Page 1

.

.................. 'Й

‘Ш 1

Electric Heating: 182,500 to 808,000 Btuh

Electric Cooling: 220,000 to 753,000 Btuh

Sirag

là

pi^eE)

©

'"((Doieg umts

1.

in®

1Ш“,

® I 1

p

Air Distribiitioin S|/steni

Jr MociM-rac

Electric Cooling: 220,000 to 744,000 Btuh

Versatile

rooftop units —

for constant or

Moduline® for

VAV system

variable air volume

applications in the

20- to 60-ton range

NOW — with energysaving features for

years of outstanding

performance

• SOLID-STATE CONTROL

LOGIC

• INTEGRATED ECONOMIZER/MECHANICAL

COOLING

• LOW-LEAKAGE

DAMPERS

• INTERTWINED COILS

• TWO-SPEED INDOOR "

FAN OPTION

' Carrier Corporation 1982

Form 50DF-2P

Page 2

£

FEATURES AND BENEFITS

OPTIONS AND ACCESSORIES

PHYSICAL DATA

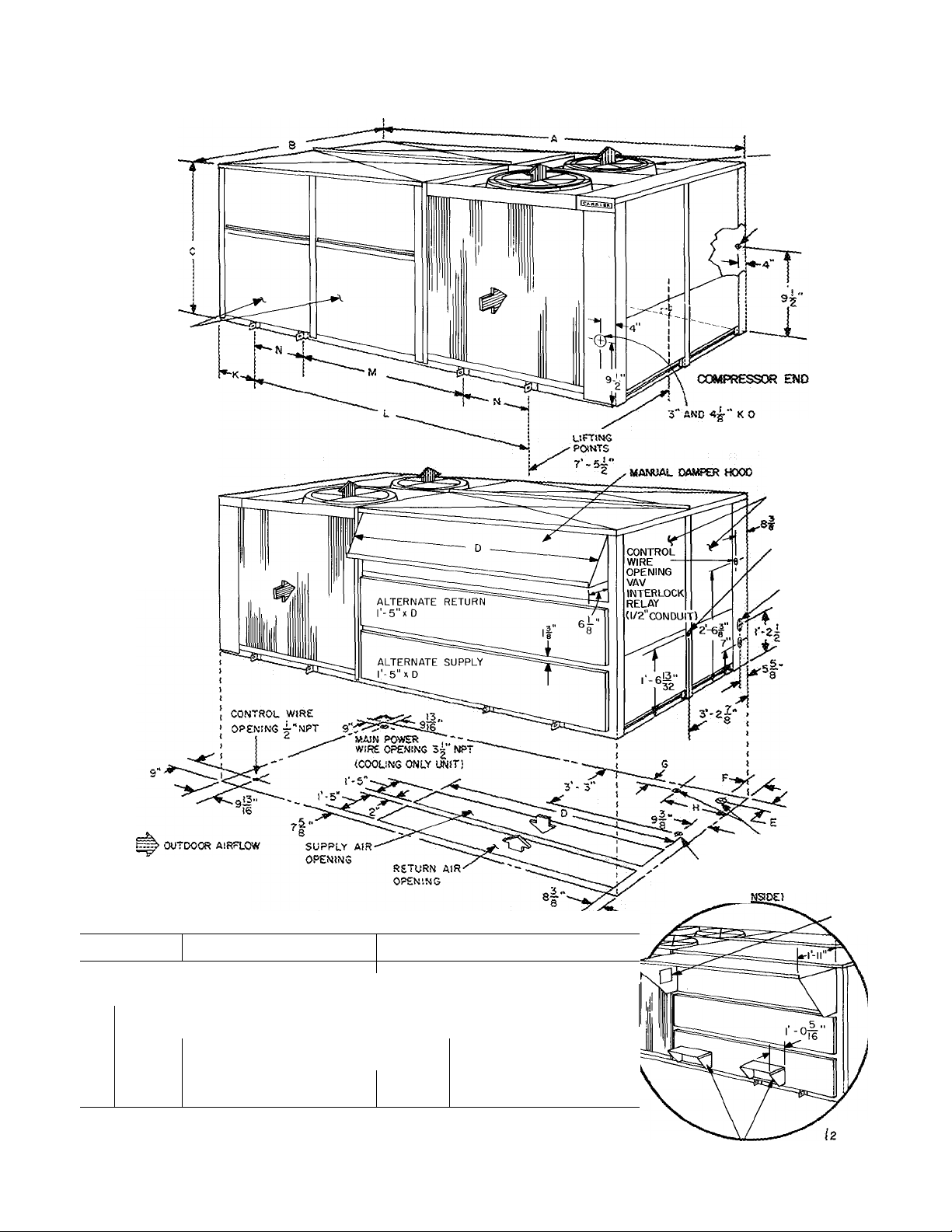

BASE UNIT DIMENSIONS

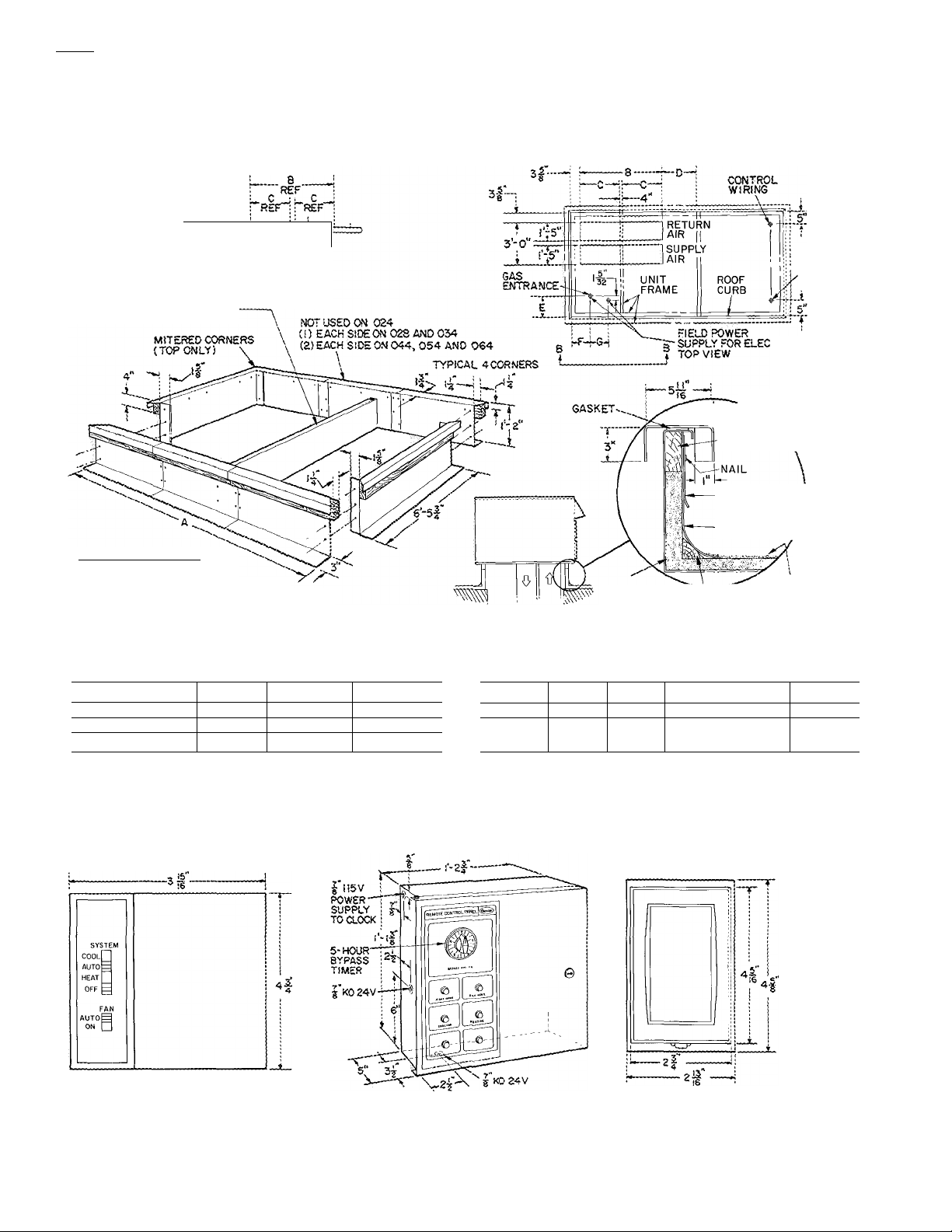

ACCESSORY DIMENSIONS

SELECTION PROCEDURE

PERFORMANCE DATA

Cooling Capacities

Heating Capacities

Optional Equipment Resistances

Indoor Air Fan Pulley Data

Fan Performance

ELECTRICAL DATA

CONTROLS

Operating Sequence

Electrical Protection

TYPICAL WIRING SCHEMATIC

APPLICATION DATA

TYPICAL PIPING AND WIRING

GUIDE SPECIFICATIONS

50DF

3

4,5

6

7

8

9

9,10

10

10

11

12

13-15

16

17

18

19

16

20,21

50DF Modu"Pac@

22-24

24

25

26

27

28

29,30

32

32

32

31

33

32

33

34

—

35

36

VL

Page 3

50DF

High quality features assure easy installation

— plus performance and energy savings

Solid-state components for precise

system control — Units contain a

solid-state control system that pro

vides maximum operating economy.

The “brain” of the system is a logic

panel that offers 2-stage heating and

cooling modes based on space re

quirements. Panel also is the logic net

work that coordinates operation of the

economizer, energy management and

two-speed indoor fan options.

Solid-state components require no

calibration, are easily replaced and

have long operating life.

Practical curb design for low in

stallation costs — The curb supports

unit on the roof. Eliminates special steel

support frames and assures a low roof

silhouette. Weatherproof enclosure

eliminates need for a rooftop adapter or

roof openings that could be sources

of troublesome leaks. All utilities enter

unit within the curb; saves time and

reduces installation costs. A wood nailstrip is also included.

Adaptable duct connections — The

Carrier design provides large duct

openings that permit low airflow veloci

ties and even air distribution. Bottom

supply and return ductwork is easily

installed. Concentric ductwork with

diffusers also may be connected to the

20-, 25-, and 30-ton units.. .with no

internal modifications.

For convenience, alternate side supply

and return openings are provided for

horizontal duct applications. Simply

relocate side supply and return panels,

place them in the bottom openings,

relocate one interior panel and the unit

is quickly converted for side duct con

nection. An accessory conversion kit

is required for units with economizer.

Factory-installed filter rack includes

2-in. filters.

115-volt convenience outlet — An

on-the-job power source for service

light or hand tools.

Pre-installed tracks for hydronic coil

application. Factory installed on units

without electric heat option.

Weather Armor cabinet stands up to

the weather. Cabinet design exceeds

UL and Carrier rain test requirements.

Units keep attractive appearance for

years — even in salt air or heavy in

dustrial environment.

Time Guard® circuit — Compressor

will not short cycle on a safety device or

power interruption. Starts outdoor air

fans 15 seconds before compressor to

minimize solar heat buildup and reduce

start-up load.

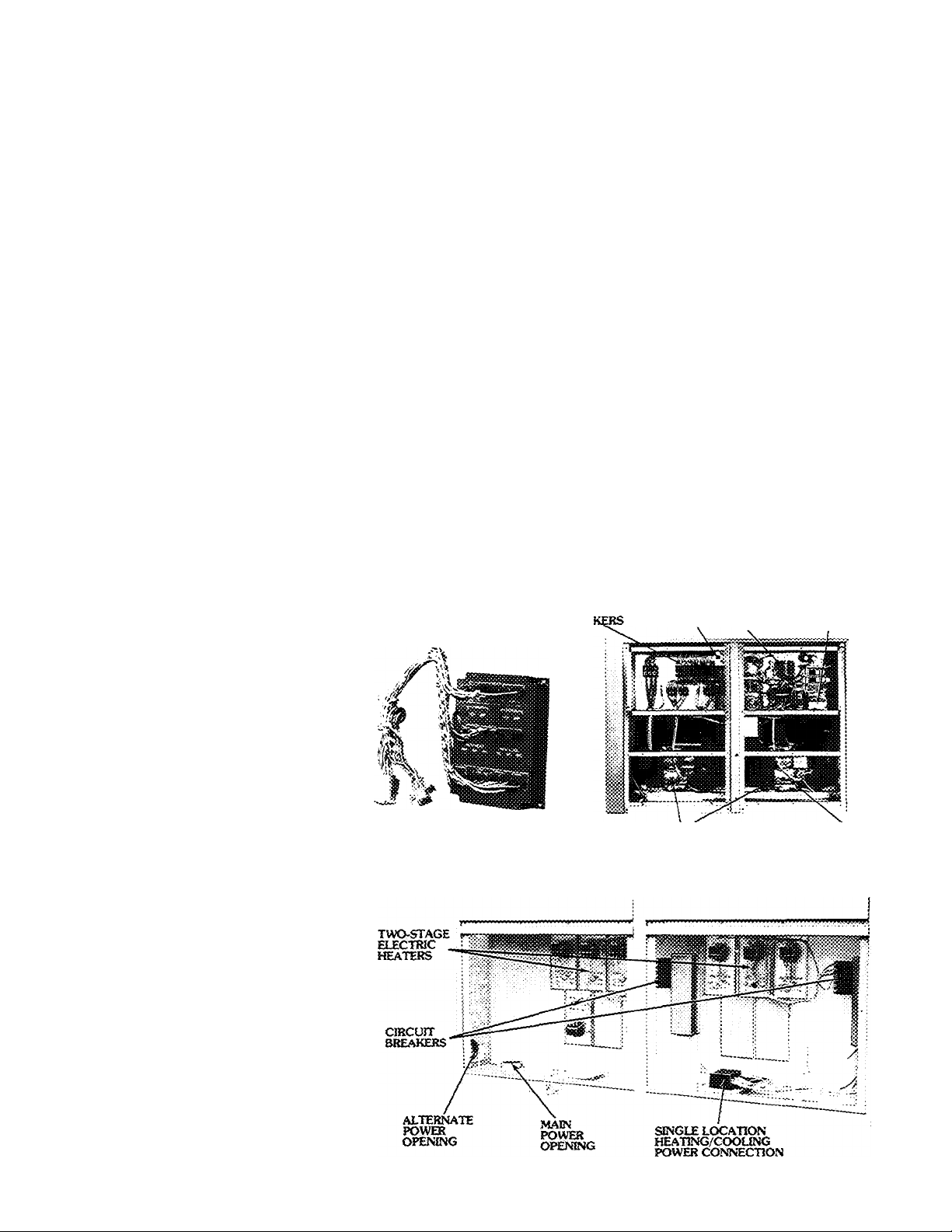

Single-location power connections

— Unit is factory wired with all heating

and cooling power circuits internally

routed to a terminal block in one com

partment. Some units, with higher heat/

cool ratios, have 2 terminal blocks. No

need to route expensive wiring to

separate heating and cooling power

locations. Saves time, money and labor.

Fixed-speed evaporator fan drive —

less vibration than variable-speed drive.

Extends belt life and minimizes drive

noise.

Manual damper, on standard units,

can be preset to admit as much as 25%

outdoor air for year-round ventilation.

Cfficurr

8REA:

LOGIC PANEL

Built-in convenience — Quick-release

access panels, slide-out filters and plug

in relays simplify routine inspection

and maintenance.

Carrier-built intertwined refrigerant

coils have staggered copper tubes with

mechanically bonded fins to ensure

optimum heat transfer. Intertwined

design provides cooling of the full air

stream with minimum compression.

Direct-drive condenser fans are

factory lubricated. Vertical discharge

moves air quietly and efficiently.

Carrier compressors have factoryinstalled service valves, crankcase

heaters, reversible oil pumps, mufflers,

overloads in the control box and

internal motor protection. Liquid line

sight glasses and filter driers are also

included.

Low-ambient temperature capa

bility permits all units to operate at out

door temperatures as low as 35 F.

CON\gv(IENCE logic LOW VOLTAGE

OUTLET , PANEL TERNHNAL BLOCK

CARRIER SERVICEABLE

HERMETIC COMPRESSORS

«LEAD

COMPRESSOR

(Uses Suction

Pressure)

Page 4

Factory-installed options and

field-installed

accessories offer flexibility to

application

Modulating outdoor air control

package (economizer) — Even when

outdoor air temperatures are low, many

installations still require cooling. The

economizer uses the cool outside air to

provide this cooling. Saves energy,

reduces compressor wear and tear and

lowers operating costs.

The economizer contains these

energy saving features:

• Electronic control logic balances

the conditioned space demand against

the cooling system output. Ensures that

the economizer modulates to correct

position or closes to minimum position

to maintain a stable temperature in the

conditioned space. Never too much or

too little cooling.

The control logic also integrates

economizer cooling with mechanical

cooling. If outdoor enthalpy permits,

economizer acts as first stage of cooling.

If conditioned space requires more

cooling, economizer works in conjunc

tion with mechanical cooling to maintain

required indoor temperature.

The integrated system supplies only

the amount of mechanical cooling

necessary.

• Low-leakage dampers limit infiltra

tion. Rated by the manufacturer at 3%

with 3-in. wg pressure differential.

• Spring return damper motor auto

matically closes the outdoor air dampers

in the event of a power failure. (Option

or Accessory)

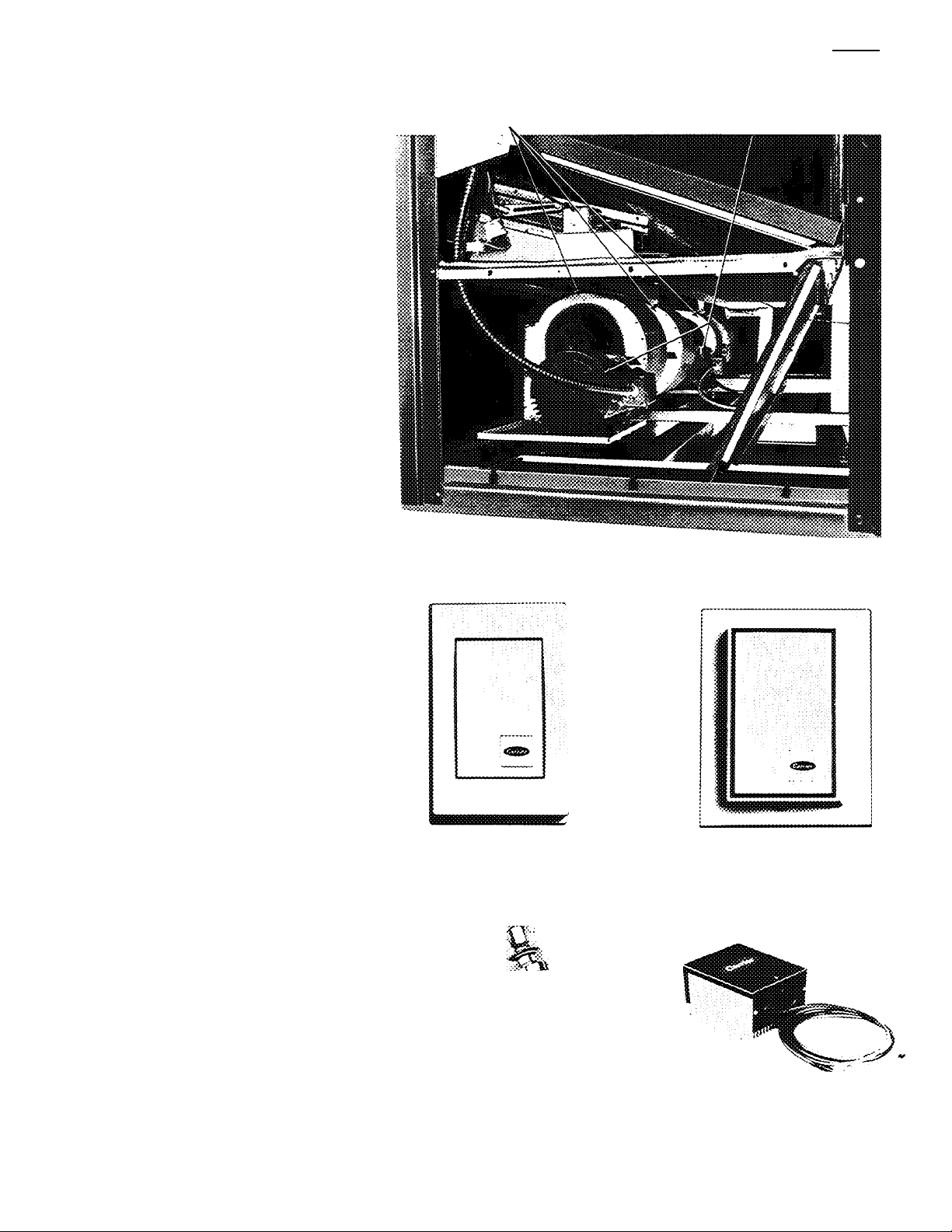

Two-speed indoor fan option —

Substantial energy cost savings can be

obtained because fans automatically

operate at low speed during most cool

ing operating hours. High speed is used

only if and when necessary to maintain

comfort conditions.

A 4-stage electronic logic panel

selects the most efficient fan speed and

compressor stage to satisfy room de

mand. Economizer performance is

optimized by utilizing low-speed opera

tion except when space conditions

require the additional capacity of high

speed “free cooling”.

The two-speed option is available in

either standard or alternate motor

sizes. All control and power wiring are

factory installed; thus, costly field wiring

and adjustments are not necessary.

The two-speed fan motors are 2

winding (4 pole/6 pole) with rpm’s of

1760/1170.

Power exhaust — Coupled with the

economizer, up to 75% of the return air

can be exhausted. Also, eliminates

over-pressurization of the building.

Designed for use with bottom duct

connection arrangements. Used only

with economizer. (Option or Accessory)

Electric heaters — Three factory-

installed and one field-installed heating

capacity are available. Factory wired for

2-stage heat. Outdoor air thermostats

can be added to provide additional

stages as required. Branch circuit pro

tection is built in on each unit. (Option

or Accessory)

Bag filter — Extended surface media

provides high filtration of 50% (NBS

Dust Spot Test). Filter frame permits

use of field-supplied bag filters to pro

most any

vide up to 95% filtering efficiency.

(Option only)

Alternate indoor fan motor and

drive provides increased perform

ance for application requirements

beyond standard unit operation range.

(Option only)

Energy management kit—Additional

energy savings occur thru the use of

the multi-feature energy management

kit which contains a setback/setup

module, a 7-day programmable clock

and morning warmup thermostat.

During unoccupied periods, the set

back/setup module provides a select

able amount of heating setback and

either cooling shutdown or a selectable

amount of cooling setup

The 7-day clock controls unit opera

tion in and out of the setback/setup

modes. Clock contains a 10-hour spring

carryover for continuous operation

during power failures. Re-programming

is not necessary.

A 5-hour bypass switch provides unit

operation during unoccupied modes.

The clock and bypass switch are con

tained in an attractive remote control

panel which installs in a convenient

location. Six status lights on the panel

indicate system operating modes.

The morning warmup thermostat

senses return air temperature and saves

energy by keeping the outdoor air

damper closed until morning warmup

is complete. Avoids using energy to

warm cold outside air. (Option or

Accessory)

REMOTE CONTROL PANEL

(Control Box)

SETBACK/SETUP MODULE

7-DAY CLOCK

Page 5

Barometric relief damper operates

automatically to help exhaust excess

air during economizer operation. Ac

cessory comes partially assembled for

easy installation.

Roof curb supports unit and frames

roof opening. Provides a strong, water

tight interface between unit and roof.

Once curb is set in place, the unit may

be rigged at any time — no need to

schedule around the roofer. Design

complies with National Roofing

Contractors Association (NRCA)

requirements.

Outdoor air thermostat allows addi

tional staging of electric heat. Multiple

thermostats permit as many stages of

control as there are heaters in the unit.

Suction pressure unloader package

— Additional staging, beyond the stand

ard 2 stages of capacity control, can be

accomplished with field-installed suc

tion pressure actuated compressor

unloaders. (024 size is excluded, uses a

standard electric unloader.)

Motormaster® head pressure con

trol modulates the speed of outdoor air

fan motor to maintain correct con

densing temperature at low outdoor air

temperatures. Permits operation to

-20 F, if required.

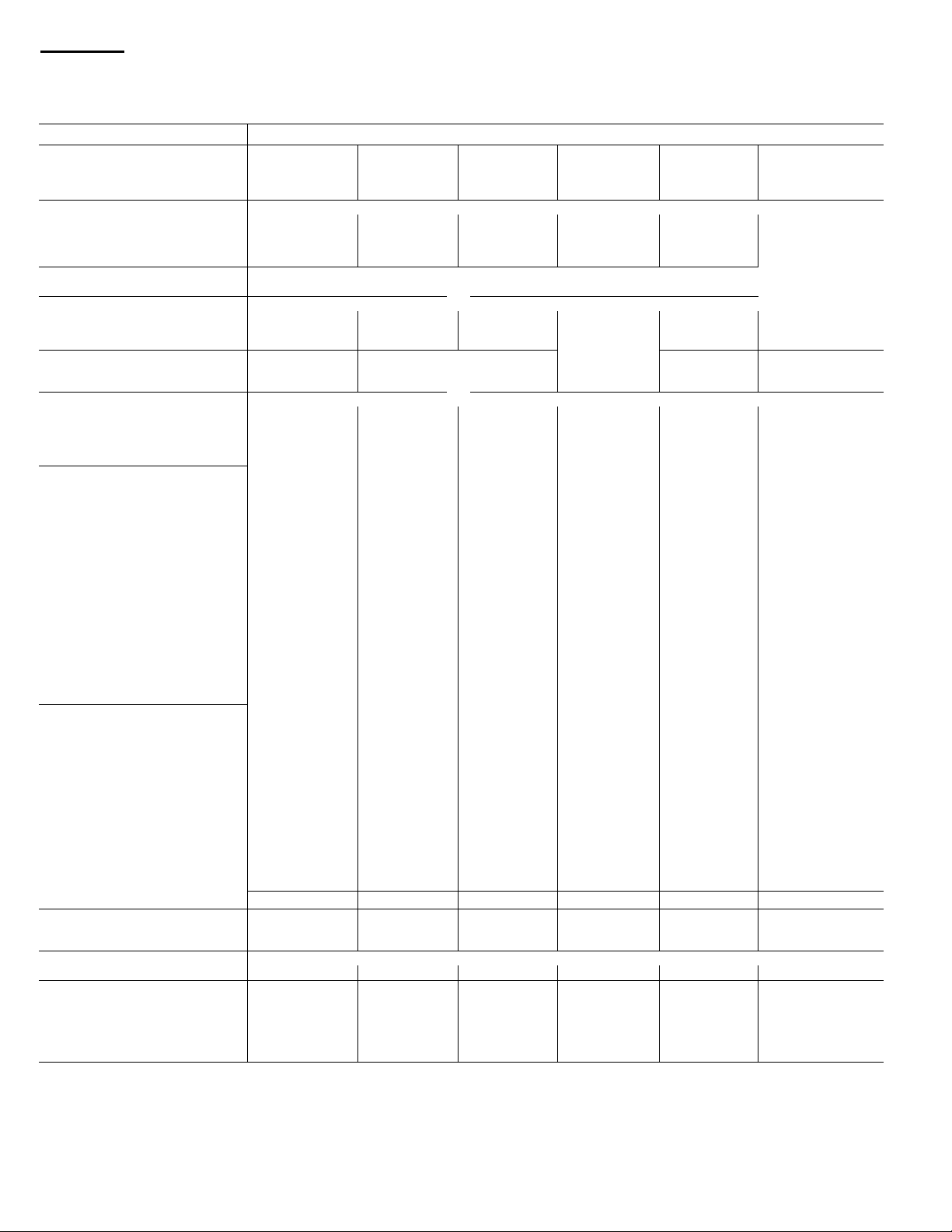

Electronic temperature sensing —

Three electronic sensing/transmitting

devices are available to meet your

specific application requirements. Each

transmitting device contains dual

(heating/cooling) set point adjustment

levers concealed under a locking cover.

Light emitting diodes (LED’s), also con

cealed under the cover, allow diagnostic

checkout of control system from the

transmitting device. The choices are:

• Thermostat with integral sensor —

A traditional application. Both the

temperature set points and the sensing

device are contained in one device

installed in the conditioned space.

• Transmitter with remote sensor —

The transmitter contains the tempera

ture set points and LED’s under its

cover. In this application, a remote wall-

mounted sensor is installed in the con

ditioned space and the transmitter is

installed in a restricted-access area.

Eliminates unauthorized adjustment of

conditioned space temperature.

• Thermostat or transmitter on subbase

—provides manual COOL-AUTO.-

HEAT-OFF system switching and

AUTO.-ON fan switching from a con

venient location. Recommended for

units without energy management kit.

fsODFl

FANS

MOTORS

I

____

PO’WER EXHAUST FANS AND MOTORS

THERMOSTAT OR

TRANSMITTER

REMOTE

SENSOR

UNLOADER PACKAGE MOTORMASTER CONTROL

Page 6

I 50DF~

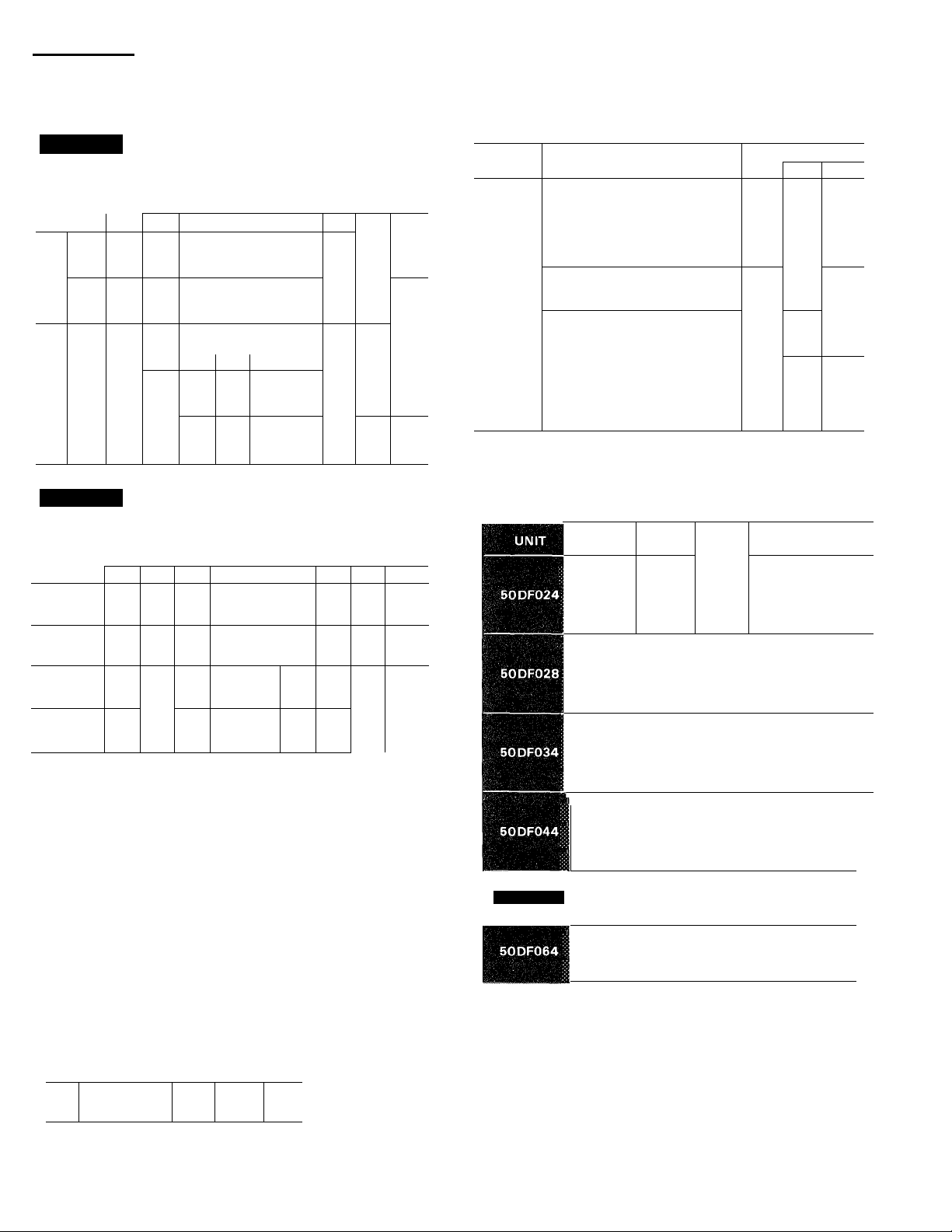

Physical data

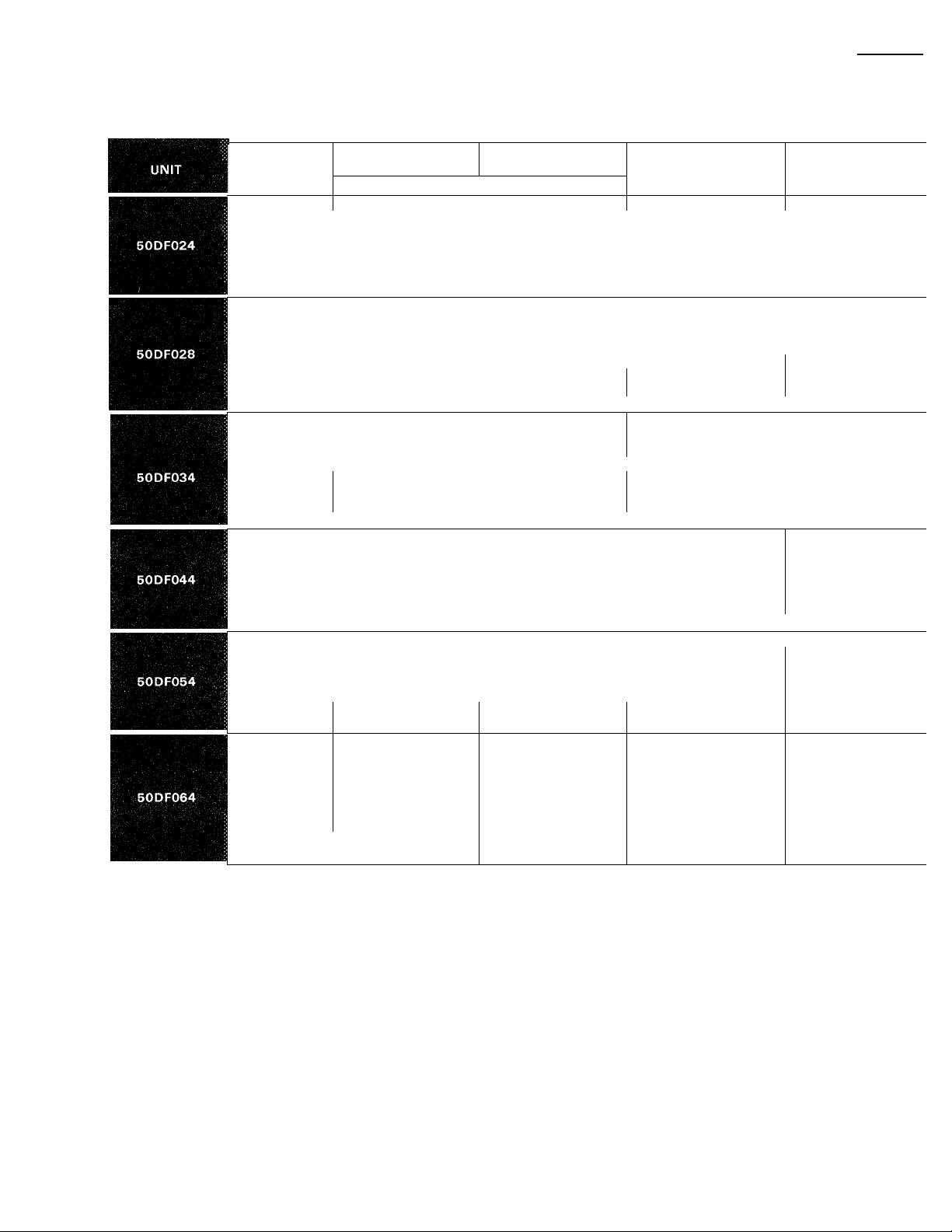

UNfT SOOF

OPERATING WEIGHT (lb)

Base Unit

Economizer 150 175 200 225 250

Roof Curb

COMPRESSOR

No ..Type

No Cylinders (ea)...Rpm

Capacity Steps (%) (Std)

With Accessory Unloaders

REFRIGERANT CHARGE Type 22; Controlled by Thermostatic Expansion Valve

Sys 1...Sys 2 (lb)

OUTDOOR AIR FANS

No ...Diameter (in.)

Nominal Cfm

Motor Hp...Rpm

CONDENSER COIL

Rows.. Fins/in.

Total Face Area (sq ft)

INDOOR AIR FANt

No. ...Size (in.)

Max Allowable Rpm

Nominal Cfm

Standard Motor and Drive

Motor Hp

Motor Frame Size

Single-Speed

Two-Speed

Fan Pulley Pitch Diam (in )

Fan Pulley Bore

Single-Speed Motor Rpm

Two-Speed Motor Rpm

Motor Pulley Pitch Diam (in.)

Pulley A

Pulley B

Resulting Fan Rpm

Single-Speed with Pulley A...B

Two-Speed with Pulley A.. B

Alternate Motor and Drive

Motor Hp

Motor Frame Size

Single-Speed

Two-Speed

Fan Pulley Pitch Diam (in.)

Fan Pulley Bore

Single-Speed Motor Rpm

Two-Speed Motor Rpm

Motor Pulley Pitch Diam (in.)

Pulley A

Pulley B

Resulting Fan Rpm

Single-Speed with Pulley A...B

Two-Speed with Pulley A...B

EXHAUST FAN MOTOR Qty...Hp

EVAPORATOR COIL

Rows...Fins/in.

Total Face Area (sq ft)

ELEC RESISTANCE HEATERS

Heat:Kw

INDOOR AIR Filters

No .. Size

Standard; 2-In Throwaway

Bag Type; 12-in. (Opt)

02A

3000

125 150

1 06E 2 060

4 1750 6 1750

50,100 60,100 50,100

—

36 0 —

2 30

14,000

1 1050 1 1050 1 1050 1 1050 1 1050 1 1150

3 139 3 139

31 1

2 15x11 2 15x15

1300

8,000 10,000

5 (460V)

7-1/2 (208-230V)

184T (460V)

213T (208-230V)

215T (460V)

254T (208-230V)

106 106

1 -3/16

1750

1750/1170

65

60 56

1073 991

1073/751

991/661 925/617

7-1/2

213T

254T

80

1-3/16

1750 1750 1750 1750 1750

1750/1170

53 5 3

56 56

1159 1225

1159/773 .

1225/817 1225/817

1 3

4 15

15 1 177

37,55,91

6 20x25

6 15x25

3 12x24 4 .12x24

3 24x24 4. .24x24 5. 24x24 6 24x24

028

3700 4400

19,38,57,100 16,33,50,100

23 75 18 25 29 0 29 0 37 0 37 0

2 30 3 .30 3 30 4 30

14,000 21,000 21,000 28,000 31,000

38.0

1300 1300 1300 1300

7-1/2

21 3T 21 5T 254T 256T

254T

1-3/16

1750 1750 1750 1750

1750/1170 1750/1170 1750/1170

65 6 5 65 6 5 5 6

1073 925 1073 925 1073 925 1073. 925 1225 1312

1073/751. 1073/751

10

215T 254T 256T 284T

256T 284T 286T 286T

80 80 80 80

1-3/16 1-11/16 1-11/16 1-11/16

1750/1170

1159 1225 1159 1225 1159 1225 1159 1225

1159/773 1159/773 , 1159/773 1159/773

1 3 1 3 2 3 2 3 2. 3

4 15

Open Nichrome Wire Elements with Multiple-Stage Control

55,73,110 55,91,128

18. 16x25

034

175

Serviceable, Hermetic

2 06D

6 1750

Direct Driven, Propeller Type

3 158

49 0

i

Belt Drive, Centrifugal Type

3 15x9 4 15x9

12,000

10 15 20

256T 284T 286T 286T

106 106

1-11/16 1-11/16 1-11/16

5 6

925/617 925/617 991/661

15 20 25t 30t

1750/1170

53 5,3 53

56 5 6

1225/817 1225/817

4 15

24 8

9, 20x25

12 16x25

5.. 12x24

044 054 064

5406

200 225

2 06E

4 1750

50,100

25,50,75,100

3 158 3 158

61 0

16,000 20,000

56

1073/751

1750/1170

4 15 4 15 4 139

30 2 35,4

73,110,165

27.. 16x25

6. 12x24

20,40,60,80,100

1073/751

6100 6485

**

2 06E*

4,6 1750

60,100

53 0 42 0 81 0 81 0

81 5

4 15x11

106

1750/1170 1750/1170

60

1750/1170

56

1225/817

91,146 91,146

9 20x25 9 20x25

21 16x25 21 16x25

7 12x24

7 24x24

250

225

2 06E

6 1750

50,100

16,33,50,67,83,100

4 30

4 158

81 25

4 15x11

1450

24,000

25

284T

80

1-11/16

1750

60

1225/817

1312/875

286T

—

60

1-11/16

1750

1750/1170

50

**

1450 —

1450/967 ,

35 4

_

#

*Unit contains one 06EA250 and one 06EA275 compressor

fStandard fan motor supplied with standard fan drive pulleys and belts;

alternate fan motor supplied with alternate fan drive pulleys and belts Other

combinations are field supplied Pulley A is installed in unit; pulley B is shipped

with unit (024-054)

itDue to large frame size, the 25 hp, 208-230 volt and 30 hp motors are avail

able in single speed only

**The 50DF064 alternate drive Is supplied with Pulley A only

1182

Page 7

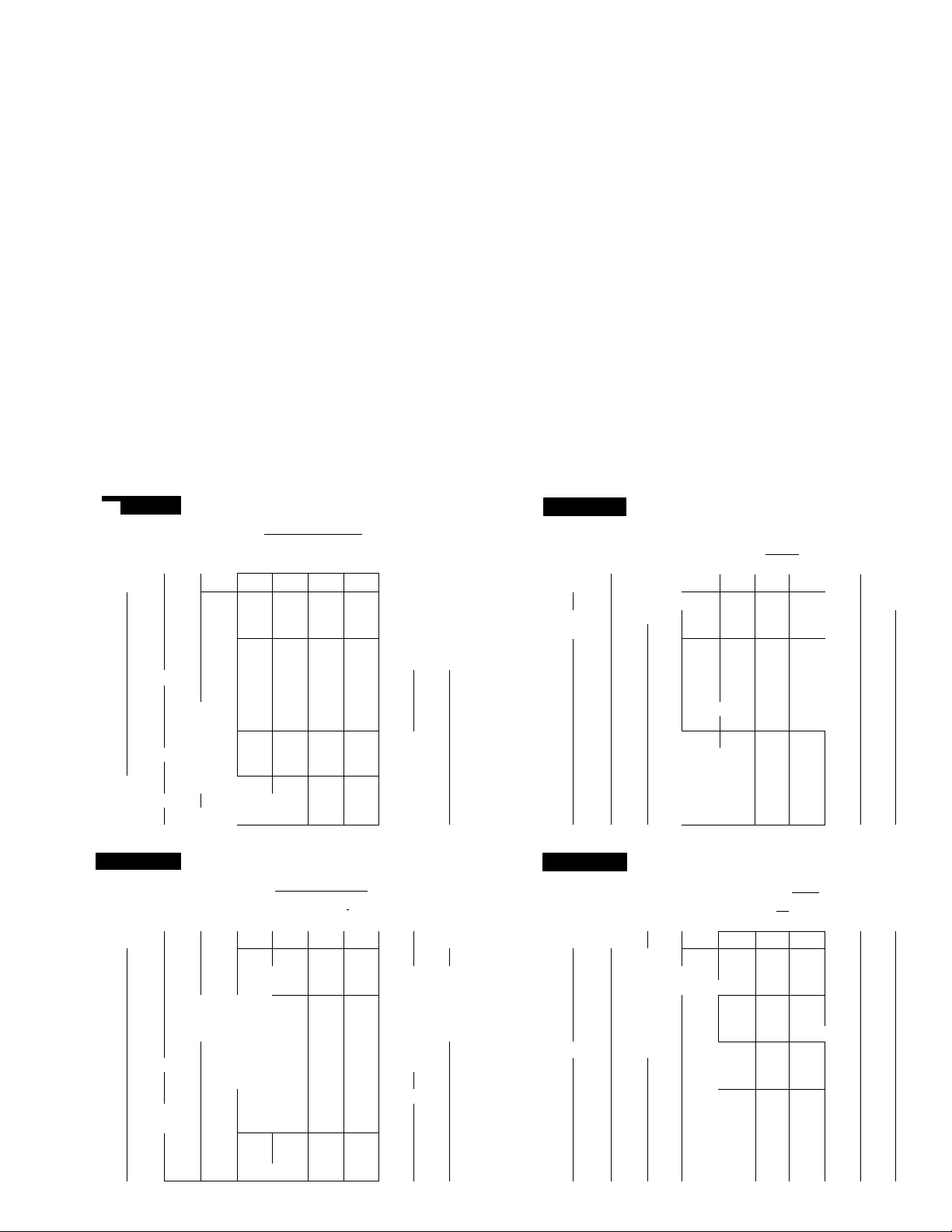

Base unit dimensions

ELECTRIC

HEATER

ACCESS

panels

50DF

OUTDOOR AIR FANS:

2- 024.028

3- 034,044

4- 054, 064

ALTERNATE

CONTROL WIRE

OPENING CONDUIT

ALTERNATE PIELO POWER WRING

ICOOLiNG ONLY UNIT)

a®OOR AtR FAN

AND FiLTEB

ACCESS PANELS

©»«PRESSOR

END

INDOOR AIRFLOW

DIMENSIONS (ft-in.)

UNIT

50DF

Cenified dimension drawings available on request.

NOTES;

1. Allow 12 ft above unit 8 ft on filter access pane! erxland 4ft on remaining sides of unit for

2 For smaller clearances, contact Carrier.

3 Refer to Roof Curb dimensions for details of roof openings

024

10-10

A

8

C

4-11

D

0-10-1/4

E

0- 9-7/8 0- 9-7/8 ¡0- 9-7/8 1- 1-1/4

F

6

H

J

K

L

M

N

airflow arwJ service clearance.

—

—

3-1/2" NPT

2- 4 2- 4 ; 2-10 2-10 2-10

6- 1-1/2 9- 0 ; 11- S :14-10-1/2

—

~

028 I 034 I 044

13- 8-1/2‘1 17- 1 ['20- 6-1/2

6-11 ■ 9-0 i 11- 0

0-10-1/4 i 0-10-5/16 0-10-5/16

4" NPT i 4" NPT 4“ NPT <ea)

— 1 — ¡4-7

7-3-1/8

4-11

— — 0- 9-3/16

— i — 1- 8-1/4

— Î — 1 5- 8-1/2

054

24-11-1/2 24-11-1/2 \

13- 0-1/2

0-10-5/16 0-10-5/16 1

1- 3

0- 9-1/8

1-10-11/32

4" NPT (ea)

19- 3-1/2

7- 7-1/2

5-10

19- 3-1/2

9- 4-1/2

Q04 AIR INTAKE HOOD

1- 3 1

2-10

6-10

OPTIONAL

13- 0-1/2 li

0- 9-1/8 \

1-10-11/32 V

4" NPT (eal V

DRAIN

2|" DiAM U"

*^MPT C0NN.,i.

alternate

drain 2~“ KO <r HURT

MAIN POWER WIRE

OPENING <J) CHEATING/

COOLING UNIT', (2ON

044,054 AND 064)

OPTIONAL JS-034

EXHAUST HOO0SÌ4-O44

CONN. iNStOE)

ALTERNATE

POWER WIRE

OPENING 3^"NPT

GCATING/COOUNG

" UNITK2 ON

044.054 AND

064)

ENTHALPY

CONTROL

LOCATION

{5-054,064

-024,028

Page 8

50Df1

Accessory dimensions

DUCT WORK (FIELD

SUPPLIED) MUST BE

NOTCHED TO CLEAR

SUPPORT

NOT USED ON 024.028

(LOCATE PER DIMENSIONS)'

ROOF CURS ASSEMBLY

NOTE:

CURB MUST BE LEVEL SO THAT UNIT

DRAINS FUNCTION PROPERLY

SEE BASE UNIT INSTALLATION INSTRUCTIONS

FOR LEVELING TOLERANCES

■ 5*i"

V1EW8-B

VIEWA-A

DIMENSIONS (ft-in.)

RIGID

INSULATION

(FIELD SUPPLIED) \

FIELD

POWER

SUPPLY

HEAT UNITS

TYPICAL 4 SIDES

ILTi^v^r-UNIT BASE

Jr \ RAIL

WOOD NAILER

(FACTORY SUPPLIED)

COUNTER FLASHINS

(FIELD SUPPLIED)

ROOFING FELT /

(FIELD SUPPLIED)

ROOFING MATERIAL

(FIELD SUPPLIED)

CANT STRIPiFIELOSUPPl

.lEO)

UNIT A

50DF024 ;10- 0-1/4

50DF028 ;12-10-3/4 : 6-11

50DF034 Ì16- 3-1/8

; 8

; 4-n

; 9- 0

SU^ASE

c D E

: „

i “

; 4-4

0-6-1/4

0-6-1/4

0-6 0-8-1/4 0-6-7/8 i -

F : G

0-5-1/8 : —

0-5-1/8 i -

UNIT

50DF044

S0DF054

50DF(^

REMOTE CONTROL PANEL

(Control Box)

A B i c O E F

19-8-1/4 11-0 15-4

24-1-3/4

13-0:6-4

THERMOSTAT/TRANSMITTER

0-6 :0-6-1/4 ;6-9-1/4

0-6 10-6-1/4 iO-6-3/4

G

0-7

0-7-11 /32

n

1182

Page 9

SctectlOîî procedure (with example)

1 Determine cooling and heating requirements at design SHC of 236,000 Btuh. Calculate SHC correction, if

conditions. required, using notes under cooling capacities tables

Given III Select heating capacity of unit to provide design condi-

Required Cooling Capacity (TC)

.......................

300,000 Btuh ^ion requirement.

Sensible Heat Capacity (SHC) ............................ 236,000 Btuh In the Heating Capacities table, note that unit 50DF028 with

Required Heating Capacity

Condenser Entering Air Temperature ........................... 95 F c j j •

Indoor Air Temperature ....

Evaporator Air Quantity......................................

External Static Pressure

Electrical Characteristics (V-Ph-Hz)

................................

...................

80 F edb, 67 F ewb Determine fan speed and power requirements at design

.......................................

..............

240,000 Btuh 73 kw heaters will provide 249150 Btuh

10,000 cfm conditions.

1 80 in wg f^an Performance table at 10,000 cfm and 1 80 in wg

460-3-60 ^^at the fan speed is 1210 rpm and the power required is

II Select unit based on required cooling capacity >^P

Enter Cooling Capacities table at condenser entering ^ Select unit that corresponds to power source available,

temperature of 95 F Unit 50DF028 at 10,000 cfm and 67 F The Electrical Data table shows that a 460-3-60 unit is available,

ewb will provide a total capacity of 308,000 Btuh and a

Performance data

COOLING CAPACITIES

50DF024

m

Temp (F)

Air Ent

TC 266

85

SHC 132 165 197

KW 21.3 20.1

TC 250 228 206

95

SHC

KW 22.6 1 2l;6 20.1

TC 243 221

100 SHC 124

KW 23 2 22 2

TC 236 214

105

SHC

KW

TC 227 207

110 SHC 119 151

KW

6000/.042

72

127

122

23 9 22 6 21 4

24 8 23 2

50DF034

Temp (F)

Air Ent

Cond

TC

85 SHC 214

TC

95

SHC 203

TC

100

SHC

TC

105

TC

110

10,000/.068 12,000/.082 | 13,500/ 088

72 67

412 380

KW 32 0

392 360

KW 34 7

383

200 255

KW

35 9

373 344

SHC 197

KW

37 4

354

SHC 191

KW

39 3 37 8

67 62

243 220

19 0

159 191

201

157 189

20 7

195 247

154 186

188

183

22 0 25 3

62

349 424

266

321

30 7 29 3

332

258 315

33 4 31 5

352

323

311

34 6

32 6 37 1

316 384

252

308

35 8

34 2

326

299

245

299

36 0 39.9

Evap Air — Cfm/BF

; SOOOAOy

Evap Air — Ewb (F)

72

278 255 233 283 260 237

147

22.0 20.8

263

142

23.4

255

139 182 212

24 0

137

24.6

238 216

135 176

Evap Air — Cfm/BF

Evap Air — Ewb (F)

72 67

226 292

33.2

401 370 342

218

35.3 33.8

392

214

211

38.1 36 2

363

206

____

{

9000/.070

67 62 72 67 62

191 231 157 206 237

239 218

184

22.0

232 212 260 236 216

22.8 21 4

225

179 206 147 192

23.4

24 1

391 360 430 397 366

31.5

283 342 231 303 347

361

280

35.0 33 2 37 5 35 7 33 6

353 325 390 358

278 325 222 297 330

335

271

38 3 36.6 40 5 38 5 36 9

22.4

19.6

218

20.8 23.7 22.5 21.1

206

22.1

198

198

22 5

62 72 67 62

356 240 311 366

29.7 33.5 31 8 29 9

31.8

334 399 367 339

334

34 6

308

308 215

21.1

243 222

268

153

198

150 196

23 1 21 7

24 3

251 229

23.7

24.9

241

220 202

144

189 202

25 6 24 4

376 347

408

34 4

36 2

227

300 339

38 7

36 8

370

340

291 312

50DF028

Temp (F)

Air Ent

TC 345 318

85

20.0

222

216

210

210 105

22.3 KW

22 8

SHC 178 229

KW

TC 330 303

95

SHC

KW 31 2

TC 320 295 271

100

SHC

KW 32 7 30 4

TC 310 286 263 315

SHC 168

TC 300 277 255

110

SHC

KW

9000/.058 ! 10,000/.068~T 11,000/ 074

72

67 62

294

29.5 27.8 26.2

174

171

34 0 31 7 29 9

165

35 3 33 1 31 0

278 185

278

272

223

27.7

29.3

220 268

29 0

216

263 176

255 171

213

50DF044

Temp (F)

Air Ent

85 SHC 281

95 SHC 269 345 419

32 4

100

330

105 SHC 258 333

34 8 KW 49 2 46 6 43 6

312

110 SHC

14.000/051 ^ 16,000/.062 i 18,000/.070

72 67 62

TC 538 499 457

KW 43.7 41 8

TC

KW 46.8 43.7 41.0

TC

SHC

KW 47 9 45 0 42 5

TC 475 436 397

TC

KW 50 8 47 9 45 2 51 3

357

436

39 5

506

465 427

491

263 339 411

458 419 380

252

411

450

397

326 380 269

Evap Air — Cfm/BF

Evap Air — Ewb (F)

72

67 62

351 322

242

28 2 25.4

30.0

335 308 283 339 312 287

236

181

31.4

29.5

325

299

233

178

33 1

30.8

290

229

34.4

32 1 30.2

281

305

226

33 4

35 5

Evap Air — Cfm/BF

Evap Air — Ewb (F)

67

72

507

549

295 383 468

45.1 42.5 33.8

516 475 436

285 369 436 301

47.1 44,5

499

460

364

280

45.6

48 3

444

483

275

358

49.8 47 1 443

■427"

'465"

353

48.5 46.0

72 67

355 327 302

298

296 194

283 190

28.2 ! 31.7 30.1 28.5

275

275

29 2

267

267

259

259 180 239 262

31 2

62

468

41 8 47 5

420 506 466

420

43 1 48 7

405 490

405 290 383

"388‘

388

253 302

30.2

28 4

248

329 303 279

187

245 279

31 3 29 6

33 3

294

318

183

242

24 7 32 3

284

309

35 7

33 6 31 7

72 67

558 515 476

408 476

312

45 4 42 9

524

481 445

394

45 0 42 7

295 390 428

46 2 44 1

450

50 6 47 5 45 2

473 433

377 395

283

51 7 49 0

62

26.6

287

270

270

30 5

262

62

40 6

445

428

412

412

395

46 8

Page 10

ПорП

Performcince data (cont)

COOLING CAPACITIES

60DF054

Temp (F)

Air Ent

18,000/ (^8~T2ao6oZo6S ] 22^000/.073

72 67 62

TC 686 639 596

85

SHC

361 462

KW 56 3 53 2

TC 650 602 558

95 SHC 347 446 546

KW 61 1

TC 629

57 6

581 538 637

100 SHC 340 438 538

105

KW

TC

SHC 333

KW

59 0 56 3

63 1

608 563 518

432

61 4

51 0

TC 589 540 496

110 SHC

325 423 496 344

KW

—

63 8 60 3

Evap Air — Cfm/BF

Evap Air — Ewb (F)

67

565

50 4

72

636 648

376 485

57 6

54.2 50.7 58 6

72 67

62

604 704 654

392

600

659 610 566 666 616 572

472

363

53 8

61.5 57.8 53.7 62 2 58 8 54 7

589

354

465

63.7

59.8

380 499 572

566

644

545

371

545

56.6 64 3 60 2 56 9

616 570 525 622

518

58 1

457

348

61 6 584

—

597 546

448

64.2 60.5

—

525 365 483

—

604 552

502

502 359 475 510

—

514

54 5

597

493 552

576

62 1

64 8

50DF064

Evap Air — Ewb (F)

55 9

600

59 6

63 4

562

1 09 X cfm

Evap Air — Cfm/BF

67^

72 :

807 ; 744

432 : 553

62.4 j

766;

418 i

66.8'

718

400 521

70.9672

74.9 i

SHC — Sensible Heat Cap

TC — Total Cap (1000 Btuh) Gross

684

658

59.4

56.6

70Г'

649

536

635

63.4

60.4 67.2 62.7

663

612

609

67.4

64.3

617

576

576

71.1

68.1

(1000 Btuh)

62

72

67

820

753 696

449

579 683

63

59.9 57 1

775

714

433

563

726

671

416

546

71 4

67 8

678 624

399 526

75 4

71 6

Temp (F)

Air Ent

Cond

85

95 SHC

105

115 SHC 365 471 556 384 • 502

BF — Bypass Factor

Ewb — Entering Wet-Bulb

KW — Compr Mtr Pwr Input

NOTES;

Direct interpolation is permissible Do not extrapolate

The following formulas may be used.

f|db fedb

f|wb

h|wb = hewb

Where:

hewb" Enthalpy of air entering evaporator coil

SHC is based on 80 F edb temp of air entering evaporator coil Below 80 Fedb,

subtract (corr factor x cfm) from SHC

21,000 / .070 i 24,000 / .081 26,400 / .090

72

67 62

TC i

796 731 669

413 521 620

SHC

KW 61 9

TC 751 693 634

KW

TC 709 650 598

SHC 387 487 579

KW 70 3 66.6

TC

58.8

397 505

66 0 62 8

665 609

KW 74 3 70 5 67 0

sensible capacity (Btuh)

Wet-bulb temperature of corresponding to enthalpy of air leaving

evaporator coil (h|^p)

total capacity (Btuh)

------------

------------------

612

612

51 6

552

532

532

58 7

510

60 9

62

660

657

61.1

624

624

65 8

591

591

71 9

62

OPTIONAL EQUIPMENT RESISTANCES (in. wg)

UNIT

MODEL

50DF

024044

50DF

054

50DF

064

OPTION

Bag Filter

Economizer

Economizer with Exhaust

Electric Heaters 0 5:1 (Low) 06

(Heat Cool Ratio)0 75 1 (Med)

1.0.1 (High)

Bag Filter

Economizer

Economizer with Exhaust

Electric Heaters 0 5:1 (Low) 12

(Heat: Cool Ratio)0 75 1 (Med)

1 0 1 (High) 22 39 61

Bag Filter

Economizer

Economizer with Exhaust

Electric Heaters 0 5 1 (Low)

(Heat Cool Ratio)0 75:1 (Med) 24 44

UNIT CFM/TON

Г3ОО 400

14

03 05

.09 .15 .23

09 15 23

.14

14

03

.11

15

20 36 55

04 07 11

13 21

18 35

HEATING CAPACITIES

50DF054 ■

VOLTS

(Nominal)

208-230

460

208-230

460

208-230

30-37

I 37

; 45-55

1 75-91

460

208-230

460 i 55 ^ 67

208-230

460

208-230

460

208-230

460 55 ; 67

208-230

460

208-230

I 460

208-230

460 i 73 ;

208-230

460 1 110

208-230

460 ; 165

208-230 i 75-91

460 ; 91 ;

208-230 120-146 :

460 ! 146

208-230

460

208-230

460

' 45-55

1

60-73 ! 50

; 73

30-110 ' 50

i 110 : 50 375,430

1 45-55

i 75-91

; 91

Ì105-128 1 57

; 128 57 436,865

! 60-73

190-110

135-165 1

1

75-91

i 91 ; 60 310,585

0 20-146 , 50

; 146 50 : 498,300

STAGE

KW ^

55

91

1%

’50

; 50

: 67

; 67

, 60

i 60

1 67

50 249,150

i 67

! 60 255,975-310,585

i 60 310,585

1

50

50

1

50

50 ! 375,430

56

56

1

66

60 ;■ -310,585

50

50

66

1

102,390-126,280

; 126,280

1153,585-187,715

; 187,715

255,975-310.585

1153,585-187,715

¡204,780-249,150

1307,170-375,430

153,585-187,715

358.365-436,865

1204,780-249,150

i 249,150

1307,170-375,430

¡460.755-563,145

: 563,145

255,975-310,586

409,560-498,300

1255,975-310,585

¡409,560-498,300

25 38

09

.25 .35

25

04

.15 .24

23 38

30

BTUH

310,585

187,715

187,715

498,300

500

08

13

38

08

46

31

54

68

9

Entering Air Dry-Bulb Temp (F)

BF

Correction Factor

.05 1.04 2 07 3 11

.10

.20 87

Interpolation is permissible

Correction Factor = 1.09 x (1 - BF) x (edb - 80)

4 Cooling capacities are gross and do not include deduction for indoor fan

motor heat

98 1 96

2 94 3 92

1 74 2.62 3.49

4 14

5 18

491

4 36

use formula

shown below

1182

«

10

Page 11

INDOOR AIR FAN PULLEY DATA

50DF I

FAN

RPM

925

931 2~3V—6.0

1073 2—3V—6.5

TÓ93

1159

1225 2—3V—5.6

1300 2—3V—6 0

925

984

1073 2—3V—6.5

1093 2—3V—5 0

1139 2_3V—6 9

1159

1225 2—3V—5.6 3_3V— 8.0

1300

925 2—3V—5.6

991

1073

1093 3—3V—5 0

1141

1159

1225

1300

925 4—3V—5.6

991

1073

1093 4—3V—5.0

1159 5—3V—5.3

1225

j 1300

1 925 4—3V—5 6

991

1039

1073

1093 5—3V—5 0

1159 5~3V—5.3 5_3V— 8.0

i 1225

1 925

I

1 1039 5—3V—4 75

1 1073 4—3V—6 5

1 1093 5—3V—5 0

1 1159

1 1225 5—3V-5.6

1 1312

I 1450 1 5—3V—5.0

MOTOR

PULLEY

No. Grooves—Type—in.

2—3V—5.6

2—3V—5 0

2—3V—5.3

2-3V-5.6

2—3V—4 5

3—3V—5.3 3~3V— 8.0

2—3V—6 0

2—3V—6 0

2-3V—6.5

4—3V—4.5

4—3V—5.3

4—3V—5.6

3—3V—6.0

3—3V—6.0

4—3V—6.5

4_3V~5.6 5—3V— 8.0

4—3V—6 0

4-3V-8.0

5—3V—4.75

4—3V—6.5

5-3V—5.6

4—3V—5 6

4—3V—6 0

5—3V—5 3

5_3V—6.0 5—3V— 8.0

FAN

PULLEY

2—3V—10.6

2—3V—10.6

2~3V—10.6

2—3V~ 8.0

2-3V— 8.0

2—3V— 8.0

2—3V— 8.0

2—3V—10.6

2—3V— 8.0

2-3V—10.6

2—3V— 8 0

2-.3V—10.6

2—3V— 8 0

2—3V—10.6

2—3V—10.6 2—3V—750

2—3V—10.6

3—3V— 8 0

4-3V— 6.9

4~3V— 8.0

4—3V— 8.0

3—3V— 8 0

4—3V—10.6

3_3V—10.6

4-3V—10.6

4—3V— 8 0

5—3V— 8.0

4—3V— 8 0

4—3V—10.6

4—3V—10.6

5-3V— 8.0

4-3V—10.6

5—3V— 8.0

5_3V— 8.0

4—3V—10 6

4—3V—10 6

5—3V— 8 0

4—3V—10 6

5—3V— 8 0

5—3V— 8.0

5—3V— 8.0

5-3V— 6.0

SINGLE-SPEED

BELT

NO.-SIZE

2—3V—710

2_3V~750

2-3V—750

2—3V—670

2—3V—670

2—3V—670

2—3V—710

2—3V—670 1

2—3V—750 : 2—3V—750

2—3V—710 i 2—3V—710

2—3V—750 ■ 2—3V—750

3_3V_710 2_3V~710

3_3V_710*

2—3V—710 i

2—3V—750

2—3V—750

3—3V—710

4—3V—670

4—3V—710

4—3V—710

3—3V—710

3—3V—750t

3—3V—750

3_3V_750t

4—3V—710

5_3V—710

5_3V_710*

4—3V—710

4~3V—750

4—3V—750

5—3V—710

4—3V—750

5—3V—710

5_3V_-710

5—3V—710

4—3V—750

4—3V—750

5—3V—710

4—3V—750

5—3V—710

5—3V—710

5—3V—710

5_3V_-710

5_3V—670

2-3V—750 i

TWO-SPEED

BELT

NO.—SIZE

2—3V—710

2—3V~750

2~3V—750

2—3V—7i0

2—3V~710

2—3V—710

2—3V—750

2—3V—750

2—3V—670

3—3V—710

2—3V—710

2—3V—750

i 2—3V—750

2—3V—750

3—3V—670

4—3V—670

4—3V—710

4—3V—710

1 3—3V—710 ■

3_^V—770

3—3V—770

3—3V—770

4—3V—710

5—3V—710

5-3V—710

1 4—3V—710

4^V—750

4—3V—770

5—3V—710

4—3V—770

5—3V—720

5—3V—720

5--3V_720

4—3V—750

4—3V—770

5—3V—710

4—3V—770

5—3V—720

5—3V—720

5~3V—720

5—3V—720

—

Shaded values indicate standard or optional pulley combi

nations available as shown in Physical Data table All

other combinations are field supplied

‘Remove one belt.

fDrive requires 3 belts; 4 belts may be used if desired.

11

Page 12

50DF

Performance data (coni)

FAN PERFORMANCE

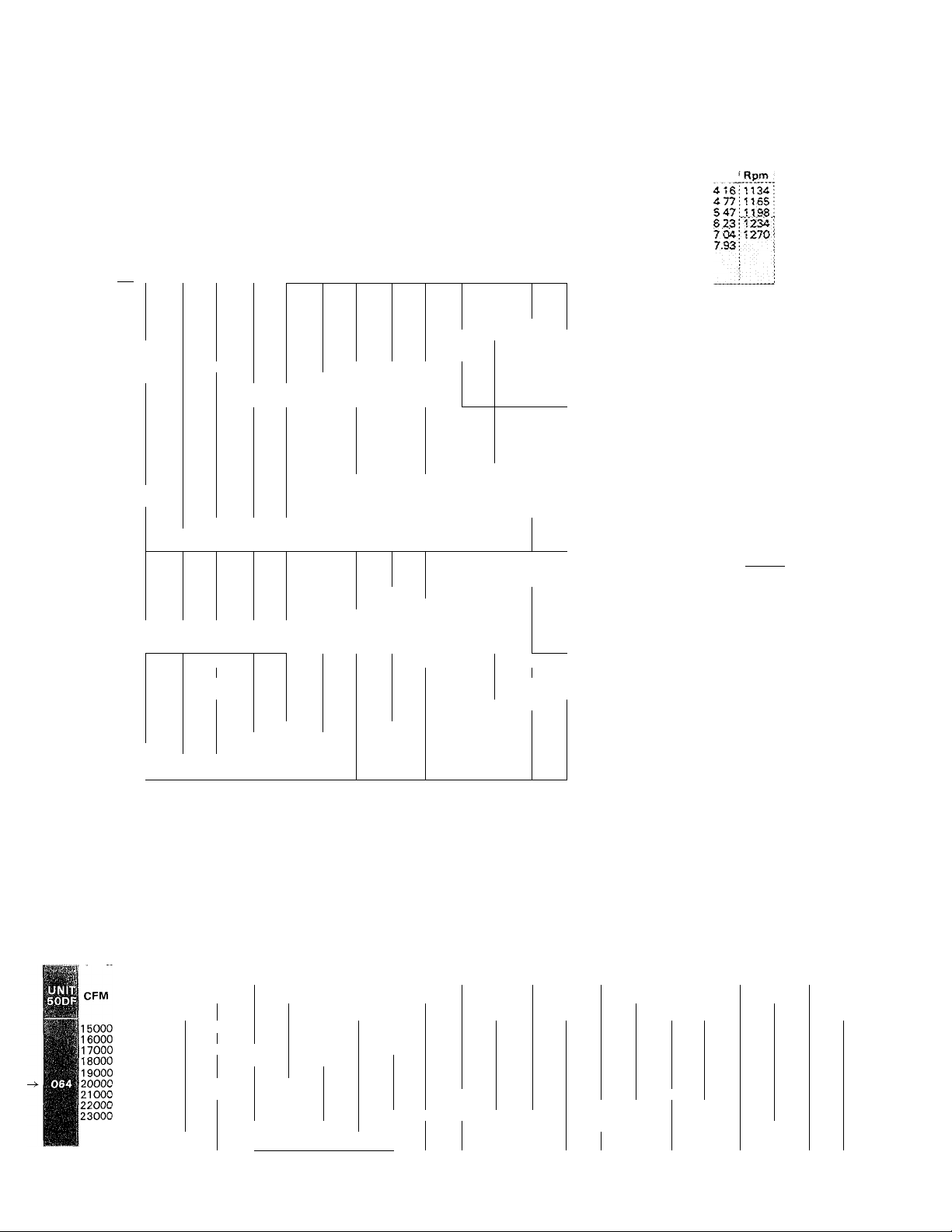

CFM

6000

6500

7000

7500

8000

8500

9000

9500

110000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

112500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

12000

13000

14000

15000

16000

17000

18000

19000

20000

15000

16000

17000

18000

19000

20000

21000

22000

23000

24000

25000

Bhp — Brake horsepower

Rpm — Revolutions per minute

NOTES:

1 Values in italics indicate that motor larger than optional fan motor is required

2 Fan performance has deductions for unit casing losses, wet coil and clean

standard filters

3 Fan motor bhp is based on minimum voltages and 80 F air across motor

0.20

Rpm I Bhp

699

1 72

2 12

746

794

2 59

3 13

843

3 74

892

4 42

941

991

5 19

1041

6.04

6.99

109

662

1 78

696

2 09 763

730

2 43

2 81 829

764

3 22

799

834

3 68

4 20 929

870

4 70 963

905

941

5 30

977

6 00

6.70

1013

2 86

690

3 29

720

3 76 813

751

782

4 28

814

4 80

5 50 901

845

877

6 10

6 80

909

7 60

941

8 50

973

1006

9 40

1038

10 30

1071

11.30

734

4 80

6 00

791

7 40

848

907

9 10

11 00

966

1026

13 30

15 70

1086

1147

18 50

1208

21.70

704

5 08

741

6 00

7 02 843

779

817

8 17

9 44 915

855

894

10 84

12 38

933

14 06 1025

972

1590

1011

1790

1051

20 05

1090

Alternate fan motor or drive is required

Field supplied drive required

0.40 0 60

Rpm

Bhp

2 04'

763

807

2 48

852

2 97

897

3 54

943

4 17

990

4 89

1037

5 68

1085

6 56

1133

7 53

2 25 791

731

2 60 820 3 07

2 99 851 3 49 905

796

341 883 3 95 933

862

3 87

895 4 37 948

4 90 981 5 60

5 50 1014 6 20 1059

997

6 10

1031 6 80 1080 7 70

1065 7.60

755 3 40 812

784

3 88

4 40 867 4 97 917

4 96 895 5 57

842

871

5 60

6 20 952 6 90

931 7 00 981

962 7 70 1010 8 50'1055

992 8 50 1039 9 40 1083

1023 9 40

1054

10 40 1099

1085 11 40

1116

12.40 1159

784 5 40 838 6 20

831 6 60 883

880 7 90 928 8 80

932 9 50

985 11 40

1040 13 50 1071

1097

1590 1122

11S4

13 60 1175

1212 21,70 1229 22.20 1255

772

6 10 829

807 7 13

8 26 898

878 9 51 933

10 87

951 12 37 1003

988 14 00 1038 15 50

15 77

1062 17 69

1100

13 78

1138

22 03

Bhp

Rpm

820

862

905

948

992

1037

1082

1128

1174

915 4 46 963

1047

1114

839

923 6 20

1069

1129

974 1040

1022

863

968

1074 17 37

mo 1940

1147 21 58 1190 23 27

1183 23 92

Rpm

872

2 34

912

2 81

3 34

953

3 94

995

1038

4 60

5 35

1081

617

1125

1169

7 08

1214

8.08

2 71

848

877

5 01 994

1027

6 90 1092

1125

1157

8.40

3 91 865

891

4 42

943

971

999 7 60 1042

7 70 1027

10 30 1112

U41

11 30

1170

12 30

1200

13.50

889

930

7 40

974

1019

1064

12 20

14 30

1170

1157

16 60

19 20:1205

6 94 882

913

8 08

9 32 946

10 68 980

12 16

1015

13 76

1050

1084

1119 1884

1155

1226

EXTERNAL STATIC PRESSURE (in. wg)

0.80

Bhp

2 64'

3 13

3 69

4 32

5 02

1080

6 79

6 65

7 59

8.62

3 21 904

3 60 928 4 15

4 03

4 49

5 01

5 59

6 20 1069 6 80 1113

690

7 60

S.40 1165

9.30

4 42

4 95 940

5 53 964

6 16

6 80 1016

8 40

9 20

1010

11.10

12 10 1181

13 20

14.40

7 00 937

8 20 977

9 70 1017

11 40

13 30

15 30

17 60

20.20 1241

23.00

7 80 933

8 93 963

10 24 993 11 21 1039 1225

11 70

13 28 1058

15 00 1092 16 11

16.85 1126 18 07

20 93 1196

25 72

1 00

Rpm

Bhp

922

2 95

959

3 46 11005

999

4 03 1042

1039

469 1081 i

5,42 1121 :

6 23 1162 :

1122

1165

7.12 1203:

1208

803Ì1246:

1?.53.

9.1S\12SS

3 76 956 4 36 1005

4 59

955

5 09

983

1012

5 63

1040 6 20 1085

1100 7 50 1142 8.20

1132 8 30

9 10

1197

10.CX)

4 94 960 5 42

916

5 49

6 09 1010

990 6 75

7 50 1059

8 20 1085

1069

9.00

1097

990

1125

1090 1163 11.60

1153 11 90 1191 12.60

1230

14 10

1203

1238 75.30

7 80

9 10

10 60

12 40

1060

1104

14 30

1150

16 50 tl.8,6Mr.6Q..

1135

18.80

21.40

1388 34.30

871

9 91

1024

12 65

14 30 1100

1161 2017 1199

22.42

24 83

1231

1266 27 39 :1303:28.93

1.20

Rpm j Bhp

969

3 26

3 79

4 39

5 06

5 81

6 65 ;.U8.9.

75711240' 801:1275

a 58 :128Ì i $ OS

5.6? : :

980 4 76

1004

5 20 1052

1029 5 70 1076

1057

6 26

6 87 1127

7 50

1171

900

1202

9,80 1240

1234

10.70

985 6 03

6 67 1051

1034

7 35 1076

8 10

8 30 1125

1110 9 70

1136

1060 1176

1218

1370

^1245

14.90

1275

76.10

987

8 70

1022

10 00

1060 11 60

13 40

1101

1142 15 30

1231

20.00

1276

22.70

983

9 68 1031

1010 1089 1057

1069

1375 1112

15 36

1717

1132

1165 19 19

21 38

23 74

1234

.28,25 1304

1268

1.40

Rpm I Bhp

1012

3 56

1048

4 13

1084 :

4 75

1121 ;

544 1160

6 21 ,1197

1159 :

.7..07.ÌÌ235

4 98

1028

5 40

5 87

6 35

1100

6 92

7 53

1155

8 20

1184

900

1212

, 9J?0

10 60:

1270

11,50;

1006

5 94 11052

1026

6 54'1071

7 22 1091

7 96 1114

1100

8 70 1139

9 50 :1164

nso

1040 :1188

11 30:1213

1230; 1238

1201

13.40:1264

1227

1254

14.50:1290

1282

15.70 :

1034

950 1081Ì1050 1125:11 40: 1169:125Q:1211 :13.70

1068

1100 1110:n 90,1165 12.90: 1195 1390

1102

1140

1181

JU2.1.

,.1S-60

1265

521,10

10 67

11 93

13 31

1083

1484

16 54

1142

1172

18 35

20 32

1203

22 54

1235

24 97

1269

27.58

1333

30 36

1.60

Rpm

l'Ó54

3 85 1094 :

1089

445: 1126:

1125

5 12: 1162:

5.83:1198

5,82] 1234'

7.49

8.46

11054

5 69 1105

11074

6 07

1096

6 55

7 0S

1120

; Ì1144

I :.U22,

1260 1145:1360

14 40 1179'1540

16.40 1217 17,50

1169

•1194

-9,20J1260

(1251

10.50

: 1279

11 40

11 10

12.0Q.Ì1249

13.10

14.10

15.30

lassifg'.sa

1299:122 30

11077 I

11 75

illOl i

12 99

'1127

14 42

15 97

1153

:1181

17 68

■1211

1958

;i241

21 62

.1273:

23ÌàXÌ308

51304;

26.19 :1338

;1337:

28 8S: 1370

Ì1371 :

31.71 :1403

7 63

8.24

390

6 48

7 10

7 77

8.51

930

0 20

1.80

Rpm Bhp

1270

1120

1140

1162

1186

mo.

1234

1236

1094

1114

1133

1152

1174

1200

.1221

1273

1298

1184 1450:1227,1,5.60.

.3220...1.6.50.

1254 518.60

1292.2090

1122

1144

1169

1194

1221

1249

1.2.78

647

6.82

7 26

7.80

8 39

-9.00.

9.70

10.40

11.30

7 02

7 57

8 36

910

990

10.80

.1.1.80.

12.80

13.30

14,90

12 82

14 13

15 54

1716

1889

20.79

.2.2,90.

25.16

27.54

30.13

33,03

2,00

Bhp I Rpm : Bhp

4 48

5 1Cp.202,

,5,.3.lil233

6,60 SI 268

7.46'

1153

7 31

1167

7,64

8 05

1183

8 55

1203

1226

9.15

8.31

1250

1273

10.50

1298

11.20

7.57

1133

8 24

1153

1174

8 97 „1.21.1,

1193

9 73

1212

1.0.50.

1233

11 40(1270

12.40

1258

1284

13.50

1257 ; 17.50

1292 ; 19.70

1166

13 87

1187

15 29

1203

16 75

1234

1834

20 14

1260

22 07

1286

1314

24.17

1343

26.49

1373

28.98

1403

31,59

1434

34 40

2.20

1173 ■

1199

1213

5.222

1244

1254

1237

1173

1190

1232

1250

1291

1237

1266

1295

1206

1228

1249

1272

1.297

1323

1349

1377

1407

1437

4.80

.5.44.

6.15

6.97

8 18

8,53

..8,8.1.

837;

9.83

10,60

8 18

8 81

9 56

10.'37

11.20

12.10

13.10

15.10

16.70

18.60

14 94

1641

17 99

19 61

.21 3.9.

'23.39

:25.S2

527.82

Ì30.36

■33.09

#

0.75

Rpm Bhp

7 56

868

871

901

10 02

935

11 45

963

1004

13 02

14 71

1038

1074

1 6 53

18 50

1109

1144

20 62

24000 1180

25000:1217

22 89

25 32

Alternate fan motor and drive required

1.

Rpm Bhp

934

963 9 90

993

1024

1058 14 30

1092

1126

1161 20 17

1196

1231

1266

60

8 72 996

11 20 1050

12 65 1080

16 1 1 1141

18 07

22 42 1243

24 83

27 40

1.25

Rpm Bhp Rpm

1022

1110

1175 19 47 1222 20 94

1208

1277

1312 ;29.30

1054

9 94

11 16 1079

1106

12 51

1133

140:

15 64 1162

17 44 1191

21 67 1253

1287

24 05

26.59 1320

1355 ;31.04

EXTERNAL STATIC PRESSURE (in. wg)

1 50 1.75

Bhp Rpm Bhp Rpm Bhp

1120 Ilio 12 55

12 46 1134 13 84

1158 15 26 1209 16 75

13 88

1547

1185

17 10

18 96

23 13 1298

25 58

28 22 1361 29.81 1403 31 56 1444

16 88

1212 18 60

20 49

1240

22 56

1269

24 78

27 18

1329

1395

32.70

2 00 2 25

1165 13 85

1186

15 29 1237

1234

18 34 1282

1260

20 16 1307

1287

2210 1332

1314

24 19 1359

1343

26.48

1373

28.95 1415

1434

34 40

12

Bhp

Rpm

1216 15 21 1266 1661 1314

16 67

1259

18 29

19 94

21 71

23 73 1376

25 89

1386

28 20 1429

30 71

33.42

___

2.50 2.75

Rpm Bhp

1286

1307

1329 21 57 1375 23 12 1419 24 71

1352

1402 27 60

Rpm

18 11

1333

19 75

1353

23 40 1396 25 13 1440 26 78

25 37

1420 27 15

1444

29 99

1361

3.Ò0

Bhp

19 54

Bhp Rpm

18 06

19 59 1378 21 12

21 27 1397 22 83

29 32

Rpm

1406

1423

1441

3.

Bhp

21 CM

22 68

24 44

t

Page 13

Electrical data

50DF024 and 028

MODEL

NOMINAL

VOLTS/PH/tHZ

50DF024 187

208-230/3/60

50DF024

460/3/60

50DF024

575/3/60

50DF028

208-230/3/60

50DF028

460/3/60

50DF028

575/3/60

COMPR — Compressor

FLA — Full Load Amps

Hp — Nominal Horsepower

Kw — Kilowatts

LRA — Locked Rotor Amps

VOLTAGE

RANGE

Min Max

414

518

187

414

518

254

508

632

254

508

660

COM PR

NO. 1

RLA LRA

80

37 0

30 0

63 5

27 5

22 0

345

173

120

266

120

96

COMPR

NO. 2

RLA

LRA

43

191

193

86

150 69

MCA MOCP RLA —

*Fuse only

OUTDOOR

FAN

MOTORS

Qty

FLA

7 6

(ea)

33

(ea)

2 7

(ea)

7 6

33

(ea)

2 7

(ea)

INDOOR

HP_

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

7 5

10

7 5

7 5

7 5

10

7 5

7 5

7 5

10

10

10

10

10

10

7 5

7 5

10

7 5

7 5

7 5

10

7 5

7 5

7 5

10

10

10

10

10

10

7 5

7 5

10

10

MOTOR

5

5

5

5

5

5

5

5

5

5

FAN

FLA

24 2

24 2

24 2

24 2

24 2

24 2

24 2

24 2 3

24 2 3

24 2 3

24 2

24 2

24 2

24 2

24 2

24 2

7 6

7 6 3

1 1 \J

1 6

7 6

7 6

11 0

7 6 3

7 6

7 6

11 0

11 0

11 0

11 0

11 0 3

11 0 3

6 1

6.1

9 0

9 0

24 2

24 2

30 8

24 2

24 2

24 2

30 8 3

24 2 3 11

24 2 3 11

24 2 3 11

30 8

30 8

30 8

30 8 3 11

30 8 3 11

30 8

11 0

11 0 3

14 0

11 0

11 0

11 0

14 0

11 0 3 48

11 0

11 0

140

140

140

140

140 3 48

140 3

9 0

90 3 39

11 0

11 0

LEGEND

Minimum Circuit Ampacity

Maximum Overcurrent Protection

Rated Load Amps

EXHAUST

FAN

MOTOR

FLA

—

-

3 11

—

—

—

—

_

11

3

11 30- 36 6

11 45- 54 9

11 75- 91 5

—

—

—

—

—

11

3

3 11

3 11

—

__

48

__

—

—

—

3

48

48 36 6

3 48 54 9

3 48 91

— —

— —

— —

3 48 36 6

48

48 91

—

—

3

3 9

—

— — —

3

3 9

— —

3 11

—

—

—

—

—

11

— —

— —

— —

3 11 90-109 8

48

- —

— —

—

—

3 4 8

3 48

3 48 109 8

—

—

—

—

_

3

48 55

48 109 8 138

— — — —

_

—

3 39

HEATERS

Kw

— —

— —

— —

30- 36 6

45- 54 9

75- 91 5

— —

30- 36 6 83- 92

45- 54 9

75- 91 5

30- 36 6

45- 54 9

75- 91 5

' — —

— —

36 6 46

54 9

91

— —

36 6

54 9

91

54 9

— —

— —

— —

— —

45- 54 9

60- 73 2 166-184

90-109 8

— —

45- 54 9

60- 73 2

90-109 8 249-276

45- 54 9

60- 73 2 166-184

90-109 8 249-276

45- 54 9

60- 73 2 166-184

83- 92

125-138

208-230

83- 92

125-138

208-230

125-138

208-230

83- 92

125-138

208-230

— —

125-138

249-276

125-138

166-184

125-138

125-138

249-276

I I

— —

55 69

73.2

109 8

— —

55 69

73 2 92

55

73 2 92

109 8

73 2 92

— —

— —

— —

NOTES:

1 All outdoor fan motors are single-phase motors

2 All heaters are 3-phase assemblies

3 Circuit no 2 is provided as indicated: total unit MCA equals

the sum of circuit no 1 MCA plus circuit no 2 MCA

FLA

115

115

115

115

_

138

138

138

50DF

POWER SUPPLY*

Circuit

No. 1

MCA

138

138-146

1 87-203

138-146

149

149-149

187-203

149-149

128-146

187-203

138-146

149-149

187-203

149-149

69

46

69

46

69

46

69

92

69

69

154

154

100

158

100

158

160

171

167

187-203

238-261

187-203

178

187-203

238-261

187-203

195-211

246-269

195-211

195-211

246-269

195-211

100

129

187

100

129

187

104

133

190

104

133

190

138

149

60

65

63

67

96

68

67

96

72

72

49

53

52

56

71

76

74

79

57

61

59

63

MOCP

200

225

200

200-200

200-225

200-200

225

225-225

225-225

225-225

200-200

200-225

200-200

225-225

225-225

225-225

90

100

100

90

90

125

100

100

100

125

100

110

150

100

110

150

70

80

80

80

225

225

225

200-225

250-250

225-225

225

225-225

250-250

225-225

225-250

250-300

225-250

225-250

250-300

225-250

90

100

100

110

125

175

100

110

125

175

125

125

175

125

125

175

70

80

80

80

MCA

156-173

156-173

156-173

156-173

156-173

156-173

156-173

156-173

Circuit

No. 2

175-200

1 75-200

175-200

175-200

175-200

175-200

175-200

1 75-200

MOCP

13

Page 14

fsOPF I

Electrical data (cont)

50DF034 and 044

MODEL

NOMINAL

VOLTS/PH/HZ

50DF034

208-230/3/60

50DF034

VOLTAGE

RANGE

Min Max

187

414

254

508

'Ì60/3/60

50DF034

575/3/60

50DF044

208-230/3/60

50DF044

460/3/60

50DF044

575/3/60

518

187

414

518

660

254

508

632

COMPR — Compressor

FLA — Full Load Amps

Hp — Nominal Horsepower

Kw — Kilowatts

LRA — Locked Rotor Amps

COMPR

NO. 1

RLA LRA

63 5

27 5

22 0

80

37 0

30 0

COMPR

NO. 2

RLA LRA

266

63 5

27 5

120

22 0

96

80

345

37 0

173

30 0

120

MCA —Minimum Circuit Ampacity

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

*Fuse only

OUTDOOR

Qty

266

120

96

345

173

120

FAN

MOTORS

INDOOR

FAN

MOTOR

FLA

Hp

10

10 30 8

15

10

10 30 8

10

15

10 30 8 3 11

7 6

10 30 8 3 11 75- 91 5

(ea)

10 30 8 3 11

15 46 0

15 46 0

15

15 46 0 3 11

15

15

10 MO

10

15 21 0

10 140

10

10 140

15 20 0 3

10 140

3 3

10 140 3

(ea)

10

15 21 0

15

15

15

15 21 0

15 21 0

10

10

2 7

15

(ea)

— —

15

15

20

15

15 46 0

15

20 53 5

15

7 6

15 46 0

(ea)

15 46 0 3

20

20 53 5

20 53 5

20 53 5 3

20 53 5

20

15 21 0

15 21 0

20

15 21 0

15 21 0

15 21 0

20

15 21 0

33

15 21 0

(ea)

15 21 0

20

20

20 27 0

20

20

20

15

15

2 7

20 20

(ea)

20 20

EXHAUST

FAN

MOTOR

FLA

Hp

— — _ —

30 8

3 11

__

46 0

— —

30 8

_

— —

30 8

46 0 3 11

—

—

— —

46 0

3

46 0

46 0 3 11 105-128 1 291-322

— — — —

140 3 48

— —

—

—

140

—

3 48

140 3

— —

_

21 0

— —

21 0

21 0

3

3 4 8 91 5

3 4 8 128 1 161

— —

11 0

11 0 3 3 9

—

—

3 39

__

46 0

46 0 3 11

— — —

53 5

—

46 0

46 0

46 0

53 5

53 5

27 0

27 0 3

27 0

27 0

27 0 3

27 0

27 0 3

154

154 3

- —

— —

3

3

3 11

—

—

—

3 11

3

—

3

— —

— —

— —

—

3

3

3

— —

—

— —

3

— — —

—

3

LEGEND

14

HEATERS

Circuit

No

1

FLA Kw FLA MCA MOCP

POWER SUPPLY*

—

—

—

— -

45- 54 9

75- 91 5 208-230 197-197 250-250

105-128 1

—

45- 54 9 125-138

105-128 1

—

45- 54 9 125-138 214-230 300-300

—

75- 91 5 208-230 212-212 250-250 156-173

105-128 1 291-322 214-230 300-300

45- 54 9 125-138 223-230 300-300

11 75- 91 5 208-230

__

_

54 9 69 104

—

—

—

91 5

128 1 161

—

54 9

91 5

54 9

91 5

128 1

54 9

—

— —

—

—

48

48

48 128 1

48

—

125-138

291-322 197-211

—

208-230 208-208 250-250 156-173

291-322 208-211

—

—

115 162

—

69 104

115 162

161

69 113

115 170 175

161

69 113 150

115 170 175

—

—

— —

—

11

11 60- 73 2 166-184

11 135-164 7 374-414

—

—

—

11 60- 73 2 166-184

11 135-164 7 374-414

—

48

—

48

48

48

48 164 7 207 142

—

48

48

48

39

— —

39

—

—

-

60- 73 2 166-184

90-109 8 249-276

135-164 7

—

90-109 8

60- 73 2 166-184

90-109 8 249-276

135-164 7

—

—

—

374-414 265-288

—

249-276

374-414 283-305

90-109 8 249-276 285-305

—

__

—

73 2

109 8

164 7 207

—

73 2

109 8 138 199 200

73 2

109 8 138 207 225

164 7 207

73 2 92

109 8

164 7 207

—

—

—

—

92

138 199 200

—

92

92

138 207

—

—

—

— 106 125

197 250

208

212

197-211 250-250

223 250

208-211

250

250

250-250 208-230

250-250

250-250 208-230

223-223

223-230

250-250

300-300

86

91

93 110

219 200

98

219

110

110

125

150

125

125

150

200

150

228 225

228 225

69 90

73 90

75 90

79

249

271

263 300

265-288 350-350

249-249 300 208-230 275-250

285

271-288 350-350

271-271 350-350

271-288 350-350 259-288 300-300

283-305 350-350

263-263 300-300 208-230

285-305

285-305

115 150

124

121

142 175

142 175

130 150

142 175

149 200

149 200 144

149 200

149 200 144

93

101 125

98 125

100 — —

300

350

350-350 259-288 300-300

350

350-350 259-288

350-350

350-350 208-230

350-350 259-288

150

150

175 144

225

no

NOTES;

1 All outdoor fan motors are single-phase motors

2 All heaters are 3-phase assemblies

3 Circuit no 2 is provided as indicated; total unit MCA equals

the sum of circuit no 1 MCA plus circuit no 2 MCA

MCA

—

— —

— —

—

156-173

—

—

—

208-230

— —

156-173

208-230

—

— -

— —

— —

— —

— —

—

— —

— —

—

— —

—

— —

— —

—

— —

— —

—

— —

— —

— —

-

— —

- —

208-230

— —

—

— —

— —

—

— —

— —

144

— —

—

— —

—

—

— —

—

___

—

___

—

Circuit

No. 2

175-200

225-250

175-200

225-250

1 75-200

225-250

175-200

225-250

MOCP

___

—

—

—

__

___

—

—

—

—

—

—

—

—

225-250

225-250

300-300

__

225-250

300-300

150

—

150

___

—

150

—

150

-—

--

—

i

Page 15

50DF054 and 064

MODEL

NOMINAL

VOLTS/PH/HZ

50DF054

208-230/3/60

50DF054

460/3/60

50DF054

575/3/60

50DF064

208-230/3/60

50DF064

460/3/60

VOLTAGE

RANGE

Min Max

187

414

518

187

414

254

508

632

254

508

COMPR

NO 1

RLA LRA

117

53 0

42 5

119

53

506

253

176

506

220

COMPR

NO 2

RLA LRA

78 5

36 0

28 6

119

53

345

173

120

506

220

OUTDOOR

FAN

MOTORS

Qty

FLA

INDOOR

FAN

MOTOR

FLA

Hp

20

60 0

20 60 0

25 75 0

20

60 0

20

60 0

20

60 0

25 75 0

20

60 0 3 11

20

60 0 3 11

20

60 0 3 11

25

75 0

25 75 0

25 75 0

25 75 0

25

75 0 3 11

25

75 0 3 11

20

27 0

20

27 0

25 34 0

20 27 0

20

27 0

20 27 0

25

34 0 3 4 8

20 27 0 3

20 27 0 3

20 27 0

25 34 0

25 34 0

25 34 0

25

34 0 3

25 34.0 3

25 34.0 3

20

22 0

20

22 0

25 27 0

25 27 0

25

75 0

25

75 0 3

30

88 0

25

75 0

25

75 0

30

88 0

25

75 0

25 75 0

30

88 0

30

88.0

30 88 0

30 88 0

25

34 0

25

34 0

30 40 0

25 34 0

25 34 0

30

40.0

25

34 0

25

34 0

30 40 0

30 40 0

30

40 0 3

30

40 0

EXHAUST

FAN

MOTOR

FLA

Hp

—

3 11

—

—

—

—

3 11

— —

— —

—

3 11

—

3 4 8

— —

—

—

— —

48 91 5

48 146 6 184

3 48 201 3

—

—

—

48 91 5

48 146 6

4.8

— — —

3 3 9

—

3

3 9 — —

—

11 0

—

— —

—

3 11 0

3 11 0 75- 91 5

3 11 0 120-146 6

— —

—

3 11 0 75- 91 5

3 11 0 120-146 6

—

3 48

—

~

—

3 48

3 48 91.5

3 48 146.6

—

—

48 91.5

3 4.8 146 6

Kw FLA

— — —

—

—

—

—

—

—

—

—

—

—

—

— —

—

75- 91 5

120-146 6

165-201 3

— —

75- 91.5

120-146 6

165-201 3

75- 91 5

120-146 6

165-201 3

75- 91.5

120-146 6

165-201 3

___ ___

— —

—

91.5 115

146 6 184

201 3

—

91.5

146.6

201 3

201 3

— —

—

— —

_

—

—

—

— — —

—

—

—

—

_

—

— —

75- 91 5

120-146.6

—

75- 91 5

120-146 6

_

—

91 5 115 187

146 6

_

91 5 115 194

146 6 184

HEATERS

MCA

312

—

208-230 335-363

332-368

457-506 335-363

208-230 335-363

332-368 334-334

457-506 335-363

208-230

332-368

457-506

208-230 354-382 500-500

332-368 349-349

457-506 354-382

—

253

—

115

253

115 187

184

253

115 187

184 273

253

___

—

___

—

208-230

332-368 370-370 400-400

—

208-230 392-392

332-368

208-230

332-368 383-383

208-230 405-405

334

327 400

312-312

349 450

354-382

327-327

354-382

141

151

148 200

178 200

264

149 200 202

158 200

178 200

264

151 200 202

273 300

158 200 202

158 200 202

113 150

121

118

126

370

392

383

370-382

405 450

392-392

383-398 500-500

332-368 405-405 450-450

___

—

184 273

—

115 187

184

115 194

184

166 200

175

172

181 200

273 300

280

280 300

rsÒDFl

POWER SUPPLY*

Cin

:;uit

. 1

No

MOCP

400

450

400-450

400-400

400-400 312-345

450-450

450-450 260-288

450-450 312-345

500-500

400-400

500-500

450-450 260-288

500-500 31 2-345

175

200

250

250

250

250

300

150

150

150

400

450

450

500-500

500-500

450-450

450-450 260-288 300-300

500-500

200

200

250

300

260-288

260-288 300-300

312-349

260-288

260-288 300-300

260-288 300-300

250

250

300

250

MCA

_

___

___

—

—

—

— —

_

_

—

—

—

—

—

—

— —

___

___

—

—

_ _

— —

_ —

_

___

_

—

—

— —

—

— —

—

___

_

—

—

—

_

—

___

___ ___

—

— —

—

Circuit

No. 2

300-300

350-400

300-300

350-400

350-400

300-300

350-400

300-300

MOCP

_

_

_

___

___

___

—

_

___

___

—

225

___

—

225

___

___

225

___

___

225

—

_

—

—

—

—

___

_

—

___

___

___

—

—

___

—

—

COMPR — Compressor

FLA — Full Load Amps

Hp — Nominal Horsepower

Kw — Kilowatts

LRA — Locked Rotor Amps

MCA

MOCP

RLA

•Fuse only

LEGEND

— Minimum Circuit Ampacity

— Maximum Overcurrent Protection

Rated Load Amps

15

NOTES:

1 All outdoor fan motors are single-phase motors

2 All heaters are 3-phase assemblies

3 Circuit no. 2 is provided as indicated; total unit MCA equals

the sum of circuit no 1 MCA plus circuit no 2 MCA.

Page 16

Typical piping and wiring

CONTROL BOX

itt

Controls

Operating sequence with economizer — (With

out energy management Option/Accessory) using

thermostat with subbase.

Cooling

System switch set at AUTO, or COOL, indoor air fan runs

continually. Thermostat set at desired setting.

When thermostat calls for cooling and outdoor air

enthalpy is below setting of enthalpy controller, economizer

modulates open. (If outdoor air enthalpy is above enthalpy

set point, economizer remains at the minimum position.)

Economizer acts as first stage of cooling, providing “free

cooling” with outside air. If outside air alone cannot satisfy

the cooling requirements of the conditioned space, econo

mizer cooling is integrated with mechanical cooling.

Compressor(s), working simultaneously with econo

mizer, will be staged on to meet cooling load.

As conditioned space temperature approaches thermo

stat’s cooling set point, stages cycle off, last stage first.