Page 1

Installation, Operation and Maintenance Instructions

50TJM

Nominal Cooling Capacity 15 - 28 Tons

HFC R - 410A Refrigerant

Note: T his manual discusses the Mechanical Installation of this unit, Start-up Procedures, Operating Sequences

Quality Assurance

04 100 950420

Package Rooftop Units

Page 1

Certificate Reg. No:

Subject to change without notice

Manufacturing point: Jeddah, Saudi Arabia

Nearest port of embarkation: Jeddah Islamic port

Product classification: Commercial

and Service Instructions.

Read thoroughly the entire insta llation ins truction m anual bef ore starti ng the unit installation, to get familiarized with

all steps and to identify if any additional reference materials as required.

The 50TJM units are single side discharge rooftop cool ing unit utilizing electric heat as an option. Units are prewired, pre-charged with R-410A refrigerant, and tested at the factory. These units can b e placed on the side of a

building or can be plac ed o n a roof without roof c urbs. Eac h unit is desi gned to occup y a minim al space. Piping an d

drain connections are readily accessible.

For a complete list of options and accessories, refer to the Product Data Catalog.

Contact your local Carrier representative for additional reference materials.

Page 2

Table of Contents

Page 2

1.0 – SAFETY CONSIDERATIONS ....................................................................................................... 3

1.1 – General ............................................................................................................................. 3

1.2 – Installation Safet y Cons iderat io ns ..................................................................................... 3

1.3 – Warranty ............................................................................................................................ 3

Physical Data ......................................................................................................................................... 5

Unit Dimensional Drawing.............................................................................................................. 6 – 7

2.0 – INSTALLATION ............................................................................................................................. 8

2.1 – Jobsite Survey ................................................................................................................... 8

2.2 – Plan for Unit Location ........................................................................................................ 8

2.3 – Rig and Place Unit ............................................................................................................ 8

2.4 – Positioning and Clearance ................................................................................................ 9

2.5 – Field Fabricate Ductwork .................................................................................................. 9

2.6 – Make Unit Duct Connections ............................................................................................ 9

2.7 – Trap Condensate Drain ................................................................................................... 10

2.8 – Outdoor Air-Vent ............................................................................................................. 10

2.9 – Make Electrical Connections ........................................................................................... 10

Electrical Data ..................................................................................................................................... 11

Electrical Resistance Heater Data ..................................................................................................... 12

Typical Wiring Schematic........................................................................................................... 13 – 14

3.0 – START–UP INSTRUCTIONS ...................................................................................................... 15

3.1 – Unit Preparation .............................................................................................................. 15

3.2 – Internal Wiring ................................................................................................................. 15

3.3 – Compressor Mounting ..................................................................................................... 15

3.4 – Refrigerant Service P or ts ................................................................................................ 15

3.5 – Compressor Rotation ...................................................................................................... 15

3.6 – Evaporator Fan ............................................................................................................... 15

3.7 – Condenser Fans and Motors ..........................................................................................

3.8 – Return – Air Filters .......................................................................................................... 16

3.9 – Base Unit Operation ........................................................................................................ 16

4.0 – SERVICE ..................................................................................................................................... 16

4.1 – Cleaning .......................................................................................................................... 16

4.2 – Lubrication ....................................................................................................................... 16

4.3 – Evaporator Fan Performance Adjustment ...................................................................... 17

4.4 – Evaporator Fan Service and Replacement ..................................................................... 17

4.5 – Belt Tension Adjustment ................................................................................................. 18

4.6 – Condenser – Fan Adjustment ......................................................................................... 18

4.7 – Refrigerant Charge.......................................................................................................... 18

4.8 – Protective Devices .......................................................................................................... 18

4.9 – Control Circuit, 24 – V ..................................................................................................... 19

5.0 – REPLACEMENT PARTS ............................................................................................................ 19

Fan Performance Table .............................................................................................................. 20 – 23

Cooling Chart .............................................................................................................................. 24 – 25

Troubleshooting .................................................................................................................................. 26

Start–up Check List ............................................................................................................................ 27

16

Page 3

1 – SAFETY CONSIDERATIONS

Page 3

1.1 – General

Improper installation, adjustment, alteration, service, maintenance or use can cause explosion, fire,

electrical shock or other conditions which may cause personal injury or property damage. Consult a

qualified installer; service agency must use factory-authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with the kits or accessories when installing.

Follow all the safety codes. Wear safety glasses and work gloves. Use quenching cloths for brazing

operations and have a fire extinguisher available. Read these instructions thoroughly and follow all

warnings or cautions attached to the unit. Consult local building codes for special requirements. In

absence of local codes, it is recommended that the USA standard ANSI/NFPA 70, National Electrical

Code (NEC), be followed.

It is important to recognize safety information. This is the safety-alert symbol . When you see

this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and NOTE. These words are used

with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury of death. WARNING signifies hazards which could result in personal injury or death.

CAUTION is used to identify unsafe practices, which may result in minor personal injury or product

and property damage. NOTE is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

1.2 – Installation Safety Considerations

After the unit has been received and when it is ready to be installed or reinstalled, it must be

inspected for damage. If damage is detected upon receipt, immediately file a claim with the shipping

company or repair.

This machine must be installed in a location that is not accessible to the public and protected against

access by non-authorized people.

This machine must not be installed in an explosive atmosphere.

Do not remove the skid or the packaging until the unit is in its final position. These units can be moved

with a fork lift truck, as long as the forks are positioned in the right place and direction on the unit.

The units can also be lifted with slings, using only the designated lifting points marked on the unit

(labels on the chassis and a label with all unit handling instructions are attached to the unit). Use

slings with the correct capacity, and always follow the lifting instructions on the certified drawings

supplied for the unit.

Safety is only guaranteed, if these instructions are carefully followed. If this is not the case, there is a

risk of material deterioration and injuries to personnel. These units are not designed to be lifted from

above.

1.3 – Warranty

Warranty is based on the general terms and conditions of the manufacturer. Any modifications to the

design and/or installation made without discussion with Carrier and without advance written

agreement will result in the loss of the right to any warranty claims and any claim for injury to

personnel as a result of these modifications.

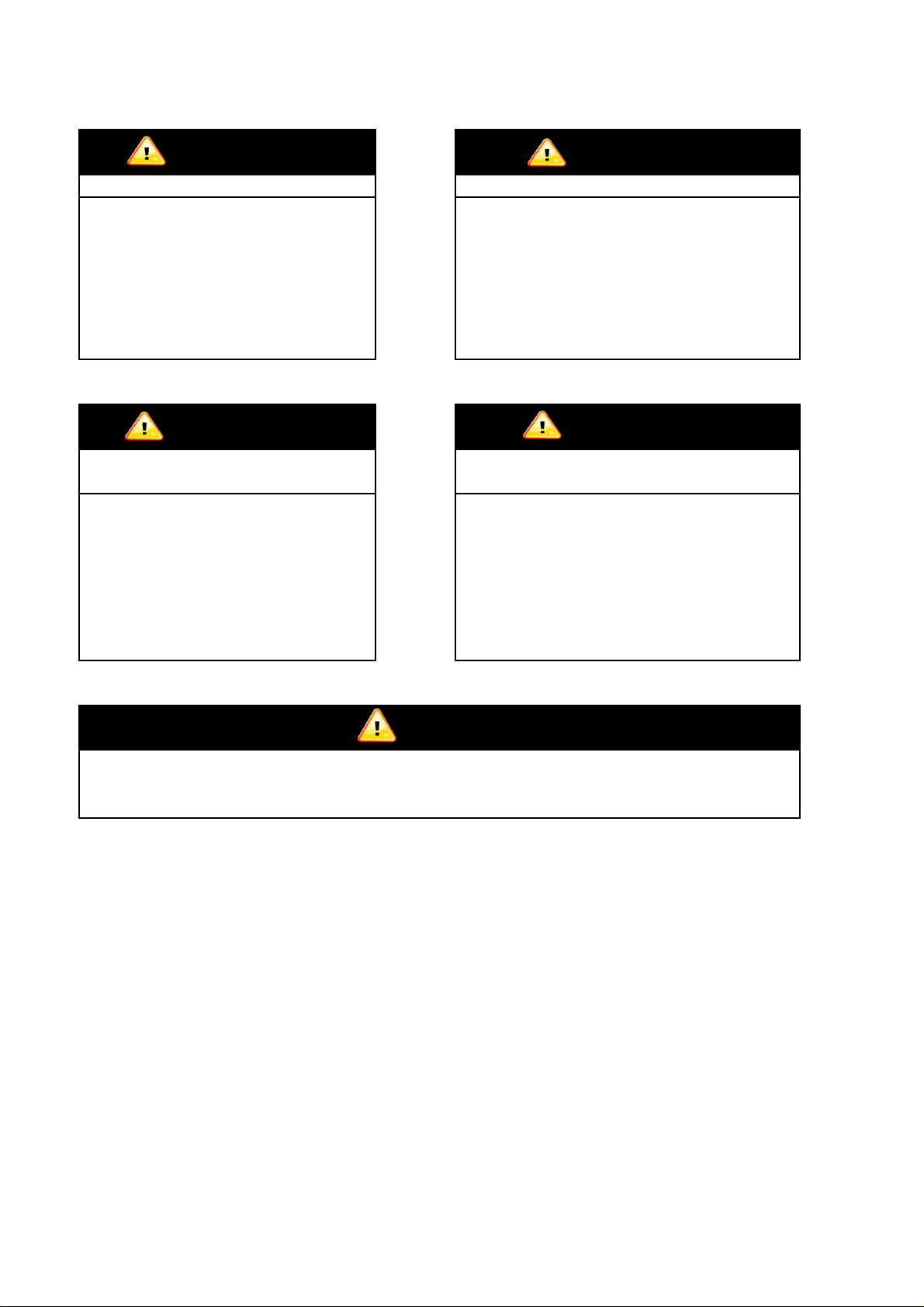

Page 4

Units have high ambient operation limits. If limits are exceeded, the unit will automatically lock the

compressor out of operation. Manual reset will be required to restart the compressor.

Failure to follow this warning could cause

personal injury, death and /or equipment

damage.

Failure to follow this warning could cause

personal injury or death damage.

Puron® (R-410A) refrigerant systems

operate at higher pressures than standard

R-22 systems. Do not use R-22 service

equipment or components on Puron®

refrigerant equipment.

Relieve pressure and recover all refrigerant

before system repair or final unit disposal.

Wear safety glasses and gloves when handling

refrigerants. Keep torches and other ignition

sources away from refrigerants and oils.

NOTE

IMPORTANT

Before performing service or maintenance

operations on unit, always turn off main

power switch to unit and install lockout

tag. Unit may have more than one power

switch.

Sheet metal parts may have sharp edges or

burrs. Use care and wear appropriate protective

clothing, safety glasses and gloves when

handling parts and servicing air conditioning

equipment

WARNING

WARNING

UNIT OPERATION AND SAFETY

HAZARD

PERSONAL SAFETY AND ENVIRONMENTAL

HAZARD

WARNING

CAUTION

ELECTRIC SHOCK HAZARD

CUT HAZARD

Failure to follow this warning could cause

personal injury or death.

Failure to follow this warning could cause

personal injury.

Page 4

Page 5

Physical Data Table - 1

Circuts No.

Low Pressure Switch (Trip / Reset) - PSIG

Fins

Qty x Face Area (ft2)

Quantity

Qty x Face Area (ft2)

Coil Test Pressure

Movable Pulley Maximum Full Turns From Closed

Position

Approx.Speed Change Per Full Turn Of Movable

Pulley Flange (rpm)

Page 5

50TJM Unit Physical Data (50Hz) (English)

Unit 50TJM Size

Unit Dimensions

Unit Operating Weight

Refrigeration System

Compressor No. / Type

Stage Of Capacity Control (%)

Refrigerant Type

Charge Per Circuit (Down / Up) -LBS 15.96 / 15.96 22.19 / 25.62 31.19 / 29.19 31.62 / 31.37

Metering Device

Filter Drier Qty / Size

High Pressure Switch (Trip / Reset) - PSIG

Freeze Protection Thermostat (Open / Close) ±1.8 0F

Condenser Coil

Coil Type

18 24 28 34

Page - 9

Page - 9

2 / Scroll

50 / 50

Puron ® R410A

2

TXV - Adjustable

2 / DML085S

630 / 480

54 / 70

-18 / -14

Copper Tube, Aluminum Double Wavy Fins

Page - 10

Page - 10

2 / DMS165S

Copper Tube,

Aluminum LSW

Standard Coil Material

Qty x Rows x FPI 1 x 3 x 16 1 x 4 x 16

1 x 26.7 2 x 28.8

Coil Test Pressure (PSIG)

Condenser Fan & Motor

Approx. Air Flow Rate (CFM) 12000 13000 18200 16700

Diameter (in) / No. of Blades

Motor Type

Motor HP / RPM

Evaporator Coil

Coil Type

Standard Coil Material

Qty x Rows Qty x FPI

Drain Pan connection Size (in)

Return Air Filter Qty x Size (in)

Evaporator Fan and Motor Section

Fan Quantity / Fan Size (in)

Fan Type

Drive Type

Motor Type

Motor BHP 4.0 7.5

Motor Frame Size / Motor Shaft Diameter (mm) 100 / 28 132 / 38

Motor Pulley Pitch Diameter (Min / Max) (in) 4.3 / 5.6

Fan RPM Range (RPM) 1030 - 745 1029 - 740

Fan Pulley Pitch Diameter (in) 8.4

Belt, Quantity...Type 1 ... BX71

Pulley Center To Center Distance(in)

30 / 4 30 / 6

Copper Tube, Aluminum LSW Fins.

2 x 3 x 17 2 x 4 x 17

2 x 9.75 2 x 10.3

4 x 33.8 x 21.7 4 x 35.4 x 21.7

1 / 15.75 x 15.75 1 / 17.7 x 17.7

Copper / Aluminium

2 x 3 x 17

450

2

Induction Motor - Totally Enclosed

1 / 950

Copper / Aluminium

350

3/4

Centrifugal - Forward Blade

Belt

Induction Motor - TEFC

5.5

112 / 28

3.7 / 4.7

1041 - 753

6.6

1 ... BX66

24.4 - 27.51

6

Factory Speed Turns Setting 1.5

Factory Belt Standard Deflection (in) @ Force (Lb) 0.39 @ 4.65 Lb 0.40 @ 6.63 Lb

48

4

0.39 @ 5.99 Lb

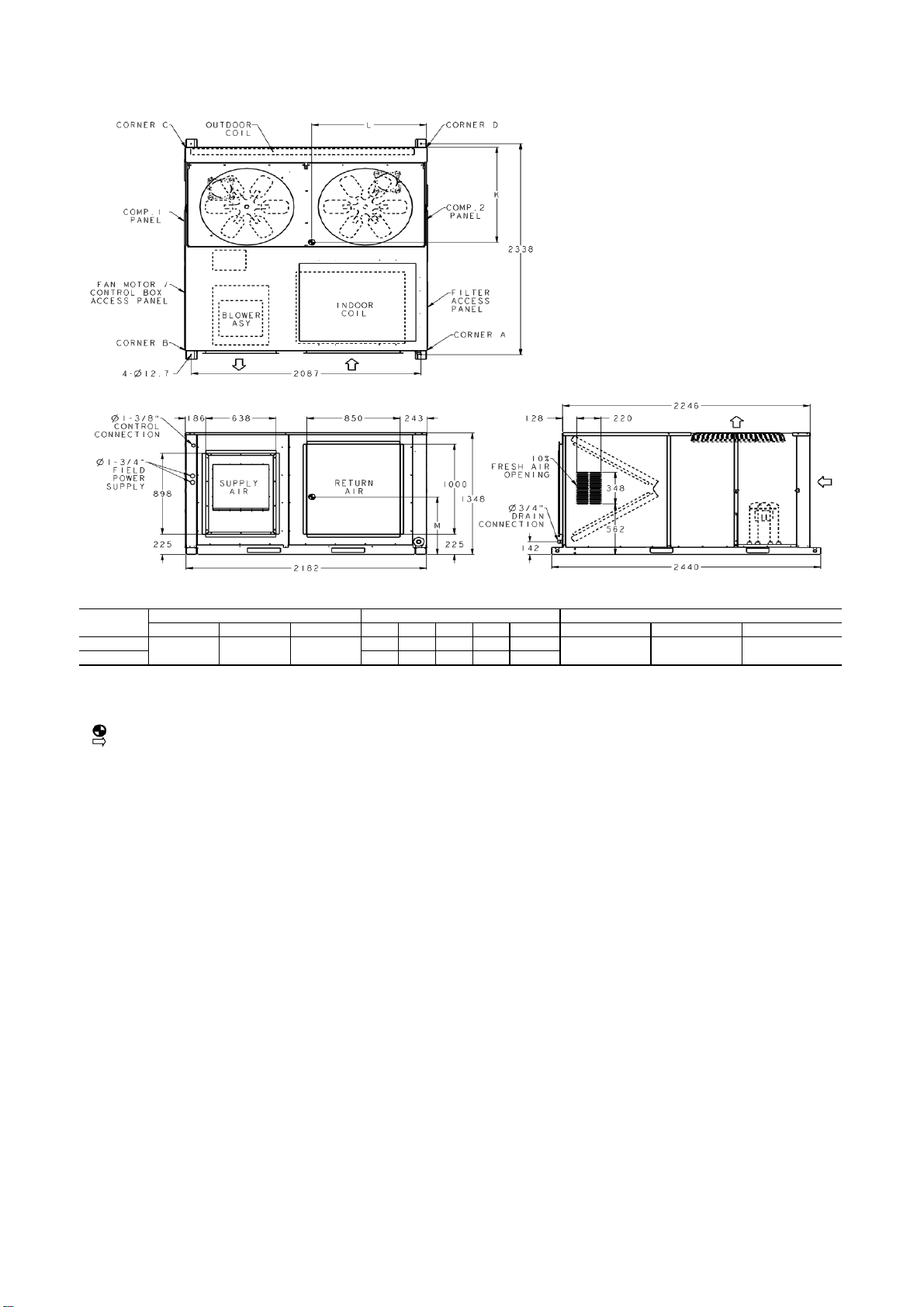

Page 6

LENGTH WIDTH DEPTH A B C D TOTAL K L M

50TJM - 18 192 178 236 254 860

50TJM - 24 197 182 241 260 880

6. Dimensions are from outside of corner post. Allow 8mm on each side for top cover drip edge.

UNIT DIMENSIONAL DRAWING: 50TJM - 18 and 50TJM - 24 (Fig - 1)

1375

1050

1050

450

UNIT

SHIPPING DIMENSIONS (mm)

CORNER WEIGHT (Kg)

CENTER OF GRAVITY (mm)

2440

2235

7. Weights are Given for aluminim evaporator and condenser coil plate fins

5. With the exception of clearance for the condenser coil and the damper / power exhaust as stated in Note no. 6, a removal fence or barricade requires no clearance.

TOP: 1829mm to assure proper condenser fan operation.

SIDE: 1219mm for Compressor, Filter and Control boxes access.

- Local codes or jurisdiction may prevail.

4. Minimum clearance:

NOTES:

REAR: 2134mm for coil removal. This dimension can be reduced to 1219mm if conditions permit coil removal from the top.

2. Center of Gravity.

3. Direction of Airflow

1. Dimensions are in millimeters.

Page 6

Page 7

LENGTH WIDTH DEPTH A B C D TOTAL K L M

50TJM - 28 248 226 310 340 1125

50TJM - 34 254 231 317 348 1150

NOTES:

6. Dimensions are from outside of corner post. Allow 8mm on each side for top cover drip edge.

7. Weights are Given for aluminim evaporator and condenser coil plate fins

REAR: 2134mm for coil removal. This dimension can be reduced to 1219mm if conditions permit coil removal from the top.

TOP: 1829mm to assure proper condenser fan operation.

SIDE: 1219mm for Compressor, Filter and Control boxes access.

- Local codes or jurisdiction may prevail.

5. With the exception of clearance for the condenser coil and the damper / power exhaust as stated in Note no. 6, a removal fence or barricade requires no clearance.

1400

1350

1160

UNIT DIMENSIONAL DRAWING: 50TJM - 28 and 50TJM - 34 (Fig - 2)

UNIT

SHIPPING DIMENSIONS (mm)

CORNER WEIGHT (Kg)

CENTER OF GRAVITY (mm)

450

1. Dimensions are in millimeters.

2. Center of Gravity.

3. Direction of Airflow

4. Minimum clearance:

3200

2485

Page 7

Page 8

2 – INSTALLATION

Page 8

2.1 – Jobsite Survey

Complete the following checks before installation.

1. Consult local building codes or the U.S.A. National Electrical Code (Ref: ANSI/NFPA 70, [American National

Standards Institute/National Fire Protection Association], latest revision) for special installation requirements.

2. Determine unit location (from project plans) or select unit location.

3. Check for possible overhead obstructions which may interfere with unit lifting or rigging.

2.2 – Plan for Unit Location

Select a location for the unit and its support system (curb or other) that provides for the minimum clearances required

for safety. This includes the clearance to combustible surfaces, unit performance and service access below, around

and above unit as specified in Fig - 3. For the centre of gravity coordinates, the position of the unit mounting holes,

and the weight distribution points, refer to the unit dimensional drawing Fig - 1 and Fig - 2.

Fig. 3 Unit Clearance Diagram

NOTES:

1. Minimum clearance:

REAR: 2134mm for coil removal. This dimension can be reduced to 1219mm if conditions permit coil

removal from the top.

TOP: 1829mm to assure proper condenser fan operation.

SIDE: 1219mm for Compressor, Filter and Control boxes access.

- Local codes or jurisdiction may prevail.

2. With the exception of clearance for the condenser coil and the damper / power exhaust as stated in Note no. 3, a

removal fence or barricade requires no clearance.

3. Dimensions are from outside of corner post. Allow 8mm on each side for top cover drip edge.

2.3 – Rig and Place Unit

Keep unit upright and do not drop. Spreader bars are not required if top crating is left on unit.

Rollers may be used to move unit across a roof Level by using unit frame as a reference; leveling tolerance is± 1/16

in. per linear ft in any direction.

Four lifting holes are provided in ends of unit base rails as shown in Fig – 4 Refer to rigging instructions on unit.

Fig. 4 Rigging Diagram

Roof mount - Check building codes for weight distribution requirements. Unit weight and dimensions is shown in unit

dimensional drawing Fig 1 and Fig 2 on page 6 & 7 and table 2.

NOTE: Consider also the effect of adjacent units.

Page 9

SHIPPING DIMENSIONS

(mm)

WEIGHT

LENGTH

WIDTH

DEPTH

GROSS (Kg)

LENGTH

WIDTH

DEPTH

NET(Kg)

50TJM - 18

2440

2235

1375

925

2440

2182

1348

860

50TJM - 24

2440

2235

1375

945

2440

2182

1348

880

50TJM - 28

3200

2485

1400

1190

3200

2432

1374

1125

50TJM - 34

3200

2485

1400

1215

3200

2432

1374

1150

NOTE

IMPORTANT

NOTE

IMPORTANT

corner weights.

UNIT DAMAGE HAZARD

CAUTION

Page 9

UNIT

Table – 2 Unit Weights and Dimensions

NOTES:

1. Remove boards at ends of unit and runners prior to rigging.

2. Rig by inserting hooks into unit base rails as shown. Use bumper boards for spreader bars.

SHIPPING

UNIT DIMENSIONS (mm) UNIT WEIGHT

All units are internally isolated against vibration.

If extra isolation required, please see “Unit

Dimensional Drawing” Fig - 1 and Fig - 2 for

Failure to follow this caution may result in

equipment damage.

All panels must be in place when rigging.

2.4 – Positioning and Clearance.

Before positioning the unit, check the following:

• The permitted loading at the site is adequate or that appropriate strengthening measures have been taken.

• The unit is installed level on an even surface (maximum tolerance is 5 mm in both axes).

• Ensure access to the components (see “Unit Dimensional Drawings” Fig 1 & 2 & “Clearance Diagram” Fig 3).

• The number of support points is adequate and that they are in the right places.

• Although the unit is weatherproof guard against water from higher level runoff and overhangs.

Unit may be installed directly on wood flooring or on approved roof - covering material when roof curb is used. Do not

install unit in an indoor location. Do not locate air inlets near exhaust vents or sources of contaminated air.

2.5 – Field Fabricate Ductwork

Secure all ducts to building structure. Use flexible duct connectors between unit and ducts as required (a space for 2.5

to 3ft is required in case of repairing or replacing the blower wheel). Insulate and weatherproof all external ductwork,

joints, and roof openings with counter flashing and mastic in accordance with applicable codes. Ducts passing through

an unconditioned space must be insulated and covered with a vapor barrier.

The 50TJM units with electric heat require a 2-in.clearance for the first 24-in. of ductwork. Outlet grilles must not lie

directly below unit discharge.

A 90-degree elbow must be provided in drain hole and must be removed in ductwork to comply with UL

(Underwriters’ Laboratories) codes for use with electric heat.

2.6 – Make Unit Duct Connections

Unit is shipped for side duct connections. Ductwork openings are shown in Fig. 1 and Fig. 2.

Page 10

WARNING

2.7 – Trap Condensate Drain

to rotate in the wrong direction. This may lead to premature compressors failure.

ELECTRIC SHOCK HAZARD

NOTE

IMPORTANT

Page 10

See Fig. 5, Fig.1 and Fig. 2 for drain pipe location. Trap should be deep enough to offset the maximum unit static

difference. Fig. 5 shows the recommended trap sizing.

Fig. 5 Condensate Drain Details

2.8 – Outdoor Air-Vent

All units have a manual outdoor side vent to provide ventilation air. Side vents can admit up to 10% outdoor air into

indoor air section return-air compartment.

2.9 – Make Electrical Con nect i on s

FIELD POWER SUPPLY – Unit is factory wired for voltage shown on nameplate.

When installing units, provide disconnect as per NEC (National Electrical Code) requirements, of adequate size. All

field wiring must comply with NEC and local requirements. Route power lines through the corner post openings as

shown in Fig. 1 and Fig. 2.

Operating voltage to compressor must be within voltage range indicated on unit nameplate. On 3-phase units,

voltages between phases must be balanced within 2% and the current must be balanced within 10%.

The correct power phasing is critical in the operation of the scroll compressors. An incorrect phasing will cause the compressor

Failure to follow this caution may result in equipment damage.

UNIT DAMAGE HAZARD

Do not use gas piping as an electrical ground. Unit cabinet must have an uninterrupted, unbroken electrical ground to minimize

the possibility of personal injury if an electrical fault should occur. This ground may consist of electrical wire connected to unit

ground lug in control compartment, or conduit approved for electrical ground when installed in accordance with local electrical

codes or in absence of local codes, it is recommended that U.S.A standard ANSI/NFPA 70, National Electrical Code be followed.

FIELD CONTROL WIRING – Install a Carrier approved accessory thermostat assembly according to the installation

instructions included with the accessory. Locate thermostat assembly on a solid wall in the conditioned space to sense

average temperature. Route thermostat cable or equivalent single leads of no. 18 AWG (American Wire Gage)

colored wire from sub-base terminals through conduit in unit to low-voltage connection. Settings may be changed

slightly to provide a greater degree of comfort for a particular installation.

For wire runs up to 50 ft, use no. 18 AWG insulated wire. For 50 to 75 ft, use no. 16 AWG insulated wire. For over 75 ft, use no.

14 AWG insulated wire. All wire larger than no. 18 AWG cannot be directly connected to the thermostat and will require a

junction box and splice at the thermostat.

Failure to follow this warning could result in personal injury or death.

Page 11

KW

40.6 50

HACR - Heating, Air-Conditioning and Refrigeration

Supply

IFM -

Unbalanced 3-Phase Supply Voltage

Electrical Data Table - 3

OFM -

MOCP -

Page 11

Unit Size

50TJM

18

24

28

34

50TJM Size 18 - 34 Compressor

Min Voltage

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

360 440 400 / 3 / 50

Max

Voltage

Power

V / Ph / Hz

No.1 No.2

RLA LRA RLA LRA Qty HP FLA HP FLA

12.2 101 12.2 101 2 1 3.4 Std. Eff. 4 6.3

12.2 101 12.2 101 2 1 3.4 High Eff. 4 6.15 - - 40.4 50

12.2 101 12.2 101 2 1 3.4 Std. Eff. 4 6.3 21 30.3 44.2 50

12.2 101 12.2 101 2 1 3.4 High Eff. 4 6.15 21 30.3 44.0 50

16.7 111 16.7 111 2 1 3.4 Std. Eff. 5.5 8.3 - - 52.7 60

16.7 111 16.7 111 2 1 3.4 High Eff. 5.5 8 - - 52.4 60

16.7 111 16.7 111 2 1 3.4 Std. Eff. 5.5 8.3 28 40.4 58.8 90

16.7 111 16.7 111 2 1 3.4 High Eff. 5.5 8 28 40.4 58.5 90

17.9 118 17.9 118 2 1 3 Std. Eff. 5.5 8.3

17.9 118 17.9 118 2 1 3 High Eff. 5.5 8 - - 57.3 70

17.9 118 17.9 118 2 1 3 Std. Eff. 5.5 8.3 28 40.4 61.8 100

17.9 118 17.9 118 2 1 3 High Eff. 5.5 8 28 40.4 61.5 100

21.8 140 21.8 140 2 1 3 Std. Eff. 7.5 11.3 - - 66.4 80

21.8 140 21.8 140 2 1 3 High Eff. 7.5 11

21.8 140 21.8 140 2 1 3 Std. Eff. 7.5 11.3

21.8 140 21.8 140 2 1 3 High Eff. 7.5 11

OFM

IFM Type

IFM

Electric

Heater

Appl.

- -

- -

- -

28 40.4

28 40.4

Legend and Notes for Electrical Data Table

FLA - Full Load Amps

Indoor (Evaporator) Fan Motor

LRA - Locked Rotor Amps

NEC - National Electrical Code

Outdoor (Condenser) Fan Motor

RLA - Rated Load Amps

MCA - Minimum Circuit Amps

Maximum Overcurrent Protection

◊ Fuse or HACR Circuit Breaker

* Application heater kW @ 400 volt (Using multiplication factor table in Electric Resistance Heater Data table on page 13)

MCA MOCP◊

FLA

57.6 70

66.1 80

66.4 100

66.1 100

Never operate a motor where phase imbalance in supply voltage is greater than 2%.

Use the following formula to determine the percentage of voltage imbalance

= 100 X

Maximum Deviation From Average Voltage

Average Voltage

Example: Supply Voltage is 400V - 3ph - 50Hz

3

392 + 404 + 395

3

= 397V

AB = 392v

BC = 404v

AC = 395v

Average Voltage =

1191

=

Determine maximum deviation from average voltage.

(AB) 397 - 392 =5v

(BC) 404 - 397 =7v

(AC) 457 - 397 =2v

Maximum Deviation is 7v.

Determine Percentage Voltage Imbalance.

% Voltage Imbalance

= 100 X

7

397

= 1.76%

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%

IMPORTANT: If the supply voltage phase imbalance is more than 2% contact your local electric utility company

Page 12

Cfm L/s

24

240 — — —

Electric Resistance Heater Data - Table 4

40

50TJ600730

Duct heater assembly, 50TJM 28 - 34 480 V

EXAMPLE: 30 kW (at 480 v) heater o

Page 12

UNIT

50TJM

18 2 50/50 4800 2265

24 2 50/50 6000 2832

28 2 50/50 7000 3304

34 2 50/50 7000 3304

HEATER kW HEATER FLA (PER STAGE)

Unit Voltages Unit Voltages

460

28kW

37kW

ACCESSORY HEATER PART NUMBER

460

17.3

HEATER

STAGES

23

HEAT

PER

STAGES

MINIMUM HEATING

CFM

UNIT

50TJM

18

28

34

Electric Heater Kits

Kit Ordering No

NOTE: Heaters are rated at 480 V. Use the Multiplication Factors table below to determine heater capacity for your particular voltage.

Multiplication Factors

Heater

Rating

Voltage

480 0.62 0.7 1

NOTE: The following equation converts kW of heat energy to Btuh: kW x 3.413 = Btuh.

= 30.0 (0.7 multiplication factor)

= 21kW

Complete Kit P.N.

50TJ600287

50TJ601162

50TJ600287

50TJ601162

50TJ600730

Duct heater assembly, 50TJM 18 480 V

Duct heater assembly, 50TJM 24 480 V

Actual Heater Voltage

380 400 480

400V

Casing P.N. Heater Element P. N.

( 1 Per Kit ) ( 2 Per Kit )

50TJ600289

50TJ600727

Description

CPHEATER036A00

CPHEATER037A00

Stages

2

2

2

Size (KW)

30

40

Heater capacity(kW) is based on heater voltage of 380v or 480v. If power distribution voltage to unit varies from heater voltage, heater kW will vary

accordindly. To Detemine heater capacity at actual unit voltage, muptiply 480v capacity by multipliers found in table " Multiplication Factors" above.

MCA calculation for 50TJM 18 - 34 size units with electric heaters over 50 kW = (1.25 x IFM amps) + (1.00 x heater FLA).

Page 13

Page 13

Fig. - 6

Page 14

Page 14

Fig. - 7

Page 15

3 – START-UP INSTRUCTIONS

50TJM-24

NOTE

IMPORTANT

the unit’s lockout and requires a manual reset. Reset accomplished by turning the thermostat on and off.

Page 15

Use the following instructions and start-up checklist provided on the last page to check out the unit PRIOR to unit

start-up.

3.1– Unit Preparation

Check that unit has been installed in accordance with these installation instructions and all applicable codes.

3.2 – Internal Wiring

Check all electrical connections in unit control boxes; tighten as required.

3.3 – Compressor Mounting

Compressors are internally spring mounted. Do not loosen or remove compressor hold down bolts.

3.4 – Refrigerant Service Ports

Each refrigerant system has a total of 3 Schrader type Service gage ports. One port is located on the suction line,

one on the compressor discharge line, and one on the liquid line. In addition Schrader-type valves are located

underneath the pressure switches. Be sure that caps on the ports are tight.

3.5 – Compressor Rotation

It is important to be certain the compressors are rotating in the proper direction. To determine whether or not

compressors are rotating in the proper direct ion:

1. Connect service gages to suction and discharge pressure fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pressure does not rise to normal levels:

1. Note that the evaporator fan is probably also rotating in the wrong direction.

2. Turn off power to the unit.

3. Reverse any two of the compressor lead wires.

4. Turn on power to the compressor.

5. Check also phase monitor all ok green led before proceeding.

The suction and discharge pressure levels should now move to their normal start-up levels.

When compressors are rotating in the wrong direction, the unit will have increased noise levels and will not provide heating and

cooling. After a few minutes of reverse operation, the scroll compressor internal overload protection will open, which will activate

3.6 - Evaporator Fan

Fan belt and variable pulleys are factory installed. Remove tape from the fan pulley. See Table 5 for Air Quantity

Limits. See Table 7 for Fan Performance data. Be sure that fans rotate in the proper direction. See Table 6 for Fan

RPM at various fan motor pulley settings. To alter fan performance, see Evaporator Fan Performance Adjustment

section.

Unit

50TJM-18

50TJM-28

50TJM-34

Minimum Maximum Minimum Maximum

4,000 7,000 4,800 7,000

5,000 7,500 6,000 7,500

5,000 8,500 7,000 8,500

7,000 10,000 7,000 10,000

Cooling Electric Heaters

Table 5 – Air Quantity Limits.

Page 16

Freq.

MOTOR PULLEY TURNS OPEN

0

1/2 1 1 1/2

2

2 1/2

3

3 1/2

4

4 1/2

5

5 1/2

6

18

830

804

775

745

24

839

813

784

753

28

839

813

784

753

34

1029

996

960

928

902

875

847

830

813

791

774

757

740

Page 16

50Hz

Unit

50TJM

- - 1030 1001 978 946 918 884

- - 1041 1011 989 956 928 894

- - 1041 1011 989 956 928 894

Bold Fan RPM is Factory Setting

860

870

870

Table 6 – Fan RPM at Motor Pulley Settings.

3.7– Condenser Fans and Motors

Fans and motors are factory set. Refer to Condenser-Fan Adjustment Section as required.

3.8– Return – Air Filters

Check that correct filters are installed in filter tracks. See Table 1 “Physical data”. Do not operate unit without

return–air filters.

3.9 – Base Unit Operation

COOLING, UNITS — when thermostat calls for cooling, terminals G and Y1 are energized. The indoor (evaporator)

fan contactor (IFC), and compressor contactor no. 1 (C1) are energized and evaporator-fan motor, compressor no. 1

and condenser fans start. The condenser-fan motors run continuously while unit is cooling. If the thermostat calls for

a second stage of cooling by energizing Y2, compressor contactor no. 2 (C2) is energized and compressor no. 2

starts.

HEATING, UNITS — (If Accessory or Optional Heater is installed) — upon a call for heating through terminal W1,

IFC and heater contactor no. 1 (HC1) are energized.

4.0 – SERVICE

4.1 – Cleaning

Inspect unit interior at beginning of each heating and cooling season and as operating conditions require. Remove

unit top panel and/or side panels for access to unit interior.

EVAPORATOR COIL — Clean as required with a commercial coil cleaner.

CONDENSER COIL — Clean condenser coil ann ua lly and as required by location and outdoor-air conditions.

Inspect coil monthly — clean as required.

CONDENSATE DRAIN — Check and clean each year at start of cooling season.

FILTERS — Clean or replace at start of each heating and cooling season, or more often if operating conditions

require. Refer to Table 1 “Physical Data” type and size.

4.2 – Lubrication

Compressors are charged with the correct amount of oil at the factory.

Replacing Compressor - In the case of a motor burnout, the majority of contaminated will be removed with the

compressor. The rest of the oil is cleaned through the use of suction and liquid line filter driers. A 100% activated

alumna suction line filter drier is recommended but must be removed after 72 hours.

The compressor contains POE oil. POE oil has a high affinity for moisture. Do not remove the compressor’s tube

plugs until ready to insert the unit suction and discharge tube ends. The discharge connection plug should be

removed first before pulling the suction connection plug to allow the dry air pressure inside the compressor to

escape.

Note: This is only valid for the R410A systems.

Page 17

CAUTION

UNIT DAMAGE HAZARD

starting the compressor.

Page 17

1. The compressor is in a Puron® refrigerant system and uses a (POE) lubricant Emkarate RL 32 3MAF. In

CONDENSER AND EVAPORATOR-FAN MOTOR BEARINGS – The condenser and evapora tor -fan motors have

permanently-sealed bearings, so no field lubrication is necessary.

4.3 – Evaporator Fan Performance Adjustment

NOTE: To remove belts only, follow Steps 1, 2 & 6. Fan motor pulleys are factory set speed shown in Table 6.

To change fan speeds:

1. Shut off unit power supply.

2. Loosen belt by loosening fan motor mounting plate nuts. Slide the Motor and remove belt.

3. Loosen movable-pulley flange setscrew (see Fig. 8).

4. Screw movable flange toward fixed flange to increase speed and away from fixed flange to decrease speed.

Increasing fan speed increases load on motor. Do not exceed maximum speed specified in Table 6. See Table 7 for

air flow.

5. Set movable flange at nearest keyway of pulley hub and tighten setscrew. (See Table 1 & 6 for speed change for

each full turn of pulley flange.)

6. Replace and tighten belts. See Belt Tension Adjustment section on table 1.

the field the oil level could be topped up with Mobil EAL Arctic 22 CC if 3MAF is not available. POE oil is

extremely hygroscopic, meaning it absorbs water readily. POE oils can absorb 15 times as much as

other oils designed for HCFC and CFC refrigerants. Avoid exposure of the oil to the atmosphere.

2. Ensure that system is not subjected to liquid abuse. Turn the crankcase heater on 12 hours before

Failure to follow this caution may result in damage to components.

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from mounting plate.

4.4 – Evaporator Fan Service and Replacement

1. Remove supply-air section panel (The bolts holding the flexible connection to the panel should be removed).

2. Remove the Control Side panel.

3. Remove the Belt (refer to the previous section for Belt removal).

4. Remove the locking device of the hub & shaft from the both sides; it can be accessed throw the fan side panel.

5. Pull the shaft gently from the control side, the blower will fall inside the blower housing.

6. Loosen the (lower) first two bolts from each side of the scroll fan housing mid-plate. This can be done from the

supply panel side, now the fan can be removed easily from the supply panel side.

7. To assemble the fan, reverse the above procedure.

Fig. 8 Evaporator – Fan Pulley Alignment and Adjustment

Page 18

4.5 – Belt Tension Adjustment

Page 18

To adjust belt tension:

1. Loosen fan motor bolts.

2. Adjust belt tension by sliding the motor on the mounting base.

3. Tighten nuts.

4. Adjust bolts and nut on mounting plate to secure motor in fixed position.

4.6 – Condenser-Fan Adjustment

1. Shut off unit power supply.

2. Remove fan top-grille assembly and loosen fan hub screws.

3. Adjust fan height on unit, using a straightedge placed across the fan orifice.

4. Tighten setscrews

Fig. 9 Condenser - Fan Adjustment

4.7 – Refrigerant Charge

Amount of refrigerant charge is listed on unit nameplate and in Table 1. Refer to Carrier GTAC II; Module 5;

Charging, Recovery, Recycling, and Reclamation section for charging methods and procedures. Unit panels must be

in place when unit is operating during charging procedure.

NOTE: Do not use recycled refrigerant as it may contain contaminants.

NO CHARGE — Use standard evacuating techniques. After evacuating system, weight in the specified amount of

refrigerant (refer to Table 1).

LOW CHARGE COOLING — Using cooling charging chart (see Fig. 10 to 13 according to the size of the unit) Add

or remove refrigerant until conditions of the chart are met. Note that charging chart is different from those normally

used. An accurate pressure gage and temperature-sensing device is required. Charging is accomplished by

ensuring the proper amount of liquid sub-cooling. Measure liquid line pressure at the liquid line service valve using

pressure gage.

Connect temperature sensing device to the liquid line near the liquid line service valve and insulate it so that outdoor

ambient temperature does not affect reading.

TO USE THE COOLING CHARGING CHART — Use the above temperature and pressure readings, and find the

intersection point on the cooling charging chart. If intersection point on chart is above line, add refrigerant. If

intersection point on chart is below line, carefully recover some of the charge. Recheck suction pressure as charge

is adjusted.

NOTE: Indoor-air CFM must be within normal operating range of unit. All outdoor fans must be operating.

4.8 – Protective Devices

COMPRESSOR PRO TECTION – Each compressor is internally protected against over temperature.

Compressor Lockout — If any of the safeties (high-pressure, low-pressure, compressor internal thermostat, external

compressor thermal overload) trip, the CLO (compressor lockout) will lock the compressors off.

To reset, manually move the thermostat setting.

Page 19

EVAPORATER AND CONDENSER-FAN MOTOR PROTECTION — Each Evaporator and Condenser-fan motor is

NOTE

IMPORTANT

Page 19

internally protected against over temperature.

HIGH- AND LOW-PRESSUR E SWITCHES — If either switch trips, or if the compressor over temperature switch

activates, that refrigerant circuit will be automatically locked out by the CLO. To reset, manually move the thermostat

setting.

FREEZE PROTECTION THERMOSTAT (FPT) — An FPT is located on the top and bottom of the evaporator coil. It

detects frost build-up and turns off the compressor, allowing the coil to clear. Once the frost has melted, the

compressor can be reenergized.

After prolonged shutdown or servicing in cold weather, energize the crankcase heaters for 12 hours before

starting the compressors.

4.9 – Control Circuit, 24-V

This control circuit is protected against over-current by a 3.2-amp circuit breaker. Breaker can be reset. If it trips,

determine cause of trouble before resetting.

5.0 – REPLACEMENT PARTS

A complete list of replacement parts may be obtained from any Carrier distributor.

Page 20

Fan Performance Table - 7

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

4000 555 0.87 1.02 622 1.06 1.25 686 1.27 1.50 747 1.49 1.75 804 1.72 2.03

8. Conversion - Bhp to KWI

Unit - 50TJM - 018 - 15 Tons - 50Hz (Standard Motor)

Available External Static Pressure (in. wg)

0.2

0.4

0.6

0.8

1.0

1.4

1.6

1.8

2.0

Available External Static Pressure (in. wg)

Bold, Italics -

1.2

1.2

1.4

1.6

1.8

2.0

6. Bold data shows the range of air flow rate for unit management system, other rpms require field-supplied drive.

7. Use of field-supplied motor may affect wiring size. Contact your Carrier representative for details.

Unit - 50TJM - 18 - 15 Tons - 50Hz (High Efficiency Motor) (cont)

BHP - Brake Horsepower Input to Fan

CFM - Cubic Feet per Minute

RPM - Revolutions Per Minute

Legend:

Notes:

1. Do not adjust motor rpm such that motor maximum bhp and/or watts is exceeded at the maximum operatin cfm.

2. Static Pressure (i.e Filters) must be added to external static pressure before entering fan performance table.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters and casing loses.

Bhp X 0.746

Motor efficiency

Page 20

Air Flow Rate

(CFM)

4000 555 0.93 1.04 622 1.13 1.27 686 1.36 1.52 747 1.59 1.78 804 1.84 2.06

4500 589 1.20 1.34 652 1.42 1.59 711 1.65 1.86 767 1.90 2.14 823 2.17 2.43

5000 624 1.51 1.69 682 1.75 1.96 737 2.01 2.25 790 2.27 2.54 841 2.54 2.85

5500 658 1.87 2.10 711 2.13 2.39 762 2.40 2.69 813 2.68 3.00 861 2.96 3.32

6000 689 2.28 2.56 739 2.55 2.86 788 2.83 3.18 835 3.13 3.51 881 3.43 3.85

6500 721 2.74 3.07 765 3.01 3.38 811 3.31 3.71 855 3.62 4.06 899 3.93 4.41

7000 745 3.20 3.59 788 3.49 3.92 830 3.80 4.26 873 4.12 4.62 914 4.45 4.99

Unit - 50TJM - 018 - 15 Tons - 50Hz (Standard Motor) (cont)

Air Flow Rate

(CFM)

4000 859 2.09 2.35 910 2.43 2.72 959 2.62 2.94 1007 2.90 3.25 1052 3.18 3.57

4500 875 2.44 2.73 924 2.72 3.05 971 3.00 3.37 1018 3.29 3.70 1062 3.60 4.04

5000 891 2.83 3.17 939 3.13 3.51 986 3.43 3.85 1030 3.74 4.20 1073 4.06 4.55

5500 909 3.27 3.66 955 3.58 4.01 998 3.89 4.36 1042 4.23 4.74 1083 4.56 5.11

6000 925 3.74 4.20 969 4.07 4.56 1012 4.40 4.94 1054 4.75 5.32 1094 5.10 5.72

6500 942 4.26 4.78 983 4.60 5.15 1024 4.94 5.54 1065 5.30 5.94 1104 5.66 6.35

7000 954 4.79 5.37 994 5.13 5.76 1034 5.49 6.16 1072 5.86 6.57 1110 6.24 7.00

Unit - 50TJM - 18 - 15 Tons - 50Hz (High Efficiency Motor)

Air Flow Rate

(CFM)

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

RPM KWI BHP RPM KWI BHP

Standard Motor and Drive Package

0.2

Available External Static Pressure (in. wg)

0.4 0.6 0.8 1.0

RPM KWI BHP RPM KWI BHP RPM KWI BHP

Available External Static Pressure (in. wg)

4500 589 1.12 1.32 652 1.33 1.57 711 1.55 1.83 767 1.79 2.10 823 2.03 2.39

5000 624 1.42 1.67 682 1.64 1.93 737 1.88 2.21 790 2.13 2.50 841 2.39 2.81

5500 658 1.76 2.07 711 2.00 2.35 762 2.25 2.65 813 2.51 2.95 861 2.78 3.27

6000 689 2.14 2.52 739 2.39 2.81 788 2.66 3.12 835 2.94 3.45 881 3.22 3.79

6500 721 2.57 3.02 765 2.83 3.32 811 3.11 3.65 855 3.40 3.99 899 3.69 4.34

7000 745 3.01 3.53 788 3.28 3.86 830 3.57 4.19 873 3.87 4.55 914 4.18 4.91

Air Flow Rate

(CFM)

4000 859 1.96 2.31 910 2.28 2.68 959 2.46 2.89 1007 2.72 3.20 1052 2.99 3.51

4500 875 2.29 2.69 924 2.55 3.00

5000 891 2.66 3.12 939 2.94 3.45 986 3.22 3.79 1030 3.51 4.13 1073 3.81 4.48

5500 909 3.07 3.60 955 3.36 3.95 998 3.65 4.29 1042 3.97 4.66 1083 4.28 5.03

6000 925 3.51 4.13 969 3.82 4.49 1012 4.13 4.86 1054 4.46 5.24 1094 4.79 5.63

6500 942 4.00 4.71 983 4.31 5.07 1024 4.64 5.45 1065 4.98 5.85 1104 5.32 6.25

7000 954 4.49 5.28 994 4.82 5.66 1034 5.15 6.06 1072 5.50 6.47 1110 5.86 6.88

Bold , Italics - High Efficiency Motor and Drive Package

KWI - Kilo Watts Input to Motor

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

971 2.82 3.31 1018 3.09 3.64 1062 3.38 3.97

5. Extensive motor and drive testing on these units ensures that the full brake horsepower and watts range of the motor can be utilized with confidence. Using

your fan motors up to the watts or bhp rating shown will not result in nuisance tripping or premature motor failure. Unit warranty will not be affected.

KWI=

Page 21

Fan Performance Table - 7 (cont)

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

5000 583 1.25 1.48 642 1.46 1.73 698 1.69 2.00 754 1.92 2.28 805 2.17 2.58

Unit - 50TJM - 24 - 19 Tons - 50Hz (High Efficiency Motor)

Unit - 50TJM - 24 - 19 Tons - 50Hz (High Efficiency Motor) (cont)

1.6

1.8

2.0

Unit - 50TJM - 24 - 19 Tons - 50Hz (Standard Motor)

Available External Static Pressure (in. wg)

1.2

1.4

Page 21

Air Flow Rate

(CFM)

5000 583 1.30 1.48 642 1.51 1.73 698 1.75 2.00 754 1.99 2.28 805 2.25 2.58

5500 617 1.62 1.86 672 1.86 2.13 724 2.10 2.41 775 2.36 2.70 825 2.63 3.01

6000 654 2.01 2.30 704 2.26 2.58 752 2.51 2.88 800 2.79 3.19 847 3.07 3.51

6500 689 2.44 2.80 735 2.71 3.10 781 2.98 3.41 826 3.27 3.74 871 3.57 4.08

7000 725 2.95 3.37 768 3.22 3.69 811 3.51 4.02 854 3.81 4.36 895 4.12 4.72

7500 761 3.51 4.02 802 3.80 4.35 842 4.11 4.70 882 4.42 5.06 921 4.74 5.43

Unit - 50TJM - 24 - 19 Tons - 50Hz (Standard Motor) (cont)

Air Flow Rate

(CFM)

5000 856 2.52 2.88 906 2.80 3.20

5500 874 2.91 3.34 920 3.20 3.67 966 3.50 4.01 1009 3.81 4.36 1052 4.13 4.72

6000 893 3.37 3.85 938 3.67 4.20 980 3.98 4.56 1023 4.30 4.93 1064 4.63 5.30

6500 913 3.87 4.43 956 4.19 4.79 998 4.51 5.17 1038 4.85 5.55 1077 5.20 5.95

7000 936 4.44 5.08 976 4.77 5.46 1016 5.11 5.85 1055 5.46 6.25 1094 5.82 6.66

7500 959 5.07 5.80 998 5.41 6.20 1035 5.77 6.60 1073 6.13 7.02 1110 6.50 7.44

Bold, Italics - Standard Motor and Drive Package

Air Flow Rate

(CFM)

5500 617 1.57 1.86 672 1.79 2.13 724 2.03 2.41 775 2.28 2.70 825 2.54 3.01

6000 654 1.94 2.30 704 2.18 2.58 752 2.42 2.88 800 2.69 3.19 847 2.96 3.52

6500 689 2.36 2.80 735 2.61 3.10 781 2.88 3.41 826 3.15 3.74 871 3.44 4.08

7000 725 2.84 3.37 768 3.11 3.69 811 3.39 4.02 854 3.68 4.36 895 3.98 4.72

7500 761 3.39 4.02 802 3.67 4.35 842 3.96 4.70 882 4.26 5.06 921 4.57 5.43

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

0.2 0.4 0.6 0.8 1.0

0.2 0.4

Available External Static Pressure (in. wg)

Available External Static Pressure (in. wg)

954 3.08 3.53 998 3.37 3.86 1040 3.67 4.20

0.6 0.8 1.0

Air Flow Rate

(CFM)

5000 856 2.43 2.88 906 2.70 3.20 954 2.97 3.53 998 3.25 3.86 1040 3.54 4.20

5500 874 2.81 3.34 920 3.09 3.67 966 3.38 4.01 1009 3.67 4.36 1052 3.98 4.72

6000 893 3.25 3.86 938 3.54 4.20

6500 913 3.73 4.43 956 4.04 4.80 998 4.36 5.17 1038 4.68 5.56 1077 5.01 5.95

7000 936 4.28 5.08 976 4.60 5.46 1016 4.93 5.85 1055 5.26 6.25 1094 5.61 6.66

7500 959 4.89 5.81 998 5.22 6.20 1035 5.56 6.60 1073 5.91 7.02 1110 6.27 7.44

Bold , Italics - High Efficiency Motor and Drive Package

Legend:

RPM - Revolutions Per Minute

KWI - Kilo Watts Input to Motor

BHP - Brake Horsepower Input to Fan

CFM - Cubic Feet per Minute

Notes:

1. Do not adjust motor rpm such that motor maximum bhp and/or watts is exceeded at the maximum operatin cfm.

2. Static Pressure (i.e Filters) must be added to external static pressure before entering fan performance table.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters and casing loses.

5. Extensive motor and drive testing on these units ensures that the full brake horsepower and watts range of the motor can be utilized with confidence. Using

your fan motors up to the watts or bhp rating shown will not result in nuisance tripping or premature motor failure. Unit warranty will not be affected.

6. Bold data shows the range of air flow rate for unit management system, other rpms require field-supplied drive.

7. Use of field-supplied motor may affect wiring size. Contact your Carrier representative for details.

8. Conversion - Bhp to KWI

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

KWI=

Motor efficiency

1.2 1.4 1.6

Bhp X 0.746

Available External Static Pressure (in. wg)

1.8 2.0

980 3.84 4.56 1023 4.15 4.93 1064 4.47 5.31

Page 22

Fan Performance Table - 7 (cont)

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

5000

753 1.95 2.31

Unit - 50TJM - 28 - 23 Tons - 50Hz (Standard Motor) (cont)

Available External Static Pressure (in. wg)

1.8

Bold, Italics - Standard Motor and Drive Package

Unit - 50TJM - 28 - 23 Tons - 50Hz (Standard Motor)

Unit - 50TJM - 28 - 23 Tons - 50Hz (High Efficiency Motor)

1.2

1.4

1.6

2.0

1.2

1.4

1.6

1.8

2.0

Available External Static Pressure (in. wg)

Page 22

Air Flow Rate

(CFM)

5000 535 1.06 1.21 592 1.27 1.45 647 1.50 1.71 700 1.75 2.00 753 2.02 2.31

5500 564 1.30 1.49 618 1.53 1.75 669 1.77 2.03 718 2.03 2.32 766 2.29 2.62

6000 596 1.59 1.82 643 1.82 2.09 692 2.07 2.37 738 2.34 2.68 783 2.63 3.01

6500 625 1.92 2.19 671 2.16 2.47 715 2.43 2.78 759 2.70 3.09 801 2.99 3.43

7000 656 2.28 2.61 698 2.54 2.91 740 2.82 3.22 781 3.10 3.55 821 3.40 3.89

7500 686 2.70 3.09 726 2.97 3.40 766 3.26 3.73 804 3.55 4.06 843 3.86 4.42

8000 714 3.15 3.61 753 3.43 3.93 790 3.74 4.28 827 4.04 4.63 864 4.37 5.00

8500 743 3.64 4.17 779 3.94

Air Flow Rate

(CFM)

5000 801 2.30 2.64 849 2.61 2.98 898 2.93 3.36 944 3.28 3.75 989 3.64 4.17

5500 813 2.60 2.97 859 2.90 3.32 904 3.23 3.70 948 3.58 4.10 990 3.94 4.51

6000 827 2.93 3.36 870 3.23 3.70 913 3.57 4.09 955 3.92 4.48 996 4.28 4.90

6500 843 3.30 3.77 884 3.62 4.15 924 3.96 4.53 964 4.30 4.93 1002 4.67 5.34

7000 861 3.72 4.25 900 4.05 4.64 939 4.39 5.02 976 4.74 5.43 1013 5.11 5.85

7500 880 4.19 4.79 917 4.52 5.18 954 4.87 5.57 989 5.22 5.98 1025 5.60 6.41

8000 899 4.69 5.37 935 5.04 5.76 969 5.39 6.17 1004 5.76 6.59

8500 919 5.23 5.99 952 5.59 6.40 985 5.96 6.82 1017 6.32 7.24 1051 6.71 7.68

Air Flow Rate

(CFM)

5500 564 1.25 1.49 618 1.47 1.75 669 1.71 2.02 718 1.96 2.32 766 2.21 2.62

6000 596 1.53 1.82 643 1.76 2.08 692 2.00 2.37 738 2.26 2.68 783 2.53 3.01

6500 625 1.85 2.19 671 2.08 2.47 715 2.34 2.78 759 2.60 3.09 801 2.89 3.43

7000 656 2.20 2.61 698 2.45 2.91 740 2.71 3.22 781 2.99 3.55 821 3.28 3.89

7500 686 2.60 3.09 726 2.87 3.40 766 3.14 3.73 804 3.42 4.06 843 3.72 4.42

8000 714 3.04 3.61 753 3.31 3.93 790 3.60 4.28 827 3.90 4.62 864 4.21 5.00

8500 743 3.51 4.17 779 3.79 4.50 815 4.10 4.86 849 4.40 5.22 884 4.71 5.60

Unit - 50TJM - 28 - 23 Tons - 50Hz (High Efficiency Motor) (cont)

Air Flow Rate

(CFM)

5000 801 2.22 2.64 849 2.51 2.98

5500 813 2.50 2.97 859 2.80 3.32 904 3.12 3.70 948 3.45 4.10 990 3.79 4.50

6000 827 2.83 3.35 870 3.12 3.70 913 3.44 4.09 955 3.77 4.48 996 4.13 4.90

6500 843 3.18 3.77 884 3.49 4.15 924 3.81 4.53 964 4.15 4.92 1002 4.50 5.34

7000 861 3.58 4.25 900 3.91 4.64 939 4.23 5.02 976 4.57 5.43 1013 4.92 5.85

7500 880 4.04 4.79 917 4.36 5.18 954 4.69 5.57 989 5.04 5.98 1025 5.40 6.41

8000 899 4.52 5.37 935 4.85 5.76 969 5.20 6.17 1004 5.55 6.59 1038 5.92 7.03

8500 919 5.05 5.99 952 5.39 6.40 985 5.74 6.82 1017 6.10 7.24 1051 6.47 7.68

Bold , Italics - High Efficiency Motor and Drive Package

Legend:

RPM - Revolutions Per Minute

KWI - Kilo Watts Input to Motor

BHP - Brake Horsepower Input to Fan

CFM - Cubic Feet per Minute

Notes:

1. Do not adjust motor rpm such that motor maximum bhp and/or watts is exceeded at the maximum operatin cfm.

2. Static Pressure (i.e Filters) must be added to external static pressure before entering fan performance table.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters and casing loses.

5. Extensive motor and drive testing on these units ensures that the full brake horsepower and watts range of the motor can be utilized with confidence. Using

your fan motors up to the watts or bhp rating shown will not result in nuisance tripping or premature motor failure. Unit warranty will not be affected.

6. Bold data shows the range of air flow rate for unit management system, other rpms require field-supplied drive.

7. Use of field-supplied motor may affect wiring size. Contact your Carrier representative for details.

8. Conversion - Bhp to KWI

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

535 1.02 1.21 592 1.22 1.45 647 1.44 1.71 700 1.69 2.00

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

KWI=

Motor efficiency

0.2 0.4

0.2

Bhp X 0.746

Available External Static Pressure (in. wg)

0.6 0.8 1.0

4.51 815 4.25 4.87 849 4.56 5.22 884 4.89 5.60

1038 6.14 7.03

Available External Static Pressure (in. wg)

0.4

898 2.83 3.35 944 3.16 3.75 989 3.51 4.17

0.6 0.8 1.0

Page 23

Fan Performance Table - 7 (cont)

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

7000 661 2.32 2.79 704 2.59 3.11 746 2.87 3.44 787 3.16 3.80 827 3.46 4.15

1.8

2.0

Available External Static Pressure (in. wg)

Unit - 50TJM - 34 - 28 Tons - 50Hz (Standard Motor)

0.6

0.8

1.0

Available External Static Pressure (in. wg)

0.2

0.4

1.2

1.4

1.6

1.2

1.4

1.6

1.8

2.0

Bold, Italics -

Unit - 50TJM - 34 - 28 Tons - 50Hz (High Efficiency Motor) (cont)

6. Bold data shows the range of air flow rate for unit management system, other rpms require field-supplied drive.

7. Use of field-supplied motor may affect wiring size. Contact your Carrier representative for details.

Page 23

Air Flow Rate

(CFM)

7000 661 2.42 2.79 704 2.69 3.11 746 2.98 3.44 787 3.29 3.79 827 3.60 4.15

7500 691 2.86 3.30 732 3.15 3.63 773 3.46 3.99 811 3.77 4.34 849 4.10 4.72

8000 723 3.36 3.87 761 3.65 4.22 798 3.96 4.57 836 4.30 4.95 872 4.64 5.35

8500 754 3.90 4.50 791 4.22 4.86 826 4.55 5.25 860 4.88 5.63 896 5.23 6.04

9000 785 4.49 5.18 819 4.83 5.57 853 5.17 5.96 887 5.52 6.37 920 5.89 6.79

9500 814 5.13 5.92 846 5.48 6.32 879 5.83 6.72 910 6.19 7.14 943 6.57 7.58

10000 843 5.83 6.72 875 6.19 7.14 905 6.56 7.56 936 6.93 8.00 966 7.32 8.44

Unit - 50TJM - 34 - 28 Tons - 50Hz (Standard Motor) (cont)

Air Flow Rate

(CFM)

7000 867 3.94 4.55 906 4.28 4.94 945 4.65 5.36 983 5.02 5.79 1020 5.41 6.24

7500 887 4.44 5.12 924 4.79 5.53 961 5.16 5.95 996 5.53 6.38 1032 5.93 6.84

8000 908 4.99 5.76 944 5.36 6.18 978 5.73 6.61 1012 6.12 7.05 1046 6.51 7.51

8500 930 5.60 6.46 964 5.97 6.89 997 6.36 7.34 1029 6.75 7.78 1062 7.16 8.25

9000 952 6.25 7.21 985 6.64 7.65 1017 7.03 8.11 1049 7.44 8.58 1080 7.86 9.07

9500 973 6.96 8.02 1004 7.34 8.47 1035 7.75 8.94 1065 8.16 9.41 1095 8.59 9.91

10000 996 7.72 8.90 1026 8.12 9.36 1055 8.54 9.84 1085 8.97 10.34 1114 9.40 10.84

Unit - 50TJM - 34 - 28 Tons - 50Hz (High Efficiency Motor)

Air Flow Rate

(CFM)

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

RPM KWI BHP RPM KWI BHP

Standard Motor and Drive Package

0.2 0.4 0.6 0.8 1.0

Available External Static Pressure (in. wg)

RPM KWI BHP RPM KWI BHP RPM KWI BHP

Available External Static Pressure (in. wg)

7500 691 2.75 3.30 732 3.02 3.63 773 3.32 3.99 811 3.62 4.34 849 3.94 4.73

8000 723 3.23 3.87 761 3.51 4.22 798 3.81 4.57 836 4.13 4.96 872 4.46 5.35

8500 754 3.75 4.50 791 4.05 4.87 826 4.37 5.25 860 4.69 5.63 896 5.03 6.04

9000 785 4.32 5.19 819 4.64 5.57 853 4.97 5.96 887 5.31 6.37 920 5.66 6.79

9500 814 4.93 5.92 846 5.26 6.32 879 5.60 6.73 910 5.95 7.15 943 6.31 7.58

10000 843 5.60 6.73 875 5.95 7.15 905 6.30 7.57 936 6.66 8.00 966 7.04 8.45

Air Flow Rate

(CFM)

7000 867 3.79 4.55 906 4.12 4.94 945 4.47 5.36 983 4.83 5.80 1020 5.20 6.24

7500 887 4.27 5.12 924 4.61 5.53

8000 908 4.80 5.76 944 5.15 6.18 978 5.51 6.61 1012 5.88 7.06 1046 6.26 7.52

8500 930 5.38 6.46 964 5.74 6.89 997 6.11 7.34 1029 6.48 7.78 1062 6.88 8.26

9000 952 6.01 7.21 985 6.38 7.66 1017 6.76 8.12 1049 7.15 8.59 1080 7.56 9.07

9500 973 6.69 8.03 1004 7.06 8.47 1035 7.45 8.94 1065 7.84 9.42 1095 8.26 9.91

10000 996 7.42 8.91 1026 7.80 9.36 1055 8.20 9.85 1085 8.62 10.35 1114 9.03 10.84

Bold , Italics - High Efficiency Motor and Drive Package

Legend:

RPM - Revolutions Per Minute

KWI - Kilo Watts Input to Motor

BHP - Brake Horsepower Input to Fan

CFM - Cubic Feet per Minute

Notes:

1. Do not adjust motor rpm such that motor maximum bhp and/or watts is exceeded at the maximum operatin cfm.

2. Static Pressure (i.e Filters) must be added to external static pressure before entering fan performance table.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters and casing loses.

5. Extensive motor and drive testing on these units ensures that the full brake horsepower and watts range of the motor can be utilized with confidence. Using

your fan motors up to the watts or bhp rating shown will not result in nuisance tripping or premature motor failure. Unit warranty will not be affected.

RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP RPM KWI BHP

961 4.96 5.95 996 5.32 6.38 1032 5.70 6.84

8. Conversion - Bhp to KWI

KWI=

Bhp X 0.746

Motor efficiency

Page 24

Cooling Chart

Page 24

140

130

120

110

100

90

80

70

Liquid Temperature at Valve (F)

60

50

40

150 200 250 300 350 400 450 500 550 600

160

140

120

100

80

Liquid Temperature at Valve (F)

60

40

150 200 250 300 350 400 450 500 550 600

CHARGING CHART 50TJM-18

Both Circuits

All outdoor fans must be operating

Add charge if above upper curve

Reduce charge if below lower curve

Liquid Pressure (PSIG)

Fig - 10 Cooling Charging Charts for 50TJM Size 18

CHARGING CHART 50TJM-24

Both Circuits

All outdoor fans must be operating

Add charge if above upper curve

Reduce charge if below lower curve

Liquid Pressure (PSIG)

Fig - 11 Cooling Charging Charts for 50TJM Size 24

Page 25

Cooling Chart (cont)

Page 25

140

130

120

110

100

90

80

70

Liquid Temperature at Valve (F)

60

50

40

140

130

120

Add charge if above upper curve

150 200 250 300 350 400 450 500 550 600

All outdoor fans must be operating

Fig - 12 Cooling Charging Charts for 50TJM Size 28

All outdoor fans must be operating

CHARGING CHART 50TJM-28

Both Circuits

Reduce charge if below lower curve

Liquid Pressure (PSIG)

CHARGING CHART 50TJM-34

Both Circuits

110

Add charge if above upper curve

100

90

80

70

Liquid Temperature at Valve (F)

60

50

40

150 200 250 300 350 400 450 500 550 600

Liquid Pressure (PSIG)

Fig - 13 Cooling Charging Charts for 50TJM Size 34

Reduce charge if below lower curve

Page 26

Troubleshooting Guide

Power failure. Call power company.

Defective thermostat, contactor, transformer, or control

Replace component.

Incorrect or faulty wiring. Check wiring diagram and rewire correctly.

Compressor motor burned out, seized, or internal over-

Determine cause. Replace compressor.

Defective overload. Determine cause and replace.

Refrigerant overcharge or undercharge.

Recover refrigerant, evacuate system, and

Defective compressor. Replace and determine cause.

Blocked condenser. Determine cause and correct.

Defective thermostat. Replace thermostat.

Faulty condenser-fan motor. Replace.

Dirty air filter. Replace filter.

Thermostat set too low. Reset thermostat.

Air in system.

Recover refrigerant, evacuate system, and

Condenser coil dirty or restricted. Clean coil or remove restriction.

Dirty drier filter. Replace filter.

Refrigerant overcharged. Recover excess refrigerant.

Air in system.

Recover refrigerant, evacuate system, and

Condenser air restricted or air short-cycling. Determine cause and correct.

Restriction in liquid tube. Remove restriction.

Faulty TXV.

1. Check TXV bulb mounting and secure tightly to

Dirty air filter. Replace filter.

Faulty TXV.

1. Check TXV bulb mounting and secure tightly to

Insufficient evaporator airflow.

Increase air quantity. Check filter and replace if

Field-installed filter drier restricted. Replace.

Table 8 — Cooling Service Analysis

Page 26

PROBLEM CAUSE REMEDY

Compressor and condenser fan will not

start.

Fuse blown or circuit breaker tripped. Replace fuse or reset circuit breaker.

relay.

Insufficient line voltage. Determine cause and correct.

Compressor will not start but condenser

fan runs.

Compressor cycles (other than normally

satisfying thermostat).

Compressor operates continuously.

Thermostat setting too high. Lower thermostat setting below room

Faulty wiring or loose connections in compressor

circuit.

load open.

Compressor locked out Determine cause for safety trip and reset lockout.

One leg of 3-phase power dead. Replace fuse or reset circuit breaker.

Insufficient line voltage. Determine cause and correct.

Defective overload. Determine cause and replace.

Restriction in refrigerant system. Locate restriction and remove.

Unit undersized for load. Decrease load or increase unit size.

Low refrigerant charge. Locate leak, repair, and recharge.

temperature.

Check wiring and repair or replace.

Determine cause.

recharge to nameplate.

Excessive head pressure.

Head pressure too low.

Excessive suction pressure.

Suction pressure too low.

recharge.

Dirty condenser coil. Clean coil.

Faulty TXV. 1. Check TXV bulb mounting and secure tightly to

suction line.

2. Replace TXV if stuck open or closed.

recharge.

Low refrigerant charge. Check for leaks, repair, and recharge.

High heat load. Check for source and eliminate.

suction line.

2. Replace TXV if stuck open or closed.

Refrigerant overcharged. Recover excess refrigerant.

Low refrigerant charge. Check for leaks, repair, and recharge.

Metering device or low side restricted. Remove source of restriction.

suction line.

2. Replace TXV if stuck open or closed.

necessary.

Temperature too low in conditioned area. Reset thermostat.

Page 27

MODEL NO: DATE:

SERIAL NO: TECHNICIAN:

Notes:

VERIFY REFRIGERANT CHARGE USING CHARGING CHART IN FIG - 10 to FIG - 13 on Page 24 and 25.

REFRIGERANT SUCTION

REFRIGERANT DISCHARGE

REFRIGERANT DISCHARGE

:PSIG

:PSIG

:PSIG

:PSIG

:WB

:WB

PRESSURES:

CIRCUIT - 1

CIRCUIT - 2

REFRIGERANT SUCTION

OUTDOOR AIR:

INDOOR SECTION ENTERING AIR:

INDOOR SECTION LEAVING AIR:

: DB

: DB

: DB

(L3):

TEMPERATURES:

(BOTH CIRCUITS OPERATING)

SUPPLY VOLTAGE:

COMPRESSOR - 1 AMPS:

COMPRESSOR - 2 AMPS:

INDOOR FAN AMPS:

(L1 - L2):

(L1):

(L1):

(L1):

(L2 - L3):

(L2):

9) CORRECT FAN ROTATION HAS BEEN CONFIRMED.

10) SEALED ALL POWER AND CONTROL WIRES ENTRY INTO THE UNIT AND INSIDE THE BOX

(L3 - L1):

(L3):

(L3):

START-UP CHECKLIST

(Remove and Store in Job File)

II. PRE-START-UP (Insert checkmark in box as each item is completed)

I. PRELIMINARY INFORMATION

2) VERIFY THAT UNIT INSTALLATION IS LEVEL.

1) ALL PACKING MATERIALS HAVE BEEN REMOVED FROM THE UNIT.

(Tear Along This Line)

(L2):

(L2):

III. START - UP

ELECTRICAL:

8) ENERGIZE CRANKCASE HEATERS FOR 12 HOURS.

3) CONDENSATE CONNECTION IS INSTALLED PER INSTALLATION INSTRUCTION.

4) UNIT GROUNDING WIRE HAS BEEN CONNECTED.

5) POWER WIRES HAVE BEEN SIZED AND INSTALLED PROPERLY TO THE UNIT.

6) CONTROL WIRING CONNECTIONS HAVE BEEN INSTALLED PROPERLY.

7) CHECK ALL WIRING TERMINALS HAVE BEEN TIGHTENED PROPERLY.

Page 27

Page 28

Page 28

Manufacturer reserves the rights to discontinue, or change at any time, specifications or designs without notice and without inc ur r in g ob ligations

Supersedes Version: 50TJM-IOM05 Version: 50 TJM-IOM06

Effective Date: 22-06-2013

Loading...

Loading...