Carrier GR-45, GR-60 Operation And Service

Bus Air

Conditioning

Equipment

Models

GR--45

GR--60

(N.A.O.)

T--295

AC Pressure Sensor

OPERATION AND

SERVICE MANUAL

BUS

AIR CONDITIONING

UNIT

Models

Carrier Refrigeration Operations

Carrier Transicold Division, Carrier Corporation, P.O. Box 4805, Syracuse, N.Y. 13221 U. S. A.

Carrier Corporation 2000 D Printed in U. S. A. 0300

GR--45

GR--60

(N.A.O.)

AC Pressure Sensor

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this

manual. They are recommended precautions that must be understood and applied during operation and maintenance

of the equipment covered herein. A listing of the specific warnings and cautions appearing elsewhere in the manual

follows the general safety notices.

FIRST AID

Aninjury,no matterhow slight, should nevergo unattended.Alwaysobtain firstaidormedicalattentionimmediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

No work should be performed on the unit until all circuit breakers and start-stop switches are placed in the OFF

position, and power supply is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop t he unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator and condenser fans. Do not open the unit cover before turning

power off.

Besurepoweristurnedoffbeforeworkingon motors, controllers, solenoid valves and electricalcontrols. Tagcircuit

breaker and power supply to prevent accidental energizing of circuit.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires. Problems

with the system should be diagnosed, and any necessary repairs performed, by qualified service personnel.

Whenperforming any arcweldingon the unit, disconnect allwireharnessconnectors from the modulesin the control

box. Do not remove wire harnessfrom the modules unless you aregrounded to the unit frame with a static-safewrist

strap.

In case of electrical fire, open circuit switch and extinguish with CO

SPECIFIC WARNINGS AND CAUTIONS

(never use water).

2

WARNING

DO NOT USE A NITROGEN CYLINDER WITHOUT A PRESSURE REGULATOR

WARNING

DO NOT USEOXYGEN IN OR NEAR A REFRIGERATION SYSTEM AS AN EXPLOSIONMAY

OCCUR.

WARNING

THE FILTER-DRIER MAY CONTAIN LIQUID REFRIGERANT. SLOWLY LOOSEN THE

FLARE NUTS AND AVOID CONTACT WITH EXPOSED SKIN OR EYES.

CAUTION

Donot under anycircumstancesattempt toservicethemicroprocessor. should aproblem developwith

the microprocessor, replace it.

CAUTION

If unit was recently operated, be careful of remaining hot coolant in the hoses when disassembling.

Safety-1

AC Pressure Sensor

T--295

TABLE OF CONTENTS

PARAGRAPH NUMBER Page

SAFETY SUMMARY Safety-1.....................................................................

DESCRIPTION 1-1...............................................................................

1.1 INTRODUCTION 1-1..............................................................

1.2 GENERAL DESCRIPTION 1-2......................................................

1.2.1 Apex Unit 1-2..................................................................

1.2.2 Condensing S ection 1-2..........................................................

1.2.3 Evaporator Section 1-3...........................................................

1.2.4 Compressor Assembly 1-4........................................................

1.2.5 Fresh Air System 1-4............................................................

1.2.6 System Operating Controls And Components 1-4.....................................

1.3 REFRIGERATION SYSTEM COMPONENT SPECIFICATIONS 1-5........................

1.4 ELECTRICAL SPECIFICATIONS -- MOTORS 1-5......................................

1.5 ELECTRICAL SPECIFICATIONS -- SENSORS AND TRANSDUCERS 1-5..................

1.6 SAFETY DEVICES 1-5.............................................................

1.7 AIR FLOW 1-6....................................................................

1.8 AIR CONDITIONING REFRIGERATION CYCLE 1-6...................................

1.9 HEATING CYCLE 1-8.............................................................

1.10 RELAY BOARD 1-9...............................................................

1.10.1 Permanent Magnet Motors with 2 speed switching from series to parallel

connection (Option 1) 1-9........................................................

1.10.2 Electronically Communtated DC Motors with 2--speed Evaporator Input Signal (Option 2) 1-11.

1.11 LOGIC BOARD 1-12................................................................

1.12 CONTROL PANEL (Diagnostic Module) 1-13............................................

OPERATION 2-1.................................................................................

2.1 STARTING, STOPPING AND OPERATING INSTRUCTIONS 2-1..........................

2.1.1 Power to Logic Board 2-1........................................................

2.1.2 Starting 2-1....................................................................

2.1.3 Self-Test and Diagnostics (Check for Errors and/or Alarms) 2-1..........................

2.1.4 Stopping 2-1...................................................................

2.2 PRE--TRIP INSPECTION 2-1........................................................

2.3 MODES OF OPERATION 2-3.......................................................

2.3.1 Temperature Control 2-3.........................................................

2.3.2 Cooling Mode 2-3..............................................................

2.3.3 Heating Mode 2-3..............................................................

2.3.4 Boost Pump 2-3................................................................

2.3.5 Vent Mode 2-3.................................................................

2.3.6 Fresh Air System 2-3............................................................

2.3.7 Compressor Unloader Control 2-3..................................................

2.3.8 Evaporator Fan Speed Selection 2-4................................................

2.3.9 Condenser Fan Control 2-4.......................................................

2.3.10 Compressor Clutch Control 2-4....................................................

i T--295

TABLE OF CONTENTS (Continued)

PARAGRAPH NUMBER Page

2.3.11 Alarm Description 2-4...........................................................

2.3.12 Hour Meters 2-4................................................................

2.4 MICROPROCESSOR DIAGNOSTICS 2-4..........................................

2.4.1 Connecting 2-4.................................................................

2.4.2 Control 2-5....................................................................

2.4.3 Diagnostic Mode 2-5............................................................

2.4.4 System Parameters 2-5...........................................................

2.4.5 Test Mode 2-5.................................................................

TROUBLESHOOTING 3-1.........................................................................

3.1 SELF DIAGNOSTICS 3-1...........................................................

3.2 SYSTEM ALARMS 3-1............................................................

3.2.1 Alarm Codes 3-1...............................................................

3.2.2 Activation 3-1.................................................................

3.2.3 Alarm Queue 3-1...............................................................

3.2.4 Alarm Clear 3-1................................................................

3.3 TROUBLESHOOTING 3-1..........................................................

3.3.1 System Will Not Cool 3-4........................................................

3.3.2 System R uns But Has Insufficient C ooling 3-4........................................

3.3.3 Abnormal Pressures 3-4..........................................................

3.3.4 Abnormal Noise Or Vibrations 3-4.................................................

3.3.5 Control System Malfunction 3-5...................................................

3.3.6 No Evaporator Air Flow Or Restricted Air Flow 3-5...................................

3.3.7 Expansion Valve Malfunction 3-5..................................................

3.3.8 Heating Malfunction 3-5.........................................................

SERVICE 4-1....................................................................................

4.1 MAINTENANCE SCHEDULE 4-1....................................................

4.2 OPENING TOP COVER 4-1.........................................................

4.3 SUCTION AND DISCHARGE SERVICE VALVES 4-1...................................

4.4 INSTALLING MANIFOLD GAUGE SET 4-2...........................................

4.5 PUMPING THE SYSTEM DOWN OR REMOVING THE REFRIGERANT CHARGE 4-2.......

4.5.1 System Pump Down For Low Side Repair 4-2........................................

4.5.2 Refrigerant Removal From An Inoperative Compressor. 4-3.............................

4.5.3 Pump Down An Operable Compressor For Repair 4-3..................................

4.5.4. Removing Entire System Charge 4-4................................................

4.6 REFRIGERANT LEAK CHECK 4-4..................................................

4.7 EVACUATION AND DEHYDRATION 4-4.............................................

4.7.1 General 4-4....................................................................

4.7.2 Preparation 4-4.................................................................

4.7.3 Procedure for Evacuation and Dehydrating System 4-4.................................

T--295

ii

TABLE OF CONTENTS (Continued)

PARAGRAPH NUMBER Page

4.8 ADDING REFRIGERANT TO SYSTEM 4-5...........................................

4.8.1 Checking Refrigerant Charge 4-5..................................................

4.8.2 Adding Full Charge 4-5..........................................................

4.8.3 Adding Partial Charge 4-5........................................................

4.9 CHECKING FOR NONCONDENSIBLES 4-5...........................................

4.10 CHECKING AND REPLACING HIGH PRESSURE SWITCH 4-5..........................

4.11 FILTER-DRIER 4-6................................................................

4.11.1 To Check Filter--Drier 4-6.........................................................

4.11.2 To Replace Filter--Drier 4-6.......................................................

4.12 CONDENSER COIL REPLACEMENT 4-6.............................................

4.13 EVAPORATOR COIL REPLACEMENT 4-7............................................

4.14 SERVICING THE HEAT VALVE 4-7..................................................

4.14.1 COIL REPLACEMENT 4-7......................................................

4.14.2 INTERNAL PART REPLACEMENT 4-7............................................

4.14.3 REPLACE ENTIRE VALVE 4-7...................................................

4.15 SERVICING THE LIQUID LINE SOLENOID VALVE 4-8.................................

4.15.1 Coil Replacement 4-8............................................................

4.15.2 Internal Part Replacement 4-8.....................................................

4.15.3.Replace Entire Valve 4-8.........................................................

4.16 CONDENSER FAN/MOTOR ASSEMBLY 4-8..........................................

4.16.1 Removal 4-8...................................................................

4.16.2 Inspection And Cleaning 4-9......................................................

4.16.3 Brush Replacement 4-9..........................................................

4.17 REPLACING EVAPORATOR FAN 4-9................................................

4.18 REPLACING RETURN AIR FILTERS 4-9.............................................

4.19 THERMOSTATIC EXPANSION VALVE 4-9............................................

4.19.1 Valve Replacement 4-9..........................................................

4.19.2 Superheat Measurement 4-10.......................................................

4.20 COMPRESSOR MAINTENANCE 4-10.................................................

4.20.1 Removing the Compressor 4-10....................................................

4.20.2 Transferring Compressor Clutch 4-11................................................

4.20.3 Compressor Oil Level 4-12........................................................

4.20.4 Checking Unloader Operation 4-12..................................................

4.21 TEMPERATURE SENSOR CHECKOUT 4-13...........................................

4.22 PRESSURE TRANSDUCER CHECKOUT 4-13..........................................

4.23 REPLACING SENSORS AND TRANSDUCERS 4-13.....................................

4.24 LOGIC BOARD CONFIGURATION 4-13...............................................

ELECTRICAL 5-1................................................................................

5--1 INTRODUCTION 5-1...............................................................

INDEX Index-1..................................................................................

iii T--295

LIST OF ILLUSTRATIONS

FIGURE NUMBER Page

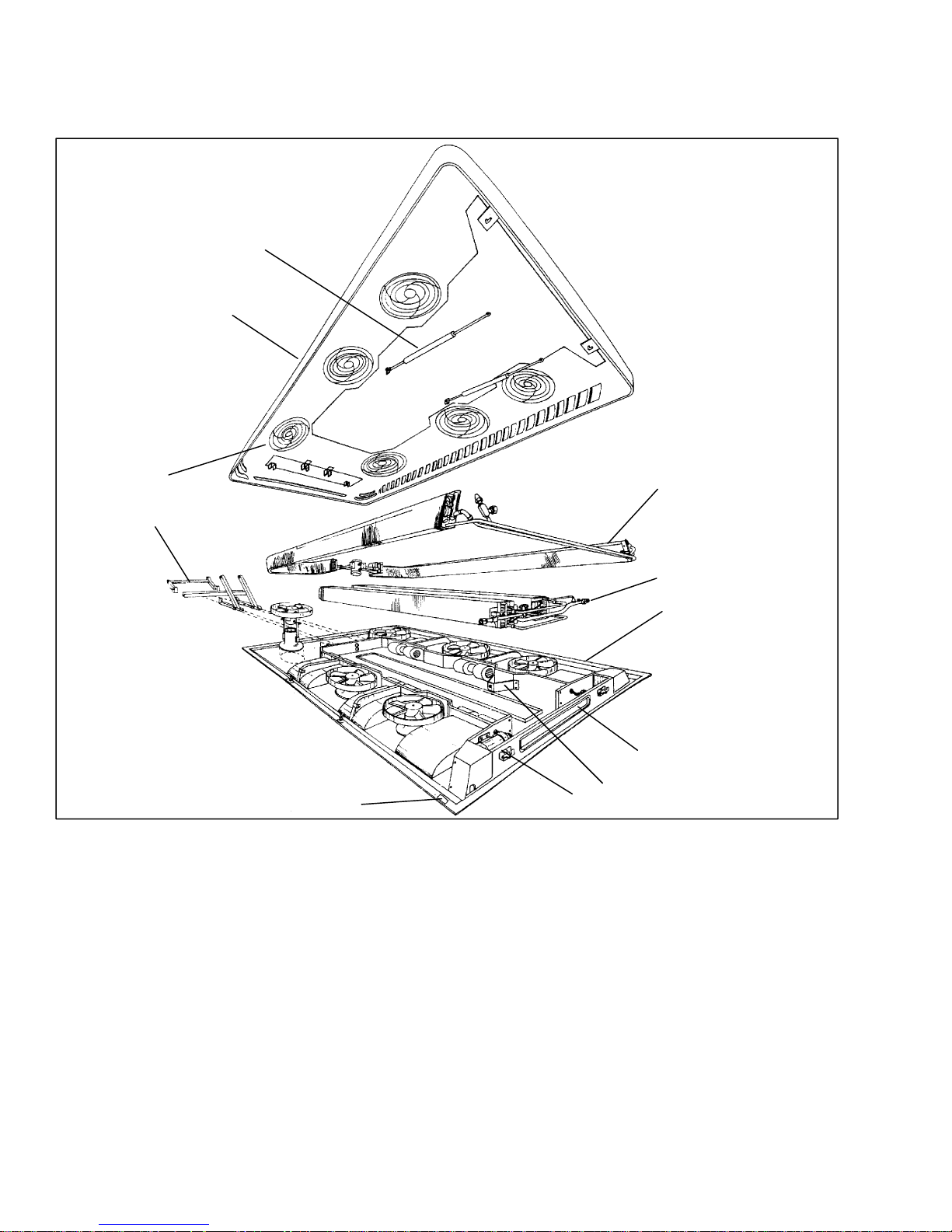

Figure 1-1. A/C Component Identification 1-1..................................................

Figure 1-2. Apex Unit Components 1-2........................................................

Figure 1-3. Condensing Section Components 1-3................................................

Figure 1-4. Evaporator Section Components 1-4.................................................

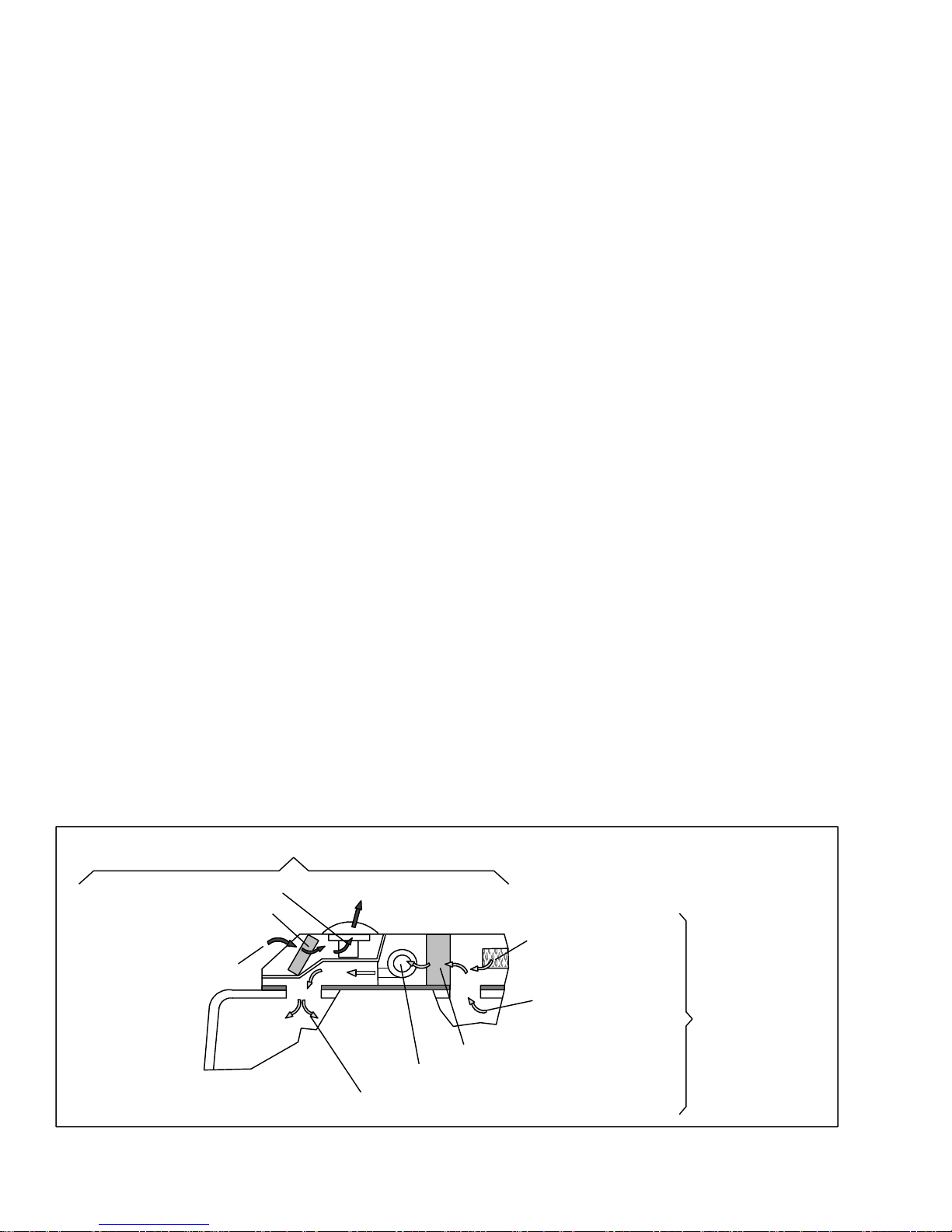

Figure 1-5. Air Flow Paths 1-6..............................................................

Figure 1-6. Refrigerant Flow Diagram 1-7.....................................................

Figure 1-7. Heating Cycle Flow Diagram 1-8...................................................

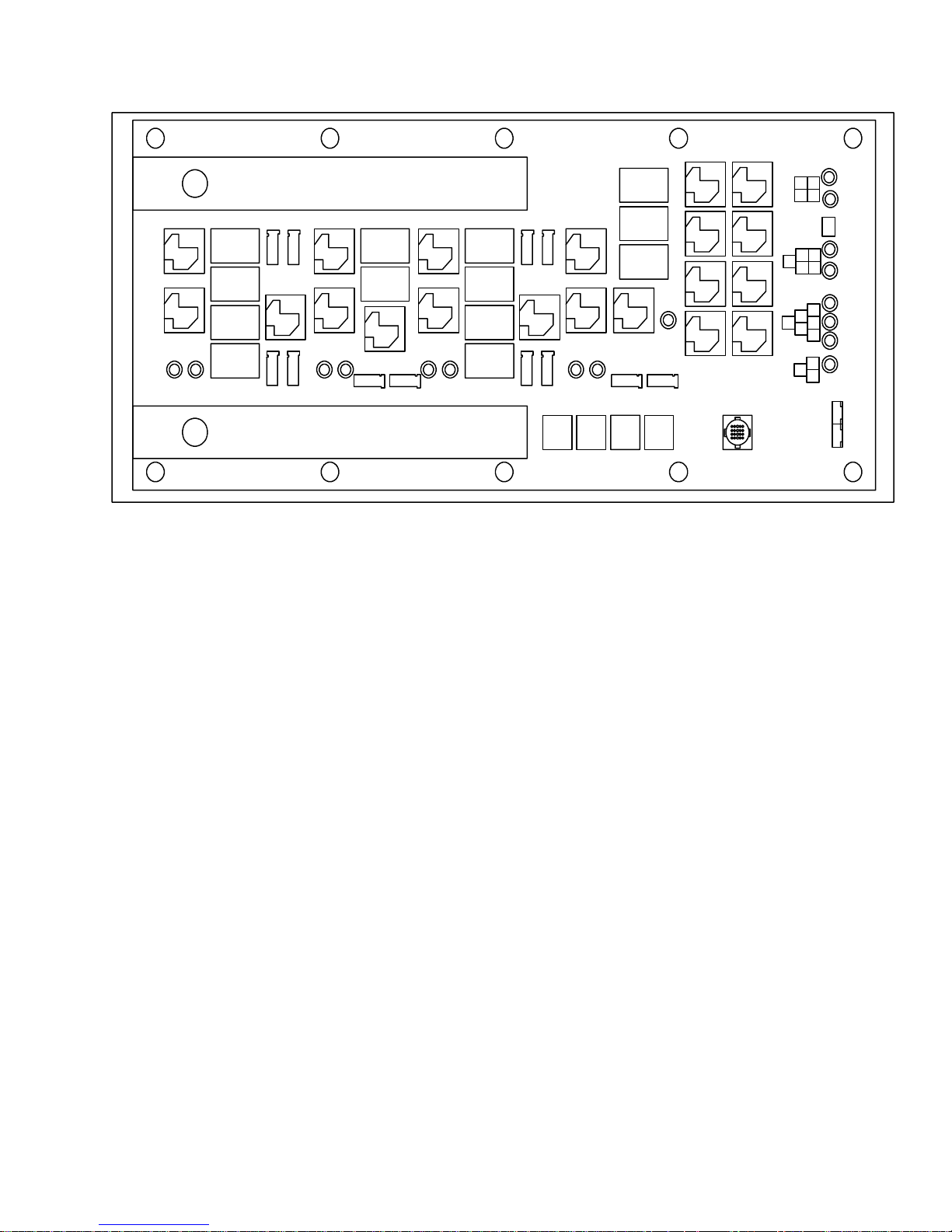

Figure 1-8 Relay Board (Option 1) 1-9........................................................

Figure 1-9 Relay Board (Option 2) 1-11........................................................

Figure 1-10 Logic Board 1-12................................................................

Figure 1-11. Micromate Control Panel 1-13.....................................................

Figure 2-1 Capacity Control Diagram 2-2......................................................

Figure 4-1. Opening Top Cover 4-1...........................................................

Figure 4-2.Suction or Discharge Service Valve 4-2...............................................

Figure 4-3. Manifold Gauge Set 4-2..........................................................

Figure 4-4. Low Side Pump Down Connections 4-3..............................................

Figure 4-5. Compressor Service Connections 4-3................................................

Figure 4-6. S ystem Charge Removal Connections 4-4............................................

Figure 4-7. Checking High Pressure Switch 4-6.................................................

Figure 4-8. Filter--Drier Removal 4-6.........................................................

Figure 4-9. Heat Valve 4-7..................................................................

Figure 4-10. Liquid Line Solenoid Valve 4-8...................................................

Figure 4-11. Condenser Fan/Motor Assembly 4-8................................................

Figure 4-12. Evaporator Fan Removal 4-9.....................................................

Figure 4-13. Thermostatic Expansion Valve 4-9.................................................

Figure 4-14.Thermostatic Expansion Valve Bulb and Thermocouple 4-10..............................

Figure 4-15.Removing Bypass Piston Plug 4-11..................................................

Figure 4-16. Compressor C lutch 4-11..........................................................

Figure 4-17. Compressors 4-12...............................................................

Figure 4-18 Transducer Terminal Location 4-13..................................................

Figure 5--1. Electrical Wiring Schematic Diagram - Legend 5-2.....................................

Figure 5--2. Wiring Schematic, Permanent Magnet Motors - Interconnection 5-3.......................

Figure 5--3. Wiring Schematic, Permanent Magnet Motors - Relays to External Components 5-4..........

Figure 5--4. Wiring Schematic, Electronically Communtated Motors - Interconnection 5-5...............

Figure 5--5. Wiring Schematic, Electronically Communtated Motors - Relays To External Components 5-6..

T--295

iv

LIST OF TABLES

TABLE NUMBER Page

Table 2-1. Evaporator Fan Speed Relay Operation 2-4.............................................

Table 2-2. C ontroller Test List 2-5.............................................................

Table 2-3. Parameter Codes 2-6...............................................................

Table 3-2 Alarm Codes 3-2..................................................................

Table 3-3 General System Troubleshooting Procedures 3-4.........................................

Table 4-1. Temperature Sensor Resistance 4-13...................................................

Table 4-2. PressureTransducer Voltage 4-14......................................................

Table 4-3. Logic Board Configuration 4-14.......................................................

v T--295

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

This manual contains Operating Instructions, Service

Instructions and Electrical Data for the Model GR Air

Conditioning and Heating equipment furnished by

Carrier Transicold Division as shown in Table 1-1.

ModelGR systems consistsofan ApexUnit,containing

the condenser and evaporator and an engine

compartment mounted compressor. To complete the

Table 1-1. Model

MODEL

GR45 ROOF MOUNTED 05K 4 4

SERIES COMPRESSOR CONDENSER

GR60 ROOF MOUNTED 05G 6 6

Table 1-2. Additional Support Manuals

MANUAL/FORM NUMBER

EQUIPMENT COVERED TYPE OF MANUAL

62--02491 O5K Compressor Operation and Service

62--02460 O5K Compressor Parts List

62--02756 O5G Compressor Operation and Service

T--200 O5G Compressor Parts List

system, the air conditioning and heating equipment

interfaces with electrical cabling, refrigerant piping,

enginecoolant piping (forheating), duct work andother

components furnished by the bus manufacturer.

Operation of the units is controlled automatically by a

microprocessor based Micromax Controller which

maintains the vehicle’s interior temperature at the

desired set point.

FANS

EVAPORATOR

FANS

4

3

2

1

13

1. Compressor

2. Refrigerant Lines

3. Compressor Harness

4. Heat Valve

5. Electronics Boards

6. Apex Unit

7. Main Harness

5

Figure 1-1. A/C Component Identification

6

12 10 9

11

7

8. Driver Control

9. Power Harness

10. Power Relay

11. Battery

12. Alternator

13. Discharge Check Valve

8

1-1

T--295

1.2 GENERAL DESCRIPTION

1.2.1 Apex Unit

The apex unit (see Figure 1-2) includes the condensing

2

1

section, evaporator section, Micromax electronics, and

theFresh AirSystem.All components are accessibleby

lifting the top cover. Descriptions of the systems are

provided in the following sub paragraphs.

11

10

9

1. Top Cover

2. Gas Spring (2)

3. Condenser Section (See Figure 1-3)

4. Evaporator Section (See Figure 1-4)

5. Base

6. Fresh Air System

7. Gas Spring Support (2)

8. Lock (2)

9. Serial Plate

Figure 1-2. Apex Unit Components

(GR-60 Shown)

1.2.2 Condensing Section

The condensing section (Figure 1-3) includes the

condenser coils, fan and motor assemblies, filter-drier,

receiver, liquid line solenoid valve, service valves, and

an ambient temperature sensor.

The condenser coils provide heat transfer surface for

condensing refrigerant gas at a high temperature and

3

4

5

6

7

8

10. Hinge

1 1. Condenser Fan Grille (4-GR45,

6-GR60)

12. Front Drain (2)*

13. Intermediate Drain (2)*

14. Evaporator Rear Drain (2)*

15. Condenser Rear Drain (2)*

* Not Shown

pressure into a liquid at high temperature and pressure.

The condenser fans circulate ambient air across the

outside of the condenser tubes at a temperature lower

than refrigerant circulating inside the tubes; this results

in condensation of the refrigerant into a liquid. The

filter-drier removes m oisture and debris from the liquid

refrigerant before it enters the thermostatic expansion

valve in the evaporator assembly.

T--295

1-2

The receiver collects and stores liquid refrigerant. The

receiver is fitted with upperand lowerliquid level sight

glasses to enable determining refrigerant liquid level.

The receiver is also fitted with a fusible plug which

protects the system from unsafe high pressure

conditions. The liquid line solenoid valve closes when

system is shut down to prevent flooding of coils with

liquidrefrigerant.The servicevalvesenable isolationof

the filter-drier for service. The ambient temperature

sensor measures ambient temperature and sends an

electrical signal to the controller.

The dischargecheck valve is a spring loaded, normally

closedvalve that opens withthe flowofrefrigerantfrom

the compressor. When the compressor clutch is

disengaged, the discharge check valve will close,

preventing the flow of high pressure liquid from the

condenser back into the compressor.

12 3

13

12

4

5

6

7

8

9

11

1. Condenser Coil (2)

2. Receiver

3. Protection Plate

4. Service Valve

5. Discharge Line

6. Precharge Valve

7. Liquid Line Solenoid Valve

8. Filter Drier Upper Support

Figure 1-3. Condensing Section Components

10

(GR-60 Shown)

1.2.3 Evaporator Section

The evaporator section (Figure 1-4) includes the

evaporator coils, six fan and motor assemblies,

evaporator/heater coil assemblies, a thermostatic

expansion valve and condensate drain connections.

The evaporator coils provide heat transfer surface for

transferring heat from air circulating over the outside

the coil to refrigerant circulating inside the tubes; thus

providing cooling. The heating coils provide heat

transfer surface for transferring heat from engine

coolant water circulating inside the tubes to air

9. Filter Drier

10. Filter Drier Lower Support

1 1 Condenser Fan and Motor Assembly

(4-GR45, 6-GR60)

12. Condenser Coil Fastener (4)

13. Condenser Motor Support

(4-GR45, 6-GR60)

circulating over the outside surface of the tubes, thus

providing heating. The fans circulate the air over the

coils. The air filters remove dirt particles from the air

before it passes over the coils. The thermostatic

expansion valve meters flow of refrigerant entering the

evaporator coils. The heat valve controls the flow of

enginecoolant water to the heatingcoils upon receipt of

a signal from the controller. The condensate drain

connections provide a means for connecting tubing for

disposing of condensate collected on the evaporator

coils during cooling operation.

1-3

T--295

4

1

23

5

6

7

8

9

1. Evaporator Coil With Integrated

Heating Coil (2)

2. Protection Plate

3. Expansion V alve

4. Evaporator Motor Fastening Clamps

(4-GR45, 6-GR60)

Figure 1-4. Evaporator Section Components

(GR-60 Shown)

1.2.4 Compressor Assembly

The compressor assembly includes the refrigerant

compressor, clutch assembly, suction and discharge

service valves, high pressure switch, low pressure

switch,suctionanddischargeservicing(charging) ports

and electric solenoid unloaders.

The compressor raises the pressure and temperature of

the refrigerant and forces it into the condenser tubes.

The clutch assembly provides a means of belt driving

the compressor by the bus engine. The suction and

discharge service valves enable servicing of the

compressor. Suction and discharge servicing(charging)

ports mounted on the service valves enable connection

of charging hoses for servicing of the compressor, as

well as other parts of the refrigerant circuit. The high

pressureswitch contacts open on a pressure rise to shut

down the system when abnormally high refrigerant

pressuresoccur. The electricunloaders provide a means

of controlling compressor capacity, which enables

controlof temperatureinside the bus. For more detailed

informationon the compressor, referto manual number

62-02756.

1.2.5 Fresh Air System

The Fresh Air System (6, Figure 1-2) consists of a

damperand damper operator. Thedamperoperatormay

becontrolled bythe driver,if aswitchisprovided.Inthe

automatic mode, it is controlled by the Micromax to

open and close thedamper to allow addition of fresh air

5. Evaporator Motor (4-GR45,

6-GR60)

6. Suction Line

7. Heating Lines

8. Service Valve

9. Evaporator Harness

into the air entering the evaporator coil. For additional

information on air flow, refer to paragraph 1.7.

1.2.6 System Operating Controls And Components

The system is operated by a Carrier Transicold

Micromaxmicroprocessorcontrollerwhichconsist of a

logic board (Figure 1-10), relay board (Figure 1-8 or

Figure 1-9), and manualoperator switches. The manual

operatingswitchesarelocatedon the driverscontroland

may consist of a single OEM supplied ON/OFF switch,

additional OEM supplied switches or a Carrier

Transicold supplied Micromate control panel

(Figure 1-11).The logic boardregulates the operational

cycles of the system by energizing or de--energizing

relays on the relay board in response to deviations in

interior temperature. Modes of operation include

Cooling, Heat andVent. On systems fitted with only an

ON/OFF switchand on systems withthe Micromateset

in the AUTO mode, the logic board will cycle the

system between the operating modes as required to

maintain desired set point temperature.

In the vent mode the evaporator fans are operated to

circulate air in the bus interior.

Intheheatmodetheheatvalve is opened to allow aflow

of engine coolant through the heat section of the

evaporatorcoil. The evaporatorfansoperateto circulate

air over the evaporator coil in the same manner as the

vent mode.

T--295

1-4

In the cooling mode the compressor is energized while

p

the evaporator and condenser fans are operated to

provide refrigeration as required. The compressor is

fitted with cylinder unloaders to match compressor

capacity to the bus requirements. Once interior

temperature reaches the desired set point, the system

may operate in the clutch cycle or reheat mode. A

controller programmed for clutch cycle will

de--energizethecompressorclutchandallowthesystem

to operate in the vent mode until further cooling is

required. A controller programmed for reheat will

maintain compressor operation and open the heatvalve

to allow reheating of the return air. In the reheat mode

interior temperature is maintained at the desired set

point while additional dehumidification takes place.

Controls may also be provided to allow manual

operation of the evaporator fans in low or high speed

andmanual controlofthefreshairdamper in the open or

closed position.

1.3 REFRIGERATION SYSTEM COMPONENT

SPECIFICATIONS

a. Refrigerant Charge

R--134a 14.3 lb (6.5 kg)

b. Compressor

UNIT MODEL

GR45 GR60

Compressor 05K 05G

No of Cylinders 4 6

Weight - Dry 108 lbs

(49 kg)

Oil Charge 5.5 pints

(2.6 liters)

137 lbs

(62 kg)

6.75 pints

(3.2 liters)

Oil Level:

Levelin sightglass betweenMin.--Max marks on

compressor crankcase (curbside)

Approved Compressor Oils - R-134a:

Castrol: Icematic SW68C

Mobil: EAL Arctic 68

ICI: Emkarate RL68H

c. Thermostatic Expansion Valve:

Superheat Setting (Non-externally adjustable):

10 to 12F

MOP Setting (Nonadjustable): 55 ±4 psig (3.74

±2.27 bar)

d. High Pressure Switch (HPS):

Opens at: 300 ±10 psig (20.41 ±0.68bar)

Closes at: 200 ±10 psig (13.61 ±0.68bar)

e. Low Pressure Switch (LPS)

Opens at: 6 ±3psig (0.41 ±0.20 bar)

Closes at: 25 ±3psig(1.7±0.20 bar)

1.4 ELECTRICAL SPECIFICATIONS -- MOTORS

a. Evaporator Fan Motor

ECDC* Permanent

Evaporator Motor

27.5

VDC

Magnet

24 VDC 12 VDC

Horsepower (kW) 0.34(.25) 1/8 (.09)

Full Load Amps

8.4 9.5 19

(FLA)

Operating Speed

High/Low (RPM)

4252/

3165

4200/

1850

Bearing Lubrication Factory Lubricated (addi-

tional grease not required)

b. Condenser Fan Motor

ECDC* Permanent

Condenser Motor

24 VDC 24 VDC 12 VDC

Magnet

Horsepower (kW) 0.15(.11) 1/8 (.09)

Full Load Amps

7 9 18

(FLA)

Operating Speed

High/Low (RPM)

4252/

NA

4200/

1850

Bearing Lubrication Factory Lubricated (addi-

tional grease not required)

* Electronically Communicated Direct Current

1.5 ELECTRICAL SPECIFICATIONS -- SENSORS

AND TRANSDUCERS

a. Suction and Discharge Pressure Transducer

Supply Voltage: 4.5 to 5.5 vdc (5 vdc nominal)

Supply current: 8 mA maximum

Output Range: 8K ohms minimum

Input Range: --6.7 to 450 psig (--0.46 to 30.62 bar)

Output Current: -1.5 mA minimum t o

1.5 mA maximum

Output Voltage: vdc = 0.0098 x psig + 0.4659

(See Table 4-2 for calculations.)

b. Temperature Sensors

Input Range: --52.6 to 158F (--47 to 70C)

Output: NTC 10K ohms at 77F(25C)

(See Table 4-1 for calculations.)

1.6 SAFETY DEVICES

System components are protectedfrom damage caused

by unsafe operating conditions with safety devices.

Safety devices with Carrier Transicold supplied

equipment include high pressure switch (HPS), low

pressure switch (LPS), circuit breakers and fuses.

a. Pressure Switches

High Pressure Switch (HPS)

During the A/C mode, compressor operation will

automaticallystop if the HPS switch contacts open due

toan unsafeoperatingcondition.OpeningHPScontacts

de-energizes, through the controller, the compressor

clutchshutting downthecompressor. The high pressure

switch (HPS) is installed in the center head of the

compressor.

1-5

T--295

Low Pressure Sw itch (LPS)

The low pressure switch is installed in the compressor

and opens on a pressure drop to shut down the system

whena lowpressurecondition occurs. Inaddition, ifthe

control monitors a pressure less than 10 psig (0.68

bar)by the suction pressure transducer mounted in the

evaporator section, the system will be shut down for at

least one minute.

b. Fuses and Circuit Breakers

The Relay Board is protected against high current by an

OEM supplied 150 amp fuse. Independent 15 amp

circuit breakers protect each motor while the output

circuits are protected by an additional 15 amp circuit

breaker.Duringahigh currentcondition,the breaker(or

OEM fuse) may open. When power is removed from a

device, a breaker alarm will be generated.

c. Ambient Lockout

The ambient temperature sensor located in the

condenser section measures the condenser inlet air

temperature. When the temperatureis below the cut out

set point the compressor is locked out until the

temperaturerisesabovethecutin setting. The set points

maybe programmedto cutoutat45F7.2C)andcutin

at 50F10C) or cut out at 25 F--3.9C) and cut in at

45F7.2C) in accordance with bus purchase

specification.This setting protects the compressorfrom

damage caused by operation at low pressures.

1.7 AIR FLOW

The paths for ambient air through the condenser and

coach air through the evaporator are illustrated in

Figure 1-5.

1.8 AIR CONDITIONING REFRIGERATION

CYCLE

When air conditioning (cooling) is selected by the

controller, the unit operates as a vapor compression

system using R-134a as a refrigerant (see Figure 1-6).

The main components of the system are the

reciprocating compressor, air-cooled condenser coils,

receiver, filter-drier, thermostatic expansion valve,

liquid line solenoid valve and evaporator coils.

The compressor raises thepressureand thetemperature

of the refrigerant and forcesit into the condenser tubes.

The condenser fan circulates surrounding air (which is

at a temperature lower than the refrigerant) over the

outside of the condenser tubes. Heat transfer is

establishedfrom the refrigerant (inside the tubes) to the

condenser air (flowing over the tubes). The condenser

tubes have fins designed to improve the transfer ofheat

from the refrigerant gas to the air; this removal of heat

causes the refrigerant to liquefy, thus liquid refrigerant

leaves the condenser and flows to the receiver.

The receiver serves as a liquid refrigerant reservoir so

that a constant supply of liquid is available to the

evaporators as needed, and acts as a storage space when

pumping down the system. The receiver is equipped

with sight glasses to observe the refrigerant for

restricted flow and correct charge level.

The refrigerant leaves the receiver and passes through

the receiver outlet/service valve, through a filter-drier

where an absorbent keeps the refrigerantclean and dry.

From the filter-drier, the liquid refrigerant then flows

through the liquid line solenoid valve to the

thermostatic expansion valve. the thermal expansion

valve reduce pressure and temperatureof the liquid and

metersthe flow of liquid refrigerant tothe evaporatorto

obtain maximum use of the evaporator heat transfer

surface.

Thelow pressure,lowtemperatureliquidthatflowsinto

the evaporator tubes is colder than the air that is

circulated over the evaporator tubes by the evaporator

fans (fans). Heat transfer is established from the

evaporatorair (flowing over the tubes)to the refrigerant

(flowing inside the tubes). The evaporator tubes have

aluminum fins to increase heat transfer from the air to

the refrigerant; therefore the cooler air is circulated to

the interior of thebus. Liquidline solenoid valvecloses

during shutdown to prevent refrigerant flow.

The transfer of heat from the air to the low temperature

liquid refrigerant in the evaporator causes the liquid to

vaporize. This low temperature, low pressure vapor

passes through the suction line and returns to the

compressor where the cycle repeats.

CONDENSER AIR FLOW

3. THROUGH FAN

2. THROUGH CONDENSER

1. FROM AMBIENT

T--295

4. RETURN TO AMBIENT

1. FROM DAMPER

3. THROUGH EVAPORAT OR

4. THROUGH FAN

5. RETURN TO COACH

Figure 1-5. Air Flow Paths

1-6

(IF ACTIVE)

2. FROM COACH

EVAPORATOR

AIR

FLOW

12

45

3

6

7

8

9

16

A

A

DISCHARGE

LIQUID

SUCTION

RECEIVER

VIEW A-A

16

17

18

MAIN ENGINE

RADIATOR

10

11

12

13

11

14

15

SUCTION

DISCHARGE

1. Condenser Fan Assembly

2. Evaporator Fan Assembly

3. Expansion V alve

4. Expansion V alve Equalizer Line

5. Liquid Line

6. Precharge Valve

7. Expansion V alve Bulb

8. Pressure Transducer, Low Side

9. Service Port, Low Side

10. Pressure Transducer, High Side

11. Service Valve With Port

12. Liquid Line Solenoid Valve

13. Filter Drier

14. Service Port, High Side

15. Discharge Check Valve

16. Receiver

17. Refrigerant Sight Glass

18. Moisture Indicator

Figure 1-6. Refrigerant Flow Diagram

(GR60 Shown)

1-7

COMPRESSOR

T--295

SUPPLY

RETURN

Figure 1-7. Heating Cycle Flow Diagram

(GR60 Shown)

1.9 HEATING CYCLE

Heating circuit (Figure 1-7) components furnished by

Carrier Transicold include the integral evaporator coil

heater cores and a solenoid operated heat valve.

Componentsfurnishedby the bus manufacturerinclude

auxiliary heater and boost water pump. The controller

automaticallycontrols theheat valveduring theheating

and reheat modes to maintain required temperatures

HEAT

VALVE

BOOST

PUMP

MAIN ENGINE

RADIATOR

COMPRESSOR

inside the bus. Engine coolant (glycol solution) is

circulatedthrough the heating circuitby the engine and

an auxiliary boost water pump. When the heat valve

solenoid i s energized, the valve will open to allow

enginecoolanttoflowthrough theheatercoil. Thevalve

is normally closed so that if a failureoccurs, the system

will be able to cool.

T--295

1-8

1.10 RELAY BOARD

1.10.1 Permanent Magnet Motors with 2 speed switching from series to parallel connection (Option 1)

JP6

K1

K2

D2 D6

CB 1

CB 2

CB 3

CB 4

EF1

EF2

K5

EF4EF3

D14

K3

K4

D17

EF6

CB 5

CB 6

K6

D26 D30

EF5

K7

K8

CB 7

CB 8

CB 9

CB 10

CF1

CF3

CF2

K11

CF4

K9

K10

D38 D41

K22K24

CB 13

CB 11

CB 12

K12

CF6 CF5

K23K21

K15K14

K17K16

K20K18

D85

K13K19

JP1

1

D57

3

4

2

D54

JP5

4

23

1

1

D63

5

D60

JP4

D72

4

2

5 6

D66

3

D51

JP3

23

1

D69

JP2

Figure 1-8 Relay Board (Option 1)

a. Relays

K1 Energizes evaporator fans 1 & 2 in high speed

or evaporator fans 1,2,3 & 4 in low speed.

K2 Energizes evaporator fans 3 & 4 in high speed

(not energized in low speed).

K3 Energizes evaporator fan 5 in high speed or

evaporator fans 5 & 6 in low speed.

K4 Energizes evaporator fan 6 in high speed (not

energized in low speed).

K5 Connects the negative side of evaporator fans

1 & 2 to ground in high speed. Connects the

negative side of evaporator fans 1 & 2 to

positive side of evaporator fans 3 & 4 in

low speed

K6 Connects the negative side of evaporator fan

5 to ground in high speed. Connects the

negative side of evaporator fan 5 to

positive side of evaporator fan 6 in

low speed

K 7 Energizes condenser fans 1 & 2 in high speed

or condenser fans 1,2,3 & 4 in low speed

K 8 Energizes condenser fans 3 & 4 in high speed

(not energized in low speed).

K 9 Energizes condenser fan 5 in high speed or

condenser fans 5 & 6 in low speed.

K10 Energizes condenser fan 6 in high speed

(not energized in low speed).

K11 Connects the negative side of condenser fans

1 & 2 to ground in high speed. Connects the

negative side of condenser fans 1 & 2 to

the positive side of condenser fans 3 & 4 in

low speed.

K12 Connects the negative side of condenser fan

5 to ground in high speed. Connects the

negative side of condenser fan 5 to

the positive side of condenser fan 6 in

low speed.

K13 Energizes the A/C clutch.

K14 Energizes unloader 1.

K15 Energizes unloader 2.

K16 Energizes the fresh air damper.

K17 Energizes the heat valve.

K18 Energizes the fault light output.

K19 Energizes the Boost Pump.

K20 Energizes the spare output.

K21 Is energized by the logic board to turn the

evaporator fans on high. The contacts of this

relay energize the coils of relays K1, K2,

K3 & K4.

K22 Is energized by the logic board to turn the

evaporator fans on low. The contacts of this

relay energize the coils of relays K1, K3,

K5 & K6.

K23 Is energized by the logic board to turn the

condenser fans on high. The contacts of this

relay energize the coils of relays K7, K8,

K9 & K10.

K24 Is energized by the logic board to turn the

condenser fans on low. The contacts of this

relay energize the coils of relays K7, K9,

K11 & K12.

1-9

T--295

Loading...

Loading...