Carrier P5 42XPL036H3P, P5 42XPL030C3P, P5 42XPL030H3P, P5 42XPL036C3P, P5 38XPL030H3 User Manual

...Page 1

- 42XPL030C3P/38XPL030C3

- 42XPL030H3P/38XPL030H3

- 42XPL036C3P/38XPL036C3

- 42XPL036H3P/38XPL036H3

Page 2

Thank you for selecting Carrier!

You can be justifiably proud of your purchase because the same pride

in craftsmanship and engineering know-how that goes into Carrier equipment for cooling the Astrodome sports complex in Texas, the United

States Capitol’s Halls of Congress and countless other installations worldwide have been built into your unit.

One of the pleasant benefits awaiting you with room air conditioning is

that in addition to being cooled, the room air is filtered and dehumidified.

This manual is designed to help you be familiar with the many comforts

and technological features your unit offers.

Moreover, it contains vital information about maintenance, service and

economical operation. Take the next few minutes to discover for yourself

how to get the most in personal comfort and economical operation from

your new Carrier room air conditioner.

Page 3

CONTENTS

PRECAUTIONS 2

OWNER’S MANUAL

BEFORE OPERATION 5

UNIT OPERATION 9

GENERAL OPERATION

AUTOMATIC OPERATION(For Heat Pump Model)

TIMER OPERATION

COMBINATION OF ON, OFF AND DAILY TIMER

SLEEP TIMER

DISCHARGE AIR LOUVER CONTROL

AIR CLEANING OPERATION

CARE AND MAINTENANCE 17

POINTS TO NOTE

CLEANING THE FILTERS AND FRONT PANEL

CLEANING THE MAIN UNIT

AFTER-SEASON CARE

INSTALLATION MANUAL

STANDARD INSTALLATION ACCESSORIES 20

CHOOSING THE UNIT LOCATION 21

INDOOR UNIT

OUTDOOR UNIT

INSTALLATION TIPS 22

INDOOR UNIT INSTALLATION 23

INSTALLING THE WALL HANG BRACKET

MAKING THE WALL PENETRATION FOR THE INTERCONNECTING PIPING

INDOOR UNIT WIRING

FORMING THE DRAIN HOSE AND REFRIGERANT PIPING

INSTALLING THE INDOOR UNIT BODY TO THE WALL HANG BRACKET

CONNECTING THE PIPING 28

CONNECTING PIPE TO THE INDOOR UNIT

CONNECTING THE INTERCONNECTING PIPE TO THE OUTDOOR UNIT VALVE

AIR PURGE 29

USING THE VACUUM PUMP

GAS LEAK CHECK 30

FINISHING 30

OUTDOOR UNIT WIRING 31

ELECTRICAL CONNECTION 32

CONNECTING THE POWER SUPPLY 32

TEST RUNNING 33

HIGH PRESSURE CONTROL 33

CONFIGURATION 34

PUMP DOWN 35

TROUBLESHOOTING 36

Page 4

PRECAUTIONS

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning equipment can be hazardous due to

system pressure and electric components. Only trained and qualified service personnel should install, repair or service air conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils

and filters, and replacing filters. And untrained personnel don’t include children

and persons who with reduced physical sensory or mental capabilities, or lack

of experience and knowledge. They should have been given supervision or

instruction concerning use of the appliance by person responsible for their safety.

All other operations should be performed by trained service personnel. When

working on air conditioning equipment, observe precautions in the literature, tags

and labels attached to the unit and other safety precautions that may apply.

all safety codes. Wear glasses and work gloves. Use a quenching cloth for

Follow

brazing and detaching brazed connections. Have a fire extinguisher available for

all brazing operations.

WARNING

• Do not install by connecting them to other indoor or outdoor units without

consulting a Carrier or other competent air conditioning engineers.

Mismatching of the units and incompatibility between control devices in

the two units could lead to damage of both unit and voiding of the Carrier

warranty.

Carrier declines any responsibility, and warranty shall be void if these

installation instructions are not observed or if change are made to the

electrical connections.Contact your Carrier distributor if you need futher

help.

• Before performing service or main

off the main power switches and breaker of the unit. Electric shock may

cause personal injury. “If the supply cord is damaged. It must be replaced

with a same size BS approved cord or contact Carrier distributor to

arrange for replacement.”

tenance operations on the system, turn

CAUTION

TO DISCONNECT THE APPLIANCE FROM THE MAIN SUPPLY.

This appliance must be connected to the main by means of a circuit

breaker or a switch with a contact separation of at least 3 min.

Check that all current national safety code requirements have been followed for the installaltion. In particular ensure that a properly sized and

connected ground wire is in place.

WARNING

Do not switch off the split system by disconnecting the electric power

supply. The unit must always be switched off using the remote control.

WARNING

Check that the impedance of the mains power supply is inconformance

with the unit power input indicated in the electric data table, on page 32.

CAUTION

The mains supply must be connected to the outdoor unit.

2

2

Page 5

PRECAUTIONS

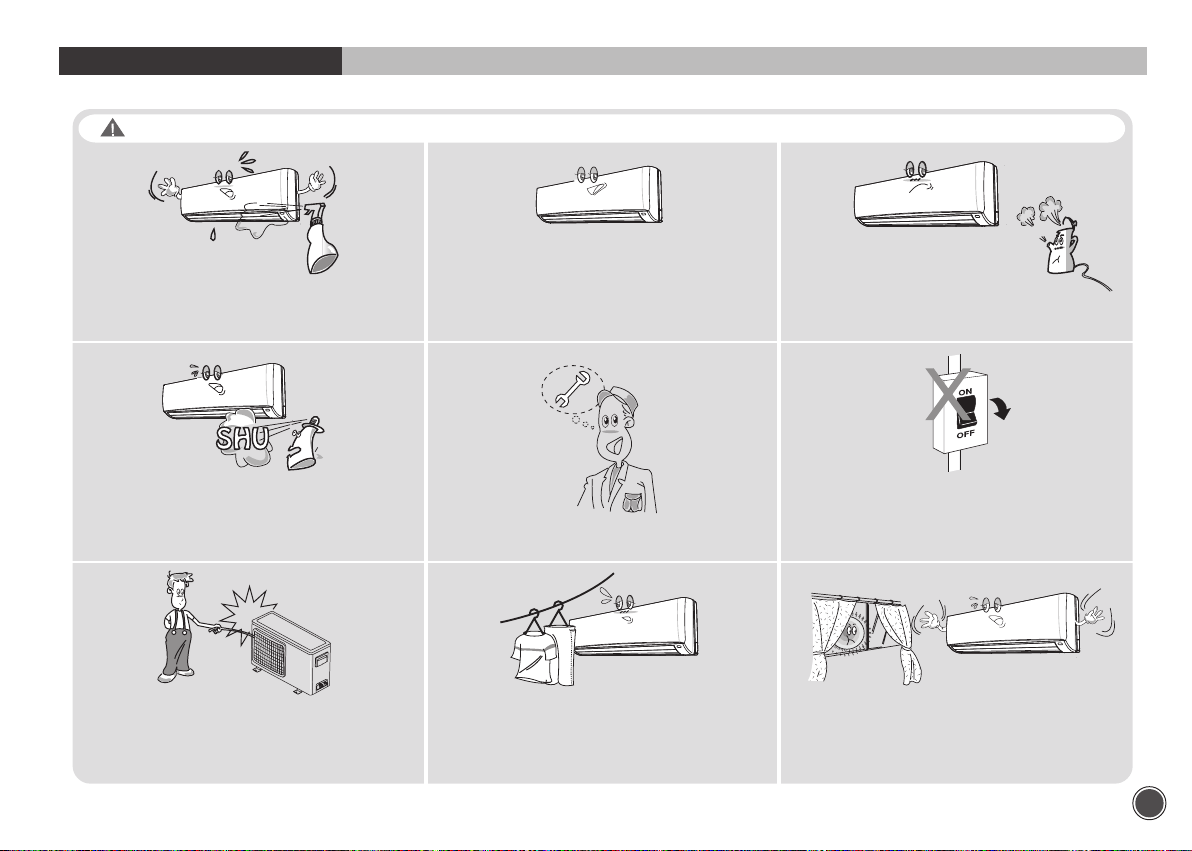

WARNING

To avoid the risk of serious electric shock,

never splash the indoor and the outdoor

unit with water.

Do not use flammable sprays near the unit.

The unit can be damaged by gasoline,

benzene, thinner,

insecticide and other chemical agents.

Do not put hands or objects into

the discharge grille of outdoor unit.

This unit has a fan running at high speed.

It is very dangerous to touch the fan.

Use the correct voltage.

Using voltage other than specified will

damage the unit.

Use only fuses of the proper amperage.

Do not obstruct the front of the discharge

grille of both units.

This will block air flow, reduce the cooling

effect and may result in unit malfunction.

Keep heat sources away from the unit,

high temperature can cause damage.

Do not use circuit breaker as a means

of turning off the unit.

The unit must always be switched off

using remote control.

In summer, if possible, prevent direct

sunlight from entering the room;

draw curtains or blinds.

3

Page 6

PRECAUTIONS

Standard Safety Instructions for Air-Conditioning Units

The air conditioner is not intended for use by young

children or special needs persons without supervision

by a person that is responsible for their safety.

Wiring connections must be secured tightly and the

cable should be routed properly to avoid the risk

Do not place the power cord near the heater

Do not touch the unit with a wet hand , there is a risk of

Electric Shock

Two or more people should lift and transport the product

and use proper Safety precautions while lifting the

product to avoid personal injury.

Young children should be supervised to ensure that they

do not play with the air conditioner.

Don’t use a damaged power cord , or loose socket as it

may cause fire or electrical shock

Install the panel and cover the control box securely

Do not place anything on the power cable , there is a

risk of fire and Electric shock

Always check for gas leakage after installation or repair

of product

4

Page 7

BEFORE OPERATION

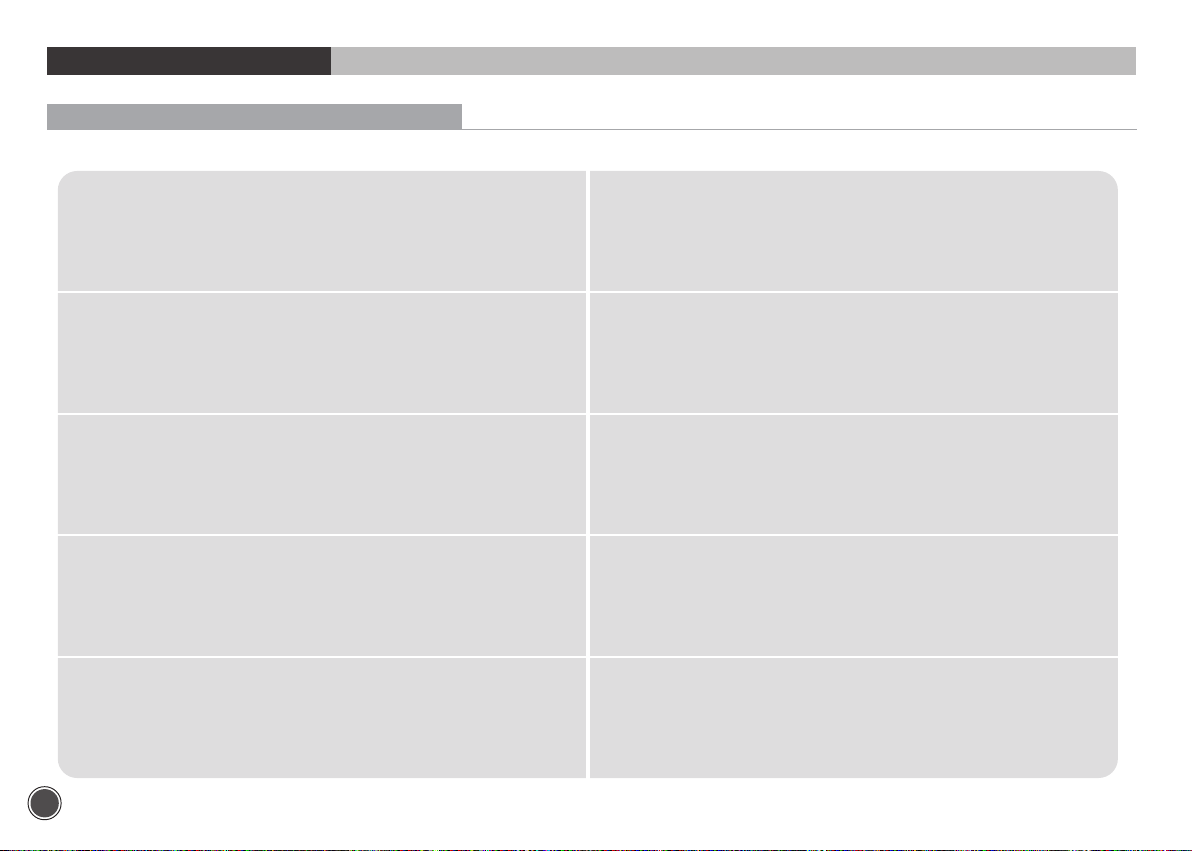

Indoor Unit Display

Ioniser(Left) light : illuminated during Ioniser activated.

Timer(Middle) light : illuminated during timer mode.

Power(Right) light : illuminated during operation.

EMER. button

Test Operation

This operation is used for checking after unit installation.

• Press the EMER. button continuously during 5~10sec. And then unit will be

operated as test mode.

• Press the EMER. button once more after checking to activate the remote

control. If there is any input signal ( remote control signal or EMER. button

press ) during test operation, the TEST mode will change to the input

signal mode.

• The setting conditions of the test operation are as follows:

- Operation mode : COOL - Fan speed : HIGH

- Timer mode : Disable - Discharge air direction : SWING

Emergency Operation

When the remote control is lost, damaged or the battery is discharged, the EMER. button can be used to run the unit.

• Press the EMER. button once briefly at the off mode condition shorter than for 5 sec.

- According to the room temperature, the unit operates the Cool mode in cool only model and the Auto mode

in Heat pump model.

• If you want to stop the emergency operation, push the EMER. button again or operate the remote control.

• The setting conditions of emergency operation are as follows:

Model Operation Preset mode Fan speed

Cooling

only

Heat

Pump

COOL 24°C AUTO Disable Horizontal

AUTO 25°C AUTO Disable

Timer mode

temperature

Discharge air direction

Preset location according

to ‘Cool’ or ‘Heat’ mode

EMER.

• EMER. button :

Can be used when the remote

control is lost or inoperative.

button

5

Page 8

BEFORE OPERATION

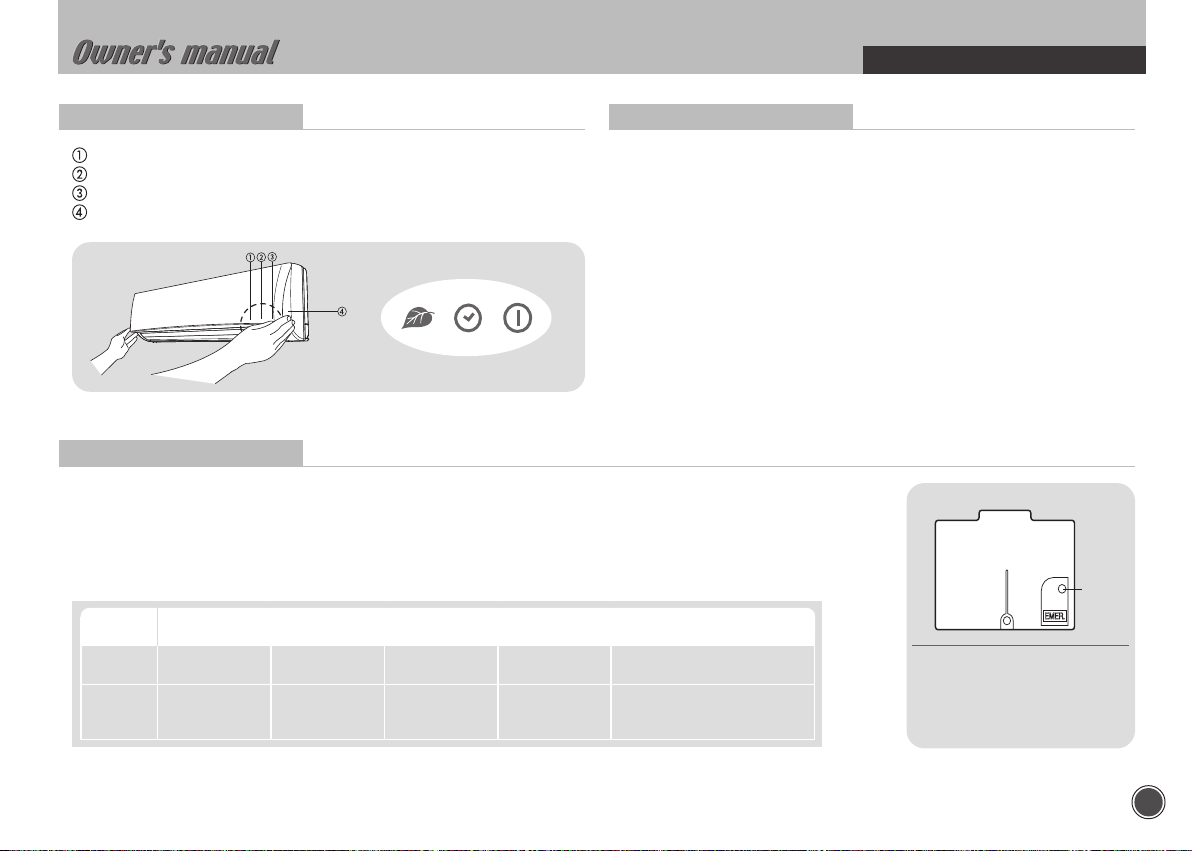

Replacing Batteries

Remove the cover of the battery compartment at the back

1

of the remote control by sliding it out in the direction of the arrow.

Remove the used batteries and insert new batteries. The remote

2

control uses two batteries.(1.5V(L)R03x2)

3

Press reset button with a sharp object if the remote control is not

operating properly or after replacing the batteries.

Setting Current Time and Reset

4

With the remote control On or OFF,

5 seconds

5

The current hour figure flashes.Press either button or to

set the current hour. Press button

set them.

For this setting always use either button or .

6

7

Once the current time is set, press button

press button for more than

to move to minutes and

to confirm it.

NOTE

• Changing batteries should be done after turning off the unit.

6

Page 9

BEFORE OPERATION

Matching Address between Indoor Unit and Remote Control

When two units are used in the same room, you can match the address of

the remote control to that of the unit.

Indoor Unit

Refer the page 35.

Remote control

Refer the page 34.

NOTE

• This function must only be performed by qualified service personnel.

Signal Receiving

Use the remote control where its signals can reach the receiver of the air

conditioner. (A distance of 5m is allowed)

• You can hear a beep from the unit which indicates that the signal is received.

CAUTION

• The air conditioner will not operate if curtained, doors or other

materials block the signals from the remote control to the unit.

• If the infrared signal receiver on the unit is exposed to direct sunlight, the air

conditioner may not work properly. Draw the curtains to avoid direct sunlight.

• A mounting bracket for the remote control is supplied with the unit.

Install the mounting bracket on the wall where the remote signal

can be easily received from the remote.

5m maximum

• If the room using the air conditioner has florescent lighting with

electronic starter, signals may not be properly received. If you are

planning to use such fluorescent lamps, consult your local dealer.

7

Page 10

BEFORE OPERATION

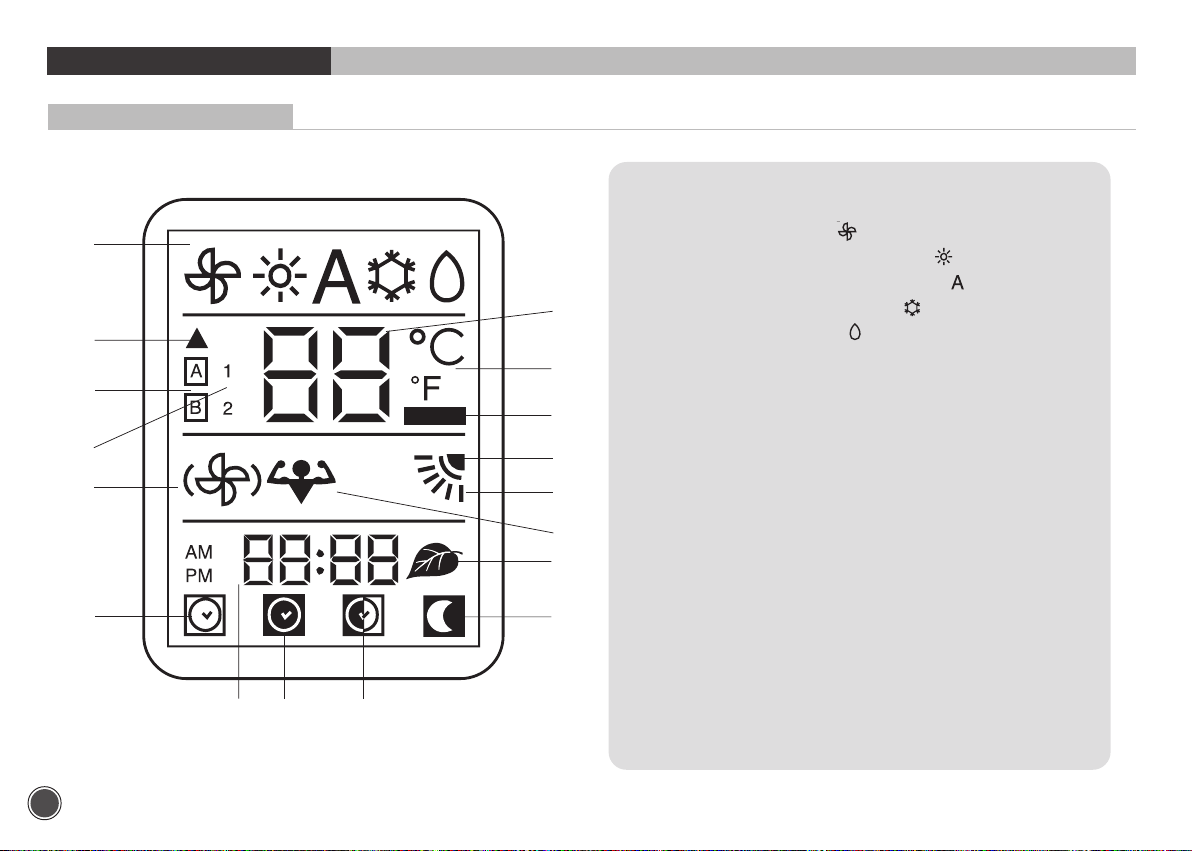

Remote Control Display

1

2

4

6

10

12

15 16 14

3

5

7

8

9

11

17

13

1. Operating mode (from left to right):

• Ventilation (fan only)

• Heating (heat pump models only)

• Automatic (heat pump models only)

• Cooling and dehumidification

• Dehumidification only

2. Signal transmission symbol

3. Temperature selected

4. Address selector

5. Temperature unit of measurement (°C or °F)

6. Unit configuration

7. Batteries exhausted indicator

8. Vertical louver swing indicator

9. Louvre positioning (Flap)

10. Fan speed

11. Turbo mode

12. ON timer selected

13. Night timer active

14. DAILY timer active (Everyday)

15. ON timer, OFF timer and current time

16. OFF timer selected

17. Ioniser active

8

Page 11

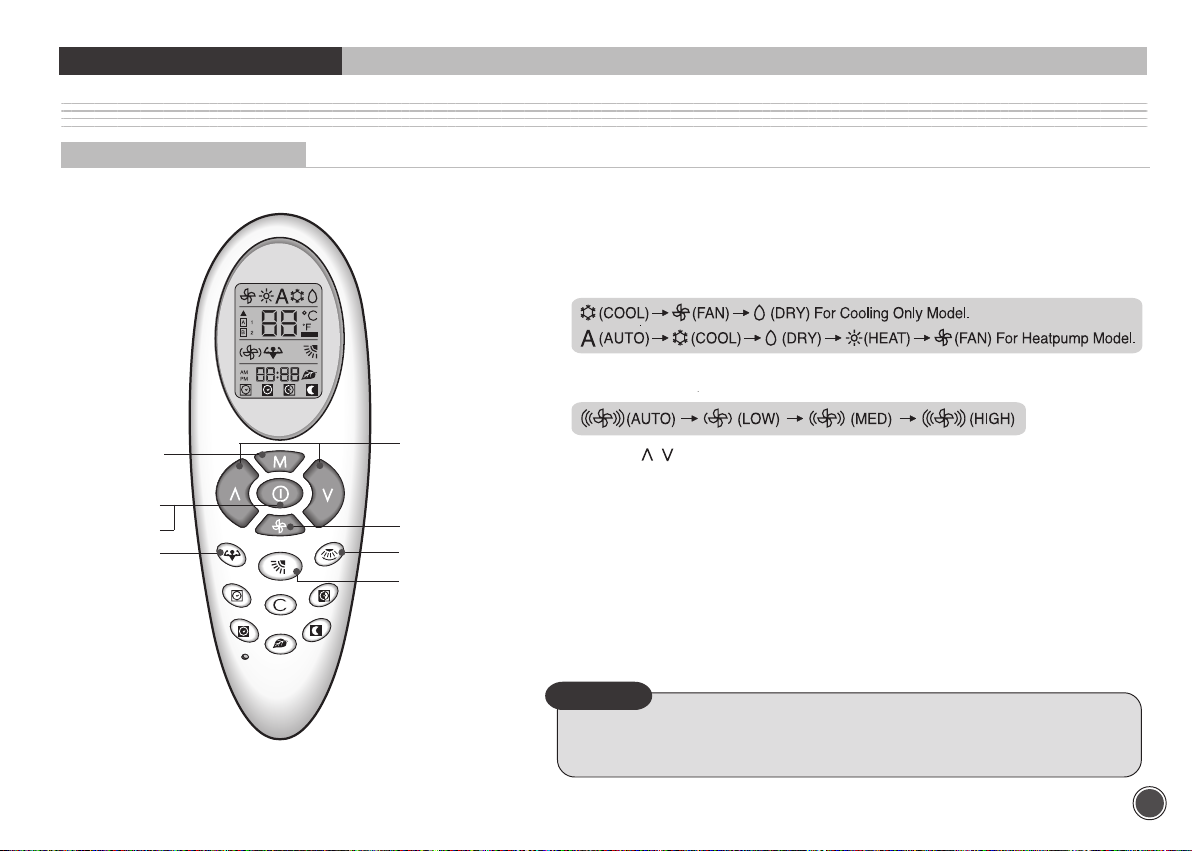

UNIT OPERATION

GENERAL OPERATION

PROCEDURE

ON/OFF button .........................................................................................................................

1

Press this button and the COOL (AUTO for Heat Pump Model) operation is indicated.

• A receiving beep is heard.

• The green UNIT ON lamp of the indoor unit display illuminates.

MODE button.............................................................................................................................

2

Press this button to select the desired operation.

3

FAN SPEED button..................................................................................................................

Press this button to select the desired fan speed.

2

4

1

7

8

3

6

5

TEMP.( ) button ...............................................................................................................

4

Press these buttons to set the desired temperature.

5

HORIZONTAL LOUVER button.......................................................................................

Press this button to control the desired air flow direction up and down.

VERTICAL LOUVER button ..............................................................................................

6

Press this button to control the desired air flow direction to the left and right side.

7

ON/OFF button

Press this button to stop the unit operation.

• A receiving beep is heard.

• The UNIT ON lamp is extinguished.

8

TURBO MODE button .........................................................................................................

Press this button to quickly cool down the indoor temperature.

NOTE

• Dry operation eliminates moisture economically by operating the compressor,

indoor and outdoor fan motor intermittently, so that the room temperature

is maintained at the set temperature.

.........................................................................................................................

9

Page 12

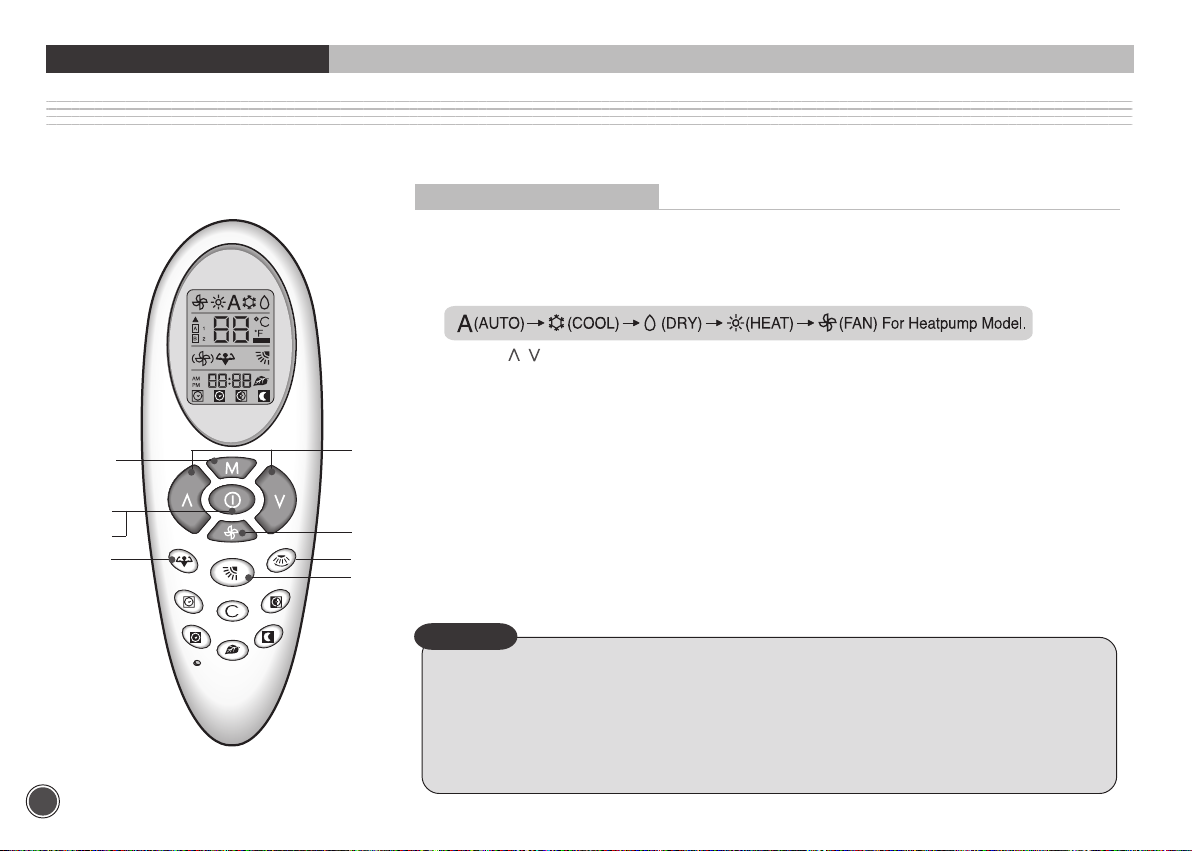

UNIT OPERATION

AUTOMATIC OPERATION (For Heat Pump Model)

Automatic operation means that the air conditioner operates automatically by selecting the COOL or HEAT mode and automatically changes the fan speed

according to the indoor condition to keep the room temperature comfortable.

PROCEDURE

ON/OFF button .......................................................................................................................................................

1

Press this button and the unit starts AUTO operation.

MODE button...........................................................................................................................................................

2

If the unit is operating in another mode, press the MODE botton to select Auto.

3

TEMP.( ) button .............................................................................................................................................

Set the desired temperature using the remote control buttons. At the start of the AUTO operation,

the temperature is set at 25°c and it is functional with in the total temperature range.

HORIZONTAL LOUVER button.....................................................................................................................

4

Press this button to control the desired air flow direction up and down.

5

VERTICAL LOUVER button ............................................................................................................................

Press this button to control the desired air flow direction to the left and right side.

FAN button ...............................................................................................................................................................

6

Set the desired fan speed. At start up, fan speed is set to AUTO.

7

ON/OFF button .......................................................................................................................................................

Press this button again to stop operation.

8

TURBO MODE button ......................................................................................................................................

Press this button to quickly cool down and heat up indoor temperature.

NOTE

• When the room temperature is between 21°c ~ 29°c.

- If the room temperature is lower 1°c or more than the set temperature : HEAT mode will be operated.

- If the room temperature is higher1°c or more than the set temperature : COOL mode will be operated.

• When the room temperature is lower than 21°c or higher than 29°c, the operation mode is restricted

regardless of the set temperature.

- If the room temperature is lower than 21°c then only the heating mode is allowed.

- If the room temperature is higher than 29°c then only the cooling mode is allowed.

• The Auto operation is not suitable for the application to the computer room or some food/wine stock storage.

10

2

3

1

7

8

6

5

4

Page 13

UNIT OPERATION

TIMER OPERATION

ON timer procedure

ON TIMER button ..........................................................

1

Press this button, even if the remote control is OFF.

The relevant icon and time figure will start to flash.

If 10 seconds have elapsed and no button is pressed,

the remote control turns OFF (if it was already OFF

when button

matically deactivates.

HOUR, MINUTE buttons(buttons and ) ............

2

If the unit is ON, the only possible selection is the

start-up time.

The unit will operate with the selections shown on the

display.

HOUR, MINUTE button(buttons and ) ..............

3

If the unit is OFF: to select the start-up time,

use the temperature control buttons

(buttons

have confirmed these by pressing button

the minutes using either button

To definitively set the time, press button

Operating mode ...............................................................

4

Choose the unit operating mode The icons will flash.

To select the mode, use the button

Once the mode has been decided, press button

The icon of the selected mode will stop flashing.

was pressed) or timer function auto-

and ). First select the hours and, after

or .

again.

.

, select

5

Desired temperature ...........................................................................................................

To select the desired temperature, the value is flashing, use either

button

Push button

6

Fan speed ..................................................................................................................................

Choose the fan speed, using button

been completed, press button

stop flashing

7

Louver positioning ...............................................................................................................

Now this icon is flashing. Use button

Press button

If you want to cancel selections up to here inserted, push button

if you want to cancel all options once timer has been set, push button

.

or .

and then .

, to confirm the selection. Numbers will stop flashing.

. When the selection has

for confirmation. The icon will

and

, to select desired position.

for confirmation. Now all icons are fixed on display.

;

11

Page 14

UNIT OPERATION

About the ON Timer

• When the ON Timer function is operating,the unit senses the room air temperature right before the start-up time.

• If you want to warm or cool the room at desired time, set the timer 30 minutes eariler than start time.

OFF timer procedure

OFF TIMER button ..........................................................................................................................................................................................

1

Press button . The OFF timer icon and numbers for time selection are flashing.This function can be set even

if the remote control is OFF.

12

HOUR/MINUTE selection button (buttons

2

To set the clock time, press either button or

To move from hour to minute, press button

NOTE

• If you reserve the ON Timer during operation, the unit will be operated continuously.

and ) .........................................................................................................................................

or .

. Press button again to confirm.

Page 15

UNIT OPERATION

Combination of ON, OFF and DAILY Timer

Procedure

DAILY timer ........................................................................................................

Push the button when the ON or OFF timer is active. The icon will appear on

display. In this way the ON and OFF timer memorization will be repeated every

day. To disactivate the daily function, press again the button

.

Combination of ON, OFF and DAILY timer procedure ...........................

If you want operation to start at 5.30 p.m. and stop at 10.30 p.m.,

proceed as follows:

1

Select ON timer at 5:30 p.m.

2

Select OFF timer at 10:30 p.m.

3

Select the desired operating mode (button

PM

PM

If you want to stop operation at 10:30 P.M. and start again at 7:30 A.M. with the

same operating mode, proceed as follows:

1

Select OFF timer at 10:30 p.m. during operation

2

Select ON timer at 7:30 A.m.

PM

AM

M

).

If you want Everyday operation to start at 5.30 p.m. and stop at 10.30 p.m., proceed

as follows:

Select ON timer at 5:30 p.m.

1

2

Select OFF timer at 10:30 p.m.

3

Press the everyday button (daily button

PM

PM

).

PM

Cancellation of ON, OFF and DAILY timer procedure ...............................................

If you want to cancel On or OFF timer setting, press the

following buttons in sequence:

1

A

B

2

PM

• button

• button .

To deactivate the Everyday function, press button

The Everyday function will remain operative until one

or

.

of the two timers (ON or OFF) is active.

NOTE

• In the ON and OFF Timer operation, the earlier setting compared to the current time will be

applied first.

• The DAILY Timer can be selected in case of a combination of the ON and OFF Timer

reservation. Daily timer is not available for sleep timer mode.

• You can change the ON/OFF reservation time during the DAILY Timer reservation.

• When the electricity fails while DAILY Timer is reserved, DAILY Timer

reservation will be canceled.

Reserve the DAILY Timer again after the electrici

• The TIMER lamp of the indoor unit will be on if either the ON Timer or the OFF Timer is

reserved.

ty comes on.

13

Page 16

UNIT OPERATION

Sleep Timer

Sleep timer procedure “night” ..........................................................................

Press this button to set the SLEEP timer with remote control on. The icon will

appear on the display.

This procedure permits setting the remaining unit operating time.

“1:hr” will be displayed together with the icon.

1

Press button (temperature increase).

2

The display will show the following settings in sequence:

1 hr, 2 hr, 3 hr, 4 hr, 5 hr, 6 hr, 7 hr, 8hr and 9 hr.

3

Once the remaining operating hours have been selected

with either button or , again press button to

confirm.

When the SLEEP timer is set, the unit will control the

4

set temperature to avoid overcooling or overheating

during operation. Also indoor fan operates at low fan

speed regardless of user selection.

The set temperature will change as follows:

NOTE

• When the SLEEP timer is set, the luminosity of the unit lamps will be dimmed

so as not to interrupt sleep.

• The SLEEP timer can be combined with the ON timer.

Turbo mode and Ioniser function

Turbo mode button

If you want more powerful capacity at Cooling and Heating mode, press

button . On the display, the powerful icon will start flashing.

During Turbo mode, you cannot control room temperature, and fan speed.

press one of the buttons or to cancel the turbo mode.

Ioniser function button ...................................................................................

....................................................................................

Turbo mode at Cooling mode

1

Performs the powerful cooling operation until room

temperature reach 17ºC or 20 minutes after pressing

turbo mode button.

At this mode, indoor fan speed is high and compressor

speed is over rating speed in order to obtain maximum

cooling capacity.

Turbo mode at Heating mode

2

Performs the powerful heating operation until room

temperature reach 32ºC or 20 minutes after pressing

turbo mode button.

At this mode, indoor fan speed is high and compressor

speed is over rating speed in order to obtain maximum

heating capacity.

Press Ioniser button to activate Ioniser function

1

during unit ON.

2

Press Ioniser button

Ioniser function.

again to stop

14

Page 17

UNIT OPERATION

DISCHARGE AIR LOUVER CONTROL

Up and Down Control

The air discharge direction can be controlled to swing up and down and can be fixed at a preferred position or at automatic position by the remote control.

CLOSE

COOL

Remote Control Auto Position

HEAT

Swing Range

HEAT

• If you select the flap position using the FLAP button in the remote control, the flap in the unit

will move to that position automatically.

Once you select the position, the unit remembers that position and whenever you turn on

the unit, the flap will be positioned to that position.

• If you select SWING, the flap will swing up and down. In the COOL, DRY and FAN mode,

the flap will swing in the cool range. In the HEAT mode, the flap will swing in the heat range.

• If you select AUTO, the flap will position itself to the preset position according to the operation mode.

Left and Right Control

If you want to adjust the direction of the discharge air left or right, Pressing the

‘vertical louver’ button. The button will set the swing on and off.

NOTE

• Please do not fix the flap at position for a long time, because this position

minimizes air circulation resulting in uneven room temperature.

• Do not adjust the flap by the hand during SWING operation because it may

damage the air swing mechanism.

• If you want maximum cooling or heating capacity, please set flap at position

Vertical louver button

.

NOTE

• Always use the remote control to adjust the flap position,

otherwise it may cause abnormal operation.

Please turn off the unit and turn it on again when you

manually adjust the flap out of range.

Horizontal Louver setting 6 and

Vertical Louver Swing Indicater

Time 1sec 1sec

Swing on

Swing off

15

Page 18

UNIT OPERATION

AIR CLEANING OPERATION

Information for filters

• Filters Standard Air Filter

Optional Filters (3 items available)

1

Active carbon filter

2

Photo catalytic filter

3

Triple filter

• Standard air filter eliminates dust and lint.

• Active carbon filter is particularly effective in eliminating odor.

• Photo catalytic filter effectively eliminates cigarette smoke in the room air.

• Triple filter (nano silver filter + vitamin filter + anti mite filter) deodorizes

ammonia, formaldehyde, toluene, and provides powerful anti-bacterial effect.

Active carbon

filter(Black)

Photo catalytic

filter(Blue)

Triple filter

(Yellow+Silver+Red)

Vitamin

Nano

Silver

Life time of filters

life of above filters varies according to the amount of air pollutant, room

• The

size and the operating time.

• Standard can be cleaned with a vacuum cleaner or rinsed under running

water after using a month.

Standard

Air filter

• The life time of Active carbon, Electrostatic, Photo-catalytic filter is

about 3 months.

Please replace them with new one every 3 months.

HOME AUTOMATION FUNCTION (optional)

• In case of fire, remote ON/OFF switching of the system is possible. In addition, the ON/OFF switching through the remote control can be locked.

• However, an adaptor and wiring connected to the central control room is necessary in the field when this function shall be feasible.

Anti mite

16

Page 19

CARE AND MAINTENANCE

POINTS TO NOTE

Operating Condition

• Temperature ran

Mode

COOL&DRY

HEAT Below 27˚C -10~24˚C -10~24˚C -10~24˚C

• When the unit operates above or below these conditions for a long time,

system diagnostics may detect a malfunction

• If the unit operates for a long time under abnormal situation of extremely high

humidity, condensed water may drip from the unit.

ges suitable for unit operation are as follows.

Indoor

(All Market)

21 ~ 32˚C 21 ~ 43˚C 21 ~ 52˚C 21 ~ 52˚C

Asia & Australia

Outdoor

Middle East Saudi Arabia

and the unit will not operate properly.

Time Delay

• If the operating mode changes from COOL and DRY to HEAT, there will be

3 minutes~3 minutes 15 sec time delay between compressor turning off

and turning on including starting the heat operation.

• If the operating mode changes from Heat to Cool and Dry, there will be

3 minutes~3 minutes 15 sec time delay .

• When heating operation starts, hot air delivery might be delayed due to

a warm up period.

Minimum Operation Time

• In normal operation, there is a minimum operation time of 3 minutes between

compressor turning on and turning off.

Defrost Operation (For Heat Pump Model)

• In the heating mode, when the outdoor coil is frosted, the indoor fan and

outdoor fan will turn off while the compressor will turn on to remove the frost

on the outdoor coil.

• The defrost mode stops after 5 minutes 20 sec or 9 minutes 40 sec according

to outdoor coil status or when compressor operates according to preset condition.

• When the power is off, the defrost operation is automatically conducted to

eliminate frost

accumulation on the outdoor coil.

Auto recovery Operation (Field selection)

• When the electricity fails while the unit is operating, the unit memorizes the

operating condition, and it will start operation automatically when the

electricity is restored.

• When you leave home during an electricity failure, please unplug the power

cord, or the unit will automatically restart in your absence.

• This function is field selectable by pressing the ‘Remote’ button upto field

requirements. Default from the factory is to have this function but it can be

selected.(Refer the page 35)

Frost Prevention of Indoor Unit

When the unit is operates at a low ambient temperature, frost may appear on

the indoor coil. When the indoor coil temperature is below 0

puter makes the compressor stop to protect the unit from frost.

º

c, the microcom-

Normal Operation

Any of the following can occur during normal operation:

• A sound like a “GURGLE” can sometimes be heard during operation or

when the unit stops.

- It is the sound of the refrigerant flowing through the unit.

• Bad smells can come

- Smells such as smoke or cosmetics can accumulate while room air

circulates through the unit.

- Cleaning the filters will reduce this problem.

• UNIT ON lamp on the indoor unit displays flashes and no air comes from the unit.

- It indicates malfunction of the unit and the compressor will stop operating.

• A “BAK-BAK” sounding noise can sometimes be heard during operation or

when the unit turns on.

- It is the sound of plastic expanding due to an abrupt temperature change.

from the unit.

17

Page 20

CARE AND MAINTENANCE

CLEANING THE FILTERS AND FRONT PANEL

Cleaning the Air Filter

1

Lift the front panel and pull the air filters

downward.

Clean the filters with a vacuum cleaner.

2

Rinse the filters under running water,

3

dry completely. and refit correctly into

their guides.

NOTE

• Turn off the unit and pull out the power plug before cleaning.

• Clean the air filters once a month.

Cleaning the Ioniser

• Clean Ioniser with a brush every three months

1) Unscrew a ioniser and open a cover

2) Rub needle on base of ioniser with brush

3) Tighten up a screw

WARNING

HIGH VOLTAGE!

The unit must be disconnected from the main supply before

maintenance or cleaning.

18

Page 21

CARE AND MAINTENANCE

Washing the Front Panel

1

Lift the front panel up to the top of the

unit and separate it from the unit.

Rinse the panel under running water

2

and dry completely in a shaded area.

Refit it correctly. Installation procedure

3

is reverse to the removal procedure.

NOTE

• Turn off the unit and pull out the power plug before washing.

• Clean the front panel if it becomes dirty and spotted.

• Front panel is removable.

CLEANING THE MAIN UNIT

• Use only a damp soapy towel.

NOTE

• When cleaning the unit, first turn it off and pull out the power plug.

AFTER-SEASON CARE

1

Clean the filters and refit them into the unit.

If the unit is to be switched off for an extended

2

period, run the unit on FAN only for two hours

to dry inside of the unit.

19

Page 22

The following installation accessories are supplied with unit. Use them as required.

Q.ty UseName and shape

STANDARD INSTALLATION ACCESSORIES

Wall hanging bracket

Screws 4xL10

Screws 3xL14

Screws 5xL25

Wirele

ss remote control

mou

The following field supplied items are required to complete the installation.

ting bracket

Electrostatic filter + photocatalytic filter +

Active carbon filter + Triple filter

1

2 F

1

14 For wall hanging bracket installation

1 For wireless remote control Installatio n

1~3

For indoor unit installation

or fixing unit and hanging bracket

For wireless remote control mounting bracket In stallatio n

For eliminating microscopic dust

and cigarette smoke, in the room air.(optional)

20

Page 23

CHOOSING THE UNIT LOCATION

1) Indoor Unit

1460mm

20cm or

more

mm043

10cm or

more

9cm or more

2m or more

2) Outdoor Unit

• Leave the space shown in Figure. 2 between the unit and any

obstruction for good air flow.

300 mm

10cm or

more

10cm or more

60cm or more

50cm

or

more

320 mm

277mm

Figure

508 mm

800 mm

600 mm

900 mm

• Leave the space shown in Figure. 1 for servicing or

removing the filter and for good air flow and for safety.

• If the room using the air conditioner has florescent

lighting with electronic starter, signals may not be

properly received. Keep the indoor unit away from

fluorescent lamp to receive the signal from remote.

CAUTION

Installation in the following places may cause

problem.

If it is unavoidable to use the unit in such places,

1

consult with your distributor.

• A place with an oily ambient.

CAUTION

Installation in the following places may cause problems.

319 mm

If it is unavoidable to use the unit in such places, consult

with your distributor.

• A place with machine oil.

• A saline place such as a seashore vicinity.

• A place with sulphur gas.

• A place where high-frequency waves are generated

by radio equipment, welders, and medical equipment.

363 mm

Figure 2

21

Page 24

INSTALLATION TIPS

The following points should be avoided.

Excessive distance between the indoor and the

outdoor unit. (Max 40m)

Kinking the connection pipes.

Dripping due to insufficient insulation of pipes.

22

Slack connections on the electrical cables for cooling only model & heat pump model.

Do not install the outdoor unit on grassy or soft

An uneven installation.

Indoor unit

Indoor unit

Max

Max

surfaces. ( Unit must be level. )

Excessive height between the indoor and the

outdoor unit. ( Max 20m )

Page 25

INDOOR UNIT INSTALLATION

• The piping can be connected to the four directions indicated by , , , .

When the piping is connected to the direction of

, or , detach the knock-

out either at the side or at the bottom of the unit. ( Fig. 3 )

Figure

3

1) Installing the Wall Hang Bracket

10cm

or more

30cm

or more

PLUMB

45cm

or more

Figure

4

• Install the wall hang bracket so that it is level. Use a plumb line if necessary.

( Figure. 4 )

• Be sure to leave the clearance spaces shown in Figure 1.

• Before installing the wall hang bracket, remove it from the unit by pushing up

marks ( ) at the bottom of the body.

• Fasten the wall hang bracket to the wall with 14 or more self-tapping screws

through the holes marked “ ” at the wall hang bracket.

•

Install the wall hang bracket so that there is no gap between the bracket and the wall.

• Check that the wall hang bracket does not move to prevent noise during

operation.

NOTE

• In case of removing the unit from the wall hang bracket after installing it

onto the wall, remove by pushing up MARKS ( ) at the bottom of

the body.

REMOVE SCREW

23

Page 26

INDOOR UNIT INSTALLATION

2) Making the Wall Penetration for the Interconnecting Piping

Rear Piping

• It is best for the piping to go through the wall behind the unit. So that the unit hides the pipes.

• For this method of installation, make a 65mm diameter hole in the wall at either point L or R. ( Figure. 5 )

50 130

5~10mm lower

Indoor side

Outdoor side

Figure

6

Side or Bottom Piping

• Remove the knock-out in the unit and pass the pipes through the wall.

• The pipe should slope downward and away from the unit to ensure good drainage.

24

Figure

5

• Drill a hole at a slope so that the outside end is lower ( 5-10mm ) than the inside

end to ensure good drainage.

• Cut the Wall Sleeve to match the wall thickness and to pass the pipe through the

hole. ( Figure. 6 )

Page 27

INDOOR UNIT INSTALLATION

3) Indoor Unit Wiring

• Lift the front panel up to the top of the unit and then it will be separated

from the unit.

• Detach the Terminal block cover and clamp wire. ( Figure. 7 )

• Connect the electrical connection cord with the screws to the terminal block

of the indoor unit as described at Figure. 8.

( Refer to the Wiring Diagram inside the Frame grille and Caution Label on the

frame grille. Caution Label is engraved on Frame grille )

• Reinstall the clamp wire and the terminal block cover with the screws

after wiring.

• Fit the front panel to the latch of the Frame grille.

Figure

7

For Cooling Only Model

For Heat Pump Model

CAUTION

• Do not connect wires when power is ON.

• The air conditioner always requires grounding. Ground the unit must be in

accordance with local codes.

• Every wire must be connected firmly. Use connection cable H07(H05, A07,

A05)RN-F 1.5mm

according to EN(IEC) 60335-2-40 and HD277.S1 standards.

• Wrong wiring causes malfunction of the unit and electric shock. Check

local electrical codes and also any specific wiring instructions or limitation.

• During installation, proceed first with refrigerant connections between in

door and outdoor units, and only then make the electrical ones; similarly,

when disassembling, disconnect the electrical wiring first and only then

open refrigerant connections.

• Unit must be installed according to applicable national installation standards.

2

, synthetic rubber insulation with Neoprene coating,

Figure

8

25

Page 28

INDOOR UNIT INSTALLATION

4) Forming the Drain Hose and Refrigerant Piping

• Drain hose and drain cap are assembled as shown in figure 9 in the factory. To do right-side(

the drain hose to right-side piping direction.(It is not necessary to exchange the location of drain hose and drain cap.)

• Tie the refrigerant pipe, the drain hose, and the electrical connection cord together.

• Form the refrigerant piping in the required direction, and bind the drain hose and the electrical connection cord together with vinyl tape.

The drain hose should be at the bottom. ( Figure. 10 )

Figure

9

• For Left Piping, fit the pipes and the wiring into the recess at the back of the unit as shown in Figure 11.

), right-botton( ) or right-back( ) piping in figure 3, draw

Figure

Figure

10

11

5) Installing the Indoor Unit Body to the Wall Hang Bracket

• Pass the pipes through the wall sleeve and then hook the indoor unit body onto the top of the wall hang bracket. ( Figure. 12 )

• For Left Piping, hang the unit onto the top of the wall hang bracket and incline the unit using a tool such as a screw

-driver set between the middle area of body and bottom right of the wall hang bracket. Connecting the pipe can be done more easily if the unit is inclined.

• Snap the marking places of the body(A, B) onto the hole of the bracket.

26

Page 29

INDOOR UNIT INSTALLATION

Wall hang

bracket

A

310 310

B

[mm]

Screw hole

• Next, check the drainage of the unit by pouring some water into the unit drain pan and ensure that the water drains out through the drain hose and

that there is no leakage from the other parts.

• After installation, if there is a significant gap between the unit and wall, it can be adjusted by securing 2 screws to the body and wall hang bracket.

Refer to the screw hole location(A, B) in Figure 12.

• Removing the frame grille ;

Hook

Detach terminal block cover by removing two screws and remove two screws from frame grille.

Pull the triangle marks located at the bottom of the frame grille and lift frame grille to the top of the unit.

NOTE

• The recommended bending of the drain

hose is shown in Figure 13.

Figure

13

Figure

12

27

Page 30

CONNECTING THE PIPING

Pay careful attention to the following points when installing the refrigerant pipes.

• Hold the pipe with one wrench while tightening the connections with a torque

• If the tightening torque is insufficient, gas will leak from the connection.

• If it is too strong, the flare will be damaged.

• Do not bend the pipe more than three times at one place.

• When extending the rolled pipe, straighten the pipe by unwinding as shown

or double-ended wrench.

wrench

Be careful not to damage the flare nut threads.

Tighten the nut with the torque shown in Table 1.

Flare nut Tightening(kgf-cm) Tourque(Nm)

6.35 mm (1/4”) 180 18

12.7 mm (1/2”) 560 55

15.88 mm (5/8”) 660 65

19.05 mm (3/4”) 1020 100

in Figure 14.

Figure

Table 1

14

1) Connecting Pipe to the Indoor Unit

a. Remove the indoor pipe flare nut. ( Check that there is no debris inside. )

b. Align the center of the flare surface, and tighten the indoor pipe union and

connection pipe flare nut with a torque wrench or double-ended wrench.

( Figure. 15 )

While aligning the center of the flare surface, tighten the nut by hand, hold the

union side with a wrench and tighten the nut according to the specified

tightening torque with a torque wrench.

Torque wrench or

double-ended wrench

Outdoor side

Figure

Indoor side

15

2) Connecting the Interconnecting Pipe to the Outdoor Unit Valve

• Repeat the procedure for flaring the tube to connect to the outdoor unit.

•

Tighten the flare nut of the connection pipe at the outdoor unit valve. ( Figure. 16 )

(Liquid pipe)

Two way valve

Interconnecting

pipework

(Gas pipe)

28

Three way valve

Figure

16

Page 31

AIR PURGE

Using the vacuum pump

For air purge, evacuate the air in the connecting pipe and indoor unit by using

vacuum pump. For details, please refer to the following procedure.

a. Connect the gauge manifold.

b. Open the low pressure valve and close the high pressure valve of the gauge

manifold completely.

c. Operate the vacuum pump during at least 20 minutes until the pressure

reaches -101Kpa (-760mm Hg).

d. Close the low pressure valve of the gauge manifold and stop the vacuum

pump operation. (If the indicator of gauge manifold is returned

within 1-2minute after stopping the vacuum pump, check the piping

connection leakage)

n both the two-way and three-way valve completely.

e. Ope

f. Close both the two-way and three-way valve caps completely.

g. Remove the gauge manifold and vacuum pump.(During the disconnection,

please be cautious not to lose any refrigerant and oil)

h. Reinstall the valve caps and service port nuts.

CAUTION

Refrigerant charging

• In case of refrigerant charging due to refrigerant leak or service refer to the nameplate on the outdoor unit.

• When the upward gas line is long, oil trap shall be installed every 10m in order to return oil to compressor.

When the connection pipe is less than 7.5m, extra amount of refrigerant per meter(If it is impossible to extract proper amount of refrigernat, please keep 7.5m piping

length by making loops or windingd for compressor reliability)

Figure

17

Connecting pipe Size Extra charge amount Example for 14.5m pipe

ø15.88mm 45 g/m (14.5 _ 7.5) x 45 = 315 g

ø19.05mm 60 g/m (14.5 _ 7.5) x 60 = 420 g

Note that the shorter connection pipe, the better the performance of system.

The maximum allowable length of the connection pipe is 40m and the maximum allowable elevation between indoor unit and outdoor unit should be less than 20m.

29

Page 32

GAS LEAK CHECK

After connecting the pipe, check the joints for gas leakage with gas leak detector or soapy water.

FINISHING

• Wrap the piping joints with the pipe insulation and fasten it with vinyl tape. ( Figure. 18, 19)

• Fill the gap between the inside of wall sleeve and the pipe with a sealer so that rain and wind does not enter. ( Figure. 20 )

30

Pipe

Pipe insulation

(Vinyl tape)

Figure

Pipe

Saddle

18

Figure

19

Wall sleeve

Indoor side

Wall

Wall cap

Sealer(Putty)

Outdoor side

Figure

20

Page 33

OUTDOOR UNIT WIRING

• Remove the service cover of the outdoor unit, and connect the end of the connection cord with screws to the terminal block. (

Refer to wiring diagram inside

the top cover and caution label on the service cover)

• When connections are completed, fasten the connection cord with the cable clamp and reinstall the service cover. ( Figure. 21 )

For Cooling Only Model

Terminal block

Ground screw

Cable clamp

Main power connection(L,N, )

Interconnection wire( ,R,C,Y)

Interconnection wire for Heatpump(O,W2,S)

For Heat Pump Model

Terminal block

Ground screw

Cable clamp

NOTE

• The air conditioner always requires grouding.

• Be sure to comply with local codes on running the wire from the indoor unit to the outdoor unit.

• Every wire must be connected firmly.

• During installation, proceed first with refrigerant connections between indoor and outdoor units, and only then

2

make the electrical ones;similarly, when disassembling, disconnect the electrical wiring first and only then open refrigerant connections.

• Unit must be installed according to applicable national installation standards.

Figure

21

31

Page 34

ELECTRICAL CONNECTION

For Cooling Only Model

CONNECTING THE POWER SUPPLY

• The mains supply must be connected to the outdoor unit.

Model

38XPL030C3

38XPL036C3

38XPL030H3

38XPL036H3

Phase

60Hz

60Hz

60Hz

60Hz

Starting

current

A

77

80

77

80

For Heat Pump Model

Main power

connection

Fuse

A

30

40

30

40

Wiresize

mm

4.0

4.0

4.0

4.0

size

n

OW2S

mm

1.0

1.0

1.0

1.0

2

Interconnectio

wire

2

RCY

mm

1.0

1.0

1.0

1.0

2

32

Page 35

TEST RUNNING

• Perform the operating test after the units have been installed in position and the gas leak test

has been completed.

• Check all electrical connections(instructions and wiring diagram).

• Insert the batteries into the remote control and leave it OFF.

• Energise the system, turning the power supply ON.

• Press the

than 5 seconds. The display will be cleared, the time segments will display the icon(Src=service

test)

When test mode is selected, the unit operates as described below:

• The green LED and the orange LED blink every 2 seconds.

• The indoor fan operates at low speed.

• The louver operates according to “Auto heat” or “Auto cool” based on operating mode.

• The system works in Cool Mode at fixed compressor frequency for 3 minutes.

• The system works in Cool Mode until Test Mode is exited.

During the cool mode and heat mode check the following conditions:

1. Difference between indoor ambient temperature and indoor unit air discharge temperature

must be greater than 3°C.

2. Indoor

3. Louver must be in auto heat or cool louver based on operating mode.

4. No fault code must be signalled by the system.

If one of the above conditions is not positive, please check the correct installation of the system.

• After test has been completed. press button

and buttons of the infrared remote control and hold them pressed for more

fan must operate at low speed.

on the remote control to leave the test menu.

NOTE

When 30 minutes have elapsed and no buttons have been pressed,

the remote control will automatically exit the test menu and resume its normal operation.

HIGH PRESSURE CONTROL

Unit for Middle East has high pressure switch to prevent head pressure from being out of limit due to high ambient.

If “High pressure switch” trips, cycle the power supply OFF and ON to reset the system, because electrical box is equipped with relay that prevent the unit from

starting, till the indoor unit is switched OFF.

When head pressure drops below 23bar, it is possible to restart the unit switching the indoor control ON.

33

Page 36

CONFIGURATION

Remote Control Configuration

• Remote Control is used for heat pump type air conditioner and cool only type

air conditioner.

Before user operates air conditioner, thus, cool only type and heat pump

type of remote configuration and other items must be selected as follows.

Press the and buttons of the infrared remote controller

1

and hold them pressed for more than 5 seconds.

The display will be cleared, the temperature segments will

2

display the first configuration item (CH = remote address) and

the time segments will display the default value of this

configuration item (Ab = control of both indoor units).

34

Press either the

3

(A) to the new value (b).

Press

4

5

Press either the

temperatures in Degrees Celsius (C) to the new value

Degrees Fahrenheit (

Press

6

7

Press either the

Heat pump in model type (HP) to new value cooling only

type(co).

8

Press

9

Press either the

Maximum heating setpoint or minimum cooling setpont.

Press

10

button repeatedly until “tU” is displayed.

button repeatedly until “rc” is displayed.

button repeatedly until “HR” or “CR” is displayed.

button repeatedly until “CL” is displayed.

or button to change the default value

or button to change the default value of

o

F).

or button to change the default value of

or button to change the default value of

Press either the or button to change the default value of

11

time format as AM/PM (12) to the new value of 24 hours time

format (24).

LOOK OUT! Whichever configuration value changed must

12

be confirmed pressing

13

Press

NOTE

When 30 seconds have elapsed and no buttons have been pressed, the

remote controller will automatically exit the configuration menu and the

procedure has to be restarted.

Confirguration item Value Description

button to leave the configuration menu.

"CH"

"tU"

"rc"

"HR"

"CR"

"CL"

A : Channel A Remote ID selection

Ab : Channel A and B

b : Channel B

C : Degrees C Temperature units

F : Degrees F Defaults to C

HP : Normal Operation Puts the Remote into

CO : Cooling Only Cooling Only Mode

17-32 : 17°~32°C Maximum heating setpoint

63-90 : 63°~90°F Degrees C or F is determined

17-32 : 17°~32°C Minimum cooling setpoint

63-90 : 63°~90°F Degrees C or F is determined

12 : 12 Hour Standard Time Format

(AM/PM) Defaults to 12

24 : 24 Hour Military

button each time.

Defaults to A

Defaults to HP

by “tU”configuration above

by “tU” configuration above

Page 37

CONFIGURATION

If you are installing two indoor units in the same room and you want them to operate in independent mode. It is necessary to assign each unit its own address so that

each unit can operate via its own remote control. For configuration, proceed as follows.

Unit configuration

• Press the and buttons of the infrared remote control and hold them pressed for more than 5 seconds.

• The display will be cleared, the time segments will display the first configuration item (rAdr=remote address) and the temperature segments will display the de

fault value of this configuration item(Ab=control of both indoor units).

• Press either the

• Press button repeatedly until “ZONE” is displayed.

• Press either the or button to change the default value of Zone number (0) to the new value(0-240).

• Press button repeatedly to configure Auto recovery function until “A St” is displayed.

• Press either the or button to change the default value of auto restart in last mode(On) to the new value of start in OFF mode(OF).

• LOOK OUT! Whichever configuration value changed must be transmitted to the indoor unit pressing button each time.

• Press button to leave the configuration menu.

NOTE

When 30 seconds have elapsed and no buttons have been pressed, the

remote control will automatically exit the configuration menu and the procedure has to be restarted.

or button to change the default value (Ab) to the new value (A) or (b).

PUMP DOWN

Pump down means collecting all the refrigerant in the system back into the outdoor unit without losing any refrigerant gas.

Pump down is used when the unit is moved or for servicing the refrigerant circuit.

• Close three-way valve halfway.

• Close two-way valve all the way.

• Turn the unit on for approximately 3 minutes in cooling mode.

• Close three-way valve all the way.

35

Page 38

TROUBLESHOOTING

Trouble Check Points Action

Check that the power cord is plugged Insert the power cord into the wall outlet.

into the wall outlet.

Unit does not Has the circuit breaker tripped or has the Reset the circuit breaker or replace the

operate fuse blown? fuse with the specified replacement fuse.

Has there been a power failure? Restart operation when power is resumed.

Does the “UNIT ON” lamp flash on and off? Call your service representative.

Is the voltage too low? Confirm the available voltage.

Is the filter blocked with dust? Clean the air filter.

Has the temperature been set properly? Check and reset it if necessary.

Cooling is Are the windows or doors open? Close the windows and doors.

abnormally low.

Heating is Has the temperature been set too low? Check and reset it if necessary.

abnormally low.

Unit stops during

operation. Has the room temperature reached the

If the above actions do not correct the operation, consult the dealer from whom you bought the unit.

Is anything obstructing the outdoor unit? Remove the obstruction.

Is the fan speed too low? Change the fan speed selection.

Is the operation mode FAN or AUTO?

Is the filter blocked with dust? Clean the air filter.

Are the windows or doors open? Close the windows and doors.

Is anything obstructing the outdoor unit? Remove the obstruction.

Is the OFF timer operating? Restart operation.

set temperature?

Change to cooling operation or reset the

temperature.

Normal operation.

36

Page 39

MODEL NO.

INDOOR

OUTDOOR

ELECTRICITY

COOL

CAPACITY

(Btu/h)

HEAT (W)

COOL

INPUT POWER

(kW)

HEAT

COOL

CURRENT

(A)

EER

HEAT

COOL

(Btu/hW)

COP (W/W)

DIMENSION

(MM)

WEIGHT

(KG)

HEAT

(R22) 1.95kg 2.5kg2.2kg 2.2kgREFRIGERANT

INDOOR

OUTDOOR

INDOOR

OUTDOOR

ANNUAL ENERGY CONSUMPTION

(KWH PER YEAR)

COUNTRY OF ORIGIN

(T1)

(T3)

(T1)

(T3)

(T1)

(T3)

(T1)

(T3)

42XPL030C3P

38XPL030C3

42XPL030H3P

38XPL030H3

42XPL036C3P

38XPL036C3

230V - 60Hz - 1Ph

28500

25000

-

2.26

2.70

-

9.9

11.9

-

12.61

9.26

-

1460*340*277

900*820*320

23

51

6102 6102 7128 7128

27000

24000

8000 - 9400

2.26

2.70

2.15

9.9

11.9

9.4

11.95

8.89

3.72

1460*340*277

900*820*320

23

58

32500

28500

2.64

3.19

-

11.7

14.1

-

12.31

8.93

-

1460*340*277

900*820*320

23

54

MADE IN KOREA

42XPL036H3P

38XPL036H3

31500

28000

2.64

3.19

2.66

11.7

14.1

11.8

11.93

8.78

3.53

1460*340*277

900*820*320

23

61

37

Page 40

P/N: 42KHC554040-R

Loading...

Loading...