Page 1

Transport Air Conditioning

OPERATION AND SERVICE

MODELS AC310 & AC350

Rooftop Air Conditioning Units

BT324 Carrier Sutrak Digital Display (CSDD)

280P/282P Electronic Thermostat

T--304 Rev A Change 07/09

for

With

or

Page 2

OPERATION AND

SERVICE MANUAL

TRANSPORT

AIR CONDITIONING UNIT

MODELS

AC310 & AC350

ROOFTOP AIR CONDITIONING UNITS

*CSDD -- BT324 (*Carrier Sutrak Digital Display)

Electronic Thermostat -- 280P & 282P

Page 3

TABLE OF CONTENTS

PARAGRAPH NUMBER Page

SAFETY SUMMARY Safety--1....................................................................

DESCRIPTION 1--1...............................................................................

1.1 INTRODUCTION 1--1.....................................................................

1.2 GENERAL DESCRIPTION 1--2.............................................................

1.2.1 Rooftop Unit 1--2......................................................................

1.2.2 Condensing Section 1--2...............................................................

1.2.3 Evaporator Section 1--4................................................................

1.2.4 Drivers Evaporator (Optional) 1--6.......................................................

1.2.5 Compressor Assembly 1--6.............................................................

1.2.6 System Operating Controls And Components 1--7.........................................

1.2.7 280P & 282P (PWM) Electronic Thermostat Controller 1--7.................................

1.2.8 CSDD BT--324 (Carrier--Sutrak Digital Display) Microprocessor 1--7..........................

1.2.9 Motor Fault Board (Optional) 1--7........................................................

1.3 REFRIGERATION SYSTEM COMPONENT SPECIFICATIONS 1--7.............................

1.4 ELECTRICAL SPECIFICATIONS -- MOTORS 1--7............................................

1.5 SAFETY DEVICES 1--8...................................................................

1.6 AIR CONDITIONING REFRIGERATION CYCLE 1--8..........................................

1.7 HEATING CYCLE 1--8....................................................................

OPERATION (Manual Controller) 2--1..............................................................

2.1 STARTING, STOPPING AND OPERATING INSTRUCTIONS 2--1..............................

2.1.1 Starting 2--1..........................................................................

2.1.2 Stopping 2--1.........................................................................

2.2 PRE--TRIP INSPECTION 2--1..............................................................

2.3 MODES OF OPERATION 2--2.............................................................

2.3.1 Temperature Control 2--2...............................................................

2.3.2 Cooling Mode 2--2.....................................................................

2.3.3 Heating Mode 2--2.....................................................................

2.3.4 Boost Pump (Optional) 2--2.............................................................

2.3.5 Vent Mode 2--2.......................................................................

2.3.6 Compressor Unloader Control (Only with 05G or 05K Compressors) 2--2.....................

2.3.7 Override Mode -- AC310 (Dehumidification) 2--2..........................................

2.3.8 Evaporator Fan Speed Selection 2--3....................................................

2.3.9 Compressor Clutch Control 2--3.........................................................

(A--6, TM--16, TM--21) 2--3....................................................................

2.4 SEQUENCE OF OPERATION (280P / 282P) 2--3.............................................

2.4.1 Electronic Thermostat 2--3.............................................................

OPERATION BT324 Controller 3--1.................................................................

3.1 STARTING, STOPPING AND OPERATING INSTRUCTIONS 3--1..............................

3.1.1 Starting

3.1.2 Stopping 3--1.........................................................................

3.2 PRE--TRIP INSPECTION 3--1.............................................................

3.3 SEQUENCE OF OPERATION BT324 CSDD 3--2.............................................

3.3.1 Function of Keys when “Engine On” and controller active: 3--2...............................

3.3.2 Illuminating Indications (Display) 3--2....................................................

3--1..........................................................................

i

T--30404/08

Page 4

TABLE OF CONTENTS Continued:

3.4 Operating Instructions BT324 3--2...........................................................

3.4.1 Display 3--2..........................................................................

3.4.2 Interior Temperature Control 3--2........................................................

3.4.3 Ventilation 3--2........................................................................

3.4.4 Reheat (optional) 3--3..................................................................

3.4.5 Temperature Indication 3--3.............................................................

3.5 CHANGING BETWEEN 5F (FAHRENHEIT) AND 5C (CELCIUS ) 3--3..........................

TROUBLESHOOTING 4--1.........................................................................

4.1 System Will Not Cool 4--1..............................................................

4.2 System Runs But Has Insufficient Cooling 4--1............................................

4.3 Abnormal Pressures 4--1...............................................................

4.4 Abnormal Noise Or Vibrations 4--1.......................................................

4.5 No Evaporator Air Flow Or Restricted Air Flow 4--2........................................

4.6 Expansion Valve Malfunction 4--2........................................................

4.7 Heating Malfunction 4--2...............................................................

SERVICE 5--1....................................................................................

5.1 MAINTENANCE SCHEDULE 5--1...........................................................

5.2 REMOVING EVAPORATOR COVER 5--1....................................................

5.3 REMOVING CONDENSER COVER 5--1.....................................................

5.4 INSTALLING MANIFOLD GAUGE SET 5--1..................................................

5.4.1 Installing R--134a Manifold Gauge/Hose SET 5--1.........................................

5.5 PUMPING THE SYSTEM DOWN OR REMOVING THE REFRIGERANT CHARGE 5--2...........

5.5.1 System Pump Down For Low Side Repair 5--2............................................

5.5.2 Removing Entire System Charge 5--3....................................................

5.6 REFRIGERANT LEAK CHECK 5--3.........................................................

5.7 EVACUATION AND DEHYDRATION 5--3....................................................

5.7.1 General 5--3..........................................................................

5.7.2 Preparation 5--3.......................................................................

5.7.3 Procedure for Evacuation and Dehydrating System 5--3....................................

5.8 ADDING REFRIGERANT TO SYSTEM 5--3..................................................

5.8.1 Checking Refrigerant Charge 5--3.......................................................

5.8.2 Adding Full Charge 5--4................................................................

5.9 CHECKING FOR NONCONDENSIBLES 5--4................................................

5.10 CHECKING AND REPLACING HIGH OR LOWPRESSURE CUTOUT SWITCH 5--4..............

5.10.1 Replacing High Or Low Pressure Switches 5--4...........................................

5.10.2 Checking High Or Low Pressure Switches 5--4............................................

5.11 FILTER-DRIER 5--5.......................................................................

5.11.1 To Check Filter--Drier 5-- 5..............................................................

5.11.2 To Replace Filter--Drier Assembly 5--5...................................................

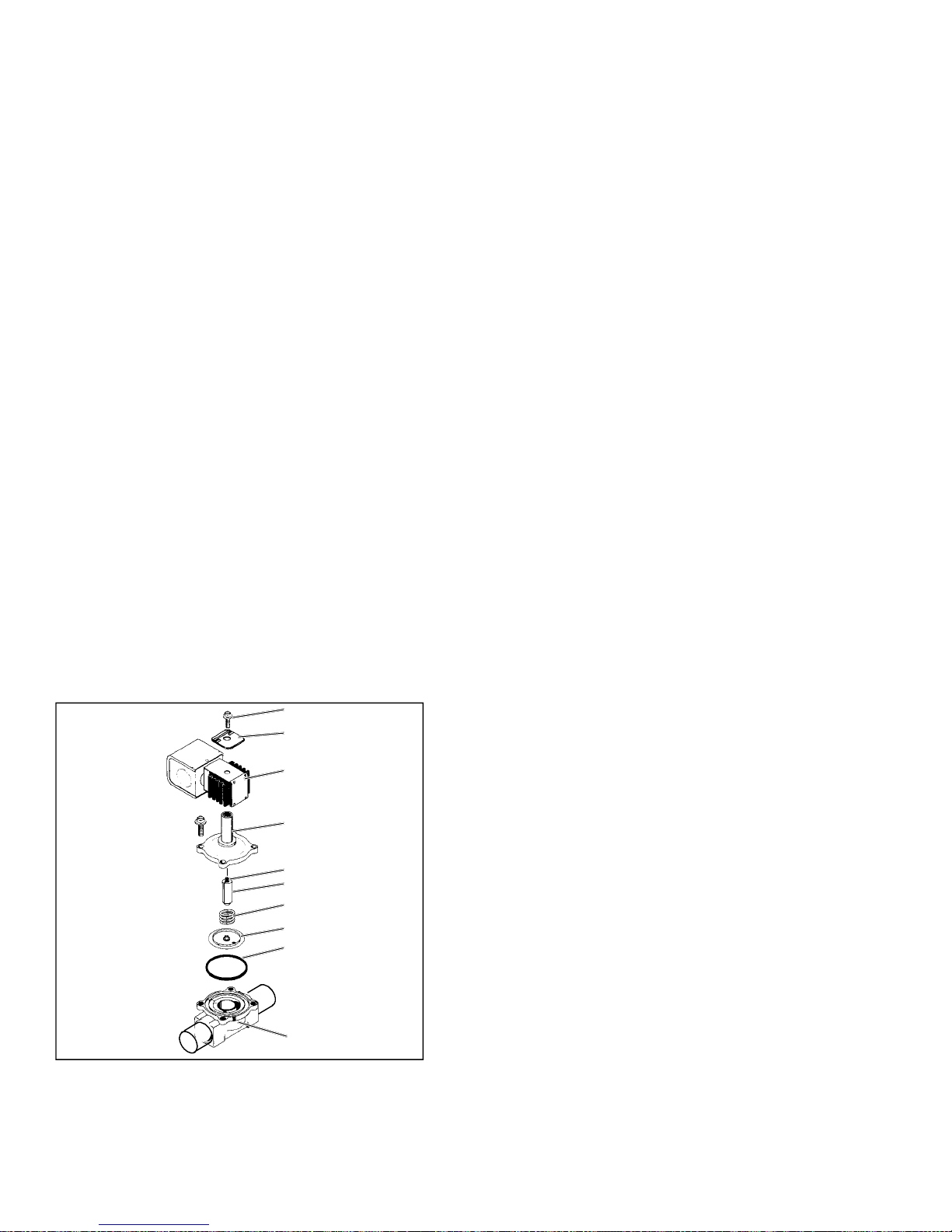

5.12 SERVICING THE HEAT VALVE 5--5........................................................

5.12.1 Coil Replacement 5--6.................................................................

5.12.2 Internal Part Replacement 5--6..........................................................

5.12.3 Replace Entire Valve 5--6

..............................................................

T--304 04/08

ii

Page 5

TABLE OF CONTENTS Continued:

5.13 SERVICING THE LIQUID LINE SOLENOID VALVE 5--6.......................................

5.13.1 Coil Replacement 5--6.................................................................

5.13.2 Internal Part Replacement 5--6..........................................................

5.13.3 Replace Entire Valve 5--6...............................................................

5.14 SERVICE VALVES 5--7....................................................................

5.15 REPLACING RETURN AIR FILTERS 5--7...................................................

5.16 THERMOSTATIC EXPANSION VALVE 5--8..................................................

5.16.1 Valve Replacement 5--8................................................................

5.16.2 Superheat Measurement 5--9...........................................................

ELECTRICAL 6--1................................................................................

6.1 INTRODUCTION 6--1.....................................................................

LIST OF FIGURES

Figure 1--1 AC310/350 Rooftop Units 1--2...........................................................

Figure 1--2 Condensing Section Components (AC310 -- Dual Loop -- GEN I) 1--3..........................

Figure 1--3 Condensing Section Components (AC350 Single Loop -- GEN II) 1--4.........................

Figure 1--4 Evaporator Section Components (AC310 --Dual Loop -- GEN I) 1--5...........................

Figure 1--5 Evaporator Section Components (AC350 Single Loop -- GEN II) 1--6..........................

Figure 1--6 Refrigerant Flow Diagram -- Cooling (Dual Loop) 1--9...........................................

Figure 1--7 Flow Diagram -- Heating 1--10...............................................................

Figure 1--8 Refrigerant Flow Diagram, Cooling (Single Loop) AC350 1--11.................................

Figure 1--9 Sheet 1 -- Electrical Control Board (280P) 1--12.............................................

Figure 1--9 Sheet 2 Legend 1--13....................................................................

Figure 1--10 AC350 With BT324 Control 1--14.........................................................

Figure 1--11 Motor Fault Board (Optional) 1--15........................................................

Figure 2.1 Control Switches (Typical) 2-- 1..............................................................

Figure 2.2 280P / 282P Thermostat 2-- 3.............................................................

Figure 3--1 Bus Dash With A/C Switch & BT324 CSDD Controller 3--1...................................

Figure 3--2 BT324 CSDD Controller 3--2.............................................................

Figure 5--1 Manifold Gauge Set (R--134a) 5--2........................................................

Figure 5--2 In--Line Service Connections 5--3.........................................................

Figure 5--3 Checking High Pressure Switch 5--4......................................................

Figure 5--4 Filter--Drier Removal 5--5................................................................

Figure 5--5 Heat Valve 5--6........................................................................

Figure 5--6 Liquid Line Solenoid Valve 5--7...........................................................

Figure 5--7 Service Valve R134a (High Side) 5--7.....................................................

Figure 5--8 Return Air Grill Assembly With Air Filter Showing 5--7.......................................

Figure 5--9 Diffuser and Filter Element 5--8..........................................................

Figure 5--10 Filter, Diffuser and Composit Frame 5--8.................................................

Figure 5--11 Return Air Grill Assembly With Diffuser And Composit Frame Showing 5--8...................

Figure 5--12 Thermostatic Expansion Valve 5--8......................................................

Figure 5--13 Thermostatic Expansion Valve Bulb and Thermocouple 5--9.................................

Figure 6--1 System Controls (Typical) 6--2...........................................................

Figure 6--2 Manual Controls With Manual Reheat Control (Sheet 1) 6--3.................................

Figure 6--3 Manual Controls With Manual Reheat Control (Sheet 2) 6--4.................................

iii

T--30404/08

Page 6

LIST OF FIGURES Continued:

Figure 6--4 Evaporator Motors 1 -- 4 6-- 5.............................................................

Figure 6--5 Evaporator Motors 5 -- 8 6-- 6.............................................................

Figure 6--6 Condenser Motors 6--7..................................................................

Figure 6--7 BT324 Controls With (1) Compressor (AC350) 6--8.........................................

Figure 6--8 BT324 Control Circuit (AC350) 6--9.......................................................

Figure 6--9 BT324 Evaporator Motors (AC350) 6--10...................................................

Figure 6--10 CSDD BT324 Condenser Motors 6--11....................................................

Figure 6--11 AC350 With BT324 Control 6--12.........................................................

Figure 6--12 CSDD BT324 Control Circuit 6--13........................................................

Figure 6--13 CSDD BT324 6--14.....................................................................

Figure 6--14 Thermostat (One/Two Compressors) 6--15................................................

Figure 6--15 Thermostat (One/Two Compressors) 6--16................................................

Figure 6--16 Thermostat (One/Two Compressors) 6--17................................................

Figure 6--17 Thermostat (One/Two Compressors) 6--18................................................

Figure 6--18 Thermostat (One/Two Compressors) 6--19................................................

LIST OF TABLES

Table 1--1 AC310 Models 1--1.......................................................................

Table 1--2 AC 350 Models 1--1......................................................................

Table 1--3 Additional Support Manuals 1--1............................................................

Table 2--1 Unloader UV1 Relay 2--2..................................................................

Table 2--2 Unloader UV2 Relay 2--2..................................................................

Table 4--1 General System Troubleshooting Procedures 4--1............................................

Table 5--1 R-134a Temperature - Pressure Chart 5--10..................................................

T--304 04/08

iv

Page 7

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this

manual. Theyarerecommended precautionsthatmust beunderstoodand appliedduring operationandmaintenance

of the equipment covered herein. A listing of the specific warnings and cautions appearing elsewhereinthe manual

follows the general safety notices.

FIRST AID

An injury, nomatter how slight, should never gounattended. Always obtain first aid or medical attention immediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

Noworkshould beperformedon theunituntilall start-stop switches areplacedin the OFF position, andpowersupply

is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator and condenser fans. Do not open the unit cover before turning

power off.

Be sure power is turned off before workingonmotors, controllers, solenoidvalvesandelectrical controls. Tagcircuit

breaker and power supply to prevent accidental energizing of circuit.

Donot bypassany electricalsafetydevices,e.g. bridginganoverload,or usinganysortof jumperwires. Problemswith

the system should be diagnosed, and any necessary repairs performed by qualified service personnel.

When performing any arcweldingon the unit, disconnect all wire harness connectors from the modulesinthecontrol

box. Donotremovewireharness fromthemodules unless you are grounded to the unit frame with a static-safewrist

strap.

In case of electrical fire, open circuit switch and extinguish with CO

(never use water).

2

04/08

Safety--1

T--304

Page 8

SPECIFIC WARNINGS AND CAUTIONS

WARNING

Be sure to observe warnings listed in the safety summary in the front of this manual before per-

forming maintenance on the hvac system

WARNING

Read the entire procedure before beginning work. Park the vehicle on a level surface, with park-

ing brake applied. Turn main electrical disconnect switch to the off position.

WARNING

Do Not Use A Nitrogen Cylinder Without A Pressure Regulator

WARNING

Do Not Use Oxygen In Or Near A Refrigeration System As An Explosion May Occur.

WARNING

The Filter-drier May Contain Liquid Refrigerant. Slowly Loosen The Connecting Nuts And Avoid

Contact With Exposed Skin Or Eyes.

CAUTION

The AC310 & AC350 Rooftop Systems have R134a service port couplings installedon the compressor and 1/4 inch flare (Acme) fittings installed on the unit piping.

CAUTION

To prevent trapping liquid refrigerant in the manifold gauge set be sure set is brought to suction

pressure before disconnecting.

T--304 04/08

Safety--2

Page 9

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

This manual contains Operating Instructions, Service

Instructions and Electrical Data for the Model AC310

and AC350 Air Conditioning and Heating equipment

furnished by Carrier Transport Air Conditioning as

shown in Table 1--1 and Table 1--2.

Model AC310/350 systems consists of a Rooftop unit

containing the condensing section, the evaporator

section and engine compartment mounted

compressor(s). To complete the system, the air

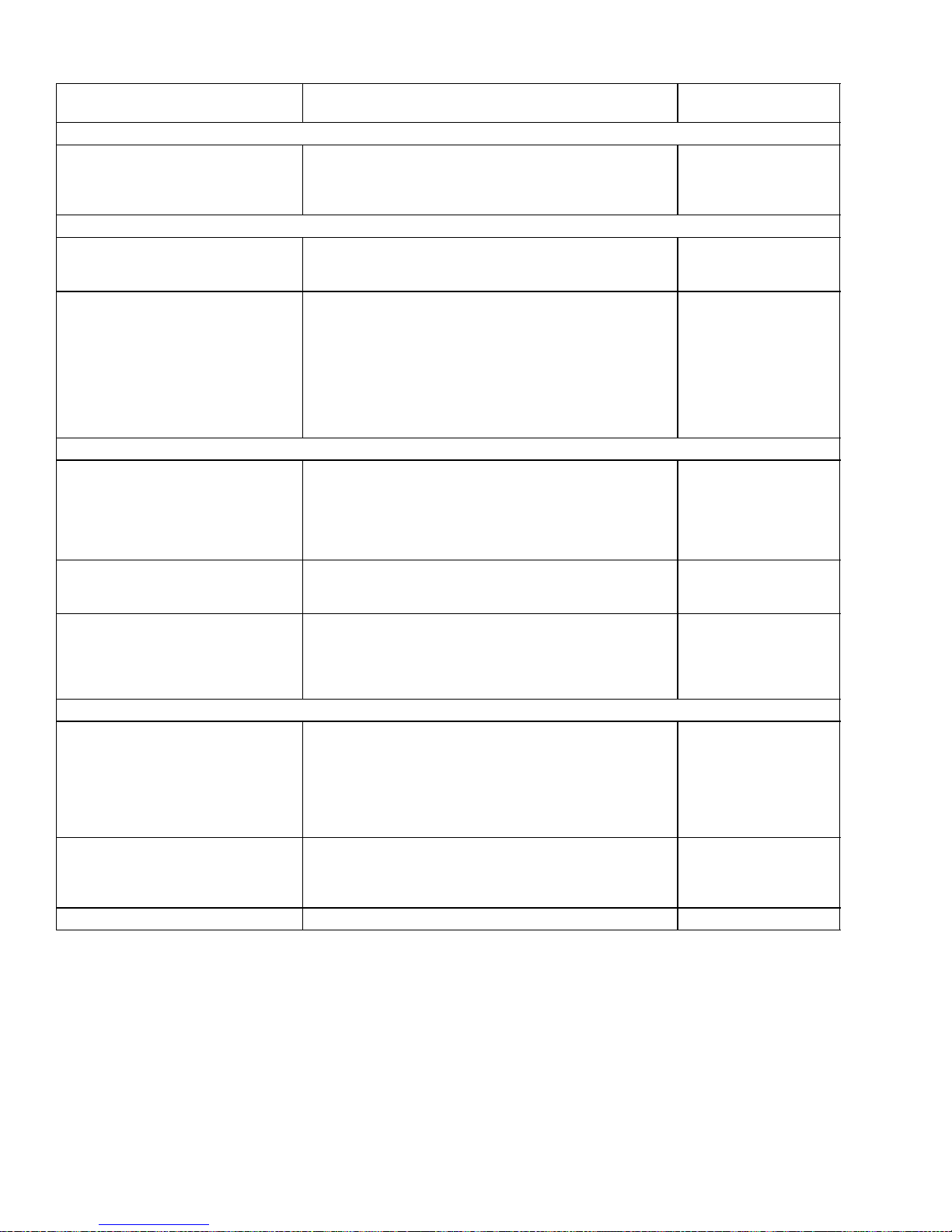

Table 1-- 1 AC310 Models

Model AC310

77--62031--00 12 VDC Manual (280P) Yes X X

77--62031--01 24 VDC Manual (280P) Yes X X

77--62031--02 12 VDC BT324 Yes X X

77--62031--03 24 VDC BT324 Yes X X

77--62032--00 12 VDC

77--62032--01 24 VDC Manual (280P) Yes X X

77--62032--02 -- -- -- -- -- -77--62032--03 12 VDC Manual (280P) Yes X X

77--62032--04 12 VDC Manual (280P) Yes X X

77--62032--05 12 VDC BT324 Yes X X

*77--62032--06 12 VDC BT324 (Tropic) Yes X X

Voltage Controller With Heat Dual Loop Single Loop W/Covers

Sytronic System

& Manual (280P)

conditioning and heating equipment interfaces with an

optional drivers evaporator (dash--air), electrical

cabling, refrigerant piping, engine coolant piping (for

heating), duct work and other components furnished by

Carrier Transport Air Conditioning and/or the bus

manufacturer.

Additional support manuals are shown in Table 1--3.

Operation of the unit is controlled automatically by an

electronic thermostat. The controlls maintain the

vehicle’s interior temperature at the desired set point.

Yes X X

*NOTE: 77--62032--06 (Tropic) -- Has an AC310 Evaporator Section & an AC350 Condenser Section.

Table 1-- 2 AC 350 Models

Part Number

77--62041--00 24 VDC -- -- -- X -77--62041--01 24 VDC Manual Yes -- Yes

77--62041--02 24 VDC Manual Yes X No

77--62041--03 24 VDC -- -- -- -- -77--62041--04 24 VDC BT324 No X No

77--62041--05 24 VDC BT324 No X Yes

77--62041--06 24 VDC BT324 Yes X Yes

77--62041--07 24 VDC BT324 Yes X No

77--62041--10 24 VDC BT324 Yes X Yes

MANUAL NUMBER

T--304PL AC--310/350 Service Parts List

T--200PL 05G Compressor Service Parts List

62--02756 05G Compressor Operation & Service

62--11052 05G Compressor -- Twin Port Workshop Manual

62--11053 05G Compressor -- Twin Port Service Parts List

62--02460 05K Compressor Service Parts List

62--02491 05K Compressor Operation & Service

Voltage Controller With Heat Dual Loop Single Loop W/Covers

Table 1-- 3 Additional Support Manuals

EQUIPMENT COVERED TYPE OF MANUAL

04/08

1--1

T--304

Page 10

1.2 GENERAL DESCRIPTION

1.2.1 Rooftop Unit

The rooftop unit includes the condenser section and the evaporator section (See Figure 1--1).

Evaporator Section

Condenser Section

AC310

AC350

Figure 1--1 AC310/350 Rooftop Units

1.2.2 Condensing Section

The dual (See Figure 1--2) and single loop (See

Figure 1--3)condensing sections includethecondenser

coils, four (4) or six (6) fan and motor assemblies,

filter-driers, receivers, and filter drier service valves.

The condenser coils provide heat transfer surface for

condensing refrigerant gas at a high temperature and

pressure into aliquidat high temperatureand pressure.

The condenser fans circulate ambient air across the

outside of the condenser tubes at a temperature lower

Evaporator Section

Condenser Section

than refrigerant circulating inside thetubes; this results

in condensation of the refrigerant into a liquid. The

filter-drier removes moisture and debris from the liquid

refrigerant before it enters the thermostatic expansion

valve in the evaporator assembly. The service valves

enable isolation of the filter-drier for service.

The receiver collects and stores liquid refrigerant. The

receiver is also fitted with a pressure relief valve which

protects the system from unsafe high pressure

conditions.

T--304

1--2

04/08

Page 11

9

9

9

8

7

2

1

1

2

3

4

1. Condenser Coil Assembly

2. Receiver

3. Service Valve (High Side)

4. Filter Drier Upper Support

5. Filter Drier

Figure 1--2 Condensing Section Components (AC310 -- Dual Loop -- GEN I)

5

3

AC310

5

4

3

Dual Loop

6

6. Filter Drier Lower Support

7. Condenser Fan and Motor Assembly

8. Condenser Motor Support

9. Discharge Line Check Valve (Location)

04/08

1--3

T--304

Page 12

5

1

44

1

1 Condenser Coil Assembly

Receiver Tank (Part Of Coil Assembly)

2 Service Valve

Figure 1--3 Condensing Section Components (AC350 Single Loop -- GEN II)

1.2.3 Evaporator Section

The dual loop AC310 & AC350 (GEN I) evaporator

section (SeeFigure 1--4) includes the evaporator coils,

eight (8) or twelve (12) single--shafted blower/motor

assemblies, two heater coil assemblies, two

thermostatic expansion valves, two liquid line solenoid

valves, and condensate drain connections.

NOTE

The GEN I seriesof AC310 & AC350 evaporators are suppliedwithsingle shaft blower/motor

assemblies. The GEN II series have dual shaft

blower/motor assemblies.

The single loop AC310 & AC350 evaporator section

(See Figure 1--5)includes the evaporator coils, four (4)

or six (6) double--shafted blower/motor assemblies,

heater coil assemblies, one thermostatic expansion

4

2

3

2

5

3 Filter Drier

4 Fan & Motor

5 Frame (Aluminum)

valve, one liquid line solenoid valve (to add in--dash

service port), and condensate drain connections.

The liquidlinesolenoid valve closes whenthe system is

shut down to prevent flooding of coils and the

compressor with liquid refrigerant. The evaporatorcoils

provide heat transfer surface for transferring heat from

air circulating over the outside of the coil to refrigerant

circulating inside the tubes;thus providing cooling. The

heating coils provide a heat transfer surface for

transferring heat from engine coolant water circulating

inside the tubes to air circulating over the outside

surface of the tubes, thus providing heating. The fans

circulate the air overthecoils.Theairfilters remove dirt

particles from theair before itpassesover thecoils.The

thermostatic expansion valve meters the flow of

refrigerant entering theevaporatorcoils.Theheat valve

controls the flow of engine coolant to the heating coils

upon receipt of a signal from the controller. The

condensate drain connections provide a means for

connecting tubingfordisposing ofcondensatecollected

on the evaporator coils during cooling operation.

T--304

1--4

04/08

Page 13

3

7

4

9

6

8

2

1

Return Air

Section

AC310

Dual Loop

6

4

5

1. Evaporator Coil Assembly

2. Heater Coil

3. Expansion Valve

4. Evaporator Blower Assembly

5. Evaporator Motor

Figure 1--4 Evaporator Section Components (AC310 -- Dual Loop -- GEN I)

6. Sight Glass

7. Heating Line

8. Access Port

9. Liquid Line Solenoid

04/08

1--5

T--304

Page 14

6

2

4

1

5

4

1. Evaporator Coil Assembly

2. Heater Coil

3. Expansion Valve

4. Evaporator Blower/Motor Assembly

Figure 1--5 Evaporator Section Components (AC350 Single Loop -- GEN II)

8

3

6

7

1

2

5. Control Panel

6. Heater Line

7. Front Evaporator Port

8. Liquid Line Solenoid

1.2.4 Drivers Evaporator (Optional)

Thedriversevaporatorassemblyis normally installedin

thevehicledashareaandinterfaceswiththerooftopunit

electrical cabeling and refrigerant piping.

The drivers evaporator assembly includes an

evaporator coil, thermalexpansion valve, blower motor

assembly and a condensate drain connection. Refer to

the OEM technical literature for driver’s evaporator

information.

1.2.5 Compressor Assembly

a. Dual Loop Compressors A--6 & TM--21

The standard AC310 dual loop compressor assembly

includes the refrigerant compressor, clutch assembly,

in--line high & low pressure switches, suction

accumulator and in--line suction and discharge

servicing (charging) ports.

b. Single Loop Compressor TM--31

The TM--31 compressor assembly used only with the

AC310 Single Loop Unit includes the refrigerant

compressor, clutch assembly, suction & discharge

service valves, high pressure switch, low pressure

switch, suction accumulator and suction anddischarge

servicing (charging) ports.

T--304

c. Single Loop Compressors 05G & 05K

The 05G (AC350) & 05K (AC310) compressor

assemblies used withthesingleloopunits,includesthe

clutch assembly, suction & discharge service valves,

high pressure switch, low pressure switch, suction and

discharge servicing (charging) ports and electric

solenoid unloaders.

Thecompressorraisesthepressureand temperatureof

the refrigerant and forces it into the condenser coil

tubes. Theclutchassemblyprovidesa means ofdriving

the compressors by the vehicle engine. Suction and

discharge servicing (charging) ports mounted on the

compressor fittings enable connection of charging

hoses for servicing of the compressor, as well as other

parts of the refrigerant circuit.Thehighpressureswitch

contacts open on a pressure rise to shut down the

system when abnormally high refrigerant pressures

occur.

The electric unloaders (05G & 05K) provide a means of

controlling compressor capacity, which enables control

of temperature inside the vehicle. The suction and

discharge service valves enable servicing of these

compressors.

1--6

04/08

Page 15

1.2.6 System Operating Controls And Components

Thesystem isoperated byanelectronicthermostattype

controller and/or manually operated switches. The

manually operated switches are located on the drivers

control and may consist of a single ON/OFF switch or

additional switches. The controller regulates the

operational cycles of the system by energizing or

de--energizing relays on the relay board in response to

deviations in interior temperature. Modes of operation

includeCoolingandHeating.Onsystemsfittedwithonly

an ON/OFF switch, the controller will cycle the system

between the operating modes as required to maintain

desired set point temperature (See Section 6 for wiring

diagrams).

In the heat mode the heat valves are opened to allow a

flow of engine coolant through the heat coils located in

the evaporator section. The evaporatorfans operate to

circulate air over the heat coils in the same manner as

the cooling mode.

In the cooling mode the compressor is energized while

the evaporator and condenser fans are operated to

provide refrigeration as required. The compressor (s)

capacity is matched to the bus requirements. Once

interior temperature reaches the desired set point, the

compressor(s) is deenergized.

1.2.7 280P & 282P (PWM) Electronic Thermostat

Controller

This typecontrollerhas three (3)modes,Cool, Ventand

Heat.

The range on the potentiometer is 62.6° -- 8 6° F

(17--30° C).

1.2.8 CSDD BT--324

(Carrier--Sutrak Digital Display)

Microprocessor

This Carrier Sutrak Digital Display (BT--324) controller

has three (3)modes,Auto, V ent(Cycleclutchtype)and

Heat.

1.2.9 Motor Fault Board (Optional)

The motor fault board(SeeFigure 1--11)consists ofred

and green LED’s, which when illuminated, will reflect

each motors state of condition. When the evaporator

and condenser motors are energized, the green LED’ s

will beilluminated.Ifared LED is energized, it willshow

an “open circuit” condition, indicative of a motor failure.

The green LED will not be illuminated at this time. The

motor fault board is a seperate circuit board that is

located at the return air section. The return air grill is

oppened to view the LED indicators.

1.3 REFRIGERATION SYSTEM COMPONENT

SPECIFICATIONS

a. Refrigerant Charge R--134a (Approximate)

NOTE

Refrigerant charge will dependon hose lengths

and diameters; or if there is an In--Dash unit

(front evaporator). The followingshouldonly be

used as a guideline.

AC310 Dual Loop A--6 or TM--21 Compressor

6 Pounds (2.7 kg) -- Curbside

8 Pounds (3.6 kg) -- Roadside

AC310 -- Single Loop TM--31 Compressor

12 Pounds (5.4 kg) without In--Dash unit

AC310 -- Single Loop 05G or 05K Compressor

13.2 to 15.4 Pounds (6.0 to 7.0 kg) without

In--Dash unit

AC350 -- Single Loop 05G or 05K Compressor

16.5 to 18.7 Pounds (7.5 to 8.5 kg) without

In--Dash unit

For systems with In--Dash unit (Optional)

Add 2 pounds (0.9 kg) to above listed charge.

b. Compressors

Compressor

Weight, (Dry) 34.5 Lbs.

Oil Charge 10 Oz. PAG (07--00333--00)

Compressor TM--21

Weight, (Dry) 7.5 Lbs. (3.4 kg)

Oil Charge

Compressor TM--31

Weight, (Dry) 21 Lbs.

Oil Charge

Compressor Carrier 05K

Weight, (Dry) 108 Lbs.

Oil Charge

Compressor Carrier 05G

Weight, (Dry) 146 Lbs. W/Clutch

Oil Charge

c. Thermostatic Expansion Valve:

Superheat Setting (Externally Adjustable) Factory

Setat9to18°F(±4°F) MOP Setting: 55 ±4 psig

(3.74 ±2.27 bar)

d. High Pressure Switch (HPS) Normally Closed

Opens at: 360 ±10 psig (20.41 ±0.68bar)

Closes at: 280 ±10 psig (13.61 ±0.68bar)

e. Low Pressure Switch (LPS) Normally Open

Opens at: 6 ±3psig (0.41 ±0.20 bar)

Closes at: 25 ±3psig(1.7±0.20 bar)

f. Water Temperature Switch (WTS)

[Bus Manufacturer Supplied -- Suggested close on

temperature rise at 105°F(41°C)]

1.4 ELECTRICAL SPECIFICA TIONS -- MOTORS

a. Evaporator Blower/Motor

Evaporator Motor

Horsepower (kW) 1/8 (.09)

Full Load Amps (FLA) 9.5 19

Operating Speed High/

Low (RPM)

Bearing Lubrication

A6 (No longer Available)

6.1 Oz. (180 cc) PAG

(46--50006--00)

16.9 Oz. (500cc) PAG

(46--50006--00)

5.5 Pints POE

(07--00317--00pk6)

7.75 Pints POE

(07--00317--00pk6)

Permanent Magnet

24 VDC 12 VDC

4200

1850

Factory Lubricated

(additional grease not required)

Change 07/09

1--7

T--304

Page 16

b. Condenser Fan Motor

Condenser Motor

Permanent Magnet

24 VDC 12 VDC

Horsepower (kW) 1/8 (.09)

Full Load Amps (FLA) 9 18

Operating Speed

(RPM)

Bearing Lubrication

(additional grease not required)

2950

Factory Lubricated

c. Temperature Sensors (Return Air Sensor)

Input Range: --52.6 to 158° F (--47 to 70°C)

Output: NTC 10K ohms at 77° F(25°C)

d. Ambient Sensor (Optional)

Opens at: 25° F(10°C)

Closes at: 35° F(1.7°C)

1.5 SAFETY DEVICES

System components are protected from damage

caused by unsafe operating conditions with safety

devices. Safety devices with Carrier Transport Air

Conditioning supplied equipment include high pressure

switch (HPS), low pressure switch (LPS), circuit

breakers and fuses.

a. Pressure Switches

High Pressure Switch (HPS)

During the air conditioning cycle, compressor clutch

operation will automatically stop if the HPS switch

contacts open due to an unsafe operating condition.

Opening HPS contacts de-energizes the compressor

clutchshuttingdownthecompressor.Thehighpressure

switch (HPS) is installed at the compressor assembly

(05G, 05K & TM--31).

Low Pressure Switch (LPS)

The low pressure switch is installed close to the

compressor andopenson apressuredrop to shutdown

the system when a low pressure condition occurs. The

lowpressureswitchisinstalledat thecompressor(05G,

05K & TM--31).

NOTE

Ondualloop systemsthatuse theA--6, TM--21

& some TM31’s,the pressure switches are not

located onthe compressors. They are installed

in--line.

b. Fuses and Circuit Breakers

TheRelayBoard is protected against highcurrentbyan

OEM supplied circuit breaker or fuse located in thebus

battery compartment (150 Amp for 12 VDC & 125 Amp

for 24 VDC systems). Independent 15 Amp, 24 VDC or

20 Amp, 12 VDC fuses protect each motor while the

output circuits are protected by an additional 5 Amp

circuit breaker. Duringahigh current condition, the fuse

may open.

1.6 AIR CONDITIONING REFRIGERATION

CYCLE

When air conditioning (cooling) is selected by the

controller, the unit operates as a vapor compression

system using R-134a as a refrigerant (See Figure 1--6

Dual Loop & Figure 1--8 Single Loop flow diagrams).

The main components of the system are the A/C

compressor, air-cooled condenser coils, receiver,

filter-drier, thermostatic expansion valve, liquid line

solenoid valve and evaporator coils.

The compressor raises the pressure and the

temperature of the refrigerant and forces it into the

condenser tubes. The condenser fan circulates

surroundingair(whichisatatemperature lowerthanthe

refrigerant) over the outside of the condenser tubes.

Heat transfer is established from the refrigerant(inside

the tubes) to thecondenserair(flowingoverthetubes).

The condensertubeshavefins designed toimprovethe

transfer of heat from the refrigerant gas to the air; this

removal of heat causes the refrigerant to liquefy, thus

liquid refrigerant leaves the condenser and flows to the

receiver.

The refrigerant leavesthereceiver and passes through

the receiver outlet/service valve, through a filter-drier

where a descecant keeps the refrigerant clean and dry.

From the filter-drier, the liquid refrigerant then flows

through the liquid line solenoid valve to the sight--glass

and then to the thermostatic expansion valve. The

thermal expansion valve reduce pressure and

temperature of the liquid and meters the flow of liquid

refrigerant to the evaporator to obtain maximum use of

the evaporator heat transfer surface.

The low pressure, low temperatureliquidthat flows into

the evaporator tubes is colder than the air that is

circulated over the evaporator tubes by the evaporator

fans (fans). Heat transfer is established from the

evaporator air (flowing over the tubes) to the refrigerant

(flowing inside the tubes). The evaporator tubes have

aluminum fins to increase heat transfer from the air to

the refrigerant; therefore the cooler air is circulated to

the interior of the bus. Liquid line solenoid valve closes

during shutdown to prevent refrigerant flow.

The transfer of heat from the air to the lowtemperature

liquid refrigerant in the evaporator causes the liquid to

vaporize. This low temperature, low pressure vapor

passes through the suction line and returns to the

compressor where the cycle repeats.

1.7 HEATING CYCLE

Heating circuit (See Figure 1--7) components furnished

byCarrier Transport AirConditioninginclude theheater

cores and solenoidoperated heat valves. Components

furnished by the bus manufacturer may include awater

temperature switch (WTS) and boost water pump.

The controller automatically controls the heat valves

during the heating mode to maintain required

temperatures inside the bus. Engine coolant (glycol

solution) is circulated through the heating circuit by the

engine and an auxiliary boost water pump. When the

heat valvesolenoidsareenergized, the valves willopen

to allow engine coolant to flow throughthe heater coils.

The valves are normally closed so that if a failure

occurs, the system will be able to cool.

T--304

1--8

04/08

Page 17

5

3

6

2

4

1

4

1

3

1 Thermal Expansion Valve

2 Liquid Line Sight Glass

3 Service Port

4 Liquid Line Solenoid

5 Evaporator Coil

6 Heat Coil

Note: Items 1 through 12 are typical, both systems.

Driver’ s

Evaporator

12

7

9

9

11

10

8

7 Subcooler

8 Compressor (TM--21 or A--6)

9 Service Valve

10 Condenser Coil

1 1 Filter--Drier

12 Receiver

Figure 1--6 Refrigerant Flow Diagram -- Cooling (Dual Loop)

04/08

1--9

T--304

Page 18

1

1

4

*

SUPPLY

RETURN

4

*

1. Heat Coil

2. Vehicle Radiator

3. Boost Pump

3

2

4. Heat Solenoid Valve

* Optional Hand V alve

Figure 1--7 Flow Diagram -- Heating

NOTE: Inordertoensurewaterisenteringtheheater coils sufficientlyheated, it issuggestedthat

theOEMsupplied WaterTemperatureSwitch(WTS)closeontemperature riseat150°F( 65.5°C).

T--304

1--10

04/08

Page 19

Discharge

Liquid

Suction

Coolant

11

Relief Valve

Dash Air

Suction Line

8

10

4

Discharge Check Valve

5

Dash Air

Liquid Line

4

9

9

CONDENSER

8

EVAPORATOR

3

3

7

Figure 1--8 Refrigerant Flow Diagram, Cooling (Single Loop) AC350

1. Thermal Expansion Valve

2. Liquid Line Sight Glass

3. Service Port R134a

4 Service Port 1/4 Flare (Acme)

5. Liquid Line Solenoid

6. Evaporator Coil

1

2

5

4

6

6

7. Compressor

8. Service Valve

9. Condenser Coil

10. Filter--Drier

1 1. Receiver

04/08

1--11

T--304

Page 20

Ref. Sutrac 60--01--21--062

28

30

32

34

36

38

40

42

44

46

29

31

33

35

37

39

41

43

45

23

24

F1A

F2A

F3A

F4A

frei

F1M

F2M

F3M

F4M

F5M

F6M

F7M

F8M

F13M

F14M

F15M

F16M

frei

frei

frei

K1A

K2A

K1M

K5M K4M K3M K2M

8

9

10

11

12

1314151617

25

26 27

22

K3A

K4A

K13M

6

A1P

5

4

3

V5

V4

V3

V2

V1

B1N

7

K9M K8M K7M K6M

K11M K10M

K12M

K14M

K15M

18

19

20

21

2

1

47

CLR1

CLR2

48

SeeFigure1--9Sheet2Legend

Figure 1--9 Sheet 1 -- Electrical Control Board (280P)

T--304

1--12

Ref. Sutrak Schematic 65--01--28--056--01--3

04/08

Page 21

LEGEND

1 V1, Diode, Dash Switch

2 V2, Diode, Dash Switch

3 V3, Diode, Dash Switch

4 V4, Diode, Thermostat, Cooling

5 V5, Diode, Thermostat, Heating

6 Thermostat

7 Return Air Sensor

8 K1M, Relay, Evaporator Low Speed

9 K2M, Relay, Evaporator High Speed

10 K3M, Relay, Evaporator High speed

1 1 K4M, Relay, Evaporator Low Speed

12 K5M, Relay, Evaporator High Speed

13 K6M, Relay, Evaporator High Speed

14 K7M, Relay, Evaporator Low Speed

15 K8M, Relay, Evaporator High speed

16 K9M, Relay, Evaporator High Speed

17 K10M, Relay, Evaporator Low Speed

18 K11M, Relay, Evaporator High Speed

19 K12M, Relay, Evaporator High Speed

20 K14M, Relay, Evaporator Main, High speed

21 K15M, Relay, Condenser Motors

22 K13M, Relay, Condenser Motors

23 K1A, Relay, Alternator Power

24 K2A, Relay, Compressor Clutch

25 K3A, Relay, Heat Valve and Water Pump

26 K4A, Relay, Evaporator Speed

27 F1A, Fuse, Alternator Output

28 F2A, Fuse, Heat Valve and Water Pump

29 F3A, Fuse, Compressor Clutch

30 F4A, Fuse, Compressor Clutch

31 SPARE

32 F1M, Fuse, Evaporator Motor

33 F2M, Fuse, Evaporator Motor

34 F3M, Fuse, Evaporator Motor

35 F4M, Fuse, Evaporator Motor

36 F5M, Fuse, Evaporator Motor

37 F6M, Fuse, Evaporator Motor

38 F7M, Fuse, Evaporator Motor

39 F8M, Fuse, Evaporator Motor

40 F13M, Fuse, Evaporator Motor

41 F14M, Fuse, Evaporator Motor

42 F15M, Fuse, Condenser Motor

43 F16M, Fuse, Condenser Motor

44 SPARE

45 SPARE

46 SPARE

47 CLR1, Clutch Lockout Relay #1

48 CLR2, Clutch Lockout Relay #2

Ambient Sensor -- (Condenser)

Humidity Control Sensor -- (Return Air)

OEM Installed Controls

CR1 & CR2, Clutch Relays

04/08

See Figure 1--9 Sheet 1 -- Electrical Control Board

Figure 1--9 Sheet 2 Legend

1--13

T--304

Page 22

1....K1A = Compressor Clutch -- LiquidLine Solenoid -- Condenser Fans

2....K2A = Heat Valve -- Boost Pump

3....K3A = Evaporator Fans

4....K1M -- K6M = Individual Evaporator Fans (M1M -- M6M)

5....K7M -- K9M = Individual Condenser Fans (M21M -- M26M)

6....Fuse = Boost Pump & Heat Valve

7....F13M -- F18M = Individual Condenser Fans

8....F1M -- F12M = Individual Evaporator Fans

9....U Reg = Evaporator Speed Regulation

10...X1 = Condenser Fans

11...X2 = Evaporator Fans

12...X3 -- X4 (Not Shown On Drawing) = Dash To Unit Interface Plug

+

K1M

K1A

K2A

K3A

+

GND

Relay Board

K2M

K3M

F1M 10A

F2M 10A

F3M 10A

K4M

K5M

F4M 10A

F5M 10A

F6M 10A

F7M 10A

F8M 10A

F9M 10A

F10M 10A

K6M

F11M 10A

F12M 10A

K7M

F13M 15A

X2

K8M

K9M

F14M 15A

F15M 15A

F16M 15A

F17M 15A

F18M 15A

K7M -- K9M

26.38.08.001

Ureg

Part Number

X1

--

Contact arrangement

Connect X1 -- X2

Figure 1--10 AC350 With BT324 Control

T--304

U3

U3A

+

Top View

SUTRAK SCHMATIC #65, 01, 28, 056--01--3

1--14

RELAYS FOR EVAP.MOTORS RELAYS FOR COND. MOTORS

UNIT

K1m -- K4M K7M -- K8M

AC310

K1M -- K6M

AC350

04/08

Page 23

R26 R25

D14

D26

Q2

Q1

U1

Q3

Q4

D15

R27

R30

D18

D30

Q6

Q5

U2

Q7

Q8

D31

D19

R31

D22

D34

Q10

Q9

U3

Q11

Q12

D35

D23

R35

D13

D25

D28D27

D16

R28

R29

D17

D29

D32

D20

R32

R33R34

D21

D33

D36

D24

R36

R37

R38

C1

R40

R41

R42

C2

R43

R44

R45

R46

C3

R47

R48 R72

R61

R62

C13

C12

C14

C15

R63R39

R64

R65

R66

C9

C8

C10

C11

R67

R68

R69

R70

C13

C12

C14

C15

R71

R73

R74

U4

R75

R76

R77

R78

U5

R79

R80

R81

R82

U6

R83

R84

OPENCIRCUIT

DS13

DS14

C16

C17

C18

DS15

DS16

DS17

DS18

DS19

DS20

DS21

DS22

DS23

DS24

R12

D12

R24

MOTORPOWER

DS1

EVAP1

DS2

EVAP2

DS3

EVAP3

DS4

EVAP4

DS5

EVAP5

DS6

EVAP6

DS7

EVAP7

DS8

EVAP8

DS9

COND1

DS10

COND2

DS11

COND3

DS12

COND4

R11

D11

R23

D10

R22

POWER10--30V

POWER

OK

DS25

T25

T26

GROUND

R90

D51

D52

C23

C22

+ +

U8

R9

R8

R10

D9

D8

R21

R20

R19

D7

R7D6R6

R18

R85

R91

F1

D49

D50

R87

R86

C19

C20

R88

C21

R89

U7

R5

R4

R3

R2

D5

D4

R17

D3

R16

R14

R15

R1

D2

D1

R13

CARRIER CRO MOTOR FAULT BOARD

D37

T13

R49

D38

R50

D39

R51

D40

R52

D41

R53

D42

R54

D43

R55

D44

R56

D45

R57

D46

12- -00524--00

R58

D47

R59

D48

R60

MOTOR

T14

MOTOR

T15

MOTOR

T16

MOTOR

T17

MOTOR

T18

MOTOR

T19

MOTOR

T20

MOTOR

T21

MOTOR

T22

MOTOR

T23

MOTOR

T24

MOTOR

RS1

EVAP1

WHT/RED

BREAKER

RS2

EVAP2

BLK/RED

BREAKER

RS3

EVAP3

WHT/YEL

BREAKER

RS4

EVAP4

BLK/YEL

BREAKER

RS5

EVAP5

WHT/ORN

BREAKER

RS6

EVAP6

BLK/ORN

BREAKER

RS7

EVAP7

WHT/GRN

BREAKER

RS8

EVAP8

BLK/GRN

BREAKER

RS9

COND1

GRN/ORN

BREAKER

RS10

COND2

GRN/WHT

BREAKER

RS11

COND3

GRN/BLU

BREAKER

RS12

COND4

BREAKERGRN/YEL

X1--1

T1

X1--2

T2

X1--3

T3

X1--4

T4

X1--5

T5

X1--6

T6

X1--7

T7

X1--8

T8

X3--1

T9

X3--2

T10

X3--3

T11

X3--4

T12

04/08

Figure 1--11 Motor Fault Board (Optional)

1--15

T--304

Page 24

SECTION 2

OPERATION (MANUAL CONTROLLER)

2.1 STARTING, STOPPING AND OPERATING

INSTRUCTIONS

The control switches supplied by Carrier Transport Air

Conditioning will be marked with international symbols

(See Figure 2.1).

Before starting, electrical power must be availablefrom

the bus power supply.

150Amp @12VDC or125Amp @24VDCfroma fusein

the battery compartment supplies power for the clutch,

evaporator and condenser assemblies.

LOW------HIGH

2.1.1 Starting

a. If the engine is not running, start the engine.

b. Actual start sequence depends on the operating co-

trol supplied. If only an ON/OFF switch is supplied,

place the switch in the ON (fan symbol) position to

start the system in the automatic mode.

c. After the pre--trip inspection is completed, the

switches may be set in accordance with the desired

control modes.

d. If low or high speed evaporator fan speed is desired,

press the FAN SPEED (fan symbol) button to bring

speed to the desired level.

2.1.2 Stopping

Placing the ON/OFF (Snowflake) switch in the OFF

position will stop the system operation by removing

power to the Logic Board.

OFF

Figure 2.1 Control Switches (Typical)

2.2 PRE--TRIP INSPECTION

After startingsystem,allow systemtostabilizefor tento

fifteen minutes and check for the following:

ON

HEATCOOL

Temperature Control

a. Listen for abnormal noises in compressoror fan mo-

tors.

b. Check compressor oil level (05G Compressor only).

c. Check refrigerant charge. (Refer to section 5.8.1 )

2--1

T--30404/08

Page 25

2.3 MODES OF OPERATION

2.3.1 Temperature Control

Temperature is controlled by maintaining the return air

temperature measured at the return air grille. To

maintain cooling, turn the temperature control knob

towards the minus (--) symbol. To start heating cycle,

turn the temperature control knob towards the plus (+)

symbol (See Figure 2.1).

2.3.2 Cooling Mode

Cooling isaccomplished byenergizingthecompressor

and condenser fans, opening the liquid line solenoid

valve and closing the heating valve. Once interior

temperature reaches the desired set point, the system

will de--energize the compressor clutch and allow the

system to operate in the vent mode until further cooling

isrequired.Thetemperaturewillbemaintained within2°

C. or 3.6° F.

A controller programed for reheat will mantain

compressor operation and cycle the heat valve to allow

reheating of the return air. In the reheat mode interior

temperature is maintained at the desiredset pointwhile

additional dehumidification takes place.

2.3.3 Heating Mode

In the heat mode the liquid line solenoid is closed and

thecompressorand condenserfansare shutdown.The

heat valve is opened to allow a flow of engine coolant

through the heat section of the evaporator coil. The

evaporator fans speed is variedasrequiredto circulate

air over the evaporator coil based on the temperature

difference from setpoint.

Operating intheheating modeiscontrolled by thewater

temperature switch (WTS). The WTS is located on the

engine blockofthevehicleand is provided bytheOEM.

It senses the engine collant temperature and reverses

its contacts on temperature rise at 105° F. The switch

prevents the circulation of cooler air throughout the

vehicle as the engine comes up to temperature.

2.3.4 Boost Pump (Optional)

Whentheunit is inthe heatmode,andifa boostpumpis

supplied by the coach manufacturer, the boost pump

relay is energized, providing 24 VDC to activate the

boost pump.

2.3.5 Vent Mode

Once the temperature is satisfied, there is a window

whenthe unitwill gointoaventmode.This iswhen there

is neither heating or cooling. Only the evaporator fans

are operating. The range of the V ent mode is 2°C. or

3.6°F. from the set point. The compressor clutch is

disengaged at this time.

2.3.6 Compressor Unloader Control (Only with

05G or 05K Compressors)

When operating in cooling, the unloaders are used to

reduce system capacity as return air temperature

approaches set point. Operation of the unloaders

balances system capacity with the load and thereby

prevents overshoot from set point.

Relay Board mounted unloader outputs control the

capacity of the compressor by energizing or

de--energizing unloader solenoid valves. The model

05Gcompressorhasthree banks oftwocylinders each.

Enercizingavalvede--activates abankofcylinders. The

outboard cylinder banks of the 05G are equipped with

unloader valves (UV1 and UV2), each controlling two

cylinders; this allows the 05G to be operated with two,

four or six cylinders.

The unloaders are used to control system capacity by

controlling compressor capacity.

Control of the unloaders is with the pressure switches.

a. Suction Pressure

The unloaders areusedtocontrolsuction pressure and

thereby prevent coil frosting:

1. Compressor Unloader UV1 Relay

-- When the suction pressure decreases below 26 psig (R--134a),

unloader UV1 is energized, unloading a cylinder

bank (2 cylinders); this output will remain energized

until the pressure increases to above 34 psig

(R--134a).

2. Compressor Unloader UV2 Relay

-- When suction

pressure decreases below 23 psig (R--134a), unloaderUV2is energized, unloadingthe secondcompressor cylinder bank; this output will remain energized until the pressure increases to above 31 psig

(R--134a).

b. Discharge Pressure

Discharge pressure is also controlledbytheunloaders:

1. Compressor Unloader UV1 Relay

-- When the discharge pressure increases above setpoint A (see

Table 2.1), unloader UV1 isenergized;thisunloader

will remain energized until the pressure decreases

below set point B (see Table 2.1).

Table 2.1 Unloader UV1 Relay

HP Switch

(PSIG)

Set Point A

(PSIG)

Set Point B

(PSIG)

300 (R--134a) 275 220

350 (R--134a)

(High Ambient)

325 270

2. Compressor UnloaderUV2Relay -- On R--134asystems when the discharge pressureincreasesabove

setpoint A (see Table 2.2), unloader UV2 is energized; this unloader will remain energized until the

pressure decreases below set point B (see

Table 2.2).

Table 2.2 Unloader UV2 Relay

HP Switch

(PSIG)

Set Point A

(PSIG)

Set Point B

(PSIG)

300 (R--134a) 285 225

350 (R--134a)

(High Ambient)

330 275

2.3.7 Override Mode -- AC310 (Dehumidification)

Wheninthe heatmodethe compressor willnotoperate.

The thermostat will allow only COOL, VENT or HEAT

modes independently. An override switch has been

installedin the return air area toallow the compressors

torunwhen intheHEATmode.Moving the switch tothe

ON position will energize both clutch relays energizing

the clutches. There are two temperature sensors that

are in series with the clutch relay circuit, Ambient

Sensor (mounted in the condenser) and Humidity

Control Sensor (mounted inthereturnair area). As long

as the return air temperature is above 60° F and the

ambient is above 25° F,the override circuit will function

when energized, providing dehumidification. (See

section 1.4 for sensor specs)

T--304 04/08

2--2

Page 26

2.3.8 Evaporator Fan Speed Selection

Evaporator fan speed(s) selection is one method of

controlling the cooling and heating throughout the bus

passenger compartment. The thermostat control is the

other.

2.3.9 Compressor Clutch Control

(A--6, TM--16, TM--21)

A belt driven electric clutch is employed to transmit

engine power to the air conditioning compressor.

De-energizing the clutch’s electric coil disengages the

clutch and removes power from the compressor. The

clutch will be engaged when in cooling and disengaged

whenthesystem is off,inheatingor duringhighand low

pressure conditions.

The clutch coil will be de-energized if the discharge

pressure rises to the 365 ±10 psig (19.42 bar) cutout

setting of the compressor mounted high pressure

switch. The clutch coilwillenergize (AutomaticRe--Set)

when the discharge pressure falls to 280 ± 10 psig

(11.41 bar).

The clutch coilwillbe de-energized (open) if the suction

pressure (LP) decreasesbelow6± 3psig (0.45 bar).

The clutch coil will energize (Automatic Re--Set) when

suction pressure rises (close)to 25 ± 3 psig (1.7 bar).

2.4 SEQUENCE OF OPERATION (280P / 282P)

2.4.1 Electronic Thermostat

With a signalfromtheHydraulicBrakeModule (or other

12 VDC source) the A/C Power Relay is grounded,

sending 12 VDC to the K1A relay. K1A relay energizes

sending battery power (Line B+) to the Dash Control

switches (S1A & S2A).

Begining with the Fan Speed Switch (S1A) in the low

speed position (vent 1)thefollowingactions takeplace:

a. Power flows from the Fan Speed Switch (S1A)

through relay K4A normally closedcontacts. Line U2

energizes evaporator fan motor low speed relays

(K1M, K4M, K7M & K10M). Closing these relays allows power to flow from the battery(line B+) through

the fan motors with two motors in series, operating

the motors at low speed.

b. The ON/OFF switch (S2A) is then placed in the ON

position. Power flows fromtheswitchtoenergizethe

Thermostat. With the Thermostat calling for cooling,

power also flows from the cooling switch:

1. Thorugh theHumidity ControlSensorandtheAmbient Sensor Switches located in the return air and

condenser respectively.If both oftheseswitchesare

in the closed position the following sequence will

take place.

2. Power will flow to the Clutch Lockout Relays (CLR1

& CLR2) allowing power to energize the Clutch Relays (CR1 & CR2). Relays CR1 & CR2 are poweredon terminal 30 from an OEM breaker, (A/C Low

Voltage Breaker). Energizing these relays will send

power through the high and low pressure switches

and to both compressor clutches energizing the

clutch coils and starting the compressor.

3. To the liquid line solenoids (Y1A & Y2A) to start the

flow of refrigerant.

4. Through line U3, to energize the condenser fan relays (K14M & K15M). Energizing these relays will

send B+ power to start the condenser fan motors.

The unit is now in low speed cooling.

5. To bring the evaporator fans to high speed the fan

speed switch (S1A) is placed in the HIGH (Vent 2)

position.Powerflows fromtheswitchthroughlineU5

to energize the high speed relay (K13M). The normally closed low speed relay (K4A) is de--energized

opening the low speed circuit. Power flows fromthe

high speed relay (K13M) to energize thehighspeed

fan relays (K2M, K3M, K5M, K6M, K8M, K9M,

K11M,& K12M). Energizingtheserelays individually

grounds eachevaporator fanmotorseparately placing them in high speed operation.

c. With the thermostat calling for heating, power flows

from the heat switch:

1. Through line UH to energize the heat relay (K3A).

With the heat realy energized, power flows from the

battery (line B+) to start the water pump and open

theheatvalve.The unitisnow intheheat mode. Fan

speeds can be adjusted the same as in the cooling

mode.

d. With the Thermostat calling for Heating and the need

for Dehumidification is required:

1. The override switch, located in the return air inlet is

switched to the ON position.

2. Power will flow through the ambient and humidity

controlswitch,if closed, andenergize thecoolingcircuits at the same time as heating.

This will put the system in a Reheat Mode of operation.

The thermostat willonlycycle the heat valveandpump.

The cooling circuit will stay energized as long as the

override switch is in the ON position and both sensor

switches are closed.

CONTROL ACTION -- CYCLING CLUTCH

RISING

TEMPERATURE

FULLCOOL

+1.8° F ABOVE

SETPOINT

SETPOINT

VENT

SETPOINT

-- 1. 8° F ABOVE

SETPOINT

HEAT

FALLING

TEMPERATURE

Figure 2.2 280P / 282P Thermostat

2--3

T--30404/08

Page 27

SECTION 3

OPERATION BT324 CONTROLLER

3.1 STARTING, STOPPING AND OPERATING

INSTRUCTIONS

The BT324 Carrier Sutrak Digital Display (CSDD) is

marked with international symbols (See Figure 3--2).

Before starting, electrical power must be availablefrom

the bus power supply (See Figure 3--1).

A 150 Amp @12 VDC or a125 Amp @ 24 VDC fuse in

the battery compartment passes power for the clutch,

evaporator and condenser assemblies.

Figure 3--1 Bus Dash With A/C Switch & BT324 CSDD Controller

3.1.1 Starting

a. If the engine is not running, start the engine.

b. When the 12/24VDC power is applied, thedriverdis-

play will illuminate and show return air set point.

Press the A/C key (Item 5 Figure 3--2) on the display

to trigger the start up sequence.

c. After the pre--trip inspection is completed, the

switches may be set in accordance with the desired

control modes.

3.1.2 Stopping

A/C

Toggling the A/C key (Item 5 Figure 3--2)onthedisplay

again will stop the system operation.

3.2 PRE--TRIP INSPECTION

After startingsystem,allow systemtostabilizefor tento

fifteen minutes and check for the following:

a. Listen for abnormal noises in compressoror fan mo-

tors.

b. Check compressor oil level (05G Compressor only).

c. Check refrigerant charge. (Refer to section 5.8.1 )

3--1

T--30404/08

Page 28

1

6

5432

10987

KEYS

Figure 3--2 BT324 CSDD Controller

1. Plus Key

2. Minus Key

3. Recirculate/Fresh Air Key

4. Blower Control Key

5. Automatic Climate Control (A/C)

3.3 SEQUENCE OF OPERATION BT324 CSDD

3.3.1 Function of Keys when “Engine On” and

controller active:

a. Plus Key-- Increasesinteriortemperaturesetpointby

1° per stroke or increases manual blower speed, depending on displayed mode.

b. Minus Key -- Decreasesinteriortemperaturesetpoint

by 1° per stroke or decreases manual blower speed,

depending on displayed mode.

c. Recirculating Air/Fresh Air -- Switches from Recircu-

lating Air to Fresh Air and vice--versa.

d. Blower Control-- Switcheson themanual blowercon-

trol.

e. Automatic Climate Control -- Switches on the Auto-

matic Temperature Control.

f. Temperature Indicator (Key2+Key3)-- Shows the

inside temperature for 10 seconds. If pressed a second time shows the outside temperature for 10 seconds (optional).

g. Reheat (optional) (Key3+Key5)-- Starts Reheat

mode for 3 minutes (duration adjustable).

h. Controller Off (A/C Switch ToOff) -- Switches off all

control functions and the display.

LEDS

6. Display

7. Fresh Air Operation (Green)

8. Manual Blower Control ’ON’ (Green)

9. Heating Mode (Green)

10. Malfunction Light (Red)

NOTE

The following blower steps are disabled when

the automatic climate control is on:

2--, 3--step blower: Off

Continuously adjustable blower: Off

3.3.2 Illuminating Indications (Display)

With “Engine--On” and Controller active

3.4 Operating Instructions BT324

Whentheengine is running, toggletheA/CSwitch to on

to activate the Air Conditioning Unit.

3.4.1 Display

When the unit is ON, the display shows the interior

setpoint temperature. When selecting individual

functions, the display shows the corresponding

information forashort periodoftime. Thedisplayisdark

when the engine and control unit are OFF.

3.4.2 Interior Temperature Control

Press the Plus (1) or Minus (2) keys to set the desired

interior temperature.

Thetemperaturecanbeadjustedbetween 64° F(18° C)

and 82° F(28° C).

When the outside temperatures are below 35° F(2° C)

(adjustable parameter), the cooling function remains

disabled.

3.4.3 Ventilation

When the unitisoperatinginAutomaticClimateControl

mode, theblower speed iscontrolled basedon theroom

temperature.

T--304

3--2

04/08

Page 29

However,theblowers maybeswitched tomanualmode

of operation by pressing the blower key.

Press the Plus orMinuskeys to define oneof 5 different

blower steps. The blowers can not be switched OFF

when Automatic Climate Control is ON.

When Automatic Climate Control is OFF, the blowers

stop when the manual control is turned to zero.

3.4.4 Reheat (optional)

The Reheat modeisused to remove air humidity and to

help defog the windshield. Press Key 3 (Recirculating

Air/FreshAir) and Key 5(Automatic Climate Control) at

the same time to activate Reheat. Heating and cooling

will be energized on for 3 minutes (adjustable

parameter). In addition, the blowers are switched to

maximum speed and the fresh air flap is closed. At the

end of the pre--set duration of time,the functions return

to the previously selected settings.

Reheatmodeisdisabledwiththeoutside temperatureis

below 35° F(2° C) (adjustable parameter), when the

sensor is notinstalled, orwhenthereis a sensorfailure.

3.4.5 Temperature Indication

Presskey2 (minus) and key3(RecirculatingAir/Fresh

Air) at the same time to display the inside temperature

for 10 seconds.

Optionally, the outside temperature may be displayed

when pressing the keys a second time.

A sensor malfunction is displayed by “ i -- -- ” or “ o -- -- ” .

3.5 CHANGING BETWEEN °F (FAHRENHEIT)

AND °C(CELCIUS)

Procedures for changing theBT324Controllerbetween

Fahrenheit and Celcius is as follows:

a. Engine “OFF” & Ignition “ON”.

b. Press Key 1 (plus) and Key 2 (minus) at the same

time until the display shows the word “Code”.

NOTE

After the display shows the word “Code” you

have 5 seconds to enter the correct access

code.

c. Press Key 1 (Plus Key) one time and release.

d. Press Key 3 (Recirculating Air/Fresh Air) one time

and release.

e. Press Key 4 (blower control) one time and release.

The display will show the mode “Fah” for temperatures

in °F or the mode “Cel” for temperatures in °C.

f. Press Key 1 (plus) or Key 2 (minus) to change the

temperature mode.

g. Press Key 5 (automatic climate control) one time to

end the program.

3--3

T--30404/08

Page 30

SECTION 4

TROUBLESHOOTING

Table 4-- 1 General System Troubleshooting Procedures

INDICATION --

TROUBLE

4.1 System Will Not Cool

Compressor will not run Drive--Belt loose or defective

Electrical malfunction Coach power source defective

4.2 System Runs But Has Insufficient Cooling

Compressor Drive-Belt loose or defective

Refrigeration system Abnormal pressures

Restricted air flow No evaporator air flow or restriction 4.5

Heating system Heat valve stuck open 4.7

4.3 Abnormal Pressures

High discharge pressure Refrigerant overcharge

Low discharge pressure Compressor valve(s) worn or broken

High suction pressure Compressor valve(s) worn or broken SeeTable1--3

Low suction pressure Suction service valve partially closed

Suction and discharge pressures

tend to equalize when system is

operating

4.4 Abnormal Noise Or Vibrations

Compressor Loose mounting hardware

Clutch coil defective

Clutch malfunction

Compressor malfunction

Circuit Breaker/safety device open

Compressor valves defective

No or restricted evaporator air flow

Expansion valve malfunction

Restricted refrigerant flow

Low refrigerant charge

Service valves partially closed

Safety device open

Liquid solenoid valve stuck closed

Noncondensable in system

Condenser motor failure

Condenser coil dirty

Low refrigerant charge

Filter-drier inlet valve partially closed

Filter-drier partially plugged

Low refrigerant charge

Expansion valve malfunction

Restricted air flow

Compressor valve defective SeeTable1--3

Worn bearings

Worn or broken valves

Liquid slugging

Insufficient oil

Clutch loose, rubbing or is defective

Drive-Belt cracked, worn or loose

Dirt or debris on fan blades

POSSIBLE CAUSES

REFERENCE

SECTION

Check

Check/Replace

Check/Replace

SeeTable1--3

Check/Repair

Check/Reset

Check

SeeTable1--3

4.3

4.5

4.6

5.11

5.8

Open

1.5

5.13

5.8.1

Check

Check

Clean

SeeTable1--3

5.8

Open

Check/Open

5.11

5.8

4.6

4.5

Check/Tighten

SeeTable1--3

SeeTable 1--3

4.6

1.3

Repair/Replace

Adjust/Replace

Clean

04/08

4--1

T-304

Page 31

Table 4-- 1 General System Troubleshooting Procedures -- Continued

INDICATION --

TROUBLE

POSSIBLE CAUSES

REFERENCE

SECTION

4.4 Abnormal Noise Or Vibrations -- Continued

Condenser or evaporator fans Loose mounting hardware

Defective bearings

Blade interference

Blade missing or broken

Check/Tighten

Replace

Check

Check/Replace

4.5 No Evaporator Air Flow Or Restricted Air Flow

Air flow through coil blocked Coil frosted over

Dirty coil

Dirty filter

No or partial evaporator air flow Motor(s) defective

Motor brushes defective

Evaporator fan loose or defective

Fan damaged

Return air filter dirty

Icing of coil

Fan relay(s) defective

Safety device open

Fan rotation incorrect

Defrost coil

Clean

Clean/Replace

Repair/Replace

Replace

Repair/Replace

Repair/Replace

Clean/Replace

Clean/Defrost

Check/Replace

1.5

Check

4.6 Expansion Valve Malfunction

Low suction pressure with high

superheat

Low superheat and liquid slugging

in the compressor

Low refrigerant charge

Wax, oil or dirt plugging valve orifice

Ice formation at valve seat

Power assembly failure

Loss of bulb charge

Broken capillary tube

Bulb is loose or not installed.

Superheat setting too low

5.8

Check

4.6

Replace

Replace

5.16

5.16

5.16

Ice or other foreign material holding valve open

Side to side temperature difference (Warm Coil)

Wax, oil or dirt plugging valve orifice

Ice formation at valve seat

Power assembly failure

Loss of bulb charge

Broken capillary

Check

5.7

Replace

Replace

5.16

4.7 Heating Malfunction

Insufficient heating Dirty or plugged heater core

Coolant solenoid valve(s) malfunctioning or plugged

Low coolant level

Strainer(s) plugged

Hand valve(s) closed

Water pumps defective

Auxiliary Heater malfunctioning.

No Heating Coolant solenoid valve(s) malfunctioning or plugged

Controller malfunction

Pump(s) malfunctioning

Safety device open

Clean

Check/Replace

Check

Clean

Open

Repair/Replace

Repair/Replace

Check/Replace

Replace

Repair/Replace

1.5

Continuous Heating Coolant solenoid valve stuck open 5.12

T--304

4--2

04/08

Page 32

SECTION 5

SERVICE

WARNING

Besure toobservewarnings listed inthesafetysummaryin thefront ofthis manual beforeperforming maintenance on the hvac system

WARNING

Read the entire procedure before beginning work. Park the coach on a level surface, with parking

brake applied. T urn main electrical disconnect switch to the off position.

NOTE

To avoid damage to the earth’s ozone layer, use a refrigerant recovery system whenever removing refrigerant. The refrigerant recovery system isavailablefromCarrier Transicold (CarrierTransicoldP/NMVSII--115

orMVSII--240).Whenworkingwithrefrigerants youmustcomplywithall localgoverment environmental laws.

5.1 MAINTENANCE SCHEDULE

SYSTEM

ON OFF

a. Daily Maintenance

X

b. Weekly Inspection

X

c. Monthly Inspection and Maintenance

5.2 REMOVING EVAPORATOR COVER

To remove the evaporator cover do the following:

1. Turn all the 1/4 turn cam locks counterclockwise.

2. Using two people carefully grasp the cover under the

bottom edge and lift up.

3. Place the evaporator cover on top of the condenser

section.

5.3 REMOVING CONDENSER COVER

To remove the condenser cover do the following:

1. Turn all the 1/4 turn cam locks counterclockwise.

2. Using two people carefully grasp the cover under the

bottom edge and lift up.

Pre-tripInspection -- after starting

X

Check tension and condition of drive belts.

X

Perform daily inspection

X

Check condenser, evaporator coils and air filters for cleanliness

X

Check refrigerant hoses, fittings and component connections for leaks

Feel filter-drier for excessive temperature drop across drier

X

Perform weekly inspection and maintenance

X

Clean evaporator drain pans and hoses

X

Check wire harnesses for chafing and loose terminals

X

Check fan motor bearings

X

Check compressor mounting bolts for tightness

SYSTEM

REFERENCE

SECTION

2.2

None

See above

None

5.6

5.11

See above

None

Replace/Tighten

None

None

3. Place the condenser cover on top of the evaporator

section.

5.4 INSTALLING MANIFOLD GAUGE SET

A manifold gauge set can be used to determine system

operating pressures, add charge, equalize or evacuate

system.

When the suction pressure hand valve is frontseated

(turned alltheway in),thesuction(low) pressure can be

read. When the discharge pressure hand valve is

frontseated, discharge (high) pressure can be read.

When both valves are open (turnedcounterclockwise),

high pressure vapor will flow into the low side. When

only the low pressure valve is open, the system can be

charged or evacuated.

04/08

5--1

T-304

Page 33

CAUTION

The AC310 & AC350 Rooftop Systemshave

R134a service port couplings installed on

the compressor and 1/4 inch flare (Acme)

fittings installed on the unit piping.

SUCTION

PRESSURE

GAUGE