Carrier 50SX024-060, 50SS018-060 User Manual

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS .................1-12

General ......................................1

RECEIVING AND INSTALLATION ...........13-26

Step 1 — Check Equipment ..................13

• IDENTIFY UNIT

• INSPECT SHIPMENT

Step 2 — Provide Unit Support ..............13

• ROOF CURB

• SLAB MOUNT

Step 3 — Provide Clearances ................13

Step 4 — Rig and Place Unit .................13

• UNITS WITHOUT BASE RAILS

• UNITS WITH OPTIONAL BASE RAILS

Step 5 — Select and Install Ductwork ........16

• CONVERTING HORIZONTAL DISCHARGE

UNITS TO DOWNFLOW (VERTICAL) DISCHARGE

— STD (NON-ICM) UNITS

• CONVERTING HORIZONTAL DISCHARGE UNITS

TO DOWNFLOW (VERTICAL) DISCHARGE

— ICM UNITS

• ACCESSORY DUCT FLANGE KIT INSTALLATION

Step 6 — Provide for Condensate Disposal ...20

Step 7 — Install Electrical Connections ......21

• HIGH-VOLTAGE CONNECTIONS

• ROUTING POWER LEADS INTO UNIT

• CONNECTING GROUND LEAD TO

WIRE-BINDING SCREW

• ROUTING CONTROL POWER WIRES — STD

NON-ICM UNITS (24 V)

• ROUTING CONTROL POWER WIRES — ICM

UNITS (24 V)

• SPECIAL PROCEDURES FOR 208-V

OPERATION

PRE-START-UP ............................26,27

START-UP ................................27-39

Check for Refrigerant Leaks .................27

Start-Up Cooling Section and

Make Adjustments ........................27

MAINTENANCE ............................40,41

Air Filter ....................................40

Unit Top Removal ...........................40

Evaporator Blower and Motor ................40

Condenser Coil, Evaporator Coil,

and Condensate Drain Pan ................41

Condenser Fan .............................41

Electrical Controls and Wiring ...............41

Refrigerant Circuit ..........................41

Evaporator Airflow ..........................41

Metering Devices ...........................41

Liquid Line Strainer .........................41

TROUBLESHOOTING COOLING CHART .....42,43

START-UP CHECKLIST .....................CL-1

50SS018-060

50SX024-060

Single-Package Cooling Units

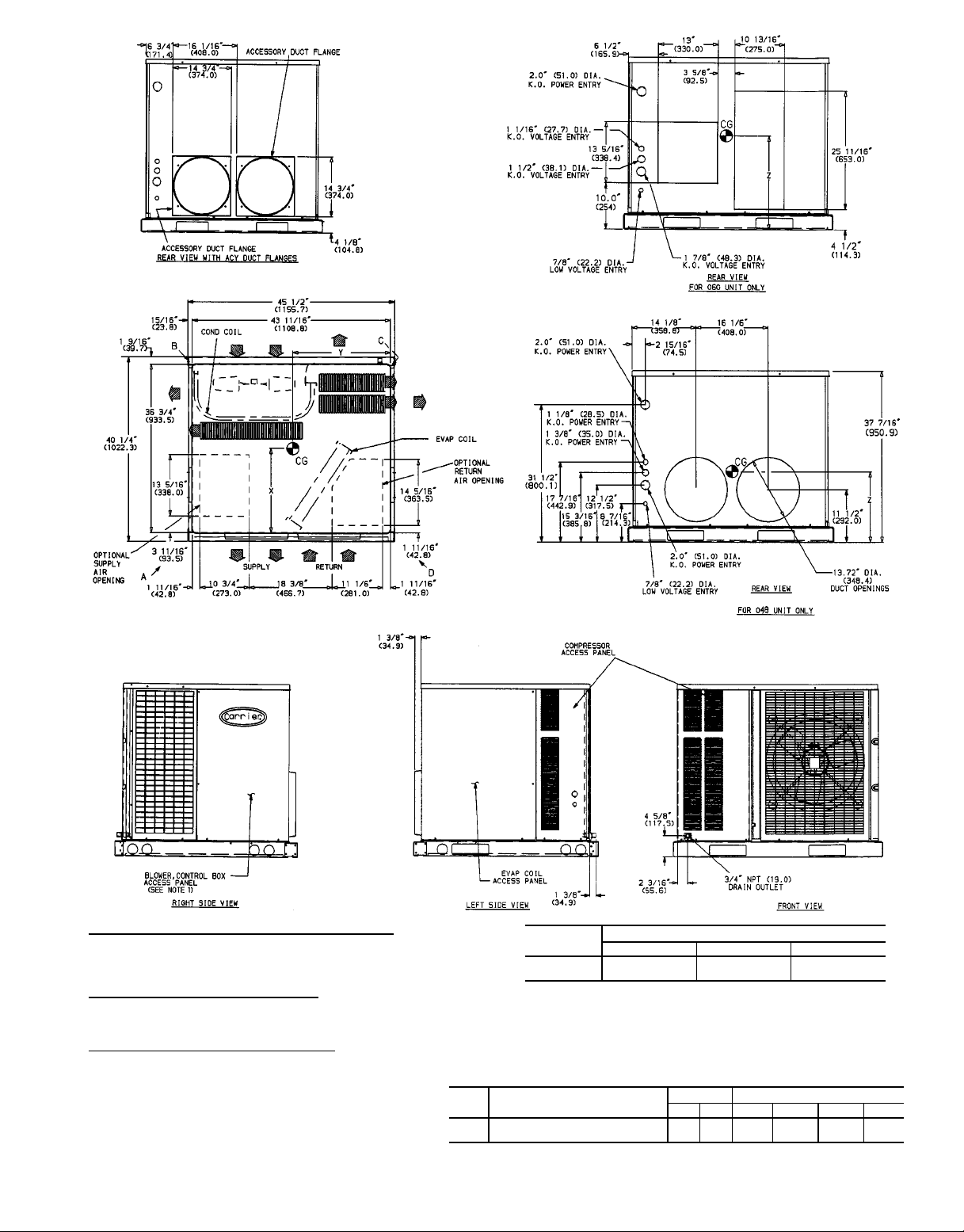

Fig. 1 — Unit 50SX With Optional Base Rail Shown

NOTE TO INSTALLER — Before the installation, READ

THESE INSTRUCTIONS CAREFULLY AND COMPLETELY. Also, make sure the Owner’s Manual and Service Instructions are left with the unit after installation.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical components. Only trained and qualified personnel should install,

repair, or service air-conditioning equipment.

Untrained personnelcan perform basicmaintenance functions of cleaning coils and filters.All other operations should

be performed by trained service personnel. When working

on air-conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and other safety

precautions that may apply.

Follow all safety codes. Wearsafety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire extinguisher available for all brazing operations.

Before performing service or maintenance operations on

system, turn off main power to unit. Turn off accessory

heater power switch if applicable. Electrical shock can

cause personal injury.

General— 50SS,SX cooling units are fully self-contained

and designed for outdoor installation. See Fig. 1. As shown

in Fig. 2-9, both small- and large-cabinet units are shipped

in a horizontal-discharge configuration for installation on

a ground-level slab. All units can be converted to downflow discharge configurations for rooftop applications. See

Fig. 10 for roof curb dimensions.

Instructions continued on page 13.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 1b 6b

PC 111 Catalog No. 535-022 Printed in U.S.A. Form 50SS,SX-4SI Pg 1 5-95 Replaces: 50SS,SX-3SI

REQUIREDCLEARANCES TOCOMBUSTIBLE MATERIAL — in.(mm)

Unit Top ................................14(356)

Duct Side of Unit ............................2(51)

Side Opposite Ducts ........................14(356)

Bottom of Unit .................................0

Vertical Discharge First 12 in. (305) of Supply Duct .......1(25)

NECESSARY REQUIRED CLEARANCES — in. (mm)

Between Units, Control Box Side ................42(1067)

Unit and Ungrounded Surfaces, Control Box Side ......36(914)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Control Box Side ...................42(1067)

REQUIRED CLEARANCES FOR SERVICING — in. (mm)

Evaporator Coil Access Side ...................30(762)

Control Box Access Side ......................30(762)

(Except for Necessary Requirements)

Unit Top ................................36(914)

Side Opposite Ducts ........................30(762)

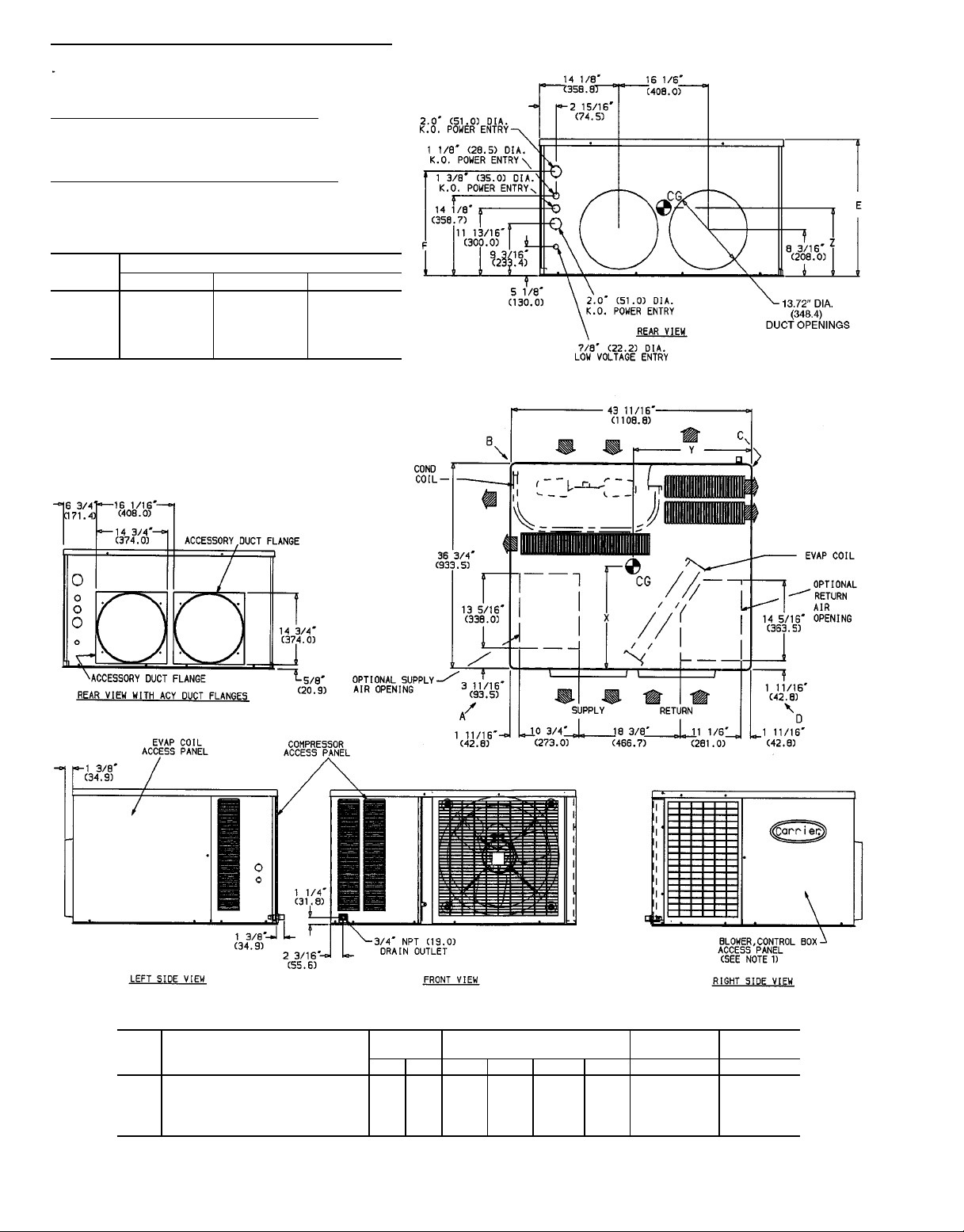

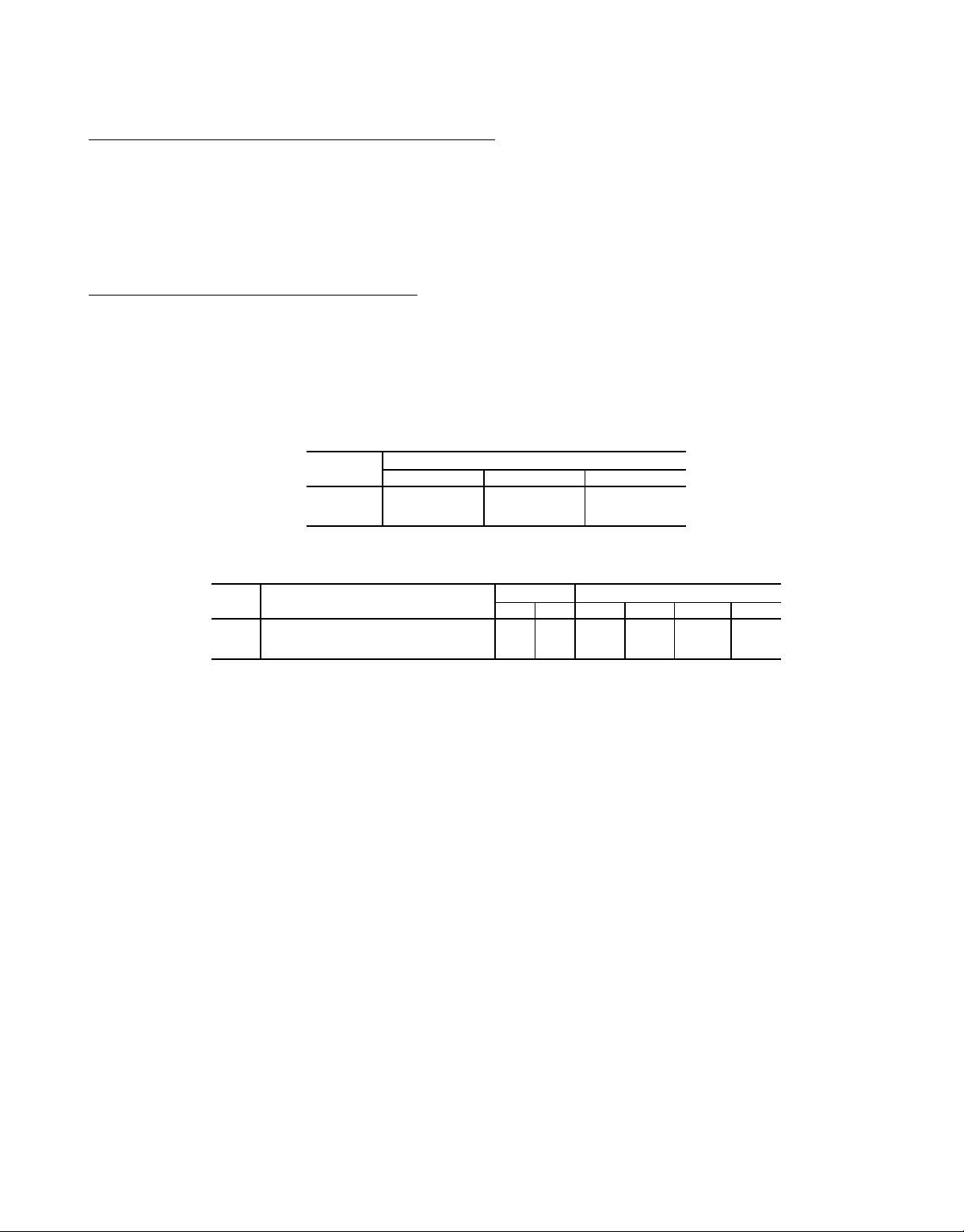

UNIT

50SS

018 19.6/499 21.7/551 10.6/269

024 22.5/570 20.9/530 10.0/254

030 22.1/561 20.3/516 10.0/253

036 21.2/538 19.9/506 9.9/251

042 21.3/540 19.9/506 11.3/286

CG — Center of Gravity NEC — National Electrical Code

COND — Condenser REQ’D — Required

MAT’L — Material

NOTES:

1. Clearances must be maintained to prevent recirculation of air from

outdoor-fan discharge.

2. Dimensions in ( ) are in millimeters.

CENTER OF GRAVITY (in./mm)

XYZ

LEGEND

UNIT

50SS

018 208/230-1-60 208 95 61/28 43/20 69/31 35/16 24.1/613 18.2/462

024 208/230-1-60 237 108 60/27 54/25 92/42 31/14 24.1/613 18.2/462

030 208/230-1-60, 208/230-3-60 254 115 61/28 58/26 96/44 39/18 24.1/613 18.2/462

036 208/230-1-60, 208/230-3-60, 460-3-60 270 123 75/35 48/22 109/50 37/17 24.1/613 18.2/462

042 208/230-1-60, 208/230-3-60, 460-3-60 300 135 81/40 57/26 117/53 45/20 28.1/714 22.2/563

ELECTRICAL

CHARACTERISTICS

UNIT WT CORNER WT (Lb/Kg)

Lb Kg A B C D E F

UNIT HEIGHT

(in./mm)

DIMENSION

(in./mm)

Fig. 2 — Dimensions; Units 50SS018-042 Without Base Rail

2

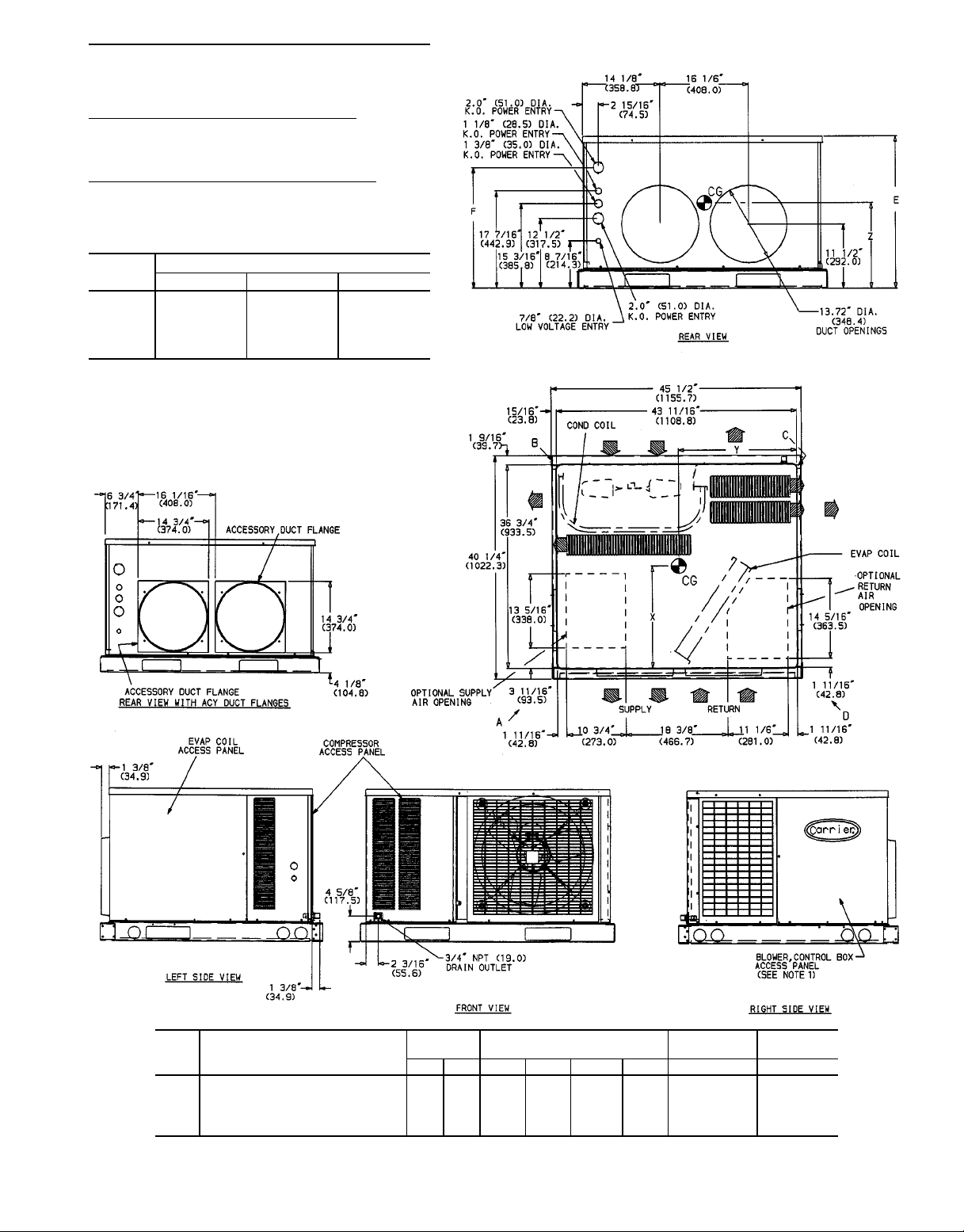

REQUIREDCLEARANCES TOCOMBUSTIBLE MATERIAL — in.(mm)

Unit Top ................................14(356)

Duct Side of Unit ............................2(51)

Side Opposite Ducts ........................14(356)

Bottom of Unit .................................0

Vertical Discharge First 12 in. (305) of Supply Duct .......1(25)

NECESSARY REQUIRED CLEARANCES — in. (mm)

Between Units, Control Box Side ................42(1067)

Unit and Ungrounded Surfaces, Control Box Side ......36(914)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Control Box Side ...................42(1067)

REQUIRED CLEARANCES FOR SERVICING — in. (mm)

Evaporator Coil Access Side ...................30(762)

Control Box Access Side ......................30(762)

(Except for Necessary Requirements)

Unit Top ................................36(914)

Side Opposite Ducts ........................30(762)

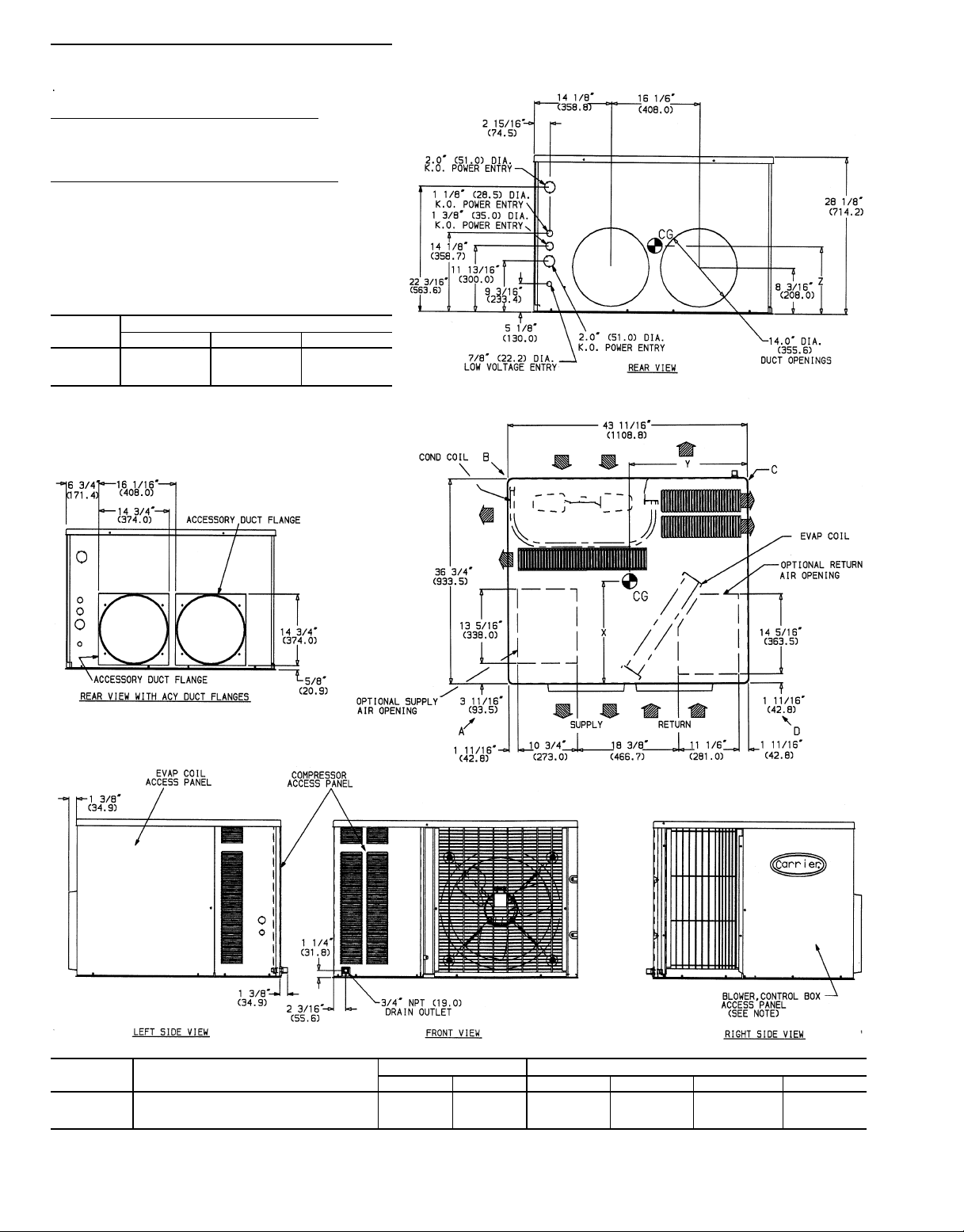

UNIT

50SS

018 19.5/495 21.7/551 12.9/328

024 22.1/562 20.9/532 12.3/313

030 21.8/554 20.4/519 12.3/312

036 21.0/533 20.1/509 12.2/310

042 21.0/532 20.1/510 13.6/344

CG — Center of Gravity NEC — National Electrical Code

COND — Condenser REQ’D — Required

MAT’L — Material

NOTES:

1. Clearances must be maintained to prevent recirculation of air from

outdoor-fan discharge.

2. Dimensions in ( ) are in millimeters.

CENTER OF GRAVITY (in./mm)

XYZ

LEGEND

UNIT

50SS

018 208/230-1-60 228 104 66/30 48/22 74/34 40/18 27.4/697 21.5/546

024 208/230-1-60 257 117 65/30 59/27 97/44 36/16 27.4/697 21.5/546

030 208/230-1-60, 208/230-3-60 274 125 66/30 63/29 101/46 44/20 27.4/697 21.5/546

036 208/230-1-60, 208/230-3-60, 460-3-60 290 132 81/37 53/24 114/52 42/19 27.4/697 21.5/546

042 208/230-1-60, 208/230-3-60, 460-3-60 320 146 86/39 62/28 122/55 50/23 31.4/798 25.5/648

ELECTRICAL

CHARACTERISTICS

UNIT WT CORNER WT (Lb/Kg)

Lb Kg A B C D E F

UNIT HEIGHT

(in./mm)

DIMENSION

(in./mm)

Fig. 3 — Dimensions; Units 50SS018-042 with Optional Base Rail

3

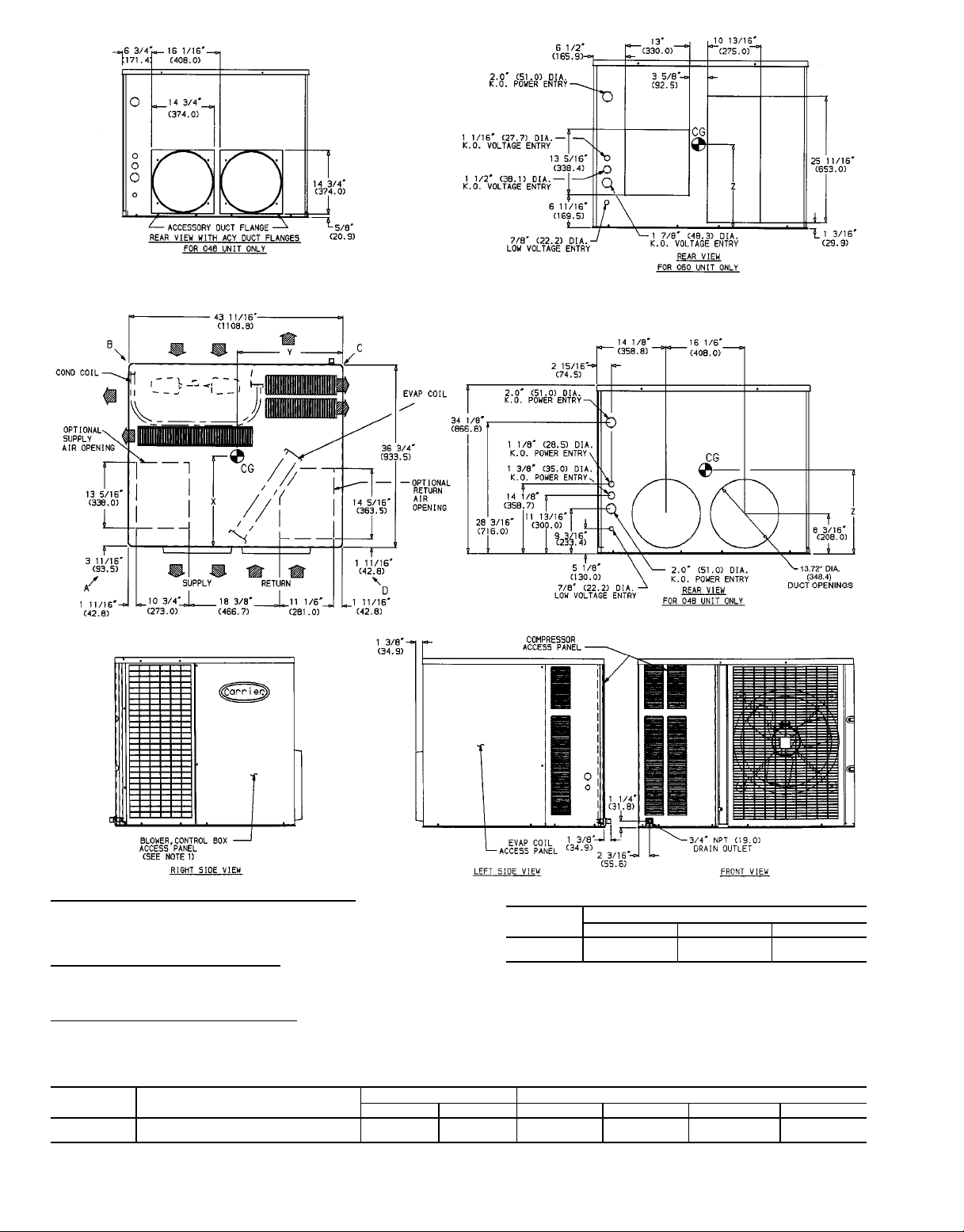

REQUIRED CLEARANCES TO COMBUSTIBLE MATERIAL — in. (mm)

Unit Top ....................................14(356)

Duct Side of Unit .................................2(51)

Side Opposite Ducts .............................14(356)

Bottom of Unit .....................................0

Vertical Discharge First 12 in. (305) of Supply Duct ...............1(25)

NECESSARY REQUIRED CLEARANCES — in. (mm)

Between Units, Control Box Side ......................42(1067)

Unit and Ungrounded Surfaces, Control Box Side ..............36(914)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Control Box Side .........................42(1067)

REQUIRED CLEARANCES FOR SERVICING — in. (mm)

Evaporator Coil Access Side .........................30(762)

Control Box Access Side ...........................30(762)

(Except for Necessary Requirements)

Unit Top ....................................36(914)

Side Opposite Ducts .............................30(762)

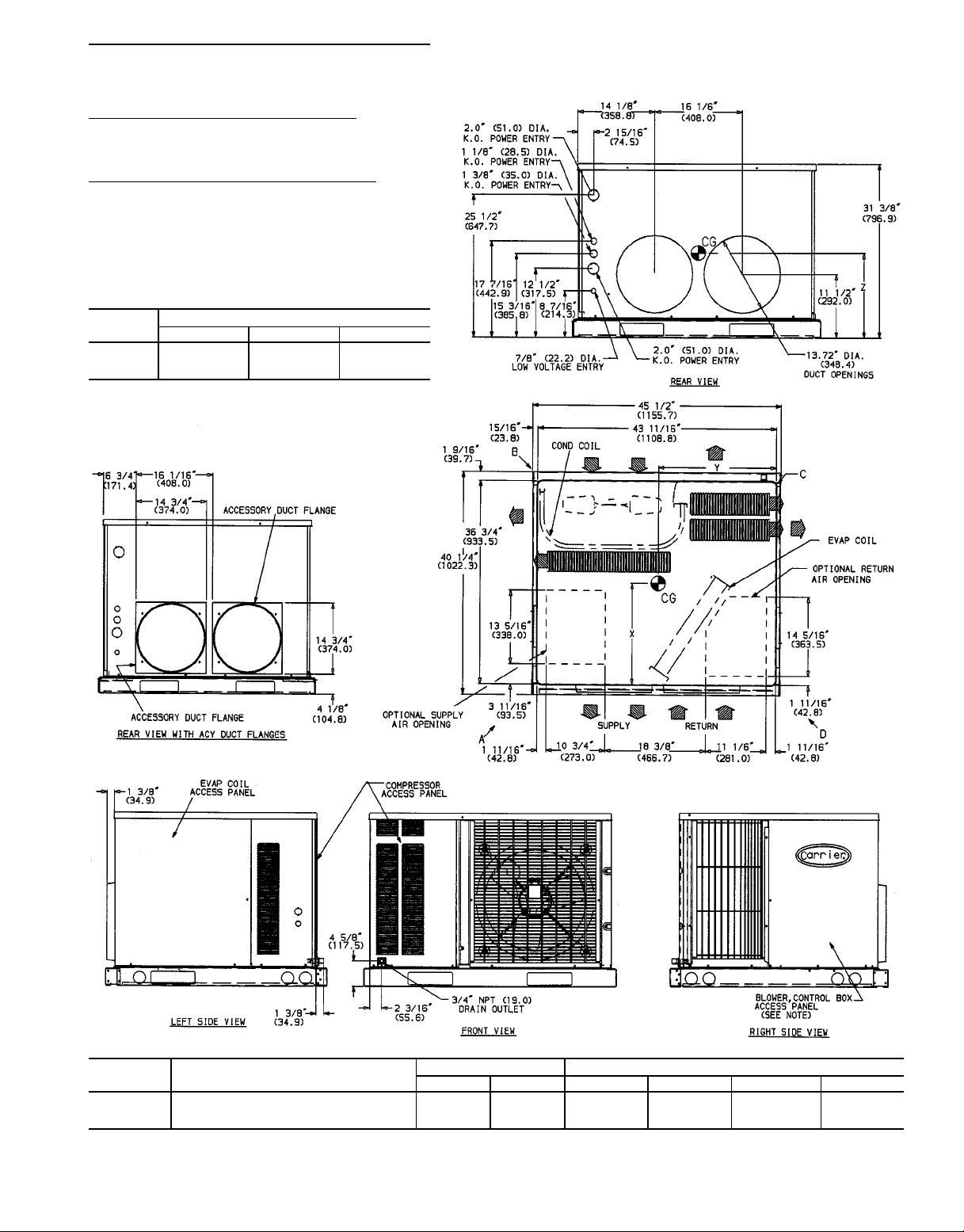

UNIT

50SS

048 21.9/555 19.6/498 13.4/341

060 22.2/565 19.8/503 13.4/340

CG — Center of Gravity NEC — National Electrical Code

COND — Condenser REQ’D — Required

MAT’L — Material

NOTES:

1. Clearances must be maintained to prevent recirculation of air from outdoor-fan discharge.

2. Dimensions in ( ) are in millimeters.

CENTER OF GRAVITY (in./mm)

XYZ

LEGEND

UNIT

50SS

048 208/230-1-60, 208/230-3-60, 460-3-60 332 151 82/37 68/31 131/60 51/23

060 208/230-1-60, 208/230-3-60, 460-3-60 359 163 65/30 99/45 120/55 75/34

ELECTRICAL

CHARACTERISTICS

UNIT WT CORNER WT (Lb/Kg)

Lb Kg A B C D

Fig. 4 — Dimensions; Units 50SS048,060 Without Base Rail

4

REQUIRED CLEARANCES TO COMBUSTIBLE MATERIAL — in. (mm)

Unit Top ..................................14(356)

Duct Side of Unit ..............................2(51)

Side Opposite Ducts ...........................14(356)

Bottom of Unit ..................................0

Vertical Discharge First 12 in. (305) of Supply Duct ............1(25)

NECESSARY REQUIRED CLEARANCES — in. (mm)

Between Units, Control Box Side ....................42(1067)

Unit and Ungrounded Surfaces, Control Box Side ............36(914)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Control Box Side ......................42(1067)

REQUIRED CLEARANCES FOR SERVICING — in. (mm)

Evaporator Coil Access Side .......................30(762)

Control Box Access Side .........................30(762)

(Except for Necessary Requirements)

Unit Top ..................................36(914)

Side Opposite Ducts ...........................30(762)

Fig. 5 — Dimensions; Units 50SS048,060 With Optional Base Rail

UNIT

50SS

048 21.7/550 19.7/501 15.7/400

060 22.0/560 19.9/506 15.7/399

CG — Center of Gravity NEC — National Electrical Code

COND — Condenser REQ’D — Required

MAT’L — Material

NOTES:

1. Clearances must be maintained to prevent recirculation of air from outdoor-fan discharge.

2. Dimensions in ( ) are in millimeters.

UNIT

50SS

048 208/230-1-60, 208/230-3-60, 460-3-60 352 160 87/40 73/33 136/62 56/25

060 208/230-1-60, 208/230-3-60, 460-3-60 379 172 70/32 104/47 125/57 80/36

ELECTRICAL

CHARACTERISTICS

CENTER OF GRAVITY (in./mm)

XYZ

LEGEND

UNIT WT CORNER WT (Lb/Kg)

Lb Kg A B C D

5

REQUIREDCLEARANCES TOCOMBUSTIBLE MATERIAL— in. (mm)

Unit Top ................................14(356)

Duct Side of Unit ............................2(51)

Side Opposite Ducts ........................14(356)

Bottom of Unit .................................0

Vertical Discharge First 12 in. (305) of Supply Duct .......1(25)

NECESSARY REQUIRED CLEARANCES — in. (mm)

Between Units, Control Box Side ................42(1067)

Unit and Ungrounded Surfaces, Control Box Side ......36(914)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Control Box Side ...................42(1067)

REQUIRED CLEARANCES FOR SERVICING — in. (mm)

Evaporator Coil Access Side ...................30(762)

Control Box Access Side ......................30(762)

(Except for Necessary Requirements)

Unit Top ................................36(914)

Side Opposite Ducts ........................30(762)

NOTES:

1. Clearances must be maintained to prevent recirculation of air from

outdoor-fan discharge.

2. Dimensions in ( ) are in millimeters.

CG — Center of Gravity NEC — National Electrical Code

COND — Condenser REQ’D — Required

MAT’L — Material

LEGEND

UNIT

50SX

024 21.7/552 20.7/527 12.7/321

030 21.9/556 20.7/525 12.7/321

036 20.8/528 20.0/507 12.7/321

CENTER OF GRAVITY (in./mm)

XYZ

UNIT

50SX

024 208/230-1-60 270 123 67/30 62/28 99/45 42/19

030 208/230-1-60 273 124 66/30 64/29 100/45 43/20

036 208/230-1-60, 208/230-3-60, 460-3-60 291 132 80/36 54/25 112/51 45/20

ELECTRICAL

CHARACTERISTICS

UNIT WT CORNER WT (Lb/Kg)

Lb Kg A B C D

Fig. 6 — Dimensions; Units 50SX024-036 Without Base Rail

6

REQUIREDCLEARANCES TOCOMBUSTIBLE MATERIAL— in. (mm)

Unit Top ................................14(356)

Duct Side of Unit ............................2(51)

Side Opposite Ducts ........................14(356)

Bottom of Unit .................................0

Vertical Discharge First 12 in. (305) of Supply Duct .......1(25)

NECESSARY REQUIRED CLEARANCES — in. (mm)

Between Units, Control Box Side ................42(1067)

Unit and Ungrounded Surfaces, Control Box Side ......36(914)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Control Box Side ...................42(1067)

REQUIRED CLEARANCES FOR SERVICING — in. (mm)

Evaporator Coil Access Side ...................30(762)

Control Box Access Side ......................30(762)

(Except for Necessary Requirements)

Unit Top ................................36(914)

Side Opposite Ducts ........................30(762)

NOTES:

1. Clearances must be maintained to prevent recirculation of air from

outdoor-fan discharge.

2. Dimensions in ( ) are in millimeters.

CG — Center of Gravity NEC — National Electrical Code

COND — Condenser REQ’D — Required

MAT’L — Material

LEGEND

UNIT

50SX

024 21.5/546 20.8/528 15.0/380

030 21.7/550 20.7/527 15.0/380

036 20.6/524 20.1/510 15.0/380

CENTER OF GRAVITY (in./mm)

XYZ

UNIT

50SX

024 208/230-1-60 290 132 72/33 67/30 104/47 47/21

030 208/230-1-60 293 133 71/32 69/31 105/48 48/22

036 208/230-1-60, 208/230-3-60, 460-3-60 311 142 85/39 59/27 117/53 50/23

ELECTRICAL

CHARACTERISTICS

UNIT WT CORNER WT (Lb/Kg)

Lb Kg A B C D

Fig. 7 — Dimensions; Units 50SX024-036 With Optional Base Rail

7

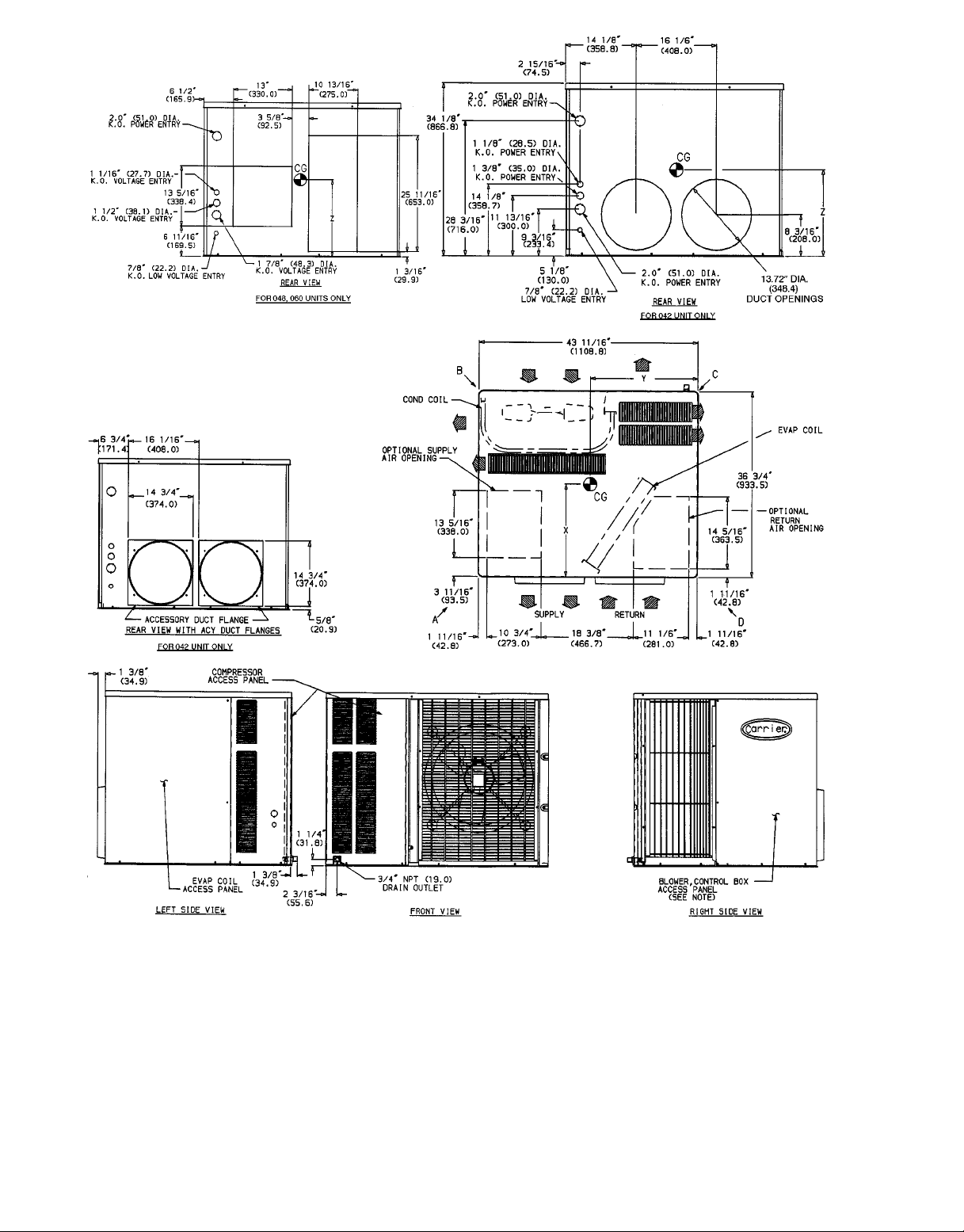

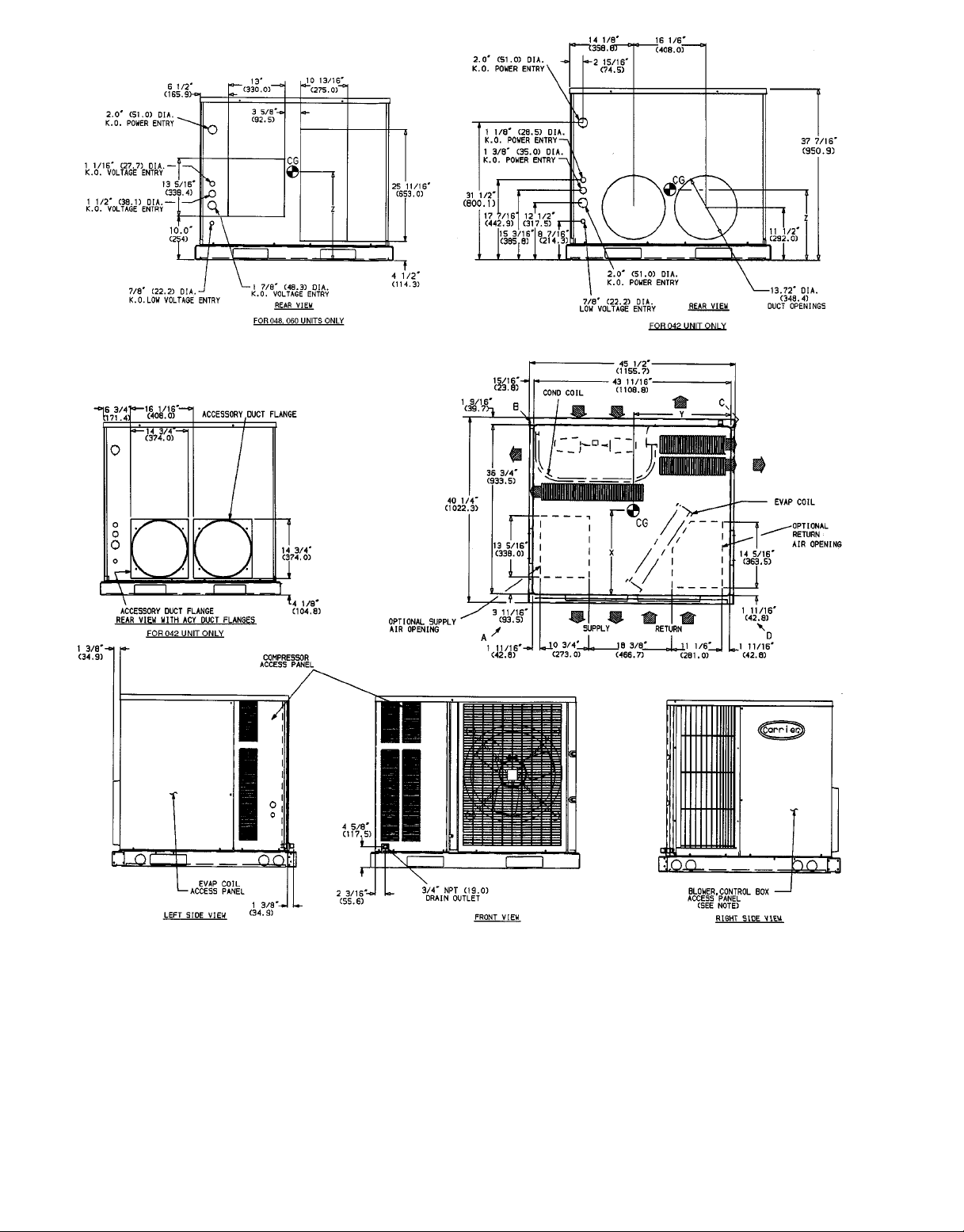

Fig. 8 — Dimensions; Units 50SX042-060 Without Base Rail

8

LEGEND

CG — Center of Gravity NEC — National Electrical Code

COND — Condenser REQ’D — Required

MAT’L — Material

REQUIRED CLEARANCES TO COMBUSTIBLE MATERIAL — in. (mm)

Unit Top ........................................14(356)

Duct Side of Unit ...................................2(51)

Side Opposite Ducts ...............................14(356)

Bottom of Unit .........................................0

Vertical Discharge First 12 in. (305) of Supply Duct ...........1(25)

NECESSARY REQUIRED CLEARANCES — in. (mm)

Between Units, Control Box Side .....................42(1067)

Unit and Ungrounded Surfaces, Control Box Side ...........36(914)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Control Box Side .........................42(1067)

REQUIRED CLEARANCES FOR SERVICING — in. (mm)

Evaporator Coil Access Side .........................30(762)

Control Box Access Side ............................30(762)

(Except for Necessary Requirements)

Unit Top ........................................36(914)

Side Opposite Ducts ...............................30(762)

NOTES:

1. Clearancesmustbemaintained to prevent recirculation of airfromoutdoor-

fan discharge.

2. Dimensions in ( ) are in millimeters.

UNIT

50SX

042 21.0/533 20.1/510 15.4/390

048 21.8/553 19.7/499 15.4/390

060 22.2/565 19.8/503 13.4/340

UNIT

50SX

042 208/230-1-60, 208/230-3-60, 460-3-60 309 140 84/38 59/27 119/54 47/21

048 208/230-1-60, 208/230-3-60, 460-3-60 340 155 84/38 70/32 133/60 53/24

060 208/230-1-60, 208/230-3-60 359 163 65/30 99/45 120/55 75/34

ELECTRICAL

CHARACTERISTICS

CENTER OF GRAVITY (in./mm)

XYZ

UNIT WT CORNER WT (Lb/Kg)

Lb Kg A B C D

Fig. 8 — Dimensions; Units 50SX042-060 Without Base Rail (cont)

9

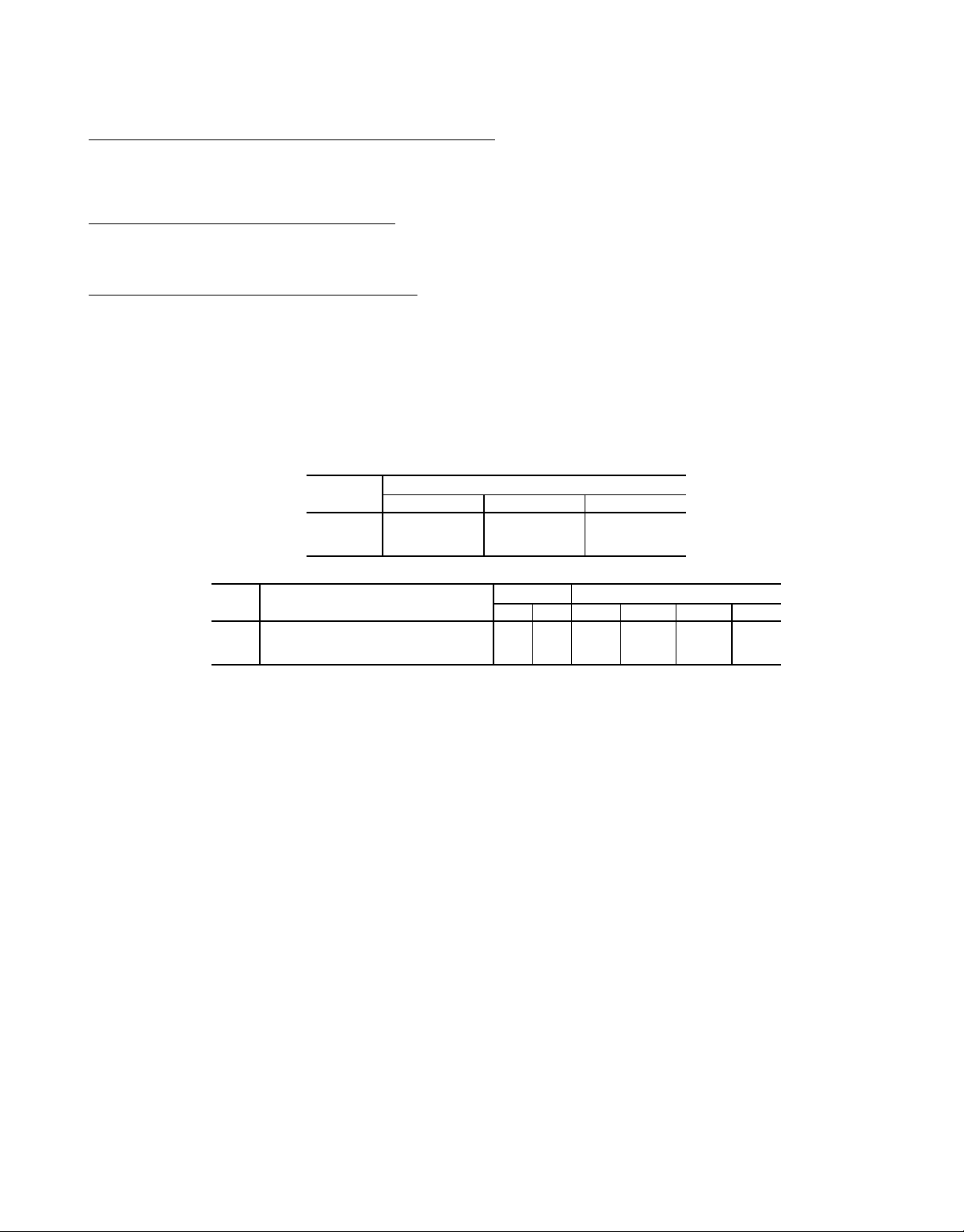

Fig. 9 — Dimensions; Units 50SX042-060 With Optional Base Rail

10

CG — Center of Gravity NEC — National Electrical Code

COND — Condenser REQ’D — Required

MAT’L — Material

REQUIRED CLEARANCES TO COMBUSTIBLE MATERIAL — in. (mm)

Unit Top ........................................14(356)

Duct Side of Unit ...................................2(51)

Side Opposite Ducts ...............................14(356)

Bottom of Unit .........................................0

Vertical Discharge First 12 in. (305) of Supply Duct ...........1(25)

NECESSARY REQUIRED CLEARANCES — in. (mm)

Between Units, Control Box Side .....................42(1067)

Unit and Ungrounded Surfaces, Control Box Side ...........36(914)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Control Box Side .........................42(1067)

REQUIRED CLEARANCES FOR SERVICING — in. (mm)

Evaporator Coil Access Side .........................30(762)

Control Box Access Side ............................30(762)

(Except for Necessary Requirements)

Unit Top ........................................36(914)

Side Opposite Ducts ...............................30(762)

NOTES:

1. Clearancesmustbemaintained to prevent recirculation of airfromoutdoor-

fan discharge.

2. Dimensions in ( ) are in millimeters.

LEGEND

UNIT

50SX

042 20.8/529 20.2/512 17.3/440

048 21.6/548 19.8/502 17.3/440

060 22.0/560 19.9/506 15.7/399

UNIT

50SX

042 208/230-1-60, 208/230-3-60, 460-3-60 329 150 89/40 64/29 124/56 52/24

048 208/230-1-60, 208/230-3-60, 460-3-60 360 164 89/40 75/34 138/63 58/26

060 208/230-1-60, 208/230-3-60 379 172 70/32 104/47 125/57 80/36

ELECTRICAL

CHARACTERISTICS

CENTER OF GRAVITY (in./mm)

XYZ

UNIT WT CORNER WT (Lb/Kg)

Lb Kg A B C D

Fig. 9 — Dimensions; Units 50SX042-060 With Optional Base Rail (cont)

11

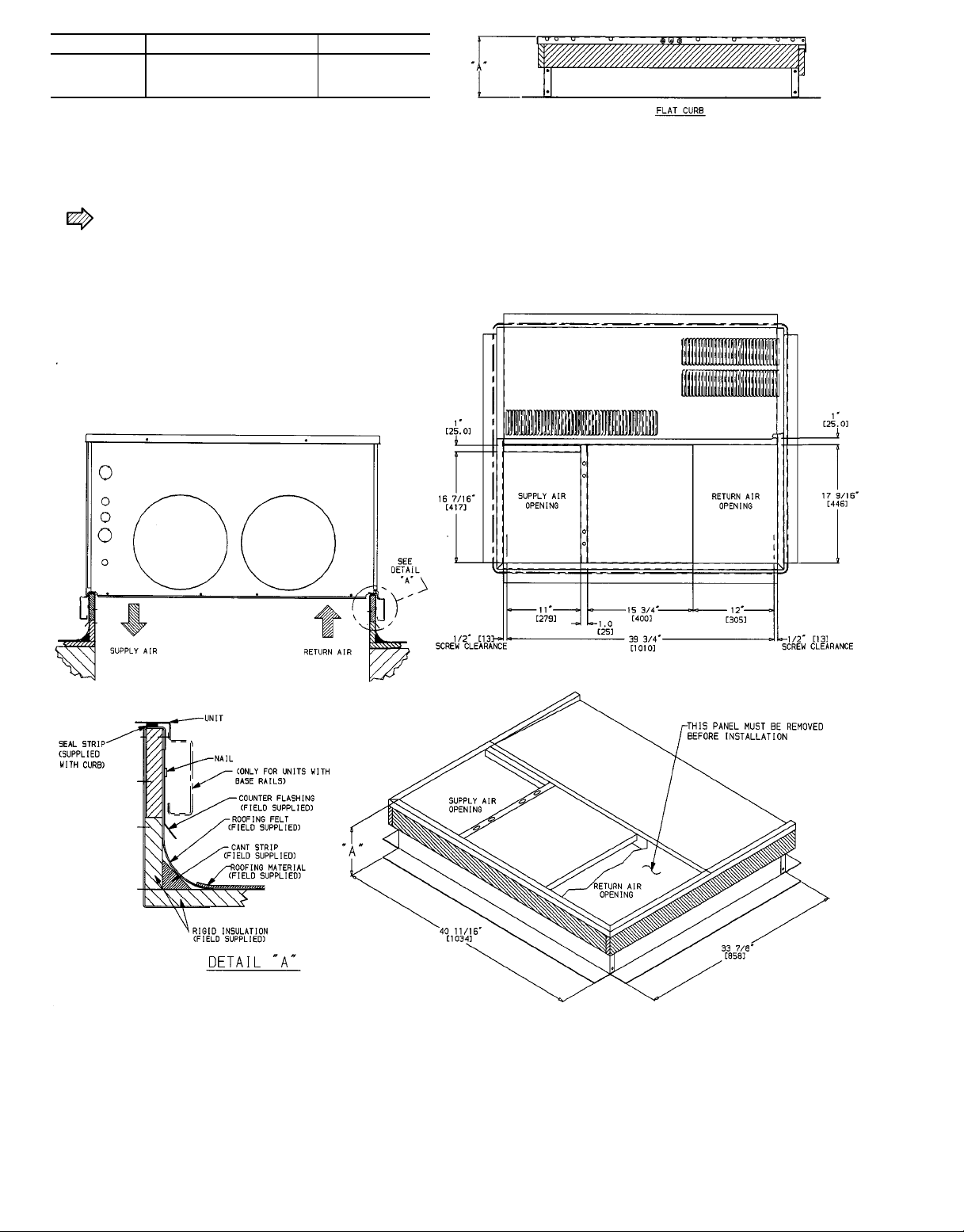

PART NUMBER ‘‘A’’

FLAT

CURB

NOTES:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied as required for unit being installed.

3. Dimensions in [ ] are in millimeters.

4. Roof curb is made of 16 gage steel.

5. Attach ductwork to curb (flanges of duct rest on curb).

6. Service clearance 4 ft on each side.

7. direction of airflow.

8. Insulated panels, 1-in. thick, fiberglass 1-lb density.

CPRFCURB001A00 89 [203]

CPRFCURB002A00 119 [279]

CPRFCURB003A00 149 [356]

Fig. 10 — Roof Curb Dimensions

12

RECEIVING AND INSTALLATION

Step 1 — Check Equipment

IDENTIFYUNIT — The unit model number and serial number are stamped on the unit identification plate. Check this

information against shipping papers.

INSPECT SHIPMENT — Inspect for shipping damage while

unit is still on shipping pallet. If unit appears to be damaged

or is torn loose from its anchorage, have it examined by transportation inspectors before removal. Forward claim papers

directly to transportation company. Manufacturer is not responsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify

the nearest Carrier Air Conditioning office if any item is

missing.

To prevent loss or damage, leave all parts in original packages until installation.

Step 2 — Provide Unit Support

ROOF CURB — Install accessory roof curb in accordance

with instructions shipped with curb. See Fig. 10. Install insulation, cant strips, roofing, and flashing. Ductwork must

be attached to curb.

IMPORTANT: The gasketing of the unit to the roof

curb is critical for a watertight seal. Install gasketing

material supplied with the roof curb. Improperly applied gasketing also can result in air leaks and poor

unit performance.

Curb should be level to within1⁄4inch. This is necessary

for unit drain to function properly. Refer to accessory roof

curb installation instructions for additional information as

required.

SLAB MOUNT — Place the unit on a solid, level concrete

pad that is a minimum of 4 in. thick with 2 in. above grade.

The slab should extend approximately 2 in. beyond the casing on all 4 sides of the unit. Install a 6-in. gravel apron in

front of condenser-air inlet to prevent obstruction of airflow

by grass or shrubs. Do not secure the unit to the slab except

when required by local codes.

Step 3 — Provide Clearances — The required mini-

mum service clearances and clearances to combustibles are

shown in Fig. 2-9. Adequate ventilation and condenser air

must be provided.

The condenser fan pushes air through the condenser coil

and discharges it through louvers on the top cover, the decorative grille, and the compressor access panel. Be sure that

the fan discharge does not recirculate to the condenser coil.

Do not locate the unit in either a corner or under an overhead obstruction. The minimum clearance under a partial overhang (such as a normal house overhang) is 48 in. above the

unit top. The maximum horizontal extension of a partial overhang must not exceed 48 inches.

Do not restrict condenser airflow. An air restriction at

either the outdoor-air inlet or the fan discharge can be

detrimental to compressor life.

Do not place the unit where water, ice, or snow from

an overhang or roof will damage or flood the unit. Do not

install the unit on carpeting, tile, or other combustible materials. The unit may be installed on wood flooring or on

Class A, B, or C roof covering materials.

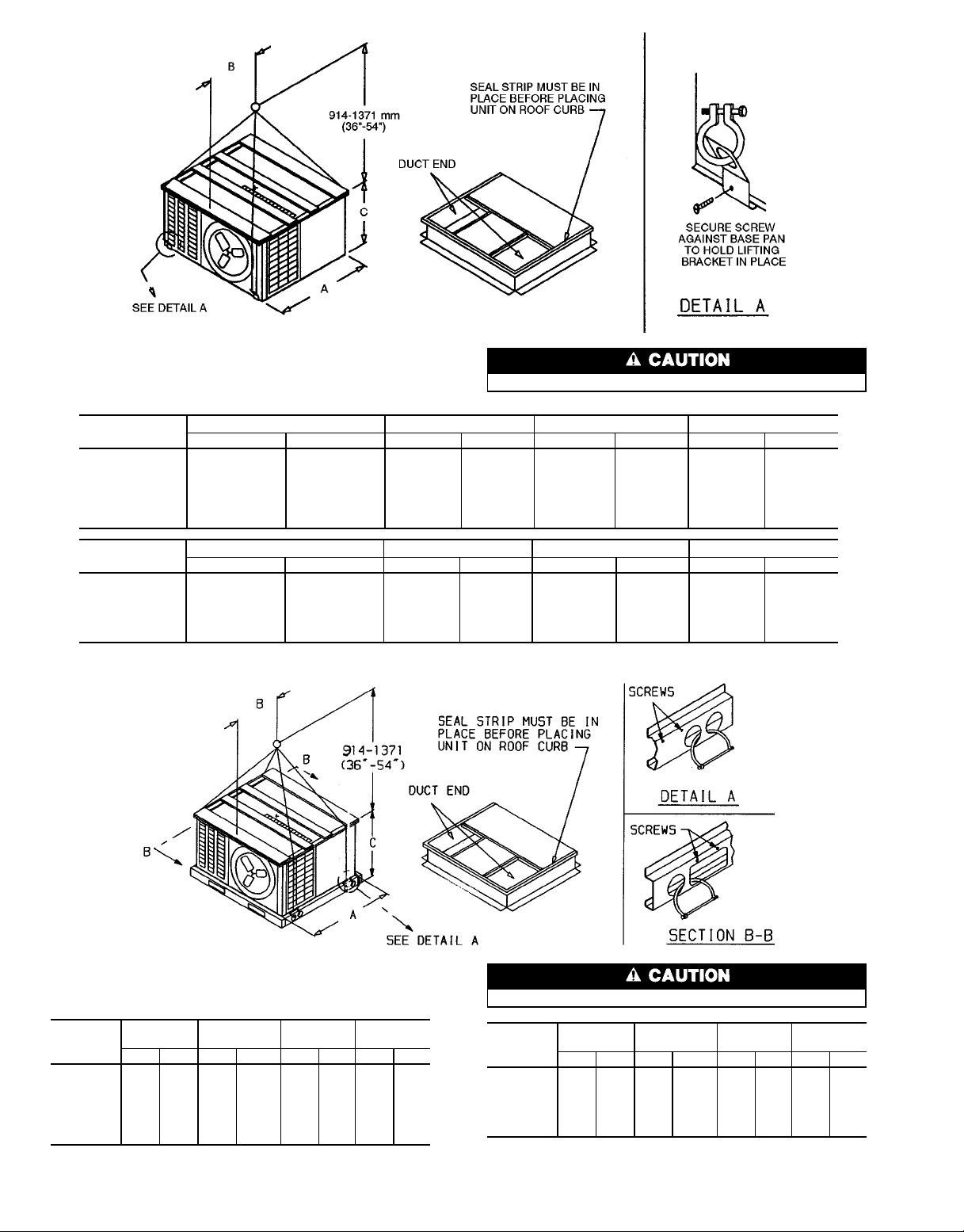

Step 4 — Rig and Place Unit — Use spreader bars

or crate top when rigging the unit. The units must be rigged

for lifting as shown in Fig. 11 and 12. Refer to Fig. 11 and

12 for rigging weights and Tables1 and 2 for operating weights.

Use extreme caution to prevent damage when moving the

unit. Unit must remain in an upright position during all rigging and moving operations.The unit must be level for proper

condensate drainage; the ground-level pad or accessory roof

curb must be level before setting the unit in place. When a

field-fabricated support is used, be sure that the support is

level and that it properly supports the unit.

UNITSWITHOUTBASE RAILS —Accessory rigging brackets are recommended to be used for rigging. Install brackets

as follows:

Secure screws and paint protectors solidly against unit

basepan to hold lifting brackets in position.

Never use lifting brackets when the temperature is below −10 F (−23 C).

Never exceed 200 lbs per bracket of lifting force.

Never use lifting brackets for lifting other models of air

conditioning units.

Lifting point should be directly over the unit center of

gravity.

1. Position brackets as close to the corners of unit as pos-

sible. Be sure brackets are well outside of center of gravity. (See Fig. 2, 4, 6, 8, and 11.)

2. Position paint protectors and foam strips between screws

and painted surface of unit. Tightenscrews until they make

contact with the paint protectors.

3. Secure device or hook of suff icientstrength to hole in bracket

as shown in detail ‘‘A’’ of Fig. 11.

4. If wood top is available, use it for a spreader bar to pre-

vent straps from damaging unit. If wood top is not available, use spreader bars of sufficient length.

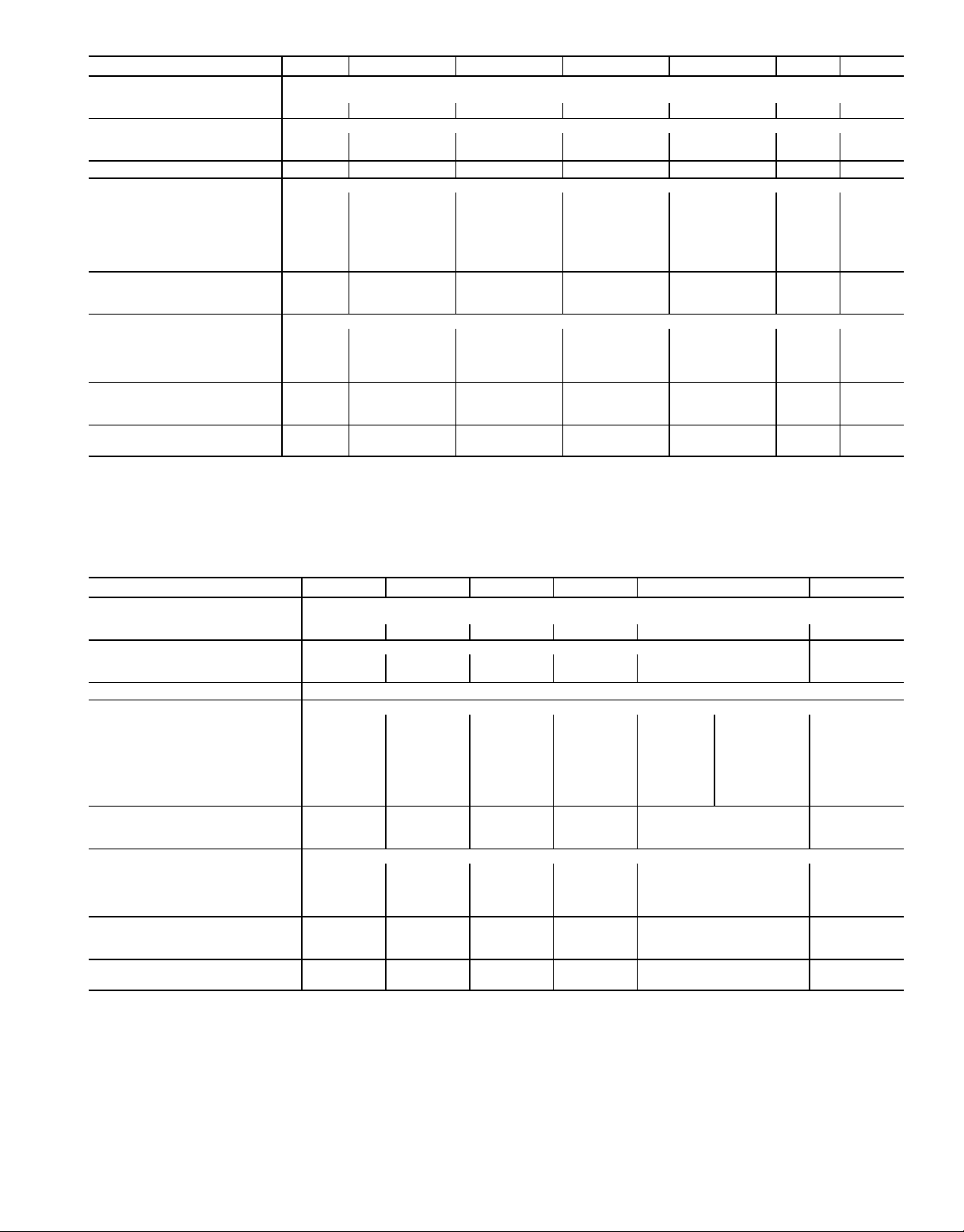

UNITS WITH OPTIONAL BASE RAILS — Keep unit upright and do not drop. Use spreader bars or top crate when

rigging unit. Rollers may be used to move unit across roof.

Level unit for proper condensate disposal. See Fig. 3, 5, 7,

and 9 for additional information. Lifting holes are provided

in base rails as shown in Fig. 12. Refer to rigging instructions on unit.

13

Hook rigging shackles through holes in lifting brackets, as shown in

NOTICE TO RIGGERS

Detail ‘‘A,’’lifting brackets to be centered around the unit center of gravity.Use

wood top skid when rigging, to prevent rigging straps from damaging unit.

All panels must be in place when rigging.

UNIT SIZE

50SS

018 260 118 36

024 289 131 36

030 306 139 36

036 322 146 36

042 333 151 36

048 384 174 36

060 411 186 36

UNIT SIZE

50SX

024 322 146 36

030 325 147 36

036 343 155 36

042 361 164 36

048 392 178 36

060 411 186 36

SHIPPING WEIGHT A B C

Lb Kg in. mm in. mm in. mm

SHIPPING WEIGHT A B C

Lb Kg in. mm in. mm in. mm

Fig. 11 — Suggested Rigging for Units Without Base Rail

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

934 18 457 241⁄

934 163⁄

934 165⁄

934 161⁄

934 167⁄

934 161⁄

934 161⁄

934 143⁄

934 141⁄

934 155⁄

934 151⁄

934 1411⁄

934 161⁄

4

16

4

16

4

4

4

2

8

2

16

4

426 241⁄

415 241⁄

412 241⁄

416 281⁄

412 341⁄

412 341⁄

375 281⁄

368 281⁄

397 281⁄

394 341⁄

373 341⁄

412 341⁄

8

8

8

8

8

8

8

8

8

8

8

8

8

613

613

613

613

714

867

867

714

714

714

867

867

867

Hook rigging shackles through holes in lifting brackets, as shown in Detail ‘‘A,’’

lifting brackets to be centered around the unit center of gravity. Use wood top

skidwhen rigging, toprevent riggingstraps from damagingunit. Remove4 screws

to slide wood support through rectangular hole in rail.

UNIT SIZE

50SS

018 247 112 36.5 926.0 17.0 431 28.2 715

024 276 125 36.5 926.0 14.3 364 28.2 715

030 293 133 36.8 926.0 14.7 372 28.2 715

036 309 140 36.5 926.0 15.5 393 28.2 715

042 339 154 36.5 926.0 15.5 394 32.2 817

048 371 168 36.5 926.0 14.8 376 38.2 969

060 398 180 36.5 926.0 14.4 366 38.2 969

SHIPPING

WEIGHT

Lb Kg in. mm in. mm in. mm

ABC

Fig. 12 — Suggested Rigging for Units with Optional Base Rail

NOTICE TO RIGGERS

14

All panels must be in place when rigging.

UNIT SIZE

50SX

024 309 140 36.5 926.0 15.0 380 32.2 817

030 312 141 36.5 926.0 14.8 376 32.2 817

036 330 150 36.5 926.0 15.8 402 32.2 817

042 348 158 36.5 926.0 15.6 397 38.2 969

048 379 172 36.5 926.0 14.9 378 38.2 969

060 398 180 36.5 926.0 14.4 366 38.2 969

SHIPPING

WEIGHT

Lb Kg in. mm in. mm in. mm

ABC

Table 1 — Physical Data — Unit 50SS

UNIT 50SS 018 024 030 036 042 048 060

REFRIGERANT R-22

Metering Device Acutrol™ System

Charge (lb) 2.60 2.75 3.40 4.30 5.20 6.50 7.00

OPERATING WEIGHT (lb)

Without Base Rails 208 237 254 270 300 332 359

With Optional Base Rails 228 257 274 290 320 352 379

COMPRESSOR TYPE Rotary Reciprocating Reciprocating Reciprocating Reciprocating Scroll Scroll

EVAPORATOR FAN Centrifugal — Direct Drive

Speeds 2333222

Nominal Rpm 825 1075 1100 1100 1100 1100 1100

Diameter (in.) 10 10 10 10 10 10 10

Width (in.) 9999999

Nominal Airflow (Cfm) 600 800 1000 1200 1400 1600 1995

Motor Hp

EVAPORATOR COIL

Rows...Fins/in. 3...15 3...15 3...15 3...15 3...15 3...15 4...15

Face Area (sq ft) 1.83 2.29 2.29 3.06 3.60 4.44 4.44

CONDENSER FAN Propeller — Direct Drive

Cfm 1700 1700 1900 1900 1900 2400 2400

Nominal Rpm 850 850 1050 1050 1050 1050 1050

Diameter (in.) 18 18 18 18 18 20 20

Motor Hp

CONDENSER COIL

Rows...Fins/in. 1...17 1...17 2...17 2...17 2...17 2...17 2...17

Face Area (sq ft) 5.95 5.95 5.95 5.95 7.00 8.66 8.66

FILTER SIZE (in.)*

Throwaway 20x20 20x20 20x24 20x24 24x24 24x30 24x30

*Recommended field-supplied filters are 1 in. thick.

1

⁄

4

1

⁄

8

1

⁄

4

1

⁄

8

1

⁄

2

1

⁄

4

1

⁄

2

1

⁄

4

3

⁄

4

1

⁄

4

3

⁄

4

1

⁄

3

1

1

⁄

3

Table 2 — Physical Data — Unit 50SX

UNIT 50SX 024 030 036 042 048 060

REFRIGERANT R-22

Metering Device Acutrol™ System

Charge (lb) 3.9 4.5 5.4 5.7 5.8 6.5

OPERATING WEIGHT (lb)

Without Base Rails 270 273 291 309 340 359

With Optional Base Rails 290 293 311 329 360 379

COMPRESSOR TYPE Scroll

EVAPORATOR FAN Centrifugal — Direct Drive

Motor Type Std Std Std Std Std* ICM ICM

Speeds 33332Variable Variable

Nominal Rpm 1075 1075 1100 1100 1125 — —

Diameter (in.) 10 10 10 10 10 10 10

Width (in.) 99999 9 9

Nominal Airflow (Cfm) 800 1000 1200 1400 1600 1600 1995

Motor Hp

EVAPORATOR COIL

Rows...Fins/in. 2...15 3...15 4...15 3...15 4...15 4...15

Face Area (sq ft) 3.60 2.70 3.60 4.44 4.44 4.44

CONDENSER FAN Propeller — Direct Drive

Cfm 2200 2200 2200 2400 2400 2400

Nominal Rpm 1100 1100 1100 1100 1100 1050

Diameter (in.) 20 20 20 20 20 20

Motor Hp

CONDENSER COIL

Rows...Fins/in. 2...17 2...17 2...17 2...17 2...17 2...17

Face Area (sq ft) 7.00 7.00 7.00 8.66 8.66 8.66

FILTER SIZE (in.)†

Throwaway 24x24 24x24 24x24 24x30 24x30 24 x 30

LEGEND

ICM — Integrated Control Motor

*460 v only.

†Recommended field-supplied filters are 1 in. thick.

NOTE: Standard motors are non-integrated control motors.

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

2

1

⁄

4

1

⁄

2

1

⁄

4

3

⁄

4

11

1

⁄

4

1

⁄

3

15

Loading...

Loading...