components, and equipment location.

Only trained, qualified installers and service technicians

should install, start up, and service this equipment.

When working on air-conditioning equipment, observe pre-

cautions in the literature and on tags, stickers, and labels

attached to the equipment.

Follow all safety codes. Wear safety glasses and work

gloves. Use care in handling equipment.

IMPORTANT: When removing refrigerant, use an

approved refrigerant recovery device. Do not vent refrigerant into the atmosphere.

INTRODUCTION

The minimum load control accessory allows 30HX and

30GXN,R chillers to have their capacities decreased below the

standard fully unloaded condition. The accessory provides

more precise control of leaving fluid temperature during light

load conditions.

The 30GXN,R and 30HX chillers have a dual-circuit

design. Each minimum load control accessory package contains the items required for both circuits. Because of a n automatic lead/lag feature on the chillers, the accessory should be

installed on both circuits.

INSTALLATION

Step 1 — Examine Package Contents —

age includes solenoid valves, ball valves, O-ring seal fittings,

and instructions. Examine each item. If any part is damaged or

missing, file a claim immediately with the shipper and notify

your Carrier representative. See Table 1 for accessory package

contents and field-supplied material.

Table 1 — Accessory Package Contents

and Field-Supplied Material

ACCESSORY PACKAGE

COMPONENTS

Solenoid Valve (2) EF23JX212 (2) EF23JX231

Ball Valve (2) EP71BA201 (2) EP71BA201

O-Ring Seal Fitting (4) 30GX503492 (4) 30GX503492

Tu be A s s e m b l y (2) 30GX503487 (2) 30GX503457

Tube Assembly (Condenser

Oil Separator)

FIELD SUPPLIED MATERIAL — REQUIRED PARTS

5

/8-in. OD Copper Tubing, Wiring, Conduit,

Thread Sealant, Electrical Supplies

(Ordered Separately)

ACCESSORY PART NUMBER

30GX-900---048 30GX-900---049

(2) 30HX402343 (2) 30HX402343

Pack-

Field Supplied

Be sure power to equipment is shut off before performing

maintenance or service.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

PC 903 Catalog No. 533-00009 Printed in U.S.A. Form 30GX,HX-14SI Pg 1 102 7-00 Replaces: 30GX,HX-7SI

Page 2

Step 2 — Install Piping

Shut off all power to the unit, then lock out and safety-tag

all disconnects before proceeding with installation.

Remove refrigerant charge from circuits using an approved refrigerant recovery device before proceedi ng with

installatio n.

NOTE: The units have 2 circuits. Perform all of the followi ng

piping installation procedures on both A and B circuits.

REMOVE MINIMUM LOAD PORT PLUGS AND INSTALL FITTINGS — Plugs must be removed from these

ports and replaced with O-ring seal fittings. Note that plugs

were factory-installed with Loctitet 554 or equivalent

refrigerant-compatible sealant. Fittings should be installed with

similar sealant on threads.

30GXN,R

nipple on discharge line, located between oil separator and condenser. Remove plug from minimum load port on cooler shell.

See Fig. 1. Using thread sealant, install O-ring seal fitting in

minimum load port on cooler. Port on nipple in discharge line

is reserved for a brazed connection.

30HX

er shell and the condenser shell (30HXC) or oil separator

(30HXA). See Fig. 2. Using thread sealant, i nstall O-ring seal

fittings in minimum load ports.

— Cut plug end off of minimum load port braze

— Remove plugs from minimum load ports on the cool-

INSTALL PIPING — On 30GXN,R units, carefully thread the

cooler tube assemblies (P/N 30GX503487) on the O-ring seal

fittings installed in the cooler port. Do not tighten. Install fieldsupplied

5

/8-in. OD copper tubing between the tube assembly

and the brazed nipple on the discharge line.

On 30HX units, carefully thread the cooler tube assemblies

(P/N 30GX503487) and the condenser oil separator tube assembly (P/N 30HX402343) on the O-ring seal fittings installed

in the cooler and condenser/oil separator ports. Do not tighten.

Install field-supplied

5

/8-in. OD copper tubing between the

tube assemblies on the cooler shell and condenser (30HXC) or

oil separator (30HXA).

INSTALL BALL AND SOLENOID VALVES — Using good

piping practice, braze ball valve and sole noid valve into

5

/8-in.

minimum load piping. Fig. 2 shows a typical 30HX installation

and Fig. 3A and 3B show a typical 30GXN,R installation, including valve locations and orientation. Ensure that ball valve

is fully open, and that both the ball and solenoid valve are protected from excess heat during brazing process. Wrap wet

cloths around valve bodies and tube assembly locking nuts

during brazing to prevent damage to the valves and O-rings

from heat.

CONNECT PIPING — Lubricate O-rings with a light coating

of polyalphaolefin lubricant suitable for R-134a systems.

Thread tube assembly nuts onto the O-ring seal fittings until

they are finger-tight. Lightly snug the nut with a wrench;

DO NOT OVER TIGHTEN. Y ou s hould be able to feel the Oring compress on the last

1

/4-turn.

IMPORTANT: DO NOT over tighten the O-ring seal

nut. Damage will occ ur to t he se al, r esult ing in le aks.

→

102

Fig. 1 — Installing Fittings, 30GXN,R (Typical Size 080-150, 160 Shown)

2

Page 3

Fig. 2 — Installing Fittings and Valves, 30HX (Typical)

30GXN,R UNITS ONLY — Using good brazing practice,

braze the

5

/8-in. minimum load tubing to the copper nipple on

the discharge line (minimum load port) between the condenser

coil and oil separator. See Fig. 1, 3A and 3B.

Step 3 — Dehydrate and Recharge Circuit —

When piping has been completed, leak test the assembly. If

one of the O-ring seal fittings leaks, slowly tighten the O-ring

nut until the leak stops. If this does not fix the leak, the connection must be reinstalled using a new O-ring in the fitting. Contact your Carrier representative for assistance in locating these

parts.

After leak testing, evacuate, dehydrate, and recharge the circuit using an approved refrigerant recovery device. Correct

type and amount of refrigerant are listed on unit nameplate and

in base unit documentation.

Step 4 — Install Control Wiring

Be sure all power to the unit is off before proceeding. Lock

out and safety-tag all disconnects.

Wires between field-installed components and unit control

box must be enclosed in field-supplied conduit. Follow all local

codes and NEC (National Electrical Code, U.S.A.). Wire size

must be no. 16 AWG (American Wire Gage) (1.5 mm

2

) mini-

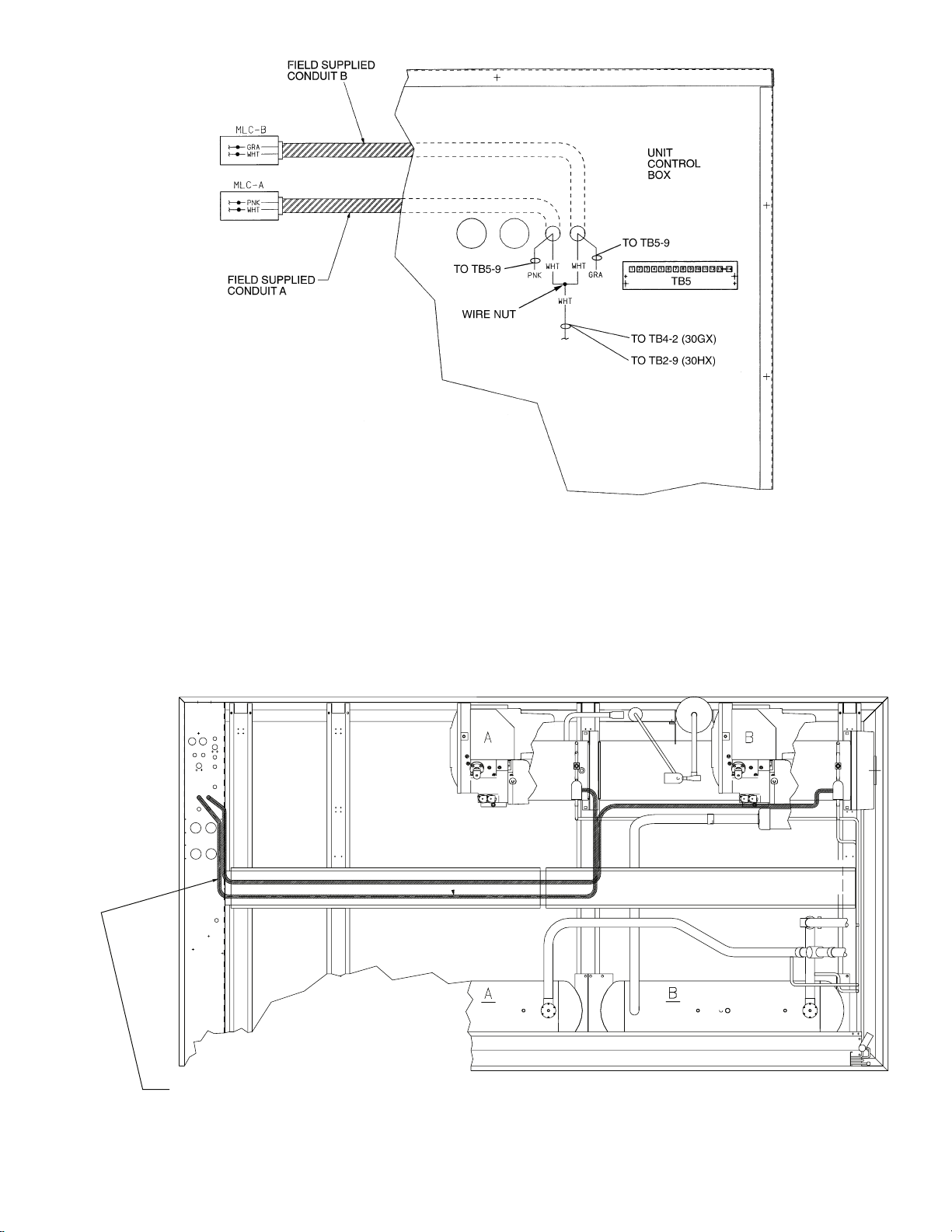

mum. See Fig. 4 and 5 for field wiring.

30HX UNITS — Remove the screws holding the right-side

access panel to the unit control box. Open the right-side access

panel.

Route wires through field-supplied conduit and attach the

conduit to the unit control box, using a suitable conduit fitting

and one of the available

7

/8-in. knockout openings. Attach the

other end of the conduit to the solenoid valve, using a suitabl e

fitting. Repeat for the other circuit. See Fig. 4.

30GXN,R UNITS —Route the field-supplied water proof conduit from the solenoid valves to the control box at the e nd of

the unit. See Fig. 4 and 5.

ALL UNITS — Using good wiring practice, connec t a white

wire from the solenoid valve on circuit A to a white wire from

the solenoid valve on circuit B. Connect both wires to TB2-9

(30HX) or TB4-2 (30GX).

Connect a pink wire to the solenoid valve on circuit A.

Connect a gray wire to the solenoid valve on circuit B. Con-

nect both the pink and gray wires to TB5-9 for all units.

Figure 4 shows the correct location of the wiring connection

points on the chiller.

3

Page 4

MINIMUM LOAD

CONTROL PORTS

CIRCUIT A (080-138)

CIRCUIT B (150, 160)

CIRCUIT B (080-138)

CIRCUIT A (150, 160)

SOLENOID VALVE (TYP)

BALL VALVE (TYP)

O-RING SEAL FITTING

AND ADAPTER (TYP)

→

O-RING SEAL

FITTING

BALL

VALV E

DETAIL C

Fig. 3A — Typical Piping and Valve Installation 30GXN,R080-178

and Associated Modular Sizes (080-150, 160 Shown)

SEE DETAIL C

SOLENOID

VALV E

FIELD INSTALLED

PIPING TO

CIRCUIT B DISCHARGE

LINE

MINIMUM LOAD PORT

CIRCUIT B

→

102

MINIMUM LOAD PORT

CIRCUIT A

FIELD INSTALLED PIPING

TO CIRCUIT A DISCHARGE LINE

Fig. 3B — Typical Piping and Valve Installation 30GXN,R204-350

and Associated Modular Sizes (204-268 Shown)

4

Page 5

30GXN,R080-178*

C —

CB —

CCP —

CLHR —

EMM —

EQUIP —

EXV —

FB —

FR —

GFI-CO —

MLC-B

CONDUIT

Contactor Compressor

Circuit Breaker

Comfort

Link™ Compressor

Protection

Cooler Heater Relay

Energy Management Module

Equipment

Electronic Expansion Valve

Fuse Block

Fan Relay

Ground Fault Interrupter Convenience Outlet

30HX076-186

LEGEND

GND —

LR —

MLC —

OPC —

PL —

PRI —

SCB —

SN —

MLC-A

CONDUIT

Ground

Loader Relay

Minimum Load Control

Oil Pump Contactor

Plug Assembly

Primary

Screw Compressor

Board

Sensor (Toroid)

SPT —

TB —

TRAN —

Suction Pressure

Transducer

Terminal Block

Transformer

Terminal Block Connection

Unmarked Splice

Factory Wiring

→

*And associated modular sizes.

Fig. 4 — Typical Minimum Load Control Wiring

5

102

Page 6

MLC-B

CONDUIT

MLC-A

CONDUIT

30HX206-271

*And associated modular sizes.

→

102

30GXN,R204-350*

Fig. 4 — Typical Minimum Load Control Wiring (cont)

6

Page 7

Fig. 4 — Typical Minimum Load Control Wiring (cont)

ROUTE CONDUITS THROUGH TRAY

AND ATTACH TO BOTTOM OF SHELF

ON TB-4 SIDE OF CONTROL BOX

Fig. 5 — Routing Field-Supplied Wiring and Conduit (30GXN,R Shown)

7

Page 8

Step 5 — Configure Unit for Minimum Load

Control —

tion are complete, the chiller must be configured for minimum

load control operation. This may be done using the Navigator.

Set the Enable/Off/Remote/Contact switch in the OFF position.

1. Press key until display reads ‘S ELECT A MENU

ITEM.’ Press key to light up Configuration mode.

Press . Press key to select sub-mode ‘OPT1’.

Press .

2. Press the down arrow key to select MLVS NO.

3. To enable the minimum load valve feature, press the

ENTER

4. The display may read as follows. (If not, skip to Step 7.)

ENTER P ASSWORD

5. Press 1 1 1 1 then key .

6. The Navigator again displays the following:

ML VS NO

7. Press key and key. The Navigator displays:

ML VS YES

The chiller is now configured for minimum load valve

control.

Once the piping installation and wiring installa-

ESCAPE

ENTER

ENTER

key.

ENTER

ENTER

Step 6 — Test Minimum Load Relay Outputs —

unit is recharged and reconfigured, test the operation of the relay and solenoid valve using the Service Test software function. T est both circuits as follows:

1. Press the key until the Navigator displays ‘SE-

2. The display may read as follows. (If not, skip to Step 4.)

3. Press 1 1 1 1 then key.

4. Press the down arrow key to select the ‘COMP’ sub-

5. Press the key.

After the accessory components are installed and the

ESCAPE

LECT A MENU ITEM.’ Press the key and light up

the Service Test mode. Press the key. Press the

ENTER ENTER

key and ‘TEST OFF’ will be displayed with ‘OFF’ flashing. Press the key then key and the Navigator

ENTER

displays ‘TEST ON.’ Switch the Enable/Off/Remote

contact switc h to the Enab le posit ion.

ENTER PASSWORD

ENTER

mode. Press the key and key to display MLV

ENTER

OFF.

ENTER

6. Press the and key to energize the relays. The

ENTER

display reads:

ML V ON

An audible click will be heard. Verify that the solenoid

valves for both circuits are energized.

7. Press the , and keys to turn the solenoids

ENTER ENTER

off. When finished, exit the Service Test mode (change

‘TEST ON’ to ‘TEST OFF’). Put the Enable/Off/Remote

Contact switch in the desired position.

After testing is compl ete, rechec k all e lectrical connections

for proper location and tightness. Replace and secure the access

panels for the unit control box.

Step 7 — Adjust Setting of Minimum Load Ball

Valve —

load ball valve mu st be adjusted to suit the ap plication. Calibrate one circuit at a time as follows:

1. Adjust the ball valve so that it is approximately half open.

2. Operate the chiller in Service Test mode, with one circuit

NOTE: Operation of the chiller in Manual Control mode is

described in the Controls, Start-Up, Operation, and Troubleshooting Guide that is included with the 30GXN,GXR,HX

ComfortLink™ chillers.

3. Record the cooler ∆T (the difference between cooler en-

4. Use the Service Test feature to enable the mini mum load

5. Observe and record the cooler ∆T with the minimum load

6. Adjust the minimum load ball valve until the cooler tem-

7. Open the ball valve to decrease the temperature differ-

Once the outputs have been tested and the ball valve adjusted, the ins tall ati on is co mple te.

Before the installation is complete, the minimum

operating, and all compressor loaders deenergized.

tering fluid temperature and cooler leaving fluid temperature) at this fully unloaded condition.

valve output.

valve energized.

perature difference reading from Step 5 is equal to half of

the temperature difference reading from Step 3.

ence or close the ball va lve to increase the temperature

difference (∆T). When the valve is adjusted correctly, the

difference between cooler entering and leaving fluid temperatures when the minimum load control is energized

must be at least half of the temperature difference when

the minimum load control is deenergized. For example, if

the difference between the cooler entering and leaving

water temperature is 3° F with the valve deenergized,

then the difference between cool er entering and leaving

water temperature must be at least 1.5° F with the val ve

energized.

Copyright 2000 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

PC 903 Catalog No. 533-00009 Printed in U.S.A. Form 30GX,HX-14SI Pg 8 102 7-00 Replaces: 30GX,HX-7SI

Loading...

Loading...