Deluxe 4-Way Multipoise Variable-Capacity

Direct-Vent Condensing Gas Furnace

Visit www.carrier.com

Service and Maintenance Instructions

For Sizes 040–120, Series 140 and 150

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

• • • • • • • • • • • • • • •

ULTRA HIGH EFFICIENCY

GAS FURNANCE

58MVP

®

A93040

TABLE OF CONTENTS

SAFETY CONSIDERATIONS.....................................................1

Introduction ....................................................................................2

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS........2

CARE AND MAINTENANCE.....................................................2

Cleaning and/or Replacing Air Filter.......................................3

Blower Motor and Wheel Maintenance...................................3

Cleaning Burners ......................................................................4

Cleaning Heat Exchangers........................................................5

Flushing Collector Box and Drainage

System ............................................................................................7

Servicing Hot Surface Ignitor ..................................................7

Electrical Controls and Wiring.................................................8

Checking Heat Tape Operation

(If Applicable)................................................................................8

Winterizing................................................................................9

WIRING DIAGRAMS.................................................................10

TROUBLESHOOTING ...............................................................10

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety

precautions that may apply.

Follow all safety codes. In the United States, follow all safety

codes including the National Fuel Gas Code (NFGC) NFPA

54-1999/ANSI Z223.1-1999 and the Installation Standards, Warm

A92496

Fig. 1—Multipoise Furnace in Upflow Orientation

EFFICIENCY

RATING

CERTIFIED

r

o

p

C

o

r

r

e

i

r

r

a

C

R

E

G

I

S

I

T

S

O

9

0

REGISTERED QUALITY SYSTEM

Air Heating and Air Conditioning Systems (NFPA 90B)

ANSI/NFPA 90B. In Canada, refer to the CAN/CGA-B/49.1- and

.2-M95 National Standard of Canada, Natural Gas and Propane

a

t

i

o

n

CERTIFIED

®

E

R

0

1

M

R

I

F

D

E

3

8

8

2

A

#

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 6a 8a

PC 101 Catalog No. 535-795 Printed in U.S.A. Form 58MVP–9SM Pg 1 10-00 Replaces: 58MVP-7SM

Installation Codes (NSCNGPIC). Wear safety glasses and work

gloves. Have a fire extinguisher available during start-up and

adjustment procedures and service calls.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

The ability to properly perform maintenance on this equipment requires certain expertise, mechanical skills, tools, and

equipment. If you do not possess these, do not attempt to

perform any maintenance on this equipment other than those

procedures recommended in the User’s Manual. FAILURE

TO FOLLOW THIS WARNING COULD RESULT IN

POSSIBLE DAMAGE TO THIS EQUIPMENT, SERIOUS

PERSONAL INJURY, OR DEATH.

Never store anything on, near, or in contact with the furnace,

such as:

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum

cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning compounds, plastic or plastic containers, gasoline, kerosene,

cigarette lighter fluid, dry cleaning fluids, or other volatile

fluids.

3. Paint thinners and other painting compounds, paper bags,

or other paper products.

Failure to follow this warning can cause corrosion of the

heat exchanger, fire, personal injury, or death.

INTRODUCTION

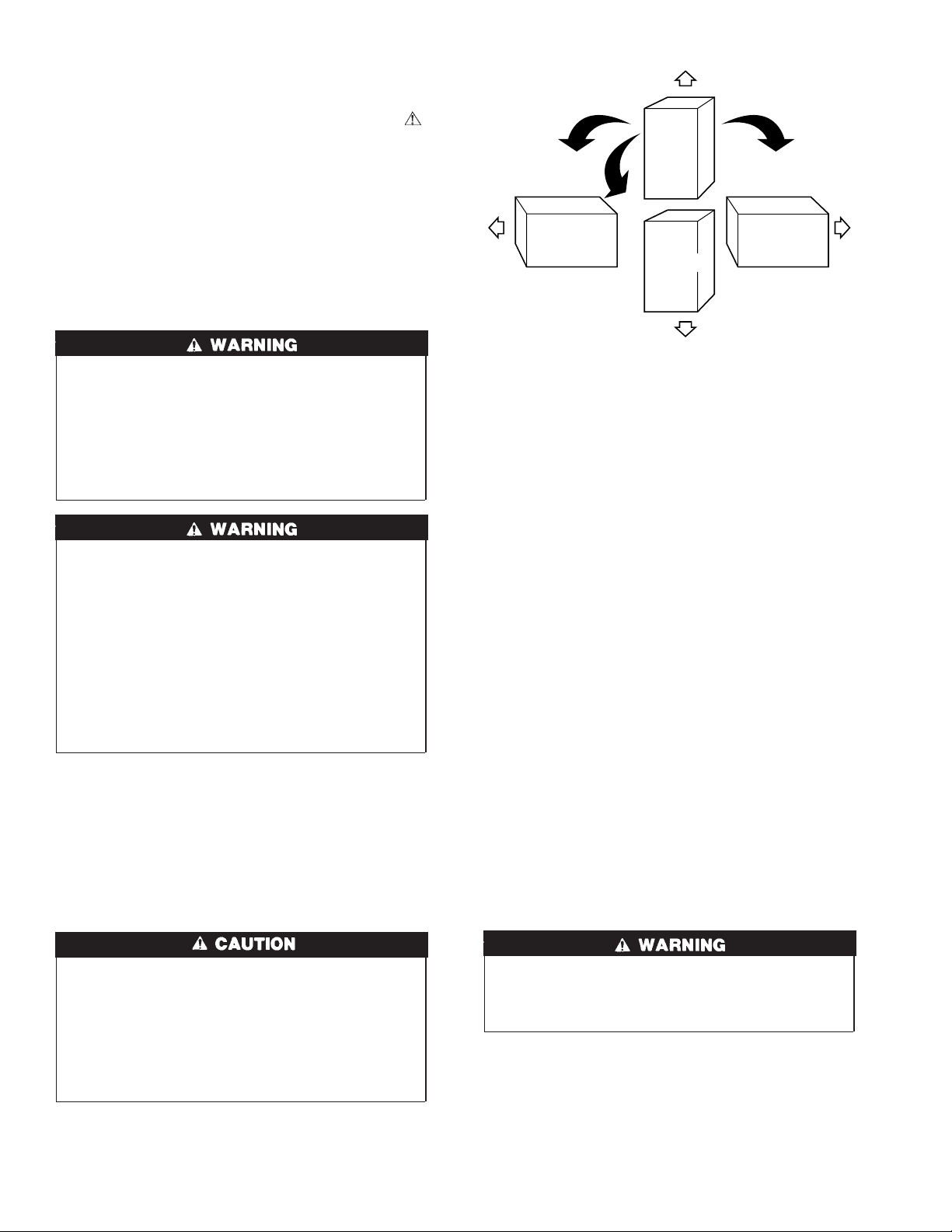

These instructions are written as if the furnace is installed in an

upflow application. An upflow furnace application is where the

blower is located below the combustion and controls section of the

furnace, and conditioned air is discharged upward. Since this

furnace can be installed in any of the 4 positions shown in Fig. 2,

you may need to revise your orientation to component location

accordingly.

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

AIRFLOW

.

UPFLOW

AIRFLOW

HORIZONTAL

LEFT

DOWNFLOW

AIRFLOW

HORIZONTAL

RIGHT

AIRFLOW

A93041

Fig. 2—Multipoise Orientation

2. Firmly touch a clean, unpainted, metal surface of the furnace

chassis which is close to the control. Tools held in a person’s

hand during grounding will be satisfactorily discharged.

3. After touching the chassis you may proceed to service the

control or connecting wires as long as you do nothing that

recharges your body with static electricity (for example; DO

NOT move or shuffle your feet, DO NOT touch ungrounded

objects, etc.).

4. If you touch ungrounded objects (recharge your body with

static electricity), firmly touch furnace again before touching

control or wires.

5. Use this procedure for installed and uninstalled (ungrounded)

furnaces.

6. Before removing a new control from its container, discharge

your body’s electrostatic charge to ground to protect the

control from damage. If the control is to be installed in a

furnace, follow items 1 through 5 before bringing the control

or yourself into contact with the furnace. Put all used AND

new controls into containers before touching ungrounded

objects.

7. An ESD service kit (available from commercial sources) may

also be used to prevent ESD damage.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equipment failure, it is essential that maintenance be performed annually

on this equipment. Consult your local dealer for maintenance and

maintenance contract availability.

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing to

protect the furnace electronic control. Precautions will prevent electrostatic discharges from personnel and hand tools

which are held during the procedure. These precautions will

help to avoid exposing the control to electrostatic discharge

by putting the furnace, the control, and the person at the same

electrostatic potential.

1. Disconnect all power to the furnace. DO NOT TOUCH THE

CONTROL OR ANY WIRE CONNECTED TO THE CONTROL PRIOR TO DISCHARGING YOUR BODY’S ELECTROSTATIC CHARGE TO GROUND.

Turn off the gas and electrical supplies to the unit before

performing any maintenance or service. Follow the operating

instructions on the label attached to the furnace. Failure to

follow this warning could result in personal injury or death.

The minimum maintenance that should be performed on this

equipment is as follows:

1. Check and clean or replace air filter each month as required.

2. Check blower motor and wheel for cleanliness annually.

3. Check electrical connections for tightness and controls for

proper operation each heating season. Service as necessary.

4. Check for proper condensate drainage. Clean as necessary.

2

5. Check for blockages in combustion-air and vent pipes annually.

6. Check burners for cleanliness annually.

Personal injury could result from sharp metal edges, etc. Use

care when removing parts.

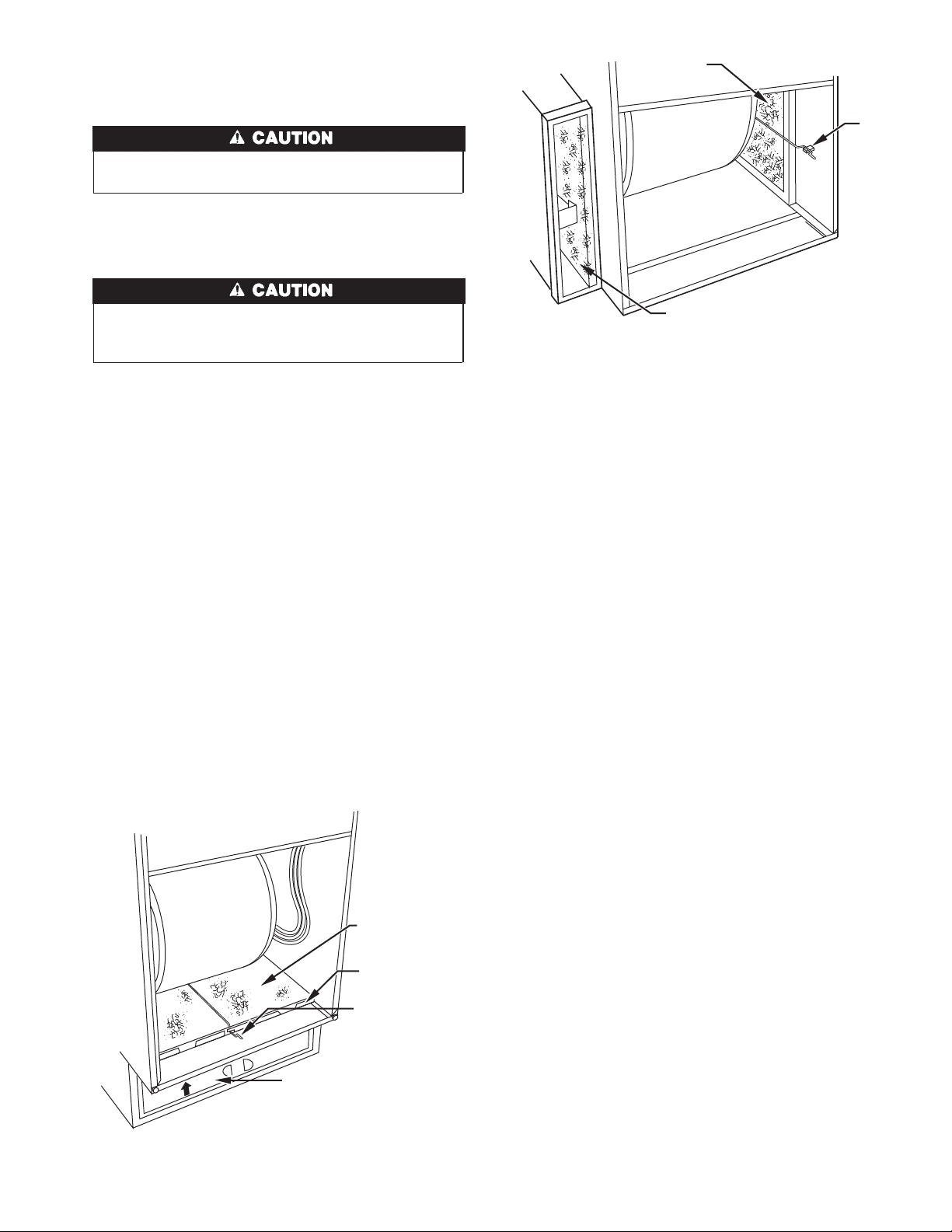

Step 1—Cleaning and/or Replacing Air Filter

The air filter arrangement may vary depending on the application

or orientation.

WASHABLE

FILTER

IN FURNACE

FILTER

RETAINER

Never operate unit without a filter or with the blower access

panel removed. Failure to follow this warning could result in

a fire or personal injury.

NOTE: If the filter has an airflow direction arrow, the arrow must

point toward the blower.

To clean or replace filters, proceed as follows:

→

If filter is installed in filter cabinet adjacent to furnace:

1. Turn off electrical supply to furnace.

2. Remove filter cabinet door.

3. Slide filter out of cabinet.

4. If equipped with permanent, washable filter, clean filter by

spraying cold tap water through filter in opposite direction of

airflow. Rinse filter and let dry. Oiling or coating of the filter

is not recommended.

5. If equipped with factory specified disposable media filter,

replace only with media filter having the same part number

and size.

6. Slide filter into cabinet.

7. Replace filter cabinet door.

8. Turn on electrical supply to furnace.

If filter is installed in furnace blower compartment:

1. Turn off electrical supply to furnace.

2. Remove main furnace door and blower access panel.

3. Release filter retainer wire. (See Figs. 3 and 4.)

WASHABLE

FILTER

FILTER

SUPPORT

FILTER

RETAINER

WASHABLE FILTER OR

DISPOSABLE MEDIA FILTER

IN FILTER CABINET

Fig. 3—Bottom Filter Arrangement

A00232

WASHABLE FILTER OR

DISPOSABLE MEDIA

FILTER IN FILTER CABINET

A00233

Fig. 4—Filter Installed for Side Inlet

4. Slide filter out of furnace.

5. Furnaces are equipped with permanent, washable filter(s).

Clean filter by spraying cold tap water through filter in

opposite direction of airflow.

6. Rinse filter and let dry. Oiling or coating filter is not

recommended.

7. Slide filter into furnace.

8. Recapture filter retaining wire.

9. Replace blower access panel and main furnace door.

10. Turn on electrical supply to furnace.

Step 2—Blower Motor and Wheel Maintenance

To ensure long life, economy, and high efficiency, clean accumulated dirt and grease from blower wheel and motor annually.

The inducer and blower motors are pre-lubricated and require no

additional lubrication. These motors can be identified by the

absence of oil ports on each end of the motor.

The following items should be performed by a qualified service

technician.

Clean blower motor and wheel as follows:

1. Turn off electrical supply to furnace.

2. Remove main furnace door and blower access panel.

3. Disconnect wires

a. Disconnect motor wiring harness plug on blower housing.

b. Disconnect auxiliary limit switch leads at switch.

c. Disconnect field thermostat connections depending on their

length and routing.

4. Position control box, transformer, and door switch assembly to

right side of furnace casing.

5. If condensate trap is located in left- or right-hand side of

furnace casing, proceed to item 6. Otherwise remove trap and

tubing as described below:

a. Disconnect field drain connection from condensate trap.

b. Disconnect drain and relief port tubes from condensate

trap.

c. Remove condensate trap from blower shelf.

6. Remove screws securing blower assembly to blower shelf and

slide blower assembly out of furnace.

3

7. Clean blower wheel and motor by using a vacuum with soft

brush attachment. Be careful not to disturb balance weights

(clips) on blower wheel vanes. Do not bend wheel or blades as

balance will be affected.

8. If greasy residue is present on blower wheel, remove wheel

from the blower housing and wash it with an appropriate

degreaser. To remove wheel:

a. Mark blower wheel location on shaft before disassembly to

ensure proper reassembly.

b. Loosen setscrew holding blower wheel on motor shaft.

NOTE: Mark blower mounting arms and blower housing so each

arm is positioned at the same hole location during reassembly.

c. Mark blower wheel orientation and cutoff plate location to

ensure proper reassembly.

d. Remove screws securing cutoff plate and remove cutoff

plate from housing.

e. Remove bolts holding motor mounts to blower housing and

slide motor and mounts out of housing.

f. Remove blower wheel from housing.

g. Clean wheel per instructions on degreaser cleaner.

9. Reassemble motor and blower wheel by reversing items 8b

through 8f. Ensure wheel is positioned for proper rotation. Be

sure to attach ground wire.

10. Reinstall blower assembly in furnace.

11. Reinstall condensate trap and tubing if previously removed.

a. Reinstall condensate trap in hole in blower shelf.

b. Connect condensate trap drain tubes. See Fig. 8 or tubing

diagram on main furnace door for proper tube location.

(1.) Connect 1 tube (blue or blue and white striped) from

collector box.

(2.) Connect 1 tube (violet or unmarked) from inducer

housing.

(3.) Connect 1 tube (relief port, green or pink) from

collector box.

c. Connect field drain to condensate trap.

NOTE: Ensure tubes are not kinked or pinched, as this will affect

operation.

12. Reinstall control box, transformer, and door switch assembly

on blower shelf.

13. Reconnect wires.

a. Refer to furnace wiring diagram and connect motor and

auxiliary limit switch leads. (See Fig. 16.)

b. Connect thermostat leads if previously disconnected.

14. Turn on electrical supply. Manually close blower access panel

door switch. Use a piece of tape to hold switch closed. Check

for proper rotation and speed changes between heating and

cooling by jumpering R to G and R to Y on control center

thermostat terminals. (See Fig. 11.)

Blower access panel door switch opens 115-v power to

control center. No component operation can occur. Caution

must be taken when manually closing this switch for service

purposes. Failure to follow this warning could result in

personal injury or death.

15. If furnace is operating properly, release blower access panel

door switch, replace blower access panel, and replace main

furnace door.

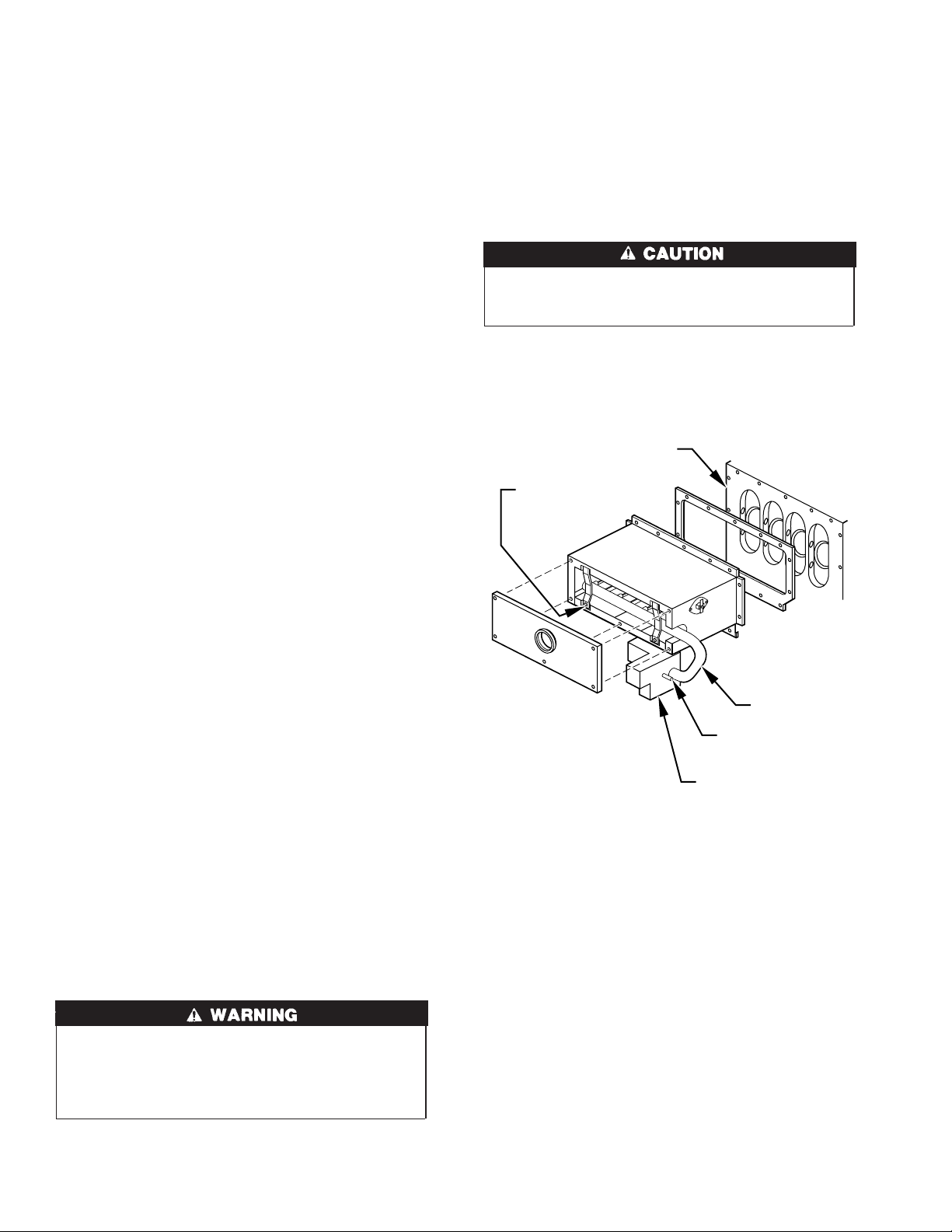

Step 3—Cleaning Burners

The following items should be performed by a qualified service

technician. If the burners develop an accumulation of light dirt or

dust, they may be cleaned by using the following procedure:

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Remove burner box cover.

4. Using backup wrench, disconnect gas supply pipe from gas

valve.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous

operation.

5. Remove wires from gas valve. Note location for reassembly.

6. Remove burner box pressure tube from gas valve regulator

fitting.

7. Remove screws that secure manifold to burner box. (See Fig.

5.)

CELL

PANEL

MANIFOLD

MOUNTING

SCREW

MANIFOLD

GAS VALVE

REGULATOR

FITTING

GAS VALVE

A96304

Fig. 5—Burner Box Assembly

8. Remove manifold, orifices, and gas valve as 1 assembly.

9. Remove screws attaching burner assembly in burner box.

10. Remove burner assembly from burner box.

NOTE: All burners are attached to burner bracket and can be

removed as 1 assembly.

11. Clean burners with soft brush and vacuum.

12. Reinstall manifold, orifice, and gas valve assembly in burner

box. Ensure manifold seal grommet is installed properly and

burners fit over orifices.

13. Reconnect wires to gas valve. Refer to furnace wiring diagram

for proper wire location.

14. Reinstall burner box pressure tube to gas valve regulator

fitting.

15. Reinstall gas supply pipe to gas valve using backup wrench on

gas valve to prevent rotation and improper orientation.

NOTE: Use propane gas resistant pipe dope to prevent gas leaks.

DO NOT use Teflon tape.

4

Gas valve switch or knob MUST be facing forward or tilted

upward. Failure to follow this warning could result in

property damage, personal injury, or death.

16. Replace burner box cover.

17. Turn on gas and electrical supplies to furnace.

18. Check for gas leaks.

Never use matches, candles, flame, or other sources of

ignition to check for gas leakage. Use a soap-and-water

solution. Failure to follow this warning could result in a fire,

personal injury, or death.

19. Replace main furnace door.

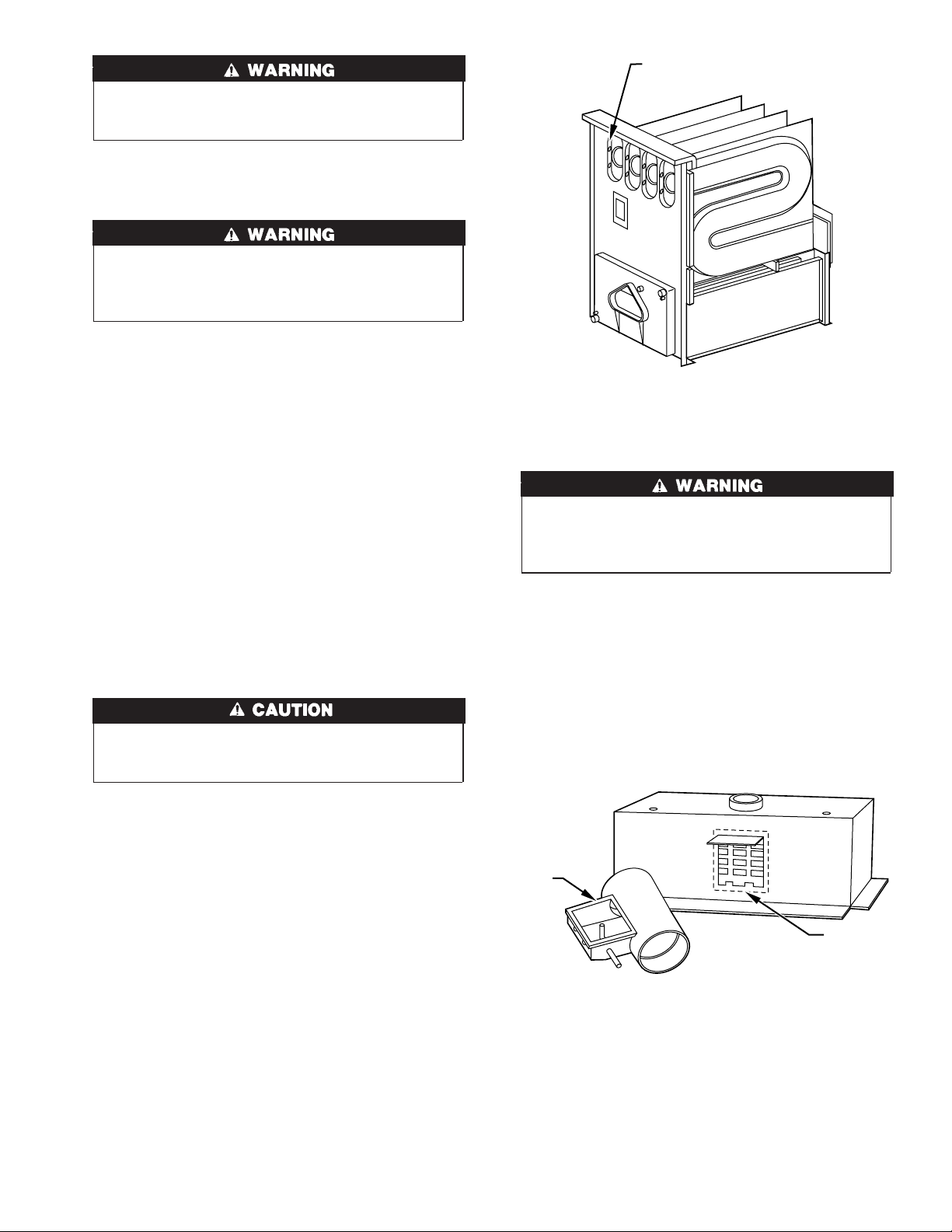

Step 4—Cleaning Heat Exchangers

The following items should be performed by a qualified service

technician.

PRIMARY HEAT EXCHANGERS

If the heat exchangers get an accumulation of light dirt or dust on

the inside, they may be cleaned by the following procedure:

NOTE: If the heat exchangers get a heavy accumulation of soot

and carbon, both the primary and secondary heat exchangers

should be replaced rather than trying to clean them thoroughly due

to their intricate design. A build-up of soot and carbon indicates

that a problem exists which needs to be corrected, such as

improper adjustment of manifold pressure, insufficient or poor

quality combustion air, improper vent termination, incorrect size

or damaged manifold orifice(s), improper gas, or a restricted heat

exchanger (primary or secondary). Action must be taken to correct

the problem.

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and hazardous operation.

PRIMARY HX

INLET OPENINGS

A96305

Fig. 6—Cleaning Inlet Openings of Primary Heat

Exchangers

12. Reverse items 4 through 10 for reassembly.

The ground wire from the gas valve MUST be attached to the

burner box attachment screw. Failure to attach this ground

wire to an adequate casing ground will cause the furnace

control to lock out.

NOTE: Be sure burner box gasket is installed between burner box

and cell panel. If gasket is damaged, replace it.

NOTE: Inspect combustion-air intake housing. If foamed gasket

was removed, check for any damage. If gasket is damaged in any

way, it must be repaired. To repair, remove damaged gasket

section, apply sealant releasing agent such as PAM cooking spray

or equivalent (must not contain corn or canola oil, aromatic or

halogenated hydrocarbons or inadequate seal may occur) to burner

box and apply a small bead of G.E. RTV 162, G.E. RTV 6702, or

Dow-Corning RTV 738 sealant to edge of combustion-air intake

housing. (See Fig. 7.)

3. Disconnect wires or connectors to rollout switch, gas valve,

ignitor, and flame sensor.

4. Disconnect combustion-air intake pipe from intake housing.

5. Remove the pressure switch tube from intake housing.

6. Remove screws attaching intake housing to burner box, and

rotate intake housing away from burner box for removal.

7. Using backup wrench, disconnect gas supply pipe from gas

valve.

8. Disconnect pressure tubing from gas valve.

9. Remove 2 screws attaching top filler panel and rotate upwards

to gain access to screws attaching burner box to cell panel.

10. Remove screws attaching burner box to cell panel. (See Fig.

5.)

NOTE: Burner box cover, manifold, gas valve, and burner

assembly should be removed as 1 assembly.

11. Clean heat exchanger openings with a vacuum and a soft

brush. (See Fig. 6.)

NOTE: After cleaning, inspect the heat exchangers to ensure they

are free of all foreign objects that may restrict flow of combustion

products.

RTV

PAM

A93087

Fig. 7—Combustion-Air Intake Housing Gasket

Repair

13. Refer to furnace wiring diagram and reconnect wires to rollout

switch, gas valve, ignitor, and flame sensor.

14. Reconnect pressure switch tubes to gas valve and intake

housing. Refer to tube routing label on main furnace door for

proper tube location. (See Fig. 8.) Be sure tubes are not

kinked.

15. Turn on gas and electrical supplies to furnace.

5

Furnace is shipped from factory in upflow configuration. Pressure tube and drain tube routing MUST match the diagrams below.

Condensate Trap; Factory Installed

in Blower Shelf

Tube location when used in UPFLOW application

(Blower access panel removed)

COLLECTOR BOX TUBE

(PINK)

COLLECTOR BO X TU BE (GREE N)

INDUCER HOUSING (MOLDED) DRAIN TUBE

(BEHIND COLLECTOR BOX DRAIN TUBE)

COLLECTOR BOX DRAIN TUBE

(BLUE)

FIELD-INSTALLED

FACTORY-SUPPLIED DR AIN TUB E

COUPLING (LEFT DRAIN OPTION)

FIELD-INSTALLED FACTORY-

SUPPLIED DRAIN TUBE

Condensate Trap on

LEFT Side

CAP

COLLECTOR B O X TUBE (GREEN)

COLLECTOR BOX DRAIN TUBE

(BLUE & WHITE STRIPED)

COLLECTOR BOX

EXTENSION TUBE

CONDENSATE TRAP

BURNER E NCLOSURE PR ES SURE

REFERENCE TUBE ASSEMBLY

INDUCER HOUSING DRAIN TUBE (VIOLET)

Tube locatio n when used in DOWNFLOW ap plicatio n

Tube location when used on

HORIZONTAL - LEFT a pplication

PLUG

CAP

BURNER

ENCLOSURE

PRESSURE

REFERENCE TUBE

ASSEMBLY

COLLECTOR BOX

EXTENSION TUBE

CONDENSATE TRAP

COLLECTOR BOX EXTENSION DRAIN TUBE

COLLECTOR B OX TU BE (PINK) RELOCA TE TUB E BETW EE N BLOWER SHELF AND

INDUCER HOUSING FOR 040,060, AND 080 HEA TING INP UT FURNACES

NOTE:

1. All tubing must be connected securely and routed to avoid kinks and traps.

2. Pressure tubing must always slope away from pressure switch to collector box connection as shown.

3. HORIZONT AL-LEFT installations require the collector box pressure tube to be relocated between the inducer housing and

the blower shelf to prevent a trap.Refer to the Installation Instructions for further details.

DRAIN TUBE

COUPLING

TUBE ROUTING

BURNER E NCLOSURE PR ES SURE

REFERENCE TUBE ASSEM BLY

CAP

PLUG

COLLECTOR BOX

DRAIN TUBE

(BLUE & WHITE STRIPED)

CONDENSATE TRAP

FIELD-INSTALLED

FACTORY-SUPPLIED DRAIN

TUBE COUPLING (RIGHT

DRAIN OPTION)

FIELD-INSTALLED

FACTORY-SUPPLIED

1/2-IN. CPVC STREET

ELBOWS (2) FOR LEFT

DRAIN OPTION

COLLECTOR BOX DRAIN TUBE

(BLUE)

COLLECTOR BOX

EXTENSION TUBE

PLUG

COLLECTOR BOX TU BE

(PINK)

COLLECTOR BO X DR AIN TUBE

(BLUE & WHITE STRIPED)

COLLECTOR

BOX TUBE

(GREEN)

INDUCER HOUSING

DRAIN TUBE

(VIOLET)

COLLECTOR BOX

DRAIN TUBE (BLUE)

COLLECTOR BO X TU BE

(PINK)

COLLECTOR BOX TU BE

(GREEN)

COLLECTOR BOX DRAIN TUBE

(BLUE)

CONDENSA T E T R AP

INDUCER HOUSING

DRAIN TUBE

(VIOLET)

COLLECTOR BOX TUBE

(GREEN)

BURNER ENCLOSURE

PRESSURE REFERENCE

TUBE ASSEMBLY

COLLECTOR BOX DRAIN TUBE

(BLUE & WHITE STRIPED)

INDUCER HOUSING

DRAIN TUBE

(VIOLET)

DRAIN TUBE

COUPLING

DRAIN TUBES ROUTED IN

FRONT OF GAS VALVE

Tube location when used on

HORIZONTAL - RIGHT application

COLLECTOR BOX DRAIN TUBE (BLUE)

PLUG

CAP

COLLECTOR BO X TU BE (GREE N)

COLLECTOR BOX DRAIN TUBE

(BLUE AND WHITE STRIPED)

Condensate Trap on LEFT

COLLECTOR BOX DRAIN TUBE

PLUG

COLLECTOR BOX EXTENSION TUBE

CONDENSATE TRAP

GAS VALVE

CO LLECTOR BOX TUBE (PINK)

INDUCER HOUSING DRAIN TUBE (VIOLET)

Side Optional

BURNER ENCLOSURE PRESSURE

REFERENCE TUBE ASSEMBLY

CAP

PLUG

COLLECTOR BOX

DRAIN TUBE

(BLUE & WHITE STRIPED)

Condensate Trap on

RIGHT Side

CAP

(BLUE)

COLLECTOR BOX TUBE

(PINK)

COLLECTOR BOX EXTENSION

DRAIN TUBE

AUXILIARY "J" BOX

RELOCATED HERE

BURNER

ENCLOSURE

PRESSURE

REFERENCE

TUBE ASSEMBLY

COLLECTOR BO X

EXTENSION TUBE

CONDENSATE TRAP

325400-201 REV. C

(LIT - BOTTOM)

Fig. 8—Furnace Pressure and Drain Tubing Diagram

16. Check furnace operation through 2 complete heat operating

cycles. Look through sight glass in burner enclosure to check

burners. Burner flames should be clear blue, almost transparent. (See Fig. 9.)

17. Check for gas leaks.

A00351

Never use matches, candles, flame, or other sources of

ignition to check for gas leakage. Use a soap-and-water

solution. Failure to follow this warning could result in a fire,

personal injury, or death.

18. Replace main furnace door.

SECONDARY HEAT EXCHANGERS

NOTE: The condensing side (inside) of the secondary heat

exchangers CANNOT be serviced or inspected. A small number of

bottom outlet openings can be inspected by removing the inducer

6

BURNER FLAME

MANIFOLD

Fig. 9—Burner Flame

RTV

PAM

BURNER

A89020

NOTE: Ensure the drain tube disconnected from the inducer

housing is higher than the collector box opening or water will flow

out tube.

9. Inspect inside area of collector box for any pieces of foreign

materials and remove if present.

DO NOT use wire brush or other sharp object to inspect or

dislodge materials in secondary heat exchangers as failure of

the secondary heat exchanger will occur. Flush with water

only.

10. Reassemble inducer assembly by reversing items 5-7. Tighten

the vent coupling clamp screw(s) to 15 in.-lb of torque.

NOTE: If seal between the inducer housing and the collector box

is damaged in any way, it must be repaired. To repair, apply

sealant releasing agent such as PAM cooking spray or equivalent

(must not contain corn or canola oil, aromatic or halogenated

hydrocarbons or inadequate seal may occur) to inducer housing.

(See Fig. 10.) Apply a small bead of G.E. RTV 162, G.E. RTV

6702, or Dow-Corning RTV 738 sealant to groove in collector

box.

11. Refer to furnace wiring diagram and reconnect wires to

inducer motor and pressure switches or connectors.

12. Reconnect pressure tubes to pressure switches. See diagram

on main furnace door for proper location of tubes. Be sure

tubes are not kinked. (See Fig. 8.)

13. Turn on gas and electrical supplies to furnace.

14. Check furnace operation through 2 complete heat operating

cycles. Check area below inducer housing, vent pipe, and

condensate trap to ensure no condensate leaks occur. If leaks

are found, correct the problem.

15. Check for gas leaks.

A93081

Fig. 10—Gasket on Collector Box

assembly. See Flushing Collector Box and Drainage System

section for details on removing inducer assembly.

Step 5—Flushing Collector Box and Drainage

System

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect inducer motor and pressure switch wires or

connectors.

4. Disconnect pressure switch tubes.

5. Disconnect vent pipe from inducer housing outlet by loosening coupling clamp on inducer outlet.

6. Disconnect drain tube from inducer housing. (See Fig. 8.)

7. Remove inducer housing assembly by removing 4 bolts

attaching assembly to cell panel.

8. Flush inside of collector box with water until discharge from

condensate trap is clean and runs freely.

Never use matches, candles, flame, or other sources of

ignition to check for gas leakage. Use a soap-and-water

solution. Failure to follow this warning could result in a fire,

personal injury, or death.

16. Replace main furnace door.

Step 6—Servicing Hot Surface Ignitor

The ignitor does NOT require annual inspection. Check ignitor

resistance before removal.

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect ignitor wire connection.

4. Check ignitor resistance.

a. Using an ohm meter, check resistance across both ignitor

leads in connector.

b. Cold reading should be between 45 ohms and 90 ohms.

c. If ohm reading is higher than 110 ohms, ignitor is cracked

and must be replaced.

5. Remove ignitor assembly.

Allow ignitor to cool before removal. Normal operation

temperatures exceed 2000°F.

a. Do not remove ignitor from bracket while assembly is in

furnace. Using a 1/4 in. nutdriver, remove screw securing

7

bracket and ignitor assembly to bottom of burner box. The

screw in the bracket is always located toward outside of

burner box. The screw may be hidden by inlet box or inlet

pipe, but can be removed without removing either. After

removing screw, slide ignitor and bracket toward outside of

burner box and pull straight out.

The ignitor is fragile. DO NOT allow it to hit the side of the

burner box opening while removing or replacing it.

b. Inspect ignitor for a white area indicating a crack may be

present. If found, replace ignitor.

NOTE: A small crack cannot be seen on a new ignitor. After a

period of operation, a white area will be visible around the crack.

c. If replacement is required, replace ignitor on ignitor bracket

external to furnace to avoid damage as the silicon portion is

very brittle and will easily crack or shatter.

d. To remove ignitor from ignitor bracket, remove screw

holding ignitor ceramic block to bracket and pull ceramic

block out of bracket.

6. To replace ignitor/ignitor assembly, reverse items 5a through

5d.

7. Reconnect ignitor wire connection.

8. Turn on gas and electrical supplies to furnace.

9. Verify ignitor operation by initiating control board self-test

feature or by cycling thermostat.

10. Replace main furnace door.

Step 7—Electrical Controls and Wiring

There may be more than 1 electrical supply to the unit. Check

accessories and cooling unit for additional electrical supplies.

The electrical ground and polarity for 115-v wiring must be

maintained properly. Refer to Fig. 11 for field wiring information

and to Fig. 15 for unit wiring information.

NOTE: If the polarity is not correct, the STATUS LED on the

control center will flash rapidly and prevent the furnace from

operating. The control system also requires an earth ground for

proper operation of the control center and flame sensing.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on the control center. (See Fig. 12.) Any direct shorts of the 24-v

wiring during installation, service, or maintenance will cause this

fuse to blow. If fuse replacement is required, use ONLY a fuse of

identical size.

With power to the unit disconnected, check all electrical connections for tightness. Tighten all screws on electrical connections. If

any smoky or burned connections are found, disassemble the

connection, clean all parts, strip wire, and reassemble properly and

securely.

Reconnect electrical supply to unit and observe unit through 1

complete operating cycle. Electrical controls are difficult to check

without proper instrumentation; if there are any discrepancies in

the operating cycle, contact your dealer and request service.

115-V

SINGLE

PHASE

115-V

FIELD-SUPPLIED

DISCONNECT

SWITCH

FURNACE

CONTROL

CENTER

WIRE

THREE-WIRE

HEATING

ONLY

AUXILIARY

J-BOX

FIVE

NOTE 5

W/W1

W2

R

G

C

Y/Y2

24-V

TERMINAL

BLOCK

Step 8—Checking Heat Tape Operation

(If Applicable)

In applications where the ambient temperature around the furnace

is 32°F or lower, freeze protection measures are required. If this

application is where heat tape has been applied, check to ensure it

will operate when low temperatures are present.

WCR GY

NOTE

3

NOTE 1

TWO WIRE

NOTES:

1.

Connect Y or Y/Y2 terminal as shown for proper cooling operation.

2.

Proper polarity must be maintained for 115-v wiring.

3.

Use W2 with 2-stage thermostat when zoning.

4.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

5.

Some thermostats require a "C" terminal connection as shown.

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-, 208/230-, 460-V WIRING

THERMOSTAT

TERMINALS

GND

GND

CONDENSING

UNIT

FIELD-SUPPLIED

DISCONNECT

208/230- OR

460-V

THREE PHASE

GND

208/230-V

SINGLE

PHASE

GND

Fig. 11—Field Wiring

8

A98325

EAC-ELECTRONIC AIR

CLEANER TERMINALS

(115-VAC 1 AMP MAX)

MAIN BLOWER

CONTROL WIRE

CONNECTOR

CONTINUOUS

FAN (CF) SETUP

SWITCHES

HOT SURFACE

IGNITOR CONNECTOR

115-V

CONNECTORS

HUM

RG

24-V THERMOST AT

TERMINALS

W/W1 Y/Y2

24V

COM

TRANSFORMER

24-V CONNECTORS

COMMUNICATION

CONNECTOR

W2

Fig. 12— Variable-Capacity Control Center

PRESSURE SWITCH

CONNECTOR

HUM-HUMIDIFIER

TERMINAL

(24-VAC 0.5 AMP MAX)

DEHUMIDIFY ENABLE (DE)

DEHUMIDIFIER (DEHUM)

CONNECTOR

3-AMP FUSE

STATUS AND DIAGNOSTIC

LED LIGHTS

AIR CONDITIONING

(A/C) SETUP SWITCH

SETUP SWITCHES

(SW) AND BLOWER

OFF DELAY SETUP

SWITCHES

MODEL PLUG

A99097

NOTE: Heat tape, when used, should be wrapped around the

condensate drain trap and drain line. There is no need to use heat

tape within the furnace casing. Most heat tapes are temperature

activated, and it is not practical to verify the actual heating of the

tape. Check the following:

1. Check for signs of physical damage to heat tape such as nicks,

cuts, abrasions, gnawing by animals, etc.

2. Check for discolored heat tape insulation. If any damage or

discolored insulation is evident, replace heat tape.

3. Check that heat tape power supply circuit is on.

Step 9—Winterizing

Freezing condensate left in the furnace will damage the

equipment.

If the furnace will be off for an extended period of time in a

structure where the temperature will drop to 32°F or below,

winterize as follows:

If this furnace is installed in an unconditioned space where

the ambient temperatures may be 32°F or lower, freeze

protection measures must be taken.

1. Turn off electrical supply to furnace.

2. Remove main furnace door.

3. Disconnect drain tube from inducer housing. (See Fig. 13.)

4. Insert funnel in drain tube and pour antifreeze, propylene

glycol (RV, swimming pool antifreeze, or equivalent) into

32°F MINIMUM INSTALLED

AMBIENT OR FREEZE

PROTECTION REQUIRED

A93058

furnace until it is visible at point where condensate enters open

drain. (See Fig. 14.)

5. Reconnect drain tube to inducer housing.

6. Replace main furnace door.

9

Fig. 13—Inducer Housing Drain Tube

A99118

Do not use ethylene glycol (Prestone II antifreeze/coolant or

equivalent automotive type). Failure of plastic components

will occur.

WIRING DIAGRAMS

See figures 11, 12 and 16 for the Deluxe 4-Way Multipoise

Furnace wiring diagrams.

TROUBLESHOOTING

For an explanation of fault codes, refer to service label located on

back of main furnace door (See Fig. 15.).

The control center stores all fault codes for a period of 5 “good or

proper” operating cycles, regardless of 115- or 24-v power

interruption.

NOTE: Removing blower access panel opens blower access

panel door switch and terminates 115-v power to control center.

Look into blower access panel sight glass for current LED status.

1. To retrieve fault code, proceed with the following:

NOTE: NO thermostat signal may be present at control center

and all blower time delay of periods must be completed.

a. Leave 115-v power to furnace turned on.

b. Remove main furnace door.

c. Look into blower access panel sight glass for current LED

status.

d. Remove blower access panel.

e. Turn setup switch SW-1 to ON position. (See Fig. 12 or 16

for location.)

f. Manually close blower access panel door switch. Use a

piece of tape to hold switch closed.

Fig. 14—Funnel in Drain and Antifreeze Running

Through Trap

Blower access panel door switch opens 115-v power to

control center. No component operation can occur. Caution

must be taken when manually closing this switch for service

purposes. Failure to follow this warning could result in

personal injury or death.

g. LEDs display last fault code to occur first, followed by any

other fault that has occurred in the last 5 “good or proper”

cycles. The remaining faults displayed will be in numerical

order starting from the lowest number first. Only 1 of each

fault code will be displayed, regardless of how many times

the fault has occurred.

h. Fault code display will continue and repeat as described

above or until setup switch SW-1 is turned off.

i. Release blower access panel door switch and replace

blower access panel.

j. Operate furnace through 1 heat cycle to test for proper

operation and check LED status.

k. If furnace is operating properly and LEDs indicate proper

operation, replace main furnace door.

2. Fault code display can be removed from control’s display

mode by performing the following. This is also called the

“Clean Up Procedure.”

a. Leave 115-v power to furnace turned on.

b. Remove main furnace door.

c. Look into blower access panel sight glass for current LED

status.

d. Remove blower access panel.

10

A99119

SERVICE

LED CO D E

RED LED1 ON

RED LED2 ON

YELLOW LED3 ON

GREEN LED4 ON

RED LED2 FLASHING

EACH OF THE FOLLOWING STATUS CODES IS A TWO DIGIT NUMBER WITH THE FIRST DIGIT

DETERMINED BY NUMBER OF FLASHES OF THE YELLOW LED AND THE SECOND DIGIT

DETERMINED BY NUMB ER O F FLASHES O F THE GREE N LED.

11 NO FAULT IN RECENT HISTORY DISPLAY - Indicates no faults have occurred within last fiv e cycles.

To read recent fault histor y put setu p switch "S W-1" in the " ON" position. To clear recent fault

history, put setup switch "SW-1" in the "ON" position and jumper thermostat terminals

"R", "W/W1", and "Y/Y2" simultaneously until an "11" is flashed.

12 BLOWER CALIBRATION LOCKOUT - Indicates RPM calculated for low heat was less than 250 RPM

or greater than 1300 RPM on two successive attempts. Auto reset after three hours. Reset

power and refer to fault #44 section.

13 LIMIT SWITCH LOCKOUT - Indicates the occurrence of 10 successive limit trips during high heat

or three successive limit trips during low h eat. Auto reset aft er three hours.

Check for: - Improper or misaligned limit and/or limit shield.

14 IGNITION LOCKOUT - Control will auto-reset after three hours. Refer to #34.

21 INVALID MODEL SELECTION - Indicates model plug is missing or incorrect. See wiring diagram

for correct connector jumper location.

22 SETUP ERROR - Indicates setup switch "SW-1" or SW-6" is positioned improperly. The following

combinations will cause the fault.

23 INVALID BLOWER AIRFLOW SELECTION - Indicates im proper "A/C" or "C F" switch setting. The 042

and 14 units can deliver 1-1/2 to 3-1/2 tons A/C and 600 to 1400 CFM for continuous fan. The

060 and 20 unit can deliver 2 to 5 tons A/C and 800 to 2000 CFM for continuous fan. If code is

flashing unit will default to closest allowable airflow.

24 SECONDARY VOLTAGE FUSE IS OP EN

Check f o r: - Short circuit in secondary voltage (24V ) wiring.

31 HIGH PRESSURE SWITCH FAULT - Indicates high pressure switch is closed at call, or in low heat,

or fails to close after call, or opens in high heat.

Check f or: - Plugged c o ndensate drain.

32 LOW PRESSURE SWITCH FAULT - Indicates low pressure switch is closed at call, or fails to close

after call, or opens during operation.

Check f or: - Plugged c o ndensate drain.

33 LIMIT OR FLAME ROLL-OUT SWITCH IS OPEN - Indicates the limit, rollout switch or auxiliary limit

switch is open or the unit is operating in high heat only mode due to two successive low heat

limit trips. Check for: - Improper or misaligned limit and/or limit shield.

34 IGNITION PROVING FAULT - Control will try three more times before a lockout #14 occurs.

Check for: - Gas valve defective or gas valve turned " OFF".

- Defective Hot Surface Ignitor - Manual valve shut-off.

- Low inlet gas pressure

- Green wire MUST be connec ted to furnace sheet metal.

- Proper flame sense microamps (.5 microamps D.C. min imu m, 4.0 - 6.0 nominal HIGH HEAT)

- Inadequate flame carryover or rough ignition.

- Oxide buildup on flame sensor (clean with fine sandpaper.)

41 BLOWER OUTSIDE VALID SPEED RANGE - Indicates the blower is not operating at the ca lculated

RPM. If this fault occur s in conjunction with faul t #44 check wiring to motor otherwise refer to

the trouble-shooting guide.

42 INDUCER OUTSIDE VALID SPEED RANGE - Indicates the inducer is not operating at the

calculated RPM, or has not starte d within 10 seconds a f ter a call for heat. Check wiring to

motor ot herwise refer to the trouble-sh ooting guide.

43 PRESSURE SWITCH CALI B R ATION F AULT - Indicates the low and high pressure switch "make"

points during high heat purge are not within the calibration range.

Check f or: - Plugged c o ndensate drain.

44 BLOWER CALIBRATION FAULT - Indicates the calculated blower speed is below 250 or above

1300 RPM. Un it will default to low or high heat mode if possible. If this fault occurs in conjunction

with fault #41 check wiring to motor otherwise refer to the trouble-shooting guide. If this fault

occurs by itself check for undersized ductwork, or excessive static caused by a dirty filter, or

closed registers.

STATUS CODE EXAMPLE

To initiate the component test sequence, shut "OFF" the room thermostat or disconnect the "R"

thermostat lead. Put setup switch "SW-6" in the "ON" position to start the component test sequence.

Once initiated the main board will turn "ON" the inducer motor-low speed, inducer motor-high speed,

hot surface ignitor, blower motor-low speed, and blower motor-high speed for 15-20 seconds each.

When component test is completed one or more of the following cod e s will flash. Ga s Valve and

Humidifier will not be turned on.

CODE DESCRIPTION

11

Indicates inducer and blower motor tested OK. Visual check of hot surface ignitor required.

22 SETUP ER ROR

41 BLOWER OUTSIDE VALID SPEED RANGE -

42 INDUCER OUTSIDE VALID SPEED RANGE -

wiring and control center.

To repe at compone nt te s t turn s e tup switch "SW -6" "OFF" and the n ba c k "O N ". A fter componen t test is

completed put setup switch "SW-6" in the "OFF" position and reconnect the "R" thermostat lead.

Furnace is o perating in emergency heat.

The microprocessor has m alf unctioned. To reset: Put setup switch "

position and jum per thermostat terminal s "

the door sw itch pushed in and po wer to the unit "

setup switch in the "

Furnace is o perating in high hea t.

Furnace is o perating in low heat.

Line voltage polarity is reversed.

- Improper high or low heat gas input adjustment.

- Stuck high heat solenoid in gas valve.

- Thermostat call with "SW-1" "ON".

- Thermostat call with "SW-6" "ON".

-"SW-1" and "SW-6" both "ON" tog ether.

- Water in vent piping, possibly sagging pipe.

- Improper pres sure switch wiring or pressure switch tubing connections.

- Failed or "Out-of-Calibra tion" pressure switc hes.

- Water in vent piping, possibly sagging pipe.

- Improper pres sure switch wiring or pressure switch tubing connections.

- Failed or "Out-of-Calibra tion" pressure switc hes.

- Improper low heat gas input adjustment.

- Stuck high heat solenoid in gas valve.

- Water in vent piping, possibly sagging pipe.

- Improper pres sure switch wiring or pressure switch tubing connections.

- Failed or "Out of Calibration" pressure switches.

RED LED2

MICROPROCESSOR

MALFUNCTION

1

21

FUSE

3

2

1

3

32

4

COUNT THE NO.

SETUP SW,(SW1-8)

OFF

YELLOW LED3

HIGH HEAT

GREEN LED4

LOW HEAT

RED LED1

EMER HEAT

OFF

1

2

3

45678

OFF

COMPONENT T E ST

- Same as code 22above.

and control center.

STATUS

R

", "

W/W1

", and "

ON

OFF

DEHUM

OF FLASHES

(4)

" posi tion. If

DE

LED2

W2

COUNT THE NO.

OF FLASHES

". Disconnect jumper and place

reappears replace main control board.

OM

C

24 V

42 FAULT

=

(2)

INDUCER OUTSIDE VALID

SPEED R ANGE

Indicates blower motor failed test. Check blower, wiring,

Indicates inducer m otor failed test. Check inducer,

SW-1

Y/Y2

" simultaneously with

320624-101 REV. H

" in the "ON"

HUMGRY/Y2W/W1

Fig. 15—Service Label

11

A99108

12

MODEL

JUMPERS

SIZE

1-4 2-5 3-6

042040

X

042060

042080

060100

060080

060120

PL10

PL11

PL11

LEGEND

A/C AIR CONDITIONING (ADJUSTA BLE TONN AGE )

ALS AUXILIARY LIMIT SWTIC H OVERTEMP - MANUAL RESET SPST-(N.C)

CF CONTINUOUS FAN (ADJUSTABLE CFM)

CPU1 MAIN MICROPROCESSOR & CIRCUITRY

CPU2 IGNITION MICROPROCESSOR & CIRCUITRY

DE DEHUMIDIFY ENABLE - IF DE CONNECTION PROVIDED REM OV E

DEHUM DEHUMIDIFICATION CONNECTION (24VA C .02 AMPS)

EAC-1 ELECTRONIC AIR CLEANER C ONNECTION (115 VAC 1.5 AMP MAX.)

EAC-2 ELECTRONIC AIR C LEANER CONNECTION (COMMON)

FRS FLAME ROLLOUT SWITCH - MANUAL RESET, SPST-(N.C.)

FSE FLAME PROVING SENSOR ELECTRODE

FU1 FUSE, 3 AMP, AUTOMOTIVE BLADE TYPE, FA CTORY INSTALLED

FU2 FUSE OR CIRCUIT BREAKER CURRENT INTERRUPT DEVICE

GND EQUIPMENT GROUND

GV GAS V ALVE

GVR GAS VALVE RELAY, DPST-(N.O.)

HI GAS VALVE HIGH STAGE OPERATOR

HPS HIGH HEAT PRESSURE SWITCH, SPST-(N.O.)

HSI HOT SURFACE IGNITOR (115 VAC)

HSIR HOT SURFACE IGNITOR RELAY, SPST-(N.O.)

HUM 24VAC HUMIDIFIER CONNECTION (.5 AMP. MAX.)

HUMR HUMIDIFIER RELAY, SPST-(N.O.)

ILK BLOWER ACCESS PANEL INTERLOCK SWITCH, SPST-(N.O.)

IND INDUCTOR (NOTE #7)

JB JUNCTION BOX

LEDS LIGHT EMITTING D IOES FOR STATUS CODES

LGPS LOW GAS PRESSURE SWITCH, SPST (N.O.)

LPS LOW HEAT PRESSSURE SWITCH, SPST-(N.O.)

LS LIMIT SWITCH, AU TO RESET, (N.C.)

MTR1 MOTOR (ICM) INDUCER

MTR2 MOTOR (ICM) BLOWER

PCB PRINTED CIRCUIT BOARD

PL1 11-CIRCUIT CONNECTOR

PL2 4-CIRCUIT PRESSURE SWITCH CONNECTOR

PL3 5-CIRCUIT BLOWER MTR CONNECTOR

PL4 2-CIRCUIT HSI CONN ECTOR

PL5 6-CIRCUIT MODEL PLUG

X

XX

X

XX

XX

FRS LS

GV

RED

GRN / YEL

9876 4321

IND.

YEL

12543

P

C

NOTE #3

RED

BLK

1

#7

NOTE

1

BLK

MTR2

BLU

M

BRN

HI

GRN/YEL

VIO

BLU

YEL

WHT

WHT

ORN

5

VIO

BLU

YEL

ORN

5

GRN/YEL

PL12

RED

3

ORN

16

VIO

8

YEL

14

BLU

6

PL13

JUMPER TO ENABLE DEHUM INPUT

(FIELD INSTALLED & SUPPLIED)

MTR1

12

FSE

3

1.5 AMP

WHT

1

PL1

BLK

5

1RED

A/C AND CF

SELECT. CHART

A/C C F

DEFAULTDEFAULT

1-1/2

TON

2

TON

2-1/2

TON

HSI

12104 6

ORN

BLK

EAC2

EAC1

YEL

3

2

4

BLU

3VIO

2ORN

600

CFM

800

CFM

1000

CFM

PCB

BRN

WHT

ORN

BRN

6

5

4YEL

5BLU

SWITCH

POS.

213

OFF

213

OFF

213

OFF

213

OFF

YEL

PL3

12

GRN

2

1

PL4

7

YEL

GRN

PL9

ALS

3

RED

SWITCH

RED

POS.

213

OFF

213

OFF

213

OFF

213

OFF

FUSED DISCONNECT SWITCH

(WHEN REQ’D)

TRAN

WHT

BLK

P1

P2

ORN

BRN

DE

FUSE

234

123

6

7

BPH

EMER. HEATMZCOMP. TEST

321

654

PL5

BLK

WHT

GND

8

BLOWER

OFF-DELAY

BLK

ILK

WHT

PL7

YEL

BLK

WHT

T 1

T 2

RED

8

1011

9

BRN

WHT

SEC-2

A/C AND CF

SELECT. CHAR T

A/C CF

3

TON

3-1/2

TON

4

TON

5

TON

WHT

BLK

RED

L1

B1

L2

B2

YEL

PL2

1234

HUM

BLK

RED

1200

CFM

1400

CFM

1600

CFM

2000

CFM

PL6 3-CIRCUIT COMM. CONNECTOR

PL7 12-CIRCUIT INDUCER MTR CONNECTOR

PL9 2-CIRCUIT HSI CONNECTOR

PL10 9-CIRCUIT BLOW ER ADAPTER CONNECTOR

PL11 1-CIRCUIT INDUCTOR SPLICE CONNECTOR

PL12 5-CIRCUIT BLOWER POWER CONNECTOR

PL1 3 16-CIRC U IT BLOWE R CTRL. CON N ECTOR

SW1 MANUAL SWITC H, FAULT DISPLAY, SPST-(N.O.)

SW2 MANUAL SWITC H, LOW HEAT, SPST-(N.O.)

SW3 MANUAL SWITC H, BYPASS HUMIDIFIER, SPST-(N.O.)

SW4 MANUAL SWITC H, EMERGENCY HEAT, SPST-(N.O.)

SW5 MANUAL SWITC H, MULTIPLE ZONE, SPST-(N.O.)

SW6 COMPONENT TEST, SPST-(N.O.)

SW7-8 M ANUAL SWITCH, BLOWER OFF-DELAY, SPST-(N.O.)

TRAN TRANSFORMER - 115V AC/24VAC

G

R

WHT

Y/Y2

W/W1

OM

C

W2

SEC-1

DEHUM

FU1

24VAC-3A

LEDS

1

(1-4)

CF A/C

123

12345

SW

(1-8)

FLT

LOW HE AT

PL6

1

JUNCTION

UNMARKED TERMINAL

PCB TERMINAL (FACTORY CONNECTED)

FACTORY WIRING (115 VAC)

FACTORY WIRING (24 VAC)

FIELD WIRING (115 VAC)

CONDUCTOR ON P CB

FIELD WIRING SCREW TERMINAL

TERMIN A L BLO C K - MA R KE D TE R MIN A L

FIELD EARTH GROUND

EQUIPMENT GROUND

FIELD SPLICE

PCB TERMINAL (FIELD CONNECTION)

PLUG RECEPTACLE

HPS

C

YEL

LPS

C

NOTE #11

ORN

BRN

BLU

RED

NOTE

#6

SELECTION CHART

NOTE #2

FU2

BLU

NO

NOTE #11

NO

LGPS

BLOWER

OFF-DELAY

78

OFF

78

OFF

8

7

OFF

78

OFF

RED

ORN

(WHEN

USED)

TO 115 VAC FIELD DISCONNECT

ILK

90

SEC.

135

SEC.

180

SEC.

225

SEC.

HUM

R

G

Y/Y2

W2

W/W1

C

OM

L1

L1

NOTE #2

PL3

L2

654

PL1

CPU1

12345

FRS

DEHUM

(WHEN USED)

HUMR

HSIR

GVR

L2

T 2

T 1

CPU2

B1 7

B2

HSIR

EAC

LS

DE

PL10

CPU1

CPU2

5

4

3

2

1

6

HUMR

EMER. HEAT

PL11

EQUIPMENT GROUND

D.C.

POWER

SUPPL Y

SW - 4

IND

NOTE #7

EAC-1 EAC-2

ALS

D.C. POWER

GVR

EAC

PL11

PL12

PL1-9

SUPPLY

SCHEMATIC DIAGRAM

(NA TURAL GAS & PROPANE)

12

6

4

MTR1

2

1

10

PL7

PCB

NOTE #5

PL13

6

14

8

16

3

5

4

3

2

1

2

PL4 PL9

1

FU1

NOTE #6

PL1-11

PL1-2

PL1-10

PL2-4

PL2-2

PL2-1

PL1-1

PCB

NOTE #5

NOTE #11

MTR2

2

1

SEC-1

P

M

HI

LGPS

(WHEN USED)

NOTES:

1. If any of the original equipment wire is replaced use wire rated for 105°C.

2. Use only copper wire between the disconnect switch and the furnace junction box (JB).

3. This wire must be connected to furnace sheet metal for control to prove flame.

4. Symbols are elec trical repre se n tation onl y.

5. Solid lines, inside circuit boa rd PCB are p rinte d cir c uit boa rd trac es and are n ot d epicted as s ho w n in th e legend .

6. Replace only with a 3 AM P fus e.

7. Inductor used on all 060 or -20 airflow units.

8. Blower-on delay, gas heating 60 seconds low heat, 35 seconds high heat, cooling or heat pump 2 seconds..

9. Blower-off delay, gas h eating 90, 135, 180 or 225 s econds, cooling or heat pump 90seconds.

10. Ignition-lockout will occur after four consecutive unsuccessful trials-for-ignition. Control will auto-reset after three hours.

11. Factory connected when LGPS not used.

HSI

P1

115VAC

TRAN

24VAC

GV

PL1-7

C

NOTE #3

NO

NOTE #11

NO

FSE

322296-101 REV. E

SEC-2

HPS

LPS

P2

C

C

Fig. 16—Wiring Diagram A00350

e. Turn setup switch SW-1 to ON position. (See Fig. 12 or 16

for location.)

f. Jumper thermostat terminals R, W, and Y on control center.

g. Manually close blower access panel door switch. Use a

piece of tape to hold switch closed.

Blower access panel door switch opens 115-v power to

control center. No component operation can occur. Caution

must be taken when manually closing this switch for service

purposes. Failure to follow this warning could result in

electrical shock, personal injury, or death.

h. h. After fault code 11 flashes for at least 2 times, remove R,

W, and Y jumpers.

i. Turn setup switch SW-1 to OFF position.

j. Release blower access panel door switch and replace

blower access panel.

k. Operate furnace through 1 heat cycle to check for proper

operation and check LED status.

l. If furnace is operating properly and LEDs indicate proper

operation, replace main furnace door.

3. The control can also assist in troubleshooting by performing a

Component Test. The Component Test will functionally

operate all furnace components, except the gas valve.

a. To initiate Component Test proceed with the following:

(1.) Leave 115-v power to furnace turned on.

(2.) Remove main furnace door.

(3.) Remove blower access panel.

(4.) Turn setup switch SW-6 to ON position.

(5.) Manually close blower access panel door switch. Use

a piece of tape to hold switch closed.

(1.) The control center goes through a brief self test. This

self test takes approximately 2 sec to complete. After

door switch is closed, red (microprocessor) LED

briefly comes on. Then green LED comes on for 1 sec,

followed by 1 sec where both the green and yellow

LEDs are on. During this time, the control is checking

itself.

(2.) Inducer motor operates for 20 sec at low speed,

operates for 20 sec at high speed, then turns off.

(3.) Hot surface ignitor is energized for 15 sec, then

de-energized.

(4.) Main blower motor operates for 20 sec at low speed,

operates at high speed for 20 sec, then turns off.

(5.) After component operation test is completed, 1 or

more fault codes (11, 22, 41, or 42) will flash. See

service label on back of main furnace door or Fig. 15

for explanation of codes.

NOTE: To repeat component test, turn setup switch SW-6 to OFF

and then back to ON.

c. After component test, perform the following:

(1.) Release blower access panel door switch and turn

setup switch SW-6 to OFF position.

(2.) Replace blower access panel.

(3.) Operate furnace through 1 heat cycle to check for

proper operation and check LED status.

(4.) If furnace is operating properly and LEDs indicate

proper operation, replace main furnace door.

Blower access panel door switch opens 115-v power to

control center. No component operation can occur. Caution

must be taken when manually closing this switch for service

purposes. Failure to follow this warning could result in

electrical shock, personal injury, or death.

b. When items (1) through (5) above have been completed,

the following will occur:

13

14

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your

knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available, using popular

video-based formats and materials. All include video and/or slides, plus companion

book.

Classroom Service Training plus "hands-on" the products in our labs can mean

increased confidence that really pays dividends in faster troubleshooting, fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-962-9212

[ ] Packaged Service Training [ ] Classroom Service Training

Fig. 16—Wiring Diagram

A94328

15

Copyright 2000 CARRIER Corp. • 7310 W. Morris St. • Indianapolis, IN 46231 58mvp9sm

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 6a 8a PC 101 Catalog No. 535-795 Printed in U.S.A. Form 58MVP–9SM Pg 16 10-00 Replaces: 58MVP-7SM

Loading...

Loading...