Page 1

GEOTHERMAL SPLIT SYSTEMS

CARRIER

INDOOR & OUTDOOR SPLIT GEOTHERMAL

HEATING AND COOLING COMFORT SYSTEMS

GT-PX INDOOR SPLIT (50YDS) SERIES - SIZES 026-064

GT-G INDOOR SPLIT (50YCS) SERIES - SIZES 018-060

GT-S OUTDOOR SPLIT (38WQS) SERIES - SIZES 018-060

Page 2

Page 3

Indoor & Outdoor Split

Geothermal Comfort Systems

Table of Contents

Geothermal Advantages ....................................................................................................................................................................................................................................... 2

Loop Systems ............................................................................................................................................................................................................................................................. 3

GT-PX Indoor Split (50YDS) Series Introduction ................................................................................................................................................................................. 4

GT-PX Indoor Split (50YDS) Series Features & Benefi ts .................................................................................................................................................................. 5

GT-G Split Indoor (50YCS) Series Features & Benefi ts ..................................................................................................................................................................... 8

GT-S Outdoor Split (38WQS) Series Introduction .............................................................................................................................................................................10

GT-S Outdoor Split (38WQS) Series Features & Benefi ts .............................................................................................................................................................. 12

ARI/ISO/ASHRAE 13256-1 Data .................................................................................................................................................................................................................... 14

Model Nomenclature .............................................................................................................................................................................................................................................16

Reference Calculations & Legend ...................................................................................................................................................................................................................17

GT-GS/GT-S Performance Correction Factors ........................................................................................................................................................................................ 17

GT-PX Performance Correction Factors ....................................................................................................................................................................................................18

GT-PX Performance Data ................................................................................................................................................................................................................................... 19

GT-GS/GT-S Performance Data .......................................................................................................................................................................................................................27

Physical Data ...............................................................................................................................................................................................................................................................34

GT-PX Dimensional Data ....................................................................................................................................................................................................................................35

GT-GS Dimensional Data .................................................................................................................................................................................................................................... 36

GT-S Dimensional Data ........................................................................................................................................................................................................................................37

Electrical Data ............................................................................................................................................................................................................................................................. 38

Thermostat Wiring ..................................................................................................................................................................................................................................................39

CXM Control Features .........................................................................................................................................................................................................................................40

Typical Wiring Diagram - GT-PX Units ........................................................................................................................................................................................................43

Typical Wiring Diagram - GT-GS Units ........................................................................................................................................................................................................ 44

Typical Wiring Diagram - GT-S Units ............................................................................................................................................................................................................ 45

Equipment Selection ............................................................................................................................................................................................................................................... 46

Engineering Guides .................................................................................................................................................................................................................................................. 49

Accessories, Options, & Warranty .................................................................................................................................................................................................................. 52

Guide Revision Log .............................................................................................................................................................................................................................Back Cover

Revised: 08/10/05D

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

1

Page 4

Carrier

Geothermal Advantages

Geothermal systems transfer heat from a build ing

to the earth in the cooling mode, or from the

earth to the building in the heating mode. Water

is used as the heat transfer medium, either in a

closed loop piping system, or by directly pumping

well water. By using this stable thermal source,

geothermal heat pumps provide energy effi cient

comfort year around.

Highest Effi ciency

The extremely high levels of effi ciency are

possible because a geothermal heat pump only

uses electricity to move heat, not produce it. A

geothermal unit typically supplies 4 kilo watts of

heat for every kilowatt of elec tric i ty used. Three of

these kilo watts of heat come directly from the ear th

itself, and are clean, free, and renewable. Overall,

geothermal technology offers the highest cooling

EER’s and heating COP’s available in the industry.

Most systems also include a hot water generator,

which diverts a portion of the supplied heat to the

domestic water heater. This provides a substantial

portion of a family’s hot water needs at a very low

cost. Overall, geothermal technology offers the

highest cooling EER’s and heating COP’s available in

the industry.

Agency (EPA) and the De part ment of Energy

(DOE). Because it is lowest in CO2 emissions,

geothermal tech nol o gy provides a solution to global

warming by primarily using the natural energy

of the earth. In contrast, traditional space

conditioning systems depend upon the exploitation

and burning of fossil energy sources with the

resultant greenhouse gas emis sions. Also, Puron®

HFC 410A refrigerant is used in the GT-PX series

equipment for minimum global warming impact and

zero ozone depletion.

Better Investment

Low life-cycle costs are provided by the low

op er at ing and maintenance costs of geothermal

systems, even when the higher initial in stal la tion costs

are considered. In new con struc tion, monthly energy

savings typically exceed the increased mort gage

payments. Therefore, cash fl ow can be positive from

the start. In retrofi t systems, a buyer who purchases

with cash usually realizes a return on in vest ment

well above certifi cate of deposit rates. And, with

equip ment life ex ceed ing 20 years, a Carrier

geothermal system is a lasting in vest ment.

Electric utilities, recognizing the dual benefi ts of

high effi ciency and low electric peak demand, often

provide incentives to purchase these systems.

Maximum Comfort

Geothermal heat pumps also provide higher

comfort levels than traditional space conditioning

equipment. By using a relatively warm source of

heat such as the earth, supply air temperatures

are signifi cantly higher in the heating mode than

traditional air-source heat pumps. Geo ther mal

heat pumps also cycle much less often than fossil

furnaces, creating a consistent indoor temperature

with comfortable relative humidity.

Environmentally Friendly

The environmental advantages of geothermal

systems have caught the eye of governmental

agencies such as the En vi ron men tal Pro tec tion

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

2

Before choosing a geothermal system, many

application factors must be evaluated including:

• Ground water availability and quality

• Loop installation costs

• Land area available

• Sub-soil conditions

• Local codes

• Owner preferences

Carrier dealers have the expertise and computer

software to determine the best type of system.

Many regions have contractors specializing in the

in stal la tion of the ground loop portion of the system.

Page 5

Indoor & Outdoor Split

Geothermal Comfort Systems

Closed Loop Systems

Closed Loop Systems consist of an underground

heat exchange network of sealed, high strength

poly eth yl ene plastic pipe and a Flow Controller

pumping module. When cooling, the loop fl uid

temperature will rise, and rejected heat is dissipated

into the cooler earth. Con verse ly, while heating, the

loop fl uid temperatures fall, and heat is absorbed

from the earth. Carrier Flow Controller pumping

modules utilize small wattage pumps to circulate the

water/antifreeze fl uid within the piping system. The

plastic heat exchange loop is closed and ther mal ly

fusion-welded at all connections in the same manner

as natural gas distribution lines. Closed loops do not

require a ground water supply or drain, and they are

not subject to mineral build up.

Closed Loops can be installed in vertical or

hor i zon tal confi gurations, or submerged in a

pond or lake. When designed properly, all three

alternatives operate with similar effi ciency. Carrier

high density poly eth yl ene plastic pipe is used for all

closed loop installations. Pipe con nec tions are heat

fused to form joints that are stronger than the pipe

itself. Carrier loop piping has a life expectancy in

excess of 50 years.

Vertical Loops are the ideal choice when available

land area is limited.

Drilling equipment is

used to bore smalldiameter vertical

holes. Two pipes

joined together with

a u-bend fi tting are

inserted into the

vertical bore. Bore hole depth ranges from 100-300

feet per system ton. Bores must be spaced from

10-15 feet apart and properly grouted. The land

space required ranges from 100-200 square feet per

system ton.

Pond (Lake) Loops are very economical to install

when a body of

surface water is

available, because

ex ca va tion costs are

mostly eliminated.

Coils or “slinky” mats

of pipe are simply

placed on the bottom

of the pond (lake). In most cases, 1/4 to 1/2 acre of

water surface, with a min i mum depth of 8-10 feet, is

needed for a typical res i dence.

Horizontal Loops are often considered when

adequate land space

is available. The

pipes are placed in

trenches, excavated

by a backhoe or chain

trencher to a depth of

4-6 feet. De pend ing

on design, from 1-6

pipes are installed in each trench. Multiple pipe

and coiled “slinky” con fi g u ra tions are often used

to conserve land re quire ments and reduce overall

installed loop costs. Horizontal boring technology

can also be used to install u-bend loops 10-15 feet

deep with minimal landscaping disruption. Trench

lengths range from 100-400 feet per system ton.

Trenches must be spaced from 6-10 feet apart. The

overall land area required ranges from 750-1,500

square feet per system ton.

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

Ground Water Systems

Open loop systems utilize ground water as a direct

energy source when

good quality water

is available at a

reasonable pumping

depth. A well must

have enough capacity

to deliver a minimum

of 1.5 gpm per system

ton during peak

op er a tion. Ditches, fi eld tiles, ponds and streams are

the most common discharge systems. Re in jec tion or

semi-closed recirculation wells can also be utilized

in some regions. In ideal con di tions, an open loop

ap pli ca tion can be the most eco nom i cal type of

system to install.

3

Page 6

GT-PX

Rounding Out the Product Line

Building upon the overwhelming market success of

the GT-PX packaged unit, the split system uses the

same components in a more fl exible confi guration.

The GT-PX split system compressor section can be

coupled with a variety of air handlers and add-on

furnace coils to achieve the highest effi ciencies of

any split system heat pump on the market today,

while still providing the fl exibility of an all-electric or

dual fuel system and a remote compressor section

location. Split systems are often used in areas where

it would be diffi cult to install a packaged unit, such as

in an attic or crawl space.

Puron® Refrigerant

Puron® is a non-chlorine based (HFC

410A) refrigerant, that with R-407C

and R-134A, is seen as the future of

all refrigerants used worldwide. HFC

410A characteristics compared to R22 are:

• Binary and near azeotropic mixture of 50% R-32

and 50% R-125.

•

Higher effi ciencies (50-60% higher

operating pressures).

• Zero ozone depletion potential and low global

warming potential.

• Virtually no glide. Unlike other alternative

refrigerants, the two components in HFC 410A

have virtually the same leak rates. Therefore,

refrigerant can be added if necessary without

recovering the charge.

Copeland Two-Stage Scroll Compressor

Achieve a greater level of comfort.

The Copeland Scroll UltraTech™

provides superior comfort than

fi xed-capacity compressors by

incorporating a revolutionary twostep design. With a unique 67%

part-load capacity step, systems

with UltraTech™ maintain precise

temperature levels and lower relative

humidity. This eliminates uneven peaks and valleys

and allows for steady cooling comfort. Homeowners

now have a better, more effi cient way to power

their heating and cooling system, raising their level of

comfort, while lowering energy bills. So when your

customers need a new heating and cooling system,

make sure it has the best technology inside – the

Copeland Scroll UltraTech™ compressor.

Save with superior effi ciency. Over 40% of summer

utility bills can come from the air conditioner

compressor operation. A system with the Copeland

Scroll UltraTech™ compressor delivers higher

effi ciency than any other single compressor system.

In fact, systems with UltraTech™ provide up to 60%

greater energy effi ciency as compared to 10 SEER

systems – which can save homeowners hundreds

of dollars a year in energy costs.

Take it easy with quieter control. Copeland

Scroll UltraTech™ is remarkably quiet at both

full- and part-load capacity. In fact, it is up to four

times quieter than a reciprocating compressor.

Homeowners can enjoy its superior effi ciency and

comfort without having to hear the operation.

Learn the beauty of the design. With Copeland Scroll

UltraTech™, two internal bypass ports enable the

system to run at 67% part-load capacity for better

effi ciency

and humidity

control. Based

on demand,

the modulation

ring is

activated,

sealing the bypass ports and instantly shifting capacity

to 100%. Take advantage of “shift on the fl y” stage

changing (no stopping and starting required like other

two-stage compressors).

Choose proven scroll performance. While Copeland

Scroll UltraTech™ builds on established scroll

technology, it is still a scroll at heart, which means

it operates with fewer moving parts, no volumetric

effi ciency drop-off or compression leakage. The result

is unsurpassed reliability and virtually silent operation

for both indoor and outdoor applications.

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

4

Page 7

Two-Stage Indoor Split

Puron® Systems

Other New Features

• Stylish two-tone look with textured black powder

coat paint and stainless steel front access panel.

• Liftout handle for front access panel.

• Factory supplied (fi eld-installed) fi lter drier for

trouble free reliability.

• Easy access low profi le horizontal control box.

• Double isolated compressor for quiet and

vibration free operation.

• Spring-mounted compressor for additional

noise suppression.

• Open Service-Friendly Cabinet (i.e, all

components in compressor section can be

serviced from the front).

The GT-PX Series Split System has abundant

features and industry leading effi ciency.

Application Flexibility

• Four Capacities 026, 038, 049, and 064.

• Extended range operation (20-120°F EWT) and

fl ow rates as low as 1.5 gpm per ton.

• Compressor section match-ups for a variety of air

handlers and add-on furnace coils for the ultimate

in system and fuel type fl exibility.

• Precharged compressor section with back-seating

service valves for quick installation.

• Circuit breaker protected loop and hot water

generator pumps.

• Field selectable freeze protection setting for well

or loop.

•

Puron® HFC 410A zero ozone depletion refrigerant.

• Highest effi ciencies for split systems in ARI/ISO/

ASHRAE/ANSI 13256-1 ratings for heating COP’s,

cooling EER’s with low water fl ow rates.

• Two-Stage operation for ultra high effi ciencies and

unsurpassed comfort.

• Operating temperature range and high effi ciency

allow shorter loops.

• Optional hot water generator with internal pump

generates hot water at considerable savings.

• Rugged and highly effi cient next generation

Copeland UltraTech™ scroll compressors provide

the industry’s highest effi ciencies and full capacity

with reduced cycling losses.

• Oversized coaxial tube water-to-refrigerant heat

exchangers operate at low liquid pressure drop.

Convoluted copper (and optional cupronickel)

water tube functions effi ciently at low-fl ow rates

and provides freeze-damage resistance.

Service Advantages

• Removable panels - 3 for compressor section

(plus removable top panel).

• Low profi le control box grants easy access to all

internal components.

• Factory supplied (fi eld installed) liquid line

fi lter/drier.

• Brass swivel-type water connections for quick

connection and elimination of wrenches or

sealants during installation.

• Bi-directional thermal expansion valve.

• CXM control features status lights with memory

for easy diagnostics.

• Unit Performance Sentinel alerts homeowner of

potential performance issues.

•

Circuit breaker protected 75VA control transformer.

• High and low pressure service ports on

refrigerant circuit.

• Accurate refrigerant sensing freeze protection.

Factory Quality

• All units are built on our Integrated Process

Control Assembly System (IPCS). The IPCS is

a unique state of the art manufacturing system

that is designed to assure quality of the highest

standards of any manufacturer in the water-source

industry. Our IPCS system:

- Verifi es that the correct components are

being assembled.

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

5

Page 8

GT-PX

- Automatically performs special leak tests on

all joints.

- Conducts pressure tests.

- Performs highly detailed run test unparalleled in

the HVAC industry.

- Automatically disables packaging for a “failed” unit.

- Creates computer database for future service

analysis and diagnostics from run test results.

• Heavy gauge galvanized steel cabinets are epoxy

powder coated for durable and long-lasting fi nish.

• All refrigerant brazing is done in a nitrogen

atmosphere.

• All units are deep evacuated to less than 100

microns prior to refrigerant charging.

• All joints are both helium and halogen leak tested

to insure annual leak rate of less than 1/4 ounce.

• Coaxial heat exchanger, refrigerant suction lines

and all water lines are fully insulated to eliminate

condensation problems in low temperature

applications.

• Noise Reduction features include: double isolation

mounted compressors, compressor springs,

insulated compressor compartment, and interior

cabinet insulation using 1/2” coated glass fi ber.

•

Safety features include: high pressure and loss of

charge to protect the compressor; condensate

overfl ow protection; low water temperature

limit sensors to safeguard the coaxial heat

exchanger and air coil; hot water high limit and low

compressor discharge temperature switch provided

to shut down the hot water generator when

conditions dictate. Fault lockout enables emergency

heat and prevents compressor operation until

thermostat or circuit breaker has been reset.

Advanced Unit Controls With

Easy Diagnostics And

Unit Protection Sentinel Functions

Options & Accessories

• Optional hot water generator with internally

mounted pump.

• Optional cupronickel coaxial heat exchanger.

• Electronic thermostat.

• Closed loop Flow Controller.

• Electronic auto-changeover thermostat with 3stage heat, 2-stage cool and indicator LED’s.

• Hose kits.

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

6

Puron® HFC 410A Refrigerant

Page 9

Features and Benefi ts

Three Easy, Lift-out

Service Access Panels with

Stainless Steel Front Panel

Fully Insulated

Water and

Refrigerant Lines

Two-Stage Indoor Split

Optional Factory

Installed Hot Water

Genorator With

Internal Pump

Puron® Systems

Brass Swivel

Water Connections

Oversized

Water Coil

Two-Stage Copeland

UltraTech™ Unloading

Scroll Compressor

Low Profi le Control Box

Backseating Brass

Service Valves with

Service Port

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

7

Page 10

GT-GS

Application Flexibility

• Eight Capacities 018, 024, 030, 036, 042, 048,

and 060.

• Voltage availability in 208-230/60/1.

• Stackable cabinets.

• Extended range operation (20-120°F EWT) and

fl ow rates as low as 1.5 gpm per ton.

• Circuit breaker protected loop and hot water

gen er a tor pumps.

• Field selectable low temperature cut-out selection

setting for well or loop.

• Corner located electrical box for wiring access

from two sides.

• Compressor mounting springs “matched” to each

compressor for maximum quietness.

• Narrow cabinet for movement through doorways.

• Precharged refrigerant circuit with backseating

service valves for quick installation.

Operating Effi ciencies

• ARI/ASHRAE/ISO 13256-1 ratings for heating

COP’s, cooling EER’s and low water fl ow rates.

• Operating and temperature range allow

shorter loops.

• Optional hot water generator with internal pump

generates hot water at considerable savings.

• Rugged, super quiet, and highly effi cient

scroll compressors.

• Oversized coaxial tube water to refrigerant heat

exchangers operate at low liquid pressure drop.

• Convoluted copper (and optional cupronickel)

water tube functions effi ciently at low-fl ow rates

and provides freeze-damage resistance.

Service Advantages

• Removable panels-3 for compressor.

• Brass swivel-type water and HWG connections

for quick connection and elimination of wrenches

or sealants during installation.

Solid state digital compressor module provides

•

reliable lockout, diagnostic, and time delay functions.

• High side loss-of-charge sensing reduces nuisance

low pressure faults.

• LED Fault and status indication with memory for

easy diagnostics.

Designed for front-access service in tight ap pli ca tions.

•

• High and low pressure service ports in the

refrigerant circuit.

• Refrigerant sensing freeze protection for more

accurate low temperature cut-out.

Factory Quality

• All units are built on our Integrated Process

Control Assembly System (IPCS). The IPCS is

a unique state of the art manufacturing system

that is designed to assure quality of the highest

standards of any manufacturer in the water-source

industry. Our IPCS system:

- Verifi es that the correct components are

being assembled.

- Automatically performs special leak tests on

all joints.

- Conducts pressure tests.

- Performs highly detailed run test unparalleled in

the HVAC industry.

Automatically disables packaging for a “failed” unit.

-

- Creates computer database for future service

analysis and diagnostics from run test results.

• Heavy gauge galvanized steel cabinets are epoxy

powder coated for durable and long-lasting fi nish.

• All refrigerant brazing is done in a nitrogen

atmosphere.

• All units are deep evacuated to less than 100

microns prior to refrigerant charging.

• All joints are both helium and halogen leak tested

to insure annual leak rate of less than 1/4 ounce.

• Coaxial heat exchanger, refrigerant suction lines

and all water lines are fully insulated to eliminate

condensation problems in low temperature

applications.

• Noise Reduction features include: double isolation

mounted compressors, compressor springs,

insulated compressor compartment, and interior

cabinet insulation using 1/2” coated glass fi ber.

Safety features include: high pressure and loss of

•

charge to protect the compressor; condensate

overfl ow protection; low water temperature

limit sensors to safeguard the coaxial heat

exchanger and air coil; hot water high limit and low

compressor discharge temperature switch provided

to shut down the hot water generator when

conditions dictate. Fault lockout enables emergency

and prevents compressor operation until

heat

thermostat or circuit breaker has been reset.

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

8

Page 11

Options & Accessories

• Optional hot water generator with internally

mounted pump.

• Optional cupronickel coaxial heat exchanger.

• Wide thermostat selection.

• Closed loop fl ow controller.

• Hose kits.

Features and Benefi ts

Single-Stage Indoor Split

R22 Systems

Epoxy Powder Coat Painted

Stackable Cabinet

Digital Controls

Easy Service Access From

Three Sides

Fully Insulated

Water and

Refrigerant Lines

Backseating Brass

Service Valves with

Service Port

Copeland Scroll Compressors

1” Brass Swivel Water Connections

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

9

Page 12

GT-S

What is the GT-S?

Carrier introduced the industry to the fi rst ever

“outdoor” geothermal split system with internal

pumping for residential applications. We are giving

the consumer choices for unit location! The unit may

be installed inside or outside, thereby satisfying the

requirements of almost any home. When installed

outside, the unit may be placed on an existing pad

and easily connected to existing electric service. And

with this installation option, the fl uid loop remains

outside avoiding extensive installation inside the home.

The GT-S is geothermal without the hassle.

Why “Paradigm Shift”?

We have defi ned the paradigm shift as follows: to

advance a model of technology beyond the familiar.

But what do we mean? Essentially, our GT-S is taking

traditional geothermal technology a step fur ther

by offering a unique split system design suitable for

any home. Home owners can now enjoy all the

savings of a geothermal system with lower installation

costs and less hassle. More importantly, the GT-S is

opening up the previously illusive retrofi t market.

Hence, our slogan “From Air to Water...”. The GT-S is

a competitive product designed to shift traditional air

source homeowners to the benefi ts of water source

geothermal technology.

From the utility perspective, the

perfectly embodies what the utility industry has been

searching for in geothermal: Lower fi rst cost, simple

and easy to service, fi ts traditional dealer practices

and broad market appeal especially for retrofi t, etc.

GT-S

The

niche into more of a mainstream segment.

can pull geothermal out of its high end

GT-S

just about

The GT-S Concept

The

GT-S

provides a unique solution to many of the

problems associated with single-package geothermal

units. In addition, it substantially reduces overall

installed costs and perhaps more importantly, opens

up the largely untapped retrofi t market (which, for

conventional equipment, is over 3 times larger than

the new construction market).

In new construction, the

over packaged geothermal units: The fl uid loop is

kept outside, which keeps large diameter piping,

fl ammable antifreezes and fl ushing carts (a large,

messy service tool) out of the home. The outdoor

compressor means noise and most service activity

will remain outside. The indoor air handlers are quiet,

require less space and allow less costly ductwork

(they don’t have to be side return with canvas collars

and plenum lining). Also, a GT-S can utilize a gas

furnace as the blower and supplemental heat (dual

fuel or add-on) which removes a major consumer

barrier in that geothermal has traditionally forced the

homeowner to make an all-electric home decision.

An add-on application also allows the option of sizing

the geothermal component to the cooling load,

rather than heating, which may further reduce fi rst

GT-S

costs. The

construction segment than geothermal currently

captures, even when marketed through existing

geothermal dealers.

In the replacement market, the

the range of suitable geothermal applications. Current

geothermal retrofi ts have required a complete change

out of all existing equipment, elaborate ductwork

modifi cations, complex routing of interior loop fl uid

lines including below grade foundation penetrations,

upgraded electrical service and unit feeders (110v

furnace being changed to 240v heat pump with

electric backup), and more. This assumes that a

geothermal package unit can even be adapted to fi t

into the existing space. This process is expensive and

disruptive to the owner (they typically don’t want to

change radically from what they have); hence the lack

of geothermal retrofi ts existing. In contrast, the

S

can be installed outside on the same line set and

electric service supplying the existing air conditioner

or heat pump condensing unit. The loop stays outside.

Only the indoor coil might need to be changed on

an existing furnace, or possibly the air handler on an

older heat pump. The purchase timing could be driven

by a fi rst-time central cooling addition; the upgrade

replacement of an aging or broken air conditioner, heat

pump or furnace; an HVAC change necessitated by a

renovation; or an effi ciency upgrade driven by a utility

marketing program.

should be able to tap a larger new

GT-S

offers many benefi ts

GT-S

greatly expands

GT-

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

10

Page 13

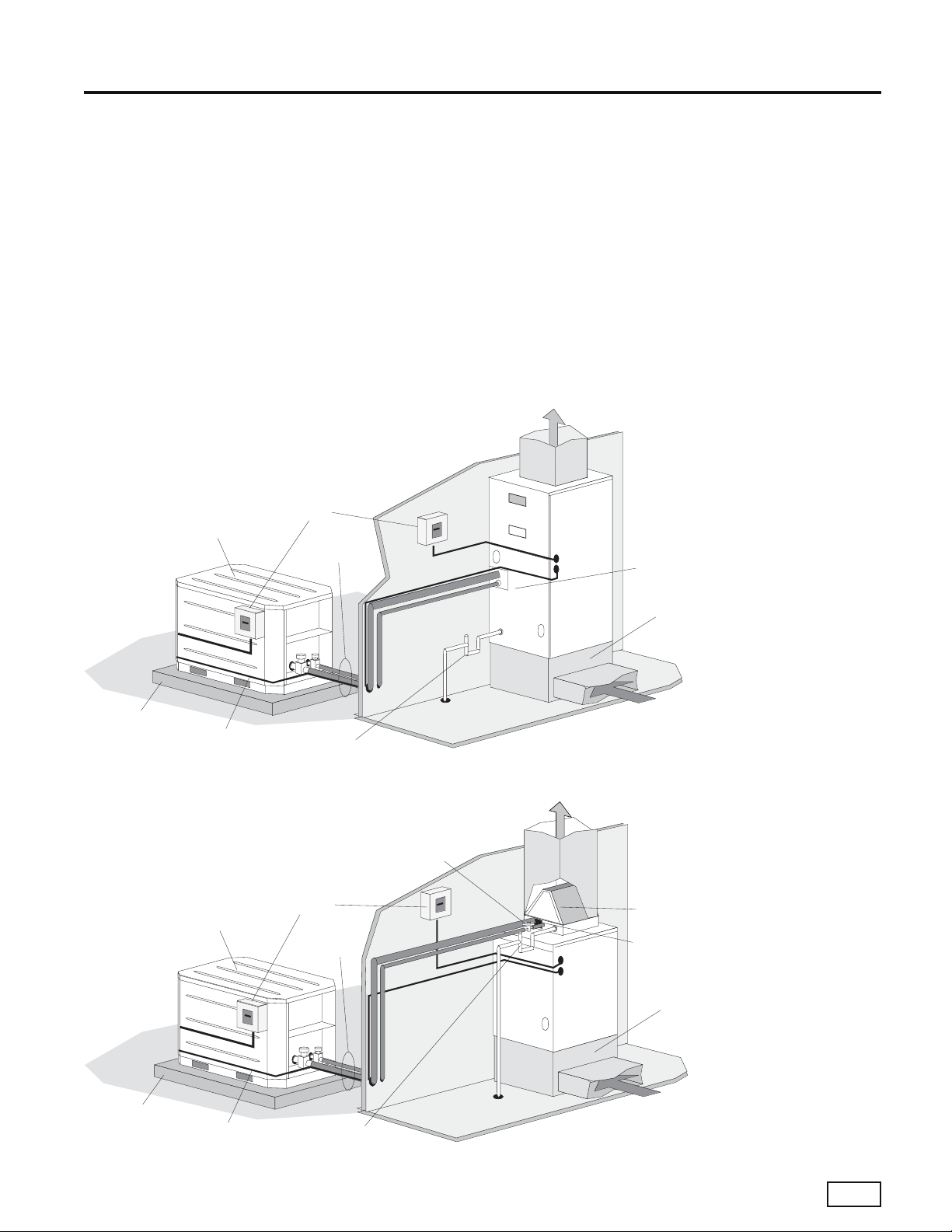

Single-Stage Outdoor Split

R22 Systems

The GT-S does not need to be located outside.

It can be placed in garages, carports, basements,

crawl spaces, etc. This may be important to some

homeowners who may be very concerned about

outdoor aesthetics. They also can utilize ground

water if placed in an appropriate indoor location.

Noise is not a problem as the GT-S is extremely

quiet (the box is sealed and insulated). The GT-S also

has excellent heating and latent cooling capacities

compared with competitive high effi ciency geothermal

units. In many cases a GT-S produces the heating

Typical GT-S / Air Handler Installation

Power

Condensing

Unit

Disconnects

Insulated line

set with UV

Paint

output of one size larger competitor unit. And the

GT-S is likely to be the highest EER per dollar cost

unit available in the geothermal industry today.

The goal for the

GT-S

Series is based upon

application fl exibility, effi ciency, reliability and a solid

state microprocessor compressor control, producing

a reliable, simple product both easy to service and

install. Its effi ciency and application fl exibility make it

the “Paradigm” of geothermal heat pumps.

Air Handler

TXV “IN” toward

outdoor

condensing Unit

Air Pad

Low Voltage Wiring

PVC Condensate

with vented trap

Typical GT-S / Add-on Coil Installation

TXV “IN” toward outdoor

condensing unit

Power

Condensing

Unit

Disconnects

Insulated line

set with

UV Paint

Fossil Furnace

Return Plenum

Add-On

“A” Coil

Air

Temperature

Limit Switch

Return Plenum

Air Pad

Low Voltage Wiring

PVC Condensate

with vented trap

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

11

Page 14

GT-S

Application Flexibility

• Eight Capacities 018, 024, 030, 036, 042, 048,

and 060.

• Voltage availability in 208-230/60/1.

• Stackable cabinets.

• Extended range operation (20-120°F EWT)

and fl ow rates as low as 2.25 gpm per ton

(geothermal closed loop operation).

• Circuit breaker protected loop and hot water

gen er a tor pumps.

• Field selectable low temperature cut-out selection

setting for geothermal closed loop operation.

• Easily accessible electrical box for wiring.

• Weather-resistent cabinet.

Internally-mounted (fi eld installed) Flow Controller

•

• Precharged refrigerant circuit with backseating

service valves for quick installation.

Operating Effi ciencies

• ARI/ASHRAE/ISO 13256-1 ratings for heating

COP’s, cooling EER’s and low water fl ow rates.

• Operating and temperature range allow

shorter loops.

• Optional remoted-mounted hot water generator

with internal pump generates hot water at

considerable savings.

• Rugged, super quiet, and highly effi cient scroll

compressors (rotary for size 018).

• Oversized coaxial tube water to refrigerant heat

exchangers operate at low liquid pressure drop.

• Convoluted copper (and optional cupronickel)

water tube functions effi ciently at low-fl ow rates

and provides freeze-damage resistance.

Service Advantages

• Removable side and top panels for easy access to

water/refrigerant circuits.

• Low ambient temperature switch activates loop

pump in extreme temperatures.

Solid state digital compressor module provides

•

reliable lockout, diagnostic, and time delay functions.

• High side loss-of-charge sensing reduces nuisance

low pressure faults.

• LED Fault and status indication with memory for

easy diagnostics.

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

12

• High and low pressure service ports in the

refrigerant circuit.

• Refrigerant sensing freeze protection for more

accurate low temperature cut-out.

Factory Quality

• All units are built on our Integrated Process

Control Assembly System (IPCS). The IPCS is

a unique state of the art manufacturing system

that is designed to assure quality of the highest

standards of any manufacturer in the water-source

industry. Our IPCS system:

- Verifi es that the correct components are

being assembled.

- Automatically performs special leak tests on

all joints.

- Conducts pressure tests.

- Performs highly detailed run test unparalleled in

the HVAC industry.

Automatically disables packaging for a “failed” unit.

-

- Creates computer database for future service

analysis and diagnostics from run test results.

• Heavy gauge galvanized steel cabinets are epoxy

powder coated for durable and long-lasting fi nish.

• All refrigerant brazing is done in a nitrogen

atmosphere.

• All units are deep evacuated to less than 100

microns prior to refrigerant charging.

• All joints are both helium and halogen leak tested

to insure annual leak rate of less than 1/4 ounce.

• Coaxial heat exchanger, refrigerant suction lines

and all water lines are fully insulated to eliminate

condensation problems in low temperature

applications.

• Noise Reduction features include: double isolation

mounted compressors, compressor springs,

insulated compressor compartment, and interior

cabinet insulation using 1/2” coated glass fi ber.

Safety features include: high pressure and loss of

•

charge to protect the compressor; condensate

overfl ow protection; low water temperature

limit sensors to safeguard the coaxial heat

exchanger and air coil; hot water high limit and low

compressor discharge temperature switch provided

to shut down the hot water generator when

conditions dictate. Fault lockout enables emergency

heat and prevents compressor operation until

thermostat or circuit breaker has been reset.

Page 15

Options & Accessories

• Optional remote-mounted hot water generator

with internally mounted pump.

• Optional cupronickel coaxial heat exchanger.

• Wide thermostat selection.

• Closed loop fl ow controller.

Features and Benefi ts

Single-Stage Outdoor Split

R22 Systems

Powder Coated Galvanized

Heavy Gauge Steel

Insulated Weather

Resistant Cabinet

Internally Mounted

Flow Controller

Copeland Scroll Compressor

(Rotary in 018)

Digital Controls

Hot Water

Generator Ready

Integral Carrying Handles

BackSeating Brass Service Valves

with Service port

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

13

Page 16

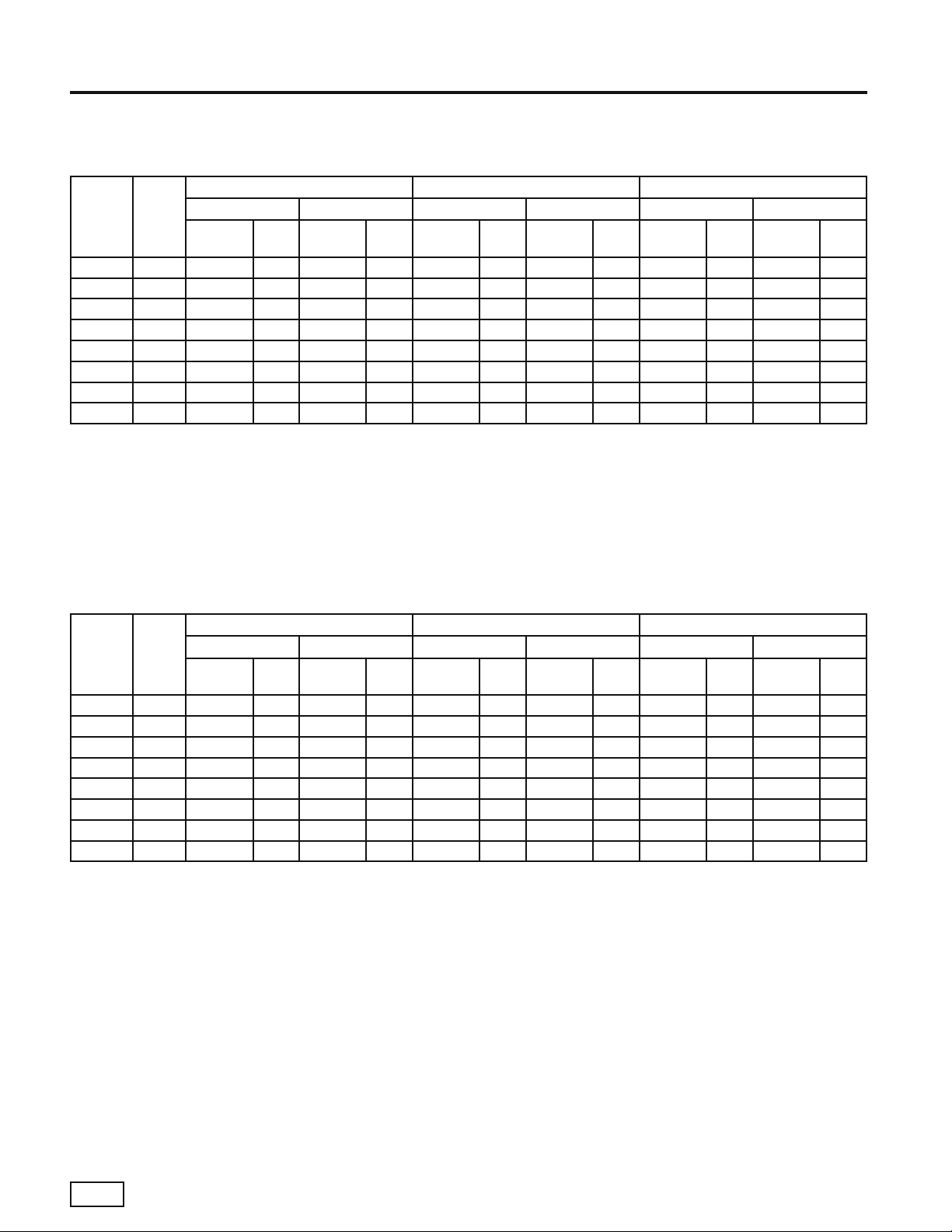

Carrier

ARI/ISO/ASHRAE 13256-1

GT-PX (50YDS) Performance Data - English (IP) Units

ARI/ISO/ASHRAE 13256-1

English (IP) Units

Water Loop Heat Pump Ground Water Heat Pump Ground Loop Heat Pump

Model Load

026 Full 24,700 15.0 31,400 5.3 28,600 23.2 25,600 4.7 26,400 18.0 19,500 3.9

026 Part 18,300 16.3 24,300 5.4 22,000 29.4 19,200 4.6 20,800 24.5 16,600 4.1

038 Full 35,900 14.8 44,700 5.0 40,100 21.4 35,900 4.5 37,300 16.7 27,000 3.8

038 Part 24,400 16.5 30,300 5.6 28,000 27.1 24,400 4.6 27,100 23.7 21,400 4.1

049 Full 48,100 14.6 59,400 5.2 53,900 20.9 47,700 4.6 50,200 16.6 37,200 4.0

049 Part 33,300 16.0 42,000 5.4 38,700 26.8 33,800 4.7 37,000 22.8 29,900 4.2

064 Full 56,900 14.5 74,000 4.7 63,800 19.2 58,800 4.3 59,500 15.3 45,700 3.6

064 Part 40,800 15.8 52,700 5.2 46,000 25.7 42,300 4.4 44,800 22.2 37,500 4.0

Cooling 86°F Heating 68°F Cooling 59°F Heating 50°F Cooling 77°F Heating 32°F

Capacity

Btuh

Btuh/W

EER

Capacity

Btuh

COP

Capacity

Btuh

EER

Btuh/W

Capacity

Btuh

COP

Capacity

Btuh

EER

Btuh/W

Capacity

Btuh

COP

GT-PX (50YDS) Performance Data - Metric (SI) Units

ARI/ISO/ASHRAE 13256-1

Metric (SI) Units

Water Loop Heat Pump Ground Water Heat Pump Ground Loop Heat Pump

Model Load

026 Full 7,239 4.4 9,203 5.3 8,382 6.8 7,503 4.7 7,737 5.3 5,715 3.9

026 Part 5,363 4.8 7,122 5.4 6,448 8.6 5,627 4.6 6,096 7.2 4,865 4.1

038 Full 10,522 4.3 13,101 5.0 11,753 6.3 10,522 4.5 10,932 4.9 7,913 3.8

038 Part 7,151 4.8 8,880 5.6 8,206 7.9 7,151 4.6 7,943 6.9 6,272 4.1

049 Full 14,097 4.3 17,409 5.2 15,797 6.1 13,980 4.6 14,713 4.9 10,903 4.0

049 Part 9,760 4.7 12,309 5.4 11,342 7.9 9,906 4.7 10,844 6.7 8,763 4.2

064 Full 16,676 4.2 21,688 4.7 18,699 5.6 17,233 4.3 17,438 4.5 13,394 3.6

064 Part 11,958 4.6 15,445 5.2 13,482 7.5 12,397 4.4 13,130 6.5 10,991 4.0

Cooling capacities based upon 80.6°F DB, 66.2°F WB entering air temperature.

Heating capacities based upon 68°F DB, 59°F WB entering air temperature.

All ratings based upon 208V operation.

Cooling 30°C Heating 20°C Cooling 15°C Heating 10°C Cooling 25°C Heating 0°C

Capacity

Watts

EER

W/W

Capacity

Watts

COP

Capacity

Watts

EER

W/W

Capacity

Watts

COP

Capacity

Watts

EER

W/W

Capacity

Watts

COP

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

14

Page 17

Indoor & Outdoor Split

ARI/ISO/ASHRAE 13256-1

GT-GS (50YCS) & GT-S (38WQS) Performance Data - English (IP) Units

Water Loop Heat Pump Ground Water Heat Pump Ground Loop Heat Pump

Model

018 16,600 14.4 20,300 4.8 18,500 22.1 15,500 4.0 17,800 16.2 12,800 3.5

024 23,500 14.5 29,300 4.7 25,700 20.6 22,800 3.9 25,200 16.6 18,600 3.5

030 28,000 14.7 34,000 4.7 30,200 20.8 26,400 3.9 29,800 16.4 21,500 3.5

036 32,800 14.5 39,200 4.4 34,900 20.1 31,900 3.9 34,700 15.9 25,900 3.3

042 39,800 14.1 48,300 4.7 44,100 19.7 37,800 3.9 42,000 15.5 31,700 3.6

048 44,500 14.2 52,500 4.8 47,500 19.3 42,000 3.9 47,400 15.9 35,800 3.6

060 55,100 13.0 72,700 4.6 57,800 17.2 57,100 3.7 57,600 14.2 47,200 3.5

Cooling capacities based upon 80.6°F DB, 66.2°F WB entering air temperature.

Heating capacities based upon 68°F DB, 59°F WB entering air temperature.

All ratings based upon 208V operation.

Cooling 86°F Heating 68°F Cooling 59°F Heating 50°F Cooling 77°F Heating 32°F

Capacity

Btuh

Btuh/W

EER

Capacity

Btuh

COP

Capacity

Btuh

EER

Btuh/W

Capacity

Geothermal Comfort Systems

Capacity

Btuh

COP

Btuh

EER

Btuh/W

Capacity

Btuh

COP

GT-GS (50YCS) & GT-S (38WQS) Performance Data - Metric (SI) Units

Water Loop Heat Pump Ground Water Heat Pump Ground Loop Heat Pump

Model

018 4,865 4.2 5,950 4.8 5,422 6.5 4,543 4.0 5,217 4.7 3,751 3.5

024 6,887 4.2 8,587 4.7 7,532 6.0 6,682 3.9 7.386 4.9 5,451 3.5

030 8,206 4.3 9,965 4.7 8,851 6.1 7,737 3.9 8.734 4.8 6,301 3.5

036 9,613 4.2 11,489 4.4 10,229 5.9 9,349 3.9 10,170 4.7 7,591 3.3

042 11,665 4.1 14,156 4.7 12,925 5.8 11,079 3.9 12,309 4.5 9,291 3.6

048 13,042 4.2 15,387 4.8 13,921 5.7 12,309 3.9 13,892 4.7 10,492 3.6

060 16,149 3.8 21,307 4.6 16,940 5.0 16,735 3.7 16,882 4.2 13,834 3.5

Cooling capacities based upon 80.6°F DB, 66.2°F WB entering air temperature.

Heating capacities based upon 68°F DB, 59°F WB entering air temperature.

All ratings based upon 208V operation.

Cooling 30°C Heating 20°C Cooling 15°C Heating 10°C Cooling 25°C Heating 0°C

Capacity

Watts

EER

W/W

Capacity

Watts

COP

Capacity

Watts

EER

W/W

Capacity

Watts

COP

Capacity

Watts

EER

W/W

Capacity

Watts

COP

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

15

Page 18

Carrier

Model Nomenclature

YDS05

026

038

049

064

UNIT TYPE:

SIZE:

OPTION

N

AIRFLOW CONFIGURATION:

UNIT SIZES 018 thru 060

RETURN

NONE

YDS = INDOOR PURON SPLIT

SYSTEM CONDENSING UNIT

GT-PX Nomenclature

YCS05

YCS = INDOOR SPLIT SYSTEM

UNIT TYPE:

CONDENSING UNIT

SIZE:

018

024

030

036

042

048

060

OPTION

AIRFLOW CONFIGURATION:

UNIT SIZES 018 thru 060

RETURN

N

NONE

GT-GS Nomenclature

321

DISCHARGE

NONE

321

DISCHARGE

NONE

3

FILTER

NONE

CONTROL:

C = CXM

2

FILTER

NONE

CONTROL:

L = CXM

86754

C08N

86754

L04N

1211109

3C

0

1

PACKAGING:

1=SINGLE PACK,DOMESTIC

REVISION LEVEL:

0 = CURRENT REVISION

VOLTAGE:

3 = 208V, 230V/1PH/60Hz

HEAT EXCHANGER OPTIONS:

C = COPPER WATER COIL

D = COPPER WATER COIL W/HOT WATER GENERATOR

N = CUPRO-NICKEL WATER COIL

P = CUPRO-NICKEL WATER COIL W/HOT WATER GENERATOR

Rev.: 08/15/05D

1211109

3C

0

1

PACKAGING:

1=SINGLE PACK,DOMESTIC

REVISION LEVEL:

0 = CURRENT REVISION

VOLTAGE:

3 = 208V, 230V/1PH/60Hz

HEAT EXCHANGER OPTIONS:

C = COPPER WATER COIL

D = COPPER WATER COIL W/HOT WATER GENERATOR

N = CUPRO-NICKEL WATER COIL

P = CUPRO-NICKEL WATER COIL W/HOT WATER GENERATOR

Rev.: 03/16/04D

1

W

83

WQS = OUDOOR SPLIT SYSTEM

UNIT TYPE:

CONDENSING UNIT

Q S 0 2

SIZE:

018

024

030

036

042

048

38WQS Nomenclature

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

16

060

5432

4

STANDARD:

SS = STANDARD

76810

S S C 3

9

11 1 2

0 1

VOLTAGE:

3=208V,230V/1PH/60Hz

HEAT EXCHANGER OPTIONS:

C = COPPER WATER COIL

N = CUPRO-NICKEL WATER COIL

PACKAGING:

1 = SINGLE PACK, DOMESTIC

REVISION LEVEL:

1 = CURRENT REVISION

Rev.: 04/18/04D

Page 19

Indoor & Outdoor Split

Geothermal Comfort Systems

Heating

LWT = EWT -

LAT = EAT +

CFM = airfl ow, cubic feet/minute

EWT = entering water temperature, ˚F

GPM = water fl ow in US gallons/minute

EAT = entering air temperature, Fahrenheit

(dry bulb/wet bulb)

HC = air heating capacity, Mbtuh

TC = total cooling capacity, Mbtuh

SC = sensible cooling capacity, Mbtuh

KW = total power unit input, KiloWatts

HR = total heat of rejection, Mbtuh

HE = total heat of extraction, Mbtuh

HE

GPM x 500

HC

CFM x1.08

LWT = EWT +

LAT (DB) = EAT (DB) -

Cooling

HR

GPM x 500

SC

CFM x1.08

HWC = Hot Water Generator (desuperheater)

capacity, Mbtuh

WPD = Water coil pressure drop (psi & ft hd)

EER = Energy Effi ciency Ratio

= BTU output/Watt input

COP = Coeffi cient of Performance

= BTU output/BTU input

LWT = leaving water temperature, °F

LAT = leaving air temperature, °F

LC = latent cooling capacity, Mbtuh

S/T = sensible to total cooling ratio

LC = TC - SC

SC

S/T =

TC

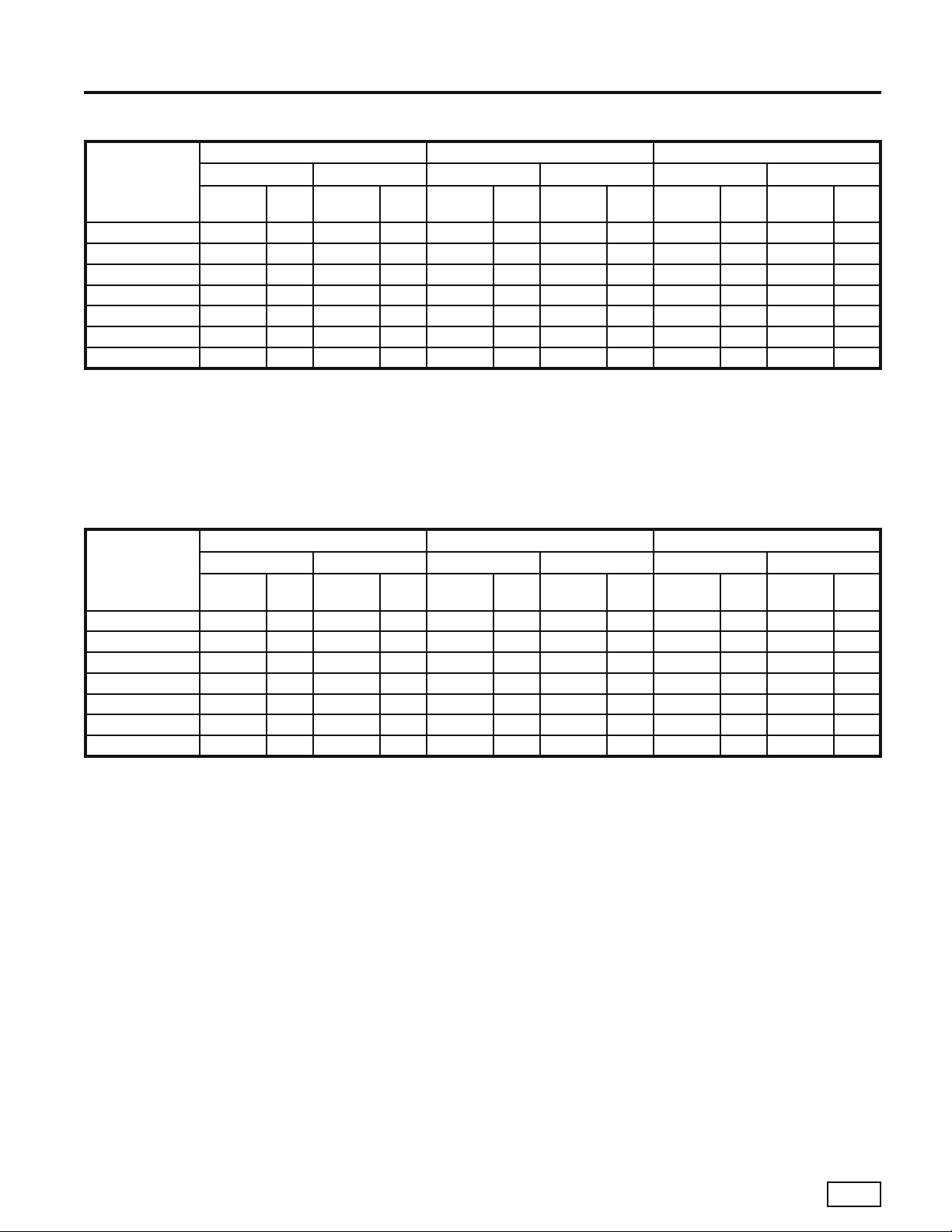

GT-GS & GT-S Performance Correction Factors

Heating Corrections Cooling Corrections

Ent Air DB°FHtg Cap Power Heat of

60 1.019 0.896 1.054 60 0.881 0.943 1.067 1.192 1.240 * * * 0.983 0.899

65 1.010 0.948 1.028 65 0.940 0.797 0.952 1.106 1.125 1.261 * * 0.991 0.949

68 1.004 0.980 1.011 66.2 0.976 0.693 0.868 1.043 1.063 1.217 * * 0.997 0.980

70 1.000 1.000 1.000 67 1.000 0.624 0.812 1.000 1.023 1.188 1.343 1.352 1.000 1.000

75 0.997 1.059 0.979 70 1.012 0.697 0.820 0.835 0.944 1.067 1.257 1.002 1.010

80 0.993 1.118 0.957 75 1.024 0.637 0.658 0.817 0.983 1.159 1.005 1.019

*

Sensible capacity equals total capacity (no latent capacity) at conditions shown as "*"

ARI/ISO/ASHRAE 13256-1 uses entering air conditions of Clg- 80.6°F DB/66.2°F WB and Htg- 68°F DB/59°F WB

Ext

Ent Air

WB °F

Total Clg

Cap

Sens Clg Cap Multiplier - Entering DB °F

70 75 80 80.6 85 90 95

Power Heat of

Rej

Rev. 5/2/00M

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

17

Page 20

GT-PX

Airfl ow Correction Factors

TT Full Load Air Flow Corrections

Airflow Cooling Heating

CFM Per

Ton of Clg

240 60 0.925 0.788 0.913 0.922 0.946 1.153 0.896

275 69 0.946 0.829 0.926 0.942 0.959 1.107 0.924

300 75 0.960 0.861 0.937 0.955 0.969 1.078 0.942

325 81 0.972 0.895 0.950 0.968 0.977 1.053 0.959

350 88 0.983 0.930 0.965 0.979 0.985 1.032 0.974

375 94 0.992 0.965 0.982 0.990 0.993 1.014 0.988

400 100 1.000 1.000 1.000 1.000 1.000 1.000 1.000

425 106 1.007 1.033 1.020 1.009 1.006 0.989 1.011

450 113 1.012 1.064 1.042 1.018 1.012 0.982 1.019

475 119 1.016 1.092 1.066 1.025 1.018 0.979 1.027

500 125 1.018 1.116 1.091 1.032 1.022 0.977 1.033

520 130 1.019 1.132 1.112 1.037 1.026 0.975 1.038

TT Part Load Air Flow Corrections

CFM Per

Ton of Clg

240 60 0.920 0.781 0.959 0.927 0.946 1.241 0.881

275 69 0.942 0.832 0.964 0.946 0.960 1.163 0.915

300 75 0.956 0.867 0.969 0.959 0.969 1.115 0.937

325 81 0.969 0.901 0.975 0.970 0.978 1.076 0.956

350 88 0.981 0.934 0.982 0.981 0.986 1.043 0.973

375 94 0.991 0.967 0.990 0.991 0.993 1.018 0.988

400 100 1.000 1.000 1.000 1.000 1.000 1.000 1.000

425 106 1.007 1.033 1.011 1.008 1.006 0.990 1.010

450 113 1.013 1.065 1.023 1.015 1.012 0.986 1.017

475 119 1.018 1.098 1.036 1.021 1.017 0.983 1.024

500 125 1.021 1.131 1.051 1.026 1.021 0.981 1.030

520 130 1.023 1.159 1.063 1.030 1.024 0.979 1.034

% of

Nominal

Airflow Cooling Heating

Nominal

Total Cap Sens Cap Power Heat of Rej Htg Cap Power Heat of Ext

% of

Total Cap Sens Cap Power Heat of Rej Htg Cap Power Heat of Ext

Performance Correction Factors

Entering Air Correction Factors

TT Full Load Entering Air Corrections

Full Load Heating Corrections Full Load Cooling Corrections

Ent Air

Ent Air DB

Htg Cap Power

°F

40 1.052 0.779 1.120

45 1.043 0.808 1.102

50 1.035 0.841 1.084

55 1.027 0.877 1.065

60 1.019 0.915 1.045

65 1.010 0.957 1.023

68 1.004 0.982 1.010

70 1.000 1.000 1.000

75 0.989 1.045 0.974

80 0.976 1.093 0.946

Heat of

Ext

* Sensible capacity equals total capacity (no latent capacity) at conditions shown as "*"

ARI/ISO/ASHRAE 13256-1 uses entering air conditions of Clg- 80.6°F DB/66.2°F WB and Htg- 68°F DB/59°F WB

Total Clg

WB

°F

Cap

60 65 70 75 80 80.6 85 90 95 100

45 0.832 1.346 1.461 1.603 0.946 0.853

50 0.850 1.004 1.174 1.357 0.953 0.870

55 0.880 0.694 0.902 1.115 1.331 0.964 0.896

60 0.922 0.646 0.875 1.103 1.329 1.356 0.977 0.932

65 0.975 0.639 0.869 1.096 1.123 1.320 0.993 0.979

66.2 0.990 0.582 0.812 1.039 1.066 1.262 1.482 0.997 0.991

67 1.000 0.545 0.774 1.000 1.027 1.223 1.444 1.000 1.000

70 1.040 0.630 0.853 0.880 1.075 1.297 1.517 1.011 1.035

75 1.117 0.601 0.627 0.821 1.046 1.275 1.510 1.033 1.101

TT Part Load Entering Air Corrections

Part Load Heating Corrections Part Load Cooling Corrections

Ent Air

Ent Air DB

Htg Cap Power

°F

40 1.084 0.732 1.161

45 1.073 0.764 1.140

50 1.060 0.802 1.117

55 1.046 0.846 1.090

60 1.031 0.893 1.061

65 1.016 0.945 1.031

68 1.006 0.978 1.013

70 1.000 1.000 1.000

75 0.984 1.058 0.968

80 0.968 1.117 0.936

Heat of

Ext

* Sensible capacity equals total capacity (no latent capacity) at conditions shown as "*"

ARI/ISO/ASHRAE 13256-1 uses entering air conditions of Clg- 80.6°F DB/66.2°F WB and Htg- 68°F DB/59°F WB

Total Clg

WB

°F

Cap

60 65 70 75 80 80.6 85 90 95 100

45 0.876 1.286 1.302 1.389 0.981 0.895

50 0.883 1.002 1.099 1.241 0.985 0.901

55 0.903 0.706 0.871 1.060 1.271 0.989 0.918

60 0.935 0.617 0.844 1.079 1.319 1.349 0.993 0.945

65 0.979 0.595 0.849 1.098 1.128 1.342 0.998 0.982

66.2 0.991 0.531 0.789 1.040 1.070 1.284 1.522 0.999 0.993

67 1.000 0.486 0.747 1.000 1.030 1.245 1.481 1.000 1.000

70 1.035 0.583 0.842 0.873 1.090 1.327 1.552

75 1.105 0.552 0.584 0.811 1.057 1.290 1.510 1.008 1.088

Sens Clg Cap Multipliers- Entering DB °F

*******

*******

******

Sens Clg Cap Multipliers- Entering DB °F

*******

*******

******

****

***

**

**

*

****

***

**

**

*

Power Heat of

Power Heat of

1.003 1.030

Rej

Rev.: 03/29/04

Rej

Rev.: 03/29/04

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

18

Page 21

50YDS026 Part Load With FV4003

Two-Stage Indoor Split

Puron® Systems

530 CFM Nominal (Rated) Airfl ow Cooling, 530 CFM Nominal (Rated) Airfl ow Heating

EWT

20 7.00 4.5 10.4 450 0 0 0 0 0 0 10.9 1.17 7.2 92.4 2.73 1.9

20 7.00 4.5 10.4 530 0 0 0 0 0 0 11.1 1.12 7.4 89.4 2.90 1.7

30 3.50 1.2 2.8 450 22.1 11.7 0.62 24.1 35.6 - 13.2 1.23 9.1 97.2 3.15 2.0

30 3.50 1.2 2.8 530 22.5 12.5 0.63 24.6 35.7 - 13.4 1.18 9.4 93.4 3.33 1.7

30 5.75 2.9 6.7 450 22.3 11.7 0.61 24.3 36.6 - 13.8 1.23 9.7 98.4 3.29 2.0

30 5.75 2.9 6.7 530 22.7 12.5 0.62 24.8 36.6 - 14.0 1.18 10.0 94.5 3.48 1.7

30 7.00 4.1 9.5 450 22.4 11.7 0.60 24.4 37.3 - 14.0 1.23 9.9 98.8 3.34 1.9

30 7.00 4.1 9.5 530 22.8 12.5 0.61 24.9 37.4 - 14.2 1.18 10.2 94.8 3.53 1.7

40 3.50 1.1 2.5 450 22.6 12.6 0.70 24.9 32.3 - 16.0 1.32 11.6 102.9 3.55 2.0

40 3.50 1.1 2.5 530 23.0 13.5 0.71 25.4 32.4 - 16.2 1.27 11.9 98.3 3.74 1.8

40 5.75 2.6 6.0 450 22.8 12.6 0.65 24.9 35.1 - 16.7 1.32 12.3 104.4 3.71 2.0

40 5.75 2.6 6.0 530 23.2 13.5 0.66 25.4 35.2 - 16.9 1.27 12.6 99.5 3.90 1.7

40 7.00 3.6 8.3 450 22.9 12.6 0.65 25.0 35.2 - 16.9 1.32 12.5 104.8 3.75 2.0

40 7.00 3.6 8.3 530 23.3 13.5 0.66 25.5 35.3 - 17.1 1.27 12.8 99.9 3.95 1.7

50 3.50 1.0 2.3 450 22.1 12.9 0.79 24.8 28.0 0.7 18.6 1.38 14.1 108.3 3.95 2.1

50 3.50 1.0 2.3 530 22.5 13.8 0.80 25.3 28.1 0.7 18.9 1.32 14.5 103.0 4.20 1.8

50 5.75 2.4 5.5 450 22.4 12.9 0.74 24.8 30.3 0.6 19.4 1.38 14.8 109.9 4.12 2.1

50 5.75 2.4 5.5 530 22.8 13.8 0.75 25.3 30.4 0.6 19.7 1.32 15.2 104.4 4.37 1.8

50 7.00 3.4 7.9 450 22.4 12.9 0.72 24.8 31.1 0.6 19.6 1.38 15.0 110.3 4.16 2.0

50 7.00 3.4 7.9 530 22.8 13.8 0.73 25.3 31.2 0.6 19.9 1.32 15.4 104.8 4.42 1.8

60 3.50 1.0 2.3 450 21.1 12.8 0.90 24.1 23.4 1.1 21.3 1.44 16.4 113.8 4.34 2.2

60 3.50 1.0 2.3 530 21.5 13.7 0.92 24.6 23.4 1.1 21.6 1.38 16.9 107.7 4.59 1.9

60 5.75 2.3 5.3 450 21.6 13.0 0.83 24.4 26.0 1.0 22.2 1.45 17.3 115.7 4.49 2.2

60 5.75 2.3 5.3 530 22.0 13.9 0.85 24.9 25.9 1.0 22.5 1.39 17.8 109.3 4.74 1.9

60 7.00 3.2 7.4 450 21.7 13.0 0.81 24.4 26.8 0.9 22.4 1.45 17.5 116.1 4.53 2.1

60 7.00 3.2 7.4 530 22.1 13.9 0.83 24.9 26.6 0.9 22.7 1.39 18.0 109.7 4.79 1.9

70 3.50 0.9 2.1 450 19.6 12.4 1.03 23.2 19.0 1.4 24.0 1.48 19.0 119.4 4.75 2.3

70 3.50 0.9 2.1 530 20.0 13.3 1.05 23.6 19.0 1.5 24.3 1.42 19.5 112.5 5.02 2.0

70 5.75 2.1 4.9 450 20.3 12.6 0.95 23.5 21.4 1.3 24.8 1.49 19.9 121.0 4.88 2.3

70 5.75 2.1 4.9 530 20.7 13.5 0.97 24.0 21.3 1.4 25.2 1.43 20.4 114.0 5.16 2.0

70 7.00 3.0 6.9 450 20.5 12.7 0.93 23.6 22.0 1.2 25.1 1.49 20.0 121.6 4.94 2.2

70 7.00 3.0 6.9 530 20.9 13.6 0.95 24.1 22.0 1.2 25.5 1.43 20.6 114.5 5.23 1.9

80 3.50 0.8 1.8 450 18.1 11.9 1.18 22.1 15.3 1.8 26.6 1.52 21.4 124.7 5.13 2.4

80 3.50 0.8 1.8 530 18.5 12.7 1.20 22.5 15.4 1.8 27.0 1.46 22.0 117.2 5.42 2.1

80 5.75 2.0 4.6 450 18.8 12.1 1.10 22.6 17.1 1.6 27.7 1.53 22.4 127.0 5.31 2.4

80 5.75 2.0 4.6 530 19.2 13.0 1.12 23.0 17.1 1.7 28.1 1.47 23.0 119.1 5.60 2.1

80 7.00 2.8 6.5 450 19.0 12.2 1.08 22.7 17.6 1.5 28.0 1.54 22.7 127.6 5.33 2.4

80 7.00 2.8 6.5 530 19.4 13.1 1.10 23.1 17.6 1.5 28.4 1.48 23.3 119.6 5.62 2.1

85 3.50 0.8 1.8 450 17.4 11.6 1.26 21.7 13.8 2.0 28.0 1.55 22.7 127.6 5.29 2.5

85 3.50 0.8 1.8 530 17.7 12.4 1.28 22.1 13.8 2.0 28.4 1.49 23.3 119.6 5.59 2.2

85 5.75 1.9 4.4 450 18.1 11.9 1.18 22.1 15.3 1.8 29.1 1.56 23.7 129.9 5.47 2.5

85 5.75 1.9 4.4 530 18.4 12.7 1.20 22.5 15.3 1.9 29.5 1.50 24.4 121.5 5.76 2.2

85 7.00 2.7 6.2 450 18.2 12.0 1.15 22.2 15.8 1.7 29.4 1.56 24.0 130.5 5.52 2.5

85 7.00 2.7 6.2 530 18.6 12.8 1.17 22.6 15.9 1.7 29.8 1.50 24.7 122.1 5.82 2.2

90 3.50 0.8 1.8 450 16.7 11.4 1.34 21.3 12.5 2.4 29.4 1.57 23.9 130.5 5.49 2.6

90 3.50 0.8 1.8 530 17.0 12.2 1.36 21.7 12.5 2.5 29.8 1.51 24.6 122.1 5.78 2.2

90 5.75 1.9 4.4 450 17.2 11.6 1.26 21.5 13.7 1.9 30.6 1.60 25.1 133.0 5.61 2.6

90 5.75 1.9 4.4 530 17.5 12.4 1.28 21.9 13.7 2.0 31.0 1.53 25.8 124.2 5.94 2.2

90 7.00 2.7 6.2 450 17.4 11.7 1.23 21.6 14.1 1.8 30.9 1.60 25.4 133.6 5.66 2.5

90 7.00 2.7 6.2 530 17.7 12.5 1.25 22.0 14.2 1.8 31.3 1.53 26.1 124.7 6.00 2.2

100 3.50 0.8 1.8 450 15.1 10.8 1.50 20.3 10.1 2.4 0 0 0 0 0 0

100 3.50 0.8 1.8 530 15.4 11.6 1.53 20.7 10.1 2.5 0 0 0 0 0 0

100 5.75 1.8 4.2 450 15.6 11.0 1.43 20.5 10.9 2.2 0 0 0 0 0 0

100 5.75 1.8 4.2 530 15.9 11.8 1.46 20.9 10.9 2.3 0 0 0 0 0 0

100 7.00 2.6 6.0 450 15.8 11.0 1.40 20.6 11.3 2.0 0 0 0 0 0 0

100 7.00 2.6 6.0 530 16.1 11.8 1.43 21.0 11.3 2.0 0 0 0 0 0 0

110 3.50 0.7 1.6 450 13.9 10.7 1.70 19.8 8.2 2.7 0 0 0 0 0 0

110 3.50 0.7 1.6 530 14.2 11.4 1.73 20.2 8.2 2.8 0 0 0 0 0 0

110 5.75 1.7 3.9 450 14.2 10.6 1.63 19.8 8.7 2.5 0 0 0 0 0 0

110 5.75 1.7 3.9 530 14.5 11.3 1.66 20.2 8.7 2.5 0 0 0 0 0 0

110 7.00 2.5 5.8 450 14.4 10.7 1.60 19.9 9.0 2.2 0 0 0 0 0 0

110 7.00 2.5 5.8 530 14.7 11.4 1.63 20.3 9.0 2.3 0 0 0 0 0 0

120 3.50 0.7 1.6 450 12.9 10.6 1.95 19.6 6.6 3.0 0 0 0 0 0 0

120 3.50 0.7 1.6 530 13.2 11.3 1.99 20.0 6.6 3.0 0 0 0 0 0 0

120 5.75 1.7 3.9 450 13.2 10.5 1.85 19.5 7.1 2.7 0 0 0 0 0 0

120 5.75 1.7 3.9 530 13.5 11.2 1.88 19.9 7.2 2.7 0 0 0 0 0 0

120 7.00 2.4 5.5 450 13.2 10.5 1.82 19.5 7.3 2.4 0 0 0 0 0 0

120 7.00 2.4 5.5 530 13.5 11.2 1.85 19.9 7.3 2.5 0 0 0 0 0 0

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating. ARI/ISO certifi ed conditions are 80.6°F DB and

66.2°F WB in cooling and 68°F DB in heating.

Table does not refl ect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit (standard on residential models).

See performance correction tables for operating conditions other than those listed above.

“-” HWG operation is limited by a discharge temperature switch.

GPM

°F

20 Operation not recommended

30

40

50

60

70

80

85

90

100

110

120

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airfl ow

CFM

TC SC kW HR EER

HWC

Performance capacities shown in thousands of Btuh

HC kW HE LAT COP HWC

Operation not recommended

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

19

Page 22

GT-PX

50YDS026 Full Load With FV4003

850 CFM Nominal (Rated) Airfl ow Cooling, 850 CFM Nominal (Rated) Airfl ow Heating

EWT

20 8.00 5.6 12.9 750 0 0 0 0 0 0 14.9 1.54 9.8 88.4 2.84 2.4

20 8.00 5.6 12.9 880 0 0 0 0 0 0 15.1 1.49 10.1 85.9 2.97 2.1

30 4.00 1.5 3.5 750 29.4 18.4 1.09 32.6 27.0 - 17.6 1.60 12.4 91.7 3.22 2.4

30 4.00 1.5 3.5 880 29.9 19.8 1.15 33.8 26.0 - 17.9 1.55 12.7 88.8 3.38 2.1

30 6.00 3.1 7.2 750 29.6 18.4 1.04 32.6 28.5 - 18.5 1.61 13.2 92.8 3.37 2.4

30 6.00 3.1 7.2 880 30.1 19.8 1.10 33.8 27.4 - 18.8 1.56 13.5 89.8 3.53 2.1

30 8.00 5.1 11.8 750 29.8 18.5 1.01 32.7 29.5 - 18.9 1.62 13.5 93.3 3.42 2.4

30 8.00 5.1 11.8 880 30.3 19.9 1.07 33.9 28.3 - 19.2 1.57 13.9 90.2 3.58 2.1

40 4.00 1.4 3.2 750 29.2 19.0 1.18 32.7 24.7 - 21.1 1.67 15.5 96.0 3.70 2.5

40 4.00 1.4 3.2 880 29.7 20.4 1.25 33.9 23.8 - 21.4 1.62 15.9 92.5 3.87 2.2

40 6.00 2.8 6.5 750 29.4 19.0 1.13 32.8 26.0 - 22.1 1.69 16.4 97.3 3.83 2.5

40 6.00 2.8 6.5 880 29.9 20.4 1.19 34.0 25.1 - 22.4 1.64 16.8 93.6 4.00 2.2

40 8.00 4.6 10.6 750 29.5 19.0 1.10 32.8 26.8 - 22.6 1.71 16.9 97.9 3.87 2.4

40 8.00 4.6 10.6 880 30.0 20.4 1.16 34.0 25.9 - 22.9 1.66 17.3 94.1 4.04 2.1

50 4.00 1.3 3.0 750 28.4 19.2 1.30 32.3 21.8 1.1 24.2 1.74 18.3 99.9 4.08 2.6

50 4.00 1.3 3.0 880 28.9 20.6 1.37 33.5 21.1 1.1 24.6 1.69 18.8 95.9 4.27 2.3

50 6.00 2.6 6.0 750 28.9 19.2 1.23 32.6 23.5 1.0 25.2 1.78 19.3 101.1 4.15 2.6

50 6.00 2.6 6.0 880 29.4 20.7 1.30 33.8 22.6 1.0 25.6 1.72 19.8 96.9 4.36 2.3

50 8.00 4.3 9.9 750 29.1 19.2 1.19 32.7 24.5 0.9 25.8 1.80 19.7 101.9 4.20 2.6

50 8.00 4.3 9.9 880 29.6 20.7 1.26 33.9 23.5 0.9 26.2 1.74 20.2 97.6 4.41 2.2

60 4.00 1.2 2.8 750 27.2 18.9 1.42 31.7 19.2 1.5 27.1 1.83 20.9 103.5 4.34 2.8

60 4.00 1.2 2.8 880 27.7 20.3 1.50 32.9 18.5 1.6 27.5 1.77 21.5 98.9 4.55 2.5

60 6.00 2.5 5.8 750 27.9 19.2 1.34 32.1 20.8 1.3 28.1 1.86 21.8 104.7 4.43 2.8

60 6.00 2.5 5.8 880 28.4 20.6 1.42 33.3 20.0 1.4 28.5 1.80 22.4 100.0 4.64 2.4

60 8.00 4.0 9.2 750 28.2 19.2 1.32 32.2 21.4 1.1 28.7 1.87 22.3 105.4 4.50 2.7

60 8.00 4.0 9.2 880 28.7 20.7 1.39 33.4 20.6 1.2 29.1 1.81 22.9 100.6 4.71 2.4

70 4.00 1.1 2.5 750 25.8 18.4 1.56 30.9 16.5 2.0 29.8 1.90 23.3 106.8 4.60 3.1

70 4.00 1.1 2.5 880 26.3 19.8 1.65 32.0 15.9 2.1 30.2 1.84 23.9 101.8 4.81 2.7

70 6.00 2.3 5.3 750 26.6 18.8 1.49 31.4 17.9 1.8 30.7 1.93 24.2 107.9 4.66 3.0

70 6.00 2.3 5.3 880 27.1 20.2 1.57 32.5 17.3 1.8 31.2 1.87 24.8 102.8 4.89 2.6

70 8.00 3.8 8.8 750 27.0 19.0 1.44 31.6 18.8 1.5 31.3 1.95 24.6 108.6 4.70 3.0

70 8.00 3.8 8.8 880 27.5 20.4 1.52 32.7 18.1 1.5 31.8 1.89 25.3 103.5 4.93 2.6

80 4.00 1.0 2.3 750 24.4 17.9 1.72 29.9 14.2 2.6 32.1 1.97 25.4 109.6 4.78 3.4

80 4.00 1.0 2.3 880 24.8 19.2 1.82 31.0 13.6 2.6 32.6 1.91 26.1 104.3 5.00 2.9

80 6.00 2.2 5.1 750 25.2 18.2 1.64 30.4 15.4 2.2 33.3 2.01 26.4 111.1 4.86 3.3

80 6.00 2.2 5.1 880 25.6 19.6 1.73 31.5 14.8 2.3 33.8 1.95 27.1 105.6 5.08 2.9

80 8.00 3.5 8.1 750 25.5 18.4 1.59 30.6 16.0 1.9 33.8 2.03 26.9 111.7 4.88 3.3

80 8.00 3.5 8.1 880 26.0 19.8 1.68 31.7 15.5 1.9 34.3 1.97 27.6 106.1 5.10 2.8

85 4.00 1.0 2.3 750 23.5 17.5 1.82 29.4 12.9 2.9 33.3 2.01 26.5 111.1 4.86 3.6

85 4.00 1.0 2.3 880 23.9 18.8 1.92 30.5 12.4 3.0 33.8 1.95 27.2 105.6 5.08 3.1

85 6.00 2.1 4.9 750 24.4 17.9 1.72 29.9 14.2 2.5 34.5 2.04 27.5 112.6 4.96 3.5

85 6.00 2.1 4.9 880 24.8 19.2 1.82 31.0 13.6 2.6 35.0 1.98 28.2 106.8 5.18 3.1

85 8.00 3.4 7.9 750 24.8 18.0 1.68 30.1 14.8 2.1 35.1 2.06 28.0 113.3 4.99 3.5

85 8.00 3.4 7.9 880 25.2 19.4 1.77 31.2 14.2 2.1 35.6 2.00 28.7 107.5 5.22 3.0

90 4.00 1.0 2.3 750 22.7 17.1 1.90 29.0 11.9 3.2 34.5 2.04 27.6 112.6 4.96 3.7

90 4.00 1.0 2.3 880 23.1 18.4 2.01 30.0 11.5 3.3 35.0 1.98 28.3 106.8 5.18 3.3

90 6.00 2.1 4.9 750 23.6 17.6 1.81 29.4 13.0 2.8 35.7 2.08 28.5 114.1 5.03 3.7

90 6.00 2.1 4.9 880 24.0 18.9 1.91 30.5 12.6 2.8 36.2 2.02 29.3 108.1 5.25 3.2

90 8.00 3.4 7.9 750 24.0 17.8 1.76 29.6 13.6 2.3 36.3 2.11 29.0 114.8 5.04 3.6

90 8.00 3.4 7.9 880 24.4 19.1 1.86 30.7 13.1 2.3 36.8 2.04 29.8 108.7 5.29 3.1

100 4.00 1.0 2.3 750 21.1 16.5 2.11 28.1 10.0 3.9 0 0 0 0 0 0

100 4.00 1.0 2.3 880 21.5 17.7 2.23 29.1 9.6 4.0 0 0 0 0 0 0

100 6.00 2.0 4.6 750 21.9 16.8 2.00 28.5 11.0 3.4 0 0 0 0 0 0

100 6.00 2.0 4.6 880 22.3 18.1 2.11 29.5 10.6 3.4 0 0 0 0 0 0

100 8.00 3.2 7.4 750 22.3 17.0 1.95 28.7 11.4 2.8 0 0 0 0 0 0

100 8.00 3.2 7.4 880 22.7 18.3 2.06 29.7 11.0 2.8 0 0 0 0 0 0

110 4.00 0.9 2.1 750 19.7 15.9 2.34 27.4 8.4 4.7 0 0 0 0 0 0

110 4.00 0.9 2.1 880 20.0 17.1 2.47 28.4 8.1 4.8 0 0 0 0 0 0

110 6.00 1.9 4.4 750 20.3 16.2 2.21 27.7 9.2 4.0 0 0 0 0 0 0

110 6.00 1.9 4.4 880 20.7 17.4 2.34 28.7 8.8 4.1 0 0 0 0 0 0

110 8.00 3.1 7.2 750 20.6 16.4 2.16 27.8 9.5 3.3 0 0 0 0 0 0

110 8.00 3.1 7.2 880 21.0 17.6 2.28 28.8 9.2 3.4 0 0 0 0 0 0

120 4.00 0.9 2.1 750 18.3 15.5 2.59 27.0 7.1 5.6 0 0 0 0 0 0

120 4.00 0.9 2.1 880 18.6 16.7 2.74 28.0 6.8 5.7 0 0 0 0 0 0

120 6.00 1.8 4.2 750 18.9 15.7 2.46 27.1 7.7 4.7 0 0 0 0 0 0

120 6.00 1.8 4.2 880 19.2 16.9 2.60 28.1 7.4 4.8 0 0 0 0 0 0

120 8.00 3.0 6.9 750 19.2 15.8 2.40 27.2 8.0 3.9 0 0 0 0 0 0

120 8.00 3.0 6.9 880 19.5 17.0 2.54 28.2 7.7 4.0 0 0 0 0 0 0

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating. ARI/ISO certifi ed conditions are 80.6°F DB and 66.2°F

WB in cooling and 68°F DB in heating.

Table does not refl ect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit (standard on residential models).

See performance correction tables for operating conditions other than those listed above.

“-” HWG operation is limited by a discharge temperature switch.

GPM

°F

20 Operation not recommended

30

40

50

60

70

80

85

90

100

110

120

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airfl ow

CFM

TC SC kW HR EER

HWC

Performance capacities shown in thousands of Btuh

HC kW HE LAT COP HWC

Operation not recommended

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

20

Page 23

50YDS038 Part Load With FV4005

Two-Stage Indoor Split

Puron® Systems

700 CFM Nominal (Rated) Airfl ow Cooling, 700 CFM Nominal (Rated) Airfl ow Heating

EWT

20 8.00 4.7 10.9 600 0 0 0 0 0 0 16.5 1.64 11.1 95.5 2.95 2.4

20 8.00 4.7 10.9 700 0 0 0 0 0 0 16.7 1.57 11.4 92.1 3.12 2.1

30 4.00 1.2 2.8 600 27.5 17.0 0.90 30.5 30.6 - 18.1 1.66 12.8 97.9 3.20 2.4

30 4.00 1.2 2.8 700 28.0 18.2 0.92 31.1 30.4 - 18.4 1.59 13.1 94.3 3.39 2.1

30 6.00 2.6 6.0 600 27.8 17.0 0.85 30.6 32.7 - 18.8 1.66 13.3 99.0 3.32 2.4

30 6.00 2.6 6.0 700 28.3 18.2 0.87 31.2 32.5 - 19.1 1.59 13.7 95.3 3.52 2.1

30 8.00 4.5 10.4 600 28.0 17.1 0.83 30.7 33.7 - 19.1 1.67 13.7 99.5 3.35 2.4

30 8.00 4.5 10.4 700 28.5 18.3 0.85 31.3 33.5 - 19.4 1.60 14.1 95.7 3.55 2.1

40 4.00 1.1 2.5 600 28.2 18.4 1.01 31.6 27.9 - 20.7 1.69 15.2 101.9 3.59 2.5

40 4.00 1.1 2.5 700 28.7 19.7 1.03 32.2 27.9 - 21.0 1.62 15.6 97.8 3.80 2.2

40 6.00 2.6 6.0 600 28.4 18.4 0.93 31.6 30.5 - 21.5 1.69 16.0 103.2 3.73 2.5

40 6.00 2.6 6.0 700 28.9 19.7 0.95 32.2 30.4 - 21.8 1.62 16.4 98.8 3.94 2.1

40 8.00 4.4 10.2 600 28.5 18.4 0.90 31.6 31.7 - 22.0 1.69 16.4 104.0 3.82 2.4

40 8.00 4.4 10.2 700 29.1 19.7 0.92 32.2 31.6 - 22.3 1.62 16.8 99.5 4.03 2.1

50 4.00 1.0 2.3 600 28.0 19.0 1.14 31.8 24.6 0.8 23.4 1.72 17.7 106.1 3.99 2.6

50 4.00 1.0 2.3 700 28.5 20.3 1.16 32.4 24.6 0.8 23.7 1.65 18.2 101.3 4.21 2.2

50 6.00 2.5 5.8 600 28.3 19.1 1.05 31.8 27.0 0.7 24.3 1.72 18.6 107.5 4.14 2.6

50 6.00 2.5 5.8 700 28.8 20.4 1.07 32.4 26.9 0.8 24.7 1.65 19.1 102.7 4.39 2.2

50 8.00 4.2 9.7 600 28.4 19.1 1.01 31.9 28.1 0.7 24.9 1.73 19.1 108.4 4.22 2.5

50 8.00 4.2 9.7 700 29.0 20.4 1.03 32.5 28.2 0.7 25.3 1.66 19.6 103.5 4.47 2.2

60 4.00 0.9 2.1 600 26.9 19.1 1.29 31.3 20.9 1.3 26.6 1.75 20.7 111.0 4.45 2.7

60 4.00 0.9 2.1 700 27.4 20.4 1.31 31.9 20.9 1.3 27.0 1.68 21.3 105.7 4.71 2.3

60 6.00 2.4 5.5 600 27.6 19.2 1.19 31.6 23.2 1.2 27.8 1.76 21.8 112.9 4.63 2.7

60 6.00 2.4 5.5 700 28.1 20.5 1.21 32.2 23.2 1.2 28.2 1.69 22.4 107.3 4.89 2.3

60 8.00 4.1 9.5 600 27.9 19.2 1.14 31.7 24.5 1.1 28.4 1.76 22.4 113.8 4.73 2.6

60 8.00 4.1 9.5 700 28.4 20.5 1.16 32.3 24.5 1.1 28.8 1.69 23.0 108.1 4.99 2.3

70 4.00 0.8 1.8 600 25.5 18.5 1.45 30.5 17.6 1.8 29.9 1.78 23.7 116.1 4.92 2.8

70 4.00 0.8 1.8 700 26.0 19.8 1.48 31.1 17.6 1.8 30.3 1.71 24.4 110.1 5.19 2.5

70 6.00 2.3 5.3 600 26.3 18.8 1.35 30.9 19.5 1.7 31.2 1.79 25.1 118.1 5.11 2.8

70 6.00 2.3 5.3 700 26.8 20.1 1.37 31.5 19.6 1.7 31.7 1.72 25.8 111.9 5.40 2.4

70 8.00 4.0 9.2 600 26.7 19.0 1.30 31.1 20.5 1.5 31.9 1.80 25.8 119.2 5.19 2.8

70 8.00 4.0 9.2 700 27.2 20.3 1.32 31.7 20.6 1.5 32.4 1.73 26.5 112.9 5.49 2.4

80 4.00 0.7 1.6 600 23.9 17.8 1.64 29.5 14.6 2.3 33.2 1.83 27.1 121.2 5.32 3.0

80 4.00 0.7 1.6 700 24.4 19.0 1.67 30.1 14.6 2.3 33.7 1.75 27.8 114.6 5.64 2.6

80 6.00 2.3 5.3 600 24.8 18.2 1.52 30.0 16.3 2.1 34.9 1.84 28.6 123.9 5.56 3.0

80 6.00 2.3 5.3 700 25.3 19.5 1.55 30.6 16.3 2.1 35.4 1.76 29.4 116.8 5.89 2.6

80 8.00 3.9 9.0 600 25.2 18.4 1.46 30.2 17.3 1.9 35.8 1.84 29.5 125.2 5.70 2.9

80 8.00 3.9 9.0 700 25.7 19.7 1.49 30.8 17.2 1.9 36.3 1.76 30.3 118.0 6.04 2.6

85 4.00 0.7 1.6 600 23.2 17.5 1.74 29.0 13.3 2.5 35.0 1.84 28.7 124.0 5.57 3.2

85 4.00 0.7 1.6 700 23.6 18.7 1.77 29.6 13.3 2.6 35.5 1.76 29.5 117.0 5.91 2.7

85 6.00 2.2 5.1 600 23.9 17.8 1.62 29.5 14.8 2.3 36.8 1.86 30.4 126.8 5.80 3.2

85 6.00 2.2 5.1 700 24.4 19.1 1.65 30.1 14.8 2.3 37.3 1.78 31.2 119.3 6.14 2.7

85 8.00 3.8 8.8 600 24.4 18.0 1.56 29.7 15.6 2.1 37.8 1.86 31.3 128.3 5.96 3.0

85 8.00 3.8 8.8 700 24.9 19.3 1.59 30.3 15.7 2.1 38.3 1.78 32.2 120.7 6.31 2.65

90 4.00 0.7 1.6 600 22.4 17.1 1.84 28.6 12.2 2.7 36.9 1.86 30.5 126.9 5.81 3.2

90 4.00 0.7 1.6 700 22.8 18.3 1.87 29.1 12.2 2.8 37.4 1.78 31.3 119.5 6.16 2.8

90 6.00 2.1 4.9 600 23.2 17.5 1.71 29.0 13.6 2.5 38.7 1.88 32.2 129.7 6.03 3.2

90 6.00 2.1 4.9 700 23.6 18.7 1.74 29.6 13.6 2.5 39.3 1.80 33.1 122.0 6.40 2.8

90 8.00 3.7 8.5 600 23.5 17.7 1.65 29.2 14.2 2.2 39.8 1.88 33.3 131.4 6.20 3.1

90 8.00 3.7 8.5 700 24.0 18.9 1.68 29.8 14.3 2.3 40.4 1.80 34.2 123.4 6.58 2.7

100 4.00 0.6 1.4 600 20.9 16.6 2.05 27.9 10.2 3.1 0 0 0 0 0 0

100 4.00 0.6 1.4 700 21.3 17.8 2.09 28.4 10.2 3.2 0 0 0 0 0 0

100 6.00 2.1 4.9 600 21.6 16.8 1.92 28.2 11.3 2.8 0 0 0 0 0 0

100 6.00 2.1 4.9 700 22.0 18.0 1.96 28.7 11.2 2.9 0 0 0 0 0 0

100 8.00 3.6 8.3 600 22.0 17.0 1.86 28.4 11.8 2.5 0 0 0 0 0 0

100 8.00 3.6 8.3 700 22.4 18.2 1.89 28.9 11.9 2.6 0 0 0 0 0 0

110 4.00 0.6 1.4 600 19.8 16.4 2.29 27.6 8.6 3.5 0 0 0 0 0 0

110 4.00 0.6 1.4 700 20.2 17.6 2.33 28.1 8.7 3.5 0 0 0 0 0 0

110 6.00 2.0 4.6 600 20.3 16.4 2.15 27.7 9.4 3.1 0 0 0 0 0 0

110 6.00 2.0 4.6 700 20.7 17.6 2.19 28.2 9.5 3.2 0 0 0 0 0 0

110 8.00 3.4 7.9 600 20.6 16.5 2.08 27.7 9.9 2.8 0 0 0 0 0 0

110 8.00 3.4 7.9 700 21.0 17.7 2.12 28.2 9.9 2.9 0 0 0 0 0 0

120 4.00 0.5 1.2 600 19.0 16.2 2.51 27.7 7.6 3.8 0 0 0 0 0 0

120 4.00 0.5 1.2 700 19.4 17.3 2.56 28.2 7.6 3.9 0 0 0 0 0 0

120 6.00 1.9 4.4 600 19.4 16.4 2.39 27.7 8.1 3.4 0 0 0 0 0 0

120 6.00 1.9 4.4 700 19.8 17.6 2.43 28.2 8.1 3.5 0 0 0 0 0 0

120 8.00 3.3 7.6 600 19.6 16.5 2.35 27.7 8.3 3.1 0 0 0 0 0 0

120 8.00 3.3 7.6 700 20.0 17.7 2.39 28.2 8.4 3.1 0 0 0 0 0 0

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating. ARI/ISO certifi ed conditions are 80.6°F DB and 66.2°F

WB in cooling and 68°F DB in heating.

Table does not refl ect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit (standard on residential models).

See performance correction tables for operating conditions other than those listed above.

“-” HWG operation is limited by a discharge temperature switch.

GPM

°F

20 Operation not recommended

30

40

50

60

70

80

85

90

100

110

120

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airfl ow

CFM

TC SC kW HR EER

HWC

Performance capacities shown in thousands of Btuh

HC kW HE LAT COP HWC

Operation not recommended

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

21

Page 24

GT-PX

50YDS038 Full Load With FV4005

1200 CFM Nominal (Rated) Airfl ow Cooling, 1200 CFM Nominal (Rated) Airfl ow Heating

EWT

GPM

°F

20 9.00 5.9 13.6 1000 0 0 0 0 0 0 23.3 2.25 15.9 91.6 3.04 2.9

20 Operation not recommended

20 9.00 5.9 13.6 1200 0 0 0 0 0 0 23.6 2.18 16.3 88.2 3.17 2.5

30 4.50 1.7 3.9 1000 41.8 21.7 1.66 46.7 25.2 - 25.7 2.32 18.0 93.8 3.25 3.0