Carrier FX4BNF048000AAAA, FX4BNF018000AAAA, FX4BNB060000AAAA, FX4BNF042000, FX4BNF036000 Installation Guide

...Page 1

Installation Instructions

Direct Expansion Fan Coil Units

For Puron® Refrigerant

J

FX4B

J

Ag8023

Fig. 1--Model FX4B

NOTE: Read the entire thstraction malmM before star_thg the thstallation.

_is symhol ,_ indicates a change sirice the last issue.

SAFETY CONSIDERATIONS

Improper installer thn, adj ustmeitt, _dtcl ation, service, maintenance, or use can cause explosion, fire, electrical shock, or othel conditions which may

cause personal injury or property damage¸ Consul_ a qLlalified installer, service agency, or yoLlr distributor or branch for in fonnatthn or assis_nce

_e qtl_lified installer or agency must Llse factory-atlthorized ki_ or _ccessories witch modifying this pl_dLIc t Refer 1o the individual instructions

packaged with kits or accessories witch instaIlthg

Follow all safety codes¸ Wear safety glasses and work gloves¸ Use quenching cloth for brazing opel-at ions Have fire extinguisher available¸ Read

these instructions thoroughly aod follow all warnings or cautions attached 1o the unit. Consult local building codes and National Electrical Code

(NEC) for special requirements

Recognize safety information This is the safoty-aler_ synthol _ When you see this symbol on the unit _od in instructions manuals, be alert 1o

the polential for personal iniury

Form: IM-FX4B-02 Cancels: IM-FX4B-01 Printed in U.SA 6-03 Catalog No. 63FX481

Page 2

POWER ENTRY_ SUPPLIED

OPTIONS_& SUPPLYDUCT

0t8,030-048 21dN.

060 24qN FRONT SERVICE

UPFLOW/DOWNFLOW -- -

CLEARANCE

SECONDARYO ,N

UPFLOW/DOWNFLOW J

PRIMARYDRAIN

SECONDARY DRAIN

ENTRY

OPTIONS

UNff A

018 12IN.

030 171N

036 191N

FIELD MODIFIED

A SIDE RETURN

2 _/2_ SLOPE COIL

LOCATION FOR

UNITS ONLY

PRIMARY DRAIN

FIELD SUPPLIED

RETURN PLENUM

A00415

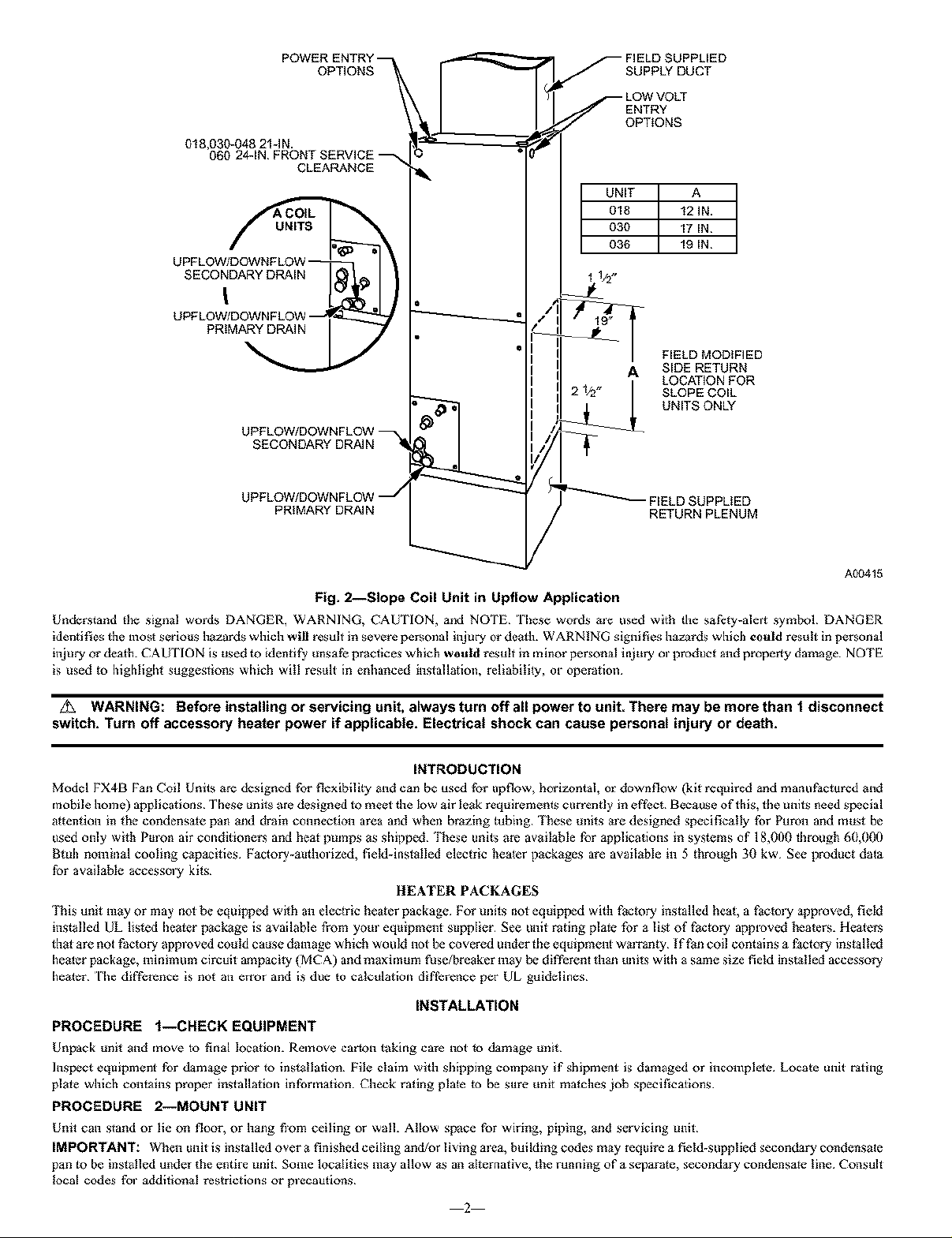

Fig. 2--Slope Coil Unit in Upflow Application

Understand the signal words DANGER, WARNING, CAUTION, and NOTE l'imse words me used with the safety-alm_ symbol DANGER

identifies the most serious hazards which will result in severe personal injury or dealh. WARNING sight fies hazards which could result in personal

m_ury or death. CAUTION is used m identify unsafe practices which would result in miner personal injury ol prcduct and properly damage NOTE

is used to highlight suggestions which will result in enhanced instafafon, reliabitgy, or opemfon

WARNING: Before installing or servicing unit, always turn off all power to unit. There may be more than t disconnect

switch. Turn off accessory heater power if applicable. Electrical shock can cause personal injury or death.

INTRODUCTION

Model FX4B Fan Coil Units are designed for flexibility and can be used for upfiow, horizontal, or down flow (kit required and manuPactured and

mobile home) applications These units are designed to meet the low air leak requirements currently in e fi'eet Because of this, the units need special

attention in the condensate pan and drain connection area and when brazing tubing These tlnits ale designed specifically for Puron and must be

used only with Pmon air conditioners and heat pinups as shipped "l_ese units are available for applications in systems of 18,000 through 60,000

13tuh nominal cooling capacities Pactory-autholized, feId-instMled electric beater packages are available in 5 through 30 kw See prcduct data

for available accesso W kits

HEATER PACKAGES

I_ds unit may or may not be equipped with an electric heater package For ungs not equipped with l_ack_ry installed heah a factory approved, field

instadled UL listed heater package is available Prom yam equipment supplier See unit rating plate for a list of l_actory approved beaters. Healers

that are not Paetory approved could cause damage which would not be covered under the equipment wm_an_y/f l_n coil contains a factory installed

hemer package, minimum circuit ampacfly (MCA) and maximum fuse/breaker may be different than units with a same size field installed accessory

healer fhe difference is not an er;or and is due to calculation difl'_rence per UL guidelines

INSTALLATION

PROCEDURE f--CHECK EQUIPMENT

Unpack t_ng and move to final location. Remove car[on laking care not to damage t_nit

Inspect equipment for damage prior to instaIlaflen File claim with shipping company if shipment is damaged or incomplete Locate unit raflng

plate which contains proper installation information Check rating plate to be sure unit matches job specifications

PROCEDURE 2--MOUNT UNIT

Unit can stand or lie on floor, or hang fiom ceiling or wall. Allow space for wiring, piping, and servicing mdt

IMPORTANT: When unit is installed over a finished ceiling and/or living mea, building cedes may require a field-supplied secondary condensate

pan _o be inslalled under the entire unik Some lecaliges may allow as an alternafve, file running of a separate, secondary condensate line Consult

local cedes fol additional restrictions or plecautions

2

Page 3

A. Upflow Installation

If return air is to be dueled through a floor, sc'l unit on flOOl over opening and use 1/8- to I/d-in thick fireproof resilient gasket between duct, unit,

and floor

Side return is a field option on slope coil models ("ut opening per dimensions (See Pig. 2) A fleld-seppbed botlom closure is required

B. Downflow Installation

I11this applicaflon, field conversion of tile evaporator is required using accessoly do_snflow kit along with ari accessory base kit Use fireproof

resilient gasket, 1/8- to l/4-in thick, between duct, unit, and floor.

NOTE: IZ_ convert ulgts for downflow epplicaflons, refer to Installation lnslruc_ions supplied with kit fol proper installation. FOl slope _ln coils,

use kit Part No KFADC0201SLP For A Pan coils use kit Par_ No KFADC0401 ACE Use fireproof resilient gasket, 1/8- m l/4-in thick, between

duct, unit, and floor

NOTE: Gasket kit number KFAHD01OISLP is also required for all downflow appbeations to maintain low air leak/low sweat performance.

CAUTION: The conversion of the fan coil to downflow requires special procedures for the condensate drains on both

A-coil and Slope units. The vertical drains have an overflow hole between the primary and secondary drain holes. This hole

is plugged for all applications except downflow, but must be used for downflow. During the conversion process, remove the

plastic cap covering the vertical drains only and discard. Remove the plug from the overflow hote and discard. At completion

of the downfiow installation, caulk around the vertical pan fitting to door joint to retain the low air leak performance of the

unit. Failure to follow this CAUTION coutd result in minor personal injury or product and property damage.

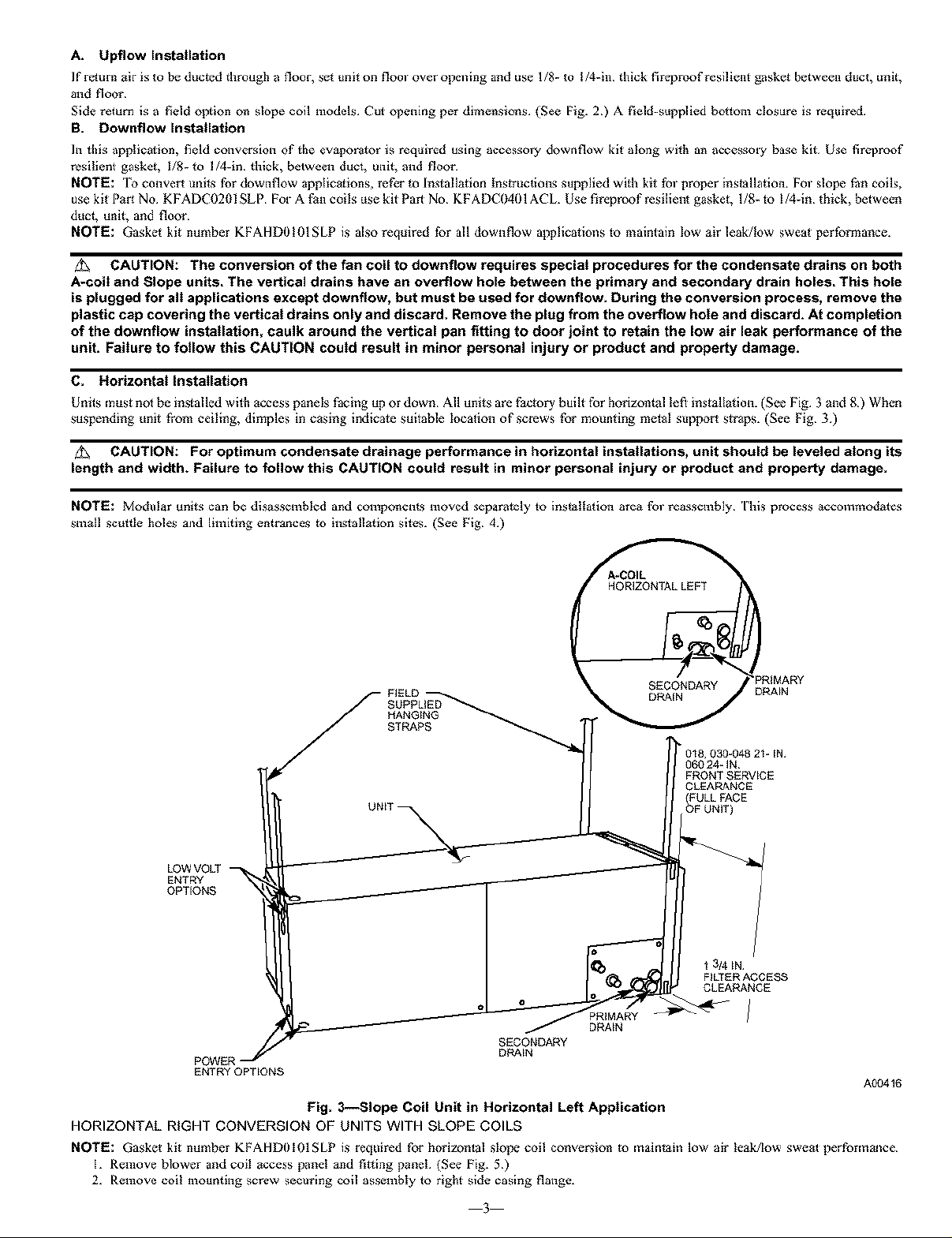

C. Horizontal Installation

Units must not be installed with access panels Pacing up or down All units are factory built for horizontad left installaflon. (See Fig 3 and 8) When

suspending unit from ceiling, dimples in c_sing indicate suitable locagon of screws for mounting metM support straps. (gee Fig 3)

CAUTION: For optimum condensate drainage performance in horizontal installations, unit should be leveled along its

length and width. Failure to follow this CAUTION could result in minor personal injury or product and property damage.

NOTE: Modular units can be disassemhled and componems moved separately to installation area fol reassemhly fhis process accommodates

small scuttle holes and limiting entrances to installation sites. (gee Pig 4)

HORIZONTAL LEFT

SECONDARY PRIMARY

• 0_8,030-048 2_- IN

06024= IN

FRONT SERVICE

CLEARANCE

FULL FACE

_F UNIT i

A00416

ENTRY

OPTIONS

POWER

ENTRY OPTIONS

FIELD _ _RA_N

SUPPLIED

HANGING

STRAp

PRIMARY

DRA_N

SECONDARY

DRA_N

Fig. 3---Slope Coil Unit in Horizontal Left Application

HORIZONTAL RIGHT CONVERSION OF UNITS WITH SLOPE COILS

NOTE: Gasket kit number KFAHDgI01SLP is required for horizontal slope coil conversion to maintain low air leak/low sweat performance

t. Remove blower and coil access p;meI and fi_flng panel (See Pig. 5)

2. Remove coil mounting screw securing coil assembly 1o right side casing flange.

3

Page 4

BLOWERBOX

-2SCREWS

BRACKET

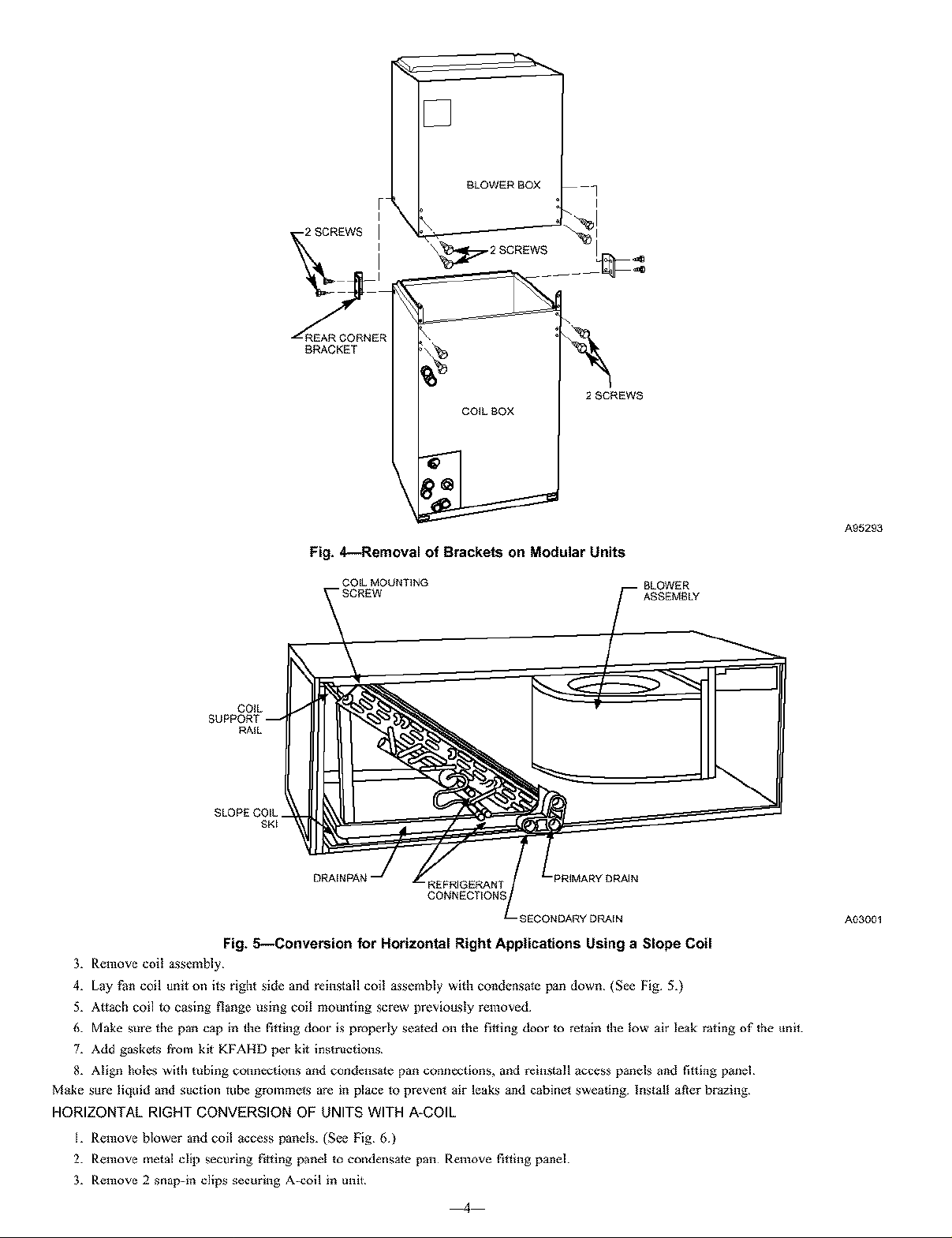

Fig. 4--Removal of Brackets on Modular Units

I

I

CORNER

COIL MOUNTING

- SCREW

_2SCREWS

COILBOX

r\

2SCREWS

Ag5293

-SECONDARYDRAEN

Fig. 5--Conversion for Horizontal Right Applications Using a Slope Coil

3. Remove coil assembly

4. L;ly _llt coil unit o11 its right side and reinstall coit assembly with condensate pan down (See Fig 5.)

5. Attach COil to casing flange using coil mounting screw previously removed

6. Make sine tile pan cap in the fitting door is properly seated on the fitting door to retain the low air leak rating of the unit.

7. Add gaskeI_ from kit KFAHD per kit instructions

8. Align holes with tubing connections and condensate pan connections, and reinstall access panels and filling panel

Make sure liquid and suction tube grommets are in place Io prevent air leaks and cabinet sweating. Install after br_aTing

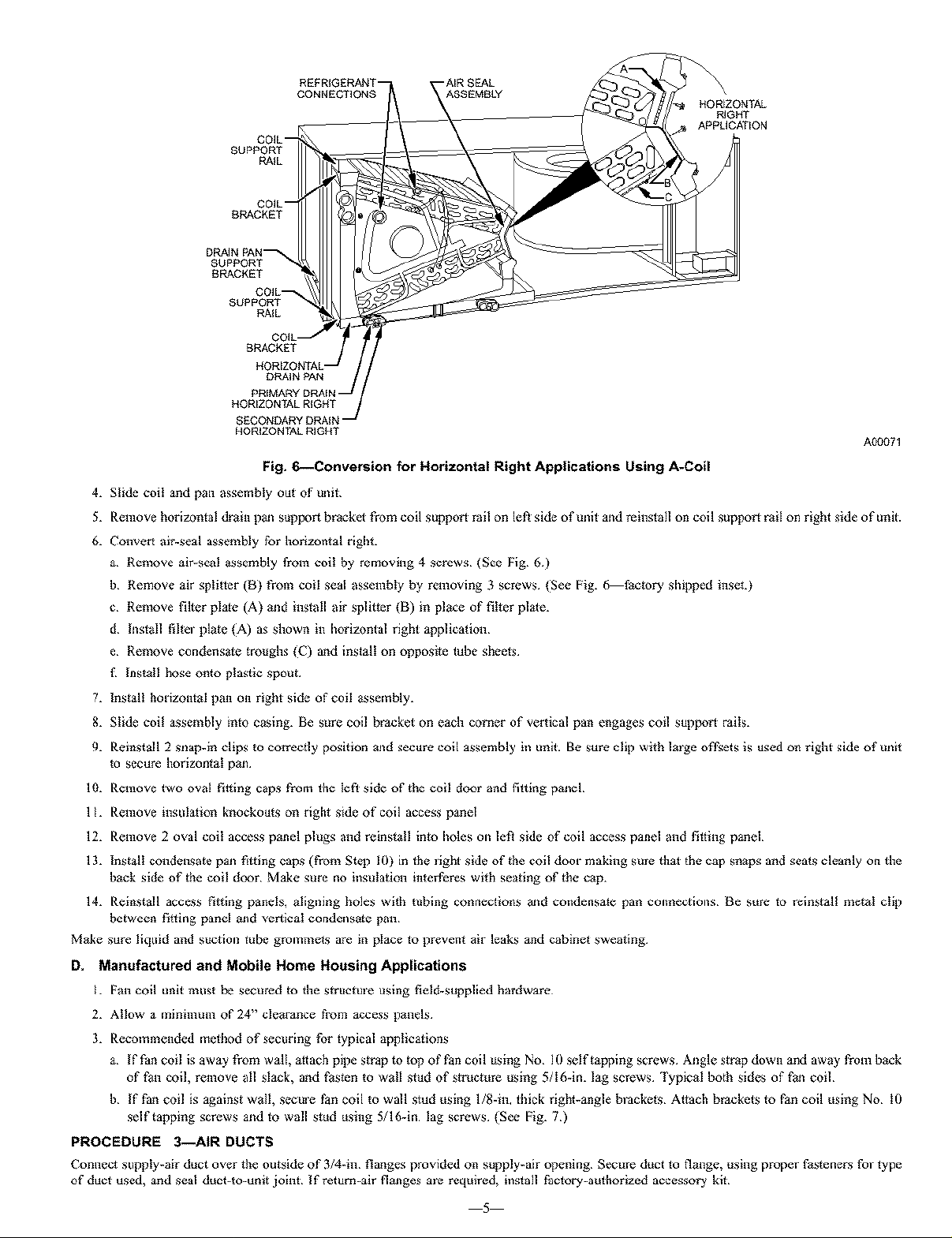

HORIZONTAL RIGHT CONVERSION OF UNITS WITH A-COIL

1+ Remove blower and coil access panels. (See Fig 6)

2. Remove metal clip securing fitting panel to condensale pan Remove fitting panel

3. Remove 2 snap-in clips securing A-coil in unit

A03001

Page 5

CONNECTIONS

SUPPORT

RAiL

HORIZONTAL

RIGHT

APPLICATION

BRACKET

DRAINpAN

HORIZONTAL RIGHT

SECONDARy DRAIN

-AIRSEAL

HORIZONTAL RIGHT

Fig. 6--Conversion for Horizontal Right Applications Using A-Coil

4. Slide coil and pan assembly out of mlg.

5. Remove horizomal drain pan support bracket from coil suppor_ rail on leR side of unit and reinslall on coil suppor_ rail on right side of unit.

6. Convert air-seal assembly for horizontal right.

a Remove air-seal assembly from coil by removing 4 screws (See Fig 6)

b Remove air splgler (B) Prom coil seal assembly by removing 3 screws {See Fig. 6 factor3, sldpped inseL}

c Remove filler plate (A) and install air splitter (B) in place of filter plale.

d Inslall fihm plate {A) as shown in I_orizontal right applicagon

e Remove condensate troughs {C) and install on opposite tube sheels

f Install hose onto plastic spout

7. Install hodzomal pan on right side of coil assembly.

8. Slide coil assembly into casing. Be sure coil bracket on e_h comer of vertical pan engages coil suppor_ raiix

9. Reinstall 2 snap-in clips to correcqy position and secure coil assembly in unit. Be sure clip with lmge ofl2set s is used on right side oPmlg

to secure horizontal pan

lO. Remove lwo oval fil_ing caps from the left side of the coil door and filfing panel

11. Remove insulation knockouts on right side of coil access panel

12. Remove 2 oval coil access panel plugs and reinstall into I_oles on leR side of coil access panel and filling panel

13. Install condensate pan fitting caps (from Sic't) 10) in lhe light side of gte coil door making sine that the cap snaps and seats cleanly on the

back side of the coil door Make sure no insulation interferes with seating of the cap.

14. Reinstall access fil_ing panels, aligning holes wgh tubing connections and condensate pan collnectiolls _e sure Io reinstall metal clip

between fitting panel and vertical condensate pan

Make sure liquid and suction tube grommets are in place Io prevent air leaks and cabinet sweating.

D, Manufactured and Mobile Home Housing Applications

1. Pan coil unit must be secured to the s_ructme using field-supplied hardware

2. Allow a minimum of 24" clearance from access panels

3. Recommended mefllod of securing for typical appticagons

a If Fan coil is away from walt, attach pipe s_rap to top of Pan coil using No 10 self tapping screws Angle strap down and away from back

of l_on coil, remove all slack, and l_osten to wail stud of s_ructure using 5/I6-in. lag screws Typical both sides of l_on coil

b If fan coil is against wail, secme Pan coil to wall stud using l/8-in, ddck right-angle b_ackets Attach brackels 1o fan coil using No 10

self tapping screws and m wall stud using 5/16-in lag screws {See Fig. 7)

PROCEDURE 3--AIR DUCTS

Connect supply-air duct over the (mtside of 3/d-in flanges provided on supply-air opening Secrete duct 1o flange, using proper Pasteners fol type

of duct used, and seal duct-to-unit joint If return-air flanges ale required, inslall Paclory-a_thorized accessory kit

5

A00071

Page 6

4" MAX

SECURE FAN COIL TO STRUCTURE

UNETAWAY FROM WALL

P_PE STRAP

(TYPICAL BOTH SIDES I

OR

_184N THICK ANGLE

MOUNTING BRACKET

(TYPICAL BOTH SIDES)

DOWN FLOW

_,_ SECURE UNITTO FLOOR

ANGLE BRACKET OR PIPE STRAp

(KFACB)

4"MAX

A02003

Fig 7--A-Coil

use flexible conn_lors between ductwork and unit 1o plevent transmission ef vibration Wbeit elecrdc beatel is instafied, use beal-]esistant material

for flexible connector belween duclwork and unit at discbarge connecgon Ductwerk p_ssing tilrough tlnconditioned space must be insulated and

covered with vapor barrier

Units equipped with 20-30kw electric beaters require a l-in cleat'.nee 1o combustiMe materials for the first 36 in of sopply duct,

A. Ductwork Acoustical Treatment

Metal duct systems dlat do not ilave a 90 ° elbew and 10 fi of main duct to first branch t_keo fl" m_y require int elTial acoustical insulaflon lining

As an a]telal_flve, fibreus ductwerk m_y be used if consm_cted and installed in accord;lnce with the latest cdflion ef _MACNA COllStrllcgon

standard on fibreus gl_ss ducts Botil _lcoustical lining and fibrous ductwork shall comply with N_flona] Fire Protection Association as tested by

UL Standard 181 for Class I air duels

PROCEDURE 4--ELECTRICAL CONNECTIONS

All producls from the fectory utilize _1printed-circuit b_md (PCB) which has a low voltage circuit pint.five pose (5 amp), Pan reeler speed tap

selecflon terminal (SPT), _lod time delay relay (TDR) jumpel To disable the TDR feature, sever the jumper wire JWI (See Fig q )

When a Pactory-approved accessory control package h_s been installed, check all Paclory wiring per unit wiring diagram and inspect l_actory wiring

connections to be sine none were loosened in transit or installation. If a difl_rent control package is required, see unit rating plale.

_& CAUTION: If a disconnect switch is to be mounted on unit, select a location where dritl or fastener will not contact

electrical or refrigerant components. Failure to follow this CAUTION could result in minor personal injury or product and

property damage,

IBefore proceeding wflh efect]icM connections, make certain thai supply voltage, frequency, phase, and ampac fly me as specified on the unit ragng

plate. See unit wiring label for proper field high- and few-vol_ge wiring¸ Make all electrical connections in accordance with the NEC aod any

local codes or erdinpa_ces _bat may apply¸ Use copper wire only¸

_e unit must have a sep_trale bmncb electric circuit with a field-soppliod disconnect sw flcb located within sight from and readily accessible from

the unfl

On units with a faclory installed disconnect with pull-out removed, service and maintenance can be safely performed o11 only the load side of the

control package.

_ WARNING: Field wires on the line side of the disconnect found in the fan coil unit remain live, even when the pull-out

is removed. Service and maintenance to incoming wiring can not he performed until the main disconnect switch (remote to

the unit) is turned off. Faiture to do so will result in electrical shock causing personal injury or death,

A. Line Voltage Connections

]f unfl contains _lecessory electric heater, remove and discard power plug from Pall coil _nd connect male plug Prom healer to female plug from

unit wiring harness. (See Elecrdc Heater Installagon festructions )

For units without electric beat:

1. Connect 208/23fly power leads Prom field disconnect 1o yellow and black slripped leads

2. Connect ground wire to unfl ground lug

Page 7

FACTORY SH_PPED CO IL

HORIZONTAL LEFT

APPMCATEON

CO_L

SUPPORT

-- RAiL

DRA_N pAN

SUPPORT

HORIZONTAL

DRA_N PAN

AIR SEAL

-- HORIZONTAL LEFT

REFRIGERANT

CONNECTIONS

PRIMARY DRAIN

SECONDARY DRAIN

HORIZONTAL LEFT

Fig. 8--A=Coit in Horizontal Left Application (Factory Ready)

C8

R10_

R7

<z >

A00072

F1

z_-

F

A03010

Fig 9--Fan Coil Printed-Circuit Board

NOTE: Units installed without eleclric heat should have a field-supplied si_eetmetal block-off'plate covering the healer opening This will reduce

air leakage and fom_afion of exterior condensation.

B, 24v Control System

CONNECTION TO UNiT

Wire low voltage in accordance with wiring label on the blower. (See Fig. l0 through 15,} Use no. I8 AWG color-coded, insulated (35°C

mimmum) wire to make the low-voltage connecgons between the thermostat, tile trait, and tile outdoor equipment, If the tbermostat is located more

than 10O ft from the _nit (as measured along the low-voltage wire), use No 16 AWG color-ceded, insulated (35°C minimum) wire All wiring

must be NEC ('lass I and must be separated from inconfing power leads

Refer to outdoor unit wiring instructions for any additional wiring procedure recommendagons.

TRANSFORMER INFORMATION

Transformer is Pactory-wired for 230v operation. For 208v applications, disconnec_ the black wire from the 23gv terminal on transformer and

connect it 1o the 208v terminal (See Fig 15)

HEATER STAGING

z_ CAUTION: If W2, W3, and E on any 3 stage heater (t8, 20, 24, or 30kw), are individually connected as with outdoor

thermostats or any other situation, emergency heat relay must be used. This relay is in kit Part No. KNAOTO20tSEC and is

normally used with kit Part No. KHAOT03Ot FST for 2 outdoor thermostat system. Failure to follow this CAUTION could result

in minor personal injury or product and property damage,

7

Page 8

THERMOSTAT (CONTROL)

FAN COIL

] WHT WHT W2

BLU W3

Fig, 1S--Wiring Layout Air Conditioning Unit

(Cooling Only)

FAN CelL

THERMOSTAT (CONTROL)

AiR COND

A94058

E

AIR COND

Fig. it--Wiring Layout Air Conditioning Unit

(Cooling and t-Stage Heat)

I]te controls ale factoly circuited for single-stage operation Fo] 2-stage operation, use outdo, or thennostal kit Par_ No KHAOT030I FST, and for

3-stage use both kits Pm_ No. KHAO'] 02OlSEC _ed KHAOT0301FST

When 2 stages me desired, cut W3 at the W2 wire nut, strip and reconnect per d_e thermostat kit instruction (See Fig. 13) When 3 stages are

desired, cut the W2 wire nut Off and discard Strip W2, W3, znd E and reconnect per thermostat kit inslrucgons. (See Fig lb)

NOTE: When 3 stages are used or znytime the E terminal is not tied to W2, tile emergency hezl relay, part of outdoor kit Part No

KHAOT0201SEC must be used

--_ C, Manufactured Housing

In M_nuPactured Housing applications, ti_e ('ode of Pedel_at Regulations, ride 24, Chapter XX, Pm_ 3280714 requires th_ supplemented electric

ile_t be locked out at outdoor temperatures above 40 dog P, except re1 a ileal primp defrost cycle. Refer 1o Fig 14 re1 typicM low vob_ge wiring

with oudoor thermostat

D. Ground Connections

WARNING: According to NEC, ANSI/NFPA 70, and local codes, the cabinet must have an uninterrupted or unbroken

ground to minimize personal injurJ if an electrical fault should occur. The ground may consist of electrical wire or metal

conduit when installed in accordance with existing electrical codes, if conduit connection uses reducing washers, a separate

ground wire must be used. Failure to follow this warning could result in electric shock, fire, or death.

A94059

NOTE: Use UL-listed conduit and conduit connector for connecgng supply wire(s) to unit to obtain proper grounding. Grounding may also be

accomplished by using grounding lugs provided in control box

E, Minimum CFM and Motor Speed Selection

Units with or without electric heaters require a minimum C'FM Refer to the unit wiring label to ensure that tile Pall speed selected is not lower

th_n the minimum P_n speed indicated

Page 9

THERMOSTAT {CONTROL)

FAN COIL

HEAT PUMP

(CONTROL)

L;_ R

L;_ c

[_ WH] W2

[]

BLU W3

L_ N2

Z:q o

L:q y

Fig. t2--Widng Layout Heat Pump Unit

(Cooling and 2-Stage Heat with No Outdoor Thermostat)

THERMOSTAT

_ R _ R

FAN COIL

{CONTROL) HEAT PUMP

-- (CONTROL1

_G

c:ko

WH1 W2

[]

[]

[_ BLU W30DTS

o

A94060

L_ y

A_I

Fig. t3--Widng Layout Heat Pump Unit

(Cooling and 2-Sfage Heat with 1 Outdoor Thermostat)

THERMOSTAT FAN COiL

(CONTROL)

HEAT PUMP

(CONTROL)

R

__ c

W_

[]

[]

[]

Fig. 14---Wiring Layout Heat Pump Unit

(Cooling and 2-Stage heat for Manufactured Housing)

P_n speed selection is done _t file Pan relay primed-circuit b_lmd "l_ change motor speeds, disconnect l_an lead used o11 relay temtinal (SPT) and

rephlce with motor speed tap desired. (See Fig 17.) Save insui_gng cap _nd place on motor lead removed from relay

NOTE: In low static applications, lower molol speed tap should be used to reduce possibility of waler being blown off coil

9

S

w2

O

A03088

Page 10

_HE_MOS_A_ {CONTROL} HEAT PUMP

_AN COIL

W2 _ W

_MERG_NCY HEAT REtAY

{CONTROL I

Fig. tS--Wiring Layout Neat Pump Unit

(Cooling and 2-Stage heat with 2 Outdoor Thermostats)

BRN

A94062

A94067

Fig. 1&--Transformer Connections

All unils have 3 motor speed taps. lx)w speed (red) is designed for mismatch outdoor unit applications Medium speed {blue) is designed for

straight matched operagons High s_eed (biack) is used with high external static duct s_tems of straight malcbed systems¸

PROCEDURE 5--REFRIGERANT TUBING CONNECTION AND EVACUATION

Use accessory tubing package o] field-supplied tubing of refrigerant grade Suction tube must be insulated. Do not use damaged, dirly, or

contaminated tubing because it may plug refrigerant grade Suction tub_ must be insulated Do not use damaged, dirty, or contaminated tubing

because it may plug refrigerant flow-control device ALWAYS evacuate the coil and fieid-suppbed tubing before opening outdoor unit service

Valves

Z_ CAUTION: A brazing shield MUST be used when tubing sets are being brazed to the unit connections to prevent

damage to the unit surface and condensate pan fitting caps. Failure to follow this CAUTION could result in minor personal

injury or product and property damage.

Units have sweat suction and bquid tube connections. Make suction tube connection first.

1. Cut tubing to correct lengg_.

2. Insert tube illtO sweat connection on unit until it bottoms

3. Braze connection using silvm bearing or non-silver beming brazing materials. Do not use solder (materials which melt below 800°F)

Consult local cede requirements

CAUTION: Wrap a wet cloth around rear of fitting to prevent damage to TXV and factory-made joints. Failure to follow

this CAUTION could result in minor personal injury or product and property damage.

4. Evacuate coil and tubing system 1o 500 microns using deep vacuum me,bed.

Page 11

_FAN DEC_

Fig. t7--Fan Coil Relay and Speed Tap Terminal

PROCEDURE 6--REFRIGERANT FLOW-CONTROL DEVICE

{]te FX4B is equipped with a Puron fXV Use outdoor units designed for Preen only.

PROCEDURE 7--CONDENSATE DRAINS

A97529

CAUTION: The conversion of the fan coil to downflow requires special procedures for the condensate drains on both

A-colt and Slope units. The vertical drains have an overflow hole between the primary and secondary drain holes. This hole

is plugged for all applications except downflow, but must be used for downflow. During the conversion process, remove the

plastic cap covering the vertical drains only and discard. Remove the plug from the overflow hote and discard. At completion

of the downflow installation, caulk around the vertical pan fitting to door joint to retain the low air leak performance of the

unit. Failure to follow this CAUTION coutd result in minor personal injury or product and property damage.

To connect draths the cap openings must be removed Use a knife to start the opening near the tab and using pliers, poll the tab lo remove the

disk. Clean the edge of the opening if necessary and instail the condensate tine Finally caulk around the lines where they exit the fitting to retain

the Iew leak rating of the mlit

Units are equipped with primary and secondary 3/4-in FPT drain connections¸ For proper condensale ithe instailations see Fig 2, 3, 5, 6, and 8

To prevent property damage and achieve opgnmm drainage performance, BOTH primary alld secondary drath gnes should be instaiIed arid include

properly-sized condensate traps¸ (See Fig. 18 and 20) Factory-approved condensate traps are avadabie, It is recommended tha_ PVC fittings be

used o11 the piastic condensate pan Finger_tigthen plus I_1/2 turns¸ Do no_ over_tigllten Use pipe dope¸

/_ CAUTION: Shallow, running traps are inadequate and DO NOT allow proper condensate drainage. (See Fig. t9.)

Failure to follow this CAUTION could result in minor personal injury or product and property damage.

NOTE: When connecting condensate dr_ain lines, avoid blocking filter access panel, thus preventing filler removal Afler connection, pdme both

primary and second_]y condensate h'aps.

NOTE: !f unit is located in or above a living sp_e where d_mage may result from condensate overflow, a field-supplied, external condensate

pan sbould be installed underneath the entire unit, and a secondary condensate line {with approprialc trap) should be run from the unit into the

pan Any condensate ill this external condensate pan sfiould be dl ained _o a noticeable place. As an alternative _o using an external COlldensate pan,

some localities may allow the use of ;1separate 3/d-in condensalc line (with apprepriate trap) to a place where the condensate will be noticeable

{'he owner of the structure must be informed th_l witch condensate flows from the secondary dlain el external condensale pan, the unit requires

servicing or water d_mage will occur

Inst;dl traps in the condensate lines as close to the coil as possible (See Fig 20) Make sine that the outlet of e_h trap is below it connection to

the condensate p_n to prevent condensale from overgowing the dry,in pan Prime all traps, test fol leaks, _nd insulate traps if located above a living

area

C_ndensate dlain lines should be pitched downward at a minimum slop of 1 in for ever?, I0 fi of length

Consult local codes for eddifional restrictions or precautions.

PROCEDURE 8--ACCESSORIES

A. Electronic Air Cleaner

{]te Electronic Air Cleaner m_y be connected to Pan coil as shown in Pig. 21. {]tis method requires a field sopplied transformer See Electronic

Air Cleaner lileralure for kit requirements¸

il

Page 12

UNIT

t

2" MIN

t

2" MIN

Fig, t8--Recommended Condensate Trap

DO NOT USE SHALLOW RUNNING TRAPS!

A03002

Fig. 1g---Insufficient Condensate Trap

B. Humidifier

Connect humidifier and ilumidistal to Fan coil unit as silown in Fig. 22 and Fig. 23 [_te cooling lockout relay is optional (See Fig 24)

A03013

12

Page 13

ACCESS

PANEL

SECONDARY DRA_N WITH

APPROPRIATE TRAp REQUIRED

(USE FACTORY KIT OR

FIELD-SUPPLkED TRAp)

{USE FACTORY KIT OR

F_ELD-SUPPLIED TRAp OF

SUFFICIENT DEPTH

STANDARD P=TRAPS ARE

NOT SUFFiCiENT SEE

FIGURE OF RECOMMENDED

CONDENSATE TRAp)

A03003

Fig* 20--Condensate Drain

PROCEDURE 9--SEQUENCE OF OPERATION

A. Continuous Fan

['hennost_l Closes R to G G energizes fan relay on PCB which comple_es circuit 1o indeor blower motor When G is de-energized, there is a 90

sec delay befot_ rel_y opens

B, Cooling Mode

13temlost_l energizes Rlo G, R to Y, _nd R to O (beat pump only) (3 energizes fro1 relay on PCB whicb completes circuit 1o indoor blower motor

When G is de-energized, lbere is a 90 sec del_y before _an relay opens

C, Heat Pump Heating with Auxiliary Electric Heat

I_tennost_l eriergizes R 1o G, R 1o Y, and R to W G energizes fan relay on PCB whicb compleles ci]ct_it to indoor blower motor W energizes

electric beat rel_y(s) which completes circuit to beater element(s) Wbeit W is de-energized, electric beat rel_y(s) open, turning oil" heater elements

When G is de-e_crgized there is a 90 sec delay befole _alt rel_y opens

D, Electric Heat or Emergency Heat Mode

I_temmstal closes R to W, W energizes electric beat relay(s) which compleles circuit to beater eIementls) Blower mo_or is energized through

normally closed contacts on fan relay When W is de-energized, electric heal relay(s) opens.

13

Page 14

222324

CONTROLBOARD

C C

II

z

208/

TO EAC

FROM MOLEX

PLUG AND

TRANSFORMER

(IN UNIT)

Fig. 2t--Wiring Layout of Electronic Air Cleaner to Fan Coil

3O

A03011

_HE_MOS_AT {CONTROL) H_AT PUMP

_AN COIL

RED {CONTROL)

[_o

BaN C

V_T BLU 2

[] ?

[Z_ Y

A95294

Fig. 22--Wiring Layout of Humidifier

to Heat Pump

Page 15

THERMOSTAT (CONTROL)

FANCOIL

[_ IWHr WHT W2

i BLLJ W3

BRN C AI I_ COND

i

i

[5_ ' ,

L _ .

A95295

Fig. 23--Wiring Layout of Humidifier to Fan Coil

with Electric Heat

SPDT

24VAC COIL

230VAC_5A

TO

DEHUMIDISTAT SPEED SPEED

(OPENS ON R_NSE) MOTOR MOTOR

t LOW

A03012

Fig 24--Latent Capacity Controt

START-UP

Refer to outdoor unil [nstal)ation Instructions for system start-up instructions and refrigerant cbarging method details

CAUTION: Never operate unit without a filter Damage to blower motor or coil may result Factory authorized filter kits

must be used when locating the filter inside the unit. For those applications where access to an internal filter is impractical,

a field-supplied filter must be installed in the return duct system. Failure to follow this CAUTtON could result in minor

personal injury or product and property damage.

CARE AND MAINTENANCE

Ikl continae higb performance and minimize possible eqt_ipment Pailure, it is essential tb_l periodic maintenance be performed ori Ibis equlpmerit

C_nstdt your local dealer as _o tbe proper frequency of maintenance cer_tlact

[]te _lbibty to properly pelform mair_ten_nee oll t|ds equipment reqtdres ee]lain mecbanicaI ski){s and tools [f you do not possess these, contac_

yore dealer fol maintenance []te only consumer service recommended or required if filter replacement or cleaning on a monthly basis

15

Page 16

PIJRON® QUICK REFERENCE GUIDE

FOR INSTALLERS AND TECHNICIANS

• Puron refrigerant operates at 50-70 pel_ent higher pressures thari R-22. Be sure that servicing equipment and

replm:ement components ale designed _o operale x_sith Puron

• Pmon refrigerant cylinders are rose colored.

Recovery cylinder service pressure rating must be 400 psig, D(_F 4BA400 or DO'I Bwq00

Pmon systems should be charged widl liquid refrigeront. Use a commel_ial lype melering device in the manifold hose

Manifold sels should be 750 psig high-side and 200 psig low-side wgh 52g psig low-side retard

Use hoses with 750 psig service pressure rating

Leak delectors should be designed to detect HFC refrigerant

Pmon, as other HFC's, ix only compatible with POE oils

Vacuum pumps will not remove moisture from oil

Do not use liquid-line fiber driers with rated working pressures less than g00 psig

Do not ins_atl a suction-line filter drier in liquid line.

POE oils absorb moisture rapidly Do not expose oil to ammsphere

POE oils may cause d_mage Io certain plastics and roofing malelials

Wrap all fifier dliers and service valves wilh wet cloth when brazing

A liquid-line fil_er drier ix required on every umt.

Do not t_se an R-22 TXV

If indoor unit is equipped wilh an R-22 TXV, it must be changed 1o a Pmon TXV

Never open syslem _o atmosphere while it is t_nder a vacuum

When system must be opened for service, break vacuum with dry nitrogen and replace fifier dliers

Do not vent Pumn into gte almosphere.

Do not use capillary tube indoor coils

Observe all warnings_ cautions and boht lext.

© 2003 CAC/BDP 7310 W Mo_ns St, In(fianapolis, iN 46231 [mf×4b02 16 Book/Tab: 1/4,3d12e Catalog No 63FX-4B1

Loading...

Loading...