Carrier NSB-10K-2-I-2, NSB-10K-2-I-8-BB2, NSB-10K-2-I-2-M304, NSB-10K-2-I-4, NSB-10K-2-I-8 Installation And Operation Manual

...Page 1

Immersion Temperat ure Sensors

Operation

Specifications subject to change without notice.

1 of 7

Catalog No. 11-808-632-01

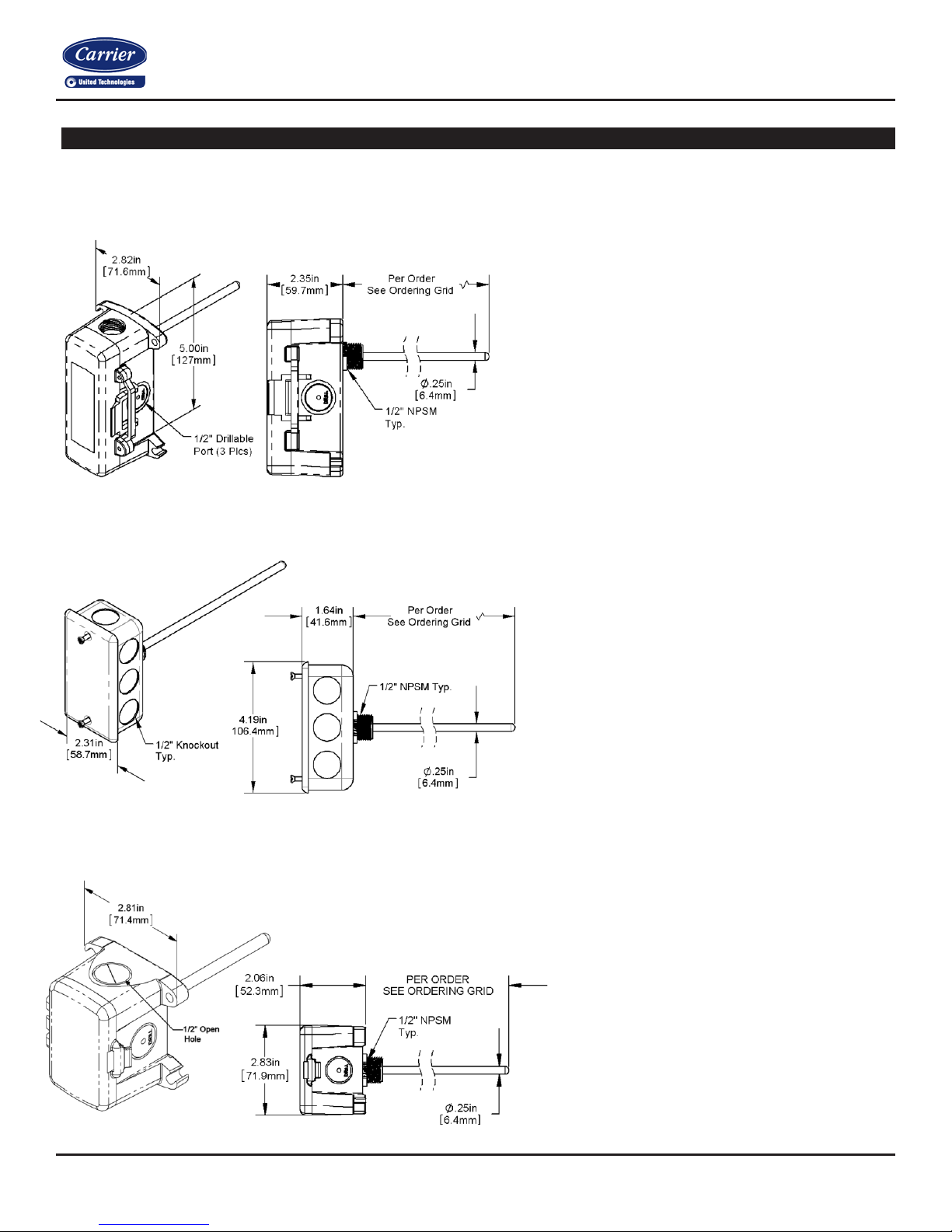

Figure 2: J-Box Immersion (Standard)

Part #

Figure 1:

Part #

NSB-10K-2-I-4-M304 (4” probe, 304 SS thermowell)

Figure

Part #

A Pierce

is available

#20907 – 2/20/19

Overview

The Immersion Temperature Sensor is made for thermowell mounting and temperature measurement in water pipes, water tanks or

cooling tower sump applications. The rigid probe is made of Stainless Steel and made in different lengths for a custom thermowell fit.

Enclosure mounting sty les come in plastic or metal for both NEMA 1 and NEMA 4 applications and are all plenum rated.

Installation and

BB2 Box Immersion

s NSB-10K-2-I-2-BB2 (2” probe, no thermowell)

NSB-10K-2-I-4-BB2 (4” probe, no thermow ell)

NSB-10K-2-I-8-BB2 (8” probe, no thermowell)

NSB-10K-2-I-2-M304 (2” probe, 304 SS thermowell)

s NSB-10K-2-I-2 (2” probe, no thermowell)

NSB-10K-2-I-4 (4” probe, no thermowell)

NSB-10K-2-I-8 (8” probe, no thermowell)

NSB-10K-2-I-2-M304 (2” probe, 304 SS thermowell)

NSB-10K-2-I-4-M304 (4” probe, 304 SS thermowell)

NSB-10K-2-I-8-M304 (8” probe, 304 SS thermowell)

3: BB4 Box Immersion

s NSB-10K-2-I-2-BB4 (2” probe, no thermowell)

NSB-10K-2-I-4-BB4 (4” probe, no thermowell)

NSB-10K-2-I-8-BB4 (8” probe, no thermowell)

able Knockout Plug (Part #NSB-PKP-100)

for the open port in the BB4.

Page 2

Immersion Temperat ure Sensors

Installation and Operation

Specifications subject to change without notice.

2 of 7

Catalog No. 11-808-632-01

Figure 4: Machined Bar Stock ThermoWell

Part #

Figure 5: Two-Part Welded Thermowell

Part #

#20907 – 2/20/19

Specifications

Sensor: Passive, 2 wire

Thermistor Thermal resistor (NTC)

Temp. Output Resistance Per Order1

Accuracy (std) ±0.36ºF, (±0.2ºC)

Stability 0.036ºF/Year, (<0.02ºC/Year)

Heat dissipation 2.7 mW/ºC

Temp. Drift <0.02ºC per year

Probe range -40º to 221ºF (-40º to 105ºC)

Sensitivity Approximate @ 32ºF (0ºC)

Thermistor Non-linier

Lead wire 22 AWG stranded

Insulation Etched Teflon, Plenum rated

Probe Rigid, 304 Stainless Steel,

0.25” OD

Probe Length 2” or 4”

Mounting ½” NPSM Plastic Threads

Enclosure Types

J-Box (-JB) With eight ½” knockouts

BB2 Box With three ½” NPSM & three ½” drill-outs

BB4 Box With three ½” drill-outs & one ½” open port

Enclosure Ratings

J-Box (-JB)

BB2 Box NEMA 4X,

IP66 BB4 Box IP10

Enclosure Materials

J-Box (-JB) Galvanized steel, UL94H-B

BB2 Box Polycarbonate, UL94V-0, UV rated

BB4 Box Polycarbonate & Nylon, UL94V-0

Ambient (Encl.) 0 to 100% RH, Non-condensing

BB2 & BB4 Boxes -40ºF to 185ºF, (-40º to 85ºC)

J-Box & No Box -40ºF to 212ºF, (-40º to 100ºC)

NEMA 1

(IP44 with Knockout Plug in the open port)

Thermowells

Thermowells are hollow tubes closed off on one end and threaded at the other end. They are permanently placed into pipes, tanks, or

sumps so that the probes on immersion temperature sensors can be inserted into the pipe. The temperature of the pipe’s contents is

transferred through the wall of the thermowell. The thermowell prevents the pipe’s contents from escaping and maintains the pressure

of pressurized pipes.

s ZSI-T-2-MB

ZSI-T-2-MSS

ZSI-T-4-MB

ZSI-T-4-MSS

ZSI-T-8-MSS

Agency RoHS, *CE

JIS C1604-1989

*Thermistors are CE compliant

s ZSI-T-2-WSS

ZSI-T-4-WSS

ZSI-T-8-WSS

Page 3

Immersion Temperat ure Sensors

Operation

Specifications subject to change without notice.

3 of 7

Catalog No. 11-808-632-01

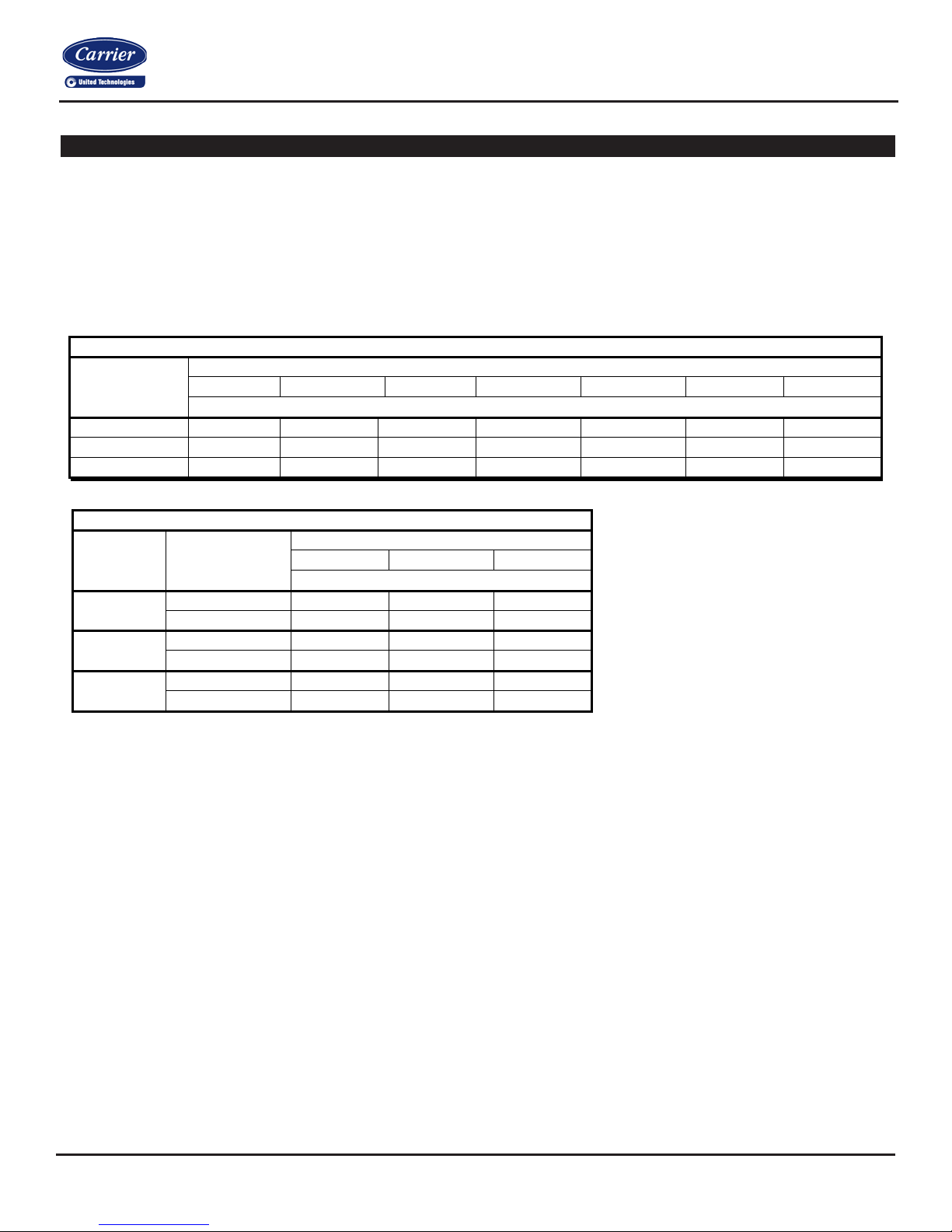

Table 2: Maximum Fluid Velocity versus Insertion Length

Insertion Length (inches)

1-2”

1-4”

1-8”

Maximum Fluid Velocity (Feet per second)

Air/Steam

207

75.5

27.3

Water

59.3

32.2

19.7

Air/Steam

169

61

20

Water

88

20

10

Air/Steam

300

109

39.5

Water

148

82.2

-

Table 1: Pressure Rating versus Temperature

Temperature in Degrees Fahrenheit

70ºF

200ºF

400ºF

600ºF

800ºF

1000ºF

1200ºF

Pressure Rating (Pounds per Square Inch)

Brass

5000

4200

1000 - - - -

Welded 304 SS

982

820

675

604

550

510

299

304 SS

7000

6200

5600

5400

5200

4500

1650

Installation and

#20907 – 2/20/19

Thermowells (continued…)

Choosing the correct Thermowell

As part of our ZS Sensor line, Carrier sells 2.5” and 4.5” machined thermowells made of Brass or 304 Stainless Steel (SS) and twopart welded thermowells made of 304 Stainless Steel. The two-part welded thermowells are not as strong as their machined

counterparts. Carrier recommends the use of welded thermowells be limited to small diameter systems in low vibration environments.

Carrier strongly encourages that single-piece machined thermow ells be used when pos si bl e. See the entries for Welded SS in the

following design tables. Additi onal ly , welded stainless steel thermowells should not be used in turbulent flow; ideally they should be

three to five pipe diameters from elbows or transitions.

Thermowell

Material

The values shown in Table 3 are based

on operating temperatures of 350ºF for

Thermowell

Material

Brass

Fluid Type

brass and 1000ºF for stainless steel.

Slightly higher velocities are possible at

lower temperatures.

Welded

304 SS

304 SS

Comparing the Wake Frequency and the Resonant Frequency

Table 2 and Table 3 were developed to insure that there will be no thermowell failures due to application stresses. Thermowell

failures, in most cases, are not due to the effects of pressure or temperature on the well. The calculations necessary to provide

adequate strength, under given conditions, are familiar enough to permit proper choice of wall thickness and material. The values

shown in Table 2 are conservative, and intended primarily as a guide.

Less familiar, and more dangerous, are the vibration effects to which thermowells are subjected. Fluid, flowing by the well, forms a

turbulent wake (called the Von Karman Trail) which has a definite frequency, based on the diameter of the thermowell and the velocity

of the fluid. It is important that the thermowell have sufficient stiffness so that the wake frequency will never equal the resonant (natural)

frequency of the thermowell itself.

If the resonant frequency of the thermowell coincided with the wake frequency, the thermowell would vibrate to destruction and break

off in the piping. Thermowells are also safe if the resonant frequency below the wake frequency or if the fluid velocity is constantly

fluctuating through the critical velocity point. Nevertheless, if the installation is not hampered by the use of a sufficiently stiff thermowell,

Carrier recommends the values given in Table 3 not be exceeded.

Page 4

Immersion Temperat ure Sensors

Installation and Operation

Specifications subject to change without notice.

4 of 7

Catalog No. 11-808-632-01

#20907 – 2/20/19

Thermowells (continued…)

Table 3: Pipe Insertion Recommendations using Carrier Thermowells

Thermowell Installation

To install a thermowell, a pipe fitter typically drills a

¾-inch hole into the pipe where the thermowell is

needed. A customer-provided fittin g, cal led a

Threadolet or Weldolet, is welded to the pipe over

the hole. The Threadolet has a ½” NPT thread in the

center. Thread sealant such as Teflon tape or pipe

dope is applied to the ½” NPT threads of the

thermowell. The thermowell is then inserted into the

Threadolet and tightened.

Figure 6 shows a 4” thermowell and 4” immersion

probe installed in a 12” pipe. In a properly

sensor

insulated pipe with liquid or steam, the temperature is

essentially the same across the entire cross-sect ion of the

pipe.Usually thermowells are sized to extend to the center

of the pipe; however, shorter thermowells will give proper

temperature readings if properly installed. The shor ter

thermowells are used in pipes with high flow velocities.

Since the wall thickness of the pipe commonly used

for HVAC plumbing is ½-inch, the thermowell sticks

four inches into the pipe. The four-inch distance is

from the inside surface of the pipe to the end of the

thermowell.

6.5” Overall

Probe Length

2” Thick

Pipe Insulation

1/2” Thick

Pipe Wall

(Schedule 80)

4” Thermowell

Insertion Length

Threadolet

Weld

Figure 6: Typical Immersion Probe Installed in a Thermowell

Page 5

Immersion Temperat ure Sensors

Operation

Specifications subject to change without notice.

5 of 7

Catalog No. 11-808-632-01

Length Per Order

*Sensor Slides

1.

Installation and

#20907 – 2/20/19

Thermowell Installation (continued…)

Pipes less than 3 inches in diameter

T- Mount

Figure 7 shows how a 2” tee and a ½” to 2” bushing

allows a 2” thermowelll to measure the temperature of the

contents of a 2” water pipe.

Be sure to use a thread sealant on the outside threads of

the thermowell.

Corner Mount

Figure 8 shows how a pipe tee can be used in an elbow

application. A 2” tee and a ½” to 2” bushing allows a 4”

thermowell to measure the temperature of the conte nts of

a 2” water pipe.

NOTE Temperatures in pipes as small as 1-1/4” may be

measured by this method. In small pipes, the diameter of

the thermowell may become a significant obstr u ctio n, so

be sure to check for proper flow rates after installation is

complete.

1/2 inch NPT

T-pipe fitting

Figure 7: Typical T-Mount

Reducer

Reducer

1/2 inch NPT

T-pipe fitting

Figure 8: Typical Corner Mount

Immersion Sensor Inst all at ion

Immersion probes come with a plastic fitting that

screws into the threads of the thermowell.

Pull the immersion probe away from the plastic fitting

until the probe is fullly extended. Insert the probe into

the thermowell until the plastic fi ttings come into contact

with the threads in the thermowell. Hand tighten the

immersion sensor snugly into the thermowell without

too much torque. The temperature probe slides back

into the enclosure as the sensor contacts the end of the

thermowell.

Make sure that the tip of the immersion sensor probe is

in good contact with the bottom of the thermowell by

pushing on the flaired end of the probe until the tip

bottoms out in the thermowell.

Pull Sensor to

Extend Fully

2.

Insert

3.

Hand Tighten

Figure 9: Immersion Sensor Before Insertion

* As the immersion sensor is hand-threaded into the thermowell, the flair end of the

probe will be pushed into the enclosure as the probe tip bottoms out in the

thermowell. The probe can slide up to 1.6”. The Junction Box enclosure is shown

above but the process is the same for the other enclosure styles.

Page 6

Immersion Temperat ure Sensors

Installation and Operation

Specifications subject to change without notice.

6 of 7

Catalog No. 11-808-632-01

Per order

*Sensor slides

1.

Pull sensor to

3.

Hand tighten

Per order

*Sensor slides

Per order

*Sensor slides

1. Pull sensor to

3. Hand tighten

4.

Pull sensor to

6.

Hand tighten

#20907 – 2/20/19

Immersion Sensor Inst all at ion (continued…)

Hand tighten into well

extend fully

2.

Insert

Figure 10: Typical Sensor Inserted Figure 11: BB4 Sensor Before Insertion

extend fully

2. Insert

extend fully

5.

Insert

Figure 12: BB2 Sensor Before Insertion Figure 13: Standard J-Box Before Insertion

*As the box is hand screwed, the probe will push into the box as the probe tip bottoms out in the well. The probe can slide up to 1.6 inches

Page 7

Specifications subject to change without notice.

7 of 7

Immersion Temperat ure Sensors

Installation and Operation

Catalog No. 11-808-632-01

Thermistor

To Controller

Analog Input (AI)

(No Polarity)

To Controller Analog

Figure 14: 2 Wire Lead Wire Termination for Thermistor

#20907 – 2/20/19

Wiring & Termination

Carrier recommends using twisted pair of at least 22AWG and sealant filled connectors for all wire connections. Larger gauge wire

may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes. Do NOT run this device’s

wiring in the same conduit as high or low voltage AC power wiring. Tests show that inaccurate signal levels are possible when AC

power wiring is present in the same conduit as the sensor wires.

Sensor

Input (AI) (No

Polarity)

Diagnostics

Problems:

Controller reports higher or lower

than actual temperature.

Possible Solutions:

-

Confirm the input is set up correctly in the front end software

-

Check wiring for proper termination and continuity (shorted or open).

-

Disconnect wires and measur e sensor res ist anc e and ver ify the “Sen sor” outp ut is corre ct.

Loading...

Loading...