Page 1

50XP

Performancet 13 SEER

Single--- Packaged Air Conditioner System with PuronR

(R ---410A) Refrigerant Single and Three Phase

2 to 5 Nominal T ons (Sizes 024--- 060)

Product Data

Easy Installation

Factory--assembled package is a fully self--contained, electric

cooling unit that is prewired, pre--piped, and pre--charged for

minimum installation expense. These units are available in a

variety of standard cooling sizes with voltage options to meet

residential and light commercial requirements. Units are

lightweight and install easily on a rooftop or at ground level. The

high tech composite base eliminates rust problems associated with

ground level applications.

Durable, dependable components

Scroll Compresso rs are designed for high efficiency. Each

compressor is hermetically sealed against contamination to help

promote longer life and dependable operation. Each compressor

also has vibration isolation to provide quieter operation. All

compressors have internal high pressure and overcurrent

protection.

Convertible duct configuration

Unit is designed for easy use in either downflow or horizontal

applications. Each unit is easily converted from horizontal to

downflow. Downflow operation is easily provided in the field to

allow vertical ductwork connections. The basepan utilizes

C99064

Fig. 1 -- Unit 50XP

Single--Packaged Products with Energy--Saving Features and

PuronR refrigerant.

S Up to 13.5 SEER

S Factory-- Installed TXV

S Variable Speed Blower--Standard

S Low Sound Levels

FEATURES/BENEFITS

One--piece cooling unit with optional electric heater, low

installation cost, dependable performance and easy maintenance.

Efficient operation

High--efficiency design with a SEER (Seasonal Energy Efficiency

Ratio) of up to 13.5.

Puron Environmentally Sound Refrigerant is Carrier’s unique

refrigerant designed to help protect the environment. Puron is an

HFC refrigerant which does not contain chlorine that can harm the

ozone layer. Puron refrigerant is in service in millions of systems

proving highly reliable, environmentally sound performance.

IdealHumidity Technology featuring Thermidistat control and

Variable Speed Blower motor that provides greater comfort,

humidity control, and energy efficiency. You can expect up to 30

times better dehumidification; economical constant fan for less

than $50 a year, which provides improved indoor air quality and

more even temperatures from room to room; and reduced indoor

noise due to lower air velocity. In addition, you’ll realize improved

installation flexibility with 3 different airflow choices for best

overall comfort.

knockout style seals on the bottom openings to ensure a positive

seal in the horizontal airflow mode.

Direct--drive variable speed blower motor is standard on all

models.

Direct--drive PSC condenser--fan motors are designed to help

reduce energy consumption and provide for cooing operation

downto55_F(13_C) outdoor temperature. Motormasterr II low

ambient kit is available as a field--installed accessory.

Thermostat controls

Time Guardr II anti--short cycle protection circuitry. If a

non--corporate thermostat without anti--short cycle protection is

used the Time Guard II field--installed anti--short cycle kit is

recommended.

Refrigerant system is designed to provide dependability. Liquid

filter driers are used to promote clean, unrestricted operation. Each

unit leaves the factory with a full refrigerant charge. Refrigerant

service connections make checking operating pressures easier.

Thermostatic Expansion Valve -- A hard shutoff, balance port

TXV maintains a constant superheat at the evaporator exit (cooling

cycle) resulting in higher overall system efficiency.

Evaporator and condenser coils are computer--designed for

optimum heat transfer and cooling efficiency. The evaporator coil

is fabricated from copper tube and aluminum fins and is located

inside the unit for protection again damage. The condenser coil is

internally mounted on the top tier of the unit. Copper fin coils and

pre--coated fin coils are available from the factory by special order.

these coils are recommended in applications where aluminum fins

are likely to be damaged due to corrosion. They are ideal for

seacoast applications.

High and Low Pressure Switches provide added reliability for the

compressor.

1

Page 2

Low sound ratings ensure a quiet indoor and outdoor

environment with sound ratings as low as 72dBA. (See Page 4.)

Easy to service cabinets provide easy single--panel accessibility to

serviceable components during maintenance and installation. The

basepan with integrated drain pan provides easy ground level

installation with or without a mounting pad. Convenient handholds

are provided to manipulate the unit on the jobsite. A nesting feature

ensures a positive basepan to roof curb seal when the unit is roof

mounted. A convenient 3/4--in. (19.05 mm) wide perimeter flange

makes frame mounting on a rooftop easy.

Louvered Grille provides hail and vandalism protection for the

coil.

Cabinets are constructed of heavyduty, phosphated, zinc--coated

prepainted steel capable of withstanding 500 hours of salt spray.

Interior surfaces of the evaporator and electric heater compartments

are insulated with cleanable semi--rigid insulation board, which

keeps the conditioned air from being affected by the outdoor

ambient temperature and provides improved indoor air quality.

(Conforms to American Society of Heating, Refrigeration and Air

Conditioning Engineers No. 62P.) The sloped drain pan minimizes

50XP

standing water in the drain. An external drain is provided.

TABLE OF CONTENTS

FEATURES/BENEFITS 1--2.............................

MODEL NUMBER NOMENCLATURE 3.................

ARI CAPACITIES 4...................................

PHYSICAL DATA 5...................................

OPTIONS AND ACCESSORIES 6.......................

BASE UNIT DIMENSIONS 8--9.........................

ACCESSORY ROOF CURB 10..........................

SELECTION PROCEDURE 11..........................

PERFORMANCE DATA 12--16..........................

TYPICAL PIPING AND WIRING 17.....................

APPLICA TION DA TA 18...............................

ELECTRICAL DATA 19--20............................

TYPICAL WIRING SCHEMATICS 21--23.................

CONTROLS 24.......................................

GUIDE SPECIFICATIONS 25--26........................

2

Page 3

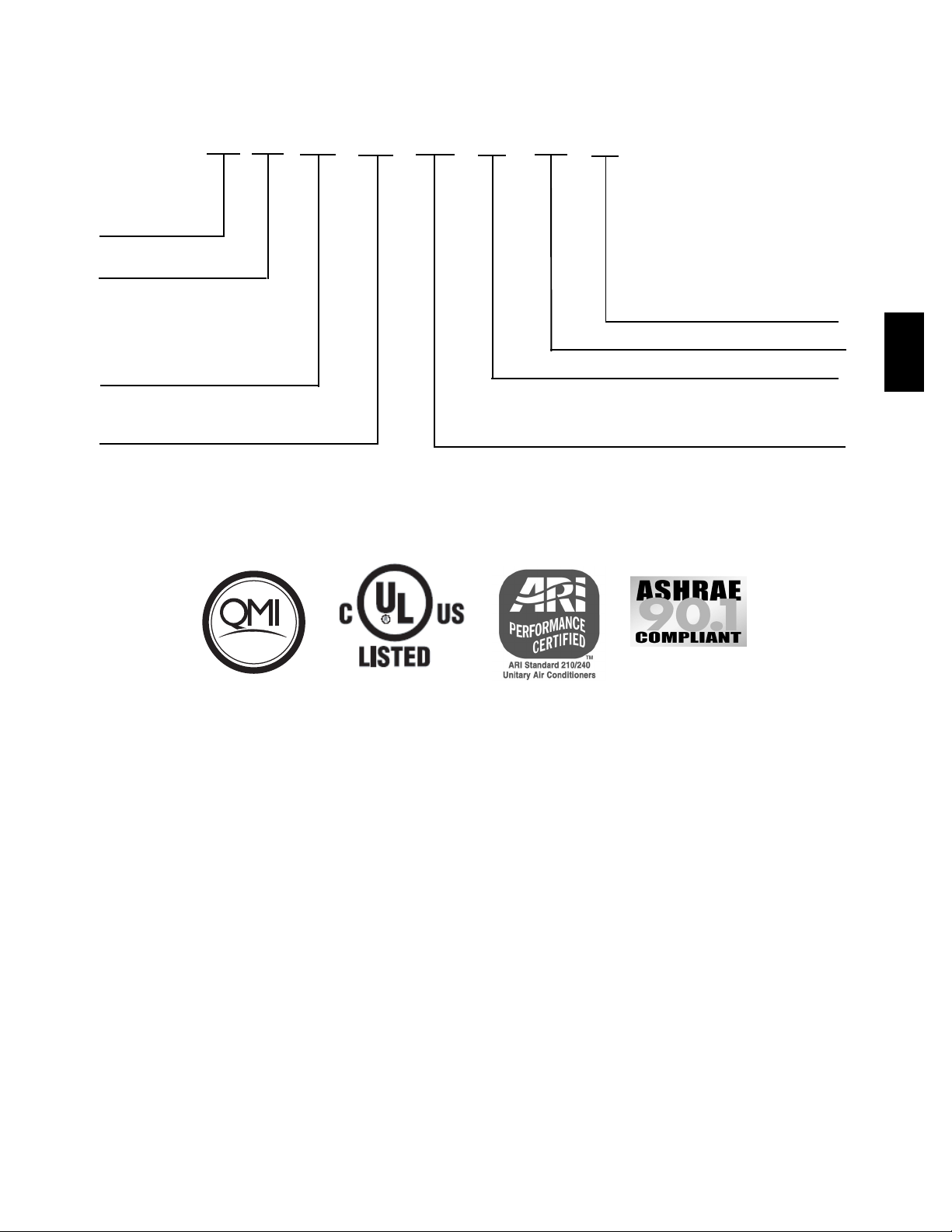

MODEL NUMBER NOMENCLATURE

pp

Type of U n it

50XP --- Single Packaged

Air Conditioner

System

N/A

Nominal Cooling Capacity

024 --- 2.0 Tons

030 --- 2.5 Tons

036 --- 3.0 Tons

042 --- 3.5 Tons

048 --- 4.0 Tons

060 --- 5.0 Tons

N/A

50XP

ISO 9001:2000

---

024

--- --- ---

3

Electrical Supply

3 --- 208/230 --- 1 --- 60

5 --- 208/230 --- 3 --- 60

0

Series

1

Pack aging

--- ---

Options

B T --- A L e v a p , v i n y l c o n d e n s e r

C C --- A L e v a p, C U c o n d e n s e r

CU --- CU evap & condenser

TP --- Base u nit with tin plated indoor coil hairpins

TV --- TP with vinyl coating on outdoor coil

TC --- TP with AL indoor coil & CU/CU outdoor

coil

See Price Page for full list of factory options.

Only used if ordering an option

LEGEND

AL --- Aluminum

CU --- Co

er

50XP

REGISTERED

3

Page 4

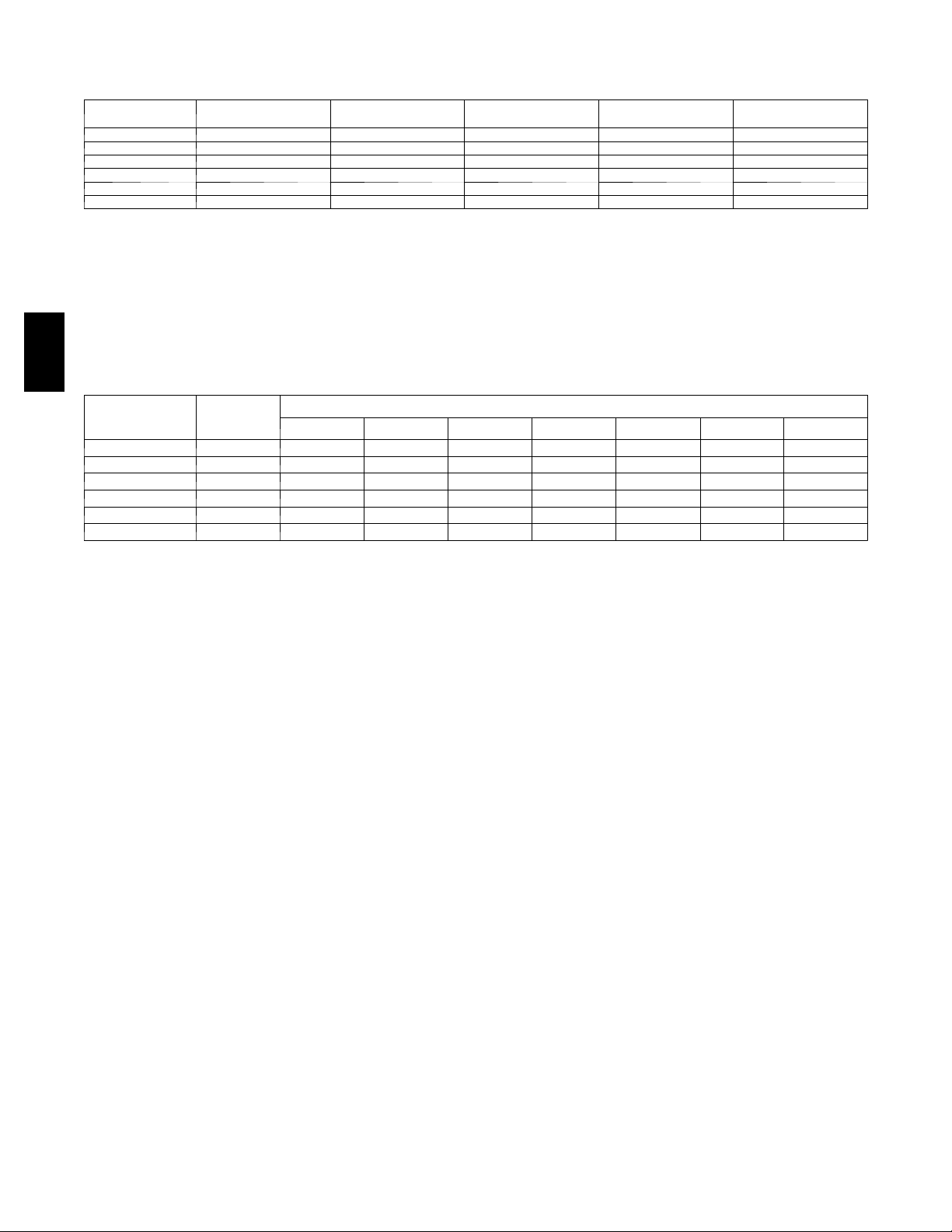

ARI* CAPACITIES

Cooling Capacities and Efficiencies

UNIT 50XP NOMINAL TONS STANDARD CFM

024 2 770 24,000 11.0 13.2

030 2-- 1/2 960 29,000 11.0 13.0

036 3 1100 36,000 11.2 13.5

042 3-- 1/2 1450 41,000 11. 2 13.0

048 4 1450 45,000 11.0 13.0

060 5 1710 57,000 11.0 13.0

LEGEND

d B --- Sound Levels (decibels)

db—Dry Bulb

SEER—Seasonal Energy Efficiency Ratio

wb—Wet Bulb

COP--- Coefficient of Performance

* Air Conditioning & Refrigeration Institu te.

**At “A” conditions --- 80_F (26.7_C) indoor db/67_F (19.4_C) indoor wb &

95_F(35_C) outdoor db.

{ Rated in accordance with U.S. Government DOE Department of Energy)

test procedures and/or ARI Standards 210/240.

50XP

A--Weighted Sound Power (dBA)

50XP

024 72 58.8 63.5 67.2 66.9 63.7 58.3 50.0

030 72 58.8 63.5 67.2 66.9 63.7 58.3 50.0

036 72 60.7 63.3 66.8 66.5 64.2 60.3 53.0

042 72 56.7 62.8 67.8 67.4 63.7 57.7 50.8

048 78 62.4 69.9 71.3 73.4 70.0 66.3 60.1

060 78 63.5 67.6 71.8 75.5 71.0 68.1 59.9

* Tested in accordance with ARI Standard 270 (not listed in ARI).

STANDARD

RATING

(dBA)

125 250 500 1000 2000 4000 8000

NET COOLING

CAPACITIES (Btuh)

Notes:

1. Ratings are net values, reflecting the effects of circulating fan heat.

Ratings are based on:

Cooling Standard: 80°F ( 26.7_C) db, 67°F wb (19.4_C ) i n d o o r e n t e r i n g --- a i r

temperature and 95°Fdb(35_C) outdoor entering---air temperature.

2. Before purchasing this appliance, read important energy cost and efficiency information available from your retailer.

TYPICAL OCTAVE BAND SPECTRUM (dBA) (without tone adjustment)

EER** SEER†

4

Page 5

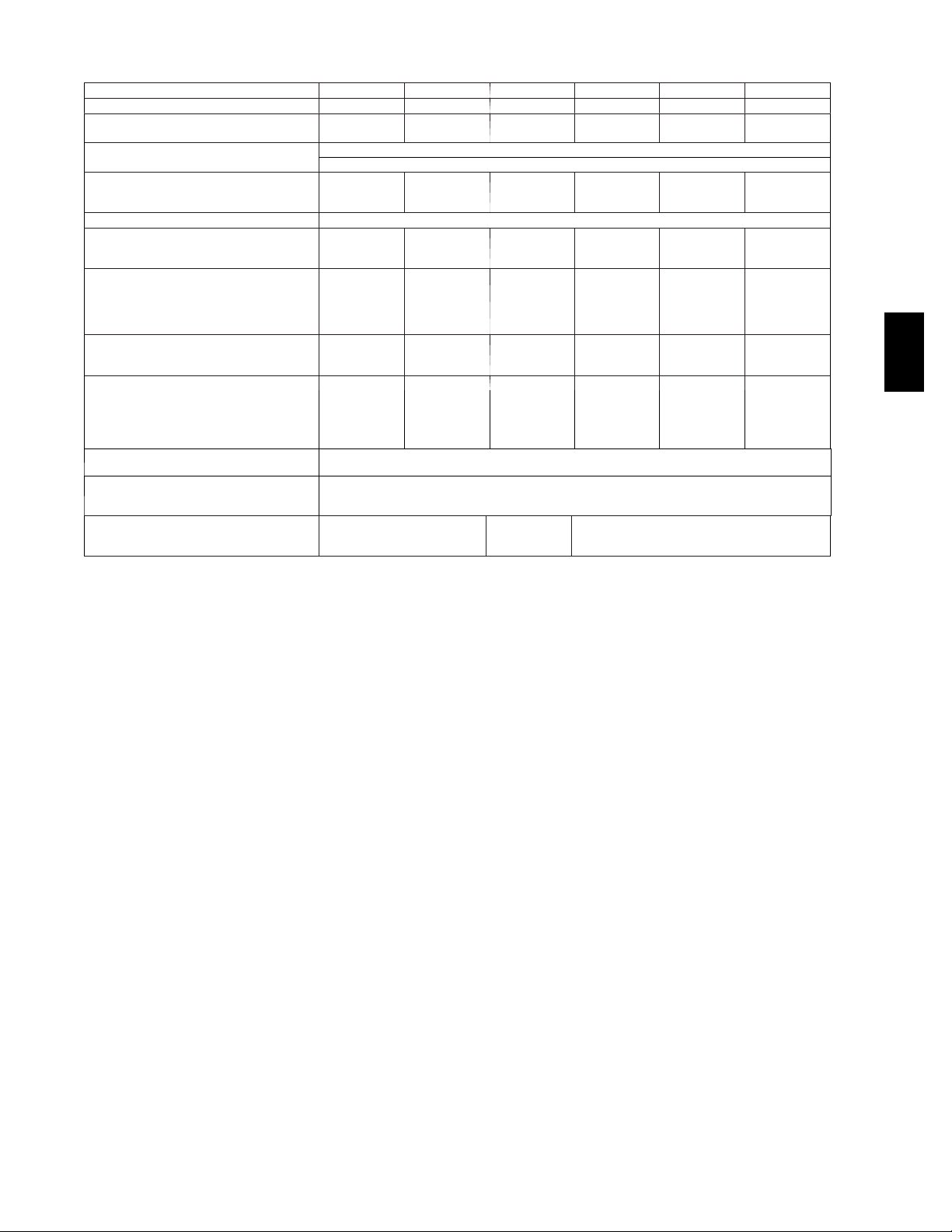

PHYSICAL DATA

Physical Data--Unit 50XP

UNIT SIZE 024 030 036 042 048 060

NOMINAL CAPACITY (ton) 2 2 --- 1 / 2 3 3 --- 1 / 2 4 5

SHIPPING WEIGH T (lb)

SHIPPING WEIGH T (kg)

COMPRESSORS

Quantity

REFRIGERANT (R -- -410A)

Quantity (lb.)

Quantity (kg)

REFRIGERANT METERING DEVICE TXV

OUTDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

OUTDOOR FAN

Nominal Cfm

Diameter (in.)

Diameter (mm)

Motor Hp (Rpm)

INDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

INDOOR BLOWER

Nominal Cooling Airflow (Cfm)

Size (in.)

Size (mm.)

Motor HP (RPM)

HIGH --- PRESSURE SWITCH

(psig) Cut--- out Reset (Auto)

L O S S --- O F --- C H A R G E / L O W --- P R E S S U R E

SWITCH (Liquid Line) (psig) cut---out Reset (auto)

RETURN--- AIR FILTERS†}

Throwaway Size (in.)

Throwaway Size (mm)

{ Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity

of 300 ft/minute for throwaway type or 450 ft/minute for high ---capacity type. Air filter pressure drop for non --- standard filters must not exceed 0.08 IN. W.C..

} If using accessory filter rack refer to the filter rack installation instructions for correct filter sizes and quantity.

356

161

7.3

3.3

2...21

11.95

2350

22

558.8

1/8 (825)

3...15

3.7

800

10x10

254x254

1/2 (1050)

508x508x25

20x20x1

360

163

8.0

3.6

2...21

12.0

2700

22

558.8

1/8 (825)

3...15

3.7

1000

10x10

254x254

1/2 (1050)

378

171

9.5

4.3

2...21

13.6

2350

22

558.8

1/8 (825)

4...15

3.7

1100

11x10

279.4x254

3/4 (1000)

20x24x1

508x610x25

Scroll

1

1/8 (825)

279.4x254

3/4 (1075)

650 +/ --- 15

420 +/ --- 25

2 0 + / --- 5

45 +/ --- 10

436

198

10.7

4.9

2...21

15.4

2800

22

558.8

3...15

4.7

1400

11x10

470

213

11.25

5.1

2...21

17.4

3300

22

558.8

1/4 (1100)

4...15

4.7

1400 1750

11x10

279.4x254

3/4 (1075) 1.0 (1040)

24x30x1

610x762x25

515

234

13.2

6.0

2...21

19.3

3300

22

558.8

1/4 (1100)

4...17

5.7

11x10

279.4x254

50XP

5

Page 6

OPTIONS AND ACCESSORIES

Factory--installed options

Coil options include Tin--Plated* indoor hairpins, copper/copper

and vinyl-- coated construction for refrigerant coils. Units are

shipped standard with copper tube/aluminum fin construction. See

model number nomenclature for coil options.

*Tin--Plated indoor coils are built with special hairpins that are

designed to resist both general pitting corrosion and excessive

indoor corrosion(Formicary Corrosion).

Field--installed accessories

Economizer with Solid -- State Controls and Barometric

Relief Dampers

Manual Air Damper (25% open)

Electric Heaters

Filter Rack

Flat Roof Curbs (8--in. and 14 -- in.) (203.2 and 355.6 mm)

Square--to--Round Duct Transition Kit

Thermidistatt

Thermostats

50XP

Crankcase Heater

Compressor Start Kit (for use on single--phase units only)

Rigging Kit

Low Ambient Kit (Motormaster® II Control)

Solid--State Time Guard® II Device

Lifting Kit

Economizer with solid--state controls and barometric relief

dampers includes filter racks and provide outdoor air during

cooling and reduce compressor operation.

Manual outside air damper includes hood and filter rack with

adjustable damper blade for up to 25% outdoor air.

Electric heaters provide additional heat in the unit when required.

Each package has a heater module that slides into the controls

compartment. Heater sizes range from 5.0 to 20.0 kW. The electric

heater design allows the use of a single--point power supply for the

entire unit, resulting in lower installed costs.

Filter Rack features easy installation, serviceability, and

high--filtering performance for vertical or horizontal applications.

Flat roof curbs in both 8 in. (203.2 mm) and 14 in. (355.6 mm)

sizes are available for roof mounted applications.

Square--to--round duct transition kit enables 024-- 048 size units

to be fitted to 14 in. (355.6 mm) round ductwork.

Thermidistat Control coupled with the system’s variable speed

indoor blower delivers Carrier’s patented IdealHumidity

Technology that allows for even greater humidity control. Along

with more precisely controlling temperature and humidity, the

Thermidistat offers full seven--day programmability allowing you

to further customize your comfort and energy savings.

Thermostats provide control for the system heating and cooling

functions. Thermostat models are available in both programmable

and non--programmable versions.

Crankcase Heater provides anti--floodback protection for

low--load cooling applications.

Compressor start kit assists compressor start--up by providing

additional starting torque on single phase units and prolongs

compressor motor life.

Rigging kit includes lifting brackets which are inserted into the

unit base rigging holds to lift unit for rooftop applications.

Low--ambient kit (Motormaster II control) allows the use of

mechanical cooling down to outdoor temperatures as low as 0_F

(--17_C) when properly installed.

Solid--state Time Guard II device provides short--cycling

protection for the compressor. Not required with corporate

electronic thermostats.

Lifting kit, including 4 metal brackets that are available to assist in

lifting this product onto a roof application.

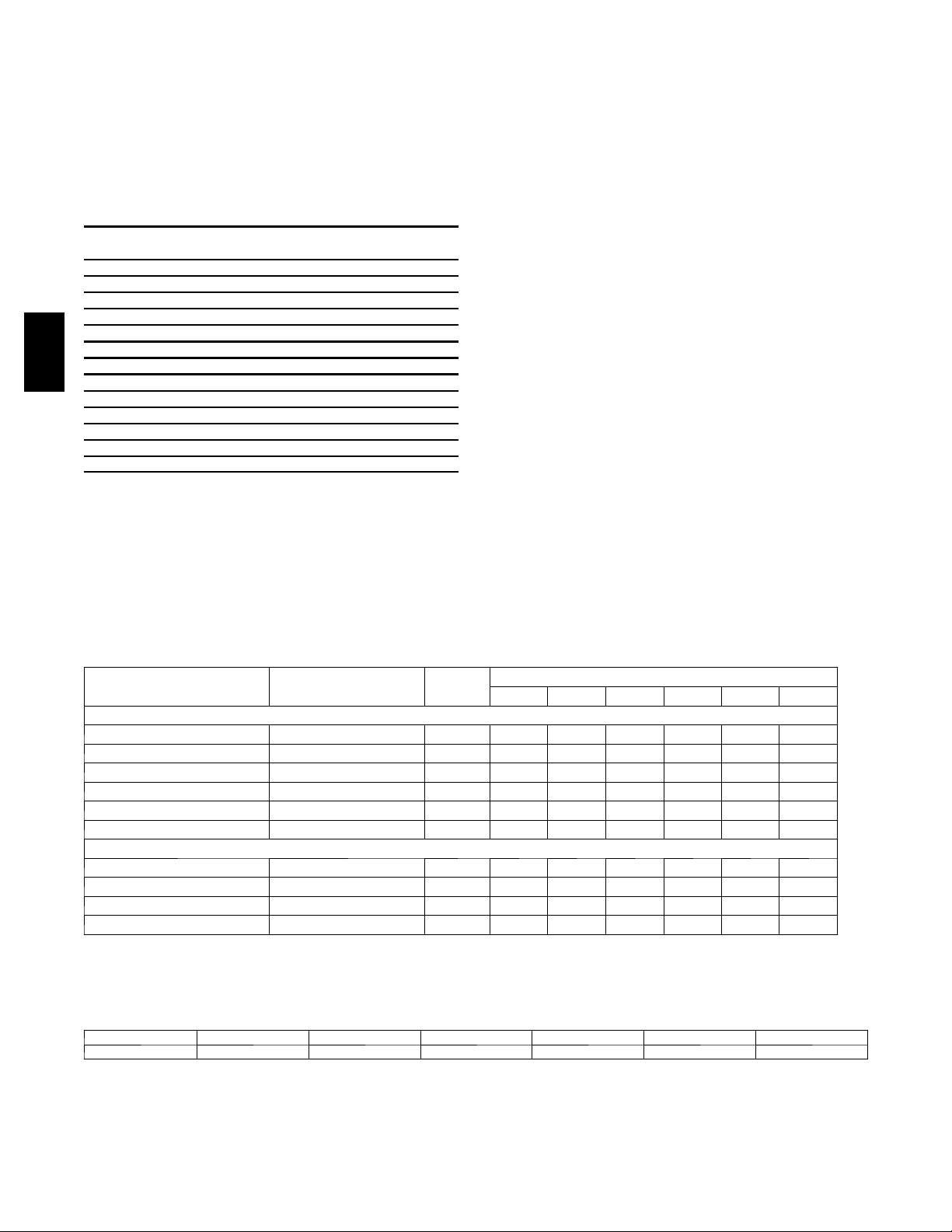

Electric Heaters

CATALOG

ORDERING NO.

CPHEATER052A00 5.0 0 X X X X X X

CPHEATER069A00 7.5 0 X X X X X X

CPHEATER065A00 10.0 0 X X X X X X

CPHEATER051A00 15.0 4 X X X X X

CPHEATER053A00 20.0 6 X X

CPHEATER054A00 20.0 6 X

CPHEATER055A00 5.0 0 X X X X X

CPHEATER056A00 10.0 0 X X X X X

CPHEATER057A00 15.0 0 X X X X

CPHEATER059A00 20.0 6 X X X

NOTE: Electric heaters are rated at 240v. Refer to Multiplication Factors table for other voltages.

X = Approved combinations.

NOMINAL

CAPACITY (kW)

ELECTRIC HEATERS (208/230 — SINGLE PHASE — 60 Hz)

ELECTRIC HEATERS (208/230 — THREE PHASE — 60 Hz)

FUSES

024 030 036 042 048 060

USED WITH SIZES

Minimum Airflow for Reliable Electric Heater Operation (CFM)

UNIT SIZE 024 030 036 042 048 060

AIRFLOW 750 1000 1250 1400 1500 1800

6

Page 7

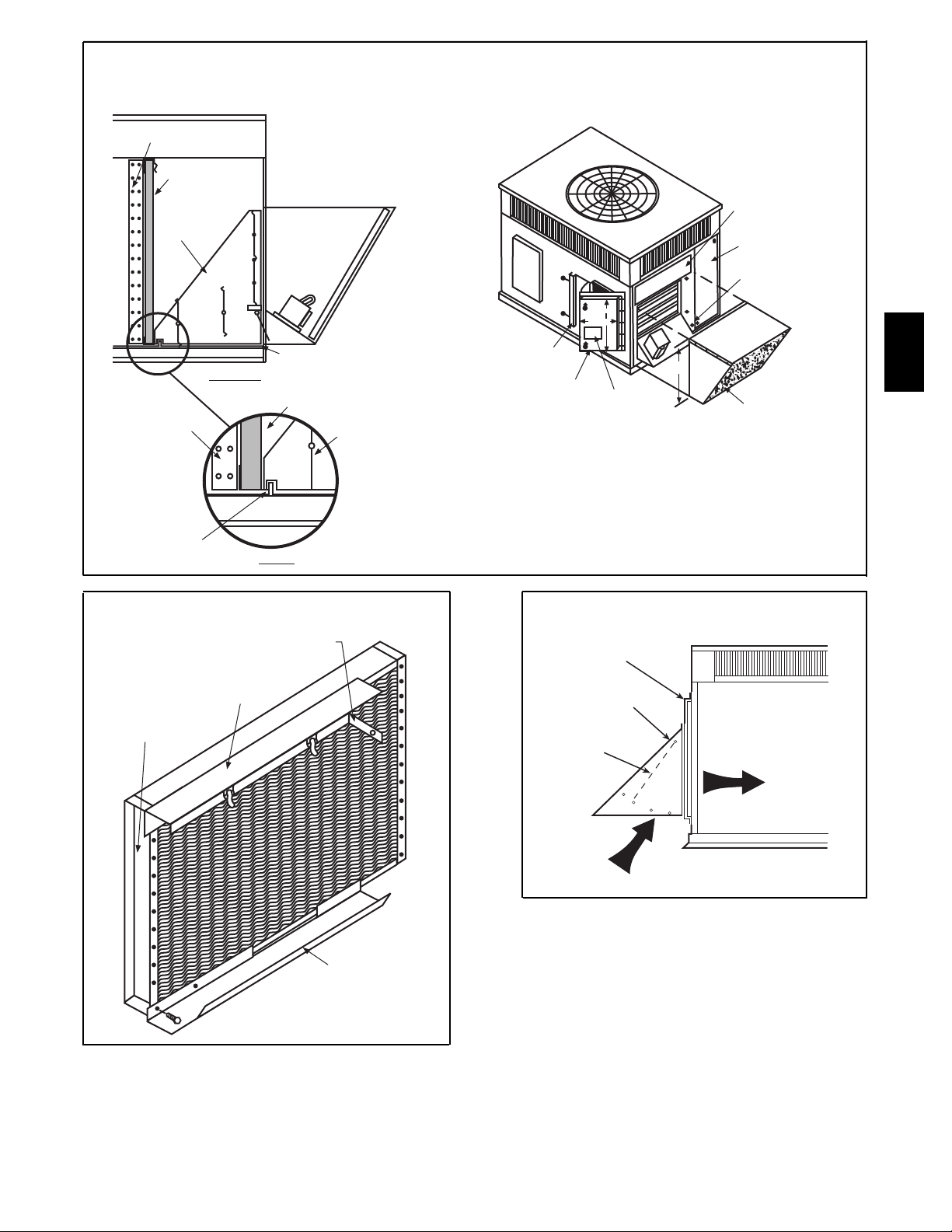

COIL

BASE

FILTER

ECONOMIZER

FILTER ACCESS DOOR

(HORIZONTAL

APPLICATION ONLY.)

DO NOT REMOVE

FROM DOWNFLOW

DISCHARGE.

ECONOMIZER

SIDE VIEW

COIL

FLANGE

ON BASE

FILTER RACK

BEND FLANGE AT 90˚-SCREW TO

DIVIDER WITH 1-IN. SCREW

CAULK BOTTOM CORNER

OF ECONOMIZER

ON EACH SIDE

FI LTER

AIL

DET

ECONOMIZER

DOOR

LATCH ANGLE

HINGED FILTER

ACCESS DOOR

17 13/32

11 13/32”

INSTALL

FILTER ACCESS

DOOR STICKER

16 1/4”

RAINHOOD

MANUAL OUTSIDE AIR DAMPER

REPLACEMENT

PANEL

REPLACEMENT

PANEL

HOLE FOR

ECONOMIZER

WIRING HARDNESS

ALUMINUM

FILTER

50XP

EV APORATOR

COIL

TOP FILTER RACK

BOTTOM FILTER

RACK

MANUAL OUTSIDE

AIR HOOD

DAMPER

BLADE

A05239

7

Page 8

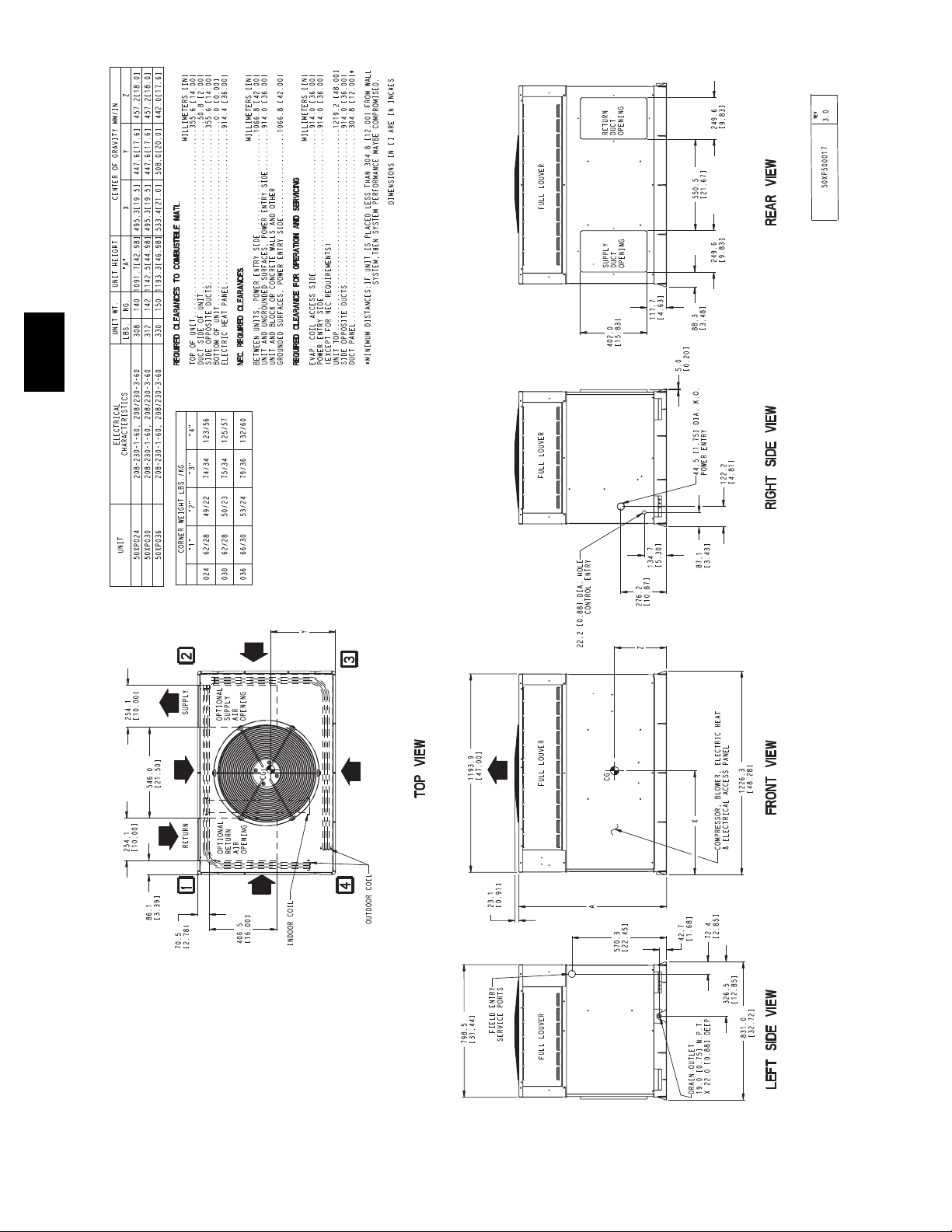

UNIT DIMENSIONS -- 50XP024--036

50XP

A08452

8

Page 9

UNIT DIMENSIONS -- 50XP042--060

50XP

A08453

9

Page 10

ACCESSORY ROOF CURB -- 50XP024--060

HVAC unit

base

Scre w

(NO TE A)

*Gask eting

outer flange

Flashing field

supplied

Roofing material

field supplied

Cant str ip

field supplied

50XP

*Provided with roofcurb

Gask eting

inner flange*

Wood nailer*

Roofcurb*

Insulation (field

supplied)

Duct wo

field supplied

Roof

Flashing field

Roofing material

field supplied

rk

Roof Curb for Small Cabinet

Note A: When unit mounting scre w is used,

retainer must also be used.

bracket

Note A: When unit mounting scre w is used,

HVAC unit

base

Scre w

(NOTE A)

*Gask eting

outer flange

supplied

Cant str ip

field supplied

*Provided with roofcurb

Roof Curb for

Gask eting

inner flange*

Large Cabinet

retainer bra cket must also be used.

Wood nailer*

Roofcurb*

Insulation (field

supplied)

Duct wo rk

field supplied

Roof

Supply opening

(B x C)

5

44

/

16

"

(1126 mm)

B Typ.

C Typ.

D

R/A

A

Gask et around

S/A

duct

Short

d

Insulate

deck pan

Return opening

(B X C)

UNIT SIZE ORDERING NUMBER

50XP024--036

50XP042--060

CPRFCURB006A00 8 (203) 11 (279) 16--1/2 (419) 28--3/4 (730)

CPRFCURB007A00 14 (356) 11 (279) 16--1/2 (419) 28--3/4 (730)

CPRFCURB008A00 8 (203) 16--3/16 (411) 17--3/8 (441) 40--1/4 (1022)

CPRFCURB009A00 14 (356) 16--3/16 (411) 17--3/8 (441) 40--1/4 (1022)

Support

Long

Support

A

IN. (MM)

NOTES:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied, as required, to unit being installed.

3. Roof curb is made of 16--gauge steel.

4. Attach ductwork to curb (flanges of duct rest on curb).

5. Insulated panels: 1--in. (25.4 mm) thick fiberglass 1 lb. density.

6. When unit mounting screw is used (see Note A), a r etainer bracket must be used as well. This bracket must also be used when required by code for h urricaneorseismic

conditions. This bracket is available through Micrometl.

Insulated

deck pan

B

IN. (MM)

Gask et around

outer edge

C

IN. (MM)

D

IN. (MM)

C00076

10

Page 11

50XP UNIT SUGGESTED RIGGING

12

(914 mm)

DETAIL A

34

A07216

Unit*

Rigging

Weight

NOTE: See dimensional drawing for corner weight distribution. Corner weights shown on drawing are based on unit---only weights and do not include packaging.

024 024 030 030 036 036

lb kg

345 156 349 158 367 166

SELECTION PROCEDURE (WITH EXAMPLE)

1. Determine cooling and heating requirements at

design conditions:

Given:

Required Cooling Capacity (TC) 34,500 Btuh..........

Sensible Heat Capacity (SHC) 26,000 Btuh............

Required Heating Capacity 15,000 Btuh...............

Condenser Entering Air Temperature 95°F(35°C)........

Indoor--Air Temperature 80°F(26°C) edb.............

67°F(19°C) ewb

Evaporator Air Quantity 1200 CFM..................

External Static Pressure 0.20 IN. W.C..................

Electrical Characteristics 230--1-- 60...................

2. Select unit based on required cooling capacity.

Enter Net Cooling Capacities table at condenser entering

temperature of 95°F(35°C). The 036 unit at 1225 CFM and 67°F

(19°C) ewb (entering wet bulb) will provide a total capacity of

36,500 Btuh and a SHC of 27,600 Btuh. Calculate SHC correction,

if required, using Note 4 under Cooling Capacities tables.

3. Select electric heat.

The required heating capacity is 15,000 Btuh.

Determine additional electric heat capacity in kW.

15,000 Btuh

3,414 Btuh/kW

Enter the Electric Heater Packages table for 208/240, single--phase,

036 unit. The 5 kW heater at 240v most closely satisfies the

heating required. To calculate kW at the 208v, multiply the heater

kW by multiplication factor 0.75 found in the Wattage

Multiplication Factors table.

5 kW x 0.75 = 3.75 kW

3.75 kW x 3414 = 12,802.50 Btuh

SMALL CABINET LARGE CABINET

lb kg lb kg

Unit*

Rigging

Weight

042 042 048 048 060 060

lb kg lb kg lb kg

425 193 459 208 504 229

4. Determine fan speed and power requirements at

design conditions.

Before entering the air delivery tables, calculate the total static

pressure required. From the given example, the Filter Pressure

Drop Ta ble, and the Accessory Electric Heat Pressure Drop table,

find:

External Static Pressure 0.200 IN. W.C.

Filter 0.130 IN. W.C.

Wet Coil Pressure Drop 0.032 IN. W

Total Static Pressure 0.362 IN. W.C.

Enter the table for Dry Coil Air Delivery—At 0.362 IN. W.C. ESP

(external static pressure) and NOM speed pin selection, the motor

will deliver 1235 cfm.

5. Select unit that corresponds to power source

available.

The Electrical Data Table shows that the unit is designed to operate

at 208 --1--60.

= 4.4kW of heat required

.C.

A08005

50XP

11

Page 12

72

(22.2)

72

(22.2)

Evaporator Air --- CFM/BF

67

(19.4)

63*

(17.2)

62

(19.7)

72

(22.2)

67

(19.4)

63*

(17.2)

Evaporator Air --- Ewb _F(_C)

62

(16.7)

67

(19.4)

63*

(17.2)

62

50XP

Evaporator Air --- CFM/BF

(19.7)

72

(22.2)

67

(19.4)

63*

(17.2)

Evaporator Air --- Ewb _F(_C)

62

(16.7)

PERFORMANCE DATA

72

67

800/0.026 900/0.032 1000/0.04

63*

62

Condenser

Te m p _F(_C)

Outdoor Air Entering

50XP024

72

875/0.06 1000/0.07 1125/0.08

Te m p _F(_C) Outdoor

(22.2)

67

(19.4)

63*

(17.2)

62

(16.7)

TC 27.9 28.6 30.7 33.6 28.8 29.4 31.6 34.5 29.3 30 32.2 35.2

TC 26.9 27.5 29.5 32.3 27.6 28.1 30.2 33.1 28.3 28.7 30.8 33.7

TC 25.6 26.2 28.2 30.8 26.3 26.8 28.8 31.5 27 27.3 29.3 32

TC 24.3 24.7 26.6 29.2 25.1 25.3 27.2 29.7 25.9 25.7 27.5 30.1

TC 22.8 23.2 24.9 27.3 23.8 23.6 25.3 27.7 24.5 24 25.7 28.1

115

SHC 21.7 18 18.8 14.8 22.3 19.3 20.2 15.7 23.7 20.5 21.5 16.6

(46.1)

kW 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2

TC 21.4 21.4 24.9 27.3 23.8 23.6 25.3 27.7 24.5 24 25.7 28.1

125

SHC 20.7 17.3 18.8 14.8 22.3 19.3 20.2 15.7 23.7 20.5 21.5 16.6

(51.7)

kW 3.5 3.5 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2

See Legend and Notes on Page 15.

kW 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.2 2.1 2.1 2.1 2.2

kW 2.3 2.3 2.4 2.4 2.3 2.4 2.4 2.4 2.4 2.4 2.4 2.4

kW 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6

(35)

105

SHC 22.4 18.6 19.3 15.4 23.8 19.9 20.8 16.3 24.4 21.1 22.1 17.2

(40.6)

kW 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9 2.9

SHC 24.1 20 20.6 16.8 26 21.2 22.1 17.8 27 22.6 23.5 18.7

SHC 23.8 19.5 20.3 16.4 25.6 20.8 21.7 17.4 26.5 22.1 23.1 18.3

SHC 23.1 19.1 19.9 16 24.7 20.5 21.3 16.9 26.2 21.7 22.6 17.8

Condenser

Air Entering

75

85

(29.4)

95

(23.9)

(22.2)

(19.4)

(17.2)

(16.7)

TC 24.0 24.5 26.5 29.1 24.6 25.1 27.1 29.8 25.1 25.5 27.4 30.4

TC 22.9 23.3 25.3 27.9 23.5 23.9 25.8 28.5 23.9 24.3 26.2 28.9

TC 21.8 22.2 24.0 26.5 22.3 22.6 24.5 27.0 22.7 23.0 24.8 27.4

TC 20.5 20.9 22.6 25.0 21.0 21.3 23.0 25.4 21.6 21.7 23.3 25.7

TC 19.2 19.5 21.1 23.3 19.8 19.9 21.5 23.7 20.7 20.4 21.7 23.6

75

SHC 21.9 21.3 18.7 15.4 23.5 22.8 19.8 16.1 25.0 24.2 20.8 16.7

(23.9)

kW 1.7 1.7 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.9

85

SHC 21.4 20.7 18.1 14.9 22.9 22.2 19.2 15.6 24.3 23.6 20.3 16.2

(29.4)

kW 1.9 1.9 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.1 2.1

95

SHC 20.8 20.2 17.6 14.3 22.3 21.6 18.7 15.0 23.6 22.9 19.7 15.6

(35)

kW 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.3 2.3

SHC 20.2 19.5 16.9 13.7 21.6 20.9 18.0 14.3 22.5 22.2 19.0 14.9

105

kW 2.4 2.4 2.4 2.4 2.4 2.4 2.5 2.5 2.5 2.5 2.5 2.5

(104.6)

115

SHC 19.4 18.8 16.3 13.0 20.6 20.2 17.3 13.7 21.5 21.2 18.3 14.1

(46.1)

kW 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.8 2.8

TC 17.8 18.0 19.4 21.4 18.5 18.5 19.5 21.7 19.0 19.0 19.9 21.9

125

SHC 18.5 18.1 15.5 12.3 19.2 19.2 16.5 12.9 19.8 19.7 17.6 13.5

(51.7)

kW 2.9 2.9 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.1 3.1

50XP030

12

Page 13

72

(22.2)

72

(22.2)

Evaporator Air --- CFM/BF

67

(19.4)

63*

(17.2)

62

(19.7)

72

(22.2)

67

(19.4)

63*

(17.2)

Evaporator Air --- Ewb _F(_C)

62

(16.7)

Evaporator Air --- CFM/BF

67

(19.4)

63*

(17.2)

62

(19.7)

72

(22.2)

67

(19.4)

63*

(17.2)

Evaporator Air --- Ewb _F(_C)

62

(16.7)

50XP

PERFORMANCE DATA (CONT)

72

67

1100/0.06 1225/0.07 1400/0.08

63*

62

Condenser

Air Entering

Te m p _F(_C) Outdoor

50XP036

1225/0.06 1400/0.07 1575/0.08

Te m p _F(_C) Outdoor

72

(22.2)

67

(19.4)

63*

(17.2)

62

(16.7)

TC 39.6 40.4 43.4 47.6 40.5 41.2 44.2 48.4 41.5 42.1 45.1 49.4

TC 37.9 38.7 41.5 45.5 38.7 39.4 42.3 46.3 39.7 40.2 43.2 47.2

TC 36.2 36.8 39.6 43.4 36.9 37.5 40.3 44.1 37.8 38.2 41.0 44.9

TC 34.2 34.8 37.4 41.0 34.9 35.4 38.0 41.6 36.0 36.0 38.7 42.3

TC 32.1 32.6 35.0 38.4 32.8 33.1 35.5 38.9 34.0 33.7 36.1 39.5

115

SHC 30.0 24.3 25.2 20.2 31.4 25.6 26.6 21.0 32.8 27.3 28.5 22.2

(46.1)

kW 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.6 4.5 4.5 4.5 4.6

TC 29.8 30.1 32.3 35.3 30.6 30.5 32.7 35.7 31.7 31.0 33.2 36.2

125

SHC 28.6 23.2 24.2 19.1 29.6 24.5 25.5 20.0 30.6 26.1 27.3 21.1

(51.7)

kW 4.9 4.9 4.9 5.0 4.9 4.9 4.9 5.0 4.9 4.9 4.9 5.0

See Legend and Notes on Page 15.

kW 3.0 3.0 3.0 3.1 3.0 3.0 3.0 3.1 3.0 3.0 3.0 3.1

kW 3.3 3.3 3.4 3.4 3.3 3.3 3.4 3.4 3.3 3.3 3.4 3.4

kW 3.7 3.7 3.7 3.8 3.7 3.7 3.7 3.8 3.7 3.7 3.7 3.8

(35)

105

SHC 31.0 25.2 26.2 21.1 32.7 26.5 27.6 22.0 34.3 28.3 29.4 23.2

(104.6)

kW 4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1

SHC 33.5 27.6 28.6 23.4 35.4 29.0 30.0 24.3 37.9 30.8 31.9 25.6

SHC 32.8 26.9 27.8 22.7 34.6 28.2 29.2 23.6 37.0 30.0 31.1 24.8

SHC 32.0 26.1 27.0 21.9 33.8 27.4 28.4 22.8 35.9 29.1 30.3 24.0

Condenser

Air Entering

75

85

(29.4)

95

(23.9)

(22.2)

(19.4)

(17.2)

(16.7)

TC 36.2 36.8 39.7 43.8 36.9 37.4 40.3 44.4 37.9 38.1 41.0 45.1

TC 34.6 35.1 37.9 41.8 35.3 35.6 38.4 42.4 36.4 36.3 39.1 43.1

TC 33.0 33.4 36.0 39.7 33.7 33.8 36.5 40.2 34.8 34.4 37.0 40.8

TC 31.3 31.5 34.0 37.5 32.1 31.9 34.3 37.9 33.1 32.4 34.9 38.4

TC 29.6 29.4 31.8 35.0 30.4 29.8 32.1 35.4 31.3 30.3 32.6 35.8

75

SHC 33.2 26.7 27.8 22.3 34.7 27.9 29.0 23.1 36.9 29.6 30.9 24.2

(23.9)

kW 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.8 2.8 2.8 2.8 2.9

85

SHC 32.4 26.0 27.1 21.6 34.0 27.1 28.3 22.4 35.6 28.9 30.2 23.6

(29.4)

kW 2.9 2.9 3.0 3.0 3.0 3.0 3.0 3.0 3.1 3.1 3.1 3.2

95

SHC 31.6 25.3 26.4 20.9 32.9 26.4 27.6 21.7 34.4 28.1 29.4 22.8

(35)

kW 3.2 3.2 3.3 3.3 3.3 3.3 3.3 3.4 3.4 3.4 3.4 3.5

SHC 30.6 24.5 25.6 20.1 31.5 25.7 26.8 20.9 32.8 27.3 28.6 22.0

105

kW 3.6 3.6 3.6 3.6 3.6 3.6 3.7 3.7 3.8 3.7 3.8 3.8

(104.6)

115

SHC 29.3 23.7 24.8 19.3 30.0 24.8 26.0 20.0 31.0 26.4 27.7 21.1

(46.1)

kW 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.1 4.1 4.1 4.2

TC 27.8 27.2 29.4 32.4 28.4 27.5 29.7 32.7 29.3 28.0 30.1 33.0

125

SHC 27.5 22.8 23.9 18.4 28.2 23.8 25.0 19.1 29.0 25.4 26.7 20.2

(51.7)

kW 4.4 4.3 4.4 4.4 4.4 4.4 4.4 4.4 4.5 4.5 4.5 4.5

50XP042

13

Page 14

72

(22.2)

72

(22.2)

67

(19.4)

63*

(17.2)

62

50XP

Evaporator Air --- CFM/BF

(19.7)

72

(22.2)

67

(19.4)

63*

(17.2)

Evaporator Air --- Ewb _F(_C)

62

(16.7)

Evaporator Air --- CFM/BF

67

(19.4)

63*

(17.2)

62

(19.7)

72

(22.2)

67

(19.4)

63*

(17.2)

Evaporator Air --- Ewb _F(_C)

62

(16.7)

PERFORMANCE DATA (CONT)

72

67

1260/0.06 1400/0.06 1600/0.08

63*

62

Condenser

Air Entering

Te m p _F(_C) Outdoor

50XP048

1500/0.04 1750/0.07 2000/0.01

Te m p _F(_C) Outdoor

72

(22.2)

67

(19.4)

63*

(17.2)

62

(16.7)

TC 57.2 58.2 62.4 68.1 58.8 59.7 64.0 69.8 60.0 60.8 64.9 70.8

TC 54.7 55.6 59.7 65.2 56.2 57.0 61.1 66.6 57.4 58.1 61.9 67.4

TC 52.2 53.0 56.9 62.0 53.5 54.3 58.0 63.2 55.0 55.3 58.7 64.1

TC 49.4 50.2 53.8 58.7 50.7 51.4 54.8 59.6 52.5 52.4 55.4 60.2

TC 46.5 47.2 50.5 55.0 48.1 48.3 51.3 56.8 49.7 49.7 51.8 57.0

115

SHC 44.3 42.7 36.4 28.7 48.1 46.6 39.2 30.6 49.7 49.7 41.8 31.7

(46.1)

kW 6.1 6.2 6.2 6.3 6.2 6.3 6.4 6.4 6.4 6.4 6.6 6.6

TC 43.3 43.9 46.7 52.2 45.2 45.1 47.4 52.5 46.4 46.4 47.9 52.2

125

SHC 42.8 41.2 34.9 27.8 45.2 45.1 37.6 28.9 46.4 46.4 40.2 29.7

(51.7)

kW 6.7 6.8 6.8 6.8 6.8 6.9 7.0 7.0 7.0 7.0 7.2 7.2

See Legend and Notes on Page 15.

kW 4.1 4.1 4.2 4.2 4.2 4.3 4.3 4.4 4.4 4.4 4.5 4.6

kW 4.5 4.5 4.6 4.7 4.7 4.7 4.8 4.9 4.8 4.9 5.0 5.0

kW 5.0 5.0 5.1 5.2 5.1 5.2 5.3 5.3 5.2 5.3 5.5 5.5

(35)

105

SHC 45.7 44.1 37.9 30.1 49.8 47.9 40.6 31.6 52.5 51.6 43.2 33.0

(104.6)

kW 5.5 5.6 5.6 5.7 5.7 5.7 5.8 5.9 5.8 5.8 6.0 6.1

SHC 49.4 47.9 41.6 33.8 53.6 51.8 44.5 35.4 57.6 55.4 47.1 36.8

SHC 48.2 46.7 40.4 32.6 52.4 50.5 43.2 34.2 56.3 54.2 45.8 35.6

SHC 47.0 45.4 39.2 31.4 51.1 49.2 41.9 32.9 55.0 52.9 44.5 34.4

Condenser

Air Entering

75

85

(29.4)

95

(23.9)

(22.2)

(19.4)

(17.2)

(16.7)

TC 45.0 45.8 49.6 54.7 46.7 47.3 51.2 56.3 48.1 48.7 52.5 57.8

TC 42.8 43.6 47.2 52.1 44.3 44.9 48.6 53.5 45.6 46.1 49.9 54.8

TC 40.6 41.3 44.7 49.4 41.8 42.4 46.0 50.7 44.2 43.7 47.0 51.8

TC 38.2 38.9 42.1 46.4 39.6 39.8 43.1 47.6 41.5 40.8 44.0 48.5

TC 35.7 36.3 39.3 43.3 38.2 37.1 40.1 44.2 38.7 37.9 40.8 45.0

75

SHC 39.3 32.0 33.4 27.2 42.6 34.3 35.8 28.9 45.8 36.8 38.4 30.6

(23.9)

kW 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.5 3.4 3.4 3.4 3.5

85

SHC 38.2 30.9 32.3 26.2 41.3 33.2 34.7 27.7 44.3 35.5 37.3 29.4

(29.4)

kW 3.7 3.7 3.8 3.8 3.7 3.7 3.8 3.8 3.8 3.8 3.8 3.8

95

SHC 36.9 29.8 31.2 25.2 39.9 32.0 33.6 26.7 43.0 34.6 36.1 28.3

(35)

kW 4.1 4.1 4.2 4.2 4.1 4.1 4.2 4.2 4.2 4.1 4.2 4.2

SHC 35.7 28.7 30.1 24.0 38.3 30.7 32.3 25.5 40.0 33.2 34.8 27.0

105

kW 4.6 4.6 4.6 4.6 4.6 4.6 4.6 4.7 4.6 4.6 4.6 4.7

(104.6)

115

SHC 34.4 27.5 28.9 22.9 35.7 29.5 31.0 24.3 38.2 31.8 33.5 25.8

(46.1)

kW 5.0 5.0 5.1 5.1 5.1 5.0 5.1 5.1 5.1 5.1 5.1 5.1

TC 33.4 33.4 36.2 39.4 34.6 34.1 36.9 40.5 36.1 34.8 37.5 41.2

125

SHC 32.1 26.2 27.6 21.5 33.8 28.2 29.7 22.9 35.6 30.2 31.9 24.4

(51.7)

kW 5.6 5.6 5.6 5.7 5.6 5.6 5.6 5.6 5.6 5.6 5.6 5.6

50XP060

14

Page 15

50XP

4.5 x cfm

total capacity (Btuh)

e w b ---

h

lwb =

h

*At75°F(24°C) entering dry bulb---Tennessee Valley Authority (TVA) rating conditions; all others at 80°F(27°C) dry bulb.

LEGEND

PERFORMANCE DATA (CONT)

(Btuh)

1.10 x cfm

Sensible capacity

---

edb

t

ldb =

BF— Bypass Factor

edb— Entering Dry ---Bulb

Ewb— Entering Wet --- Bulb

kW — Total Unit Power Input

SHC— Sensible Heat Capacity (1000 Btuh)

TC — Total Capacity (1000 Btuh) (net)

rh—Relative Humidity

COOLING NOTES:

1. Ratings are net; they account for the effects of the evaporator--- fan motor power and heat.

2. Direct interpolation is permissible. Do not extrapolate.

t

3. The following formulas may be used:

lwb)

h

ewb = En thal py of air entering evaporator coil

Wet---bulb temperature corresponding to enthalpy

air leaving evaporator coil (

h

lwb =

t

4. The SHC is based on 805 F (26.6_ C) edb temperature of air entering evaporator coil. Below 80_F (26.6_C) edb, subtract (corr factor x cfm) from SHC.

Where:

Above 80_F (26.6_C) edb, add (corr factor x cfm) to SHC.

Correction Factor = 1.10 x (1 + BF) x (edb + 80).

5. Integrated capacity is maximum (instantaneous) capacity less the effect of frost on the outdoor coil and the heat required to defrost it.

15

Page 16

PERFORMANCE DATA (CONT)

Economizer 1--in. Filter Pressure Drop (IN. W.C.)

UNIT50XP PRESSURE DROP

024--036 0.20

042--060 0.25

Multiplication Factors

HEATER kW RATING VOLTAGE DISTRIBUTION V/3/60 MULTIPLICATION FACTOR

240

Filter Pressure Drop Table (IN. W.C.)

FILTER SIZE

in. (mm)

20X20X1

(508X508X25)

20X24X1

(508X610x25)

24X30X1

50XP

(610X762x25)

Electric Heat Pressure Drop Tables (IN. W.C.)

Small Cabinet: 024--036

STATIC

5kW 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.02 0.04 0.06 0.07

7.5 kW 0.00 0.00 0.00 0.00 0.00 0.00 0.02 0.03 0.05 0.07 0.08 0.09

10 kW 0.00 0.00 0.00 0.00 0.00 0.02 0.04 0.06 0.07 0.09 0.10 0.11

15 kW 0.00 0.00 0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 0.16 0.18

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

0.05 0.07 0.08 0.10 0.12 0.13 0.14 0.15 — — — — — — — — — — —

— — — 0.09 0.10 0.11 0.13 0.14 0.15 0.16 — — — — — — — —

— — — — — — — 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600

200

208

230

240

0.69

0.75

0.92

1.00

CFM

CFM

Large Cabinet: 042--060

STATIC

5kW 0.00 0.00 0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12

7.5 kW 0.00 0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13

10 kW 0.00 0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13

15 kW 0.00 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15

20 kW 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16

1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

CFM

ECM Dry Coil Airflow--Small Cabinet

UNIT

SIZE

024

030

036

CFM ADJUST PIN SELECT LO PIN NOM PIN HI PIN

EXTERNAL STATIC

PRESSURE RANGE

COOLING 800 725 -- 885 805 730 990 930 855

COOLING DEHUMIDIFY 715 670 -- 715 695 645 795 775 745

COOLING 1010 920 825 1105 1030 930 1255 1160 1050

COOLING DEHUMIDIFY 890 845 795 890 865 825 1010 980 925

COOLING 1110 1025 970 1235 1175 1115 1400 1355 1280

COOLING DEHUMIDIFY 990 960 910 990 975 940 1125 1110 1085

0.0--0.39 0.4-- 0.69 0.7--1.0 0.0--0.39 0.4--0.69 0.7-- 1.0 0.0-- 0.39 0.4--0.69 0.7--1.0

ECM Dry Coil Airflow--Large Cabinet

UNIT SIZE

042

048

060

CFM ADJUST PIN SELECT LO P IN NOM PIN NOM PIN

EXTERNAL STATIC PRESSURE RANGE 0.1--1.0 0.1--1.0 0.1-- 1.0

COOLING 1100 1225 1410

COOLING DEHUMIDIFY 980 980 1125

COOLING 1260 1400 1610

COOLING DEHUMIDIFY 1120 1120 1290

COOLING 1575 1750 2010

COOLING DEHUMIDIFY 1400 1400 1610

W et Coil Pressure Drop (IN. W.C.)

Unit

Size

600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100

024 0.005 0.007 0.010 0.012 0.015

030 0.007 0.010 0.012 0.015 0.018 0.021 0.024

036 0.019 0.023 0.027 0.032 0.037 0.042 0.047

042 0.014 0.017 0.020 0.024 0.027 0.031 0.035 0.039 0.043

048 0.027 0.032 0.036 0.041 0.046 0.052 0.057 0.063 0.068

060 0.029 0.032 0.036 0.040 0.045 0.049 0.053

Standard CFM (S.C.F.M)

16

Page 17

TYPICAL PIPING AND WIRING

ROOF-MOUNTING

CURB

SUPPLY-AIR

FLEXIBLE DUCT

ROOF

RETURN-AIR

FLEXIBLE DUCT

50XP

CONCENTRIC DIFFUSER BOX

(FIELD-SUPPLIED)

TOP COVER

RETURN

AIR

CEILING

INDOOR

THERMOSTAT

FROM

POWER

SOURCE

DISCONNECT

PER NEC*

C00023

17

*NEC - NATIONAL ELECTRICAL CODE

C00063

Page 18

APPLICATION DA TA

Condensate trap — A 2--in. (51 mm) condensate trap must be

field supplied.

1” (25 mm) MIN

.

TRAP

OUTLET

2” (51 mm) MIN.

Ductwork — Secure downflow discharge ductwork to roof curb.

For horizontal discharge applications, attach ductwork to unit with

flanges.

To convert a unit to downflow discharge — Units are equipped

with factory --installed inserts in the downflow openings. Removal

of the inserts is similar to removing an electrical knock--out. Leave

on duct covers to seal the horizontal discharge openings in the unit.

Units installed in horizontal discharge orientation do not require

50XP

duct covers.

A08001

Maximum cooling airflow — To minimize the possibility of

condensate blow--off from the evaporator, airflow through the units

should not exceed 450 cfm per ton.

Minimum cooling airflow — Minimum cooling airflow is 350

cfm per ton for standard cooling modes. Airflow can be lower in

certain modes when humidity removal is an issue.

Minimum cooling operating outdoor air temperature —All

standard units have a minimum outdoor operating temperature of

55_F(13_C). With accessory low ambient temperature kit, units

can operate at temperatures down to 0_F(--17_C).

Maximum cooling operating outdoor air temperature —

Maximum outdoor operating air temperature is 125_F(52_C).

18

Page 19

ELECTRICAL DATA

UNIT

50XP-024 208/230-1-60 187 253 13.5 61.0 0.8 4.3

50XP-030 208/230-1-60 187 253 15.9 73.0 0.8 4.3

50XP-036

50XP-042

50XP-048

50XP-060

NOMINAL

V --- P H --- H Z

208/230-1-60 187 253 16.9 83.0 0.8 6.8

208/230-3-60 187 253 12.2 77.0 0.8 6.8

208/230-1-60 187 253 22.4 105.0 0.8 6.8

208/230-3-60 187 253 15.4 88.0 0.8 6.8

208/230-1-60 187 253 21.3 109.0 1.6 6.8

208/230-3-60 187 253 14.7 91.0 1.6 6.8

208/230-1-60 187 253 27.0 145.0 1.6 9.1

208/230-3-60 187 253 19.2 137.0 1.6 9.1

VOLTAGE

RANGE

MIN MAX RLA LRA FLA FLA

COMPRESSOR OFM IFM

ELECTRIC HEAT POWER SUPPLY

NOMINAL

KW

-/- -/- 22.0/22.0 30/30 ---

3.8/5 18.1/20.8 27.9/31.4 30/35 ---

5.4/7.2 26/30 37.9/42.9 40/45 ---

7.5/10 36.1/41.7 50.5/57.5 60/60 ---

-/- -/- 23.6/23.6 30/30 ---

3.8/5 18.1/20.8 27.9/31.4 30/35 ---

5.4/7.2 26/30 37.9/42.9 40/45 ---

7.5/10 36.1/41.7 50.5/57.5 60/60 ---

11.3/15 54.2/62.5 73.1/83.5 - 80/90

-/- -/- 26.9/26.9 35/35 ---

3.8/5 18.1/20.8 31.1/34.5 35/35 ---

5.4/7.2 26/30 41.0/46.0 45/50 ---

7.5/10 36.1/41.7 53.6/60.6 --- 60/70

11.3/15 54.2/62.5 76.2/86.6 --- 80/90

-/- -/- 23.0/23.0 30/30 --5 10.4/12 23.0/23.5 30/30 ---

10 20.8/24.1 34.6/38.6 35/35 --15 31.3/36.1 47.6/53.6 50/60 ---

-/- -/- 30.9/30.9 45/45 ---

3.8/5 18.1/20.8 31.1/34.5 45/45 ---

5.4/7.2 26/30 41.0/46.0 45/50 ---

7.5/10 36.1/41.7 53.6/60.6 --- 60/70

11.3/15 54.2/62.5 76.2/86.6 --- 80/90

15/20 72.2/83.3 98.8/112.7 --- 100/125

-/- -/- 27.0/27.0 35/35 ---

3.8/5 10.4/12 27.0/27.0 35/35 ---

7.5/10 20.8/24.1 34.6/38.6 35/35 ---

11.3/15 31.3/36.1 47.6/53.6 50/60 --15/20 41.6/48 60.5/68.5 --- 70/70

-/- -/- 33.9/33.9 45/45 ---

3.8/5 18.1/20.8 33.9/34.5 45/45 ---

5.4/7.2 26/30 41.0/46.0 45/50 ---

7.5/10 36.1/41.7 53.6/60.6 --- 60/70

11.3/15 54.2/62.5 76.2/86.6 --- 80/90

15/20 72.2/83.3 98.8/112.7 --- 100/125

-/- -/- 26.7/26.7 35/35 ---

3.8/5 10.4/12 26.7/26.7 35/35 ---

7.5/10 20.8/24.1 34.6/38.6 35/35 ---

11.3/15 31.3/36.1 47.6/53.6 50/60 --15/20 41.6/48 60.5/68.5 --- 70/70

-/- -/- 44.3/44.3 60/60 ---

3.8/5 18.1/20.8 44.3/44.3 60/60 ---

5.4/7.2 26/30 44.3/48.9 60/60 ---

7.5/10 36.1/41.7 56.5/63.5 --- 60/70

11.3/15 54.2/62.5 79.1/89.5 --- 80/90

15/20 72.2/83.3 101.6/115.5 --- 100/125

-/- -/- 33.0/33.0 40/40 ---

3.8/5 10.4/12 33.0/33.0 40/40 ---

7.5/10 20.8/24.1 37.4/41.4 40/45 ---

11.3/15 31.3/36.1 50.5/56.5 60/60 --15/20 41.6/48 63.3/71.3 --- 70/80

FLA MCA

MAX

FUSE or

CKT BKR

MOCP

50XP

*Heater capacity (kW) based on heater voltage of 208v, 240v, &

480v. If power distribution voltage to unit varies from rated

heater voltage, heater kW will vary accordingly.

19

457

464

457

452

457

455

460-3-60.

452 v

464 v

455 v

452

464 455

1371

457

5

7

2

7

7

457

1.53

Page 20

TYPICAL WIRING SCHEMATIC 208/230--1--60

50XP

20

A08460

Page 21

TYPICAL WIRING SCHEMATIC 208/230--3--60

50XP

21

A08461

Page 22

CONTROLS

Operating sequence

Cooling — When the system thermostat calls for cooling, 24 V is

supplied to the “Y” and “G” terminals of the thermostat. This

completes the circuit to the contactor coil (C) and indoor fan

board. The normally open contacts of C close and complete the

circuit to compressor motor (COMP) and to outdoor (condenser)

fan motor (OFM). Both motors start instantly. The IFM starts

according to the selection pin set--up on the Easy Select Board.

On the loss of the thermostat call for cooling, 24 V is removed

from both the “Y” and “G” terminals (provided the fan switch is in

the “AUTO” position) de--energizing the compressor contactor and

opening the contacts supplying power to compressor/OFM. After a

preselected delay, the IFM shuts off. If the thermostat fan selector

switch is in the “ON” position, the IFM will run continuously at

speed selected on Easy Select Board

50XP

Heating — If accessory electric heaters are installed, on a call for

heat, circuit R--W is made through the thermostat contacts. Circuit

R--G is made which energizes the IFM. If the heaters are staged,

then the thermostat closes a second set of contacts (W2) when

second stage is required. When thermostat is satisfied, contacts

open, deenergizing the heater relay. After a preselected delay, the

IFM shuts off. If the thermostat fan selector switch is in the “ON”

position, the IFM will run continuously at speed selected on Easy

Select Board.

NOTE: On units with a Time Guard

compressor has started and then stopped, it cannot be restarted

again until 5 minutes have elapsed.

The indoor blower operation with a call for fan operation (G) in

cooling mode will perform by the on/off delay profile selected at

start up on the Easy Select Board.

®

II device: Once the

22

Page 23

GUIDE SPECIFICATIONS

Packaged Electric Cooling Unit

Constant Volume Application

HVAC Guide Specifications

Size Range: 2to5Tons,NominalCooling

Model Number: 50XP

Part 1 — General

SYSTEM DESCRIPTION

Outdoor rooftop mounted or ground mounted, electric cooling

unit utilizing a hermetic compressor for cooling duty and

optional electric heating. Unit shall discharge supply air

vertically or horizontally as shown on contract drawings.

Condenser fan/coil section shall have a draw--thru design with

vertical discharge for minimum sound levels.

QUALITY ASSURANCE

A. Unit shall be rated in accordance with ARI Standards

210/240 and 270.

B. Unit shall be designed in accordance with UL Standard

1995.

C. Unit shall be manufactured in a facility registered to ISO

9001 manufacturing quality standard.

D. Unit shall be UL listed and c--UL certified as a total

package for safety requirements.

E. Roof curb shall be designed to conform to NRCA

Standards.

F. Insulation and adhesives shall meet NFPA 90A

requirements for flame spread and smoke generation.

G. Cabinet insulation shall meet ASHRAE Standard 62P.

DELIVERY, STORAGE AND HANDLING

Unit shall be stored and handled per manufacturer’s

recommendations.

Part 2 — Products

EQUIPMENT

A. General:

Factory--assembled, single--piece, cooling unit. Contained

within the enclosure shall be all factory wiring, piping,

controls, refrigerant charge with R-- 410A refrigerant, and

special features required prior to field start--up.

B. Unit Cabinet:

1. Unit cabinet shall be constructed of phosphated,

zinc--coated, pre--painted steel capable of with--standing 500

hours in salt spray.

2. Normal service shall be through a single removable cabinet

panel.

3. The unit shall be constructed on a rust proof unit base that

has an externally trapped, integrated sloped drain pan.

4. Evaporator fan compartment top surface shall be insulated

with a minimum 1/2--in. (13 mm) thick, flexible fiberglass

insulation, coated on the air side and retained by adhesive

and mechanical means. The evaporator wall sections will be

insulated with a minimum semi--rigid foil--faced board capable of being wiped clean. Aluminum foil--faced fiberglass

insulation shall be used in the entire indoor air cavity

section.

5. Unit shall have a field--supplied condensate trap.

C. Fans:

1. The evaporator fan shall be direct--drive variable speed

motor and control, as shown on equipment drawings.

2. Fan wheel shall be made from steel, be double--inlet type

with forward curved blades with corrosion resistant finish.

Fan wheel shall be dynamically balanced.

3. Condenser fan shall be direct drive propeller type with aluminum blades riveted to corrosion resistant steel spiders, be

dynamically balanced, and discharge air vertically.

D. Compressor:

1. Fully hermetic compressors with factory--installed vibration

isolation.

2. Scroll compressors shall be standard on all units.

E. Coils:

Evaporator and condenser coils shall have aluminum plate fins

mechanically bonded to seamless copper tubes with all joints

brazed. (Copper/copper and vinyl-- coated construction

available as option). Tube sheet openings shall be belled to

prevent tube wear.

F. Refrigerant Components:

Refrigerant expansion device shall be of the TXV

(thermostatic expansion valve) type.

G. Filters:

Filter section shall consist of field--installed, throwaway, 1--in.

(25 mm) thick fiberglass filters of commercially available

sizes.

H. Controls and Safeties:

1. Unit controls shall be complete with a self--contained low

voltage control circuit.

2. Units shall incorporate an internal compressor protector that

provides reset capability.

3. Unit shall provide High and Low/Loss--of--Charge Pressure

Safety Protection.

I. Operating Characteristics:

1. Unit shall be capable of starting and running at 125_F

(51_C) ambient outdoor temperature,exceeding maximum

load criteria of ARI Standard 210.

2. Compressor with standard controls shall be capable of operationdownto55_F(13_C) ambient outdoor temperature.

3. Indoor Fan on/off delay profile is selected (for cooling) on

the Easy Select board.

J. Electrical Requirements:

All unit power wiring shall enter the unit cabinet at a single

location.

K. Motors:

1. Compressor motors shall be of the refrigerant--cooled type

with line--break thermal and current overload protection.

2. All fan motors shall have permanently lubricated bearings,

and inherent, automatic reset, thermal overload protection.

3. Condenser fan motor shall be totally enclosed.

L. Grille:

1. Louvered Grille:

Louvered grille shall be standard on all units.

50XP

23

Page 24

M. Special Features:

1. Coil Options:

2. Economizer:

3. Flat Roof Curb:

4. Manual Outdoor Air Damper:

50XP

5. Thermostat:

GUIDE SPECIFICATIONS (CONT)

Shall include factory-- installed optional tin--plated indoor,

copper/copper and vinyl--coated refrigerant coils.

a. Economizer controls capable of providing free cooling

using outside air.

b. Equipped with low leakage dampers not to exceed 3%

leakage, at 1.0 IN. W.C. pressure differential.

c. Spring return motor shuts off outdoor damper on power

failure.

Curbs shall have seal strip and a wood nailer for flashing

and shall be installed per manufacturer’s instructions.

Package shall consist of damper, birdscreen, and rainhood

which can be preset to admit outdoor air for year--round

ventilation.

To provide for one--stage heating and cooling in addition

manual or automatic changeover and indoor fan control.

6. Low Ambient Package:

Shall consist of a solid--state control and condenser coil

temperature sensor for controlling condenser--fan motor operation, which shall allow unit to operate down to 0_F

(--18_C) outdoor ambient temperature when properly

installed.

7. Filter Rack Kit:

Shall provide filter mounting for downflow or horizontal

applications.

8. Square--To--Round Duct Transitions (024--048):

Shall have the ability to convert the supply and return openings from rectangular to round. (024--048 only)

9. Compressor Protection:

Solid--state control shall protect compressor by preventing

“short cycling.“

10. Crankcase Heater:

Shall provide anti--floodback protection for low--load cooling applications.

11. Electric Heaters:

a. Electric heater shall be availabel as a field--installed

option.

b. Heater elements shall be open wire type, adequately

supported and insulated with ceramic bushings.

c. Electric heater packages must provide single point

power connection capability.

12. Compressor Start Kit (single phase units only):

Shall provide additional starting torque for single--phase

compressors.

Copyright 2008 Carrier Corp. D 7310 W. Morris St. D Indianapolis, IN 46231 Printed in U.S.A. Edition Date: 09/08

Manufacturer reserves the r ight to change, at any time, specifications and designs without notice and without obligations.

24

Catalog No: 50XP --- 05PD

Replaces: 50XP ---4PD

Loading...

Loading...