Carrier Neos 100S, Integra 20X, Integra 35X, Integra 30S, Integra 40X Installation And Commissioning Manual

...Page 1

Installation & Commi ss ioning Manua l:

Truck Refrigeration

Neos 100S, 20X, 30S, 35X , 40X, 50X

INST ALLA TION AND

COMMISSIONING MANUAL

for

Neos 100S

62-11165 Rev D

62-11165 Rev D

®

Integra 20X, 30S, 35X, 40X,

Direct Drive Refrigeration Units

© 2017 Carrier Corporation • Printed in U. S. A. 0217

50X

1

Page 2

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Safety Precautions

Electrical Power

Beware of HIGH VOLTAGE supplied by the main power as

the unit may start automatically.

Before working on any unit, make sure that the main

Run/Stop switch is in STOP position and the negative

battery terminal is disconnected.

Fan Blades

All refrigeration units are equipped with Automatic Start/Stop

and may start at any time without warning. Beware all fan

®

62-11165 Rev D

blade, belts, and other moving parts.

Vehicle Battery

Vehicles are equipped with a lead-acid type battery. The

battery normally vents small amounts of flammable

hydrogen gas. Keep any flame, lighted object, or source of

spark away. A battery explosion can cause serious physical

harm and/or blindness

2

Page 3

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Safety Precautions

Electrical Conn ection

DISCONNECT the battery ground (-) on the vehicle battery.

Personal Protective Equipment

Always use personal protective equipment while doing

anything on this refrigeration unit.

Engine Coolant

All engines have a pressurized coolant system. Under

normal operating conditions, the coolant in the engine and

radiator is under high pressure and very hot. Do not remove

®

62-11165 Rev D

the cap from a hot radiator. If the cap has to be removed, do

so very slowly in order to release pressure without spray.

Refrigerants

The refrigerant contained in the refrigeration system of the

units can cause frostbite, severe burns, or blindness when in

direct contact with the skin or eyes.

3

Page 4

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evaporator Clearances

B

A

®

62-11165 Rev D

Do not obstruct the evaporator fan

inlet(s) or outlet

For any movable bulkheads, there

must be a MINIMUM distance “A”

between the evaporator outlet and

any obstruction.

When mounting X Series

evaporators, it is recommended to

leave a MINIMUM distance “B” for

installation and service access.

MODEL

NEOS 100S, 20X

30S

35X,40X, 50X

“A” Minimum Distance

Inches (millimeters)

20.0” (500)

32.0” (800)

40.0” (1,000)

“B” Minimum Distance

Inches (millimeters)

6.0” (150)

Not Applicable

6.0” (150)

4

Page 5

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Condenser Installation – Roof T op A pplication

NEOS 100S

20X

8.86”

(225)

4 x Ø 0.56”

(4 x Ø 15)

21.65” (550)

3.54”

(90)

1.25” to 9.25”

(30 to 235)

Ø 3.50”

(Ø 90)

14.57” (370)

35X

®

62-11165 Rev D

30S

28.35” (720)

12.20”

(310)

4 x Ø 0.56”

(4 x Ø 15)

Note: For 30S, use the black ma rking on the

bottom cover of the unit as a template for drilling

the large refrigerant and electrical pass-thru hole.

Roof Top Applications

Mark and drill the four condenser

mounting holes, as well as the

larger refrigerant and electrical

pass-thru hole, as indicated

above (depending on unit model)

5

Page 6

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Condenser Installation – Roof T op A pplication

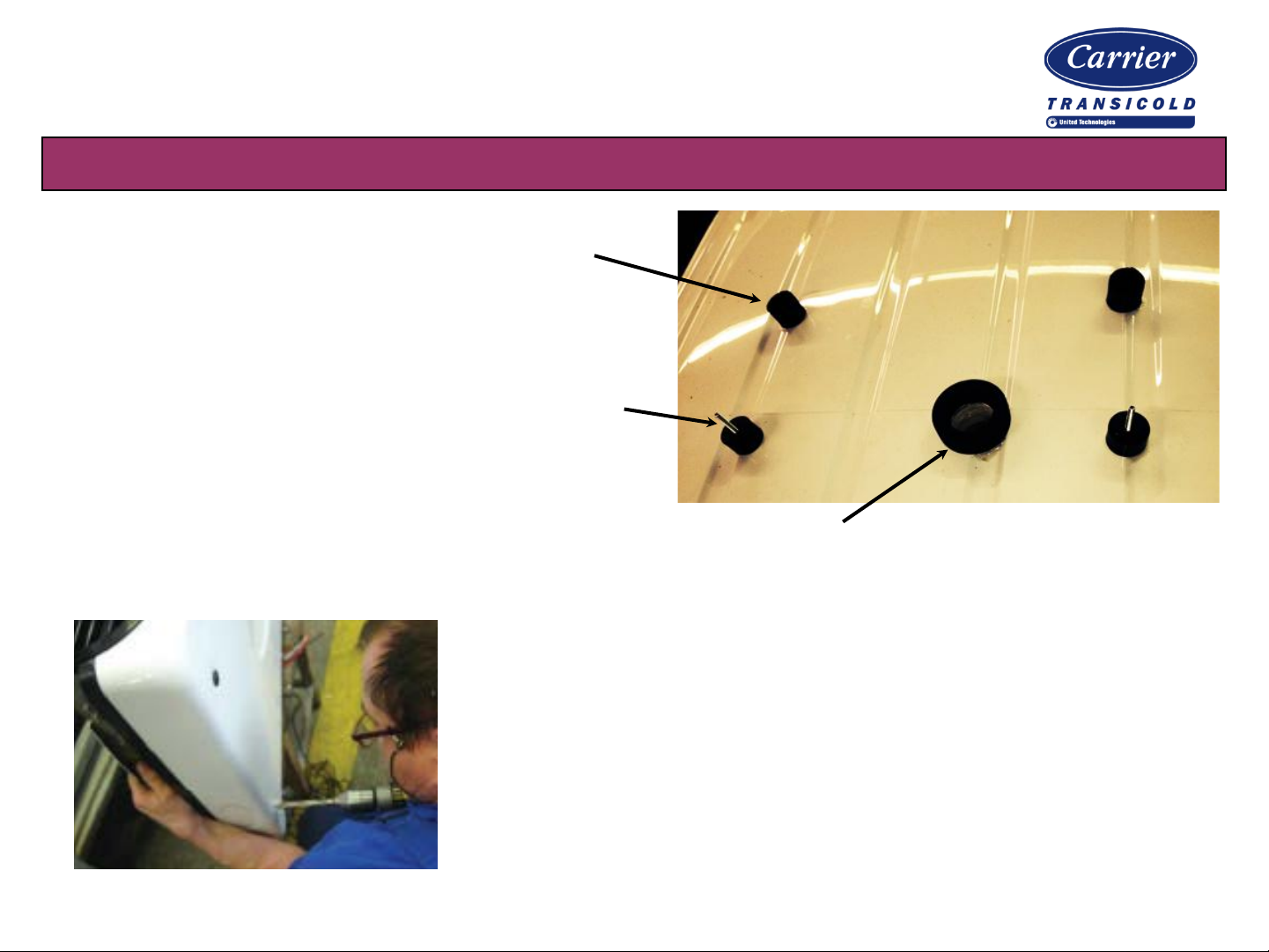

Install the four condenser mounting pads

by first applying waterproof silicone caulk

to the bottom cups in each pad.

Apply waterproof silicone caulk to each of the

four condenser mounting screws to prevent

water entry around the screw.

Apply waterproof silicone caulk to both sides of the center pad, which is used for

hoses and wiring, and install the center pad.

62-11165 Rev D

®

Remove the condenser cover. On the bottom cover of the

unit, drill the four 0.56” (15mm) mounting holes and the

larger electrical/hose hole as per the diagram on page 5.

Mount the condenser on the mounting pads in fasten in

place using the hardware supplied in the kit.

6

Page 7

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

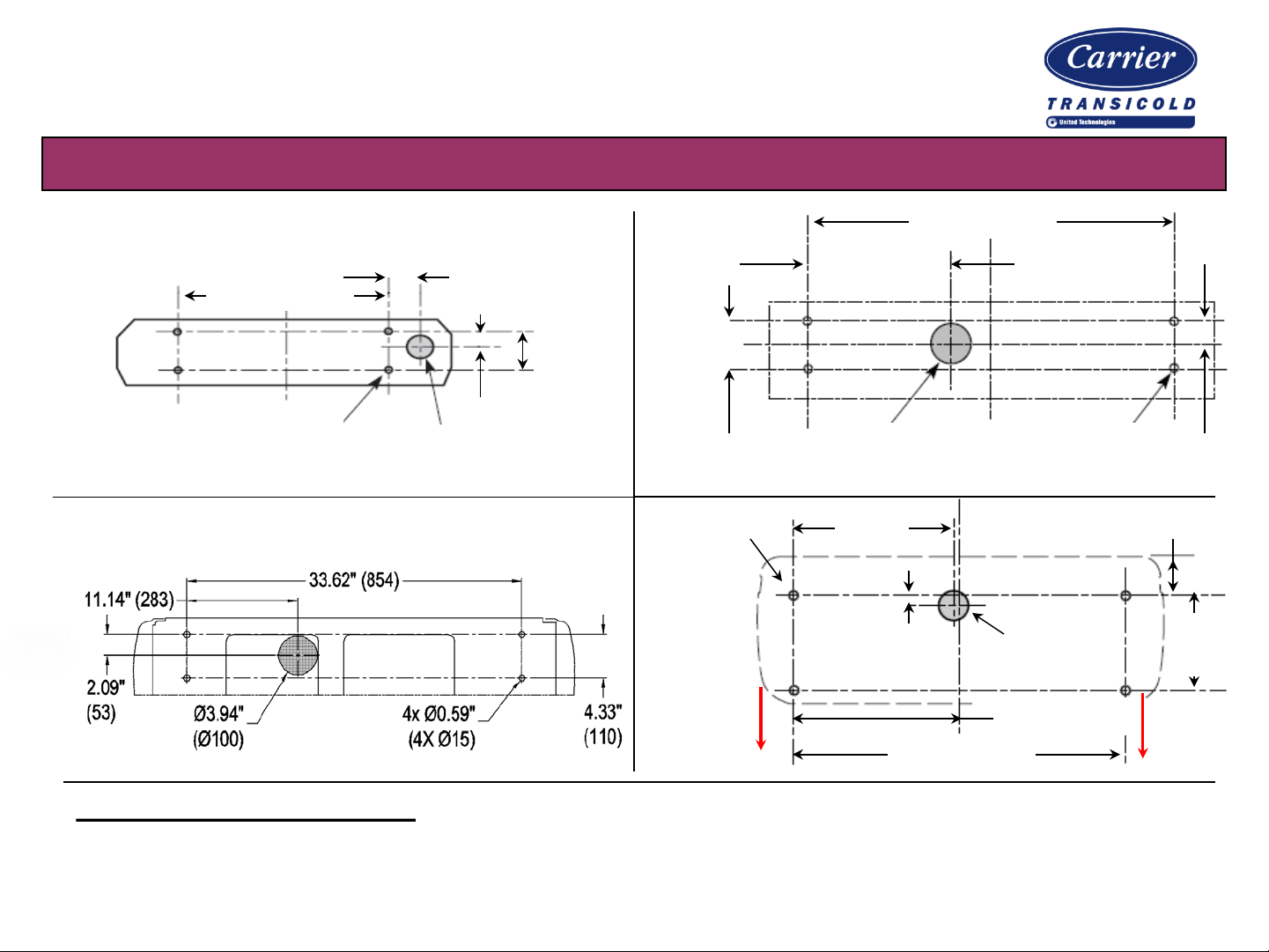

Condenser Installation – Front Mount Application

NEOS 100S, 20X

24.41” (620)

2.36”

(60)

5.12”

(130)

2.36” (60)

4 x Ø 0.56”

(4 x Ø 15)

35X

Ø 3.50”

(Ø 90)

4 x Ø 0.63”

(4 x Ø 16)

40X

50X

30S

4.33”

(110)

12.75”

(324)

Ø 4.0”

(Ø 100)

21.26”

(540)

1.18”

(30)

62-11165 Rev D

33.66” (855)

4 x Ø 0.56”

(4 x Ø 15)

Ø 4.0”

(Ø 100)

®

2.17”

(55)

5.31” (135)

12.6”

(320)

6” MIN to

cab roof

44.1” (1,120)

22.05” (560)

Front Mount Applications: Mark and drill the four condenser mounting holes, as well as the

larger refrigerant and electrical pass-thru hole, as indicated above (depending on unit model)

Bolt the condensing unit in place using the hardware supplied in the mounting kit.

7

Page 8

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evaporator Mounting Preparation

20.86”

(530)

Neos

15.95”

(405)

30.71”

(780)

20X

100S

35X

40X

17.72”

(450)

17.72”

(450)

50X

30S

53.54” (1,360)

®

62-11165 Rev D

33.66”

(855)

18.5”

(470)

26.77” (680)

21.85”

(555)

40.55” (1,030)

Remove evaporator access panels. If the box has mounting studs, fasten the evaporator using supplied

hardware; otherwise, mark the mounting holes as indicated above (depending on unit model). Leave a

minimum of 6” (150mm) between the box wall and the rear of the evaporator.

58.27” (1,480)

29.13” (740)

8

Page 9

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

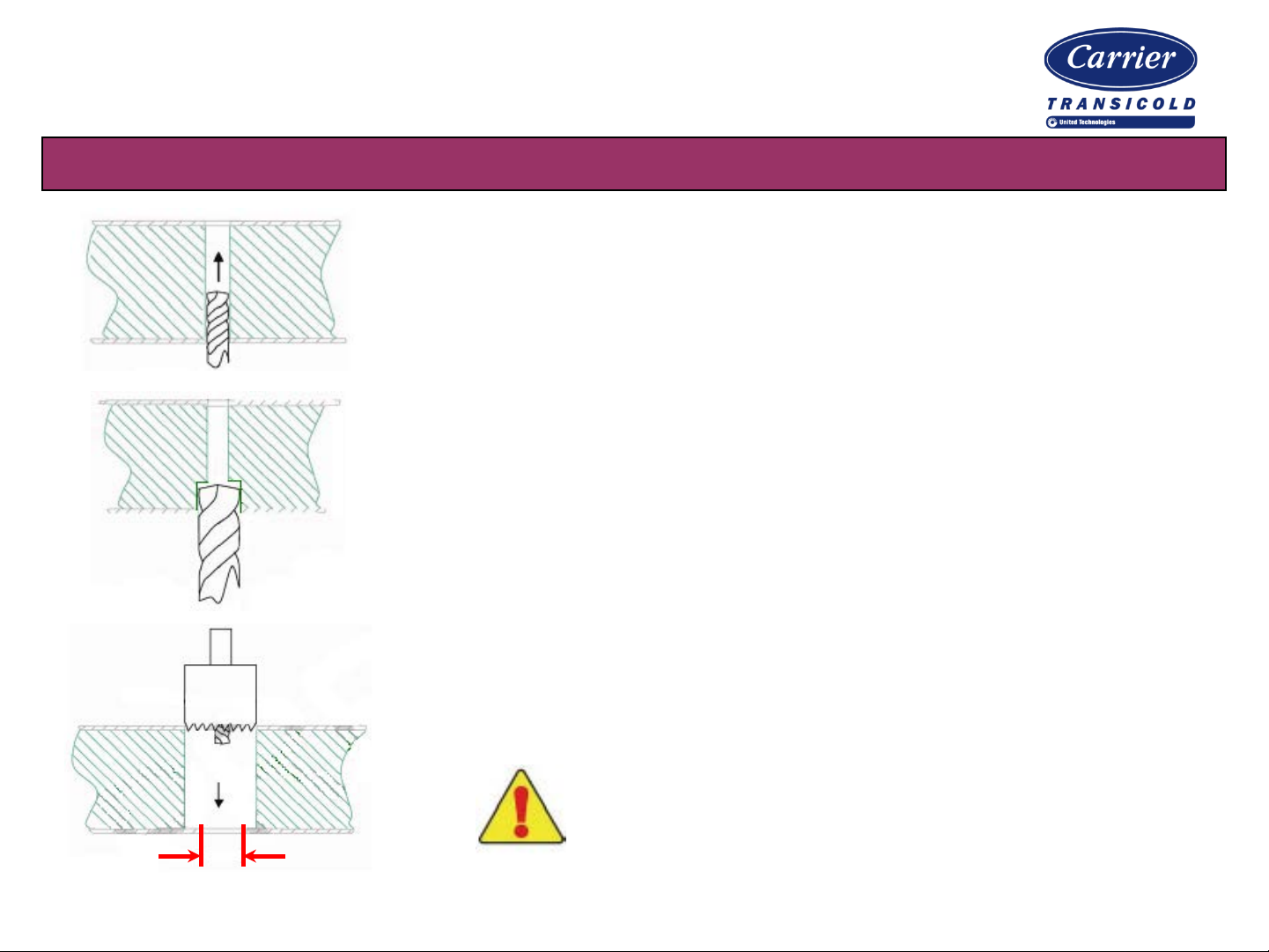

Evaporator Mounting Preparation – M ushroom Dri lling

From the inside of the box, drill 4 holes completely through

the roof of the vehicle using a 7/32” (5mm) drill bit.

From the inside of the box, step drill only through the inside

skin of the vehicle using a ½” (12.5mm) drill bit.

®

62-11165 Rev D

From the outside of the box, us e a 7/8” (22mm) hol e saw to

drill the outer roof of the box and the insulating foam.

0.50” (12.5)

Make certain NOT to drill all the way through

the roof. The ½” (12.5mm) hole in the inside

skin of the vehicle must remain intact.

9

Page 10

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evaporator Mounting Preparation – M ushroom Instal lation

L

L

1

2 3

Measure the roof depth from the outside of the roof to the inside

of the inner box skin (distance “L”).

Measure mushrooms from the bottom of the head

to end of the mushroom. Mark and cut them to the

same length “L”. Apply waterproof silicone caulk to

the underside of the mushroom head and tap into

the vehicle roof to slightly crush the caulk. Bolt the

evaporator in place using the hardware supplied.

The correct bolting arrangement is show with the mushrooms

®

62-11165 Rev D

4

5 6 7

8

and evaporator in place. Note that the evaporator should not

press directly against the mushrooms due to the step drilling.

1) Mushroom (34-01262-00)

2) Silicone caulk

3) V ehicle roof

4) Box insulation

5) Inner box skin

6) Evaporator housing

7) Washer

8) Mounting screw

10

Page 11

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evaporator Mounting – Drain Line Installation

Install the evaporator drain lines.

A MINIMUM drop of 4.0” (100mm) is

recommended between the drain pan outlet

and where the drain lines exit the vehicle.

Note the difference in drain line recommendations

4.0” (100)

For perishable applications, connect the water drain hoses

together and route outside the vehicle. Note the diagram

showing recommended ways of routing the lines.

for perishable versus frozen applications

®

62-11165 Rev D

For frozen applications, do NOT tee drain lines together. It is

important for each line to directly exit the vehicle in as short a

distance as possible to prevent condensate from freezing.

Make certain there are no low spots that can

trap w ater in any of the drain line routings .

Secure drain lines in place using ty-wraps or clamps.

11

Page 12

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Refrigerant Hose Installation – Handling Recommendations

For proper functioning of the refrigeration unit,

the hoses must be kept clea n and dry

It is recommended to leave the caps installed on

the ends of the hoses while routing them to

prevent internal dama ge or moi stur e entry.

Make sure to use the clamps provided in the installation kit to

secure the hoses and keep them from vibrating or rubbing.

When securing hoses, note the hoses will slightly change length

under pressure. When securing and clamping the hoses, make

sure to account for the slight variations in length that will occur.

®

62-11165 Rev D

Minimum Bend Radius

#6 hose (3/8”) 3.5” (90mm)

#8 hose (1/2”) 4.0” (100mm)

#10 hose (5/8”) 4.5” (115mm)

#12 hose (3/4”) 5.25” (135mm)

Use the rubber grommets provided in the installation kit when

passing through holes and bulkheads to prevent the hoses and

electrical wires from rubbing on any sharp edges.

As shown in the diagram, do not twist, curve or

route the hoses in any manner which will stress

the hose. Use as large a bend radius as possible.

Use elbows and fitting as necessary to ease

installation and increase hose life.

12

Page 13

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Refrigerant Hose Installation – Installation Preparation

Always use the required tools as follows:

Hose Cutting / Crimping Kit: 07-60117-00

Fitting Insertion Tool: 07-60177-00

Cut the hose to the required length using

the Carrier hose cutting tool.

®

62-11165 Rev D

Lubricate the inside of the hose end with

POE oil.

Widen the internal hose clearance using

the expanding tool before sliding the

double zinc clamp over the hose.

13

Page 14

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Refrigerant Hose Installation – Installation Preparation

Lubricate the fitting and O-ring with POE oil.

Insert the connector into the hose.

To avoid damaging to the O-ring, do NOT twist

the fitting during or after inser tion i nto the hose

®

62-11165 Rev D

Crimp the double zinc clamp using the required crimping tool.

You will need to prepare up to 5 refrigerant lines, as indicated:

• Oil return line (all units EXCEPT 20X)

• Discharge line

• Liquid line

• Hot gas line

• Suction line

14

Page 15

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Refrigerant Connection Lines – Neos 100S / 20X ONLY

Liquid

90° ORS 3/8”

Hot Gas

90° ORS 3/8”

Road Suction

O-Ring pilot 5/8”

Road Suction

90° ORS 5/8”

Low Pressure

Service Valve

5/8”

High Pressure

Service Valve

1/2”

®

62-11165 Rev D

Evaporator

Liquid Line

90° ORS 3/8”

Hot Gas

90° ORS 3/8”

Neos 100S /

20X

ONLY

Road Compressor

Road Discharge

O-Ring pilot 1/2”

Road Discharge

90° ORS 1/2”

Condenser

15

Page 16

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Refrigerant Connection Lines – 30S ONLY

Standby

Hot Gas

90° ORS 3/8”

Road Suction

O-Ring pilot 5/8” -> ¾”

Road Suction

90° ORS ¾”

Low Pressure

Service Valve

3/4”

High Pressure

Service Valve

Suction

90° ORS 5/8”

½”

Liquid

90° ORS 3/8”

Standby Units

Hot Gas

90° ORS 3/8”

62-11165 Rev D

Evaporator

ONLY

Liquid Line

®

90° ORS 3/8”

30S ONLY

Road

Compressor

Oil Return

90° ORS ¼” -> 3/8”

Road Discharge

O-Ring pilot ½”

Road Discharge

90° ORS ½”

Condenser

Standby Suction

90° ORS 5/8”

16

Page 17

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Refrigerant Connection Lines – 35X, 40X, 50X ONLY

Standby

Hot Gas

90° ORS 3/8”

Road Suction

O-Ring pilot 5/8” -> ¾”

Road Suction

90° ORS ¾”

Low Pressure

Service Valve

3/4”

High Pressure

Suction

90° ORS 5/8”

Service Valve

5/8”

90° ORS 3/8”

90° ORS 3/8”

Liquid

Hot Gas

Evaporator

Standby Units

ONLY

®

62-11165 Rev D

Liquid Line

90° ORS 3/8”

35X, 40X, 50X

ONLY

Road

Compressor

Oil Return

90° ORS ¼” -> 3/8”

Road Discharge

O-Ring pilot ½”

Road Discharge

90° ORS 5/8”

Condenser

Standby Suction

90° ORS 5/8”

17

Page 18

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Electrical Connections

®

62-11165 Rev D

If required, route the Return Air Sensor

(RAS) and mount to the evaporator fan inlet.

Make all required electrical connections.

Note that most are connectors that are “plug

and play”. The required electrical

connections are listed as follows:

Evaporator Connections:

• Evaporator fan motor(s)

• Return Air Sensor (RAS)

• BPV (quench valve)

• Low Pressure switch

Engine Compartment:

• CLHR (road clutch)

• BBT (quench thermostat)

18

Page 19

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Cab Command Installation

Route the cab command harness to the interior of the vehicle

Protect the harness from all sharp sheet metal

Make sure the harness is not in c ontact with anything hot

Make certain the harness is secured from vibration

Mount the cab command in a accessible location

where it may not be damaged; for example, where

the rear view mirror would otherwise be mounted.

®

62-11165 Rev D

Be careful not to damage any of the vehicle hoses or wires.

If it is mounted i n the das hboard, k eep as far as possibl e from heating ducts.

Maximum exposure temperature: 158°F (70°C).

Do not mount it where it can be exposed to constant, dire ct sunl ight

19

Page 20

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Compressor Mounting

Install the road compressor on the vehicle following the bracket manufacturer’s

installation instructions.

Connect the high pressure line (HP) and the larger

HP

suction line (LP).

Install the injection thermostat (BPT) on the compressor

BPT

high pressure line using the supplied clamp.

Make sure the injection thermostat is making

LP

good contact with the high pressure line.

62-11165 Rev D

®

Make electrical connections for the injection thermostat and

the compressor clutch. Place wires in protective split loop.

After connecting the injection thermostat terminals,

insulate the injection thermostat body with the

insulating material supplied.

20

Page 21

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Battery and Ignition Harness Connections

Route the neiman cable to the vehicle fuse box. Connect the wire

to the 1 A mp fuse holder supplied in the mounting kit.

Connect to a +12Volt DC switched circuit (refer to the specific

vehicle manufacturer’s recommendations).

Cut the battery harness to the required length. Strip back both the

positive (+) and negative (-) harness wires, crimp the electrical

terminals on, and connect to the corresponding terminals on the

fuse holder.

It is recommended to also use soft solder on the

terminal connections.

®

62-11165 Rev D

Mount road fuse holder as close as possible to the vehicle battery.

Put electrical grease on fuse holder connections, install the road

fuse supplied in the installation kit, and put protective cap on.

Connect the unit ground (-) to the vehi cle chassis.

Re-connect the vehicle battery ground (-) to the battery.

21

Page 22

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evacuation, Leak Checking, and Refrigerant Charging

The presence of moisture in a refrigeration system can have many undesirable

effects, such as sludge formation, “freezing up” of metering devices, and metal

corrosion caused by acid formation. Make every effort to keep the system dry.

After performing a pressure leak test, evacuate and dehydrate the system.

Essential tools to properly evacuate and

dehydrate a system include a good

vacuum pump (5 cfm=8m

P/N 07-00176-01) and a good vacuum

gauge indicator (P/N 07-00414-00).

NOTE: a compound gauge is NOT recommended

3

H displacement,

®

62-11165 Rev D

Keep the ambient temperature above 60°F (16°C) to speed evaporation of moisture. If the

ambient is lower than 60°F (16°C), ice may form before moisture removal is complete. If

necessary, heat lamps or alternate sources m ay be used to raise system temperature.

The unit is shipped with a dry nitrogen holding charge. Remove the nitrogen, and then

evacuate and dehydrate the system by connecting three hoses (do not use standard

service hoses) to the vacuum pump and refrigeration unit. Connect an evacuation manifold

with evacuation hoses only to the vacuum gauges and refrigerant recovery system.

22

Page 23

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evacuation, Leak Checking, and Refrigerant Charging

Check the evacuation system for leaks: Without being connected to the inline service ports,

open the vacuum pump and manifold gauge valves and start the pump and draw a deep

vacuum. Shut off the pump and check to see that the vacuum holds. Repair if necessary.

Connect the manifold gauge set hoses to the service ports. Open the

vacuum pump and manifold gauge valves (if they are not already open)

and start the vacuum pump. Evacuate unit until the vacuum gauge

indicates 2,000 microns. Close the vacuum gauge and vacuum pump

valves. Wait a few minutes to be sure the vacuum holds.

62-11165 Rev D

®

Break the vacuum with clean, dry nitrogen. Raise system

pressure to approximately 2 psig

Repeat the steps outlined above one more time.

23

Page 24

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evacuation, Leak Checking, and Refrigerant Charging (Final Step)

Evacuate the unit to 500 microns. Close off the vacuum pump valve and stop the pump. Wai t

five minutes to see if the vacuum holds. This checks for residual moisture and/or leaks.

With a vacuum still in the unit, the refrigerant charge may be drawn into the system from a

refrigerant container on weight scales. The correct amount of refrigerant may be added by

monitoring the scales.

Make sure to use the correct

refrigerant for each refrigeration unit.

When the correct charge has been added, close the unit

manifold valves and disconnect the manifold gauges.

MODEL Refrigerant

Type

Refrigerant Charge

Pounds Kilograms

62-11165 Rev D

®

Neos 100S R134a 2.2 lb. 1 kg

20X R404a 3.10 lb. 1.4 kg

30S R134a 4.00 lb. 1.8 kg

35X R404a 3.30 lb. 1.5 kg

40X R404a 6.60 lb. 3.0 kg

50X R404a 7.05 lb. 3.2 kg

24

Page 25

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evacuation Process

5000

4500

4000

3500

3000

2500

2000

(Inches of Hg)

®

62-11165 Rev D

1st Step

2nd Step

1500

Final Step

1000

Vacuum Indicated By The Meter

500

0

Dry & Tight Circuit

0 1 2 3 4 5 6 min

25

Page 26

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evaporator CPR Adjustment

The Compressor Regulation Valve (CPR) is designed to regulate the flow of refrigerant

returning to the compressor from the evaporator and ensures the correct capac ity of the unit.

The CPR also reduces compressor start-up and operation load. It is critical it is set correctly.

CPR adjustment MUST be done under the foll owing conditions:

• Road operation at 2,400 compressor RPM

• Heat or Defrost mode

Connect manifold gauges to the CPR fitting port.

Start the unit in Heating or Defrost mode. Check that

the road compressor speed is 2,400 RPM

Remove the cap on the CPR valve.

62-11165 Rev D

®

Adjust the CPR with an 8mm Allen (hex head) wrench

to get correct gauge pressure (see next page).

• To raise the suction pressure, turn the set screw

clockwise

• To low e r the suction pr ess ure, turn the s et

screw counter-clockwise.

26

Page 27

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evaporator CPR Adjustment

* The CPR adjustment must be INCREASED by approximately +0.5 psi for

every additional foot (+ 0.1 bar per meter) that the evaporator is locate d

(distance D minus 6”) fr om the front wall of the vehicle.

MODEL CPR Setting at CPR Port

PSI BAR

Neos 100S 10.3 psi .7 bar

20X 27.5 psi 1.9 bar

30S* 18.9 psi 1.3 bar

35X 30.5 psi 2.1 bar

40X 33.4 psi 2.3 bar

50X 37.7 psi 2.6 bar

®

62-11165 Rev D

D

*Only the 115V standby versio n o f the 30S has a CPR .

No other 30S versions require adjustment.

When the setting has been adjusted, tighten the

jam nut securely against the setting screw to

prevent any vibration of the set screw (and to

prevent disruption of the CPR setting).

Replace the CPR cap and remove gauges.

27

Page 28

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evaporator TXV Setting

®

62-11165 Rev D

The Thermo Expansion Valve (TXV) is

designed to precisely meter the flow of

liquid refrigerant into the evaporator

and control the refrigerant gas leaving

the evaporator.

The evaporator outlet pressure (P2)

must be converted to saturation

temperature (T3) using a P/T chart.

The superheat is the difference

between the temperature at the bulb

location (T1) and the evaporator outlet

T1

P2

saturation temperature (T3).

Connect a gauge to the evaporator

outlet fitting. Put a thermocouple at

the expansion valve bulb location and

insulate it. Run the unit in Cool mode.

28

Page 29

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

Evaporator TXV Setting

To INCREASE superheat, turn clockwise

To DECREASE superheat, turn counter-clockwise

®

62-11165 Rev D

Repeat process a

minimum of 3 times

SUPERHEAT = T1 – T3

Superheat at

MODEL

ALL 14.5°F

To complete the installation, re-install any evaporator panels.

32°F (0°C) Box

8°C

Superheat at

0°F (-20°C) Box

7°F

4°C

29

Page 30

Installation & Commi ss ioning Manua l:

Neos 100S, 20X, 30S, 35X , 40X, 50X

North America

Carrier Transicold

700 Olympic Drive

Athens, GA 30601 USA

Tel: 1-706 -357 -7223

Fax: 1-706 -355 -5435

Central America

and Mexico

Ejercito Nacional 253 - A Piso 5

Colonia Anahuac

11320 Mexico, D.F.

Tel: 55315010

Fax: 55315010 ext. 1005

®

62-11165 Rev D

Carrier Transicold Division,

Carrier Corporation

P.O. Box 4805

Syracuse, N.Y. 13221 U.S.A.

www.carrier.transicold.com

A member of the United Technologies Corporation family. Stock symbol UTX

30

Loading...

Loading...