Page 1

48DJ,DK,NP034-074

50DJ,DK,DW,DY,NB,NP034-074

Single Package Heating and Cooling Units

Installation, Start-Up and

Service Instructions

CONTENTS

Page

GENERAL ...................................2

SAFETY CONSIDERATIONS ...................2

INSTALLATION .............................2-37

Rigging and Unit Placement ..................2

Roof Curb ...................................2

Roof Mount ..................................2

Slab Mount ..................................2

Positioning ..................................3

Field-Fabricated Ductwork ....................6

Condensate Drains ..........................10

Install Outdoor Hoods .......................10

• UNIT SIZES 034 AND 044

• UNIT SIZES 054-074

Outdoor-Air Inlet Adjustments ...............10

• MANUAL OUTDOOR-AIR DAMPER

• ECONOMIZER SETTINGS

Field Wire Routing ..........................17

• UNIT SIZES 034 AND 044

• UNIT SIZES 054-074

Field Electrical Connections .................17

• POWER WIRING

• CONTROL WIRING

Gas Piping (48 Series Units Only) ............36

Installing Flue/Inlet Hoods (48 Series Units

Only) ......................................36

• UNIT SIZES 034 AND 044

• UNIT SIZES 054-074

PRE-START-UP ............................38-41

Unit Preparation ............................38

Compressor Mounting .......................38

Evaporator-Fan Shipping Brackets ...........38

• UNIT SIZES 034 AND 044

• UNIT SIZES 054-074

Internal Wiring ..............................38

Refrigerant Service Valves ...................38

Crankcase Heaters ..........................38

Compressor Oil .............................38

Gas Manifold Pressure (48 Series

Units Only) ................................39

Unit Voltage ................................39

Leak Test and Dehydration ..................39

Evaporator-Fan Belts, Pulleys, and Sheaves ..39

Condenser Fans and Motors .................40

Return-Air Filters ...........................40

Economizer Inlet Screens ...................40

Economizer Dampers .......................40

25% Outdoor-Air Damper ....................40

Initial Check ................................41

START-UP .................................41,42

General .....................................41

Operating Sequences .......................41

• COOLING, UNITS WITHOUT ECONOMIZER

• HEATING, UNITS WITHOUT ECONOMIZER

• COOLING, UNITS WITH ECONOMIZER

Page

• HEATING, UNITS WITH ECONOMIZER

• VENTILATION AIR CIRCULATION (Continuous Fan)

• AUTOMATIC CHANGEOVER USING AUTOMATIC

CHANGEOVER THERMOSTAT

Head Pressure Control ......................42

SERVICE ..................................42-53

Service Access .............................42

• COMPRESSORS

• LIQUID SERVICE VALVES, FILTER DRIERS, AND

SIGHT GLASSES

• EVAPORATOR-FAN MOTORS, PULLEYS, AND

BELTS

• POWER EXHAUST MOTORS, PULLEYS, AND

BELTS

• UNIT CONTROL BOX

• GAS HEAT SECTION (48 Series Units Only)

• MAIN AND PILOT BURNERS (48 Series Units Only)

• FLUE GAS PASSAGEWAYS (48 Series Units Only)

• COMBUSTION AIR BLOWER (48 Series Units Only)

• ECONOMIZER DAMPER MOTOR

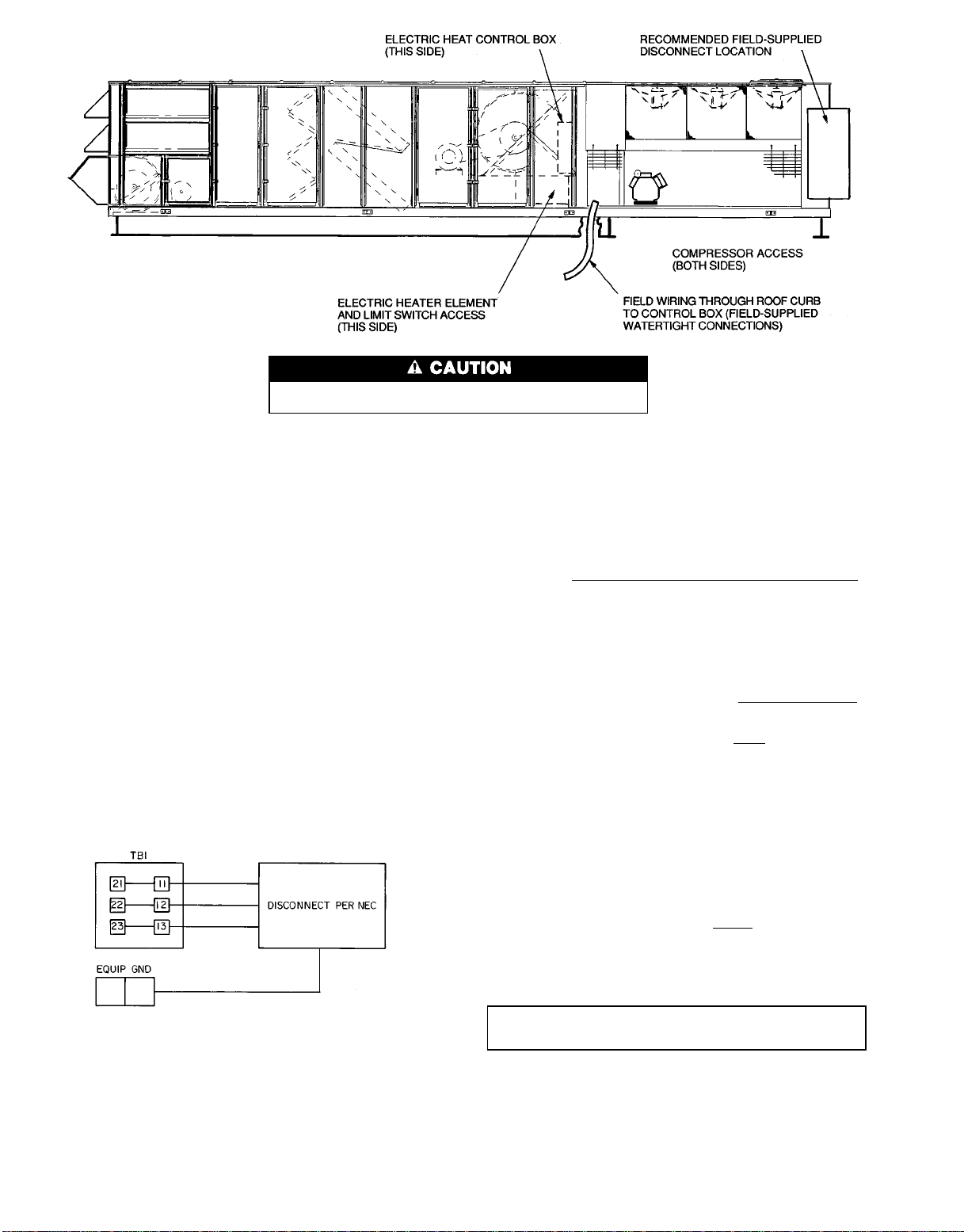

• ELECTRIC HEATER CONTROL BOX (50 Series

Units Only)

• HEATER BOX (50 Series Units Only)

• 25% OUTDOOR-AIR DAMPER

• MODULATING POWER EXHAUST DAMPER

MOTOR

• RETURN-AIR FILTERS

• CONDENSER FANS AND FAN MOTORS

• INLET GUIDE VANE MOTOR

Cleaning ....................................45

Lubrication .................................45

• COMPRESSORS

• FAN SHAFT BEARINGS

• INLET GUIDE VANE BEARINGS (Units With

Optional Inlet Guide Vanes)

• FAN MOTOR BEARINGS

• DOOR HINGES

Adjustments ................................46

• EVAPORATOR FAN AND POWER EXHAUST

MOTOR PLATE

• MODULATING POWER EXHAUST DIFFERENTIAL

PRESSURE SWITCH

• INLET GUIDE VANE DIFFERENTIAL PRESSURE

SWITCH (Units With Optional Inlet Guide Vanes and

Static Pressure Control)

• BELT INSTALLATION AND TENSIONING

• PULLEY ALIGNMENT

• INSTALLING ALTERNATE MOTOR PULLEY

(Evaporator Fan Only)

• CONDENSER FAN ADJUSTMENT

• 25% OUTDOOR-AIR DAMPER

• REFRIGERANT CHARGE

• PILOT LIGHT OFF (48 Series Units Only)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 1

Tab 1a 1b

PC 111 Catalog No. 564-818 Printed in U.S.A. Form 48/50D,N-9SI Pg 1 3-96 Replaces: 48DJ,DK-3SI;

48/50NB,NP-1SI; 50DJ,DK-9SI

Page 2

CONTENTS (cont)

• AUTOMATIC PILOT ADJUSTMENT (48 Series

Units Only)

• GAS VALVE ADJUSTMENT (48 Series Units Only)

• MAIN BURNER ADJUSTMENT (48 Series

Units Only)

Main Burner Removal (48 Series Units Only) ..50

Switch Adjustment .........................50

Refrigerant Feed Components ...............50

Thermostatic Expansion Valve (TXV) .........50

Moisture/Liquid Indicator ....................51

Filter Drier ..................................51

Liquid Line Service Valve ....................51

Compressor Discharge Service Valve ........51

Compressor Suction Service Valve ...........51

Protective Devices ..........................51

• COMPRESSOR PROTECTION

• EVAPORATOR-FAN MOTOR PROTECTION

• CONDENSER-FAN MOTOR PROTECTION

• HIGH- AND LOW-PRESSURE SWITCHES

Relief Devices ..............................51

Control Circuit, 115 V .......................52

Control Circuit, 24 v .........................52

Electric Heat (50 Series Units Only) ..........52

• OVERCURRENT

• OVERTEMPERATURE

Gas Heat (48 Series Units Only) ..............52

• LIMIT SWITCHES

• ROLLOUT SWITCH

TROUBLESHOOTING ......................52-69

Economizer .................................52

• ECONOMIZER MOTOR CHECKOUT

• ECONOMIZER CONTROL BOARD CHECKOUT

Unit Control Board Checkout ................53

• BASIC CHECK

• DETAILED CHECK

START-UP CHECKLIST .....................CL-1

Before performing service or maintenance operations on

unit, turn offmain power switch to unit. Electrical shock

could cause personal injury.

Do not try to light any appliance. Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions. If you cannot reach your gas supplier, call the fire department.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

Improper installation, adjustment, alteration, service, or

maintenance can cause injury or property damage. Refer to this manual. For assistance or additional information, consult a qualified installer, service agency, or

the gas supplier.

Disconnect gas piping from 48 Series units when leak

testing at pressures greater than 0.5 psig. Pressures greater

than 0.5 psig will cause gas valve damage resulting in

a hazardous condition. If gas valve is subjected to pressure greater than 0.5 psig, it must be replaced. When

pressure testing field-supplied gas piping at pressures of

0.5 psig or less, the unit connected to such piping must

be isolated by manually closing the gas valve.

GENERAL

This installation instruction contains base unit installation, start-up, and service instructions only. For complete information on PIC (Product Integrated Controls) and variableair volume (VAV) controls and troubleshooting, refer to

appropriate Controls and Troubleshooting literature also enclosed in this literature packet.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service personnel. When working on air-conditioning equipment, observe precautions in the literature, tags and labels attached

to the unit, and other safety precautions that may apply.

Follow all safety codes, including ANSI (American National Standards Institute) Z223.1. Wear safety glasses and

work gloves. Use quenching cloth for unbrazing operations.

Have fire extinguisher available for all brazing operations.

INSTALLATION

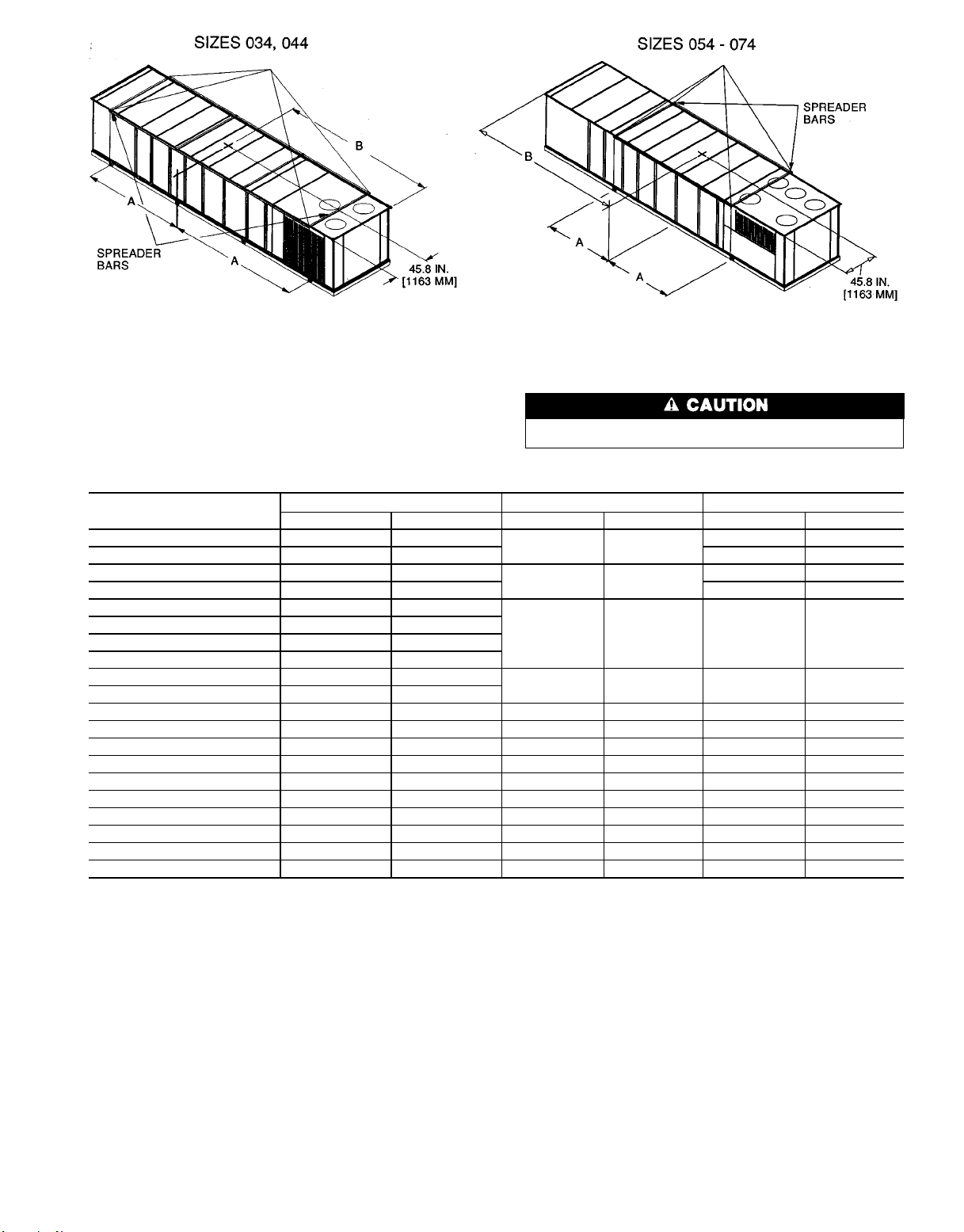

Riggingand UnitPlacement —

portation damage. File claim with transportation agency. Do

not drop unit; keep upright. Use spreader bars over unit to

prevent sling or cable damage. Sheets of plywood placed along

the condenser coils will provide additional protection. All

lifting lugs MUST be used when lifting unit. Level by using

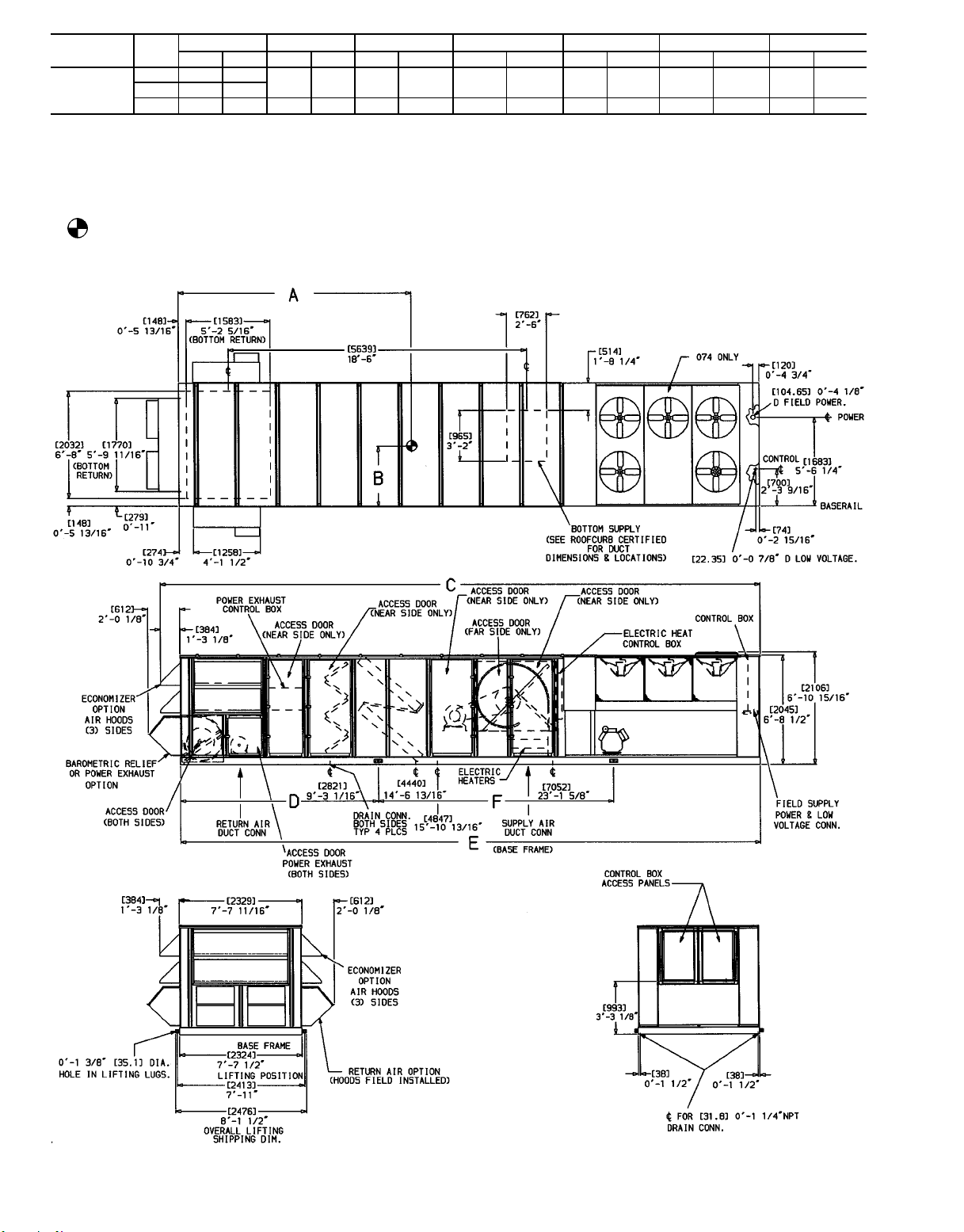

unit frame as a reference. See Fig. 1 for information. Unit

and accessory weights are shown in Tables 1A, 1B, and 2.

Weight distribution and center of gravity can be found in

Fig. 2.

Inspect unit for trans-

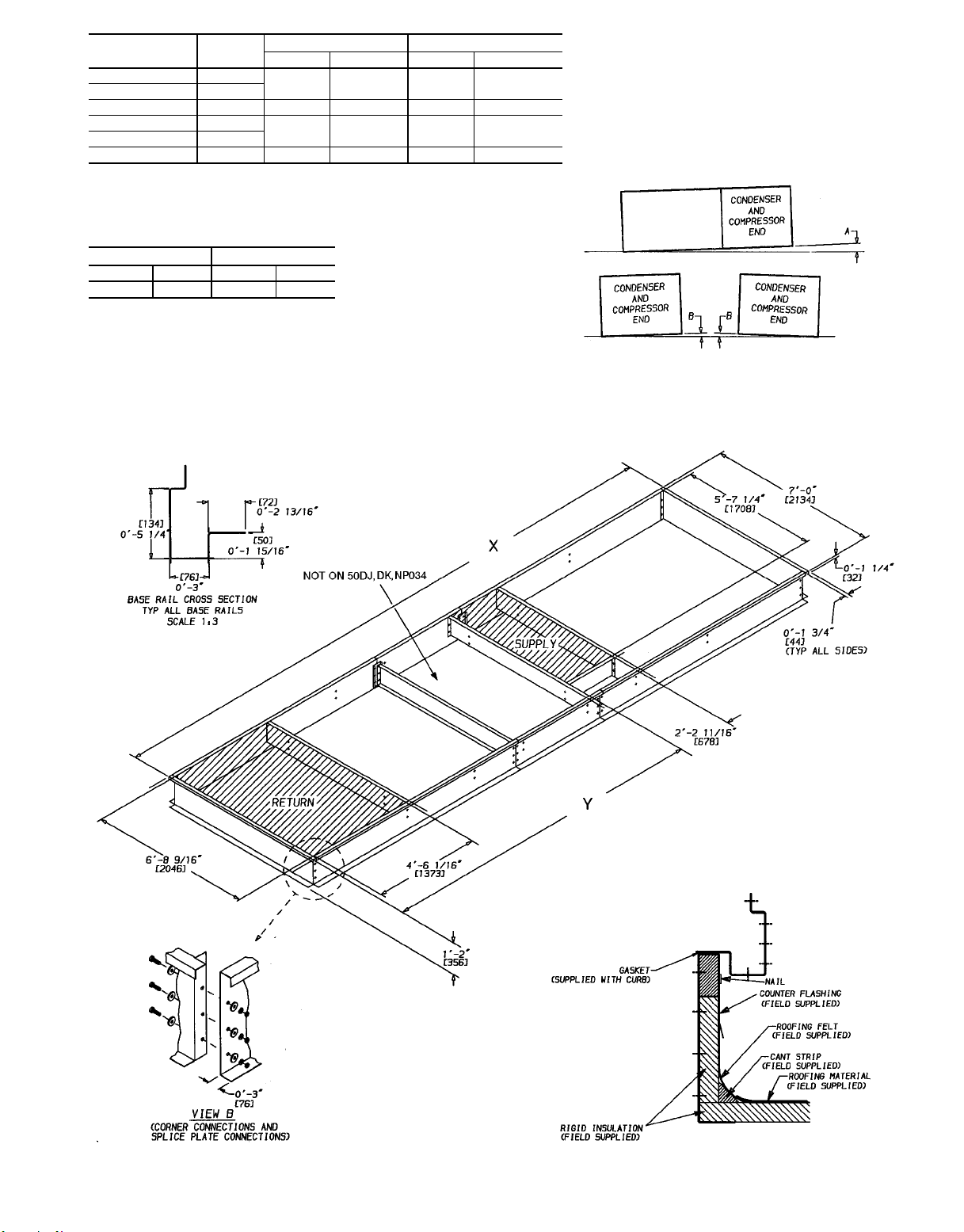

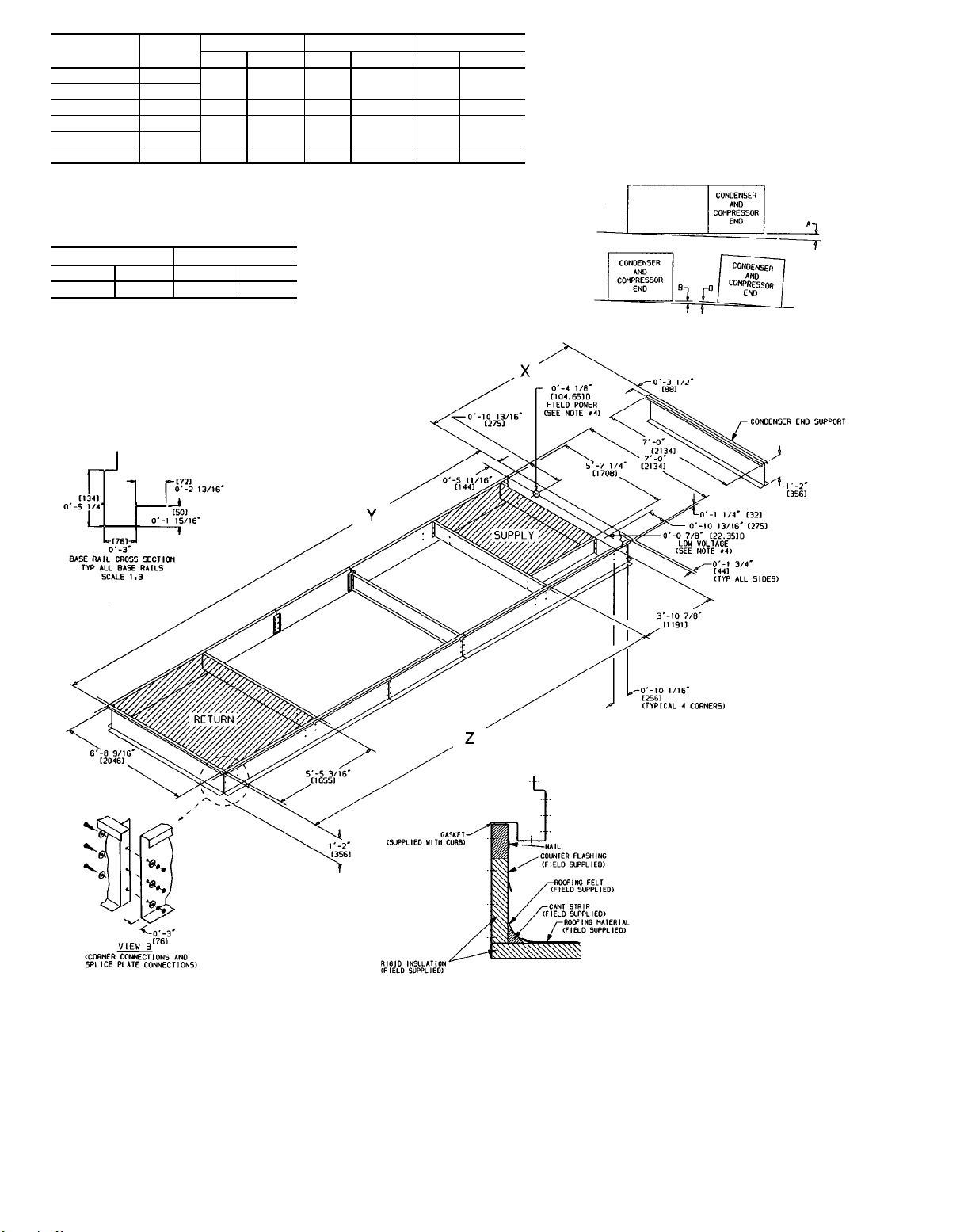

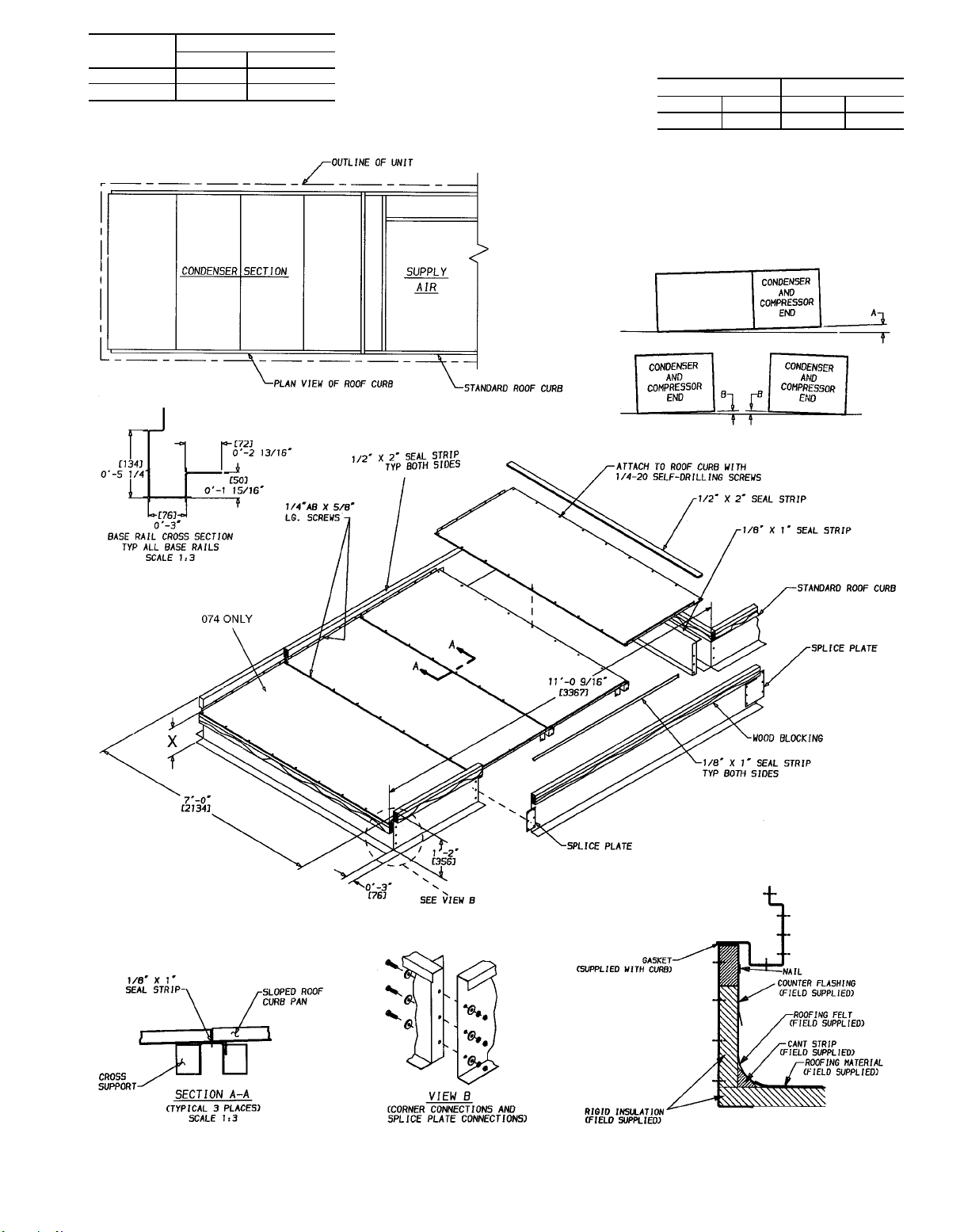

Roof Curb — Assemble and install as described in in-

structions shipped with the accessory. Accessory roof curb

and information required to field fabricate a roof curb is shown

in Fig. 3A-3C. Install insulation, cant strips, roofing and counter

flashing as required. For unit condensate drains to function

properly, curb must be level or within tolerances shown in

Fig. 3A-3C.

Roof Mount — Check building codes for weight distri-

bution requirements. Unit weight is shown in Tables 1A and

1B. Unit may be mounted on class A, B, or C roofing

material.

Slab Mount — Provide a level concrete slab that ex-

tends beyond unit cabinet at least 6 inches. Make a slab 8 in.

thick with 4 in. above grade. Use gravel apron in front of

condenser coil air inlet to prevent grass and foliage from obstructing airflow.

2

Page 3

NOTES:

1. Sizes 034,044:Rigwith4 cables and spread with two 95 in. (2413 mm) and

2 8A 1 A8 long spreader bars.

Sizes 054-074:Rigwith 4 cables and spread withfour 95 in. (2413 mm) and

2 8A 1 B 1 A8 long spreader bars.

2. Center of gravity includes economizer.

RIGGING WEIGHTS AND DIMENSIONS

1. All panels must be in place when rigging.

2. Unit is not designed for handling by forklift truck.

UNIT

48DJD,DKD,NPD034 5941 2694.8

48DJE,NPE034 6070 2753.4 110.4 2804

48DJD,DKD,NPD044 6841 3103.1

48DJE,NPE044 6970 3161.6 128.6 3267

48DJD,DKD,NPD054 9230 4186.7

48DJE,NPE054 9350 4241.2

48DJD,DKD,NPD064 9530 4322.8

48DJE,NPE064 9650 4377.2

48DJD,DKD,NPD074 9950 4513.3

48DJE,NPE074 10,080 4572.3

50DJ,DK,NP034 5700 2585.5 84.8 2153 120.8 3067

50DW,DY,NB034 6270 2844.1 76.4 1940 102.5 2604

50DJ,DK,NP044 6350 2880.4 92.6 2353 126.6 3216

50DW,DY,NB044 6920 3138.9 86.0 2185 108.4 2753

50DJ,DK,NP054 8230 3733.1 120.8 3066 126.8 3221

50DW,DY,NB054 8780 3982.6 109.0 2769 109.0 2769

50DJ,DK,NP064 8530 3869.2 120.9 3071 120.9 3071

50DW,DY,NB064 9080 4119.7 120.8 3066 126.8 3221

50DJ,DK,NP074 8960 4064.3 131.7 3345 137.6 3495

50DW,DY,NB074 9500 4309.2 109.0 2769 109.0 2769

*Includes optional economizer.

UNIT WEIGHT* A B

Lb Kg in. mm in. mm

86.0 2185

92.6 2353

121.5 3086 126.8 3221

134.7 3421 134.7 3421

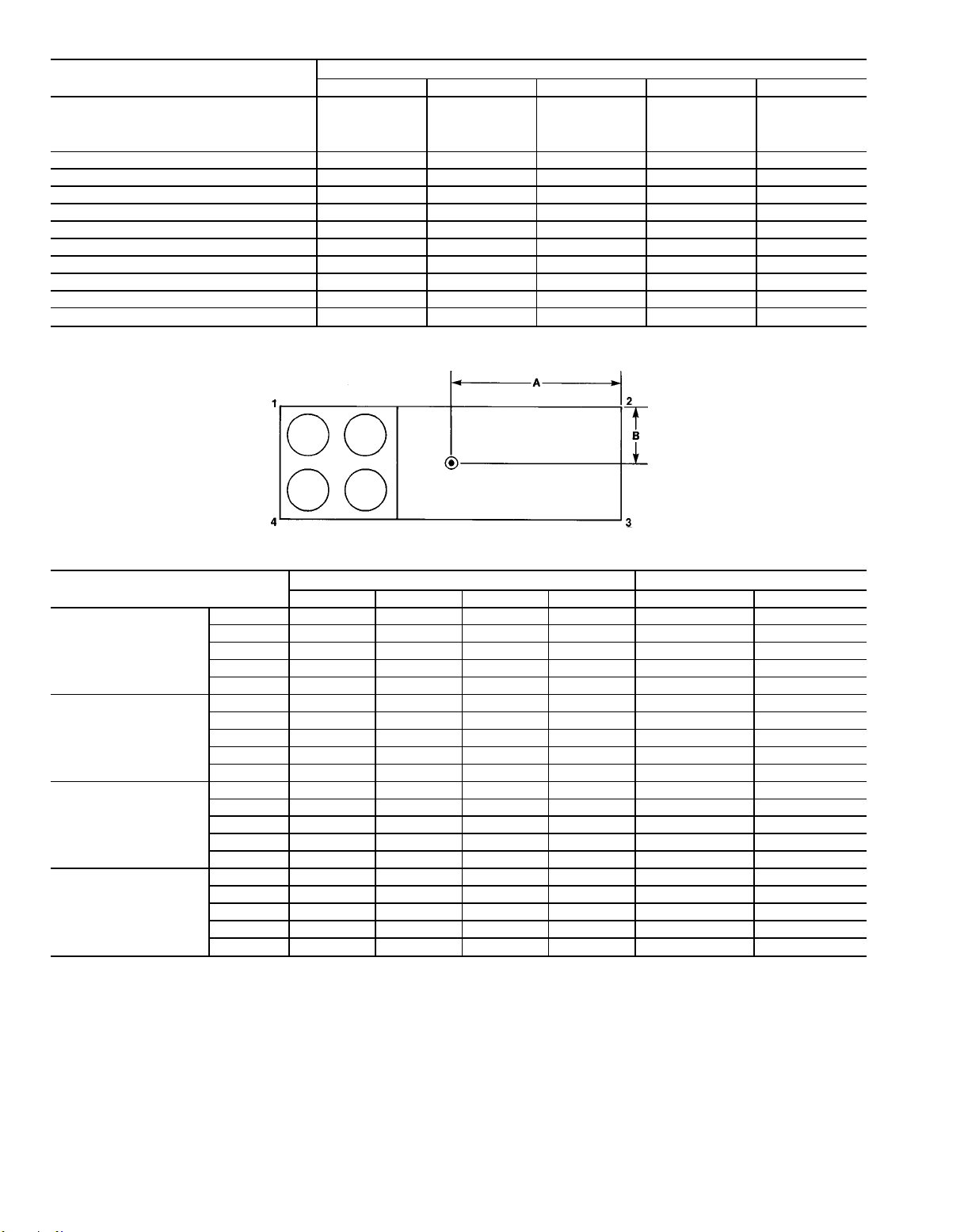

Fig. 1 — Rigging Label

109.4 2780

127.6 3240

If roof curb is not used, support unit with steel beams along

its entire length and then support steel as required.As a minimum, unit must be supported across its width at each lifting

lug location.

Positioning — Provideclearance around and above unit

for airflow,safety,and service access. Do not restrict top (area

above condenser fans) in any way. Allow at least 6 ft on all

sides for rated performance, code compliance, and service.

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated

air.

On units equipped with or power exhaust option, high velocity air is exhausted out the hoods. Unit should be positioned with at least 10 ft clearance between the exhaust hoods

and any obstruction. Although unit is weatherproof, guard

against water from higher level runoff and overhangs.

3

Page 4

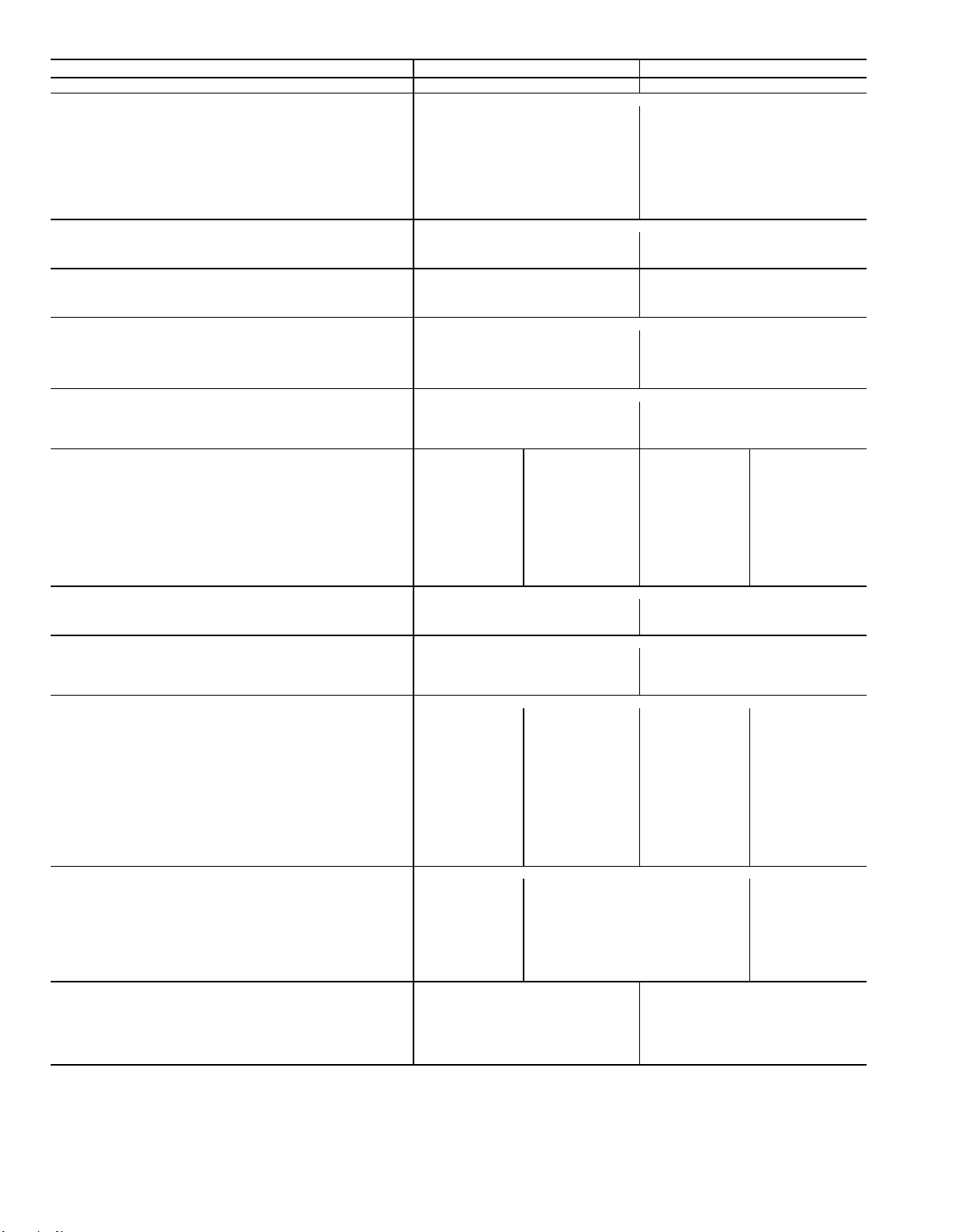

Table 1A — Physical Data; 034, 044 Units

BASE UNIT* 034 044

NOMINAL CAPACITY (tons) 30 40

OPERATING WEIGHT (lb)

Base Unit

48 Series, Low Heat 5641 6541

48 Series, High Heat

50 Series, Horizontal Discharge 5970 6620

50 Series, Vertical Discharge 5400 6050

With Economizer

48 Series, Low Heat 5941 6841

48 Series, High Heat 6070 6970

50 Series, Horizontal Discharge 6270 6920

50 Series, Vertical Discharge 5700 6350

COMPRESSORS

Quantity...Type 2...06D 2...06E

Capacity Steps (%) 17, 33, 50, 66, 83, 100 25, 50, 75, 100

Number of Refrigerant Circuits 22

REFRIGERANT

Operating Charge (lb), Sys 1/Sys 2

Without Hot Gas Bypass

With Hot Gas Bypass 31.0/29.0 42.0/40.0

CONDENSER COILS

Quantity 22

Rows...Fins/in.

Aluminum

Copper (Optional) 3...13.7 3...13.7

Total Face Area (sq ft) 37.5 50.0

EVAPORATOR COILS

Quantity

Rows...Fins/in. 3...15.0 3...15.0

Total Face Area (sq ft) 32.1 45.5

Refrigerant Feed Device...No. per Circuit TXV...1 TXV...2

HEATING SECTION (48 Series Units Only) Low Heat High Heat Low Heat High Heat

Number of Heat Exchangers

Input (MBtuh) 264 529 264 529

Output (MBtuh) 211 423 211 423

Temperature Rise Range (F) 0-30 15-45 0-30 15-45

Efficiency (%) 79 79 79 79

Burner Orifice Diameter

Quantity (in. ...drill no.) 6 (.1285...30) 12 (.1285...30) 6 (.1285...30) 12 (.1285...30)

Pilot Orifice Diameter

Quantity (in. ...drill no.) 1 (.076...48) 2 (.076...48) 1 (.076...48) 2 (.076...48)

Firing Stages 2222

Number of Gas Valves

CONDENSER FANS Propeller Type

Quantity...Diameter (in.) 2...30 3...30

Nominal Cfm 18,600 26,000

Motor Hp...Rpm 1.0...1140 1.0...1140

EVAPORATOR FAN Centrifugal 25 x 25 in.

Nominal Cfm 10,500 14,000

Maximum Allowable Cfm 15,000 20,000

Maximum Allowable Rpm 900 900

Shaft Diameter at Pulley (in.) 1

EVAPORATOR-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 7.5 10.0 15.0 20.0

Motor Frame Size 213T 215T 254T 256T

Efficiency at Full Load (%)

Standard Efficiency 82.9 85.6 84.5 87.5

High Efficiency† — 89.5 90.0 91.0

Fan Pulley Pitch Diameter (in.) 13.7 13.7 13.7 13.7

Motor Pulley Pitch Diameter (in.) 34.4 4.3 4.9 5.5

Resulting Fan Rpm 405 510 580 660

Belts Quantity...Model No.

48 Series and 50 Series, Horizontal Discharge 2...BX60 2...5VX630 2...5VX630 2...5VX630

50 Series, Vertical Discharge 2...BX60 2...5VX630 2...5VX630 2...5VX630

Center Distance Range (in.)

48 Series and 50 Series, Horizontal Discharge 17.74...14.30 17.74...14.30 17.63...14.01 17.63...14.01

50 Series, Vertical Discharge 19.86...15.87 19.86...15.87 19.04...15.00 19.04...15.00

OPTIONAL POWER EXHAUST Centrifugal, 15 x 15 in. (Any motor available on any unit)

Quantity...Motor Hp 2...3.0 2...5.0 2...7.5

Motor Frame Size 56HZ 184T 213T

Efficiency at Full Load (%) 81.0 84.0 82.9

Fan Pulley Pitch Diameter (in.) 6.9 6.9 6.9

Motor Pulley Pitch Diameter (in.) 3.35 4.12 5.0

Shaft Diameter at Pulley (in.) 1

Resulting Fan Rpm 843 1040 1264

Maximum Allowable Rpm 1300 1300 1300

Belts Quantity...No. 2...3VX670 2...3VX670 2...3VX710

FILTERS

Standard Efficiency Throwaway (Standard) 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 4...16 x 20 x 2 4...16 x 20 x 2

Medium Efficiency (30%) Pleated (Optional) 12...20 x 25 x 2 12...20 x 25 x 2

Quantity...Size (in.) 4...16 x 20 x 2 4...16 x 20 x 2

High Efficiency (90%) Bag Filters with Prefilters (Optional) 6...20 x 24 x 22 6...20 x 24 x 22

Quantity...Size (in.) 6...20 x 20 x 22 6...20 x 20 x 22

612612

1212

3

TXV — Thermostatic Expansion Valve

*Data is for all 48 and 50 Series units of the size listed unless otherwise specified.

†Not available on 575-v units.

5770 6670

Semi-Hermetic

29.0/29.0 40.0/40.0

3

⁄8-in. Tube Diameter

3...15.0 3...15.0

1

12

11

⁄

16

⁄

16

⁄2-in. Tube Diameter

13⁄

16

111⁄

16

13⁄

16

4

Page 5

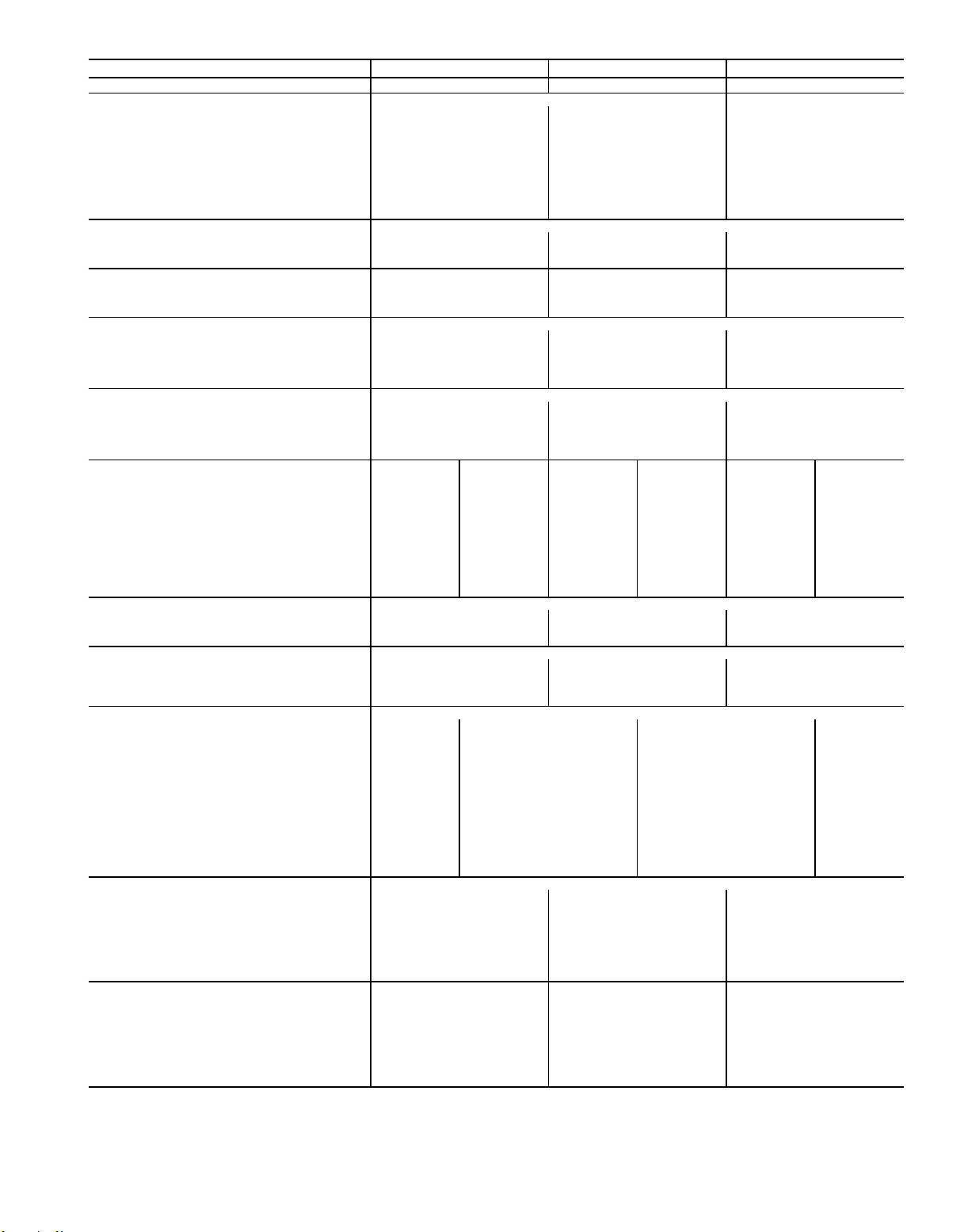

Table 1B — Physical Data; 054-074 Units

BASE UNIT* 054 064 074

NOMINAL CAPACITY (tons) 50 60 75

OPERATING WEIGHT (lb)

Base Unit

48 Series, Low Heat 8700 9000 9420

48 Series, High Heat 8820 9120 9550

50 Series, Horizontal Discharge 8250 8550 8970

50 Series, Vertical Discharge 7700 8000 8430

With Economizer

48 Series, Low Heat 9230 9530 9950

48 Series, High Heat 9350 9650 10,080

50 Series, Horizontal Discharge 8780 9080 9500

50 Series, Vertical Discharge 8230 8530 8960

COMPRESSORS Semi-Hermetic

Quantity...Type 2...06E 2...06E 2...06E

Capacity Steps (%) 20, 40, 60, 80, 100 17, 33, 50, 66, 83, 100 14, 28, 43, 71, 85, 100

Number of Refrigerant Circuits 222

REFRIGERANT

Operating Charge (lb), Sys 1/Sys 2

Without Hot Gas Bypass 59.0/44.5 61.0/61.0 70.5/64.5

With Hot Gas Bypass 62.0/44.5 64.0/61.0 73.5/64.5

CONDENSER COILS

Quantity 444

Rows...Fins/in.

Aluminum 2...17.0, 3...17.0 3...17.0 3...17.0

Copper (Optional) 2...15.7, 3...15.7 3...15.7 3...15.7

Total Face Area (sq ft) 72.4 72.4 108.4

EVAPORATOR COILS

Quantity 222

Rows...Fins/in. 3...17.0 4...17.0 4...17.0

Total Face Area (sq ft) 61.5 61.5 61.5

Refrigerant Feed Device...

No. per Circuit

HEATING SECTION (48 Series Units Only) Low Heat High Heat Low Heat High Heat Low Heat High Heat

Number of Heat Exchangers 12 18 12 18 12 18

Input (MBtuh) 540 810 540 810 540 810

Output (MBtuh) 432 648 432 648 432 648

Temperature Rise Range (F) 5-35 15-45 5-35 15-45 5-35 15-45

Efficiency (%) 80 80 80 80 80 80

Burner Orifice Diameter

Quantity (in. ...drill no.) 12 (.1285...30) 18 (.1285...30) 12 (.1285...30) 18 (.1285...30) 12 (.1285...30) 18 (.1285...30)

Pilot Orifice Diameter

Quantity (in. ...drill no.) 2 (.076...48) 3 (.076...48) 2 (.076...48) 3 (.076...48) 2 (.076...48) 3 (.076...48)

Firing Stages 222222

Number of Gas Valves 232323

CONDENSER FANS Propeller Type

Quantity...Diameter (in.) 4...30 4...30 5...30

Nominal Cfm 40,000 40,000 50,000

Motor Hp...Rpm 1.0...1140 1.0...1140 1.0...1140

EVAPORATOR FAN Centrifugal 30 x 27 in.

Nominal Cfm 17,500 21,000 24,500

Maximum Allowable Cfm 25,000 30,000 30,000

Maximum Allowable Rpm 750 750 750

Shaft Diameter at Pulley (in.) 1

EVAPORATOR-FAN MOTOR AND DRIVE (Any motor available on any unit)

Motor Hp 15.0 20.0 25.0 30.0

Motor Frame Size 254T 256T 284T 286T

Efficiency at Full Load (%)

Standard Efficiency 84.5 87.5 87.1 88.3

High Efficiency† 90.0 91.0 91.7 92.4

Fan Pulley Pitch Diameter (in.) 13.7 13.7 13.7 15.5

Motor Pulley Pitch Diameter (in.) 4.5 5.1 5.5 5.9

Resulting Fan Rpm 555 625 660 700

Belts Quantity...Model No.

48 Series and 50 Series, Horizontal Discharge 2...5VX1120 2...5VX1150 2...5VX1150 2...5VX1180

50 Series, Vertical Discharge 2...5VX1230 2...5VX1230 2...5VX1230 2...5VX1230

Center Distance Range (in.)

48 Series and 50 Series, Horizontal Discharge 48.25...44.00 48.25...44.00 48.50...44.25 48.50...44.25

50 Series, Vertical Discharge 44.25...39.75 44.25...39.75 44.00...40.00 44.00...40.00

OPTIONAL POWER EXHAUST Centrifugal, 18 x 15 in. (Any motor available on any unit)

Quantity...Motor Hp 2...5.0 2...7.5 2...10.0

Motor Frame Size 184T 213T 215T

Efficiency at Full Load (%) 84.0 82.9 85.6

Fan Pulley Pitch Diameter (in.) 10.6 10.6 10.6

Motor Pulley Pitch Diameter (in.) 4.5 5.0 5.6

Shaft Diameter at Pulley (in.) 1

Resulting Fan Rpm 740 820 920

Maximum Allowable Rpm 925 925 925

FILTERS

Standard Efficiency

Throwaway (Standard) 15...20 x 25 x 2 15...20 x 25 x 2 15...20 x 25 x 2

Quantity...Size (in.) 5...16 x 20 x 2 5...16 x 20 x 2 5...16 x 20 x 2

Medium Efficiency (30%) Pleated (Optional) 15...20 x 25 x 2 15...20 x 25 x 2 15...20 x 25 x 2

Quantity...Size (in.) 5...16 x 20 x 2 5...16 x 20 x 2 5...16 x 20 x 2

High Efficiency (90%) Bag Filters

with Prefilters (Optional) 6...20 x 24 x 22 6...20 x 24 x 22 6...20 x 24 x 22

Quantity...Size (in.) 6...24 x 24 x 22 6...24 x 24 x 22 6...24 x 24 x 22

TXV...2 TXV...2 TXV..2

11

⁄

16

7

⁄

16

TXV — Thermostatic Expansion Valve

*Data is for all 48 and 50 Series units of the size listed unless otherwise specified.

†Not available on 575-v units.

3

⁄8-in. Tube Diameter

1

⁄2-in. Tube Diameter

111⁄

16

17⁄

16

111⁄

17⁄

16

16

5

Page 6

Table 2 — Operating Weights of Options and Accessories

OPTION OR ACCESSORY

Roof Curb

Condenser Section Roof Curb — — 540 540 625

Economizer 300* 300* 530* 530* 530*

Power Exhaust 600* 600* 710* 710* 710*

Barometric Relief 200 200 200 200 200

High-Efficiency Filters 20 20 20 20 20

Bag filters 35 35 40 40 40

Hail Guard 120 150 145 145 210

Copper Condenser Coil Fins 180 235 235 235 420

Electric Heat† 150 150 150 150 150

Inlet Guide Vanes 95 95 115 115 115

*Includes hood.

†50 Series vertical discharge units.

48DJ,DK,NP

50DW,DY,NB

50DJ,DK,NP

034 044 054 064 074

450

450

380

480

480

465

UNIT SIZE

515

560

515

515

560

515

515

560

515

UNIT

034 1754 1213 1216 1758 14- 9 3- 8

044 2035 1382 1385 2039 17- 3 3- 8

48DJD,DKD,NPD

48DJE,NPE

50DW,DY,NB

50DJ,DK,NP

NOTE: Weights include economizer.

054 2334 2276 2281 2339 19- 7 3-10

064 2431 2328 2334 2437 19- 7 3-10

074 2452 2518 2523 2457 21- 0 3-10

034 1781 1251 1253 1785 14- 8 3-10

044 2057 1424 1428 2061 17- 2 3-10

054 2375 2295 2300 2380 19- 7 3-10

064 2393 2373 2378 2506 19- 7 3-10

074 2494 2541 2546 2499 21- 0 3-10

034 1864 1268 1271 1867 13- 3 3-10

044 2070 1387 1389 2074 15-10 3-10

054 2381 2005 2009 2385 19-10 3-10

064 2461 2074 2078 2467 19-10 3-10

074 2551 2194 2199 2556 21- 3 3-10

034 1674 1173 1175 1678 13- 9 3-10

044 1879 1292 1295 1884 16- 3 3-10

054 2090 2021 2025 2094 18- 2 3-10

064 2188 2073 2077 2192 18- 2 3-10

074 2212 2263 2269 2216 21- 3 3-10

UNIT CENTER OF GRAVITYAND CORNER WEIGHTS

CORNER WEIGHT (lb) DIMENSIONS (Ft-in.)

1234 A B

Fig.2—Weight Distribution and Center of Gravity

Field-FabricatedDuctwork — Units are designed for

vertical supply/return only.Field-fabricated ductwork should

be attached to the roof curb. Supply and return duct dimensions are shown in Fig. 3A-3C.

To attach ductwork to roof curb, insert duct approximately 10 to 11 in. up into roof curb. Connect ductwork to

14-gage roof curb material with sheet metal screws driven

from inside of the duct.

Secure all ducts to the building structure, using flexible

duct connectors between roof curb and ducts as required. Ducts

passing through an unconditioned space must be insulated

and covered with a vapor barrier. Outlet grilles must not lie

directly below unit discharge. The return duct must have a

90-degree elbow before opening into the building space if

unit is equipped with power exhaust.

Design supply duct strong enough to handle expected static

pressures.

6

Page 7

UNIT

MODEL

48DJ,DK,NP 034

50DW,DY,NB 034

UNIT

SIZE

mm ft-in. mm ft-in.

6606 21-8

50DJ,DK,NP 034 6131 20-1

48DJ,DK,NP 044

50DW,DY,NB 044

7825 25-8

50DJ,DK,NP 044 7344 24-1

UNIT LEVELING TOLERANCES

DIMENSIONS*

(degrees and inches)

AB

Deg in. Deg in.

1.0 2.0 .50 .75

*From edge of unit to horizontal.

XY

1

⁄

16

3

⁄

8

1

⁄

16

1

⁄

8

4056 13- 311⁄

3311 10-103⁄

4893 16- 05⁄

4141 13- 71⁄

16

8

8

16

NOTES:

1. Roof curb is shipped unassembled.

2. Roof curb: 14 gage (VA03-56) steel.

3. Dimensions in [ ] are millimeters.

NOTE: To prevent the hazard of stagnant water build-up in the

drain pan of the indoor-air section, unit can only be pitched as

shown.

Fig. 3A — Roof Curb; 034, 044 Units

7

Page 8

UNIT

MODEL

48DJ,DK,NP 054,064

50DW,DY,NB 054,064

UNIT

SIZE

mm ft-in. mm ft-in. mm ft-in.

2474 8-1

50DJ,DK,NP 054,064 2458 8-0

48DJ,DK,NP 074

50DW,DY,NB 074

3383 11-1

50DJ,DK,NP 074 3367 11-0

UNIT LEVELING TOLERANCES

DIMENSIONS*

(degrees and inches)

AB

Deg in. Deg in.

1.0 2.0 .50 .75

*From edge of unit to horizontal.

XY Z

3

⁄88476 27-911⁄166965 22-103⁄

3

⁄47444 24-51⁄

3

⁄168476 27-911⁄166965 22-103⁄

9

⁄167444 24-51⁄

16

16

5933 19- 59⁄

5933 19- 59⁄

16

16

16

16

NOTES:

1. Roof curb is shipped unassembled.

2. Roof curb: 14 gage (VA03-56) steel.

3. Dimensions in [ ] are millimeters.

4. Suggested hole location for field wiring

through roof curb (holes to be field drilled).

NOTE: To prevent the hazard of stagnant water build-up in the

drain pan of the indoor-air section, unit can only be pitched as

shown.

Fig. 3B — Roof Curb; 054-074 Units

8

Page 9

UNIT

SIZE

DIMENSION X

mm Ft-in.

054,064 270 0-10

074 255 0-101⁄

UNIT LEVELING TOLERANCES

DIMENSIONS*

5

⁄

8

16

Deg in. Deg in.

(degrees and inches)

AB

1.0 2.0 .50 .75

*From edge of unit to horizontal.

NOTE: To prevent the hazard of stagnant water

build-up in the drain pan of the indoor-air section,

unit can only be pitched as shown.

Fig. 3C — Condenser Section Roof Curb (054-074 Units Only)

9

Page 10

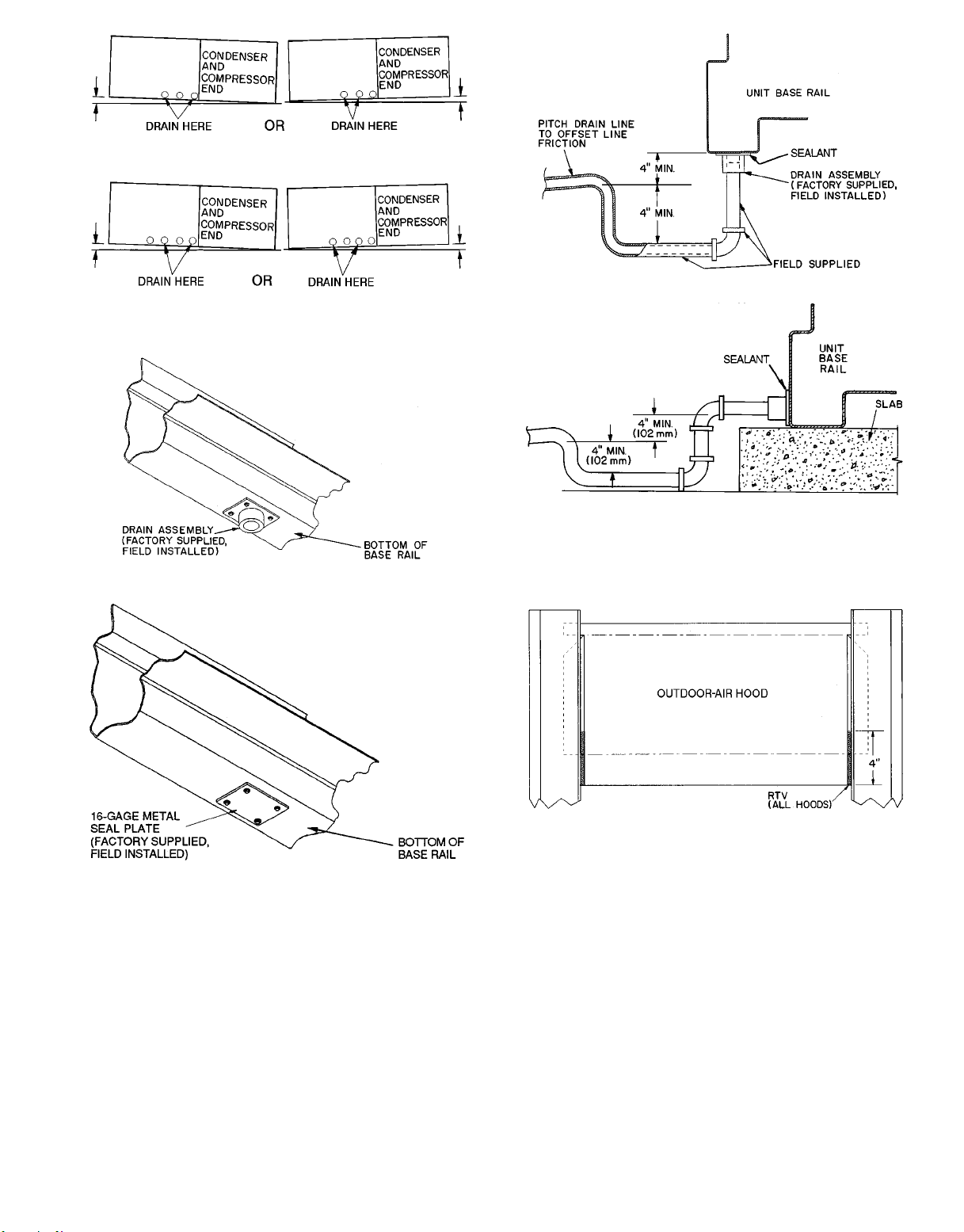

Condensate Drains — See Fig. 4A-4D and Fig. 5 for

drain locations. The drain assemblies, each consisting of a

10-gage plate with a 11⁄4-in. half coupling welded to it, are

shipped in the unit fan section. Also included are 16-gage

seal plates to cover the drain holes not being used. Open the

access door marked FANSECTION to find the drain assemblies, seal plates, and 4 screws for each mounting taped to

the unit basepan.

After the unit has been set in place on the roof:

1. Select the appropriate drain locations. The 034 units have

6 drain holes (3 per side), and the 044-074 units have 8

drain holes (4 per side). Two holes on each side must be

selected for condensate drains as shown in Fig. 5, and the

remaining holes must be sealed.

2. Remove the drain assemblies and attach them to the bottom of the unit base rails at the preferred drain locations

using the screws provided. See Fig. 6.

NOTE: Use a trap at least 4-in. deep.

3. Cover the remaining drain holes with the seal plates and

screws provided. See Fig. 7.

4. Apply a bead of RTV or similar sealant around the drain

assemblies and seal plates where they attach to the base

rail. See Fig. 8.

NOTE: If unit is slab mounted, holes will need to be drilled

in the side of the base rail and the holes factory-drilled in the

bottom of the base rail will need to be plugged.

Install Outdoor Hoods

UNIT SIZES 034 AND 044

25% Outdoor-Air Hoods (Units Without Economizer

Option)

1. Outdoor-air hoods are shipped bolted to the unit in a shipping position. Remove the 6 screws holding each 25% air

hood shipping cover in place.

2. Replace the 6 screws.

3. Remove the holddown screw from each upper corner of

each hood.

4. Pivot hoods outward (2 hoods total).

5. Install 17 screws around outside of each hood. (Screws

are in the fastener package taped to the basepan inside

the fan section.)

6. Apply a bead of RTV or similar sealant to corner of each

hood at pivot point to prevent water leaks. See Fig. 9.

Economizer Hoods (Units WithEconomizer Option) — Follow the same procedure described in 25% Outdoor-Air Hoods

section above.

UNIT SIZES 054-074

25% Outdoor-Air Hoods — The outdoor-air hoods are fac-

tory installed on the 054-074 units.

Economizer Hoods (Units With Economizer Option)

1. Remove the 6 screws holding each of the 4 economizer

shipping covers in place.

2. Replace the screws.

3. Remove the holddown screw from each upper corner of

each economizer hood.

4. Pivot hoods outward. (There is a total of 4 hoods.)

5. Install 18 screws, (5 each side, 6 top, and 2 bottom), around

the outside of each hood. (Screws are in the fastener package taped to the basepan inside the fan section.)

6. Apply a bead of RTV or similar sealant to corner of economizer hood at pivot point to prevent water leaks. (See

Fig. 9.)

Outdoor-Air Inlet Adjustments

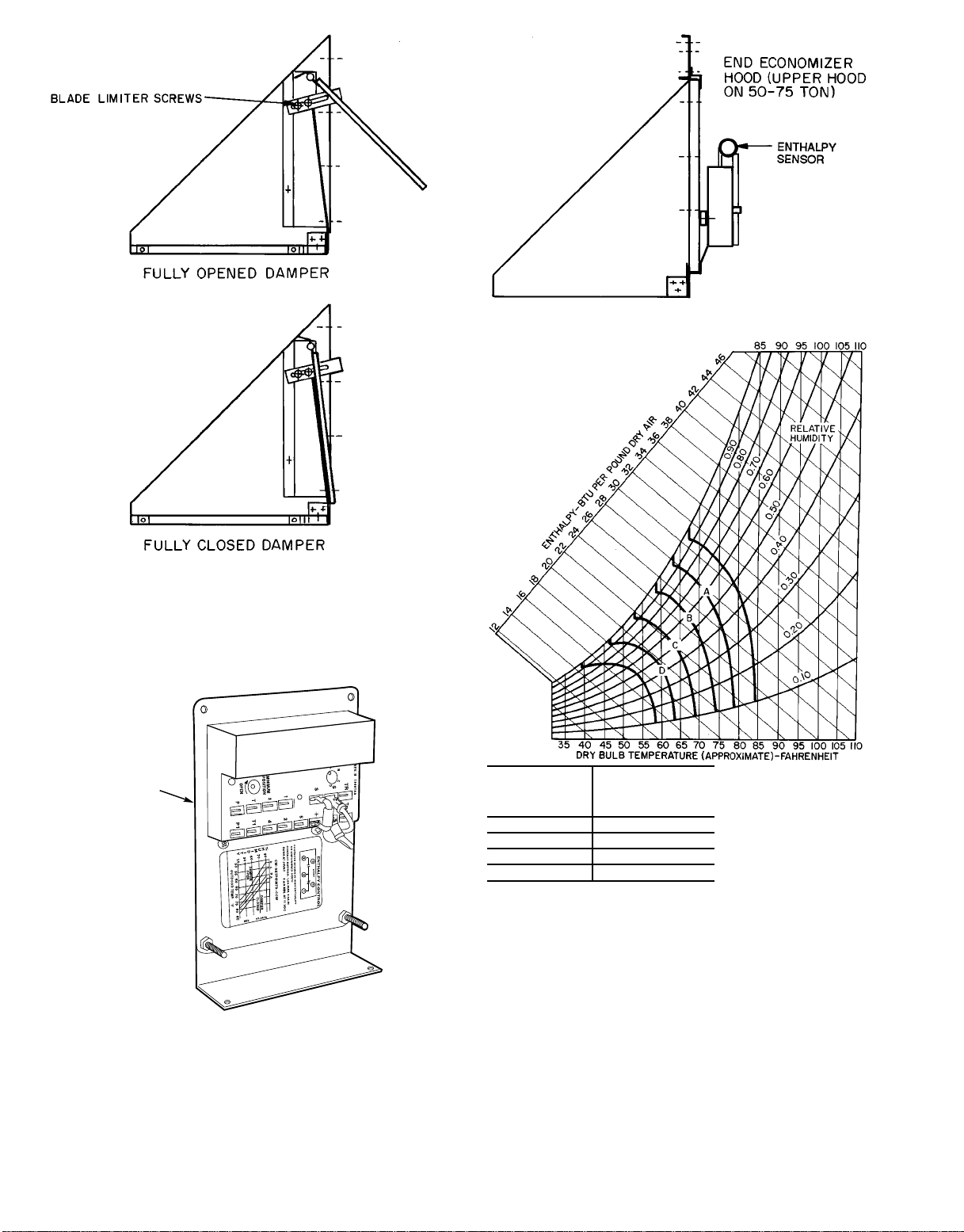

MANUALOUTDOOR-AIRDAMPER (Units WithoutEconomizer Option) —All units except those equipped with a factoryinstalled economizer have a manual outdoor-air damper to

provide ventilation air. This damper can be preset to admit

up to 25% outdoor air into the return-air compartment. To

adjust, loosen the blade limiter screws as shown in Fig. 10

and move the damper to the desired position. Then retighten

the blade limiter screws to secure the damper. See Fig. 10.

(T omake this adjustment, it is necessary to remove the screens

covering the hood opening and make adjustments from inside the hood.)

ECONOMIZER SETTINGS

Enthalpy Sensor (See Fig. 11.) — This sensor is located be-

hind the filters in the end economizer hood (the upper hood

on sizes 054-074). See Fig. 12. For maximum benefit of outdoor air, set enthalpy sensor control to the A setting. At this

setting, when the relative humidity is 50%, and the outdoor

air is below 74 F, the sensor’s relay contacts will be closed.

See Fig. 13 and 14.

NOTE: Enthalpy control setting dial is on the economizer

motor.

Mixed-Air Thermistor (MAT) — This control set point adjustment is on the top of the economizer motor. This motor

is located in the return-air section, and is accessed by opening the access panel marked FILTER SECTION. See

Fig. 15. Set MAT set point adjustment dial to the desired

setting. The factory setting is 55F±5°F;range is 40 to

90 F. The MAT is located on the filter rack.

Damper Vent Position — The position setting adjustment is

located on the cover of the economizer motor. See Fig. 15.

Adjust by setting the fan switch at ON position (continuous

fan operation), and setting the system selector switch to OFF

position. Then turn adjustment screw slowly until the dampers assume the desired vent position. Do not manually operate the damper motor; damage to the motor may result.

Economizer Damper Linkage Adjustment — When replacing economizer damper motors, or if the linkage has come

loose, it is critical that the linkages be adjusted correctly.

They are sensitive, and incorrect adjustment can cause the

motor to stall.

NB,NPUnitMinimum Position Set Point — Minimum economizer position is set using the keypad and display module.

Refer to Control and Troubleshooting literature for more

details.

10

Page 11

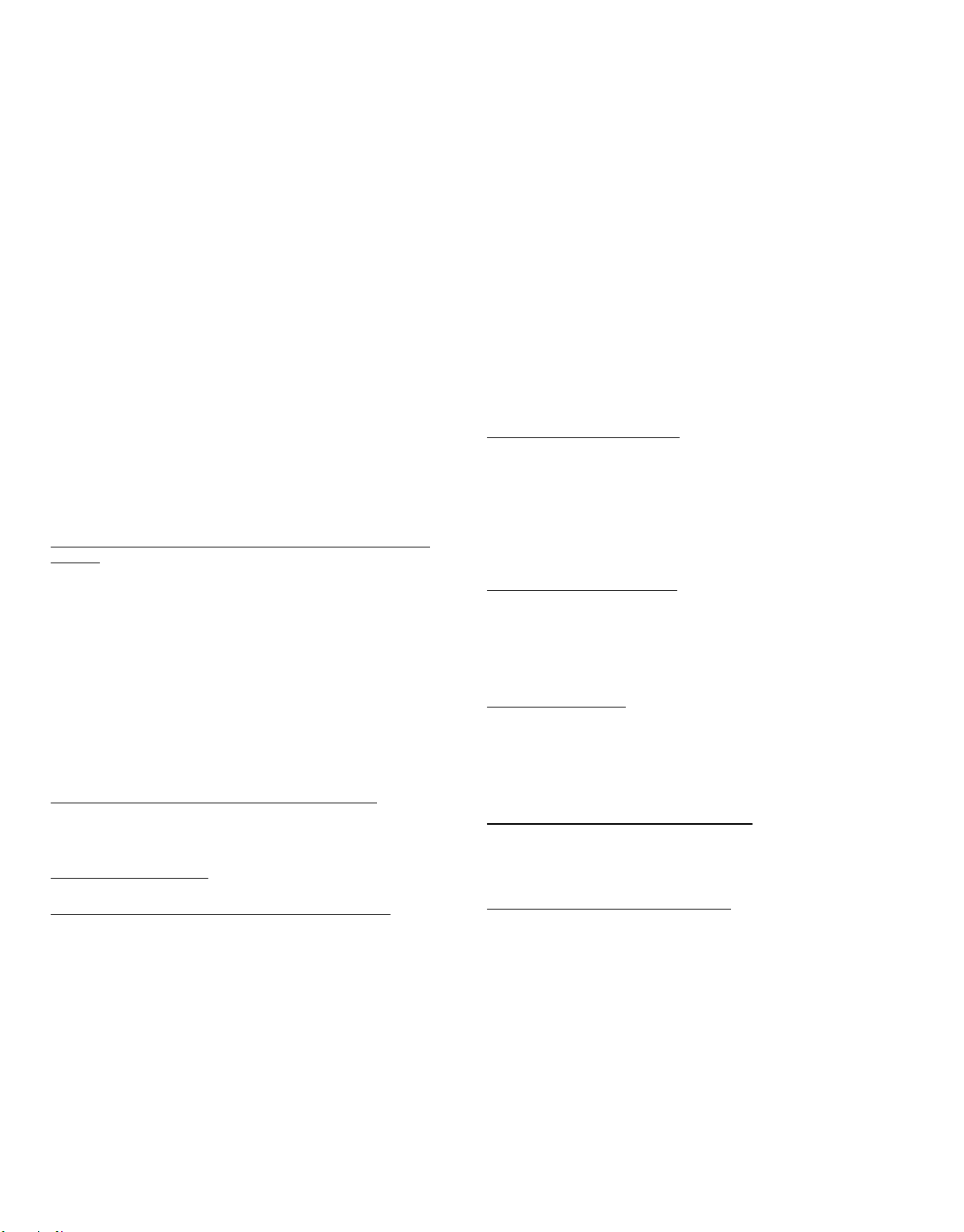

UNIT SIZE

48DJD,DKD,NPD

48DJE,NPE 5770 2617 4474 14-81⁄

WEIGHT A B C D E F G H J

lb kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

5641 2559 4498 14-9

034

50DW,DY,NB 5970 2708 4044 13-31⁄

48DJD,DKD,NPD

48DJE,NPE 6670 2708 5229 17-17⁄

6541 2967 5255 17-27⁄

044

50DW,DY,NB 6620 3003 4823 15-97⁄

UNIT SIZE

KL

mm ft-in. mm ft-in.

48DJD,DKD,NPD

48DJE,NPE

034 4741 15-6 6797 22-3

50DW,DY,NB

48DJD,DKD,NPD

48DJE,NPE

044 5576 8-3

1

⁄28015 26-39⁄

50DW,DY,NB

1

⁄

8

3662 12-03⁄167278 23-109⁄161709 5-75⁄162216 7- 31⁄44228 13-107⁄162746 9-01⁄8— — 3626 12-109⁄

8

4

8

4497 14-91⁄168496 27-101⁄22328 7-75⁄82091 6-105⁄164706 15-5 3363 11-03⁄83769 12-43⁄84762 15-71⁄

8

8

LEGEND

CONN — Connection

DIM — Dimension

NOTES:

1. Dimensions in [ ] are in millimeters.

5

⁄

8

2. Center ofGravity includeseconomizer.Unit weightdoes

not include economizer.

3. Unit clearances:

Top — Do not restrict condenser fans

16

Control Box End — 68-09

Sides — 68-09

Economizer End — 68-09 (except power exhaustunits 108-09)

Forsmaller service and operational clearances, contact Carrier Product Engineering Department.

4. Vertical discharge ducts designed to be attached to

accessory roof curb. If unit is mounted on dunnage,

support the ducts using cross bracesas doneon the

accessory roof curb.

5. When unit is slab mounted, locate the condensate

drain as low as possible on vertical face of base rail

atthe samelocation asthe standard condensatedrain

(usingfactory suppliedfitting). Plugfactory drilled condensate hole.

16

2

Fig. 4A — Base Unit Dimensional Drawing; 48DJ,DK,NP/50DW,DY,NB034,044 Units

11

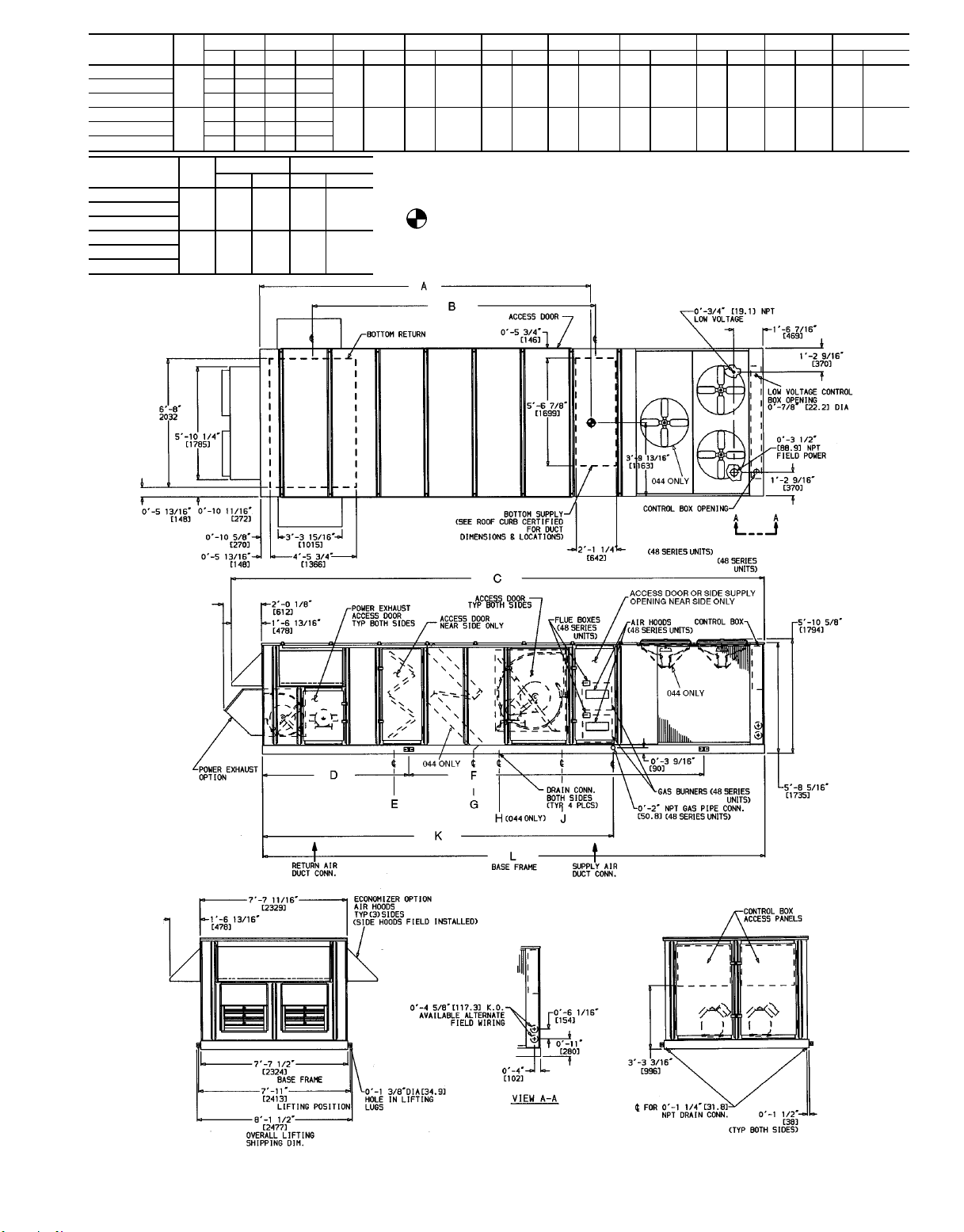

Page 12

UNIT SIZE

50DJ,DK,NP

UNIT SIZE

50DJ,DK,NP

WEIGHT A B C D E F G H

lb kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

034 5400 2449 4198 13-9

044 6050 2744 4948 16-2

JK

mm ft-in. mm ft-in.

034 4168 13-8

1

044 4999 16-413⁄167534 24-85⁄

1

⁄42916 9-613⁄166802 22-313⁄161711 5-73⁄82216 7- 31⁄44428 9-01⁄83762 12-43⁄8——

13

⁄163746 12-31⁄28015 26-39⁄162247 7-47⁄162091 6-105⁄163363 11-03⁄84306 14-11⁄23769 12-43⁄

⁄166321 20-87⁄

LEGEND

CONN — Connection

DIM — Dimension

NOTES:

8

1. Dimensions in [ ] are in millimeters.

8

2. Center of Gravity includes economizer. Unit

weight does not include economizer.

3. Unit clearances:

Top — Do not restrict condenser fans

Control Box End — 68-09

Sides — 68-09

EconomizerEnd —68-09 (except power exhaust units

108-09)

Forsmaller service and operational clearances, contact Carrier Product Engineering Department.

4. Vertical discharge ducts designed to be attached to

accessory roof curb. If unit is mounted on dunnage,

support the ducts using cross bracesas doneon the

accessory roof curb.

5. When unit is slab mounted, locate the condensate

drain as low as possible on vertical face of base rail

atthe samelocation asthe standard condensatedrain

(usingfactory suppliedfitting). Plugfactory drilled condensate hole.

8

Fig. 4B — Base Unit Dimensional Drawing; 50DJ,DK,NP034,044 Units

12

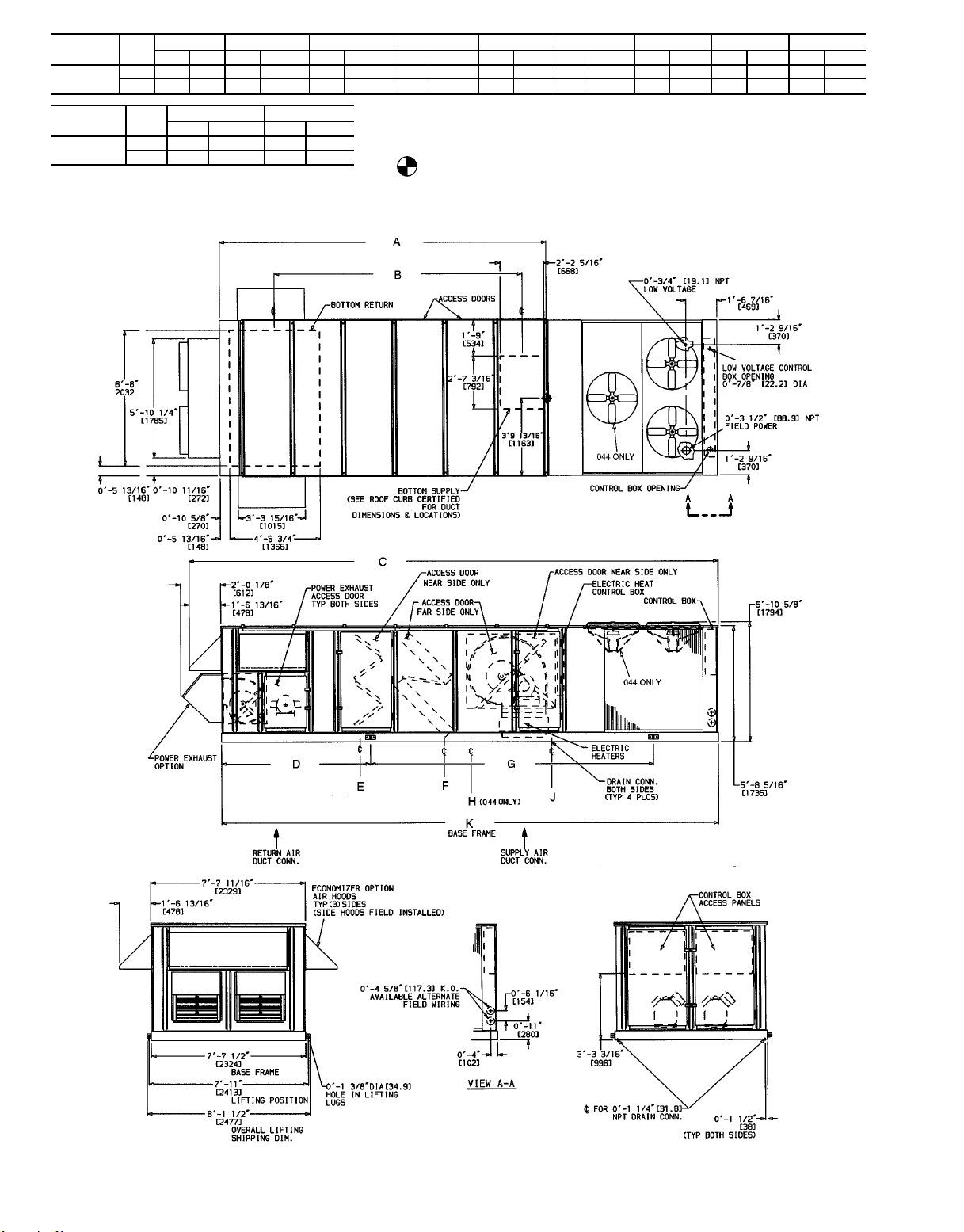

Page 13

UNIT SIZE

48DJD,DKD,NPD

48DJE,NPE 8820 4000

50DW,DY,NB 8250 3742 6045 19-10 7676 25-2

48DJD,DKD,NPD

48DJE,NPE 9120 4137

50DW,DY,NB 8550 3878 6045 19-10 7676 25-2

48DJD,DKD,NPD

48DJE,NPE 9550 4332

50DW,DY,NB 8970 4069 6477 21-3 7676 25-2

LEGEND

CONN — Connection

DIM — Dimension

*Dimension shown is for 48 series units. On 50 series units, dimension given is measured from

economizer end of unit to drain connection closest to condenser fans.

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of Gravity includes economizer. Unit weight does not include economizer.

3. Unit clearances:

Top — Do not restrict condenser fans

Control Box End — 68-09

Sides — 68-09 (except power exhaust units 108-09)

WEIGHT A B C D E F G

lb kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

054

064

074

8700 3946

9000 4082

9420 4273

5969 19-7 6717 22-0

5969 19-7 6717 22-0

6401 21-0 6717 22-0

7

⁄

16

1163 3-913⁄1611,524 37-911⁄

3

⁄

16

7

⁄

16

1163 3-913⁄1611,524 37-911⁄

3

⁄

16

7

⁄

16

1163 3-913⁄1612,433 40-91⁄

3

⁄

16

2718 8-11 6541 21-51⁄

16

2

11,140 36-69⁄

16

2830 9-33⁄46427 21-1

2718 8-11 6541 21-51⁄

16

2

11,140 36-69⁄

16

2830 9-33⁄46427 21-1

3543 11-71⁄25715 18-9

2

12,049 39-6

3

⁄

8

3694 12-13⁄45563 18-3

Economizer End — 68-09 (except power exhaust units 108-09)

For smaller service and operational clearances, contact Carrier Product Engineering

Department.

4. Verticaldischarge ductsdesigned tobe attachedto accessoryroof curb.If unitis mounted

on dunnage, support the ducts using cross braces as done on the accessory roof curb.

5. When unit is slab mounted, locate the condensate drain as low as possible on vertical

face of base rail at the same location as the standard condensate drain (using factory

supplied fitting). Plug factory drilled condensate hole.

Fig. 4C — Base Unit Dimensional Drawing; 48DJ,DK,NP/50DW,DY,NB054-074 Units

13

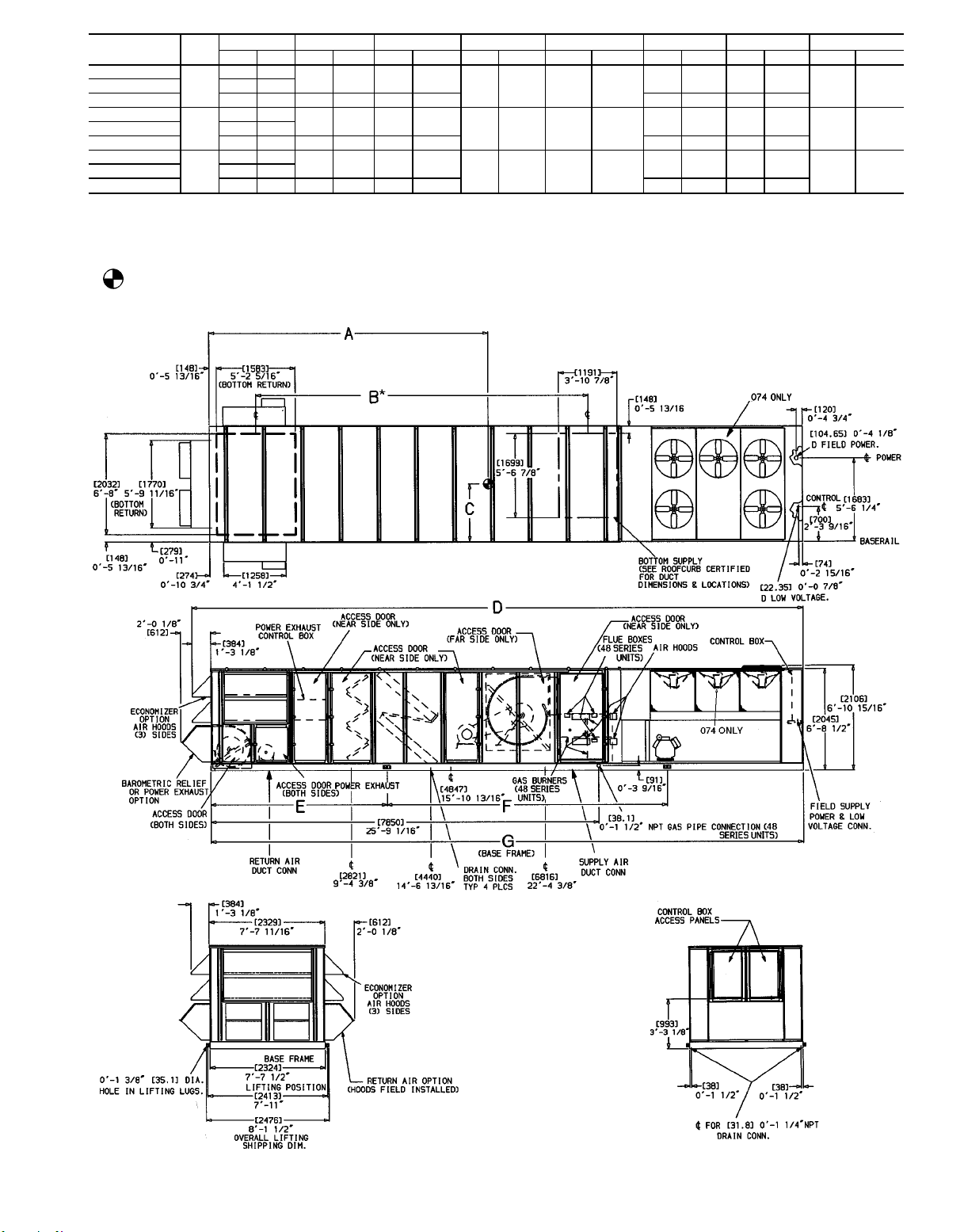

Page 14

UNIT SIZE

50DJ,DK,NP

054 7700 3493

064 8000 3629

Weight A B C D E F

Lb Kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

5537 18-2 1163 3-9

074 8430 3824 5969 21-3 1163 3-9

LEGEND

CONN — Connection

DIM — Dimension

*Dimension shown is for 48 series units. On 50 series units, dimension given

is measured from economizer end of unit to drain connection closest to condenser fans.

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of Gravity includes economizer. Unit weight does not include

3. Unit clearances:

economizer.

Top — Do not restrict condenser fans

Control Box End — 68-09

Sides — 68-09 (except power exhaust units 108-09)

13

⁄1610,476 34-47⁄162864 9-43⁄410,092 33-15⁄165347 17-61⁄

13

⁄1611,385 37-41⁄43727 12-23⁄411,001 36-11⁄84483 14-81⁄

Economizer End — 68-09 (except power exhaust units 108-09)

For smallerservice and operational clearances, contactCarrier Product Engineering Department.

4. Verticaldischarge ducts designed to be attached to accessory roof curb. If

unit is mounted on dunnage, support the ducts using cross braces as done

on the accessory roof curb.

5. When unit is slab mounted, locate the condensate drain as low as possible

on vertical face of base rail at the same location as the standard condensate drain (using factory supplied fitting). Plug factory drilled condensate

hole.

2

2

Fig. 4D — Base Unit Dimensional Drawing; 50DJ,DK,NP054-074 Units

14

Page 15

034 UNITS

044-074 UNITS

Fig. 5 — Drain Location Selection

Fig. 6 — Condensate Drain Location

ROOF MOUNT DRAIN

SLAB MOUNT DRAIN

Fig. 8 — Condensate Drain Piping Details

Fig. 7 — Seal Plate Location

Fig. 9 — Outdoor-Air Hood

15

Page 16

Fig. 12 — Enthalpy Sensor Location

Fig. 10 — Outdoor-Air Damper Adjustments

(Inside of Hood Shown)

ENTHALPY

SENSOR

O

CONTROL

CURVE

A 73

B 68

C 63

D 58

CONTROL

POINT

(Approx Deg)

AT 50% RH

Fig. 13 — Psychrometric Chart for

Enthalpy Control

Fig. 11 — Enthalpy Sensor

16

Page 17

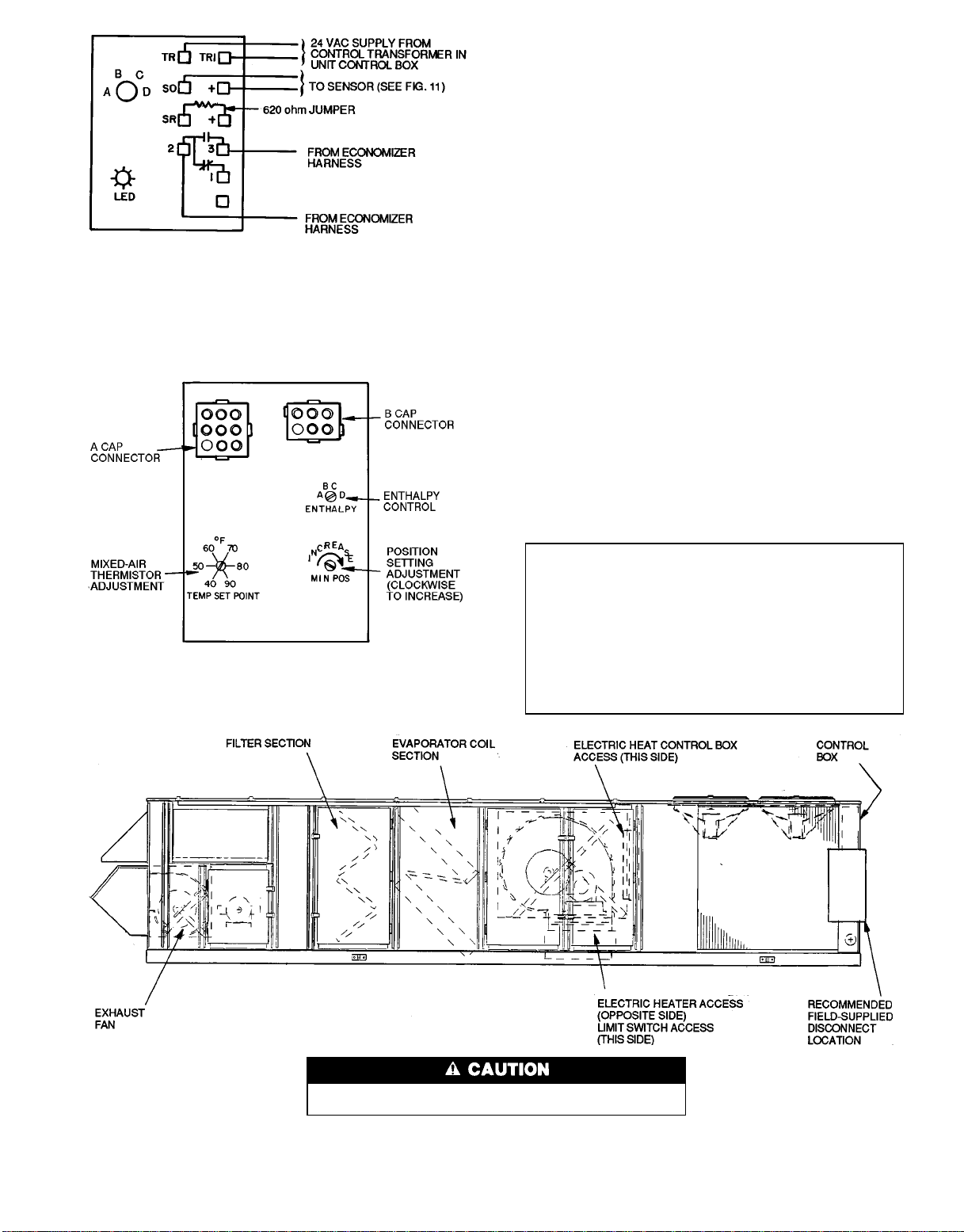

NOTES:

1. Switches shown in high enthalpy state. Terminals 2 and 3 close

on enthalpy decrease.

2. When standard economizer is used with accessory differential enthalpy sensor, set enthalpy control to ‘‘D’’ setting.

Fig. 14 — Wiring Connections for Solid-State

Enthalpy Sensor (HH57AC077)

Fig. 15 — Mixed-Air Thermistor and Economizer

Position Setting Adjustments

(Top of Economizer Motor)

Field Wire Routing

UNIT SIZES 034 AND 044 — Field wiring can be brought

into the unit through the basepan and roof curb or through

the corner post in the side of the unit next to the control box.

A 3-1/2 in. NPT coupling for field power and a 3/4-in.

NPT coupling for 24 v control wiring are provided in the

basepan. There are two 4-5/8 in. knockouts in the corner post

for field power wiring.

If field power wiring is brought through the roof curb, route

wiring out through one of the 4-5/8 in. knockouts to the fieldsupplied disconnect and then back into the unit through the

other knockout. See Fig. 16 for recommended disconnect

location.

If power wiring is brought through the side of the unit,

route wiring from field-supplied disconnect through top

4-5/8 in. knockouts into unit.

If control wiring is to be brought in through the side of the

unit, a 7/8-in. diameter hole must be drilled in the corner

post next to the control box.

UNIT SIZES 054-074 — Field wiring is brought into the

unit through the bottom of the control box. Wiring can be

brought through the roof curb through field-supplied watertight connections. See Fig. 17.

A 4-5/32 in. hole for field power wiring and a 7/8-in. hole

for 24 v control wiring are provided in the bottom of the

control box. Field-supplied couplings must be used when routing wiring into the control box.

See Fig. 17 for recommended disconnect location.

Field Electrical Connections

IMPORTANT: The 48/50DK,DY,NB,NP units generate, use, and can radiate radio frequency energy. If units

are not installed and used in accordance with these

instructions, they may cause radio interference. They

have been tested and found to comply with limits of a

Class A computing device as defined by FCC (Federal

Communications Commission) regulations, Subpart J

of Part 15, which are designed to provide reasonable

protection against such interference when operated in

a commercial environment.

Use care when drilling into corner post to avoid damage to condenser coil.

Fig. 16 — Disconnect Location, 034 and 044 Units

(50 Series Vertical Discharge Unit Shown)

17

Page 18

Use care when drilling into corner post to avoid damage to condenser coil.

Fig. 17 — Disconnect Location, 054-074 Units

(50 Series Horizontal Discharge Shown)

POWER WIRING — Units are factory wired for the voltage

shown on the unit nameplate. The main terminal block is

suitable for use with aluminum or copper wires. Maximum

wire size is 3/0 AWG (American Wire Gage).

When installing units, provide a disconnect per NEC

(National Electrical Code) of adequate size (MOCP [Maximum Overcurrent Protection] of unit is on the informative

plate). All field wiring must comply with NEC and all local

codes. Size wire based on MCA (Minimum Circuit Amps)

on the unit informative plate. See Fig. 18 for power wiring

connections to the unit power terminal block and equipment

ground.

Operating voltage to the compressor must be within the

voltage range indicated on the unit nameplate. Voltages between phases must be balanced within 2%, and the current

must be balanced within 10%. See Tables 3-7 for unit electrical data.

LEGEND

EQUIP — Equipment

GND — Ground

NEC — National Electrical Code

TB — Terminal Block

Fig. 18 — Field Power Wiring Connections

Use the following formula to determine the percent

voltage imbalance.

% Voltage Imbalance

= 100 x

max voltage deviation from average voltage

average voltage

Example: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

452 1 464 1 455

3

1371

=

3

457

=

Determine maximum deviation from average voltage:

(AB) 457 – 452=5v

(BC) 464 – 457=7v

(AC) 457 – 455=2v

Maximum deviation is 7 v.

Determine percent voltage imbalance:

% Voltage Imbalance = 100 x

7

457

= 1.53%

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance

is more than 2%, contact local utility immediately.

Unit failure as a result of operation on improper line voltage or excessive phase imbalance constitutes abuse and may

cause damage to electrical components.

18

Page 19

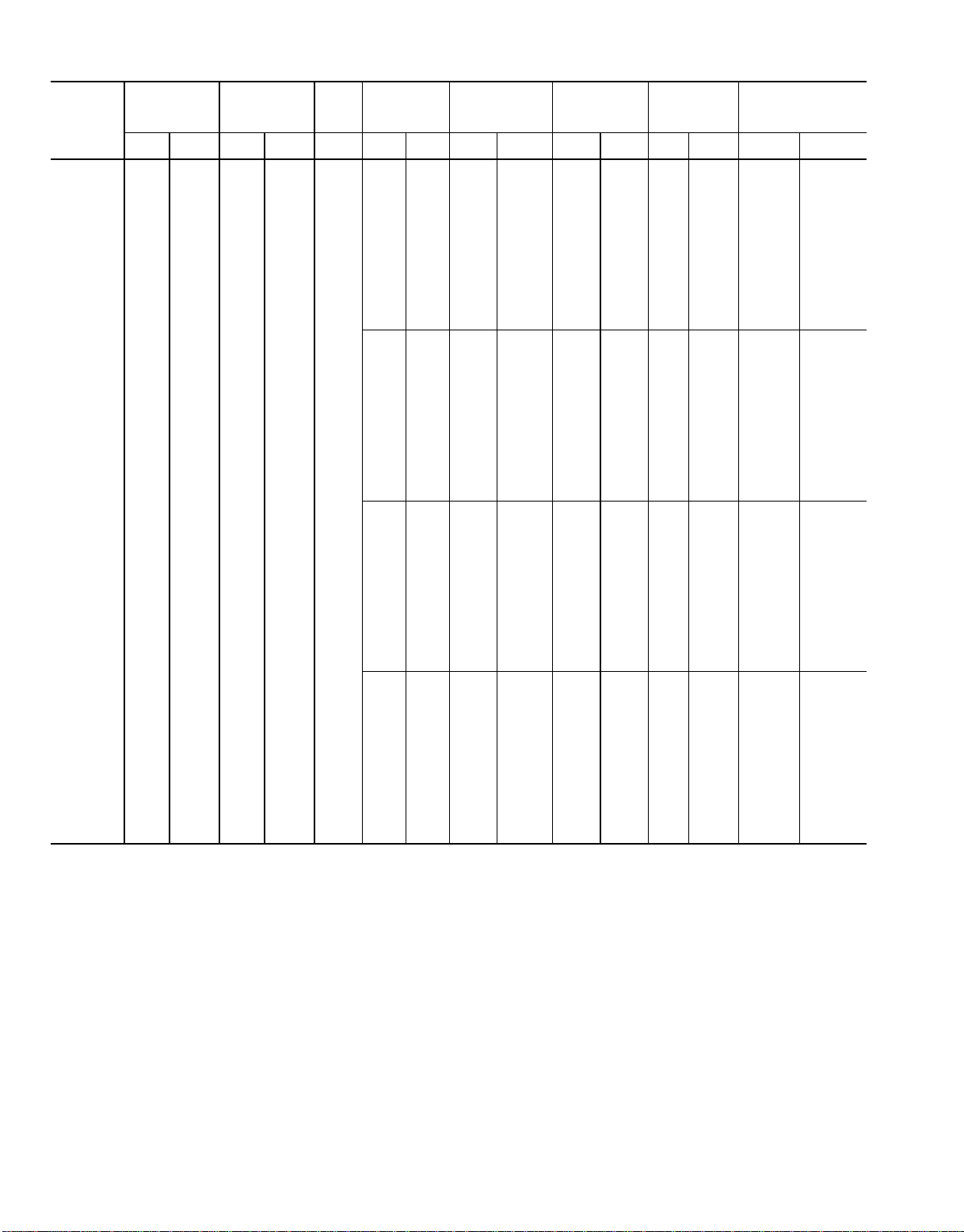

Table 3 — Electrical Data, 034 Units

COMPR

VOLTAGE

RANGE

187-254 53.2 266.0 53.2 266.0 10.8

CV — Constant Volume

ETL — ETL Testing Laboratory

FLA — Full Load Amps

Hp — Nominal Horsepower

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (for wire sizing)

MOCP — Maximum Overcurrent Protection

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Electric heat available on 50 Series vertical discharge units.

†108 kW available on CV applications only.

NO. 1

RLA LRA RLA LRA

LEGEND

COMPR

NO. 2

OFM IFM

Total

FLA

10.0

15.0

20.0

208/230-3-60 (V-Ph-Hz)

BASE UNIT

ONLY

Hp FLA MCA MOCP

24.2/

7.5

22.0

30.8/

28.0

46.2/

42.0

59.4/

54.0

154.7/

152.5

161.3/

158.5

176.7/

172.5

191.4/

184.7

200/

200

200/

200

225/

225

250/

225

EXHAUST

FAN

TotalHpTotal

10.0 33.4/30.0 — — 188.1/182.5 225/225

15.0 48.4/44.0 — — 203.1/196.5 250/225

10.0 33.4/30.0 29/ 36 78.9/ 91.0 188.1/182.5 225/225

10.0 33.4/30.0 59/ 72 157.7/182.0 227.4/255.0 250/300

10.0 33.4/30.0 88/108† 236.6/273.0 326.0/368.8 350/400

15.0 48.4/44.0 29/ 36 78.9/ 91.0 203.1/196.5 250/225

15.0 48.4/44.0 59/ 72 157.7/182.0 227.4/255.0 250/300

15.0 48.4/44.0 88/108† 236.6/273.0 326.0/368.8 350/400

10.0 33.4/30.0 — — 194.7/188.5 225/225

15.0 48.4/44.0 — — 209.7/202.5 250/250

10.0 33.4/30.0 29/ 36 78.9/ 91.0 194.7/188.5 225/225

10.0 33.4/30.0 59/ 72 157.7/182.0 235.6/262.5 250/300

10.0 33.4/30.0 88/108 236.6/273.0 334.2/376.3 350/400

15.0 48.4/44.0 29/ 36 78.9/ 91.0 209.7/202.5 250/250

15.0 48.4/44.0 59/ 72 157.7/182.0 235.6/262.5 250/300

15.0 48.4/44.0 88/108† 236.6/273.0 334.2/376.3 350/400

10.0 33.4/30.0 — — 210.1/202.5 250/250

15.0 48.4/44.0 — — 225.1/216.5 250/250

10.0 33.4/30.0 29/ 36 78.9/ 91.0 210.1/202.5 250/250

10.0 33.4/30.0 59/ 72 157.7/182.0 254.9/280.0 300/350

10.0 33.4/30.0 88/108 236.6/273.0 353.5/393.8 400/400

15.0 48.4/44.0 29/ 36 78.9/ 91.0 225.1/216.5 250/250

15.0 48.4/44.0 59/ 72 157.7/182.0 254.9/280.0 300/350

15.0 48.4/44.0 88/108† 236.6/273.0 353.5/393.8 400/400

10.0 33.4/30.0 — — 224.8/214.7 250/250

15.0 48.4/44.0 — — 239.9/228.7 250/250

10.0 33.4/30.0 29/ 36 78.9/ 91.0 224.8/214.7 300/300

10.0 33.4/30.0 59/ 72 157.7/182.0 271.4/295.0 350/350

10.0 33.4/30.0 88/108† 236.6/273.0 370.0/408.8 450/450

15.0 48.4/44.0 29/ 36 78.9/ 91.0 239.9/228.7 300/300

15.0 48.4/44.0 59/ 72 157.7/182.0 271.4/295.0 350/350

15.0 48.4/44.0 88/108† 236.6/273.0 370.0/408.8 450/450

NOTES:

1. Electric resistance heaters are rated at 208/240 v, 480 v, or 575 v. To

determine heater capacity (kW) at unit operating voltage, multiply 240 v,

480 v, or 575 v capacity by appropriate multiplier below.

2. Boldface indicates 48 and 50 Series units. All other data is for 50 Series

units only.

FLA

6.0 21.2/20.0 — — 175.9/172.5 225/225

— — 29/ 36 78.9/ 91.0 154.7/152.5 200/200

— — 59/ 72 157.7/182.0 227.4/255.0 250/300

— — 88/108† 236.6/273.0 326.0/368.8 350/400

6.0 21.2/20.0 29/ 36 78.9/ 91.0 175.9/172.5 225/225

6.0 21.2/20.0 59/ 72 157.7/182.0 227.4/255.0 250/300

6.0 21.2/20.0 88/108† 236.6/ 273.0 326.0/368.8 350/400

6.0 21.2/20.0 — — 182.5/178.5 225/225

— — 29/ 36 78.9/ 91.0 161.3/158.5 200/200

— — 59/ 72 157.7/182.0 235.6/262.5 250/300

— — 88/108† 236.6/273.0 334.2/376.3 350/400

6.0 21.2/20.0 29/ 36 78.9/ 91.0 182.5/178.5 225/225

6.0 21.2/20.0 59/ 72 157.7/182.0 235.6/262.5 250/300

6.0 21.2/20.0 88/108† 236.6/273.0 334.2/376.3 350/400

6.0 21.2/20.0 — — 197.9/192.5 250/225

— — 29/ 36 78.9/ 91.0 176.7/172.5 250/250

— — 59/ 72 157.7/182.0 254.9/280.0 300/350

— — 88/108† 236.6/273.0 353.5/393.8 400/400

6.0 21.2/20.0 29/ 36 78.9/ 91.0 197.9/192.5 250/250

6.0 21.2/20.0 59/ 72 157.7/182.0 254.9/280.0 300/350

6.0 21.2/20.0 88/108† 236.6/273.0 353.5/393.8 400/400

6.0 21.2/20.0 — — 212.6/204.7 250/250

— — 29/ 36 78.9/ 91.0 191.4/184.7 300/300

— — 59/ 72 157.7/182.0 271.4/295.0 350/350

— — 88/108† 236.6/273.0 370.0/408.8 450/450

6.0 21.2/20.0 29/ 36 78.9/ 91.0 212.6/204.7 300/300

6.0 21.2/20.0 59/ 72 157.7/182.0 271.4/295.0 350/350

6.0 21.2/20.0 88/108† 236.6/273.0 370.0/408.8 450/450

HEATER kW

RATING

240

480

575

Electric heaters are tested and ETL approved at maximum

total external static pressure of 1.9 in. wg.

ELECTRIC

HEAT*

kW FLA MCA MOCP

MULTIPLICATION FACTORS

VOLTAGE

DISTRIBUTION

V-3-60

200

208

230

240

440

460

480

550

575

600

BASE UNIT WITH

EXHAUST FAN

AND/OR

ELECTRIC HEAT*

MULTIPLICATION

FACTOR

0.694

0.751

0.918

1.000

0.840

0.918

1.000

0.915

1.000

1.089

19

Page 20

Table 3 — Electrical Data, 034 Units (cont)

460-3-60 (V-Ph-Hz)

COMPR

VOLTAGE

RANGE

414-508 28.8 120.0 28.8 120.0 5.4

NO. 1

RLA LRA RLA LRA

COMPR

NO. 2

OFM IFM

Total

Hp FLA MCA MOCP

FLA

7.5 11.0 81.2 100

10.0 14.0 84.2 110

15.0 21.0 91.2 110

20.0 27.0 97.2 125

BASE UNIT

ONLY

EXHAUST

FAN

TotalHpTotal

FLA

6.0 9.6 — — 90.8 110

10.0 15.2 — — 96.4 125

15.0 22.0 — — 103.2 125

— — 36 46.3 81.2 100

— — 72 93.0 130.0 150

— — 108† 139.0 187.5 200

6.0 9.6 36 46.3 90.8 110

6.0 9.6 72 93.0 130.0 150

6.0 9.6 108† 139.0 187.5 200

10.0 15.2 36 46.3 96.4 125

10.0 15.2 72 93.0 130.0 150

10.0 15.2 108† 139.0 187.5 200

15.0 22.0 36 46.3 103.2 125

15.0 22.0 72 93.0 130.0 150

15.0 22.0 108† 139.0 187.5 200

6.0 9.6 — — 93.8 110

10.0 15.2 — — 99.4 125

15.0 22.0 — — 106.2 125

— — 36 46.3 84.2 110

— — 72 93.0 133.7 150

— — 108† 139.0 191.2 200

6.0 9.6 36 46.3 93.8 110

6.0 9.6 72 93.0 133.7 150

6.0 9.6 108† 139.0 191.2 200

10.0 15.2 36 46.3 99.4 125

10.0 15.2 72 93.0 133.7 150

10.0 15.2 108† 139.0 191.2 200

15.0 22.0 36 46.3 106.2 125

15.0 22.0 72 93.0 133.7 150

15.0 22.0 108† 139.0 191.2 200

6.0 9.6 — — 100.8 125

10.0 15.2 — — 106.4 125

15.0 22.0 — — 113.2 125

— — 36 46.3 91.2 125

— — 72 93.0 142.5 175

— — 108† 139.0 200.0 200

6.0 9.6 36 46.3 100.8 125

6.0 9.6 72 93.0 142.5 175

6.0 9.6 108† 139.0 200.0 200

10.0 15.2 36 46.3 106.4 125

10.0 15.2 72 93.0 142.5 175

10.0 15.2 108† 139.0 200.0 200

15.0 22.0 36 46.3 113.2 125

15.0 22.0 72 93.0 142.5 175

15.0 22.0 108† 139.0 200.0 200

6.0 9.6 — — 106.8 125

10.0 15.2 — — 112.4 125

15.0 22.0 — — 119.2 125

— — 36 46.3 97.2 150

— — 72 93.0 150.0 200

— — 108† 139.0 207.5 225

6.0 9.6 36 46.3 106.8 150

6.0 9.6 72 93.0 150.0 200

6.0 9.6 108† 139.0 207.5 225

10.0 15.2 36 46.3 112.4 150

10.0 15.2 72 93.0 150.0 200

10.0 15.2 108† 139.0 207.5 225

15.0 22.0 36 46.3 119.2 150

15.0 22.0 72 93.0 150.0 200

15.0 22.0 108† 139.0 207.5 225

ELECTRIC

HEAT*

kW FLA MCA MOCP

BASE UNIT WITH

EXHAUST FAN

AND/OR

ELECTRIC HEAT*

20

Page 21

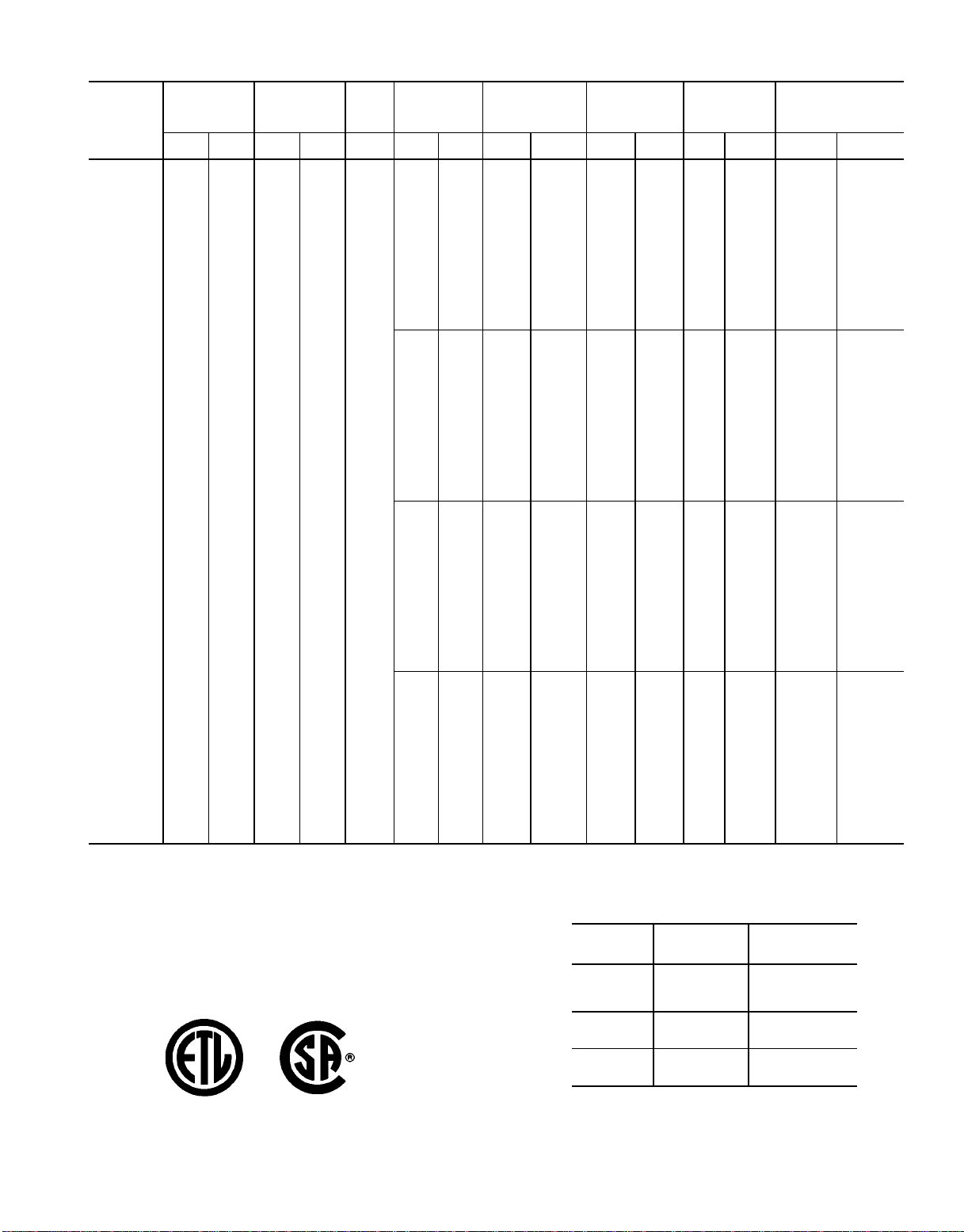

Table 3 — Electrical Data, 034 Units (cont)

575-3-60 (V-Ph-Hz)

COMPR

VOLTAGE

RANGE

518-632 23.1 96.0 23.1 96.0 4.8

CV — Constant Volume

ETL — ETL Testing Laboratory

FLA — Full Load Amps

Hp — Nominal Horsepower

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (for wire sizing)

MOCP — Maximum Overcurrent Protection

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Electric heat available on 50 Series vertical discharge units.

†108 kW available on CV applications only.

NO. 1

RLA LRA RLA LRA

LEGEND

COMPR

NO. 2

OFM IFM

Total

FLA

BASE UNIT

ONLY

Hp FLA MCA MOCP

7.5 9.0 65.8 80

10.0 11.0 67.8 90

15.0 17.0 73.8 90

20.0 22.0 78.8 100

NOTES:

1. Electric resistance heaters are rated at 208/240 v, 480 v, or 575 v. To

determine heater capacity (kW) at unit operating voltage, multiply 240 v,

480 v, or 575 v capacity by appropriate multiplier below.

2. Boldface indicates 48 and 50 Series units. All other data is for 50 Series

units only.

EXHAUST

FAN

TotalHpTotal

10.0 12.2 — — 78.0 100

15.0 18.0 — — 83.8 100

10.0 12.2 36 36.0 78.0 100

10.0 12.2 72 72.0 101.3 110

10.0 12.2 108† 108.0 146.2 150

15.0 18.0 36 36.0 83.8 100

15.0 18.0 72 72.0 101.3 110

15.0 18.0 108† 108.0 146.2 150

10.0 12.2 — — 80.0 100

15.0 18.0 — — 85.8 100

10.0 12.2 36 36.0 80.0 100

10.0 12.2 72 72.0 103.7 110

10.0 12.2 108† 108.0 148.7 150

15.0 18.0 36 36.0 85.8 100

15.0 18.0 72 72.0 103.7 110

15.0 18.0 108† 108.0 148.7 150

10.0 12.2 — — 86.0 100

15.0 18.0 — — 91.8 110

10.0 12.2 36 36.0 86.0 100

10.0 12.2 72 72.0 111.2 125

10.0 12.2 108† 108.0 156.2 175

15.0 18.0 36 36.0 91.8 110

15.0 18.0 72 72.0 111.2 125

15.0 18.0 108† 108.0 156.2 175

10.0 12.2 — — 91.0 110

15.0 18.0 — — 96.8 110

10.0 12.2 36 36.0 91.0 110

10.0 12.2 72 72.0 117.5 150

10.0 12.2 108† 108.0 162.5 175

15.0 18.0 36 36.0 96.8 110

15.0 18.0 72 72.0 117.5 150

15.0 18.0 108† 108.0 162.5 175

HEATER kW

RATING

Electric heaters are tested and ETL approved at maximum

total external static pressure of 1.9 in. wg.

FLA

6.0 7.8 — — 73.6 90

— — 36 36.0 65.8 80

— — 72 72.0 101.3 110

— — 108† 108.0 146.2 150

6.0 7.8 36 36.0 73.6 90

6.0 7.8 72 72.0 101.3 110

6.0 7.8 108† 108.0 146.2 150

6.0 7.8 — — 75.6 90

— — 36 36.0 67.8 90

— — 72 72.0 103.7 110

— — 108† 108.0 148.7 150

6.0 7.8 36 36.0 75.6 90

6.0 7.8 72 72.0 103.7 110

6.0 7.8 108† 108.0 148.7 150

6.0 7.8 — — 81.6 100

— — 36 36.0 73.8 100

— — 72 72.0 111.2 125

— — 108† 108.0 156.2 175

6.0 7.8 36 36.0 81.6 100

6.0 7.8 72 72.0 111.2 125

6.0 7.8 108† 108.0 156.2 175

6.0 7.8 — — 86.6 100

— — 36 36.0 78.8 110

— — 72 72.0 117.5 150

— — 108† 108.0 162.5 175

6.0 7.8 36 36.0 86.6 110

6.0 7.8 72 72.0 117.5 150

6.0 7.8 108† 108.0 162.5 175

MULTIPLICATION FACTORS

240

480

575

ELECTRIC

HEAT*

kW FLA MCA MOCP

VOLTAGE

DISTRIBUTION

V-3-60

200

208

230

240

440

460

480

550

575

600

BASE UNIT WITH

EXHAUST FAN

AND/OR

ELECTRIC HEAT*

MULTIPLICATION

FACTOR

0.694

0.751

0.918

1.000

0.840

0.918

1.000

0.915

1.000

1.089

21

Page 22

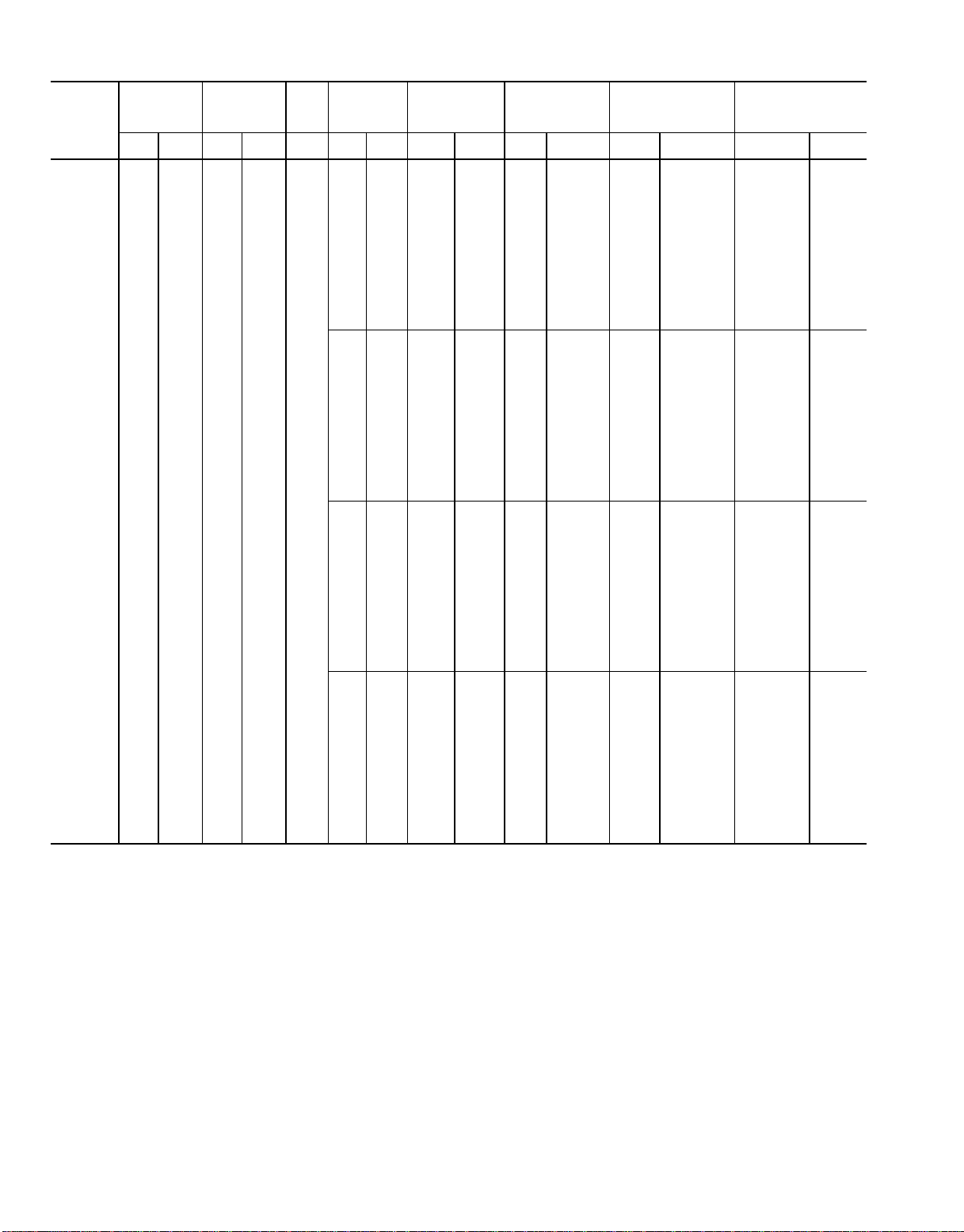

Table 4 — Electrical Data, 044 Units

208/230-3-60 (V-Ph-Hz)

COMPR

VOLTAGE

RANGE

187-254 69.2 345.0 69.2 345.0 16.2

NO. 1

RLA LRA RLA LRA

COMPR

NO. 2

OFM IFM

Total

Hp FLA MCA MOCP

FLA

24.2/

7.5

22.0

30.8/

10.0

28.0

46.2/

15.0

42.0

59.4/

20.0

54.0

BASE UNIT

ONLY

196.1/

193.9

202.7/

199.9

218.1/

213.9

231.3/

225.9

EXHAUST

FAN

TotalHpTotal

10.0 33.4/30.0 — — 229.5/223.9 250/250

15.0 48.4/44.0 — — 244.5/237.9 300/300

250/

250

10.0 33.4/30.0 29/ 36 78.9/ 91.0 229.5/223.9 250/250

10.0 33.4/30.0 59/ 72 157.7/182.0 229.5/255.0 250/300

10.0 33.4/30.0 88/108† 236.6/273.0 326.0/368.8 350/400

15.0 48.4/44.0 29/ 36 78.9/ 91.0 244.5/237.9 300/300

15.0 48.4/44.0 59/ 72 157.7/182.0 244.5/255.0 300/300

15.0 48.4/44.0 88/108† 236.6/273.0 326.0/368.8 350/400

10.0 33.4/30.0 — — 236.1/229.9 300/250

15.0 48.4/44.0 — — 251.1/243.9 300/300

250/

250

10.0 33.4/30.0 29/ 36 78.9/ 91.0 236.1/229.9 300/250

10.0 33.4/30.0 59/ 72 157.7/182.0 236.1/262.5 300/300

10.0 33.4/30.0 88/108† 236.6/273.0 334.2/376.3 350/400

15.0 48.4/44.0 29/ 36 78.9/ 91.0 251.1/243.9 300/300

15.0 48.4/44.0 59/ 72 157.7/182.0 251.1/262.5 300/300

15.0 48.4/44.0 88/108† 236.6/273.0 334.2/376.3 350/400

10.0 33.4/30.0 — — 251.5/243.9 300/300

15.0 48.4/44.0 — — 266.5/257.9 300/300

250/

250

10.0 33.4/30.0 29/ 36 78.9/ 91.0 251.5/243.9 300/300

10.0 33.4/30.0 59/ 72 157.7/182.0 254.9/280.0 300/350

10.0 33.4/30.0 88/108† 236.6/273.0 353.5/393.8 400/400

15.0 48.4/44.0 29/ 36 78.9/ 91.0 266.5/257.9 300/300

15.0 48.4/44.0 59/ 72 157.7/182.0 266.5/280.0 300/350

15.0 48.4/44.0 88/108† 236.6/273.0 353.5/393.8 400/400

10.0 33.4/30.0 — — 264.7/255.9 300/300

15.0 48.4/44.0 — — 279.7/269.9 300/300

300/

250

10.0 33.4/30.0 29/ 36 78.9/ 91.0 264.7/255.9 300/300

10.0 33.4/30.0 59/ 72 157.7/182.0 271.4/295.0 350/350

10.0 33.4/30.0 88/108† 236.6/273.0 370.0/408.8 450/450

15.0 48.4/44.0 29/ 36 78.9/ 91.0 279.7/269.9 300/300

15.0 48.4/44.0 59/ 72 157.7/182.0 279.7/295.0 350/350

15.0 48.4/44.0 88/108† 236.6/273.0 370.0/408.8 450/450

FLA

6.0 21.2/20.0 — — 217.3/213.9 250/250

— — 29/ 35 78.9/ 91.0 196.1/193.9 250/250

— — 59/ 72 157.7/182.0 227.4/255.0 250/300

— — 88/108† 236.6/273.0 326.0/368.8 350/400

6.0 21.2/20.0 29/ 36 78.9/ 91.0 217.3/213.9 250/250

6.0 21.2/20.0 59/ 72 157.7/182.0 227.4/255.0 250/300

6.0 21.2/20.0 88/108† 236.6/273.0 326.0/368.8 350/400

6.0 21.2/20.0 — — 223.9/219.9 250/250

— — 29/ 36 78.9/ 91.0 202.7/199.9 250/250

— — 59/ 72 157.7/182.0 235.6/262.5 250/300

— — 88/108† 236.6/273.0 334.2/376.3 350/400

6.0 21.2/20.0 29/ 36 78.9/ 91.0 223.9/219.9 250/250

6.0 21.2/20.0 59/ 72 157.7/182.0 235.6/262.5 250/300

6.0 21.2/20.0 88/108† 236.6/273.0 334.2/376.3 350/400

6.0 21.2/20.0 — — 239.3/233.9 300/300

— — 29/ 36 78.9/ 91.0 218.1/213.9 250/250

— — 59/ 72 157.7/182.0 254.9/280.0 300/350

— — 88/108† 236.6/273.0 353.5/393.8 400/400

6.0 21.2/20.0 29/ 36 78.9/ 91.0 239.3/233.9 300/300

6.0 21.2/20.0 59/ 72 157.7/182.0 254.9/280.0 300/350

6.0 21.2/20.0 88/108† 236.6/273.0 353.5/393.8 400/400

6.0 21.2/20.0 — — 252.5/245.9 300/300

— — 29/ 36 78.9/ 91.0 231.3/225.9 300/300

— — 59/ 72 157.7/182.0 271.4/295.0 350/350

— — 88/108† 236.6/273.0 370.0/408.8 450/450

6.0 21.2/20.0 29/ 36 78.9/ 91.0 252.5/245.9 300/300

6.0 21.2/20.0 59/ 72 157.7/182.0 271.4/295.0 350/350

6.0 21.2/20.0 88/108† 236.6/273.0 370.0/408.8 450/450

ELECTRIC

HEAT*

kW FLA MCA MOCP

BASE UNIT WITH

EXHAUST FAN

AND/OR

ELECTRIC HEAT*

22

Page 23

Table 4 — Electrical Data, 044 Units (cont)

460-3-60 (V-Ph-Hz)

COMPR

VOLTAGE

RANGE

414-508 34.6 173.0 34.6 173.0 8.1

CV — Constant Volume

ETL — ETL Testing Laboratory

FLA — Full Load Amps

Hp — Nominal Horsepower

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (for wire sizing)

MOCP — Maximum Overcurrent Protection

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Electric heat available on 50 Series vertical discharge units.

†108 kW available on CV applications only.

NO. 1

RLA LRA RLA LRA

LEGEND

COMPR

NO. 2

OFM IFM

Total

FLA

BASE UNIT

ONLY

Hp FLA MCA MOCP

7.5 11.0 96.9 125

10.0 14.0 99.9 125

15.0 21.0 106.9 125

20.0 27.0 112.9 125

NOTES:

1. Electric resistance heaters are rated at 208/240 v, 480 v, or 575 v. To

determine heater capacity (kW) at unit operating voltage, multiply 240 v,

480 v, or 575 v capacity by appropriate multiplier below.

2. Boldface indicates 48 and 50 Series units. All other data is for 50 Series

units only.

EXHAUST

FAN

TotalHpTotal

10.0 15.2 36 46.3 128.1 150

10.0 15.2 72 93.0 150.0 200

10.0 15.2 108† 139.0 207.5 225

15.0 22.0 36 46.3 134.9 150

15.0 22.0 72 93.0 150.0 200

15.0 22.0 108† 139.0 207.5 225

HEATER kW

RATING

240

480

575

Electric heaters are tested and ETL approved at maximum

total external static pressure of 1.9 in. wg.

FLA

6.0 9.6 — — 106.5 125

10.0 15.2 — — 112.1 125

15.0 22.0 — — 118.9 150

— — 36 46.3 96.9 125

— — 72 93.0 130.0 150

— — 108† 139.0 187.5 200

6.0 9.6 36 46.3 106.5 125

6.0 9.6 72 93.0 130.0 150

6.0 9.6 108† 139.0 187.5 200

10.0 15.2 36 46.3 112.1 125

10.0 15.2 72 93.0 130.0 150

10.0 15.2 108† 139.0 187.5 200

15.0 22.0 36 46.3 118.9 150

15.0 22.0 72 93.0 130.0 150

15.0 22.0 108† 139.0 187.5 200

6.0 9.6 — — 109.5 125

10.0 15.2 — — 115.1 125

15.0 22.0 — — 121.9 150

— — 36 46.3 99.9 125

— — 72 93.0 133.7 150

— — 108† 139.0 191.2 200

6.0 9.6 36 46.3 109.5 125

6.0 9.6 72 93.0 133.7 150

6.0 9.6 108† 139.0 191.2 200

10.0 15.2 36 46.3 115.1 125

10.0 15.2 72 93.0 133.7 150

10.0 15.2 108† 139.0 191.2 200

15.0 22.0 36 46.3 121.9 150

15.0 22.0 72 93.0 133.7 150

15.0 22.0 108† 139.0 191.2 200

6.0 9.6 — — 116.5 150

10.0 15.2 — — 122.1 150

15.0 22.0 — — 128.9 150

— — 36 46.3 106.9 125

— — 72 93.0 142.5 175

— — 108† 139.0 200.0 200

6.0 9.6 36 46.3 116.5 150

6.0 9.6 72 93.0 142.5 175

6.0 9.6 108† 139.0 200.0 200

10.0 15.2 36 46.3 122.1 150

10.0 15.2 72 93.0 142.5 175

10.0 15.2 108† 139.0 200.0 200

15.0 22.0 36 46.3 128.9 150

15.0 22.0 72 93.0 142.5 175

15.0 22.0 108† 139.0 200.0 200

6.0 9.6 — — 122.5 150

10.0 15.2 — — 128.1 150

15.0 22.0 — — 134.9 150

— — 36 46.3 112.9 150

— — 72 93.0 150.0 200

— — 108† 139.0 207.5 225

6.0 9.6 36 46.3 122.5 150

6.0 9.6 72 93.0 150.0 200

6.0 9.6 108† 139.0 207.5 225

MULTIPLICATION FACTORS

ELECTRIC

HEAT*

kW FLA MCA MOCP

VOLTAGE

DISTRIBUTION

V-3-60

200

208

230

240

440

460

480

550

575

600

BASE UNIT WITH

EXHAUST FAN

AND/OR

ELECTRIC HEAT*

MULTIPLICATION

FACTOR

0.694

0.751

0.918

1.000

0.840

0.918

1.000

0.915

1.000

1.089

23

Page 24

Table 4 — Electrical Data, 044 Units (cont)

575-3-60 (V-Ph-Hz)

COMPR

VOLTAGE

RANGE

518-632 26.7 120.0 26.7 120.0 7.2

NO. 1

RLA LRA RLA LRA

COMPR

NO. 2

OFM IFM

Total

Hp FLA MCA MOCP

FLA

7.5 9.0 76.3 100

10.0 11.0 78.3 100

15.0 17.0 84.3 110

20.0 22.0 89.3 110

BASE UNIT

ONLY

EXHAUST

FAN

TotalHpTotal

FLA

6.0 7.8 — — 84.1 110

10.0 12.2 — — 88.5 110

15.0 18.0 — — 94.3 110

— — 36 36.0 76.3 100

— — 72 72.0 101.3 110

— — 108† 108.0 146.2 150

6.0 7.8 36 36.0 84.1 110

6.0 7.8 72 72.0 101.3 110

6.0 7.8 108† 108.0 146.2 150

10.0 12.2 36 36.0 88.5 110

10.0 12.2 72 72.0 101.3 110

10.0 12.2 108† 108.0 146.2 150

15.0 18.0 36 36.0 94.3 110

15.0 18.0 72 72.0 101.3 110

15.0 18.0 108† 108.0 146.2 150

6.0 7.8 — — 86.1 110

10.0 12.2 — — 90.5 110

15.0 18.0 — — 96.3 110

— — 36 36.0 78.3 100

— — 72 72.0 103.7 110

— — 108† 108.0 148.7 150

6.0 7.8 36 36.0 86.1 110

6.0 7.8 72 72.0 103.7 110

6.0 7.8 108† 108.0 148.7 150

10.0 12.2 36 36.0 90.5 110

10.0 12.2 72 72.0 103.7 110

10.0 12.2 108† 108.0 148.7 150

15.0 18.0 36 36.0 96.3 110

15.0 18.0 72 72.0 103.7 110

15.0 18.0 108† 108.0 148.7 150

6.0 7.8 — — 92.1 110

10.0 12.2 — — 96.5 110

15.0 18.0 — — 102.3 125

— — 36 36.0 84.3 110

— — 72 72.0 111.2 125

— — 108† 108.0 156.2 175

6.0 7.8 36 36.0 92.1 110

6.0 7.8 72 72.0 111.2 125

6.0 7.8 108† 108.0 156.2 175

10.0 12.2 36 36.0 96.5 110

10.0 12.2 72 72.0 111.2 125

10.0 12.2 108† 108.0 156.2 175

15.0 18.0 36 36.0 102.3 125

15.0 18.0 72 72.0 111.2 125

15.0 18.0 108† 108.0 156.2 175

6.0 7.8 — — 97.1 110

10.0 12.2 — — 101.5 125

15.0 18.0 — — 107.3 125

— — 36 36.0 89.3 110

— — 72 72.0 117.5 150

— — 108† 108.0 162.5 175

6.0 7.8 36 36.0 97.1 110

6.0 7.8 72 72.0 117.5 150

6.0 7.8 108† 108.0 162.5 175

10.0 12.2 36 36.0 101.5 125

10.0 12.2 72 72.0 117.5 150

10.0 12.2 108† 108.0 162.5 175

15.0 18.0 36 36.0 107.3 125

15.0 18.0 72 72.0 117.5 150

15.0 18.0 108† 108.0 162.5 175

ELECTRIC

HEAT*

kW FLA MCA MOCP

BASE UNIT WITH

EXHAUST FAN

AND/OR

ELECTRIC HEAT*

24

Page 25

Table 5 — Electrical Data, 054 Units

208/230-3-60 (V-Ph-Hz)

COMPR

VOLTAGE

RANGE

187-254 107.7 506.0 74.4 345.0 21.6

CV — Constant Volume

ETL — ETL Testing Laboratory

FLA — Full Load Amps

Hp — Nominal Horsepower

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (for wire sizing)

MOCP — Maximum Overcurrent Protection

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Electric heat available on 50 Series vertical discharge units.

†108 kW available on CV applications only.

NO. 1

RLA LRA RLA LRA

LEGEND

COMPR

NO. 2

OFM IFM

Total

FLA

BASE UNIT

ONLY

Hp FLA MCA MOCP

46.2/

15.0

20.0

25.0

30.0

42.0

59.4/

54.0

74.8/

68.0

88.0/

80.0

276.8/

272.6

290.0/

284.6

305.4/

298.6

318.6/

310.6

350/

350

350/

350

400/

400

400/

400

EXHAUST

FAN

TotalHpTotal

10.0 33.4/30.4 — — 310.2/303.0 400/400

15.0 48.4/44.0 — — 325.2/316.6 400/400

20.0 61.6/56.0 — — 338.4/238.6 400/400

10.0 33.4/30.4 29/ 36 78.9/ 91.0 310.2/303.0 400/400

10.0 33.4/30.4 59/ 72 157.7/182.0 310.2/303.0 400/400

10.0 33.4/30.4 88/108† 236.6/273.0 353.5/393.8 400/400

15.0 48.4/44.0 29/ 36 78.9/ 91.0 325.2/316.6 400/400

15.0 48.4/44.0 59/ 72 157.7/182.0 325.2/316.6 400/400

15.0 48.4/44.0 88/108† 236.6/273.0 353.5/393.8 400/400

20.0 61.6/56.0 29/ 36 78.9/ 91.0 338.4/328.6 400/400

20.0 61.6/56.0 59/ 72 157.7/182.0 338.4/328.6 400/400

20.0 61.6/56.0 88/108† 236.6/273.0 353.5/393.8 400/400

10.0 33.4/30.4 — — 323.4/315.0 400/400

15.0 48.4/44.0 — — 338.4/328.6 400/400

20.0 61.6/56.0 — — 351.6/340.6 450/400

10.0 33.4/30.4 29/ 36 78.9/ 91.0 323.4/315.0 400/400

10.0 33.4/30.4 59/ 72 157.7/182.0 323.4/315.0 400/400

10.0 33.4/30.4 88/108† 236.6/273.0 370.0/408.8 450/450

15.0 48.4/44.0 29/ 36 78.9/ 91.0 338.4/328.6 400/400

15.0 48.4/44.0 59/ 72 157.7/182.0 338.4/328.6 400/400

15.0 48.4/44.0 88/108† 236.6/273.0 370.0/408.8 450/450

20.0 61.6/56.0 29/ 36 78.9/ 91.0 351.6/340.6 450/400

20.0 61.6/56.0 59/ 72 157.7/182.0 351.6/340.6 450/400

20.0 61.6/56.0 88/108† 236.6/273.0 370.0/408.8 450/450

10.0 33.4/30.4 — — 338.8/329.0 400/400

15.0 48.4/44.0 — — 353.8/342.6 450/450

20.0 61.6/56.0 — — 367.0/354.6 450/450

10.0 33.4/30.4 29/ 36 78.9/ 91.0 338.8/329.0 400/400

10.0 33.4/30.4 59/ 72 157.7/182.0 338.8/329.0 450/450

10.0 33.4/30.4 88/108† 236.6/273.0 389.3/426.3 500/500

15.0 48.4/44.0 29/ 36 78.9/ 91.0 353.8/342.6 450/450

15.0 48.4/44.0 59/ 72 157.7/182.0 353.8/342.6 450/450

15.0 48.4/44.0 88/108† 236.6/273.0 389.3/426.3 500/500

20.0 61.6/56.0 29/ 36 78.9/ 91.0 367.0/354.6 450/450

20.0 61.6/56.0 59/ 72 157.7/182.0 367.0/354.6 450/450

20.0 61.6/56.0 88/108† 236.6/273.0 389.3/426.3 500/500

10.0 33.4/30.4 — — 352.0/341.0 450/400

15.0 48.4/44.0 — — 367.0/354.6 450/450

20.0 61.6/56.0 — — 380.2/366.6 450/450

10.0 33.4/30.4 29/ 36 78.9/ 91.0 352.0/341.0 450/400

10.0 33.4/30.4 59/ 72 157.7/182.0 352.0/341.0 500/500

10.0 33.4/30.4 88/108† 236.6/273.0 405.7/441.3 500/500

15.0 48.4/44.0 29/ 36 78.9/ 91.0 367.0/354.6 450/450

15.0 48.4/44.0 59/ 72 157.7/182.0 367.0/354.6 500/500

15.0 48.4/44.0 88/108† 236.6/273.0 405.7/441.3 500/500

20.0 61.6/56.0 29/ 36 78.9/ 91.0 380.2/366.6 450/450

20.0 61.6/56.0 59/ 72 157.7/182.0 380.2/366.6 500/500

20.0 61.6/56.0 88/108† 236.6/273.0 405.7/441.3 500/500

NOTES:

1. Electric resistance heaters are rated at 208/240 v, 480 v, or 575 v. To

determine heater capacity (kW) at unit operating voltage, multiply 240 v,

480 v, or 575 v capacity by appropriate multiplier below.

2. Boldface indicates 48 and 50 Series units. All other data is for 50 Series

units only.

FLA

— — 29/ 36 78.9/ 91.0 276.8/272.6 350/350

— — 59/ 72 157.7/182.0 276.8/280.0 350/350

— — 88/108† 236.6/273.0 353.5/393.8 400/400

— — 29/ 36 78.9/ 91.0 290.0/284.6 350/350

— — 59/ 72 157.7/182.0 290.0/295.0 350/350

— — 88/108† 236.6/273.0 370.0/408.8 450/450

— — 29/ 36 78.9/ 91.0 305.4/298.6 400/400

— — 59/ 72 157.7/182.0 305.4/312.5 450/450

— — 88/108† 236.6/273.0 389.3/426.3 500/500

— — 29/ 36 78.9/ 91.0 318.6/310.6 400/400

— — 59/ 72 157.7/182.0 318.6/327.5 500/500

— — 88/108† 236.6/273.0 405.7/441.3 500/500

HEATER kW

RATING

240

480

575

Electric heaters are tested and ETL approved at maximum

total external static pressure of 1.9 in. wg.

ELECTRIC

HEAT*

kW FLA MCA MOCP

MULTIPLICATION FACTORS

VOLTAGE

DISTRIBUTION

V-3-60

200

208

230

240

440

460

480

550

575

600

BASE UNIT WITH

EXHAUST FAN

AND/OR

ELECTRIC HEAT*

MULTIPLICATION

FACTOR

0.694

0.751

0.918

1.000

0.840

0.918

1.000

0.915

1.000

1.089

25

Page 26

Table 5 — Electrical Data, 054 Units (cont)

460-3-60 (V-Ph-Hz)

COMPR

VOLTAGE

RANGE

414-508 50.6 253.0 34.6 173.0 10.8

NO. 1

RLA LRA RLA LRA

COMPR

NO. 2

OFM IFM

Total

FLA

Hp FLA MCA MOCP

15.0 21.0 129.6 175

20.0 27.0 135.6 175

25.0 34.0 142.6 175

30.0 40.0 148.6 175

BASE UNIT

ONLY

EXHAUST

FAN

TotalHpTotal

10.0 15.2 — — 144.8 175

15.0 22.0 — — 151.6 200

20.0 28.0 — — 157.6 200

10.0 15.2 36 46.3 144.8 175

10.0 15.2 72 93.0 144.8 175

10.0 15.2 108† 139.0 200.0 200

15.0 22.0 36 46.3 151.6 200

15.0 22.0 72 93.0 151.6 200

15.0 22.0 108† 139.0 200.0 200

20.0 28.0 36 46.3 157.6 200

20.0 28.0 72 93.0 157.6 200

20.0 28.0 108† 139.0 200.0 200

10.0 15.2 — — 150.8 200

15.0 22.0 — — 157.6 200

20.0 28.0 — — 163.6 200

10.0 15.2 36 46.3 150.8 200

10.0 15.2 72 93.0 150.8 200

10.0 15.2 108† 139.0 207.5 225

15.0 22.0 36 46.3 157.6 200

15.0 22.0 72 93.0 157.6 200

15.0 22.0 108† 139.0 207.5 225

20.0 28.0 36 46.3 163.6 200

20.0 28.0 72 93.0 163.6 200

20.0 28.0 108† 139.0 207.5 225

10.0 15.2 — — 157.8 200

15.0 22.0 — — 164.6 200

20.0 28.0 — — 170.6 200

10.0 15.2 36 46.3 157.8 200

10.0 15.2 72 93.0 158.7 225

10.0 15.2 108† 139.0 216.3 250

15.0 22.0 36 46.3 164.6 200

15.0 22.0 72 93.0 164.6 225

15.0 22.0 108† 139.0 216.3 250

20.0 28.0 36 46.3 170.6 200

20.0 28.0 72 93.0 170.6 225

20.0 28.0 108† 139.0 216.3 250

10.0 15.2 — — 163.8 200

15.0 22.0 — — 170.6 200

20.0 28.0 — — 176.6 225

10.0 15.2 36 46.3 163.8 200

10.0 15.2 72 93.0 166.2 250

10.0 15.2 108† 139.0 223.7 250

15.0 22.0 36 46.3 170.6 200

15.0 22.0 72 93.0 170.6 250

15.0 22.0 108† 139.0 223.7 250

20.0 28.0 36 46.3 176.6 225

20.0 28.0 72 93.0 176.6 250

20.0 28.0 108† 139.0 223.7 250

FLA

— — 36 46.3 129.6 175

— — 72 93.0 142.5 175

— — 108† 139.0 200.0 200

— — 36 46.3 135.6 175

— — 72 93.0 150.0 200

— — 108† 139.0 207.5 225

— — 36 46.3 142.6 175

— — 72 93.0 158.7 225

— — 108† 139.0 216.3 250

— — 36 46.3 148.6 200

— — 72 93.0 166.2 250

— — 108† 139.0 223.7 250

ELECTRIC

HEAT*

kW FLA MCA MOCP

BASE UNIT WITH

EXHAUST FAN

AND/OR

ELECTRIC HEAT*

26

Page 27

Table 5 — Electrical Data, 054 Units (cont)

575-3-60 (V-Ph-Hz)

COMPR

VOLTAGE

RANGE

518-632 39.1 176.0 28.8 120.0 9.6

CV — Constant Volume

ETL — ETL Testing Laboratory

FLA — Full Load Amps

Hp — Nominal Horsepower

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (for wire sizing)

MOCP — Maximum Overcurrent Protection

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Electric heat available on 50 Series vertical discharge units.

†108 kW available on CV applications only.

NO. 1

RLA LRA RLA LRA

LEGEND

COMPR

NO. 2

OFM IFM

Total

FLA

BASE UNIT

ONLY

Hp FLA MCA MOCP

15.0 17.0 104.3 125

20.0 22.0 109.3 125

25.0 27.0 114.3 150

30.0 32.0 119.3 150

NOTES:

1. Electric resistance heaters are rated at 208/240 v, 480 v, or 575 v. To

determine heater capacity (kW) at unit operating voltage, multiply 240 v,

480 v, or 575 v capacity by appropriate multiplier below.

2. Boldface indicates 48 and 50 Series units. All other data is for 50 Series

units only.

EXHAUST

FAN

TotalHpTotal

HEATER kW

RATING

240

480

575

Electric heaters are tested and ETL approved at maximum

total external static pressure of 1.9 in. wg.

FLA

10.0 12.2 — — 116.5 150

15.0 18.0 — — 122.3 150