Carrier FF1DNE030000AAAA, FF1DNE030005AAAA, FF1DNE030075AAAA, FF1DNE024011AAAA, FF1DNE024000AAAA Installation Guide

...Page 1

Installation Instructions

Direct Expansion

Fan Coil Unit

FF1D

A98329

Fig. 1--FF1D Unit

NOTE: Read the entire instruction manual before starting the installation.

This symbol -_ indicates a change since the last issue.

SAFETY CONSIDERATIONS

hnproper installation, adjustment, alteration, service, maintenance, 02"use can cause explosion, fire, electrical shock, or other conditions which may

cause personal injury or property damage. Consult a qualified installer, service agency, distributor or branch for information or assistance.

Qualified installer or agency must use factory authorized kits or accessories. Refer to individual instructions packaged with kits or accessories

when installing.

Follow all safety codes. Wear safety glasses and work gloves. Read these instructions thoroughly and follow all warning or cautions attached to

the unit. Consult local building codes and National Electrical Code (NEC) for special requirements. Recognize safety information. This is the

safety alert symbol z_ • When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION and NOTE. These words are used with the safety alert symbol. DANGER

identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe practices, which would result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

INTRODUCTION

FFID Fan Coils are designed with application flexibility in mind and are suitable for closet and flush mount installations. The FF1D is available

in bare box or with _actory-installed heat and disconnect. It is also available with or without a factory installed TXV. Units are used indoors as

the air handler for split-system heat pumps or air conditioners. Units are available in 18,000, 24,000, and 30,000 Btuh nominal cooling capacities.

(See Fig. i.)

Form: IM-FF1D-03 Cancels: IM-FF1D-02 Printed in U.S.A. 6-02 Catalog No. 63FF-1D4

Page 2

REFRIGERANT -_

NOTE" LINES ENTRY ,X

1. SERIES DESIGNAT!ON IS _ '

THE 14TH POSITION _3_"

OF UNIT MODEL NUMBER. zp

15 3/I6"_ I

2 3/4"'1_ __'11- 8 1/4""1_ 1-'-4 3/16" 7/8""-I_

t

3

o

TOP VIEW

22 1/8""""""'"

i-.,,,-113A6".-=-I-.,,,_10 1A6"..-_

It" ",1

LOW VOLTAGE ENTRY

( 7/8" DIA. HOLE)

7/8" DIA. HOLE

2 13A6"

.___1 eAG"

/-- BLOWER, CONTROL AND

ELECTRIC HEATER

ACCESS PANEL

TUBE

LIQUID TUBE

UNIT CONNECTION SIZES

SUCTION, 018,024,030 - 3/4"I.D. SWEAT

LIQUID, 3/8" ID. SWEAT

CONDENSATE, 3/4" NPT

5 _s

SIDE VlEW

1

24 1/16"

_ _ FILTER MEDIA

PRIMARY DRAIN

FRONT VIEW

----11 1A6'_.- I

4

PATCH PLATE I_--[J_ _-_

FAN CO L BASE "-/I

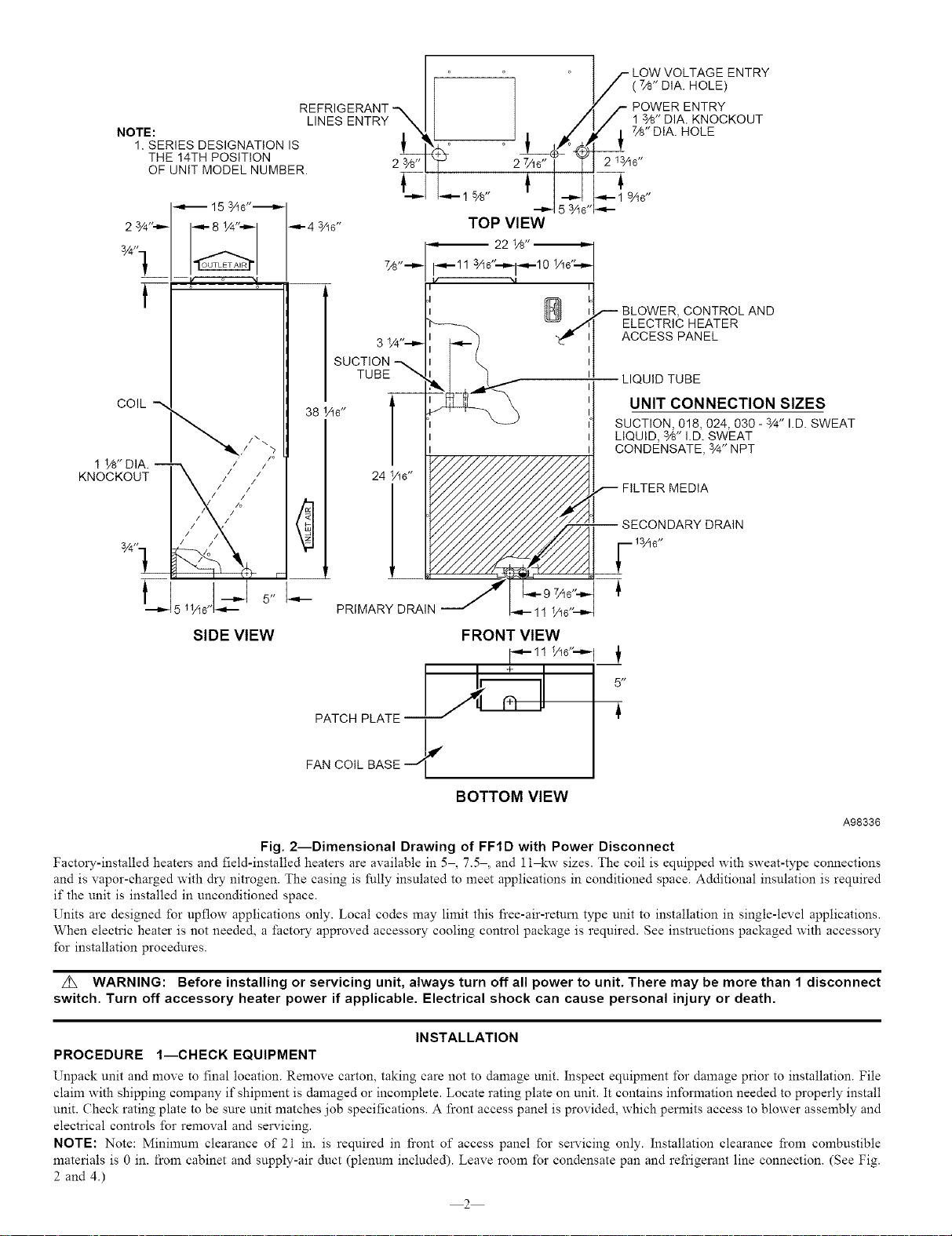

Fig. 2--Dimensional Drawing of FFID with Power Disconnect

Factory-installed heaters and field-installed heaters are available in 5 , 7.5 , and llkw sizes. The coil is equipped with sweat-type connections

and is vapor-charged with dry nitrogen. The casing is fully insulated to meet applications in conditioned space. Additional insulation is required

if the unit is installed in unconditioned space.

Units are designed for upflow applications only. Local codes may limit this free-air-return type unit to installation in single-level applications.

When electric heater is not needed, a factory approved accessory cooling control package is required. See instructions packaged with accessory

for installation procedures.

/

BOTTOM VIEW

A98336

z_x WARNING: Before installing or servicing unit, always turn off all power to unit. There may be more than 1 disconnect

switch. Turn off accessory heater power if applicable. Electrical shock can cause personal injury or death.

INSTALLATION

PROCEDURE 1--CHECK EQUIPMENT

Unpack unit and move to final location. Remove carton, taking care not to damage unit. Inspect equipment for damage prior to installation. File

claim with shipping company if shipment is damaged or incomplete. Locate rating plate on unit. It contains information needed to properly install

unit. Check rating plate to be sure unit matches job specifications. A front access panel is provided, which permits access to blower assembly and

electrical controls for removal and servicing.

NOTE: Note: Minimum clearance of 21 in. is required in fi'ont of access panel for servicing only. Installation clearance from combustible

materials is 0 in. from cabinet and supply-air duct (plenum included). Leave room for condensate pan and refrigerant line connection. (See Fig.

2 and 4.)

2

Page 3

TEFLON SEAL "-_

BRASS j

-/o ssL

HEX NUT

Fig. 3--Refrigerant Flow-Control Device

(Non TXV Models)

PROCEDURE 2--MOUNT FAN COIL

The unit is designed for free-air return as enclosed in a closet with louvered door or for flush mounting in a wall. A factory-authorized louvered

grille kit is available for flush mount application (KFBLG0101LGL). When unit is installed in a closet with a louvered door in return-air path,

the free area of louvered opening in the door must be a minimum of 2.25 sq R. Either align door opening with unit inlet or provide a 10-in. clearance

between door and unit. If unit is to be flush mounted in a wall, provide adequate support underueath base of unit. To assure proper condensate

&ainage, be sure unit is level.

NOTE: Do not remove seals from coil until tubing connections are ready to be made. See instructions packaged with outdoor unit for connecting

refrigerant tubes.

Before connecting refrigerant tubing, be sure _actory-supplied indoor reliqgerant flow-control device is correct for outdoor unit size used. Refer

to outdoor unit rating plate. When changing piston, use a backup wrench and do not over tighten. Hand tighten hex nut, then tighten with wrench

i/2 turn. Do not exceed 30 It-lb. (See Fig. 3.)

--) z_ CAUTION: Wrap a wet cloth around rear of fitting to prevent damage to TXV.

--) z_ CAUTION: If using a TXV in conjunction with a single-phase reciprocating compressor, a compressor start capacitor

and relay are required. Consult outdoor unit pre-sale literature for start assist kit part number.

HEXBODY

f_- ALTERNATE

DRAIN EXiT

A93530 DRAIN

Fig. 4--Condensate Drain

PRIMARY

NOTE: Use plastic pipe from

condensate pan to

exterior of fan coil.

2-iN MIN TRAP

SECONDARk

DRAIN

(TRAP EXTERNAL

TO UNIT)

A02171

Move unit into place and install refrigerant tubing as tbllows:

1. Route tubing to connection points.

2. Remove plugs from liquid and suction tubes.

3. Braze connections using either silver bearing or non-silver bearing brazing material. Do not use soft solder (materials which melt below

800°F). Consult local code requirements.

4. Pressurize system and leak-test. Repeat procedure until leak-free.

Z_ CAUTION: Do not vent refrigerant to atmosphere. Recover during system repair or final unit disposal.

PROCEDURE 3--DUCTWORK SPECIFICATIONS

Connect supply-air duet over 3,4-in. flange provided on supply-air opening. Secure duct to flange using applicable fasteners for type of duct used,

and seal duct-to-unit joint.

NOTE: Short duct runs tend to increase noise level.

When _an coil is equipped with an electric heater, install air ducts in accordance with standards 90A and 90B of National Fire Protection

Association (NFPA). Use of flexible connectors between ductwork and unit will prevent transmission of vibration. When electric heater is installed,

use heat-resistant material for a flexible connector between ductwork and unit air discharge connection. Ductwork passing through unconditioned

space must be insulated and covered with a vapor barrier.

NOTE: Unit is intended for nonducted return-air applications. Local codes may limit this unit to single-level applications.

PROCEDURE 4---CONDENSATE DRAIN

Condensate pan has primary and secondary drain connections to meet FHA requirements. (See Fig. 4.) These connections have 3 4-in. female pipe

threads. Tubing for all condensate drains should be a minimum of 7/8-in. OD. Drain lines from condensate pan to exterior of unit must be plastic

pipe. Drain should be pitched downward at a slope of 1 in. per 10 ft. If coil is located in or above a living space where damage may result from

condensate overflow, a separate 3/4-in. &ain must be provided from secondary drain connection. Run this drain to a place in compliance with local

installation codes where it will be noticed when unit is operational. Condensate flowing from secondary &ain indicates a plugged primary drain.

Install a 3-in. trap in condensate drain line as close to coil as possible. A factory approved &ain trap kit, KFAET0150ETK, is available. Make

sure that the top of trap is below connection to drain pan to prevent condensate from overflowing &ain pan. Prime trap with water. Insulate drain

if located above a living area and test condensate line for leaks. Consult local codes for additional restrictions or precautions.

3

Page 4

THERMOSTAT

FAN COIL

CONTROL

THERMOSTAT

FAN COIL

CONTROL)

HEAT PUMP

'CONTROL'

[]-

z:;z R

[]-

[2b

w2

[]-

4: -0

[]

AIR COND.

Fig. 5--Wiring Layout Air Conditioning Unit

(Cooling and 1-Stage Heat)

PROCEDURE 5--FIELD INSTALLATION OF CONTROLS

FF1D units shipped from factory without controls require a field-installed cooling control kit or heater. These kits are completely assembled and

_actory-wired for easy installation. See Installation Instructions packaged with control panel for installation procedures. These unit Installation

Instructions are to be used in conjunction with instructions packaged with heater or cooling control. When installing accessory heat, optional

cooling control kit is not required.

PROCEDURE 6--ELECTRICAL CONNECTIONS

A98330

[]

Fig. 6--Wiring Layout Heat Pump Unit

(Cooling and 2-Stage Heat)

w2

4:Z o

A98331

z_ WARNING: Before installing or servicing fan coil, always turn off all power to unit. There may be more than 1

disconnect switch. Turn off accessory heater power if applicable. Electrical shock can cause personal injury or death.

NOTE: Before proceeding with electrical connections, make certain that voltage, frequency, and phase correspond to that specified on rating plate.

Also, check to be sure that the service provided by utility is sufficient to handle additional load imposed by this equipment.

Refer to unit wiring label for proper field high- and low-voltage wiring. Make all electrical connections in accordance with NEC and any local

codes or ordinances that might apply. Unit must have a separate branch electrical circuit. When equipped with _actory- or field-installed control

kit, the FF1D has a _actory-installed disconnect switch located within sight and readily accessible to the unit.

z_ WARNING: Field wires on side of disconnect found in fan coil remain live, even when pull-out is removed. Service and

maintenance to incoming wiring can not be performed until main disconnect switch (remote to the unit) is turned off. Failure

to do so will result in electrical shock causing personal injury or death.

NOTE: All control kits are shipped from _actory wired for 230-v transformer operation. For 208-v operation, move black primary lead Ii'om 230-v

terminal to 208-v terminal.

See Fig. 5 and 6 for field low-voltage wiring. See Fig. 2 for location of the electrical inlets. For maximum ampacity and over-current protection,

see unit rating plate.

i. Provide power supply for unit being installed in accordance with unit wiring diagram and rating plate.

2. Connect line-voltage leads to field lugs. Use copper wire only.

3. Use UL listed conduit and conduit connector for connecting line-voltage leads to unit and obtaining proper ground. If conduit connection

uses reducing washers, a separate ground wire must be used. Grounding can also be accomplished by using the ground lug provided in the

control box.

4. Install rubber grommet packed with unit in hole for low-voltage wires.

5. Connect low-voltage leads to thermostat and outdoor unit. See Fig. 5 and 6 and the outdoor unit wiring label.

Refer to unit wiring instructions for recommended wiring procedures. Use No. 18 AWG color-coded, insulated (35°C minimum) wire to make

low-voltage connections between thermostat and unit. If thermostat is located more than 100 ft from unit as measured along low-voltage wire, use

No. 16 AWG color-coded, insulated (35°C minimum) wire.

4

Page 5

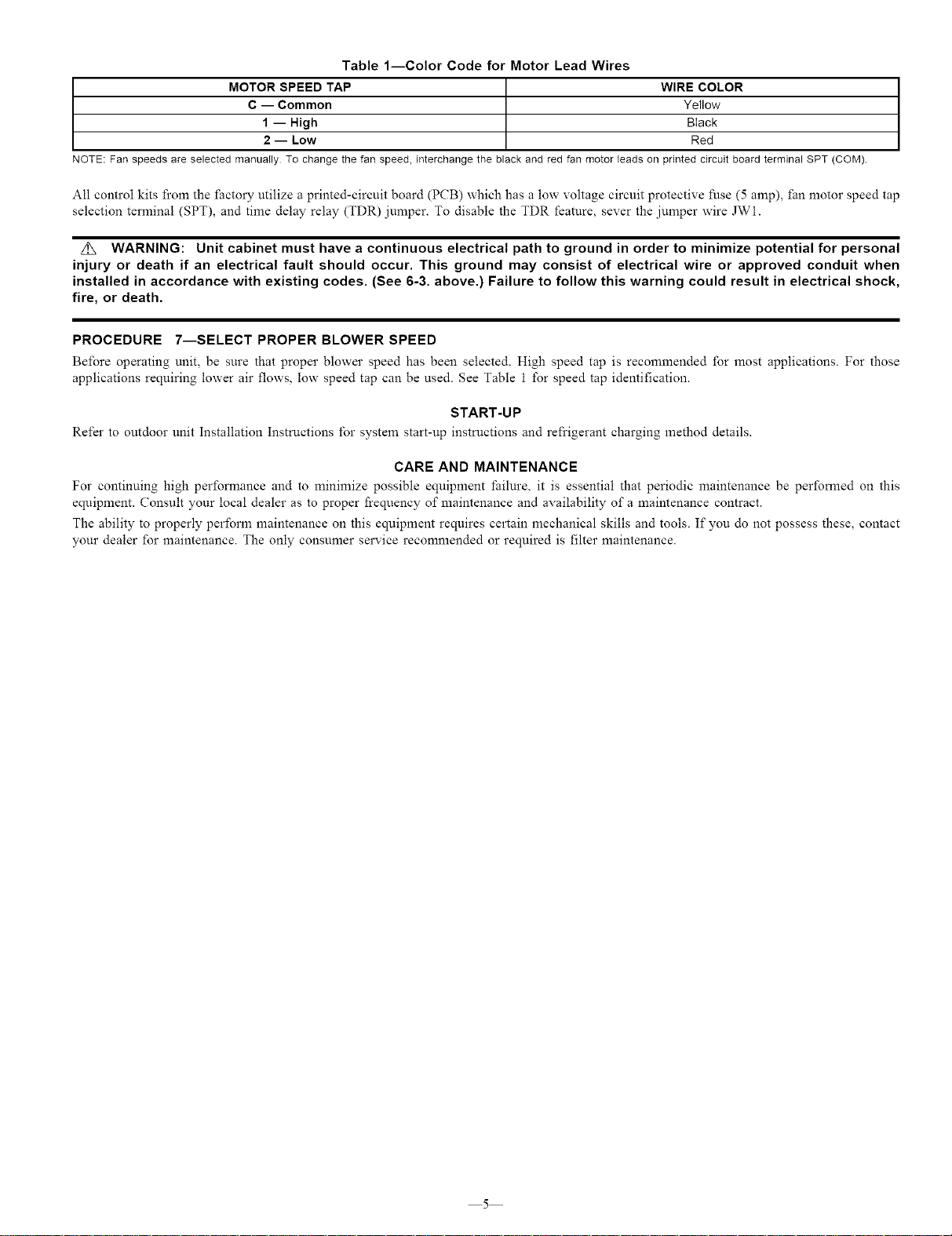

Table 1--Color Code for Motor Lead Wires

C -- Common Yellow

I MOTOR SPEED TAP WIRE COLOR

NOTE: Fan speeds are selected maeuNly To change the fan speed, interchangethe black and red fan motor leads on printed circuit board terminal SPT (COM)

All control kits fi'om the factory utilize a printed-circuit board (PCB) which has a low voltage circuit protective fuse (5 amp), fan motor speed tap

selection terminal (SPT), and time delay relay (TDR) jumper. To disable the TDR feature, sever the jumper wire JW1.

z_ WARNING: Unit cabinet must have a continuous electrical path to ground in order to minimize potential for personal

injury or death if an electrical fault should occur. This ground may consist of electrical wire or approved conduit when

installed in accordance with existing codes. (See 6-3. above.) Failure to follow this warning could result in electrical shock,

fire, or death.

PROCEDURE 7--SELECT PROPER BLOWER SPEED

Before operating unit, be sure that proper blower speed has been selected. High speed tap is recommended for most applications. For those

applications requiring lower air flows, low speed tap can be used. See Table 1 for speed tap identification.

1 -- High Black

2 -- Low Red

S TART -UP

Refer to outdoor unit Installation Instructions for system start-up instructions and refrigerant charging method details.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equipment failure, it is essential that periodic maintenance be perfomled on this

equipment. Consuh your local dealer as to proper frequency of maintenance and availability of a maintenance contract.

The ability to properly perform maintenance on this equipment requires certain mechanical skills and tools. If you do not possess these, contact

your dealer for maintenance. The only consumer service recommended or required is filter maintenance.

5

Page 6

© 2002 CAC/BDP 7310 W. Morris St, Indianapolis, IN 46231 imffld03 6 Catalog No. 63FF-1D4

Loading...

Loading...