Page 1

GB

D

F

I

USE & MAINTENANCE INSTRUCTIONS

BEDIENUNGSANLEITUNG

INSTRUCTIONS D'USAGE ET ENTRETIEN

MANUALE USO E MANUTENZIONE

C

C

U

U

-

-

O

O

Page 2

2 Carrier

SERVICE SHEET - SERVICEBLATT - FICHE DE SERVICE - FOGLIO SERVIZIO

DATE - DATUM OPERATION - MASSNAHME SERVICE FIRM - SERVICEFIRMA

SIGNATURE - UNTERSCHRIFT

DATE - DATA OPERATION - OPERAZIONE ETS DE SERVICE - DITTA ASSISTENZA SIGNATURE - FIRMA

Page 3

1. Description of the unit ....................................................................page 4

1.1 How the unit works ............................................................................page 4

1.2 Safety devices and safety measures ................................................page 4

1.3 Synopsis of signs ..............................................................................page 5

1.4 Residual risks ....................................................................................page 6

2. Technical features of the unit ........................................................page 7

3. Intended uses ..................................................................................page 7

3.1 Dangers deriving from using the unit for purposes

other than those it is designed for ....................................................page 7

4. Moving the unit................................................................................page 8

5. Installation........................................................................................page 8

5.1 Signs..................................................................................................page 8

5.2 Dimensions of unit and packing ........................................................page 8

5.3 Commissioning ..................................................................................page 9

5.4 Area surrounding the unit to be kept clear ........................................page 9

6. Assembly and preparation for commissioning ............................page 9

6.1 Cleaning the unit................................................................................page 11

6.2 Connecting the unit to external power sources ................................page 11

6.2.1 Power mains connection ..................................................................page 11

6.2.2 Water mains connection ....................................................................page 12

6.3 Checks, adjustments and settings ....................................................page 12

6.4 Setting of the controll and power devices..........................................page 12

7. Start-up ............................................................................................page 13

7.1 Electrical controls ..............................................................................page 13

7.1.1 Control panel ....................................................................................page 13

8. How to use the unit ........................................................................page 13

8.1 Description of the unit’s work cycle ..................................................page 13

8.2 Diagram of the unit’s electrical system ..............................................page 13

9. Maintenance and repairs ................................................................page 14

9.1 General maintenance operations ......................................................page 14

9.2 Special maintenance operations ......................................................page 14

9.3 Operations to be carried out by qualified personnel

or by the manufacturer ......................................................................page 14

9.4 Troubleshooting guide ......................................................................page 14

9.5 Parts subject to wear and spares ......................................................page 15

10. Disposal of packaging ....................................................................page 15

11. Disassembling the unit ..................................................................page 15

GB

D

F

I

Carrier 3

List of contents

Page 4

Thank you for choosing a uniblock product.

Please read this booklet carefully - it has been specially designed to provide

advice and information on how to install, use and maintain the unit correctly, so

as to use it to the best of its capacities.

The term CAUTION is used to indicate situations that may cause damage to

the unit. These appear in italics.

The term WARNING is used to indicate situations that might endanger the

safety of operators. These appear in italics and, in some case, also in bold.

All measures indicated in this catalogue are stated in millimetres

T he CU-O range consists in:

1. a condenser unit, with air or water condensation installed external to the cell

2. an electrical control panel, located on the condenser unit

1.1 How the unit works The units CU-O are condensing parts operating by means of a sealed or semisealed a/c mains powered refrigerating compressor (three-phase), using HFC

refrigerating liquids.

1.2 Safety devices and safety measures

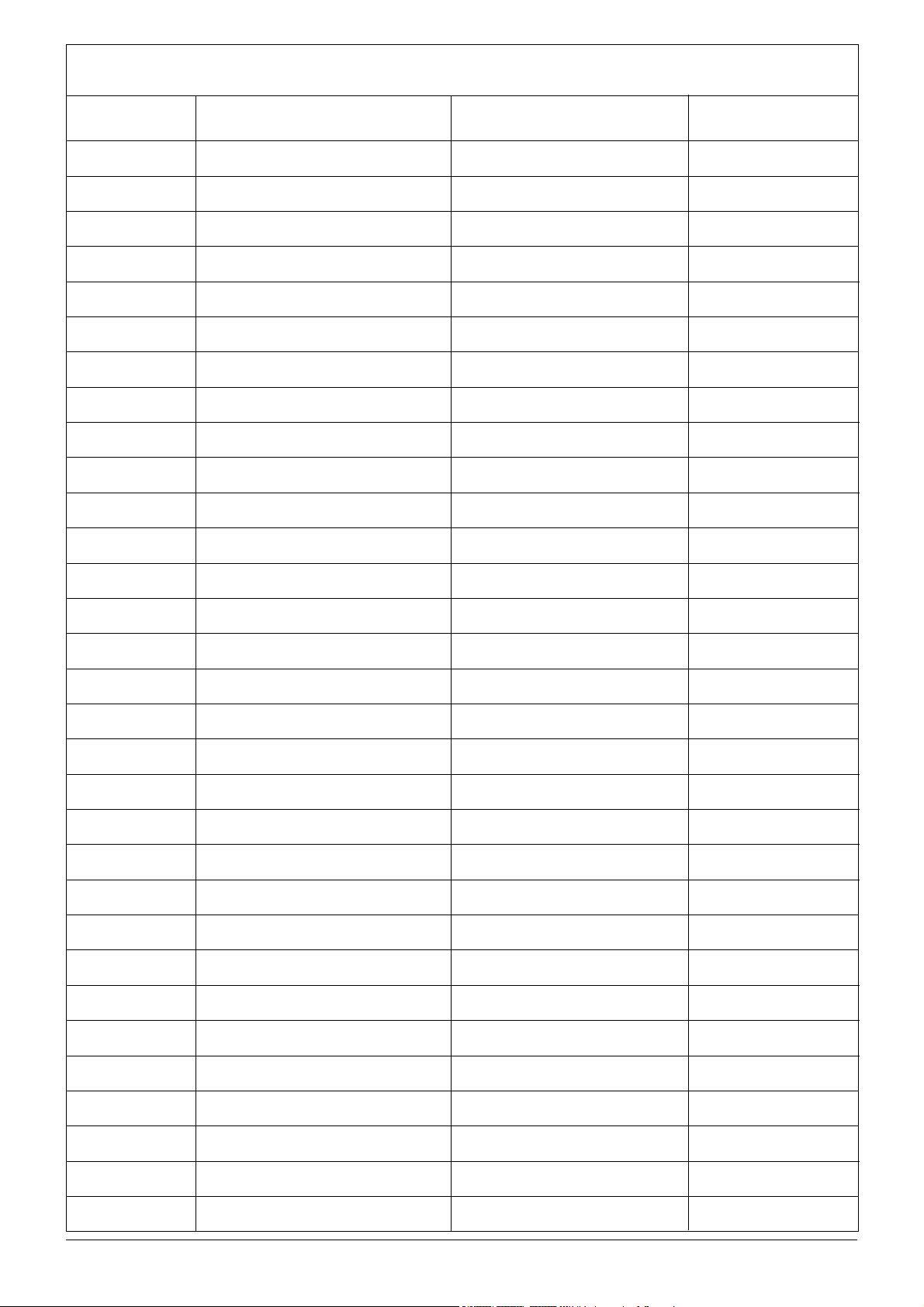

The following mechanical safety devices are supplied by the manufacturer (fig. 2):

1. fixed side guards of the evaporator and condenser units: these are fixed to the

metal casing with locking screws.

GB

D

F

I

4 Carrier

LEGENDA

fig.1

1

2

fig.2

1

1

1

1

1. DESCRIPTION OF UNIT

Page 5

The following electrical safety devices are supplied by the manufacturer:

1. Fan thermal protection (incorporated into the motors) with manual resetting:

protects electric fans against excessive current absorption.

2. High pressure switch with manual resetting: protects against excessively high

pressure.

3. Thermistors or thermostats with manual resetting: protects the motor against

overheating.

4. Minimum/maximum tension electronic relay (monitor) with automatic resetting

(optional).

WARNING

Safety devices have been designed by the manufacturer to ensure the safety of

operators while carrying out their work

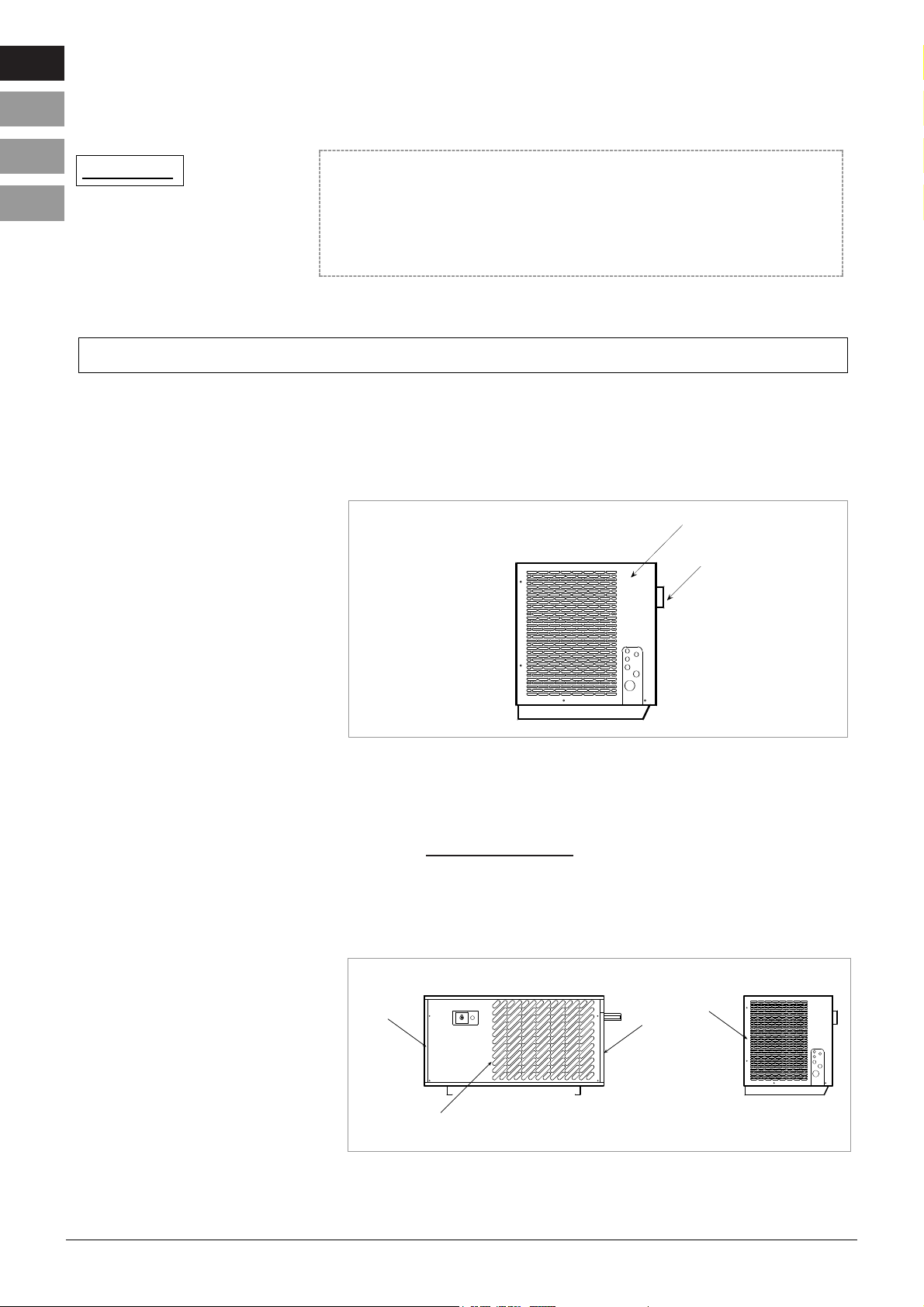

1.3 Synopsis of labels The following caution and warning signs have been placed on the unit by the

manufacturer:

INDICATION:

TYPE OF REFRIGERATING LIQUID

WARNING:

CAUTION!

hot and/or cold parts

CAUTION:

GB

D

F

I

Carrier 5

ATTENZIONE! PERICOLO

Volt

Phases

Hz

COLLEGAMENTO UNIBLOCK

UNIT ELECTRICAL CONNECTION

CONNEXION DE L'UNITE'

EL EK TR ISCH. AN SCHLU S S

CONEXION DE L'UNIDAD

COLLEGARE QUESTO CAVO AD UN INTERRUTTORE MAGNETOTERMICO. MAI

DIRETTAMENTE ALLA LINEA PRINCIPALE.

CONNECTION SHOULD ALWAYS BE MADE FROM A FUSED ISOLATOR. NEVER CONNECT

THE CABLE TO THE MAINS SUPPLY LINE DIRECTLY

LA CONNEXION DOIT ETRE EFFECTUEE AU MOYEN D'UN INTERRUPTEUR MAGNETOTHERMIQUE. JAMAIS CONNECTER LE CABLE A LA LIGNE PRINCIPALE DIRECTEMENT

DER ANSCHLUSS DES KABELS SOLL DURCH EINEN THERMOMAGNETSCHALTER

FOLGEN. KEIN DIREKTER ANSCHLUSS DER HAUPTSPEISELEITUNG

CONNECTAR EL CABLE A UN INTERRUPTOR MAGNETOTERMICO. Y NUNCA

A LA LINEA DIRECTAMENTE

R 404 A

3ETA237

SCARICO CONDENSA

CONDENSATE DRAIN LINE

ECOULEMENT DE CONDENSATION

KONDENSATABLAßROHR

DESAGÜE CONDENSACíON

Page 6

Direction of rotation

1.4 RESIDUAL RISKS

Below we list all the situations - from the delivery of the unit to its demolition

- in which the user will need to exercise caution in order to avoid damage to

persons.

CHAPTER 4 - Positioning the unit

Maximum caution should be used in ensuring that no one passes through

the area while the suspended load is being handled, in order to avoid any

chance of damage to persons.

CHAPTER 9 - Maintenance

Condenser and evaporator groups’ fins: any maintenance operations must

be carried out using personal protection devices (e.g. gloves) in order to

avoid any chance of damage to hands.

GB

D

F

I

6 Carrier

GIALLO/VERDE JAUNE/VERT

GELB/GRUEN YELLOW/GREEN

L2

L1

L3

V.400/3~/50 Hz.

Page 7

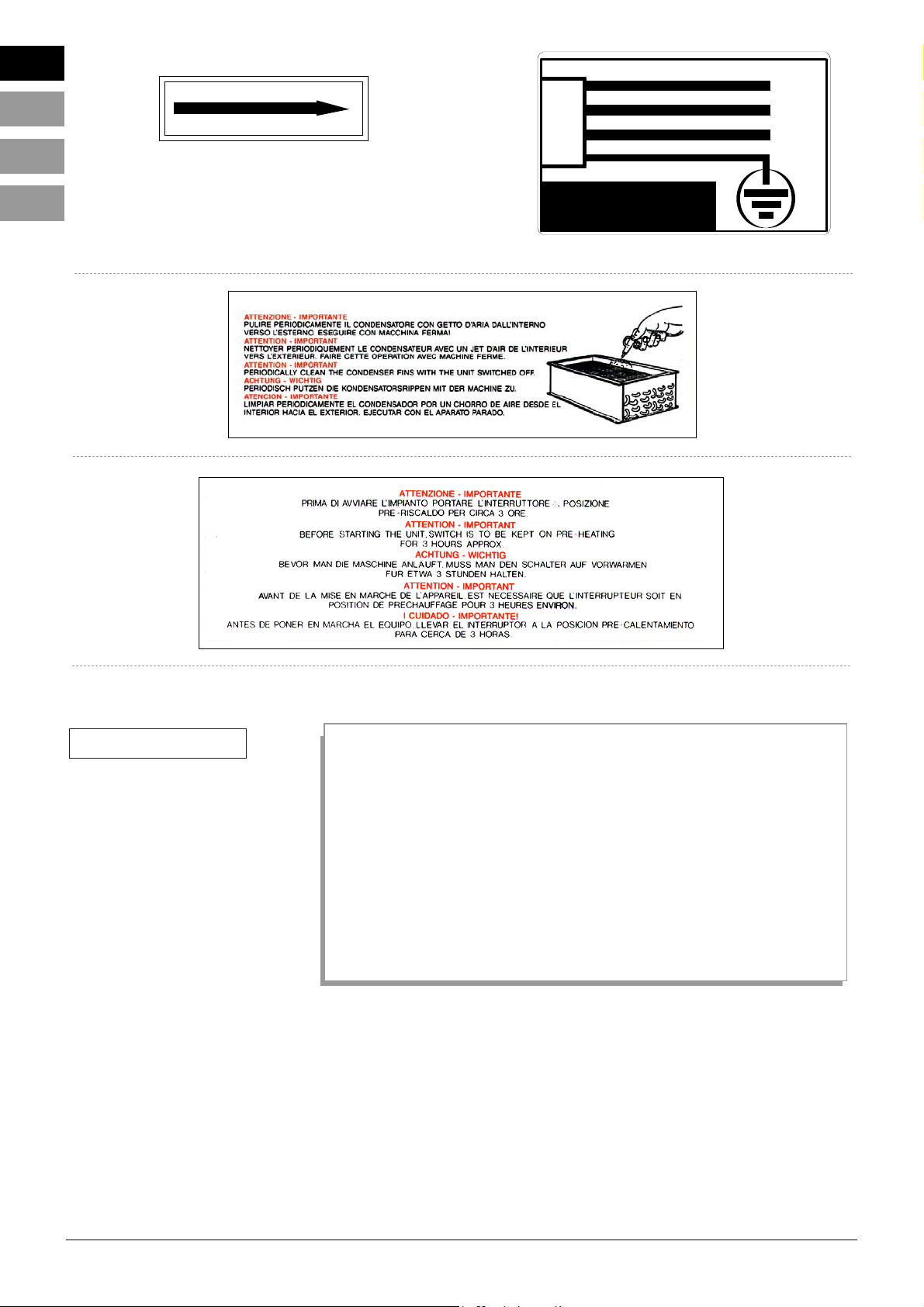

The specific technical features of each CU model are indicated on the data plate

attached to the unit (fig. 3).

The CU-O ranges are air condensing units manufactured to operate automatically.

Using the machine for any purposes other than those envisaged represents an anomaly and may seriously endanger people’s safety.

3.1 Dangers deriving from using the The unit is not designed to operate in premises where explosives are stored.

unit for purposes other than Therefore, it is categorically forbidden to use it in locations where any risk of

those it is designed for explosion exists.

Should the user wish to use the unit for any purposes or in any fields other than

those intended (see ch. 8, section 8.2 of this manual), or wish to modify the unit

in any way, he should consult the manufacturer/distributor about any contraindications or dangers that may derive from the incorrect use of the unit.

GB

D

F

I

Carrier 7

2. TECHNICAL FEATURES OF THE UNIT

fig.3

Mod.

Mod.

Matricola

Serial Number

Ten si on e

Vol tage

Assorb. Marcia

Run Absorption

Refrigerante

Refrigerant

Massa

Mass

AKw

Kg

Via Martin L. King, nr. 30

46020 PEGOGNAGA

(Mantova) - Italy

ZANOTTI

SS..pp..AA..

Modello

Model

Potenza compressore

Compressor power

A

Assorb. Max

Max Absor.

Kw

Schemi

Diagr.

1) Anno di costruzione

2) Codice unità "CARRIER"

3) Numero matricola

4) Tensione

5) Assorbimento Marcia (Macchina)

6) Assorbimento massimo

7) Assorbimento di spunto (Macchina all' avviamento)

8) Potenza nominale compressore

9) Refrigerante : Tipo ; Quantità

10) Massa macchina

11) Numero schema elettrico (Progetto)

Carrier Refrigeration AB

A

Ass. Spunto

Start. Abs.

Kg

3. INTENDED USES

1) Year of manufacture

2) Carrier unit code

3) Serial number

4) Voltage

5) Operating current

6) Maximum current

7) Starting current

8) Compressor’s nominal power

9) Refrigerating liquid Type; Quantity

10) Mass of the unit

11) Electric diagram (Project) number

Page 8

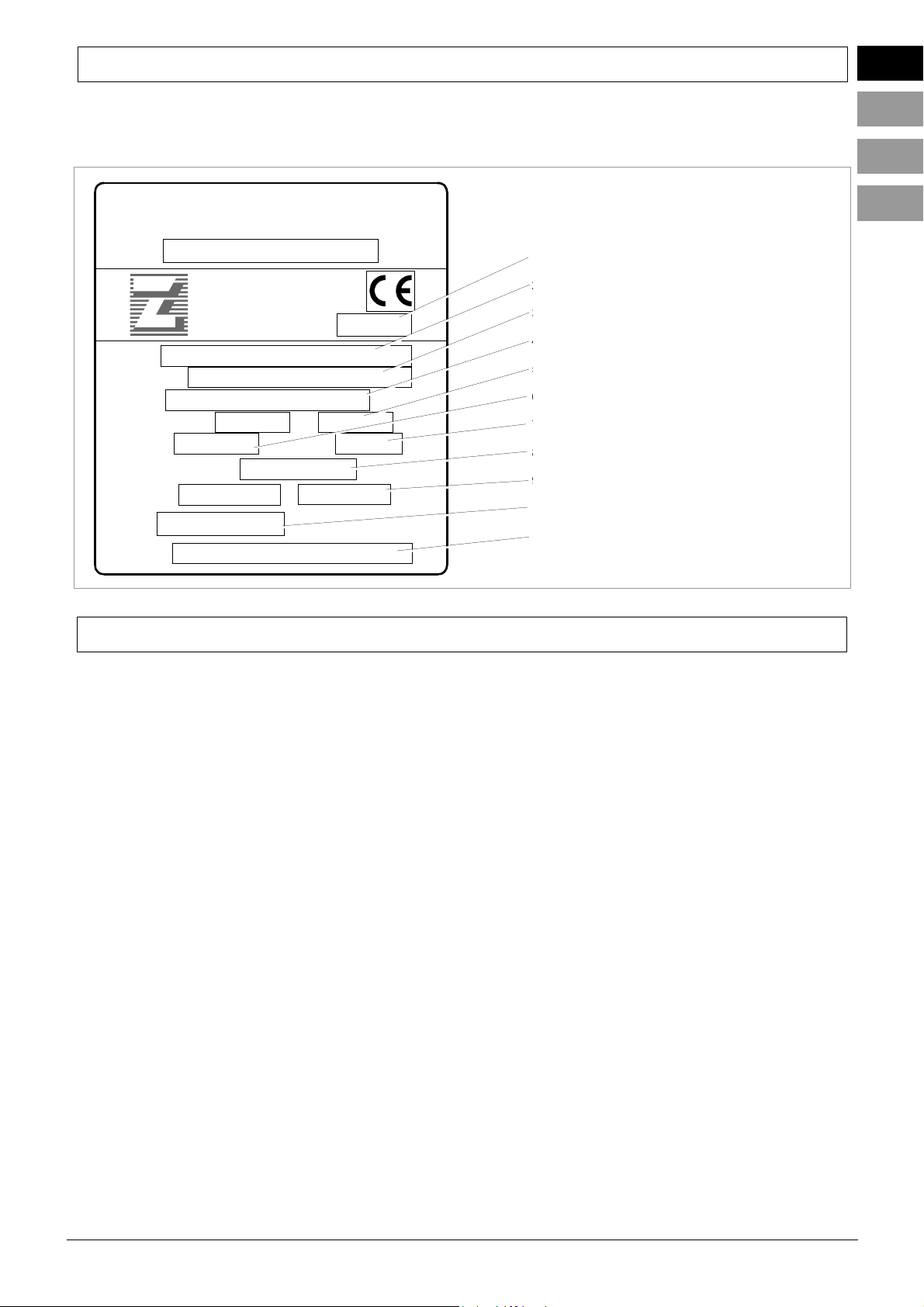

The unit can be moved with lifting and transport devices. (Fig.4)

WARNING

Take the utmost care in ensuring no one passes through the platform truck’s

manoeuvring area, so as to avoid any risk to personnel while the load is

being handled.

The unit is shipped packed in a wooden case or in a wooden crate: the

movement has to be done securing the packaging with a sling in an appropriate way.

Take special care in ensuring that the packing crate containing the unit is not lif-

ted too quickly to avoid oscillations which may damage or break the unit.

5.1 Signs The Manufacturer has envisaged the posting of the following caution and warning signs:

Caution: Low /high temperature

Switch off before handling the unit

Caution: danger

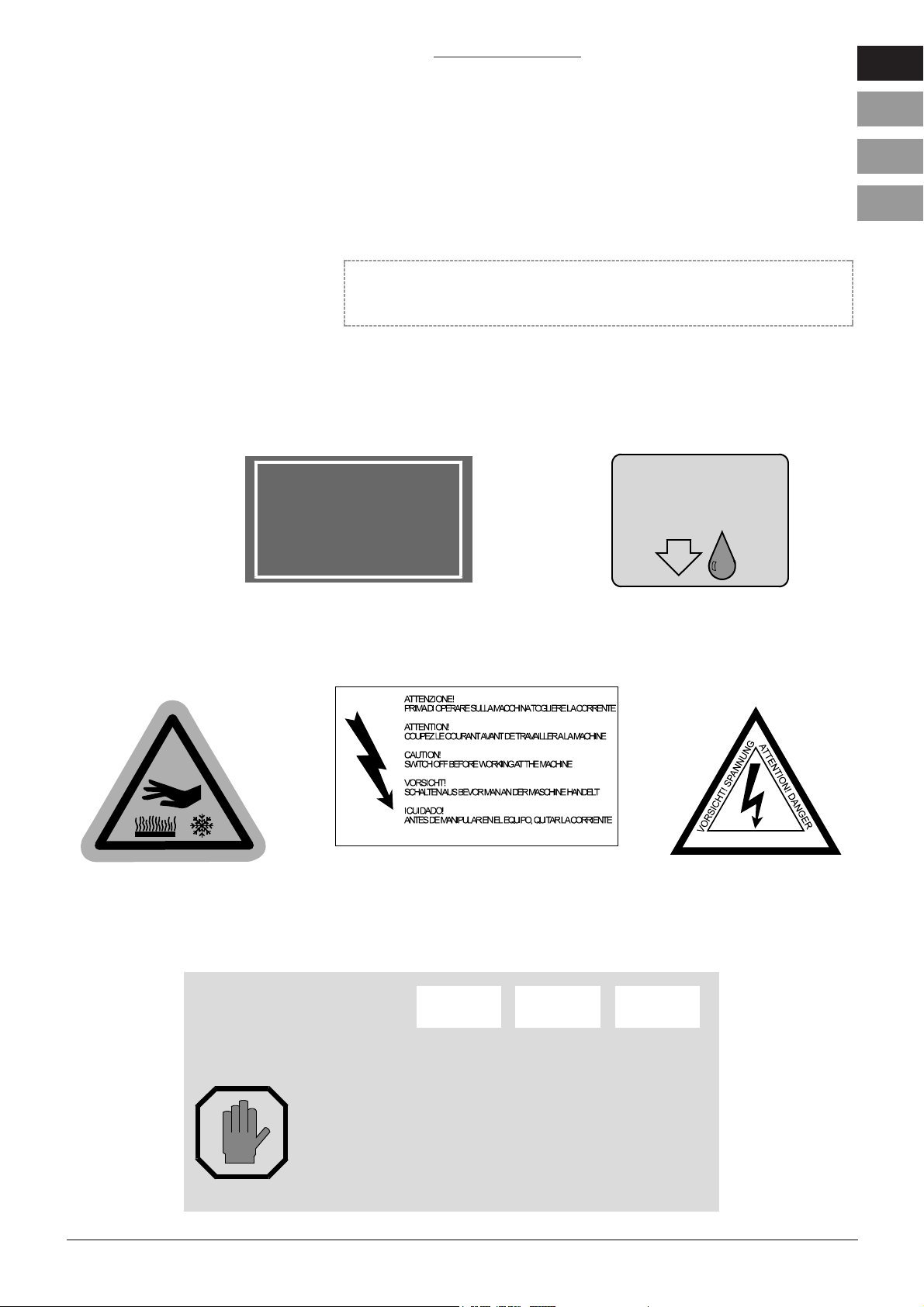

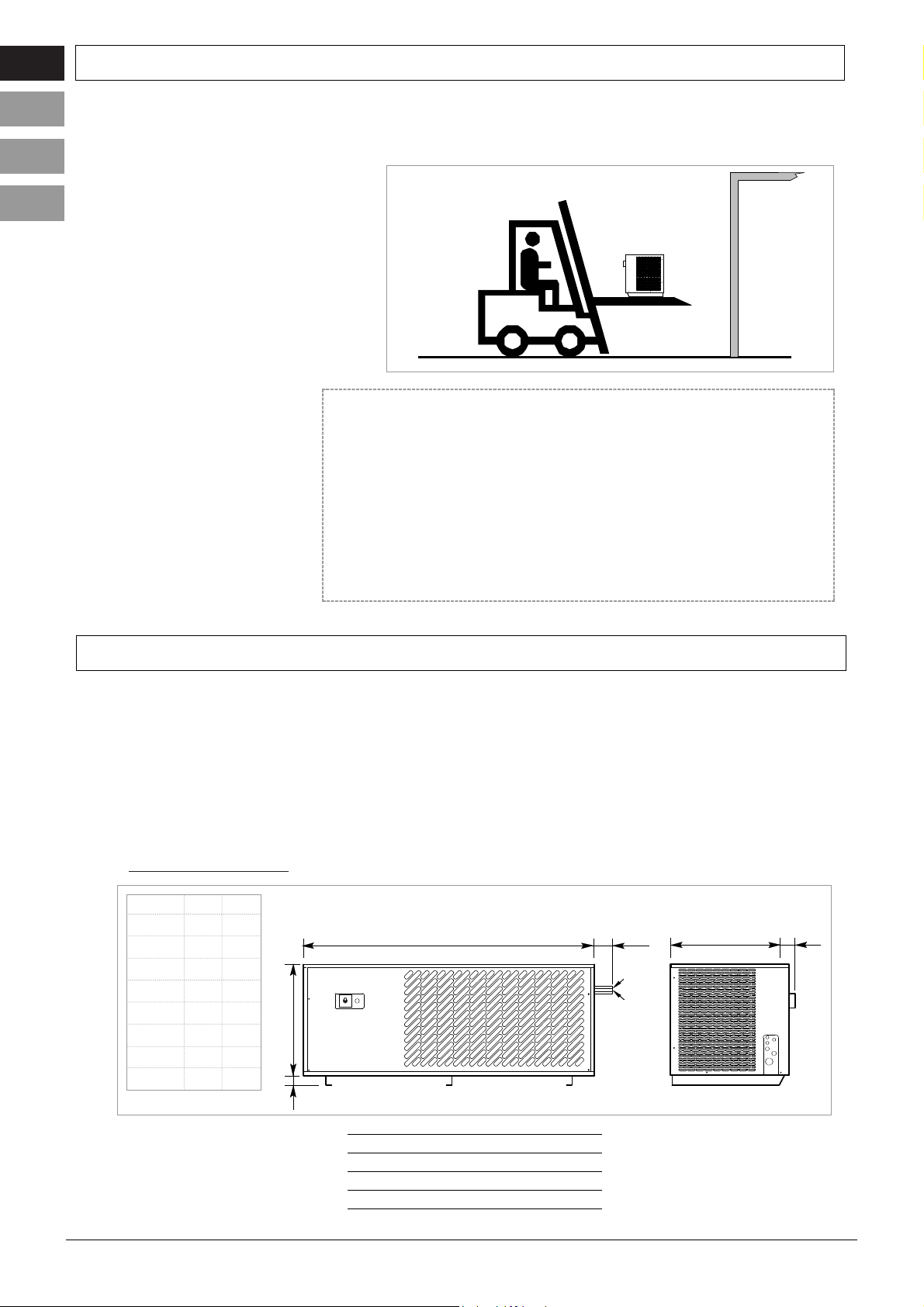

5.2 Dimensions of unit and packing CU range units come in different sizes, as indicated in the following diagrams (fig. 5-6).

CU 401 - 451 - 501 - 631 /O

GB

D

F

I

8 Carrier

5. INSTALLATION

fig.4

4.

POSITIONING THE UNIT

fig.5

* delivery pipe

** suction pipe

Cod. H G

GCU401 10 22

HCU401 10 28

GCU451 12 28

HCU451 12 35

GCU501 12 28

HCU501 12 35

GCU631 12 28

HCU631 12 42

Mod. A B C D E F

CU401 52 542 1075 105 532 28

CU451 52 602 1575 105 642 28

CU501 52 602 1575 105 642 28

CU631 83 802 1725 105 742 28

C

D

ø G**

ø H*

E

F

A

B

Page 9

PACKING

5.3 Commissioning In order to achieve optimum performance, the unit must be:

a) Place the cell in a well ventilated room, away from heat sources .

b) Check that the unit has adequate aspirating and extracting power.

5.4 Area surrounding the unit In order to allow it to work properly and to facilitate its maintenance in safety conditions, the unit should be installed providing the minimum spatial requirements

for opening the unit, indicated in figs 5.

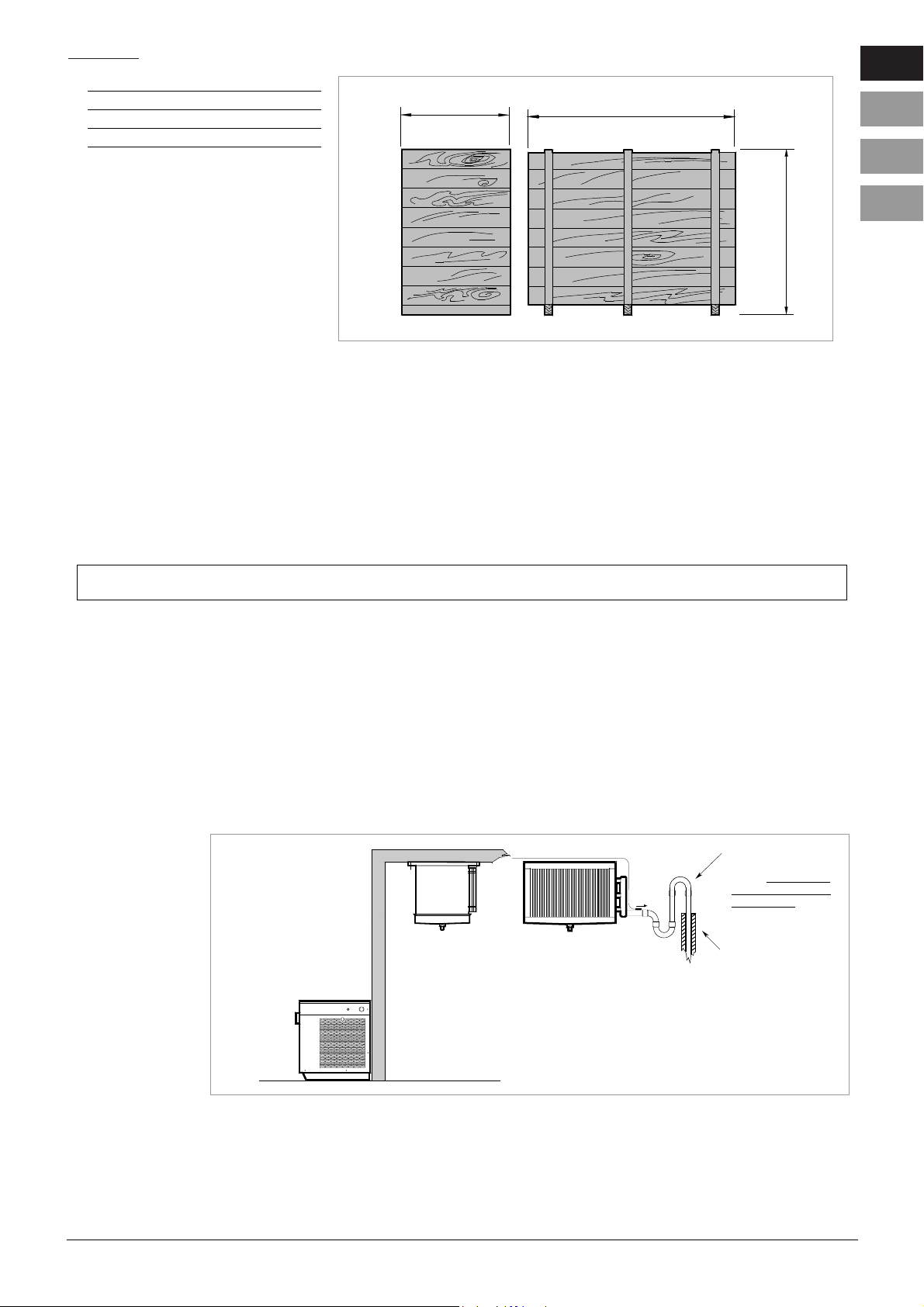

Ensure that no damage has occurred to the unit or the equipment it contains

during transportation, particularly to the components fixed to the electric control

panel door and to the refrigerating system pipes. To install the unit, proceed as

indicated in the diagrams, taking special care to level the unit (fig.7).

Connect the condensing unit to its evaporator following the diagrams of the fig.7

and using pipes with the correct diameter as indicated in the enclosed tables.

GB

D

F

I

Carrier 9

fig.6

Mod. A B C Kg

CU401-O 670 1350 810 56

CU451/501-O

780 1850 865 89

CU631-O 880 2000 1100 114

A

B

C

6. ASSEMBLY AND PREPARATION PRIOR TO COMMISSIONING

fig. 7

PIANO PAVIMENTO

fig. 7.a

-Section of suction

line in an installation

having the compres

sor sited underneath

heevaporator

Insulate the whole

suction line

FLOOR PLANE

Page 10

GB

D

F

I

10 Carrier

PIANO PAVIMENTO

fig.7.b

Insulate the whole suc-

tion line

-First section of the

suction line in an

installation having

the compressor

sited above the

evaporator (difference of level less

than 3 mt)

fig.7

PIANO PAVIMENTO

fig.7.c

Insulate the whole

suction line

-First section of the

suction line in an

installation having

the compressor

sited above the

evaporator (difference of level

more than 3 mt).

FLOOR PLANE

FLOOR PLANE

Page 11

D

F

I

Carrier 11

6.1 Cleaning the unit

Carefully clean the unit with detergents or degreasing substances, removing dust, dirt

and any foreign matter that may have deposited on it during transportation.

CAUTION! Do not use solvents

6.2 Connecting the unit to external 6.2.1 Power mains connection

energy sources Before making the electrical connection, ensure that the voltage and frequency of

the mains supply are as indicated on the unit’s serial plate and that the power

supply is within +/- 10% of nominal value

Having conducted a preliminary inspection of the elements of the panel, make the

electrical connection. Connection to the mains supply must be made through a

magnetothermal or fused switch.

Safety devices (magnetothermal and/or fused switches ) should be installed on the

power supply line taking into account the current absorption indicated on the plate.

For instance:

Current absorption indicated on the plate:

Operating current 12KW - 28,5 A

Maximum current 40 A

Starting absorption 134A

In this case, a 40A magnetothermal switch with a “C” curve (CEI 23.3 IV -EN 60-

898) should be installed. Alternatively, an appropriately sized fused switch should

be used for the maximum 40A current, which should also be capable of withstan-

ding a 134A starting current without being tripped. The system must be fitted with

an adequate equipotential safety circuit (earth connection).

It is also advisable to install a differential switch at source.

Follow the diagram below to make the electrical connection correctly for CU-O :

Id

Esempio con

CON FUSIBILI

INTERRUTTORE

N

L3

L2

L1

400V 3~ N 50Hz

Id

42

N

5

3

1

N6

MAGNETOTERMICO

Esempio con

400V 3~ N 50Hz

INT.

DIFFERENZIALE

INTERRUTTORE GENERALE

INT.

DIFFERENZIALE

INTERRUTTORE GENERALE

N

L3

L2

L1

UNITÀ CONDENSANTE

GB

Id

Esempio con

CON FUSIBILI

INTERRUTTORE

N

L3

L2

L1

400V 3~ N 50Hz

Id

42

N

5

3

1

N6

MAGNETOTERMICO

Esempio con

400V 3~ N 50Hz

INT.

DIFFERENZIALE

INTERRUTTORE GENERALE

INT.

DIFFERENZIALE

INTERRUTTORE GENERALE

N

L3

L2

L1

UNITÀ CONDENSANTE

CONDENSER UNIT

Ex: MAGNETOTHERMAL

SWITCH

Ex.: FUSED SWITCH

MAINS SWITCH

DIFFERENTIAL SWITCH

MAINS SWITCH

DIFFERENTIAL SWITCH

fig.8

Page 12

GB

D

F

I

12 Carrier

When a cell contains more than one unit, each should be fitted with its own

magnetothermal switch.

Now connect the unit paying attention to the colour of the wires that make up the

power supply cable:

a) 230V/3~/50-60 Hz 4 wires Blue = phase

Yellow/green = earth

Brown = phase

Black = phase

b) 400V/3N~/50-60 Hz 5 wires Blue = neutral

Yellow/Green = earth

Brown = phase

Black = phase

Black = phase

N.B.: All units are supplied with terminals 3-4 to which it is possible to connect

any device not alive; for example an ambient thermostat.

CAUTION

Magnetothermal safety switches should be used to protect the main power sup-

ply line from power surges.

Only qualified personnel is authorised to replace the safety thermal relays fitted

on motors.

Only qualified personnel must be authorised to make electrical connections.

6.2.2 Connection to the water mains (water condenser)

The water condenser must be connected to the water mains following the indications

on the plates next to the tubes, which are marked IN (ENTRATA) and OUT (USCITA). The diameter of the pipes used to make the connection must not be smaller

than the unit’s outlet tubes. Pressure in the water circuit must be at least 1 bar.

6.3 Checks, adjustments and settings Before switching the machine on, ensure that:

- locking screws are fixed tight

- electrical connections have been made correctly

When the unit is opened, check that:

- no tools have been left inside

- assembly has been correctly performed

- there are no gas leaks

- panels have been correctly fixed.

6.4 Setting of the control and During the testing on make the setting of these devices. Below we list the rated

power devices values of the pressure switches settings; these values must be considered

approximates as size order.

Low pressure switch 0,2 bar

high pressure switch 28 bar working with R404A

Page 13

D

F

I

Carrier 13

I ON

GB

To start the machine up proceed as follows:

A) Adjust the ambient thermostat, which is on the evaporator, to the desired tempera-

ture inside the refrigerating cell. Units with remote control panels are equipped with

an electronic room thermostat which is located on the remote control panel itself.

The thermostat can be connected following the scheme; or it can work on the sole-

noid valve which pipes the refrigerant to the evaporator.

B) Position the switch preheating/stop/running, arranged by the customer, on

preheating (the indication for the connection is in the electric scheme).

C) Move the mains switch to position (ON). Leave the unit in the pre-start position

for at least 4 hours. If the temperature is particularly cold, keep the unit in the

pre-start position for at least 12 hours.

D) At the end of the pre-start phase, move the pre-start/stop/start switch to opera-

ting position.

E) If the compressor fails to start, check:

- connection to the power supply

- a blockage in the minimum pressure switch due to the lack of refrigerating gas. In this case the leak must be identified and repaired before

refilling the compressor and proceeding again with the operations

illustrated above.

- Faulty auxiliary fuse = identify and eliminate the cause.

7.1 Electrical controls 7.1.1 Control panel

The CU-O units use only one model of control panel. (fig.9)

8.1 Description of the unit Uniblock CU refrigerating units operate through a sealed or semi-sealed refrige-

working cycle rating compressor, powered by mains a/c supply (three phase) and use HFC

refrigerating liquids.

8.2 Diagram of the unit’s Units in the CU-O range feature a special electrical system, a diagram

electrical system of which is attached to this manual.

7. PLACING INTO SERVICE OF THE UNIT

I ON

fig.9

Mains

switch

8. HOW TO OPERATE THE UNIT

Page 14

GB

D

F

I

14 Carrier

Adequate maintenance is an important factor to ensure the long life and optimum

performance of the unit and the safety conditions required by the Manufacturer.

9.1 General maintenance It is essential to clean the condenser which is located in the lower part of the

compressor unit (externally to the cell) in an easily accessible position.

The condenser is used to cool the refrigerating gas and it will work more effecti-

vely if it is kept free of dust.

The unit can be cleaned by simply using a dry brush and reaching deep between

the condenser’s fins or, better still, by using an air jet and blowing from the inside

out. This operation must be carried out while the unit is switched off.

If there are traces of oil on the condenser, check where they come from and,

having repaired the leak, clean using a detergent such as alcohol or petrol.

WARNING: To avoid cutting your hands, use protective gloves.

9.2 Special maintenance operations Periodically check the wear of electrical contacts and remote control switches

and replace if necessary.

9.3 Operations to be carried out Below is a list of maintenance operations that require specific technical compe-

by qualified personnel or by tencies and must therefore be carried out by qualified personnel or by the

the Manufacturer Manufacturer.

The User must on no account:

- replace electrical components

- tamper with the electric system

- make repairs on mechanical parts

- tamper with the refrigerating system

- tamper with the control panel

- tamper with safety and protection devices

9.4 Troubleshooting guide Technical problems that may occur during the operation of the machine:

1. In case of malfunction of the system, check the refrigerating gas through the flow

indicator located on all units (this must be checked when the unit is operating and the

cell temperature is close to the required temperature). Normally the indicator is clear,

while, in the absence of gas, gas bubbles will appear.

2. If the compressor or fan stop, check the following:

- whether the safety fuses of the main and auxiliary circuit have been blown, in

which case they should be replaced, after checking the suitability of the mains

tension and ensuring that phase polarity is correct.

- if the compressor has blocked, it is necessary to wait for the automatic resetting

of the internal protention.

- if the fan is blocked, it will automatically reactivate, never the less it is necessary

to look for the cause of the blocking.

WARNING:

It absolutely forbidden to remove the safety devices provided by the anufacturer

to protect operators while the machine is in operation.

3. Other malfunctions may be due to the triggering of the following electrical

safety devices:

a) Fan thermal protection (incorporated in the motor) - automatic resetting. This

device is designed to safeguard electrical fans against excessive current absorption due to:

- overheating

- lack of one phase (only for three phase models)

- dirt in the condenser

9. MAINTENANCE AND REPAIRS

Page 15

b) High pressure switch - manual resetting

It is designed to protect the compressor from excessive pressure, which cause

the pressure switch to be triggered too often, deriving from:

- dirt in the condenser

- condenser fans not working

- excessive temperature in the room where the system is located

- use of the system in unsuitable conditions or with inappropriate products.

To reset press the button on the pressure switch.

c) Low pressure switch - automatic resetting.

If the thermostat, arranged by the customer, works on the solenoid valve which

pipes the refrigerant to the evaporator, the unit will stop at every closure of the

solenoid valve, through the switch L/P (pump down). The intervention of the air

pressure switch can be caused even by some anomalies as:

- lack of gas due to the breakage of a pipe or to loose hub

- clogged up filters

- solenoid valve failure

- ice in the evaporator

The minimum and maximum temperature pressure switches and the oil pressure

switch are located inside the motor casing. Before resetting, disconnect from mains.

d) Thermistors or thermostats - automatic resetting

These are inserted in the compressor’s coil to protect the motor from overheating

(see electrical diagram)

e) Minimum and maximum tension electronic relay (Monitor)optional - auto-

matic reset (where applicable). It is used to protect the unit against anomalies in

the power supply (+/-12% of nominal value). The unit starts with a delay of 8

minutes, indicated on the panel by a LED.

The main factors that cause the triggering of the device are anomalies in the

power supply (for further information see attachment)

f) Condenser fan pressure switch

it is designed to control the condensing temperature.

In case of failure it can determine the activation of the h.p. pressure switch.

9.5 Parts subject to wear and spares Only qualified personnel or the Manufacturer are authorised to replace worn

parts.

Materials such as wood, plastics, polystyrene are used in packing and must be

disposed of in compliance with local legislation.

When, for whatever reason, the owner wishes to dispose of the machine and

dismantle it, it is necessary to follow some fundamental rules for protecting

human health and the environment in which we live.

Conduits, flexible tubes, plastic or non-metallic components must be disassem-

bled and disposed of separately.

Electrical components such as switches, transformers, etc. must be disassem-

bled in order to be reused if they are still in good condition, or to be reconditioned

and recycled where possible.

Pneumatic and electrical components such as valves, electrical valves, pressure

regulators must be disassembled in order to be reused if they are still in good

condition, or to be reconditioned and recycled where possible.

The refrigerating liquid must be drained completely and disposed of by specialists.

The casing and all metal parts of the unit should be disassembled and different

materials should be separately grouped. The various parts thus obtained will thus

D

F

I

Carrier 15

GB

10. DISPOSAL OF PACKING MATERIAL

11. DISMANTLING THE UNIT

Page 16

GB

D

F

I

16 Carrier

be allowed to be demolished and melted to allow the recycling of the unit’s components.

LIST OF FUSES

GCU401NO170F R404A 400V/3N~/50 3 20

GCU401TO170F R404A 400V/3N~/50 3 25

HCU401NO170F R404A 400V/3N~/50 3 50

GCU451NO170F R404A 400V/3N~/50 3 35

HCU451TO170F R404A 400V/3N~/50 3 50

GCU501TO170F R404A 400V/3N~/50 3 35

HCU501NO170F R404A 400V/3N~/50 3 63

HCU501TO170F R404A 400V/3N~/50 3 80

GCU631NO170F R404A 400V/3N~/50 3 63

GCU631TO170F R404A 400V/3N~/50 3 63

HCU631NO170F R404A 400V/3N~/50 3 63

HCU631TO170F R404A 400V/3N~/50 3 80

Power current fuse

UNIBLOCK

MODEL Gas Voltage nº. Ampere

POWER CURRENT FUSE: This is a fuse fitted in the line.

Page 17

Carrier 59

12.

REFRIGERATION DIAGRAM-KÄLTETECHNIKSCHEMA-SCHEMA FRIGORIFIQUE-SCHEMA FRIGORIFERO

CU-O 401-451-501 GCU631

HCU631

N DESCRIPTION BESCHREIBUNG DESCRIPTION DESCRIZIONE

1 COMPRESSOR KOMPRESSOR COMPRESSEUR COMPRESSORE

2 H.P. SWITCH HOCHDRUCKSCHALTER PRESSOSTAT H.P. PRESSOSTATO ALTA PRESS.

3 CONDENSER KONDENSATOR CONDENSEUR CONDENSATORE

4 CONDENSER FAN KONDENSATORVENTILATOR VENTILATEUR CONDENSEUR MOTOVENTILATORE COND.

5 LIQUID RECEIVER FLÜSSIGKEITSSAMMLER RESERVOIR LIQUIDE RICEVITORE LIQUIDO

6 FILTER FILTER FILTRE FILTRO

7 SIGHT GLASS SCHAUGLAS VOYANT LIQUIDE SPIA LIQUIDO

8 FLANGE FLANSCH BRIDE FLANGIA

17 CONDENSER FAN SWITCH

KOND. VENTILATORPRESSOSTAT

PRESSOSTAT VENTILATEUR CONDENSEUR

PRESSOSTATO VENTOLA CONDENSATORE

19

SHUT-DOWN VALVE ROTALOCK

SPERRVENTIL ROTALOCK

SOUPAPE DE RETENUE ROTALOCK

RUBINETTO ROTALOCK

20 L/P SWITCH NIEDERDRUCKPRESSOSTAT

PRESSOSTAT HAUTE PRESSION

PRESSOSTATO BASSA PRESSIONE

7

6

19

5

8

8

1

19

4

19

PH

17

2

PF

PL

20

M

3

8

7

1

19

6

4

19

5

M

19

2

PH

3

17

PF

20

PL

Page 18

60 Carrier

95

14 CU401

18/05/99 Arfini

Tav n° Modello :

Data : Disegnatore :

4

12

9

6

79

92

109

102

10

103

96

11

99

80

78

15

16

46

67

50

88

87

94

81

101

107

77

89

90

3

60

108

74

59

69

76

32

33

73

63

58

49

48

98

55

53

70

54

47

5

Page 19

Code-Code

Code-Codice

Pos.

Description - Beschreibung - Description - Descrizione

English Deutsch Francais Italiano

LEGEND - LEGENDE - LEGENDE - LEGENDA :

Carrier 61

3 UNIT BASE FRAME RAHMENGESTELL BASE BASAMENTO 2235441/B 1 1 1

4 RIGHT-HAND SIDE RECHTE SEITENWAND FLANC DROIT FIANCO DESTRO 2235442/A 1 1 1

5 LEFT-HAND SIDE LINKE SEITENWAND FLANC GAUCHE FIANCO SINISTRO 2235443/A 1 1 1

6 SUPPORT HALTERUNG SUPPORT SUPPORTO 2235446/A 1 1 1

9 FRONTAL PANEL KOPFBAND PANNEAU FRONTAL FRONTALE 2235445/A 1 1 1

10 COVER ABDECKUNG COUVERCLE COPERCHIO 2235444/A 1 1 1

11 DEFLECTOR SWITCH ABLEITER DETOURNEUR DEVIATORE 2235410/A 1 1 1

12 SHROUD LUFTLEITER CONVEYEUR D’AIR CONVOGLIATORE 2235405 1 1 1

15 SUPPORT HALTERUNG SUPPORT PIEDE 2235431 1 1 1

16 SUPPORT HALTERUNG SUPPORT PIEDE 2235432 1 1 1

32 TERMINAL KLEMME BORNE MORSETTO 3MRS007 15 15 15

33 TERMINAL KLEMME BORNE MORSETTO 3MRS004 1 1 1

46 ELECTRIC PANEL SCHALTTAFEL PANNEAU ELECTRIQUE QUADRO ELETTRICO 2QEC3330 1

2QEC3475 1

2QEC3232 1

47 ELEC.PAN.BOX DOSE BOITE SCATOLA Q.E. 2235448/A 1 1 1

48 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2235411 1 1 1

49 COVER ABDECKUNG COUVERCLE COPERCHIO 2235449/A 1 1 1

50 COVER ABDECKUNG COUVERCLE COPERCHIO 2235465 1 1 1

53 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF014 1 1 1

54 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF041 1 1 1

55 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF050 1 1 1

58 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB137 3

3FSB138 3

3FSB168 3

59 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB160 1 1 1

60 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB164 1 1 1

63 SELECTOR WÄHLER SECTIONNEUR SEZIONATORE 3ING026 1 1

3ING028 1

67 HANDLE HANDGRIFF POIGNÉE MANIGLIA 3MNG009 1 1 1

69 TERMINAL BOARD KLEMMKASTEN BOITE A’BORNES MORSETTIERA 3MRS028 1 1 1

70 EXTENSION VERLÄNGERUNG RALLONGE PROLUNGA 3PRL009 1 1 1

73 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR192 1

3TLR191 1

3TLR170 1

74 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR152 1 1 1

76 TERMNAL KLEMME BORNE TERMINALE 3TRM005 1 1 1

77 COMPRESSOR KOMPRESSOR COMPRESSEUR COMPRESSORE 3CMP483 1

3CMP382 1

3CMP854 1

78 HEATER HEIZELEMENT RESISTANCE RESISTENZA 3RST014 1 1 1

79 SIGHT GLASS SCHAUGLAS VOYANT LIQUIDE INDICATORE 3INU006 1 1 1

80 FILTER FILTER FILTRE FILTRO 3FLT043 1 1 1

81 RECEIVER SAMMLER RESERVOIR SERBATOIO 3ACL051 1 1 1

87 SWITCH L/P PRESSOSTAT MIN PRESSOS. BAS. PRES. PRESSOSTATO MIN 3PRS011 1 1 1

88 H/P SWITCH HOCHDRUCKSCHALTER PRESSOSTAT H.P. PRESSOSTATO MAX 3PRS009 1 1 1

89 VALVE VENTIL VANNE RUBINETTO 3RBN038 1 1

3RBN042 1

90 VALVE VENTIL VANNE RUBINETTO 3RBN071 1 1 1

3RBN059 1

92 VALVE VENTIL VANNE RUBINETTO 3RBN113 1 1 1

94 VALVE VENTIL VANNE RUBINETTO 3RBN102 1 1 1

95 CONDENSER KONDENSATOR CONDENSEUR CONDENSATORE 3CND124 1 1 1

96 MOTOR DRIVEN FAN ELEKTROVENTILATOR ELECTROVENTILATEUR MOTOVENTILATORE 3MOT028 1 1 1

98 ELEC. CONDENSER ELEC. KONDENSATOR CONDENSEUR ELEC. CONDENSATORE ELET. 3COE011 1 1 1

99 FAN GUARD GITTER GRILLE GRIGLIA 3GRI042 1 1 1

101 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2235406 1 1 1

102 CLAMP BUEGEL PIECE D’APUI STAFFA 2235454 1 1 1

103 SUPPORT HALTERUNG SUPPORT SUPPORTO 2730027 1 1 1

107 CLAMP BUEGEL PIECE D’APUI STAFFA 2235408/A 1 1 1

108 TIMER ZEITSCHALTER TEMPORISATEUR TEMPORIZZATORE 3TMP039 1 1 1

109 PRESSURE SWITCH DRUCKSCHALTER PRESSOSTAT PRESSOSTATO 3PRS006 1 1 1

GCU401NO170F

GCU401TO170F

HCU401NO170F

Tav

.n° 14

CU401

Page 20

62 Carrier

9

15

CU451

18/05/99 Arfini

Tav n° Modello :

Data : Disegnatore :

12

6

9

8

4

109

102

80

96

3

94

93

88

87

89

77

79

92

103

7

10

49

81

11

48

96

55

53

78

90

63

60

15

101

73

59

16

70

74

69

108

46

67

50

76

32

33

58

54

47

5

Page 21

Carrier 63

3 UNIT BASE FRAME RAHMENGESTELL BASE BASAMENTO 2335441/B 1 1

4 RIGHT-HAND SIDE RECHTE SEITENWAND FLANC DROIT FIANCO DESTRO 2335442/A 1 1

5 LEFT-HAND SIDE LINKE SEITENWAND FLANC GAUCHE FIANCO SINISTRO 2335443/A 1 1

6 SUPPORT HALTERUNG SUPPORT SUPPORTO 2335452/A 1 1

7 REAR PANEL RUECKBLENDE PANNEAU POSTERIEUR SCHIENA 2335446/B 1 1

8 COVER ABDECKUNG COUVERCLE COPERCHIO 2335435/A 1 1

9 FRONTAL PANEL KOPFBAND PANNEAU FRONTAL FRONTALE 2335451/A 1 1

10 COVER ABDECKUNG COUVERCLE COPERCHIO 2335444/A 1 1

11 DEFLECTOR SWITCH ABLEITER DETOURNEUR DEVIATORE 2335424/A 1 1

12 SHROUD LUFTLEITER CONVEYEUR D’AIR CONVOGLIATORE 2335434/B 1 1

15 SUPPORT HALTERUNG SUPPORT PIEDE 2335429 2 2

16 SUPPORT HALTERUNG SUPPORT PIEDE 2335430 1 1

32 TERMINAL KLEMME BORNE MORSETTO 3MRS007 15 15

33 TERMINAL KLEMME BORNE MORSETTO 3MRS004 1 1

46 ELECTRIC PANEL SCHALTTAFEL PANNEAU ELECTRIQUE QUADRO ELETTRICO 2QEC3331 1

2QEC3476 1

47 ELEC.PAN.BOX DOSE BOITE SCATOLA Q.E. 2335448/A 1 1

48 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2335415 1 1

49 COVER ABDECKUNG COUVERCLE COPERCHIO 2335449 1 1

50 COVER ABDECKUNG COUVERCLE COPERCHIO 2335461 1 1

53 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF014 1 1

54 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF041 1 1

55 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF050 1 1

58 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB141 3 3

59 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB160 1 1

60 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB164 1 1

63 SELECTOR WÄHLER SECTIONNEUR SEZIONATORE 3ING028 1 1

67 HANDLE HANDGRIFF POIGNÉE MANIGLIA 3MNG009 1 1

69 TERMINAL BOARD KLEMMKASTEN BOITE A’BORNES MORSETTIERA 3MRS028 1 1

70 EXTENSION VERLÄNGERUNG RALLONGE PROLUNGA 3PRL009 1 1

73 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR170 1

3TLR173 1

74 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR152 1 1

76 TERMNAL KLEMME BORNE TERMINALE 3TRM005 1 1

77 COMPRESSOR KOMPRESSOR COMPRESSEUR COMPRESSORE 3CMP461 1

3CMP406 1

78 HEATER HEIZELEMENT RESISTANCE RESISTENZA 3RST014 1 1

79 SIGHT GLASS SCHAUGLAS VOYANT LIQUIDE INDICATORE 3INU007 1 1

80 FILTER FILTER FILTRE FILTRO 3FLT047 1 1

81 RECEIVER SAMMLER RESERVOIR SERBATOIO 3ACL095 1 1

87 SWITCH L/P PRESSOSTAT MIN PRESSOS. BAS. PRES. PRESSOSTATO MIN 3PRS011 1 1

88 H/P SWITCH HOCHDRUCKSCHALTER PRESSOSTAT H.P. PRESSOSTATO MAX 3PRS009 1 1

89 VALVE VENTIL VANNE RUBINETTO 3RBN042 1

3RBN110 1

90 VALVE VENTIL VANNE RUBINETTO 3RBN059 1 1

3RBN038 1

92 VALVE VENTIL VANNE RUBINETTO 3RBN114 1 1

93 VALVE VENTIL VANNE RUBINETTO 3RBN065 1

3RBN073 1

94 VALVE VENTIL VANNE RUBINETTO 3RBN071 1 1

95 CONDENSER KONDENSATOR CONDENSEUR CONDENSATORE 3CND131 1 1

96 MOTOR DRIVEN FAN ELEKTROVENTILATOR ELECTROVENTILATEUR MOTOVENTILATORE 3MTV011 1 1

101 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2340427 1 1

102 CLAMP BUEGEL PIECE D’APUI STAFFA 2335453 1 1

103 SUPPORT HALTERUNG SUPPORT SUPPORTO 2335411 1 1

108 TIMER ZEITSCHALTER TEMPORISATEUR TEMPORIZZATORE 3TMP039 1 1

109 PRESSURE SWITCH DRUCKSCHALTER PRESSOSTAT PRESSOSTATO 3PRS006 1 1

Code-Code

Code-Codice

Pos.

Description - Beschreibung - Description - Descrizione

English Deutsch Francais Italiano

GCU451NO170F

HCU451TO170F

Tav

.n° 15

CU451

LEGEND - LEGENDE - LEGENDE - LEGENDA :

Page 22

64 Carrier

12

9

16

CU501

18/05/99 Arfini

Tav n° Modello :

Data : Disegnatore :

6

8

4

79

92

103

7

3

109

80

94

96

93

9

11

81

46

67

50

88

78

15

16

10

102

87

77

89

49

48

5

96

55

53

90

47

63

60

101

73

59

70

54

74

69

108

76

32

33

58

Page 23

Carrier 65

3 UNIT BASE FRAME RAHMENGESTELL BASE BASAMENTO 2335441/B 1 1 1

4 RIGHT-HAND SIDE RECHTE SEITENWAND FLANC DROIT FIANCO DESTRO 2335442/A 1 1 1

5 LEFT-HAND SIDE LINKE SEITENWAND FLANC GAUCHE FIANCO SINISTRO 2335443/A 1 1 1

6 SUPPORT HALTERUNG SUPPORT SUPPORTO 2335452/A 1 1 1

7 REAR PANEL RUECKBLENDE PANNEAU POSTERIEUR SCHIENA 2335446/B 1 1 1

8 COVER ABDECKUNG COUVERCLE COPERCHIO 2335409/A 1 1 1

9 FRONTAL PANEL KOPFBAND PANNEAU FRONTAL FRONTALE 2335445/A 1 1 1

10 COVER ABDECKUNG COUVERCLE COPERCHIO 2335444/A 1 1 1

11 DEFLECTOR SWITCH ABLEITER DETOURNEUR DEVIATORE 2335424/A 1 1 1

12 SHROUD LUFTLEITER CONVEYEUR D’AIR CONVOGLIATORE 2335405/B 1 1 1

15 SUPPORT HALTERUNG SUPPORT PIEDE 2335429 2 2 2

16 SUPPORT HALTERUNG SUPPORT PIEDE 2335430 1 1 1

32 TERMINAL KLEMME BORNE MORSETTO 3MRS007 15 15 15

33 TERMINAL KLEMME BORNE MORSETTO 3MRS004 1 1 1

46

ELECTRIC PANEL SCHALTTAFEL PANNEAU ELECTRIQUE QUADRO ELETTRICO

2QEC3329 1

2QEC3477 1

2QEC3478 1

47 ELEC.PAN.BOX DOSE BOITE SCATOLA Q.E. 2335448/A 1 1 1

48 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2335415 1 1 1

49 COVER ABDECKUNG COUVERCLE COPERCHIO 2335449 1 1 1

50 COVER ABDECKUNG COUVERCLE COPERCHIO 2335461 1 1 1

53 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF014 1 1 1

54 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF041 1 3

3BSF042 1

55 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF050 1 1 1

58 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB140 3

3FSB141 1

3FSB144 3

59 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB160 1 1 1

60 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB164 1 1 1

63 SELECTOR WÄHLER SECTIONNEUR SEZIONATORE 3ING028 1 1

3ING029 1

67 HANDLE HANDGRIFF POIGNÉE MANIGLIA 3MNG009 1 1 1

69 TERMINAL BOARD KLEMMKASTEN BOITE A’BORNES MORSETTIERA 3MRS028 1 1 1

70 EXTENSION VERLÄNGERUNG RALLONGE PROLUNGA 3PRL009 1 1 1

73 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR171 1 1

3TLR173 1 1

74 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR152 1 1 1

76 TERMNAL KLEMME BORNE TERMINALE 3TRM005 1 1 1

77 COMPRESSOR KOMPRESSOR COMPRESSEUR COMPRESSORE 3CMP385 1

3CMP855 1

3CMP986 1

78 HEATER HEIZELEMENT RESISTANCE RESISTENZA 3RST014 1 1 1

79 SIGHT GLASS SCHAUGLAS VOYANT LIQUIDE INDICATORE 3INU007 1 1 1

80 FILTER FILTER FILTRE FILTRO 3FLT047 1 1 1

81 RECEIVER SAMMLER RESERVOIR SERBATOIO 3ACL095 1 1 1

87 SWITCH L/P PRESSOSTAT MIN PRESSOS. BAS. PRES. PRESSOSTATO MIN 3PRS011 1 1 1

88 H/P SWITCH HOCHDRUCKSCHALTER PRESSOSTAT H.P. PRESSOSTATO MAX 3PRS009 1 1 1

89 VALVE VENTIL VANNE RUBINETTO 3RBN042 1

3RBN110 1 1

90 VALVE VENTIL VANNE RUBINETTO 3RBN059 1

3RBN038 1 1

92 VALVE VENTIL VANNE RUBINETTO 3RBN114 1 1 1

93 VALVE VENTIL VANNE RUBINETTO 3RBN065 1

3RBN073 1 1

94 VALVE VENTIL VANNE RUBINETTO 3RBN071 1 1 1

95 CONDENSER KONDENSATOR CONDENSEUR CONDENSATORE 3CND125 1 1 1

96

MOTOR DRIVEN FAN ELEKTROVENTILATOR ELECTROVENTILATEUR MOTOVENTILATORE

3MTV014 1 1 1

101 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2340427 1 1 1

102 CLAMP BUEGEL PIECE D’APUI STAFFA 2335453 1 1 1

103 SUPPORT HALTERUNG SUPPORT SUPPORTO 2335411 1 1 1

108 TIMER ZEITSCHALTER TEMPORISATEUR TEMPORIZZATORE 3TMP039 1 1 1

109 PRESSURE SWITCH DRUCKSCHALTER PRESSOSTAT PRESSOSTATO 3PRS006 1 1 1

Code-Code

Code-Codice

Pos.

Description - Beschreibung - Description - Descrizione

English Deutsch Francais Italiano

GCU501TO170F

HCU501NO170F

HCU501TO170F

Tav

.n° 16

CU501

LEGEND - LEGENDE - LEGENDE - LEGENDA :

Page 24

66 Carrier

95

17

GCU631

18/05/99 Arfini

Tav n° Modello :

Data : Disegnatore :

12

6

9

8

4

109

102

80

96

3

94

93

88

87

77

89

79

92

103

7

10

49

81

11

74

46

69

108

32

76

67

50

33

58

13

48

96

55

53

78

90

63

14

15

101

60

16

73

59

70

54

47

5

Page 25

Carrier 67

3 UNIT BASE FRAME RAHMENGESTELL BASE BASAMENTO 2340444/B 1 1

4 RIGHT-HAND SIDE RECHTE SEITENWAND FLANC DROIT FIANCO DESTRO 2340448/A 1 1

5 LEFT-HAND SIDE LINKE SEITENWAND FLANC GAUCHE FIANCO SINISTRO 2340447/A 1 1

6 SUPPORT HALTERUNG SUPPORT SUPPORTO 2340449/A 1 1

7

REAR PANEL RUECKBLENDE PANNEAU POSTERIEUR SCHIENA

2340445/B 1 1

8 COVER ABDECKUNG COUVERCLE COPERCHIO 2340407/A 1 1

9 FRONTAL PANEL KOPFBAND PANNEAU FRONTAL FRONTALE 2340432/A 1 1

10 COVER ABDECKUNG COUVERCLE COPERCHIO 2340446/A 1 1

11 DEFLECTOR SWITCH ABLEITER DETOURNEUR DEVIATORE 2340410/A 1 1

12 SHROUD LUFTLEITER CONVEYEUR D’AIR CONVOGLIATORE 2340412 1 1

13 SUPPORT HALTERUNG SUPPORT SUPPORTO 2340450 1 1

14 SUPPORT HALTERUNG SUPPORT SUPPORTO 2340451 1 1

15 SUPPORT HALTERUNG SUPPORT PIEDE 2340415 2 2

16 SUPPORT HALTERUNG SUPPORT PIEDE 2340416 1 1

32 TERMINAL KLEMME BORNE MORSETTO 3MRS007 15 15

33 TERMINAL KLEMME BORNE MORSETTO 3MRS004 1 1

46

ELECTRIC PANEL SCHALTTAFEL PANNEAU ELECTRIQUE QUADRO ELETTRICO

2QEC3328 1

2QEC3328A 1

47 ELEC.PAN.BOX DOSE BOITE SCATOLA Q.E. 2335448/A 1 1

48 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2335415 1 1

49 COVER ABDECKUNG COUVERCLE COPERCHIO 2335449 1 1

50 COVER ABDECKUNG COUVERCLE COPERCHIO 2340457 1 1

53 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF014 1 1

54 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF042 1 1

55 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF050 1 1

58 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB143 3 3

59 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB160 1 1

60 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB165 1 1

63 SELECTOR WÄHLER SECTIONNEUR SEZIONATORE 3ING028 1 1

67 HANDLE HANDGRIFF POIGNÉE MANIGLIA 3MNG009 1 1

69 TERMINAL BOARD KLEMMKASTEN BOITE A’BORNES MORSETTIERA 3MRS028 1 1

70 EXTENSION VERLÄNGERUNG RALLONGE PROLUNGA 3PRL009 1 1

73 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR173 1 1

74 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR152 1 1

76 TERMNAL KLEMME BORNE TERMINALE 3TRM005 1 1

77 COMPRESSOR KOMPRESSOR COMPRESSEUR COMPRESSORE 3CMP407 1

3CMP406 1

78 HEATER HEIZELEMENT RESISTANCE RESISTENZA 3RST014 1 1

79 SIGHT GLASS SCHAUGLAS VOYANT LIQUIDE INDICATORE 3INU007 1 1

80 FILTER FILTER FILTRE FILTRO 3FLT047 1 1

81 RECEIVER SAMMLER RESERVOIR SERBATOIO 3ACL095 1 1

87 SWITCH L/P PRESSOSTAT MIN PRESSOS. BAS. PRES. PRESSOSTATO MIN 3PRS011 1 1

88 H/P SWITCH HOCHDRUCKSCHALTER PRESSOSTAT H.P. PRESSOSTATO MAX 3PRS009 1 1

89 VALVE VENTIL VANNE RUBINETTO 3RBN042 1 1

90 VALVE VENTIL VANNE RUBINETTO 3RBN034 1 1

92 VALVE VENTIL VANNE RUBINETTO 3RBN114 1 1

93 VALVE VENTIL VANNE RUBINETTO 3RBN065 1 1

94 VALVE VENTIL VANNE RUBINETTO 3RBN071 1 1

95 CONDENSER KONDENSATOR CONDENSEUR CONDENSATORE 3CND126 1 1

96 MOTOR DRIVEN FAN ELEKTROVENTILATOR ELECTROVENTILATEUR MOTOVENTILATORE 3MTV015 1 1

101 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2340427 1 1

102 CLAMP BUEGEL PIECE D’APUI STAFFA 2340433 1 1

103 SUPPORT HALTERUNG SUPPORT SUPPORTO 2335411 1 1

108 TIMER ZEITSCHALTER TEMPORISATEUR TEMPORIZZATORE 3TMP039 1 1

109 PRESSURE SWITCH DRUCKSCHALTER PRESSOSTAT PRESSOSTATO 3PRS006 1 1

Code-Code

Code-Codice

Pos.

Description - Beschreibung - Description - Descrizione

English Deutsch Francais Italiano

GCU631NO170F

GCU631TO170F

Tav

.n° 17

GCU631

LEGEND - LEGENDE - LEGENDE - LEGENDA :

Page 26

68 Carrier

95

18

HCU631

18/05/99 Arfini

Tav n° Modello :

Data : Disegnatore :

12

6

9

8

4

109

102

80

96

3

94

93

88

77

87

79

103

7

10

49

81

78

11

74

46

69

108

32

76

67

58

50

33

13

48

96

55

92

53

101

63

60

15

14

16

73

59

70

54

47

5

Page 27

Carrier 69

3 UNIT BASE FRAME RAHMENGESTELL BASE BASAMENTO 2340444/B 1 1

4 RIGHT-HAND SIDE RECHTE SEITENWAND FLANC DROIT FIANCO DESTRO 2340448/A 1 1

5 LEFT-HAND SIDE LINKE SEITENWAND FLANC GAUCHE FIANCO SINISTRO 2340447/A 1 1

6 SUPPORT HALTERUNG SUPPORT SUPPORTO 2340449/A 1 1

7 REAR PANEL RUECKBLENDE PANNEAU POSTERIEUR SCHIENA 2340445/B 1 1

8 COVER ABDECKUNG COUVERCLE COPERCHIO 2340407/A 1 1

9 FRONTAL PANEL KOPFBAND PANNEAU FRONTAL FRONTALE 2340432/A 1 1

10 COVER ABDECKUNG COUVERCLE COPERCHIO 2340446/A 1 1

11 DEFLECTOR SWITCH ABLEITER DETOURNEUR DEVIATORE 2340410/A 1 1

12 SHROUD LUFTLEITER CONVEYEUR D’AIR CONVOGLIATORE 2340412 1 1

13 SUPPORT HALTERUNG SUPPORT SUPPORTO 2340450 1 1

14 SUPPORT HALTERUNG SUPPORT SUPPORTO 2340451 1 1

15 SUPPORT HALTERUNG SUPPORT PIEDE 2340415 2 2

16 SUPPORT HALTERUNG SUPPORT PIEDE 2340416 1 1

32 TERMINAL KLEMME BORNE MORSETTO 3MRS007 19 19

33 TERMINAL KLEMME BORNE MORSETTO 3MRS004 1 1

46 ELECTRIC PANEL SCHALTTAFEL PANNEAU ELECTRIQUE QUADRO ELETTRICO 2QEC3479 1

2QEC3480 1

47 ELEC.PAN.BOX DOSE BOITE SCATOLA Q.E. 2335448/A 1 1

48 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2335415 1 1

49 COVER ABDECKUNG COUVERCLE COPERCHIO 2335449 1 1

50 COVER ABDECKUNG COUVERCLE COPERCHIO 2340457 1 1

53 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF014 1 1

54 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF042 1 1

55 FUSE HOLDER SICHERUNGSOCKEL SUPPORT FUSIBLE BASE FUSIBILE 3BSF050 1 1

58 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB143 3

3FSB145 3

59 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB160 1 1

60 FUSE SICHERUNG FUSIBLE FUSIBILE 3FSB165 1 1

63 SELECTOR WÄHLER SECTIONNEUR SEZIONATORE 3ING029 1 1

67 HANDLE HANDGRIFF POIGNÉE MANIGLIA 3MNG009 1 1

69 TERMINAL BOARD KLEMMKASTEN BOITE A’BORNES MORSETTIERA 3MRS028 1 1

70 EXTENSION VERLÄNGERUNG RALLONGE PROLUNGA 3PRL009 1 1

73 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR173 1

3TLR175 1

74 CONTACTOR FERNSCHALTER TELERUPTEUR TELERUTTORE 3TLR152 1 1

76 TERMNAL KLEMME BORNE TERMINALE 3TRM005 1 1

77 COMPRESSOR KOMPRESSOR COMPRESSEUR COMPRESSORE 3CMP628 1

3CMP643 1

78 HEATER HEIZELEMENT RESISTANCE RESISTENZA 3RST029 1 1

79 SIGHT GLASS SCHAUGLAS VOYANT LIQUIDE INDICATORE 3INU007 1 1

80 FILTER FILTER FILTRE FILTRO 3FLT047 1 1

81 RECEIVER SAMMLER RESERVOIR SERBATOIO 3ACL095 1 1

87 SWITCH L/P PRESSOSTAT MIN PRESSOS. BAS. PRES. PRESSOSTATO MIN 3PRS011 1 1

88 H/P SWITCH HOCHDRUCKSCHALTER PRESSOSTAT H.P. PRESSOSTATO MAX 3PRS009 1 1

92 VALVE VENTIL VANNE RUBINETTO 3RBN114 1 1

93 VALVE VENTIL VANNE RUBINETTO 3RBN073 1 1

94 VALVE VENTIL VANNE RUBINETTO 3RBN071 1 1

95 CONDENSER KONDENSATOR CONDENSEUR CONDENSATORE 3CND126 1 1

96 MOTOR DRIVEN FAN ELEKTROVENTILATOR ELECTROVENTILATEUR MOTOVENTILATORE 3MTV015 1 1

101 SUPPORT PLATE HALTERUNGSPLATTE PLAQUE SUPPORT PIASTRA SUPP. 2340428 2 2

102 CLAMP BUEGEL PIECE D’APUI STAFFA 2340433 1 1

103 SUPPORT HALTERUNG SUPPORT SUPPORTO 2335411 1 1

108 TIMER ZEITSCHALTER TEMPORISATEUR TEMPORIZZATORE 3TMP039 1 1

109 PRESSURE SWITCH DRUCKSCHALTER PRESSOSTAT PRESSOSTATO 3PRS006 1 1

Code-Code

Code-Codice

Pos.

Description - Beschreibung - Description - Descrizione

English Deutsch Francais Italiano

HCU631NO170F

HCU631TO170F

Tav

.n° 18

HCU631

LEGEND - LEGENDE - LEGENDE - LEGENDA :

Page 28

70 Carrier

BA

SONDA TEMPERATURA AMBIENTE

ROOM SENSOR

SONDE CHAMBRE FROIDE

RAUMSONDE

SONDA CAMARA

SONDA TEMPERATURA AMBIENTE

BVR

VARIATORE DI VELOCITA’

SPEED REGULATOR

VARIANT VITESSE

GESCHWINDIG- KEITSREGLER

VARIADOR DE VELOCIDAD

VARIADOR DE VELOCIDADE

BVRS

SONDA VARIATORE VELOCITA’

SPEED REGULATOR SENSOR

SONDE VARIATEUR VITESSE

GESCHWINDIGKEITSREGLERSONDE

SONDA VARIADOR VELOCIDAD

SONDA VARIADOR DE VELOCIDADE

CPM

MODULO PROTEZIONE COMPRESSORE

COMPRESSOR PROTECTION CARD

FICHE PROTECTION COMPRESSEUR

KOMPRESSORSCHUTZKARTE

MÓDULO PROTECCIÓN COMPRESSOR

MÓDULO DE PROTEÇÃO DO COMPRESSOR

E1

RESISTENZA CARTER COMPRESSORE

M1

COMPRESSOR CRANKCASE HEATER

RESISTANCE CARTER COMPRESSEUR

KOMP.-ÖLSUMPFHEIZUNG

RESISTENCIA DEL CARTER DEL COMPRESOR

RESISTêNCIA DO CARTER COMPRESSOR M1

F1

FUSIBILE COMPRESSORE M1

COMPRESSOR Nr.1 FUSE

FUSIBLE COMPRESSEUR Nr.1

KOMPRESSORSICHERUNG (Nr.1)

FUSIBLE COMPRESOR Nº1

FUSíVEIS DO COMPRESSOR M1

F13

FUSIBILE MONITOR

VOLTAGE REGULATOR FUSE

FUSIBLE MONITOR

MONITORSICHERUNG

FUSIBLE MONITOR

FUSíVEIS DO MONITOR

F1T

RELE’ TERMICO COMPRESSORE M1

COMPRESSOR OVERLOAD RELAY M1

RELAIS THERMIQUE COMPRESSEUR

M1

KOMPR.-THERMORELAIS M1

RELE’TERMICO COMPRESOR M1

RELÉ TÉRMICO DO COMPRESSOR M1

F1TR

TERMISTORE COMPRESSORE M1

COMPRESSOR M1 THERMISTOR

THERMISTEUR COMPRESSEUR M1

KOMPRESSORTHERMISTOR (M1)

TERMISTOR COMPRESOR M1

TERMISTOR COMPRESSOR M1

F20

FUSIBILE AUSILIARIO

AUXILIARY FUSE

FUSIBLE AUXILIAIRE

HILFSICHERUNG

FUSIBLE AUXILIAR

FUSíVEIS AUXILIARES

F5

FUSIBILE VARIATORE VELOCITA’

SPEED REGULATOR FUSE

FUSIBLE VARIATEUR VITESSE

GESCHW.-REGLERSICHERUNG

FUSIBLE VARIADOR VELOCIDAD

FUSíVEL DO VARIADOR DE VELOCIDADE

F5TK

TERMOCONTATTO VENTOLA COND. M5

CONDENSER FAN SAFETY OVERLOAD CONTACT(M5)

THERMOCONTACT PROTECTION VENTILATEUR CONDENSEUR M5

THERMOKONTAKT ZUM KOND.-VENTILATORSCHUTZ (M5)

TERMOCONTACTO PROTECCION VENTILADOR CONDENSADOR M5

TERMOCONTATO DO VENTILADOR

COND. M5

F6

FUSIBILE VENTOLA CONDENSATORE

CONDENSER FAN FUSE

FUSIBLE VENTILATEUR CONDENSEUR

KOND.-VENTILATORSICHERUNG

FUSIBLE VENTILADOR CONDENSADOR

FUSíVEL DO VENTILADOR DO CONDENSADOR

F6TK

TERMOCONTATTO VENTOLA COND. M6

CONDENSER FAN SAFETY OVERLOAD

CONTACT(M6)

THERMOCONTACT PROTECTION VENTILATEUR CONDENSEUR M6

THERMOKONTAKT ZUM KOND.-VENTILATORSCHUTZ (M6)

TERMOCONTACTO PROTECCION VENTILADOR CONDENSADOR M6

TERMOCONTATO DO VENTILADOR

COND. M6

FM

MONITOR

VOLTAGE REGULATOR

MONITOR

MONITOR

MONITOR

MONITOR

FMF

MAGNETOTERMICO

THERMOMAGNETIC SWITCH

INTERRUPTEUR MAGNETOTHERMIQUE

THERMOMAGNET- SCHALTER

INTERRUPTOR MAGNETOTERMICO

DISJUNTOR

FTA

TERMOSTATO AMBIENTE

ROOM THERMOSTAT

THERMOSTAT CHAMBRE

RAUMTHERMOSTAT

TERMOSTATO AMBIENTE

TERMOSTATO AMBIENTE

K1

TELERUTTORE COMPRESSORE M1

(Part-winding)

COMPRESSOR M 1 CONTACTOR ( Part

winding )

TELERUPTEUR COMPRESSEUR M 1 (

Part -winding )

KOMPRESSORFERNSCHALTER M 1

(Teilwicklung)

CONTACTOR COMPRESOR M 1 ( Partwinding )

INTERRUPTOR COMPRESSOR M1

(Part-winding)

K39

TIMER LIMITATORE MANOVRE

COMPR.CONTROL TIMER

TIMER CONTROLE COMPRESSEUR

KOMPR.-KONTROLLZEITREGLER

TEMPORIZADOR CONTROL COMPRESOR

TIMER LIMITADOR DE OPERAÇãO

K5

TELERUTTORE VENTOLA CONDENSATORE M5

CONDENSER FAN CONTACTOR M 5

TELERUPTEUR VENTILATEUR CONDENSEUR M 5

KOND.-VENTILATORFERNSCHALTER

( M 5)

CONTACTOR VENTILADOR CONDENSADOR M 5

INTERRUPTOR VENTILADOR DO CONDENSADOR M5

K6

TELERUTTORE VENTOLA CONDENSATORE M6

CONDENSER FAN CONTACTOR M 6

TELERUPTEUR VENTILATEUR CONDENSEUR M 6

KOND.-VENTILATORFERNSCHALTER

(M 6)

CONTACTOR VENTILADOR CONDENSADOR M 6

INTERRUPTOR VENTILADOR CONDENSADOR M6

KP1MX

RELE’ AUSILIARIO PRESSOSTATO VENTOLA COND.

PRESSURE SWITCH

AUX.RELAY(COND.FAN)

RELAIS AUX. PRESSOSTAT

(VENT.COND.)

PRESSOSTATHILFRELAIS(KOND.-VENTIL.)

RELE’

AUX.PRESOSTATO(VENTIL.COND.)

RELÉ AUXLIAR PRESSOSTATO VENTILADOR COND.

KP2MX

RELE’ AUSILIARIO PRESSOSTATO VENTOLA COND.

PRESSURE SWITCH AUX.RELAY

(COND. FAN)

RELAIS AUX. PRESSOSTAT (VENT.

COND.)

PRESSOSTATHILFRELAIS (KOND.-VENTIL.)

RELE’ AUX. PRESOSTATO (VENTIL.

COND.)

RELÉ AUXLIAR PRESSOSTATO VENTILADOR COND.

M1

MOTORE COMPRESSORE nº1

COMPRESSOR MOTOR Nr.1

MOTEUR COMPRESSEUR Nr.1

KOMPRESSORMOTOR Nr.1

MOTOR COMPRESOR Nº1

MOTOR COMPRESSOR nº1

M5

MOTORE VENTOLA CONDENSATORE

nº1

CONDENSER Nr.1 FAN MOTOR

MOTEUR VENTILATEUR CONDENSEUR

Nr.1

KOND.-VENTILATORMOTOR Nr.1

MOTOR VENTILADOR CONDENSADOR

Nº1

MOTOR VENTILADOR CONDENSADOR

nº1

M6

MOTORE VENTOLA CONDENSATORE

nº2

CONDENSER Nr.2 FAN MOTOR

MOTEUR VENTILATEUR CONDENSEUR

Nr.2

KOND.-VENTILATORMOTOR Nr.2

MOTOR VENTILADOR CONDENSADOR

nº2

MOTOR VENTILADOR CONDENSADOR

nº2

P1MX

PRESSOSTATO INSERZIONE VENTOLA

COND.

COND. FAN STARTING PRESSURE

SWITCH

PRESSOSTAT MISE EN MARCHE VENTILATEUR COND.

KOND.-VENTILATORANLAUFPRESSOSTAT

PRESOSTATO INSERCION VENTILADOR COND.

PRESSOSTATO ACIONADOR VENTILADOR COND.

WIRING DIAGRAM - SCHALTPLAN - SCHEMA ELETRIQUE - LEGENDA SCHEMA ELETTRICO

Page 29

Carrier 71

P2MX

PRESSOSTATO INSERZIONE VENTOLA

COND.

COND.FAN STARTING PRESSURE

SWITCH

PRESSOSTAT MISE EN MARCHE VENTILATEUR COND.

KOND.-VENTILATORANLAUFPRESSOSTAT

PRESOSTATO INSERCION VENTILADOR COND.

PRESSOSTATO ACIONADOR VENTILADOR COND.

PMI

PRESSOSTATO BASSA PRESSIONE

L/P SWITCH

PRESSOSTAT BASSE PRESSION

NIEDERDRUCKPRESSOSTAT

PRESOSTATO BAJA PRESION

PRESSOSTATO BAIXA PRESSãO

PMX

PRESSOSTATO ALTA PRESSIONE

H/P SWITCH

PRESSOSTAT HAUTE PRESSION

HOCHDRUCKPRESSOSTAT

PRESOSTATO ALTA PRESION

PRESSOSTATO ALTA PRESSãO

PO

PRESSOSTATO OLIO

OIL PRESSURE SWITCH

PRESSOSTAT HUILE

ÖLPRESSOSTAT

PRESOSTATO ACEITE

PRESSOSTATO óLEO

Q1

INTERRUTTORE GENERALE

MAIN SWITCH

INTERRUPTEUR GENERAL

HAUPTSCHALTER

INTERRUPTOR GENERAL

INTERRUPTOR GENERAL

S3

INTERRUTTORE PRERISCALDO/ ARRESTO/ MARCIA COMPRESSORE

COMPR. PRE-HEATING/STOP/ RUN SWITCH

INTERRUPTEUR PRECHAUFFAGE/ ARRET/

MARCHE COMPR.

KOMP.-VORWÄRMEN. / ‘AUS’/’EIN’ SCHALTER

INTERRUPTOR PRECALENTAMIENTO/ PARADA/

MARCHA COMPR.

INTERRUPTOR PREAQUECIMENTO/ ARRESTO/

MARCHA COMPRESSOR

X

MORSETTIERA-CONNETTORE

TERMINAL BOARD-CONNECTOR

PLAQUE DE JONCTION-CONNECTEUR

KLEMMKASTEN-VERBINDER

REGLETA-CONECTOR

TERMINAL-CONECTOR

Page 30

72 Carrier

NNOOTTEE ((NNOOTTEESS)) :

:

Page 31

Carrier 73

NNOOTTEE ((NNOOTTEESS)) :

:

Page 32

0MAN090/C del 04/2001

Loading...

Loading...