Page 1

Aquazone™ System Control Panel

Water Source Heat Pump Units

Installation Instructions

50RLP

CONTENTS

SAFETY CONSIDERATIONS

GENERAL

Aquazone System Control Panel Functionality

Stand-Alone Systems

CCN Systems Using PremierLink™ Controls

COMPONENTS

Aquazone System Control Panel Hardware

Water Source Heat Pumps with

PremierLink Controller Hardware

Field-Supplied Hardware

for Stand-Alone Systems

Field-Supplied Hardware for CCN Applications

INSTALLATION

Inspection

Mounting Location

Mounting

Wiring

Install Thermostat, Sensors and Switches

Install Loop Water Supply and Return

Temperature Sensors

Install Loop Water Pressure Sensor

Install Loop Water Flow Switch

Connect to CCN Communication Bus

START-UP

LID Power Up Display

Log On to the LID Display

Change the Default Password

Set the Clock

Configure Schedules

Program Set Points

Check System Parameters

Display Alarm History

Configure the Custom Programming Selections

Set the Aquazone System Control Panel

Controller Address

Log Off from Controller

LID Operation

Sequence of Operation

• HEAT REJECTION

• H EAT ADDITION

• WATER CIRCULATION

CONFIGURATION

Hardware Points

Software Points

Loop Supply Water Set Point

System Pressure Set Point

Global Dictionary

Heat Pump Default Configuration

Cool Source Default Configuration

Heat Source Default Configuration

Occupancy Configuration Screen

Network Time Schedule

Holiday Schedules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

IMPORTANT: Read the ent ire instruction manual before

starting installation.

. . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . .2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

. . . . . . . .2

. . . . . . . . . .2

. . . . . . . . . . . . . . . . . .7

. . . . . . . . . . . . . . . . . . . . . . . . . .8

. . . . . .9

. . . . . . . . . .13

. . . . . . . . . . . . . . . . . . . . . . . . . . . .13

. . . . . . . . . . . . . . . .13

. . . . . . . . . . . . . . . . . . . . .13

. . . . . . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . .15

. . . . . . . . . . . . . . . . . . . . . . . . . .16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

. . . . .16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

. . . . . . . . . . . . . . . . . . . . . . .24

. . . . . . . . . . . . . . . . . . . . . . . . .24

. . . . . . . . . . . . . . . . . . .26

. . . . . . . . . . . . . . . . .26

. . . . . . . . . . . . . . . . .26

. . . . . . . . . . . . . . . . . .26

. . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Page

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance

functions. All other operations should be performed by trained

service personnel. When working on air-conditioning equipment, observe precautions in the literature, tags and labels

attached to the unit, and other safety precautions that may

apply.

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock or

other conditions which may cause personal injury or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified installer or agency must use factory-authorized kits or

accessories when modifying this product. Refer to the individual instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have fire

extinguisher available. Read these instructions thoroughly and

follow all warnings or cautions attached to the unit. Consult

local building codes and the National El ectrical Code (NEC)

for special installation requirements.

Understand the signal words — DANGER, WARNING,

and CAUTION. DANGER identifies the most serious

hazards which will result in severe personal injury or death.

WARNING signifies hazards that could result in personal

injury or death. CAUTION is used to identify unsafe practices,

which would result in minor personal injury or product and

property damage.

Recognize safety information. This is the safety-alert

symbol ( ). When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

Electrical shock can cause personal injury or death. Before

installing or servicing system, always turn off main power

to system. There may be more than one disconnect switch.

Turn off accessory heater power if applicable.

GENERAL

IMPORTANT: The installation of water source heat pump

units and all associated components, parts, and accessories

which make up the installation shall be in accordance with

the regulations of ALL authorities having jurisdiction and

MUST conform to all applicable codes. It is the responsibility of the installing contractor to determine and comply

with ALL applicable codes and regulations.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Ta b 5 a 5 a

PC 111 Catalog No. 535-00077 Printed in U.S.A. Form 50RLP-1SI Pg 1 1-03 Replaces: New

Page 2

The Aquazone™ System Control Panel is a single packaged

system control panel for use with Aquazone water source heat

pumps (WSHPs) in stand-alone or direct digital control

applications using the Carrier Comfort Network (CCN). The

Aquazone system control panel controls and monitors the

operation of the water source heat pumps, the ancillary heat

rejection, the heat addition, and the system pumps to coordinate entire system operation. The Aquazone System Control

Panel is used with the following units: 50HQL, KQA, KQD,

RDS, RHC, RHR, RHS, RTG, RVC, RVR, RVS, RWS,

VQA, VQD.

The Aquazone system control panel includes a preprogrammed 6400 main logic comfort controller as the central

processing unit. The Aquazone system control panel is compatible for use in boiler/tower (water loop) or geothermal (ground

loop, ground water) water source heat pump arrangements.

Other system hardware components are specified in the

50RLP model nomenclature. Components can be added to customize the Aquazone System Control Panel for the specific

type of functionality desired, including staged heat rejection

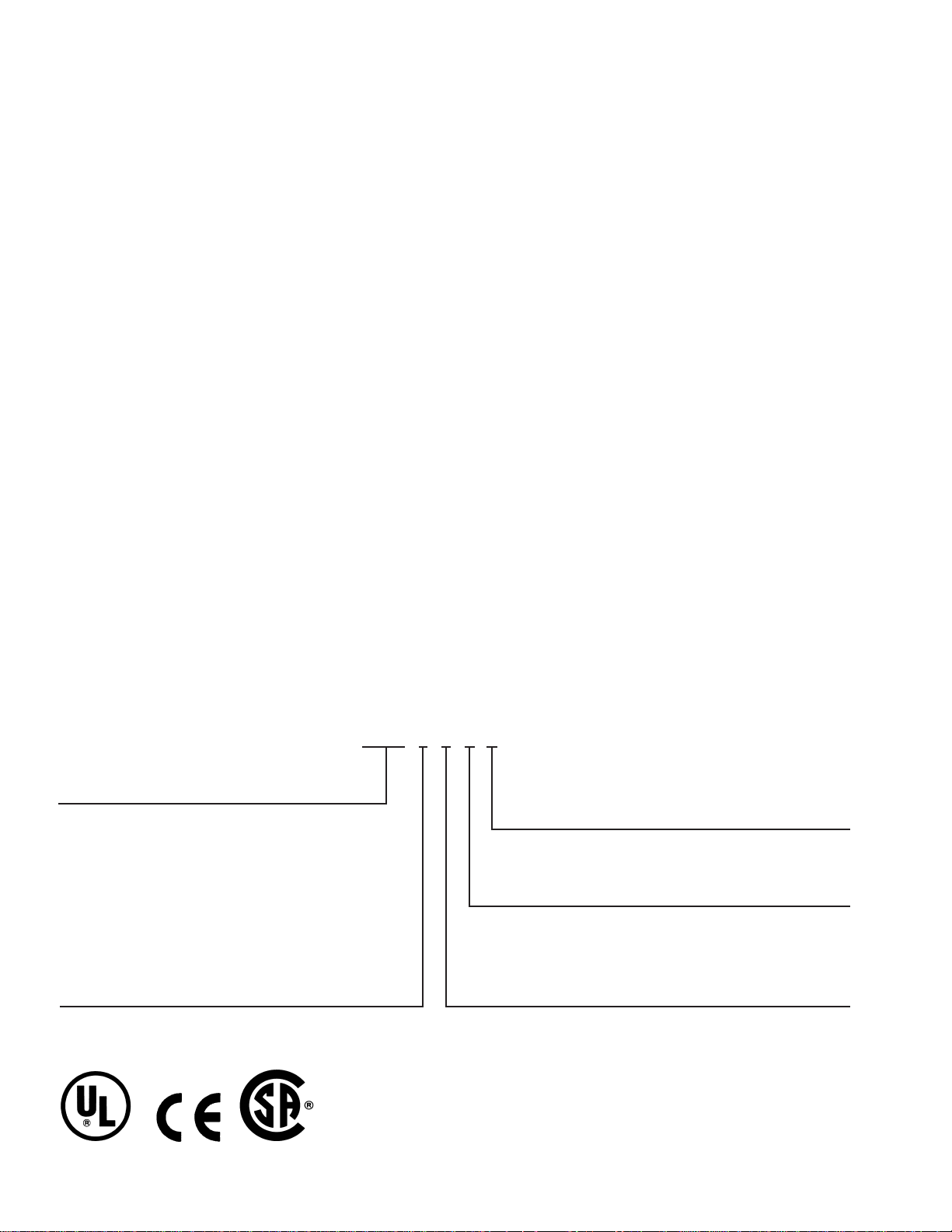

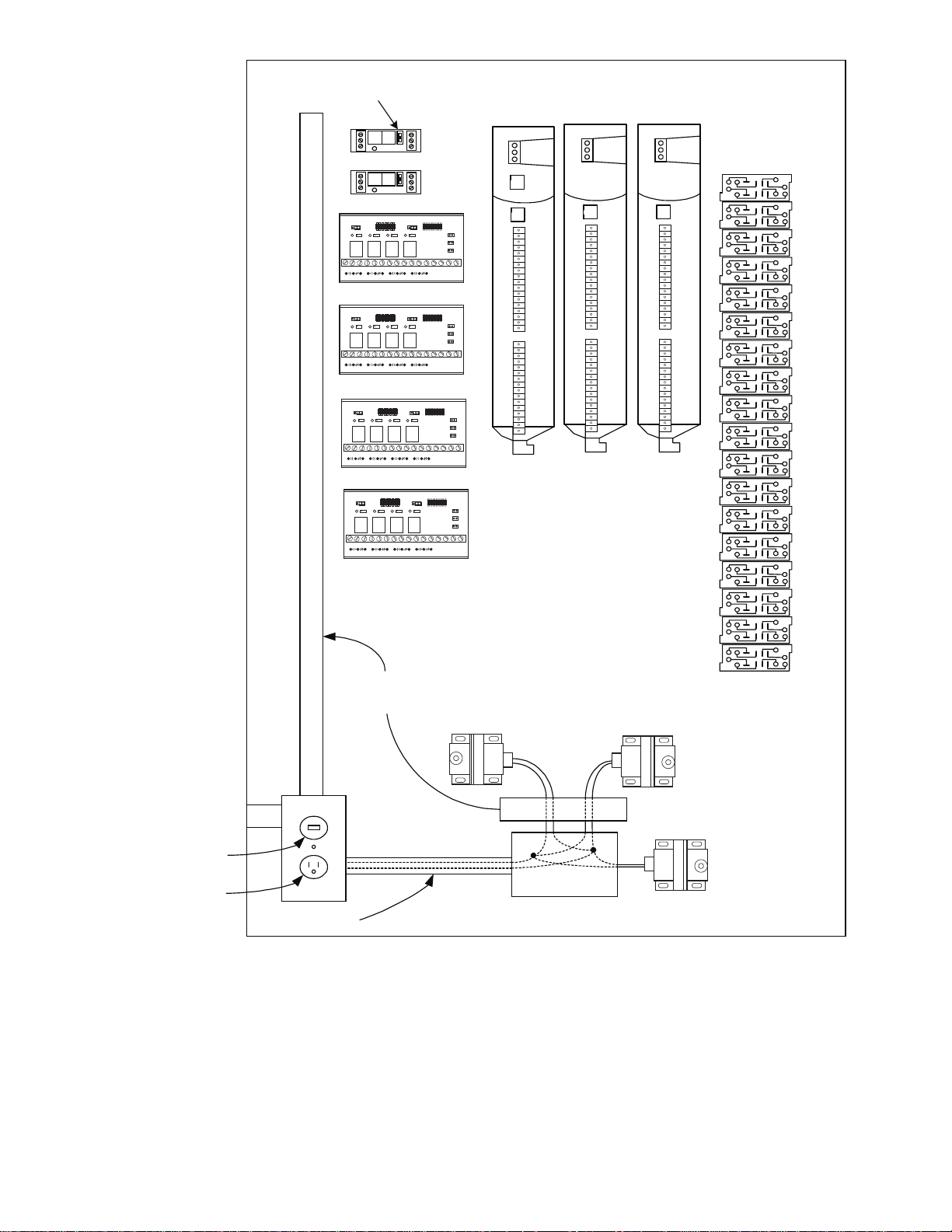

and addition, dual or variable speed pump operation, and standalone or CCN installations. See Fig. 1.

Aquazone System Control Panel Functionality —

Functionality includes the ability to control up to two

water-circulating pumps and monitor water temperature to

initiate up to eight stages of cooling tower and/or boiler operation. The system control panel has the capability to work with

variable speed pumping arrangements for maximum energy

efficiency. In addition, the panel provides system control for

both stand-alone and DDC water source heat pump systems

(units installed with a factory-mounted PremierLink™ CCN

controller).

Stand-Alone Systems —

trol strategy, non-communicating Aquazone water source heat

pump thermostats are utilized to initiate the operation of

individual water source heat pump equipment for eac h zone.

The Aquazone System Control Panel can be ordered with the

appropriate hardware to accommodate and initiate scheduled

control of either 10 or 18 zones of WSHP units in stand-alone

operation. See Fig. 2.

In a stand-alone type of con-

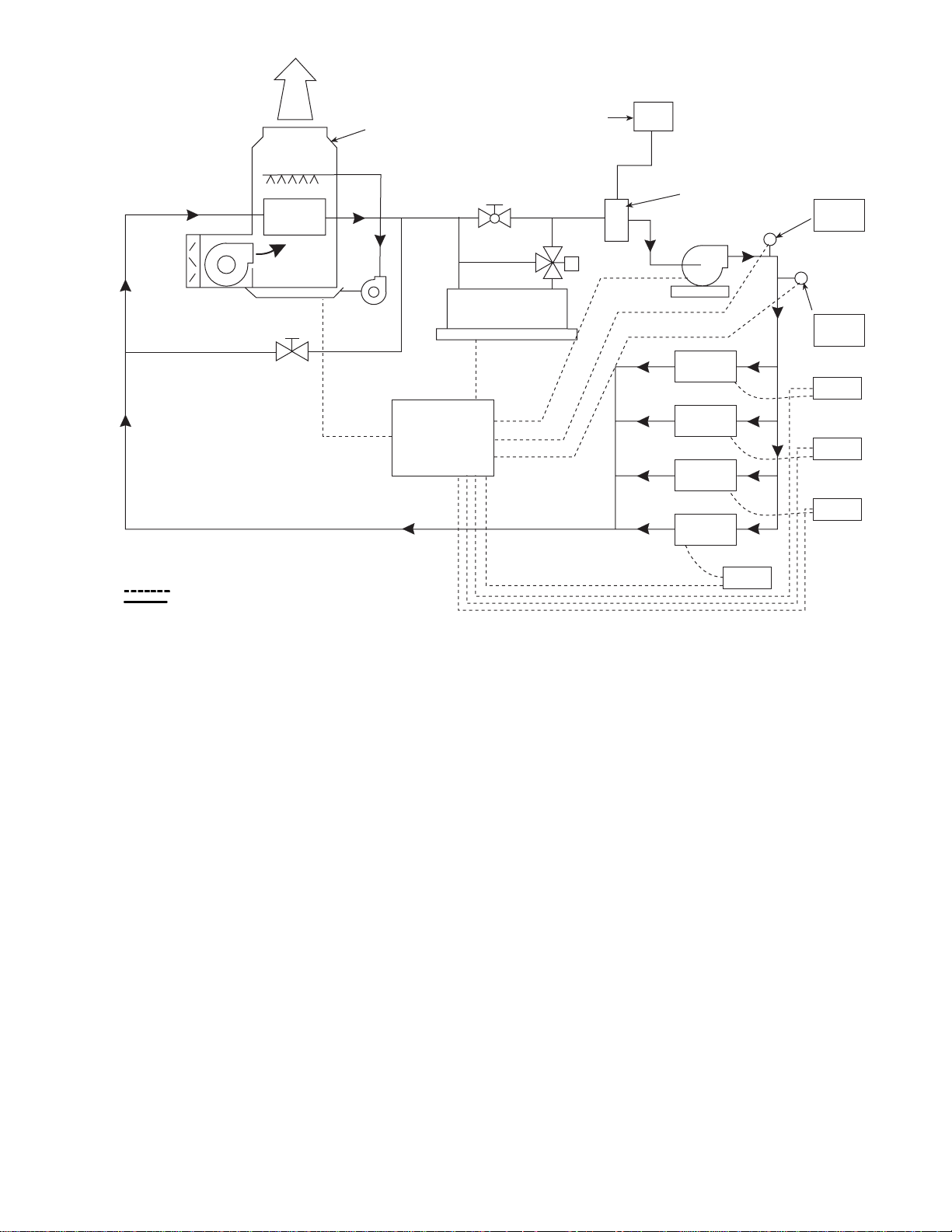

CCN Systems Using PremierLink Controls —

To

implement a direct digital control type of water source heat

pump system strategy , individual WSHP units are ordered with

a factory-installed PremierLink controller. The Aquazone system control panel has been pre-programmed to w ork specifically with th e Pr e m ie r L in k co ntroller to trans f er a n d c o ntrol all

modes of cooling/heating operation, transmit unit number,

zone temperature, zone temperature set points, discharge air

temperature, fan status, stages of heating, stages of cooling,

leaving water temperature, and alarm status information. See

Fig. 3.

COMPONENTS

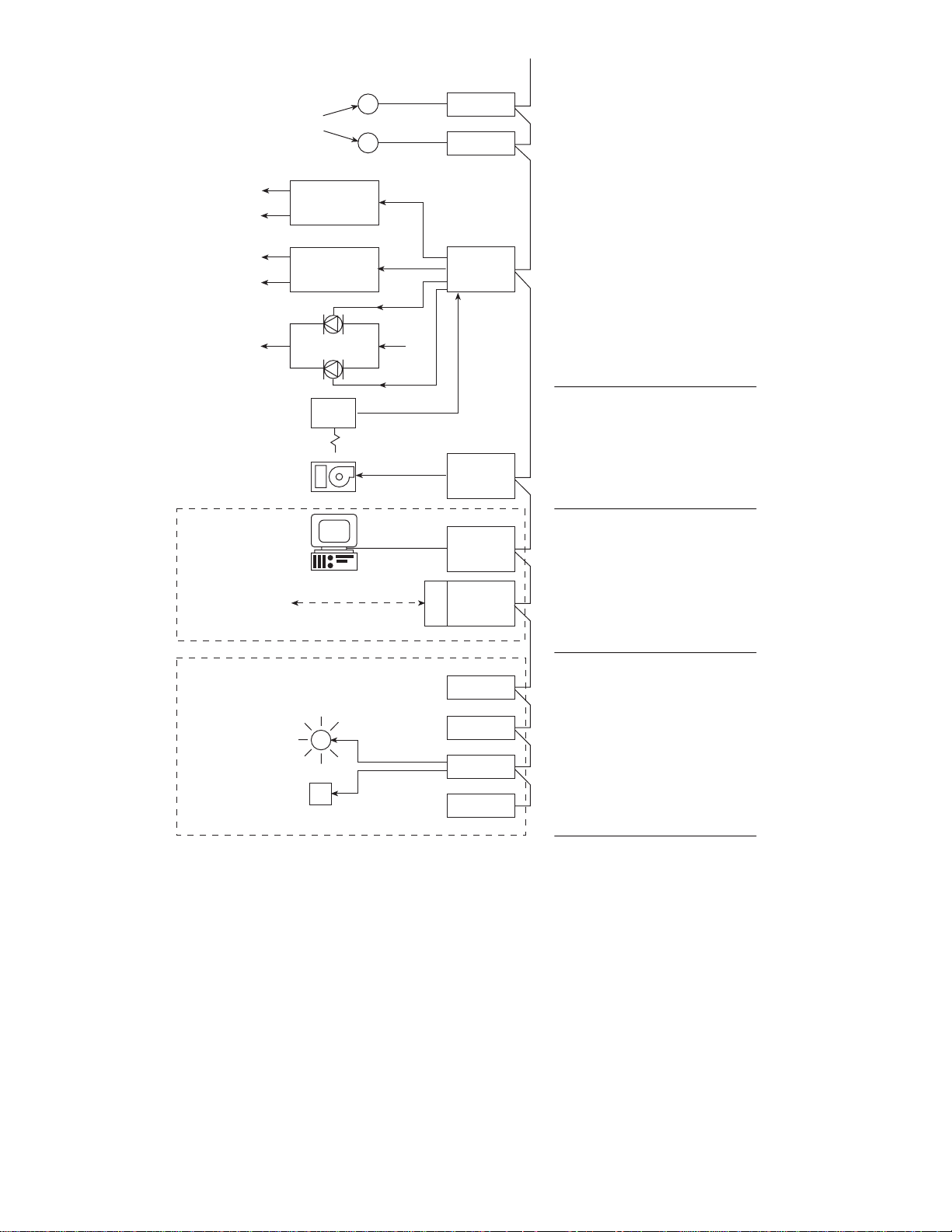

Aquazone System Control Panel Hardware —

The 50RLP Aquazone System Control Panel package consists

of the following hardware. See Fig. 4.

ENCL OS U RE — The Aquazone system control panel enclosure is constructed of perforated 16-gage steel and finished in a

gray powder-coated finish. The panel has a height of 42 in., a

width of 30 in. and a depth of 7 inches.

PROC ESSO R — The central processing units for the Aquazone system control panel are Carrier 6400 Comfort Controllers. The Comfort Controller provides general purpose HVAC

control and monitoring capability in a stand-alone or network

environment using closed-loop, direct digital control. The 6400

Comfort Controller has been pre-programmed to work in either

stand-alone or CCN water source heat pump system installations. Specifications for the 6400 Comfort Controller may be

found in the Comfort Controller literature.

PUMP CON TROL RELAYS — For both stand-alone and

CCN systems (based on the type of pumping operation

required) the Aquazone system control panel can be orde red

with a combination of multi-voltage control relays to provide

start/stop or lead/lag operation for single or dual pumps. The

combination desired is specified in the 50RLP model nomenclature in digit 8. See Fig. 1.

50RLP 0 0 0 0

Unit

50RLP – Aquazone System Control Panel

System Heat Rejection

0 – 2-Stage Card (2 Stages of Cooling Tower Operation)

1 – 4-Stage Card (4 Stages of Cooling Tower Operation)

2 – 2- and 4-Stage Cards (6 Stages of Cooling Tower Operation)

3 – Two 4-Stage Cards (8 Stages of Cooling Tower Operation)

4 – No Card, Variable Speed Cooling Tower Operation

*Option is utilized with Aquazone Thermostat for each WSHP unit.

†Option is utilized with PremierLink DDC control option on individual WSHP units.

**Accepts signals from a variable frequency device.

Fig. 1 — Model Number Nomenclature

WSHP Zone Operation

0 – 10 Relays, Control 10 Zones for Stand-Alone WSHP Units*

1 – 18 Relays, Control 18 Zones for Stand-Alone WSHP Units*

2 – No Relays, Carrier Comfort Network (CCN) System†

System Pumping Operation

0 – Both Relays, Start/Stop or Lead/Lag Operation for Single or

Dual Pumps

1 – No Relays, Variable Frequency Pump Operation**

System Heat Addition

0 – 2-Stage Card (2 Stages of Boiler Operation)

1 – 4-Stage Card (4 Stages of Boiler Operation)

2 – 2 and 4-Stage Cards (6 Stages of Boiler Operation)

3 – Two 4-Stage Cards (8 Stages of Boiler Operation)

4 – No Card, Modulating Valve Operation for Steam or

Hot Water

2

Page 3

COOLING

TOWER

BOILER

EXPANSION

TANK

AIR SEPARATOR

PUMP

WSHP

FLOW

SENSOR

TEMP.

SENSOR

T-S TAT

AQUAZONE

SYSTEM

CONTROL

PANEL

LEGEND

Control Wiring

Loop Water Piping

Fig. 2 — Typical Stand-Alone WSHP System

If variable frequency drives are utilized for system pumps,

no pump control relays are specified. Each relay contains a red

light-emitting diode (LED), which indicates the relay coil is

energized. The pump control relays are located in the upper left

hand corner of the system control panel. See Fig. 4. Wiring is

shown in Fig. 5A-5C. Specifications for the pump control

relays are as follows:

Voltage Input: 24 vdc @ 15 mA, 14 vac @ 30 mA,

115 vac @ 20 mA, 230 vac

@ 20 mA.

Contact Rating: 10 A res. @ 115 vac,

7 A res. @ 230 vac/28 vdc,

1

N.O.:

/6 hp @ 115 vac.

T emperature Range: –60 F to 185 F

Indication: LED

Enclosure: 18 ga. metal back

Dimensions: 5.125-in. x 3.125-in. x 2.5-in.

(HxWxD) or 5.125-in. x 9.5-in. x

2.5-in. (HxWxD)

OUTPUT TRANSDUCERS — For both stand-alone and

CCN systems (based on the stages of heat addition or rejection

required) the Aquazone™ system control panel can be ordered

with a combination of 2-stage and 4-stage output transducers to

provide 2, 4, 6, or 8 stages. The combination desired i s specified in the 50RLP model nomenclature in digit 6 to specify heat

rejection stages and digit 7 to specify heat addition stages. See

Fig. 1. If variable speed cooling tower fan operation and/or

WSHP

T-S TAT

WSHP

T-S TAT

WSHP

T-S TAT

modulating valve operation for steam or water a re utilized, no

output transducer card is specified. The output transducer is a

solid-state multi-stage device used for staging control from a

single analog signal. Output transducers are located in the

upper left hand corner of the Aquazone System Control Panel

underneath the pump control relays. See Fig. 4. Specificat ions

for the pump control relays are as follows:

Supply Voltage: 24 vac ± 10% @ 100 mA,

24 vdc ± 10% @ 50 mA

Input Signal: 4-20 mA

Output: 2 SPDT relays for 2-stage,

4 SPDT relays for 4-stage.

Relay rating: 5A @ 120 vac

Accuracy & repeatability: ± 1%

Set point adjustment: 25-turn potentiometers

Input impedance: 250 W (mA input), 10 kW

(V input)

T emperature Range: 32 F to 158 F

Humidity Limit: 5 to 95% relative humidity

non-condensing

Dimensions: 3.25-in. x 3.5-in. x 1.375-in.

(HxWxD) for 2-stage, 3.25-in. x

5.5-in. x 1.375-in. (HxWxD)

for 4-stage

Relay Differential: 0.5 mA or 0.375 V.

3

Page 4

ZONE 2

ZONE 1

ROOM SENSOR

S

S

WSHP 2

WSHP 1

PREMIERLINK

WSHP CONTROLLER

PREMIERLINK

WSHP CONTROLLER

FAN(S)

SPRAY PUMP

STAGE 2

STAGE 1

MAIN

STANDBY

LOOP TEMP

VENTILATION

FAN

COMPUTER

COMPUTER

–PC ACCESS

LOCAL

REMOTE

TOWER

BOILER

PUMPS

LT

TELEPHONE

LINE

AQUAZONE SYSTEM

LCP

LOOP CONTROL PANEL

(CARRIER COMFORT

CONTROLLER)

CARRIER COMFORT NETWORK BLDG.

MASTER CONTROL PANEL

MCP

R

T

M

(CARRIER COMFORT

CONTROLLER)

REPEATER: INTERFACE

PC TO NETWORK

TELINK WITH

MODEM CONTROLLER

DATA COLLECTION

LOADSHED

COMFORT CONTROLLER

TENANT BILLING

LIGHTS

EQUIPMENT

D.C.

L

E

L.S.

CC6400

T.B.

BLDG./SYST. MANAGEMENT

Fig. 3 — CCN Water Source Heat Pump System with PremierLink™ Controllers

4

Page 5

g

g

g

g

y

FLT SEQ

FLT SEQ

MODE

A

MODE

A

FLT SEQ

A

A

MODE

A

FLT SEQ

A

MODE

A

A

HOA

Pump 1

Pump 2

B

C

B

Cool Sta

B

C

B

Cool Stages 2

B

C

B

Heat Sta

B

C

B

Heat Sta

Processor Input/Output 1 Input/Output 2

Low Volta

e

Zone Thermostat

Control Rela

UCS-421

MODE

INPUT

FLT SEQ

TYPE

H3

MODE

D

UCS-421

D

UCS-421

D

CH

V

H4

H5

MA

24V

INPUT

CHAIN

SIGNAL

POWER

OUTPUT

COMMON

INPUT

TYPE

H3

CH

V

H4

H5

MA

24V

INPUT

CHAIN

SIGNAL

POWER

OUTPUT

COMMON

INPUT

TYPE

H3

CH

V

H4

H5

MA

24V

INPUT

CHAIN

SIGNAL

POWER

OUTPUT

COMMON

D

C

es 1

MODE

FLT SEQ

D

C

FLT SEQ

D

C

s

es 1

UCS-421

MODE

INPUT

FLT SEQ

TYPE

H3

D

C

CH

V

H4

H5

MA

24V

INPUT

CHAIN

D

SIGNAL

POWER

OUTPUT

COMMON

es 2

POWER SWITCH

CONVENIENCE

OUTLET

PANDUCT®

WIRING DUCT

Transformer 1 Transformer 2

CONDUIT

Fig. 4 — Aquazone™ System Control Panel

Trans former 3

5

Page 6

COMPLETE C CONTROL

(IN WSHP)

RYW OGC

SYSTEM

ZONE

RELAYS

(1-18)

NO

R

W1

G

THERMOSTAT

Y1

W2

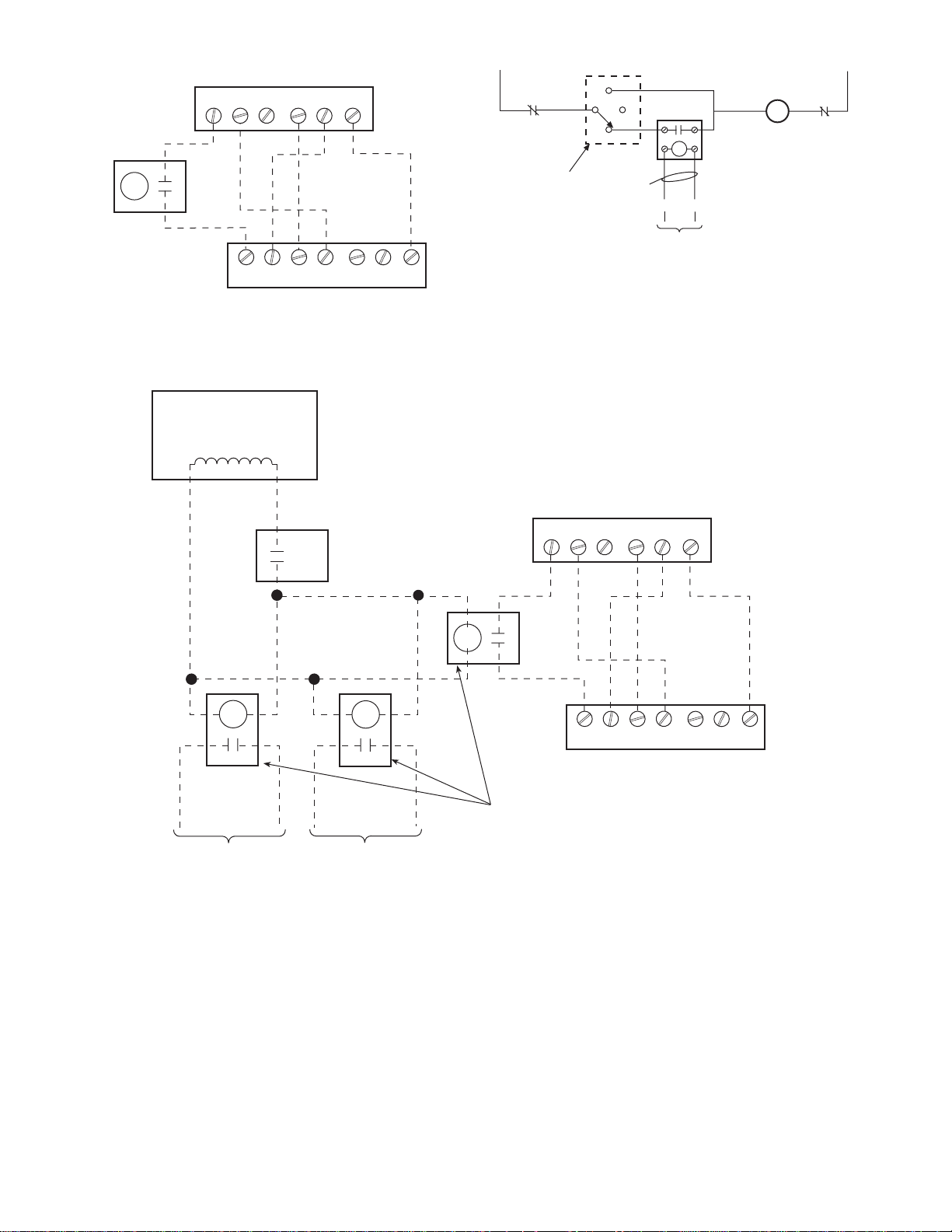

Fig. 5A — System Zone Relay Wiring

(Aquazone™ System Control Panel Used to

Control a Single Thermostat)

PANEL 24 VAC POWER

Y2

X1

H

FIRE

FREEZE,

ETC.

SWITCH S-1

C

Fig. 5C — Control Relay Wiring for Pump

Start/Stop or Cooling Tower Fan

O

A

TP WIRES

L

(+)

(-)

TO COMFORT

CONTROLLER

STARTER

COIL

M

CONTROL RELAY

OR

STAGING CARD

OL’

X2

s

N

TO OTHER WSHP COMPLETE C CONTROLS AND THERMOSTATS

H

SYSTEM ZONE

RELAYS

(1-18)

Fig. 5B — System Zone Relay Wiring

(Aquazone System Control Panel Used to Control Multiple Thermostats)

COMPLETE C CONTROL

RYW OGC

TYPICAL

FIELD-INSTALLED

RELAYS

(ONE PER WSHP)

(IN WSHP)

G

R

W1

THERMOSTAT

Y1

W2

Y2

C

ZONE THERMOSTAT CONTROL RELAYS — A unique

feature of the Aquazone system control panel is the capability to

add zone ther mostat contr ol rela ys. T his feat ure is used w hen th e

Aquazone system control panel i s utilized in a st and-alone type

of installation. Eithe r a set of 10 or 18 relays can be selected

from the 50RLP model nomenclat ure in digi t 9 to control ei the r

10 or 18 zones, respectively. If selected in the model nomencl ature, zone control relays are located on the right hand side of the

system control panel. See Fig. 4. See Fig. 5A-5C for wiring.

CONTROL TRANSFORMERS — Control transformers are

supplied with the Aquazone system control panel and are wired

to the power switch and convenience outlet. The control

transformers provide power to the nominal 24 VAC circuit in

Aquazone system control panel. The contractor will supply the

primary power to the power switch and conve nience outlet in

the field. Transformers include a manual reset button for resetting the circuit breaker. Control transformers are located on the

bottom half of the system control panel. Specifications for the

control transformers are as follows:

Primary: 120/208/240 vac

Secondary: 24 vac

Frequency: 60 Hz

MOUNTING RAILS AND WIRING DUCT — All exposed

panel wiring is low voltage. Line voltage wiring to the control

transformers, control circuits for pumps, cooling tower fans,

and boilers is factory-installed in conduit, using wiring duct,

and on mounting rails.

6

Page 7

POWER RECEPTACLE — A power receptacle is provided

in the Aquazone™ system control panel and is located in the

bottom left corner. Specifications for the power receptacle are

as follows:

Power: 120 vac

Rating: 15A @ 120 vac for receptacles

15A @ 120 vac for switch

250 V for fuse

WATER TEMPERATURE SENSORS — Two water temperature sensors and thermowells have been provided with the

Aquazone system control panel. The first sensor is utilized to

read loop supply water temperature, such that the system

control panel can adjust heat rejection and heat addition

equipment to maintain the loop temperature based on user

input. The second sensor may be installed to monitor return

loop water temperature. The active sensing element is a highly

stable precision thermistor material accurate to within ± 0.36 F.

The temperature range of the sensor is 10 F to 230 F.

WATER PRESSURE SENSOR — A water pressure sensor is

provided with the Aquazone system control panel with variable

speed pumping only , and is utilized to operate variable frequency drives for system pumps. The water sensor senses system

pressure and the pressure is sent to the system control panel.

The Aquazone system control panel speeds up or slows down

the variable frequency drive to control the pump in order to

keep the system at the correct pressure.

When a variable frequency drive is used for system pumping, the Aquazone water source heat pumps are typically

furnished with a factory or field-mounted solenoid valve that

allows water to flow though the heat pump. When solenoid

valves open, the system pressure drops, which results in the

variable frequency drive speeding up to allow the pump to

provide more water. When solenoid valves close, the system

pressure rises, which results in the variable frequency drive

slowing down to allow the pump to provide less water.

WATER FLOW SWITCH — A factory-provided wat er flow

switch is included with the Aquazone system control panel and

must be field-installed in the water loop piping. The flow

switch is connected to the control panel by a cable with a

watertight connector. This device uses a triac output that cannot

be connected directly to the Main Base Board. Therefore, a

control relay is used to signal the Main Base Board that loop

water flow is detected. The switch contains a fifteen-turn

adjustment potentiometer, to be used to adjust the set point in a

range of 3 to 60 cm/sec. The factory set point is 20 cm/sec.

The potentiometer switch may be adjusted down to zero

velocity (no flow) or above 60 cm/sec, however operation

in those ranges may not be linear or reliable.

Water Source Heat Pumps with PremierLink™

Controller Hardware —

tion is implemented, a factory-mounted PremierLink controller

is provided with the water source heat pump units. The package

from the factory includes the PremierLink controller, supply air

temperature sensor , and leavi ng water t emperatur e sensor.

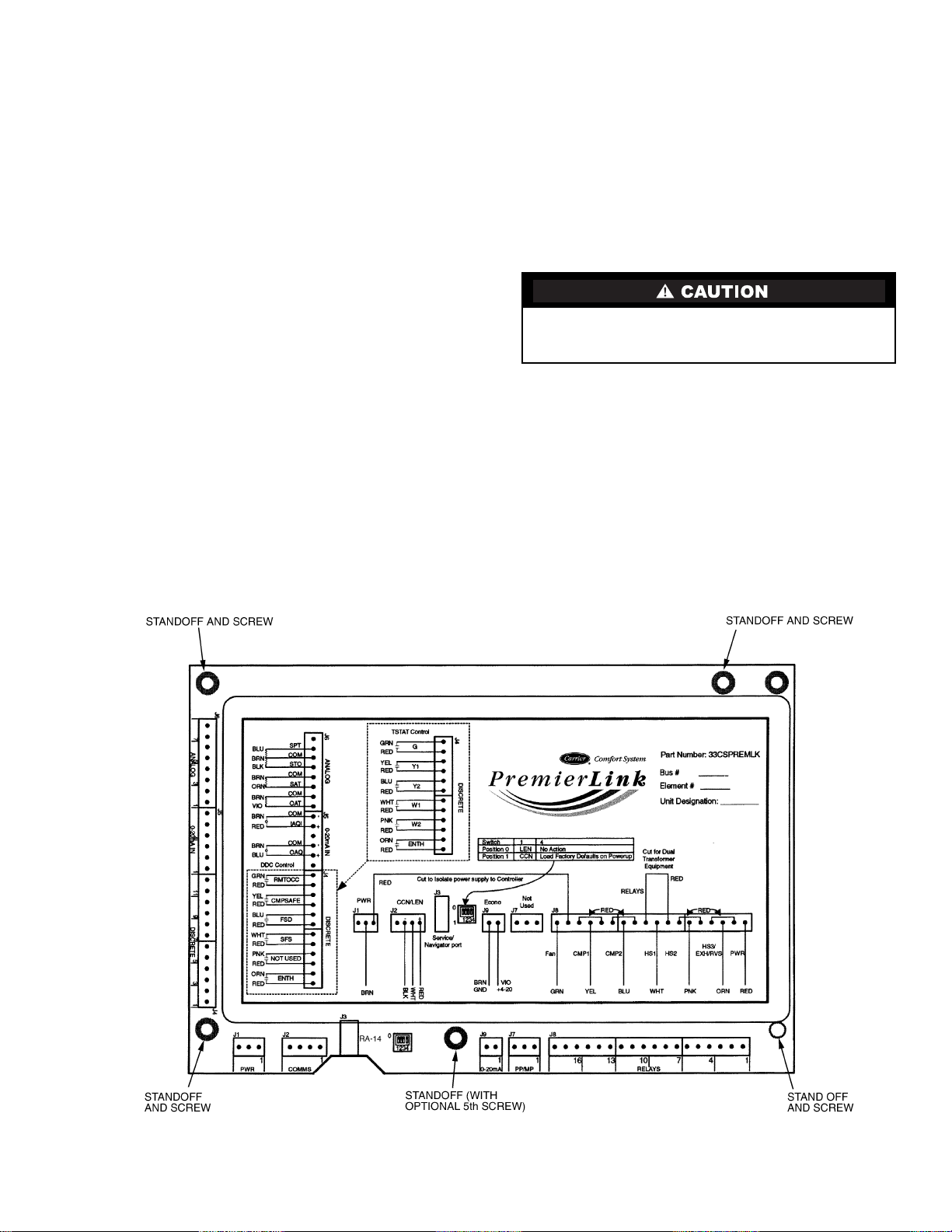

PREMIERLIN K CONTROLLER — PremierLink controllers

can be provided with any Aquazone water source heat pump

product by selecting this option in the model nomenclature.

See Fig. 6.

The PremierLink controller is provided with the Complete C

unit controller . F actory sup plied wiring is i llustrated in F ig. 7.

When a CCN system installa-

Fig. 6 — PremierLink™ Control Module

7

Page 8

Carrier’s diagnostic standard tier display tools such as

Navigator™ or Scrolling Marquee can be used with the

PremierLink™ controller. Access is available via an RJ-11

connection or a 3-wire connection to the communication bus.

Computers equipped with Carrier user interface software such

as Service Tool, ComfortVIEW™, or ComfortWORKS®

software are used to int erface with the system. W hen used as

part of the CCN, other devices such as the CCN data transfer,

Linkage Thermostat, or system control panel comfort

controller can read data from or write data to the PremierLink

Controller.

SUPPLY AIR TEMP ERATURE SENSOR — A factoryinstalled supply air temperature sensor is provided with the

PremierLink controller. Wiring of the temperature sensor is

shown in Fig. 7. The sensor is a 10 kohm thermistor, which is

protected by a stainless steel housing probe. Probe is

1

/4-inch in

diameter and 1.5-in. long. Wire is 22 AWG (American Wire

Gage), 7/30 copper wire, PVC white, 2 conductor type.

LEAVING WATER TEMPERATURE SENSOR — A factoryinstalled leaving water temperature sensor is provided with

PremierLink controller. Wiring of the temperature sensor is

shown in Fig. 7. The sensor is a 10 kohm thermistor is protected by a stainless steel housing probe. Probe is

1

/4-inch. in diameter and 1.5-in. long. Wire is 22 AWG , 7/30 copper wi re, PVC

white, 2 conductor type.

Field-Supplied Hardware for Stand-Alone Systems —

stand-alone configuration, individual Aquazone thermostats

(or compatible equivalent) are required for water source heat

pump units.

AQUAZONE THERMOSTAT — A field-supplied Carrier

thermostat is required to maintain space temperature for standalone water source heat pump installations. There are five

different Aquazone thermostats available for stand-alone applications. See Table 1.

T o utilize the Aquazone™ system control panel in a

LEGEND

CR —

LW T —

SAT —

SPT —

NOTE: Reversing valve is on in Cooling

mode.

Control Relay

Leaving Water Temperature Sensor

Supply Air Temperature Sensor

Space Temperature Sensor

J6

S

P

T

J5

L

S

A

W

T

T

PREMIER

LINK

J8

PWR

J1

CMPSAFE

PWR

HS1/EXH/RVS

CMP1

FAN

J4

CR

CR

COMPLETE

C

CONTROL

Y

W

O

G

R

C

AL1

AL2

A

Fig. 7 — PremierLink Controller Applications with Complete C Control

8

Page 9

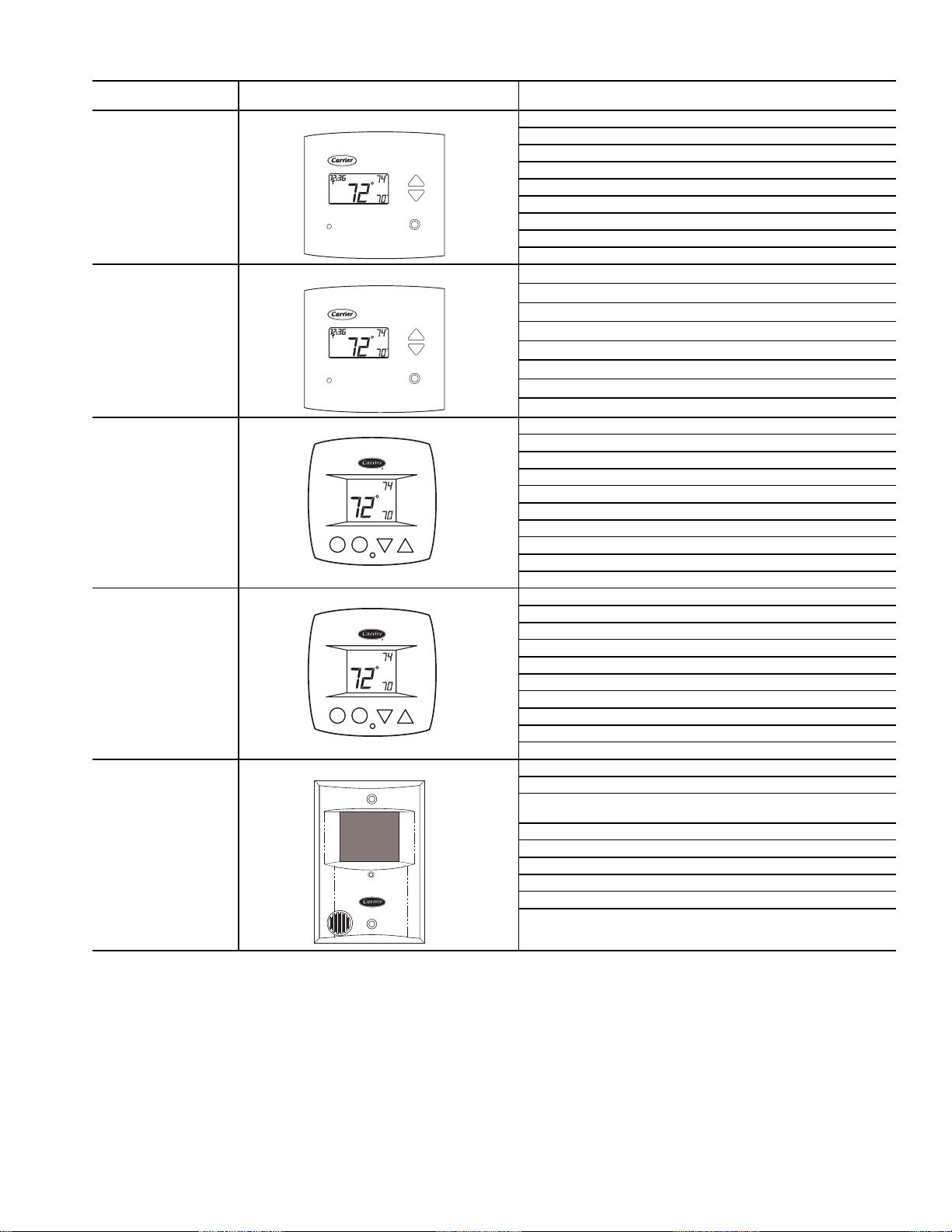

Table 1 — Aquazone™ Thermostats

ORDERING

NUMBER

50QE900-220WS

50QE900-220LA

50QE900-NPWS

50QE900-511WS

50QE900-250FS

THERMOSTAT TYPE FUNCTIONS

Aquazone 7-Day Programmable 2 stages heating, 2 stages cooling, auto changeover

Fahrenheit and Celsius temperature scales

Carrier

AUTO

®

Pm

COOL

HEAT

4 settings per day

24 vac

Backlit LCD

Keypad

5-minute compressor protection

NEVERLOST™ memory

3 security levels

Aquazone Light Activated, 7-Day Programmable

2 stages heating, 2 stages cooling, auto changeover

4 settings per day

Carrier

AUTO

®

Pm

COOL

HEAT

24 vac

Keypad lockout

5-minute compressor protection

Occupied with lights on, unoccupied with lights off

NEVERLOST memory

3 security levels

Aquazone Non-programmable 2 stages heating, 2 stages cooling, auto changeover

5-minute built-in compressor protection

R

Locking cover included

Fahrenheit and Celsius temperature scales

AUTO

COOL

HEAT

Large display

Keypad lockout

Backlit display or B terminal

NEVERLOST memory

Dual set point with adjustable deadband

Back plate with terminals

Aquazone 5-1-1 day programmable 2 stages heating, 2 stages cooling, auto changeover

5-minute built-in compressor protection

R

Keypad lockout and locking cover included

Fahrenheit and Celsius temperature scales

AUTO

COOL

HEAT

4 settings per day

Backlit and configurable display

O or B terminal

NEVERLOST memory

Dual set point with adjustable deadband

Self prompting program

Aquazone Flush Mount, 7-Day Programmable 2 stages heating, 2 stages cooling, auto changeover

4 settings per day, Holiday/vacation programming

Self prompting program with copy command locking

cover plate with tamperproof screws

Fahrenheit and Celsius temperature scales

Set point limiting

Mounts flush to the wall

NEVERLOST memory

Dual set point with adjustable deadband and B terminal

Remote sensor capability (sold separately): Wireless,

(33CSRFS-RC transmitter and 33CSRFS-RE receiver),

wired with override (33CSCEN-WB), duct mounted (33CSSEN-DS)

Field-Supplied Hardware For CCN Applications —

the water source heat pump unit is configurable with a variety

of Carrier space temperature sensors.

SP A CE TEMPERATURE SENSOR (SPT) — A field-supplied

Carrier space temperature sensor i s required to mai ntain spac e

temperature in sensor mode. There are three sensors ava ilable

for this application: the 33ZCT55SPT Space Temperature

Sensor with Override Button, the 33ZCT56SPT Space

Temperature Sensor with Override Button and Set Point

Adjustment, and the 33ZCT58SPT T58 Communicating Room

The factory-installed PremierLink™ controller for

Sensor with Override Button, Set Point Adjustment, and

Manual fan control.

INDOOR AIR QUALITY CO

quality sensor is required for CO

SENSOR — An indoor air

2

level monitoring. Three

2

different CO2 sensors are available for this application: the

33ZCSENCO2 sensor is an indoor, wall-mounted sensor with

an LED display, the 33ZCT55CO2 sensor is an indoor,

wall-mounted sensor without display (also includes a space

temperature sensor with override button), the 33ZCT56CO2

sensor is an indoor, wall-mounted sensor without display (also

includes a space temperature sensor with override button and

temperature offset).

9

Page 10

INSTALLATION

Inspection —

fects that may have occurred during shipping. If there is any

damage, contact your local representative before proceeding.

Mounting Location —

panel should be located indoors. Be sure the location preve nts

moisture and rain from coming into contact with the internal

hardware. Avoid areas where excessive moisture, corrosive

fumes, or vapors are present. The ambient temperature range at

the location should be between 32 to 125 F. Do not install the

Aquazone system control panel in electrical interference or

high radio frequency areas. Select a location which will be safe

from water damage and allow sufficient access for service and

Inspect the package contents for visual de-

The Aquazone™ system control

wiring. For proper service of the Aquazone system control

panel, the following service clearances are recommended:

Height: 54 in.

Width: 42 in.

Depth: 36 in.

Mounting —

Mount the Aquazone system control panel to

a wall with screws or bolts (not provided). Attach through the

mounting holes provided in enclosure. Provide clearance to

open key-locked access door. Refer to the mounting sheet included with the Aquazone system control panel for additional

detailed mounting instructions.

Wiring —

The Aquazone System Control Panel inputs and

outputs are shown in Table 2.

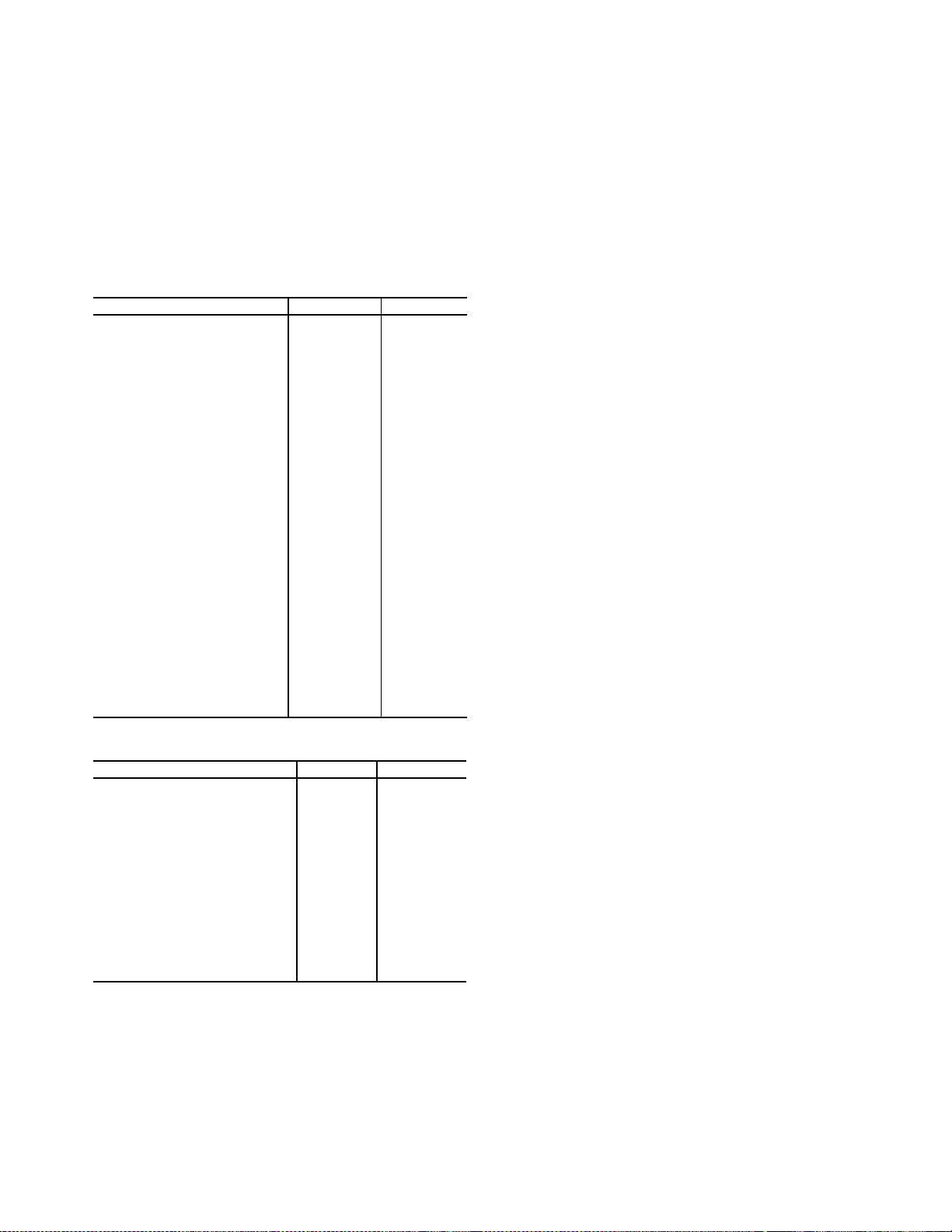

Table 2 — Aquazone System Control Panel Inputs and Outputs

PARAMETER POWER INPUT/OUTPUT TERMINAL

Processor Module

Loop Water Flow 24 vdc Input FLOW

System Supply Water Temp. 10 K thermistor Input SSWT

System Return Water Temp. 10 K thermistor Input SRWT

System Differential Pressure 4-20 mA Input SDP

Remote Occupied Mode 24 vdc Input RMTOCC

System Shut Down 24 vdc Input ALLSYS

Override Input for Zones 1 & 2 24 vdc Input OVRIZ1, OVRIZ2

Pump Number 1 & 2 Speeds 4-20 mA Output PUMP1, PUMP2

Cooling Tower 1 & 2 Speed/Level 4-20 mA Output CTL1, CTL2

Heat Source 1 & 2 Speed/Level 4-20 mA Output BLRL1, BLRL2

System Enable for Zone 1 & 2 24 vdc Output SYSZ1, SYSZ2

First Optional I/O Module

Override Input for Zone 3 to 10 24 vdc Input OVRIZ3 — OVRI Z10

System Enable for Zone 3 to 10 24 vdc Input SYSZ3 — SYSZ10

Second Optional I/O Module

Override Input for Zone 11 to 18 24 vdc Input OVRIZ11 — OVRIZ18

System Enable for Zone 11 to 18 24 vdc Input SYSZ11 — SYSZ18

Pump Control

Occupancy Schedule 1 to 18 Logic Internal Parameter —

Network Global Schedule 65 to 82 Logic Internal Parameter —

Override Input 1 to 18 Logic Input OVRIZ1 — OVRIZ1 8

System Enable Outputs Logic Output SYSZ1 — SYSZ18

Remote Occupied Mode Logic Input RMTOCC

System Differential Pressure Logic Input SDP

System Differential Pressure Set point Logic User Configuration —

Loop Water Flow Logic Input FLOW

Control Type Logic User Configuration —

Pump Number 1 & 2 Speeds Logic Output PUMP1, PUMP2

Shut Down Command Logic Output ALLSYS

Heat Rejection Control

System Supply Water Temp. Logic Input SSWT

System Return Water Temp. Logic Input SRWT

System Loop Temperature Set points Logic User Configuration —

Fluid Cooler/Tower Control Logic User Configuration —

Loop Water Flow Logic Input FLOW

Cooling Tower 1 & 2 Speed/Level Logic Output CTL1, CTL2

Heat Addition Control

System Supply Water Temp. Logic Input SSWT

System Return Water Temp. Logic Input SRWT

System Loop Temperature Set points Logic User Configuration —

Boiler Control Type Logic User Configuration —

Loop Water Flow Logic Input FLOW

Boiler 1 & 2 Speed/Level Logic Output BLRL1, BLRL2

10

Page 11

PREMIERLINK™ CONTROLLER INPUTS AND OUTPUTS — When PremierLi nk controllers are factory mounted

with water source heat pump equipment to implement a CCN

system installation, the inputs and outputs are shown in T able 3.

CONNECT POWER — The Aquazone™ system control

panel requires an uninterrupted 110-v, single-phase, 60 Hz

power supply. All field wiring must comply with all local and

national fire, safety and electrical codes. It is recommended

that the power supply be separate from the power source

supplying the water source heat pumps. The Aquazone system

control panel is internally fused and a power switch is located

Table 3 — PremierLink Controller Inputs and Outputs

INPUTS POWER TERMINAL(S)

SPACE TEMPERATURE (SPT)

SET POINT ADJUSTMENT (STO)

SUPPLY AIR TEMPERATURE (SAT)

LEAVING WATER TEMPERATURE

IAQ SENSOR (IAQI)

REMOTE TIME CLOCK (RMTOCC)

COMPRESSOR LOCKOUT (CMPSAFE)

FIRE SHUTDOWN (FSD)

SUPPLY FAN STATUS (SFS)

NOT USED

OUTPUTS POWER TERMINALS

FAN (SF)

COOL STAGE 1 (CMP1)

COOL STAGE 2 (CMP2)

HEAT STAGE 1 (HS1)

HEAT STAGE 2 (HS2)

HEAT 3/EXHAUST/REVERSING VALVE (HS3/EXH/RVS)

inside the enclosure. Supply power to the Aquazone system

control panel through the convenience outlet in the bottom left

hand corner of the Aquazone system control panel. Do not

apply power until all connections have been made and voltage

supply has been verified. Ground in accordance with NEC and

local electrical codes. Connect the dedicated ground wire to the

position in relationship to the main supply line and use shield

cable to protect from any electrical interference.

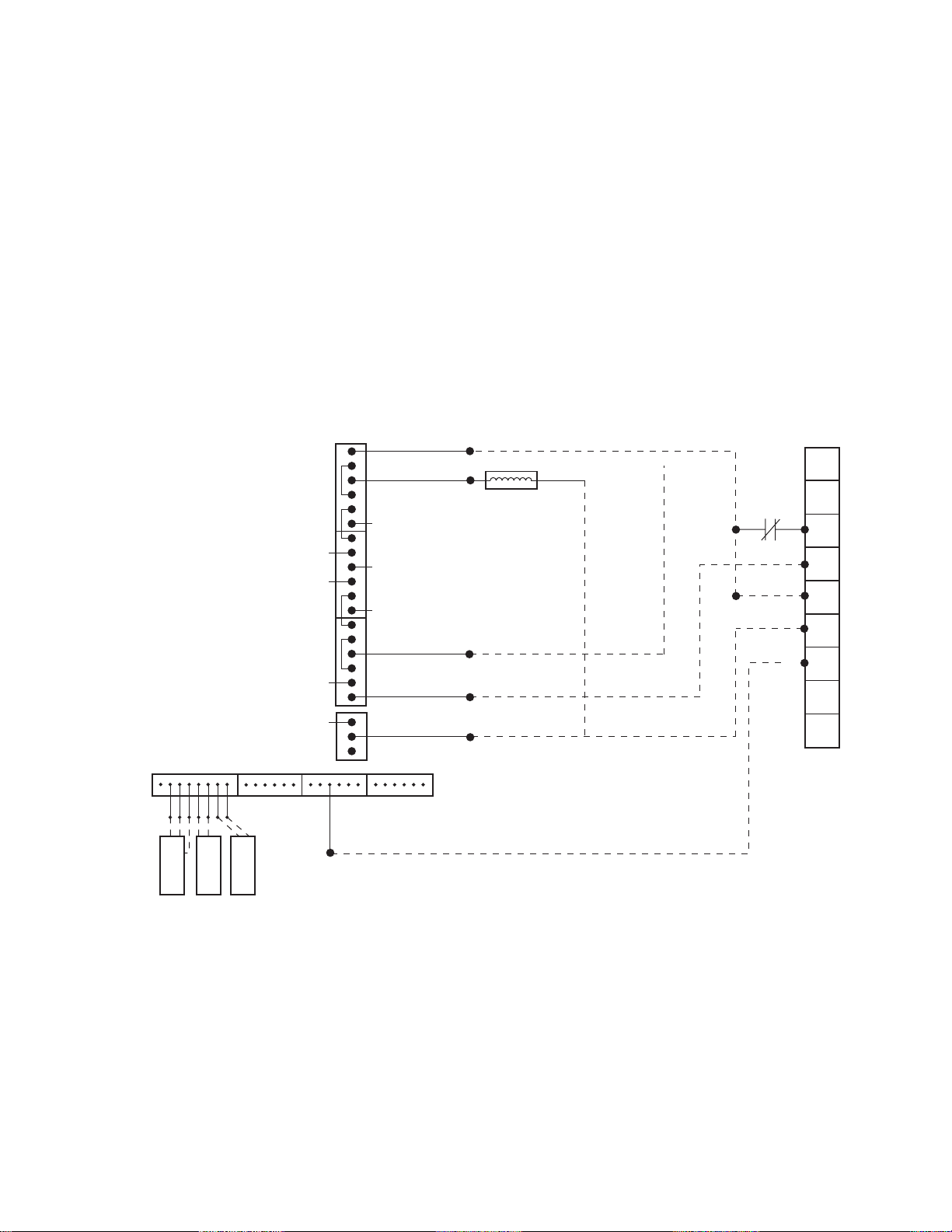

CONTROL WIRING — Low voltage wiring for the Aquazone system control panel is shown in Fig. 8.

AI (10 K Thermistor) J6-7, J6-6

AI (10 K Thermistor) J6-5, J6-6

AI (10 K Thermistor) J6-3, J6-4

AI (10 K Thermistor) J6-1, J6-2

(4-20 mA) J5-5, J5-6

DI (24 vac) J4-11, J4-12

DI (24 vac) J4-9, J4-10

DI (24 vac) J4-7, J4-8

DI (24 vac) J4-5, J4-6

——

DO Relay (24 vac, 1A) J8-18

DO Relay (24 vac, 1A) J8-15

DO Relay (24 vac, 1A) J8-12

DO Relay (24 vac, 1A) J8-9

DO Relay (24 vac, 1A) J8-6

DO Relay (24 vac, 1A) J8-3

LEGEND

AI —

DI —

DO —

Analog Input

Digital Input

Digital Output

11

Page 12

SYSZ18

2345 1678

45

PCB1

SW1

12345678

SW2

12345678

SW3

12345678

SW4

12345678

SW5

1

2

SW6

1

2

RED

PCB2

SW1

1

2345678

SW2

12345678

SW3

12345678

SW4

12345678

SW5

1 234

SW6

1 234

PCB2

RED

PCB3

SW1

1 2345678

SW2

1

2345678

SW3

1

2345678

SW4

12345678

SW5

1 234

SW6

1 234

AB

GRN

1

J2

2

BLK

3

RED

16

15

14

13

12

11

10

9

J4

8

1

7

0

6

INT

5

EXT

4

4-20mA

3

OTHER

2

0-10VDC

1

4-20mA

18

DO

34

17

AO

16

DO

34

15

AO

14

13

12

11

10

J3

9

8

7

6

5

4

3

J7

2

123

1

BLK

WHT

1

123

2

J7

3

J2

16

15

14

13

12

11

10

9

J4

8

7

1

0

6

5

INT

EXT

4

3

4-20mA

2

OTHER

1

0-10VDC

4-20mA

18

DO

17

AO

16

DO

15

AO

14

13

12

11

10

J3

9

8

7

6

5

4

To

3

2

J7

1

BLK

WHT

1

123

2

J7

J2

3

16

15

14

13

12

11

10

9

J4

8

7

1

0

6

5

INT

EXT

4

3

4-20mA

2

OTHER

1

0-10VDC

4-20mA

18

DO

17

AO

16

DO

15

AO

14

13

12

11

10

J3

9

8

7

6

5

4

3

2

1

GRN

BRN

RED

GRN

BRN

RED

TB1

+

-

TB3

TB2

TB5

TB4

78 OVRZ 2

56 OVRZ1

34 ALLSYS

12 RMTOCC

SDP

SRWT

SSWT

64 FLOW

78 OVRZ 10

56 OVRZ9

34 OVRZ8

12 OVRZ 7

78 OVRZ 6

56 OVRZ5

34 OVRZ4

12 OVRZ 3

78 OVRZ 18

56 OVRZ 17

34 OVRZ 16

12 OVRZ 15

78 OVRZ 14

56 OVRZ 13

34 OVRZ 12

12 OVRZ 11

8

SYSZ1

7

SYSZ2

7

AB

Fig. 8 — Typical Aquazone™ System Control Panel

C

D

E

Loop PanelLOW VOLTAGE CONTROL WIRING

TBP

1

RED

8

24 VAC

Common

Signal

Input

Chan

Output

24 VAC

Common

Signal

Input

Chan

BLRL1

Output

CTL2

2

24 VAC

Common

CB1

BLU

FLOW

1

Signal

Input

Chan

Output

CTL1

8

FLOW

7

24 VAC

Common

OFF

AUTO

T1

24 V

Signal

Input

Chan

Output

BLRL2

RED

SW

PUMP2

ON

OFF

AUTO

TBP

RED

3

BLU

TBP

RED

5

BLU

C

CB2

CB3

D

SW

PUMP1

ON

RED

T2

24 V

SYSZ10

7

7 8SYSZ9

7 8SYSZ8

7 8SYSZ7

7

SYSZ6

7 8SYSZ5

7 8SYSZ4

7 8SYSZ3

T3

24 V

7

SYSZ18

7 8

SYSZ17

7 8

SYSZ16

7 8

SYSZ15

SYSZ14

7

7 8

SYSZ13

7 8

SYSZ12

7 8

SYSZ11

GRN

TBP

YB

YEL

BLK

2345 1678

BRN

GRN

X2X1

YEL

8

BRN

BRN

BRN

BRN

8

BRN

BRN

BRN

BRN

BRN

GRN

X2X1

YEL

8

BRN

45

BRN

BRN

BRN

8

BRN

BRN

BRN

BRN

E

12

Page 13

ALLSYS —

BLRL1 —

BLRL2 —

CB —

CTL1 —

CTL2 —

FLOW —

OVRIZ1 —

OVRIZ2 —

OVRIZ3 —

OVRIZ4 —

OVRIZ5 —

OVRIZ6 —

OVRIZ7 —

OVRIZ8 —

OVRIZ9 —

OVRIZ10 —

OVRIZ11 —

System

Heat Source 1 Speed/Level

Heat Source 2 Speed/Level

Circuit Breaker

Cooling Tower 1 Speed/Level

Cooling Tower 2 Speed/Level

Loop Water Flow

Override Input for Zone 1

Override Input for Zone 2

Override Input for Zone 3

Override Input for Zone 4

Override Input for Zone 5

Override Input for Zone 6

Override Input for Zone 7

Override Input for Zone 8

Override Input for Zone 9

Override Input for Zone 10

Override Input for Zone 11

OVR IZ 12 —

OVR IZ 13 —

OVR IZ 14 —

OVR IZ 15 —

OVR IZ 16 —

OVR IZ 17 —

OVR IZ 18 —

PCB —

PUMP1 —

PUMP2 —

RMTOCC —

SDP —

SRWT —

SSWT —

SYSZ1 —

SYSZ2 —

SYSZ3 —

SYSZ4 —

LEGEND FOR FIG. 8

Override Input for Zone 12

Override Input for Zone 13

Override Input for Zone 14

Override Input for Zone 15

Override Input for Zone 16

Override Input for Zone 17

Override Input for Zone 18

Comfort Controller Circuit Board

Pump Number 1

Pump Number 2

Remote Occupied Mode

System Differential Pressure

System Return Water Temperature

System Supply Water Temperature

System for Zone 1

System for Zone 2

System for Zone 3

System for Zone 4

SYSZ5 —

SYSZ6 —

SYSZ7 —

SYSZ8 —

SYSZ9 —

SYSZ10 —

SYSZ11 —

SYSZ12 —

SYSZ13 —

SYSZ14 —

SYSZ15 —

SYSZ16 —

SYSZ17 —

SYSZ18 —

T —

TB —

TBP —

System for Zone 5

System for Zone 6

System for Zone 7

System for Zone 8

System for Zone 9

System for Zone 10

System for Zone 11

System for Zone 12

System for Zone 13

System for Zone 14

System for Zone 15

System for Zone 16

System for Zone 17

System for Zone 18

Transformer

Terminal Block

Terminal Block or Pin Connector

Install Thermostat, Sensors and Switches —

In

all installations, the loop supply water temperature sensor and

water flow switch must be installed in the field. The water

pressure sensor is used to sense water system pressure to

operate in conjunction with pump variable frequency drives.

A thermostat is used in stand-alone systems. A space temperature sensor is used in conjunction with water source heat

pumps provided with PremierLink™ controllers. Refer to the

accessory installation instructions literature provided with each

accessory that is used for accessory installation instructions.

NOTE: All thermostats, sensors, and switches are fieldinstalled accessories.

Install Loop Water Supply and Return Temperature Sensors —

sor in the main water supply, located before the water source

heat pumps. Install the water loop return sensor in the return

water piping from the water source heat pumps. The sensors

must be inserted fully into an immersion well ( provided). Seal

immersion well threads with tape and install into pipe tee or reducing fitting. The well screws into a

Thredolet fitting) furnished by the installing contractor. Screw

the sensor into the well via the

nate wiring with butt splice or soldering. Wire nuts are not recommended. Use full 8 ft of lead length provided to avoid moisture migration up the wire. Wire the supply sensor to terminals

SSWT. Wire the return sensor to terminals SRWT. See Fig. 8.

Sensors may be located in any position in relationship to the

main supply line. Use shield cable to protect from any electrical interference.

Install Loop Water Pressure Sensor —

pressure sensor on the discharge side of the circulating pump(s)

in a common supply main so that total system pressure rather

than individual pump(s) flow is detected. The pr essure sensor

must be placed in a vertical position and must match the actual

water flow direction with flow switch direction indicators. Seal

the switch fitting with Teflon tape and insert in a

Install the water loop supply sen-

1

/2-in. NPT saddle (or

1

/8-in. NPT brass fitting. Termi-

Install the

1

/4-in.

standard pipe tee (Thredolet fitting) or reducing fitting, with at

least three pipe diameters straight run upstream and downstream of the switch. Wire sensor to terminals SDP. See Fig. 8.

Install Loop Water Flow Switch —

Install the loop

water flow switch on the discharge side of the circulating

pump(s) in a common supply main so that total system flow

rather than individual pump(s) flow is detected. The flow

switch must be placed in a vertical position and must match the

actual water flow direction with flow switches direction indicators. Seal the switch fitting with Teflon tape and insert in a standard pipe tee or reducing fitting, with at least three pipe diameters straight run upstream and downstream of the switch.

Electrical connection can be made to the switc h. Two wires

should be run to the switch for 24 VAC power. The switch is

supplied with wire leads for connection to the FLOW terminal.

When power is supplied to the device, a warm-up period is

initiated. During this period, the right green LED will be lit.

Each LED to the left is successively lit until the farthest left red

LED is lit. Each LED will be turned off when the next is lit.

The warm-up period may take up to 30 seconds.

When flow is detected, a red LED at the far left will be lit.

With increasing flow, successive red LEDs will be lit. When

the switch determines sufficient flow is present, the amber

LED lights indicating the output has closed. This is not an indication of minimum flow. As flow increases, the first green

LED will be lit. Each successive green LED indicates greater

flow. The switch closure does not indicate minimum flow for

the machine. With one green LED lit, minor fluctuations in

water flow may cause nuisance alarms. Additional green LEDs

indicate higher flow rates, and can avoid the nuisance alarms.

The switch is calibrated to light the amber LED at a fluid

velocity of 0.8 ft/sec (0.24 m/sec). The flow rate will depend on

the nozzle size. See Table 4. See Table 5 for Water Flow

Switch Troubleshooting. If the water flow switch is not working correctly, refer to Table 5.

SIZE

4

5

6

8

Table 4 — Loop Water Flow Switch LED Display

SCHEDULE 40 PIPE

O.D. (in.) Wall Thickness (in.) I.D. (in.) Area (Ft

4.5 .237 4.026 0.09 32

5.563 .258 5.047 0.14 50

6.625 .28 6.065 0.20 72

8.625 .322 7.981 0.35 125

2

)GPM

13

Page 14

Table 5 — Water Flow Switch Troubleshooting

ENTER

PROBLEM SOLUTION

No display or output from the flow sensor

Flow sensor indicates zero flow

when flow is present

Flow Sensor indicates flow

when no flow is present

Check for 24 VAC across pins 1 and 3. These are small pins and caution should

be used when measuring the voltage in the harness so as not to damage the connector.

Check flow switch pin connections for damage.

Check for air in the chilled water system.

Check for 24 vac across pins 1 and 3. These are small pins and caution should be used

when measuring the voltage in the harness so as not to damage the connector.

Check for fouling on the sensor switch, which could inhibit the dissipation of heat from the probe.

Consider replacing the flow switch. The switch might be out of calibration,

the internal heater may have been damaged by extreme temperatures, pressure

or vibration, or mechanical damage to the tip of the device may have occurred.

Check for 24 vac across pins 1 and 3. These are small pins and caution should

be used when measuring the voltage in the harness so as not to damage the connector.

Low voltage can lead to less heat generated by the internal heater.

Consider replacing the flow switch. The switch might be out of calibration, the internal

heater may have been damaged by extreme temperatures, pressure or vibration, or

mechanical damage to the tip of the device may have occurred.

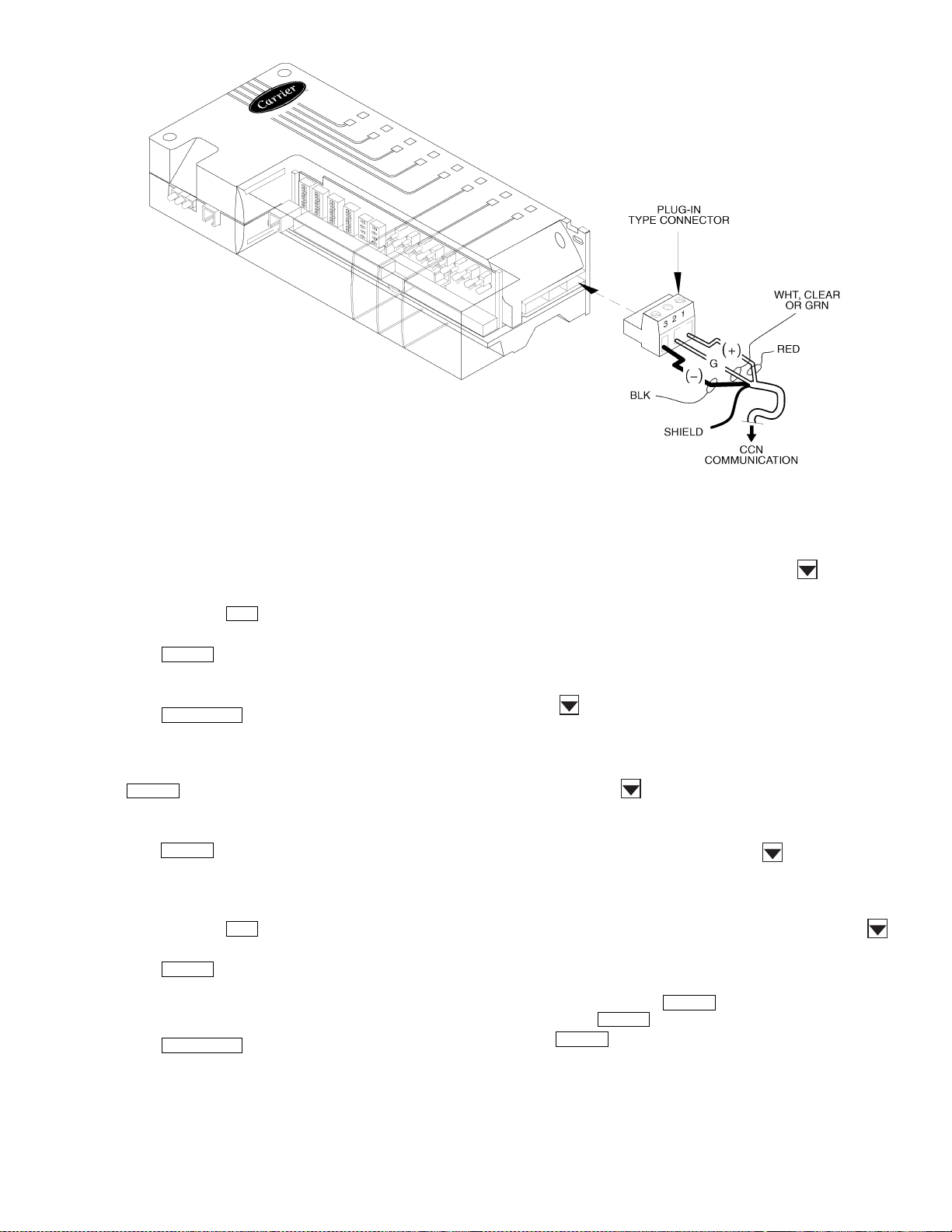

Connect to CCN Communication Bus —

The

Aquazone™ system control panel primary controller connects

to the bus in a daisy chain arrangement. Negative pins on each

component must be connected to respective negative pins and

likewise positive pins on each component must be connected to

respective positive pins. The controller signal pins must be

wired to the signal ground pins. Wiring connections for CCN

must be made at the 3-pi n pl ug. See Fig . 9.

At any baud (9600, 19200, 38400 baud), the number of

controllers is limited to 239 devices maximum. Bus length may

not exceed 4000 ft, with no more than 60 total devices on any

1000-ft section. Optically isolated RS-485 repeaters are

required every 1000 ft.

NOTE: Carrier device default is 9600 baud.

COMMUNICATION BUS WIRE SPECIFICATIONS —

The CCN Communication Bus wiring is field-supplied and

field-installed. It consists of shielded three-conductor cable

with drain (ground) wire. The cable selected must be identical

to the CCN Communication Bus wire used for the entire

network. See Table 6 for recommended cable.

Table 6 — Recommended Cables

MANUFACTURER CABLE PART NO.

Alpha

American

Belden

Columbia

2413 or 5463

A22503

8772

02525

NOTE: Conductors and drain wire must be at least 20 AW G

(American Wire Gage), stranded, and tinned copper. Individual

conductors must be insulated with PVC, PVC/nylon, vinyl,

Teflon, or polyethylene. An aluminum/polyester 100% foil

shield and an outer jacket of PVC, PVC/nylon, chrome vinyl,

or Teflon with a minimum operating temperature range of

–20 C to 60 C is required.

The communication bus shields must be tied together at

each system element. If the communication bus is entirely

within one building, the resulting continuous shield must be

connected to ground at only one single point. If the communication bus cable exits from one building and enters another

building, the shields must be connected to the grounds at a

lightning suppressor in each building (one point only).

START-UP

LID Power Up Display —

the Aquazone System Control panel, the red LED on the top

front of the processor module will flash at a rapid pace (about

twice a second) for the first 20 seconds. This rapid flash will

then be replaced by a slower pace of about once per second.

The green LED below the red LED will start flashing. This

LED indicates input/output communications for accessory input

output modules and t he LID di spla y.

The first six red LEDs on the controller will light.

The yellow LED will flash when the controller is broadcasting CCN messages to a laptop or other computer.

The LID display will show the controller identification,

time and date as shown below.

Aquazone System

hh:mm mm-dd-yy

Log On to the LID Display —

display of the Aquazone System Control panel, perform the

following procedure:

1. Press 3 and then . The LID display will show:

Controller Password

2. Press . The LID display will show:

Log in to Controller

Enter Password

NOTE: The LID display has two modes: Edit mode and

Status/Maintenance mode. If the LID display is in Edit

mode, then the display will only show the word “password.” Press the key to toggle to the Status

mode.

3. Key in the password and press .

NOTE: The default password is 1111.

4. The LID display will show:

Log in to Controller

Logged In

SET

EXPN/EDIT

When power is applied to

To Log On to the LID

ENTER

14

Page 15

CLEAR

NOTE: Do not bundle power and

communication wiring with sensor

and device wiring.

Fig. 9 — Connection to CCN Bus

Change the Default Password —

To change the

default password, perform the following procedure:

NOTE: The password must have already been entered to per-

form this procedure.

1. Press 3 and then . The LID display will show:

SET

Controller Password

2. Press . The LID display will show:

ENTER

Log in to Controller

Enter Password

3. Press . The LID display will show:

EXPN/EDIT

Password

1111

4. Enter the new password (up to 8 digits) and press

ENTER

. The LID display will show:

Password

(New Password)

5. Press to leave the password screen and return to

CLEAR

the default display screen.

Set the Clock —

The user must be logged in to set the

clock. To set the clock, perform the following procedure:

1. Press 1 and then . The LID display will show:

SET

Set Clock

2. Press . The LID display will show:

ENTER

No Maintenance

NOTE: There is no maintenance informat ion regarding

setting the clock.

3. Press . The LID display will show:

EXPN/EDIT

Time

00:00

4. Enter the time. The time is entered in military time (for

example 14.59 for 2.59 pm). Press the button. The

LID display will show:

Day of W eek

1

5. Enter the day of week. The numbers 1 through 7 correspond to the days of the week (1 = MON, 2 = TUE,

3 = WED, 4 = THUR, 5 = FRI, 6 = SAT, 7 = SUN). Press

. The LID display will show:

Month

1

6. Enter the number of the corresponding month (1 through

12). Press . The LID display will show:

Day

1

7. Enter the day of the month. Press . The LID display

will show:

Year

95

8. Enter the last two digits of the current year. Press .

The LID display will show:

Update Clock

No

9. Press 1 and then to change display to a YES.

ENTER

Press . The clock will be updated. Press

ENTER

twice to view the default display and the clock

should update to the input time and date.

15

Page 16

Configure Schedules —

ALGO

ENTER

ENTER

CLEAR

perform the following procedure:

1. Press 1 and then . The LID display will show:

Occupancy Algorithm

2. Press . The LID display will show:

3. There are 18 occupancy algorithms: OCCPC01 to

4. Press . If the LID display shows “MODE 0”

5. Press . The LID display will show:

6. Press the button. The LID display will show:

7. Input the Occupancy Start time for this period.

8. Press the to input the Occupied To time for period 1.

9. Input the days and times for periods 2 through 8 as

10. Press clear to leave the occupancy programming.

ENTER

Occupancy 01

OCCPC01

OCCPC18. There is one algorithm for each of the

18 zone relay outputs. Use the up and down arrows to

select the desired schedule to modify then press

ENTER

Time Schedule

Enter to select

ENTER

then the user is in Maintenance mode and the LID display

is showing the maintenance information for the occupancy schedule. Press to enter the configuration mode. The LID display will show:

Manual Override Hours

0 hours

This is the first configuration for each occupancy algo-

rithm and is used to put the schedule in or out of occupancy override for the number of hours entered.

Period 1: Day of week

00000000

The eight digits represent if this period should apply to

certain days of the week or holidays. The digits represent

M, Tu, W, Th, F, Sa, Su, and Hol, respectively. Enter a

series of 0s or 1s with a 1 corresponding to the days that

this period should apply to and a 0 for the days that this

schedule should not apply to. As an example, entering

11111000 would make the schedule apply to days Monday through Friday and not apply to Saturday, Sunday, or

Holidays.

Period 1 occupied from

00:00

NOTE: 12.00 represents 12:00 pm.

required.

SCHD

. The LID display will show:

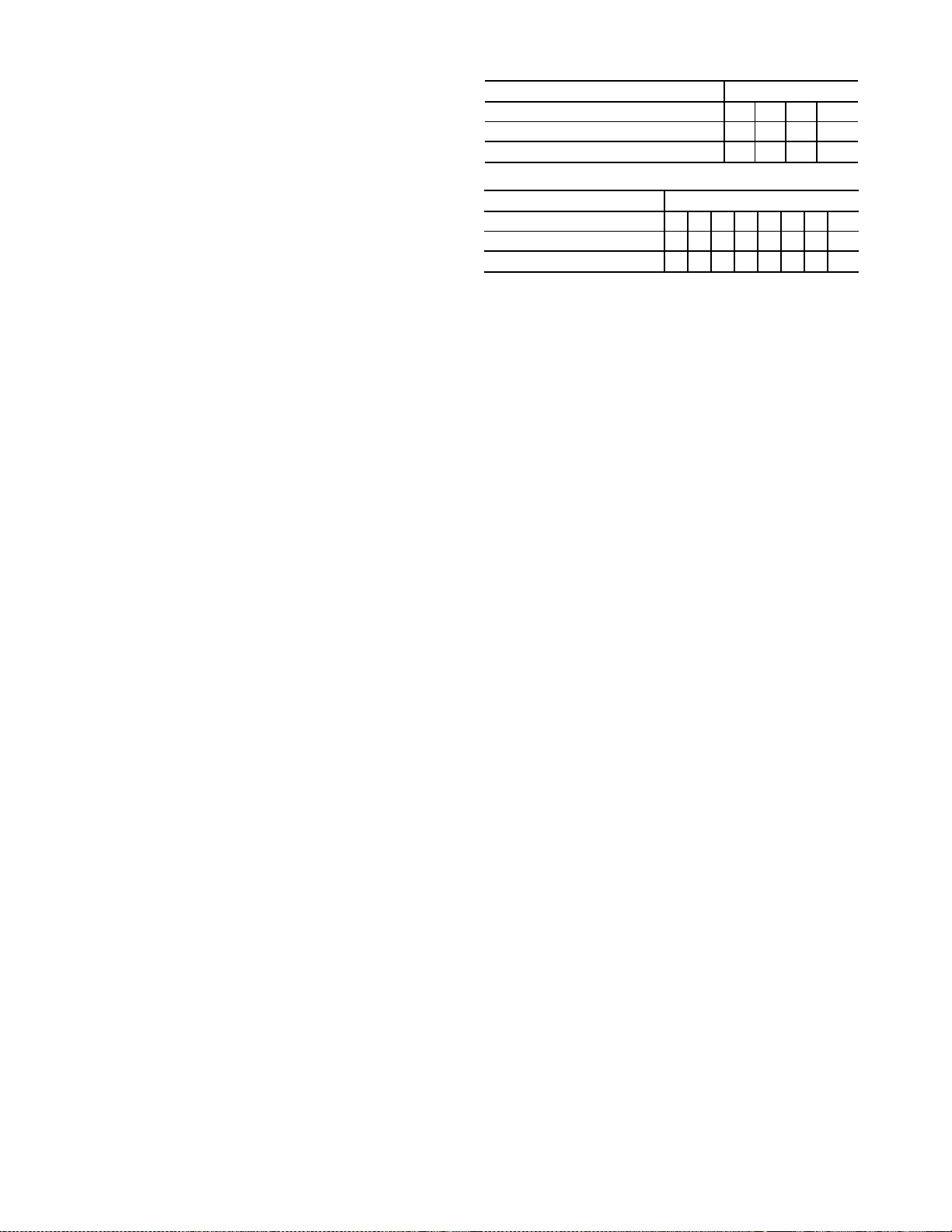

Program Set Points —

form the following procedure:

1. Press 2 and then . The LID display will show:

Setpoint Schedule

2. Press . The LID display will show:

3. Press .

4. If “No maintenance” is displayed, pres s t o

ENTER

Loop W ater Supply

SETPT01

ENTER

view the set point information. The LID display will

show:

Occupied Lo Setpoint

60.00

SCHD

To configure the schedules,

EXPN/EDIT

To program the set points, per-

EXPN/EDIT

This set point is the Loop Low Water Temperat ure set

point.

5. Press . The LID display will show:

Occupied Hi Setpoint

90.00

This set point is the Loop High Water Temperature set

point.

The down or up arrow will also display the Unoccupi ed

Low and High Temperature set points. These values

should be kept the same as the occupied values.

6. The system pressure set point (SETPT02) is used for

controlling variable speed pumps. This can be accessed

by pressing the down or up arrow when SETPT01 is on

the display.

7. Pressing the button will take the user out of the

set point configuration mode.

Check System Parameters —

parameters, press the button. The LID display will

show: “Hardware Points”. Pr ess to view the hardware points. The user can navigate up and down through the

points with the up and down arrows.

Press 2 and to display the software points. The user

can navigate up and down through the points with the up and

down arrows.

Refer to the Configuration section for a listing of the hardware and software points.

Display Alarm History —

there are alarms, the user can view the alarm history by

pressing the button. The LID display will show “Alarm

History.” Press . The LID display will show the date

and type of alarm.

As an example, if the LID display shows:

ALARM — 10:55 11-27-02

SSWT

That display indicates that on 11/27/02 at 10:55 the system

Supply W ater Temperature sensor went into an alarm condition.

The user can view other stored alarms by pressing the up

and down arrows. The five most recent alarms are stored.

CLEAR

To check system

STAT

ENTER

STAT

If the controller is indicating

HIST

ENTER

Configure the Custom Programming Selections —

perform the following procedure:

1. Press 37 . The LID display will show:

2. Press . The LID display will show:

3. Press if the display indicates “No Data.” Press

4. Press 1 and then to change to variable speed

5. Use the down and up arrows to select the other configura-

To configure the custom programming selections,

Custom Program

Global Dictionary

AQUAZONE

then press . Press again.

The LID display should now show:

PUMPS 0=ON/OFF, 1 = VFD

0.00

pumping (if required).

tion parameters as required. See the Configuration section

for an explanation of the configuration parameters.

EXPN/EDIT ENTER

ENTER

16

Page 17

Set the Aquazone™ System Control Panel

-

Controller Address —

Aquazone System Control panel controller, perform the

following procedure:

1. Press 7 and then . Press and then

EXPN/EDIT

.

2. Type in the CCN element number and press .

3. Press the button. Type in the CCN bus number and

press .

ENTER

Log Off from Controller —

zone System Control panel controller Press 3 and then .

Press . Press the button and then press 1. Press

ENTER

ENTER

to log off.

LID Operation —

CCN operator interface that gives the user the capability to

view and modify all configuration and service data for the

Aquazone System Control Panel Controller. The LID also

gives the user the capability to override all point display and

maintenance data.

MENU STRUCTURE — The LID operates on a hierarchy of

four levels (menus).

The top level contains the LID’s major functions. Each

function has a corresponding key on the LID. For an explanation of each function key, refer to Table 7.

The second level separates the major functions (items) into

types with corresponding type numbers that can be used for

quick access.

The third level gives the user the capability t o access each

occurrence of an item. For example, the application may

require two DO — Analog Comparison algorithms. Thus, the

Aquazone System Control Panel Controller would have two

occurrences of the DO — Analog Comparison algorithm.

The fourth level gives the user the capability to access maintenance and configuration data associated with the selected

occurrence of the item.

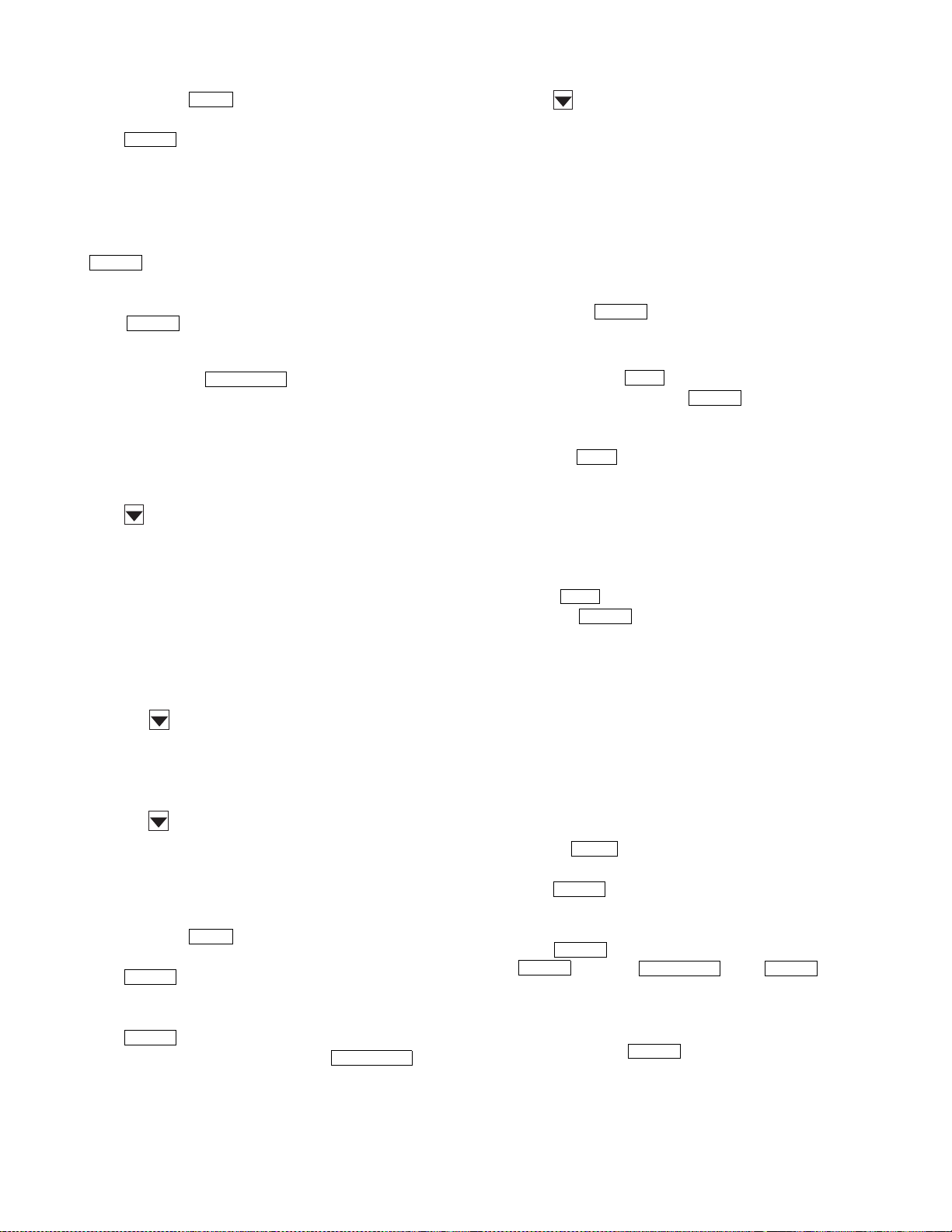

Table 7 — LID Function Keys

To set the address of the

SRVC ENTER

ENTER

To log off from the Aqua-

SET

The Local Interface Device (LID) is a

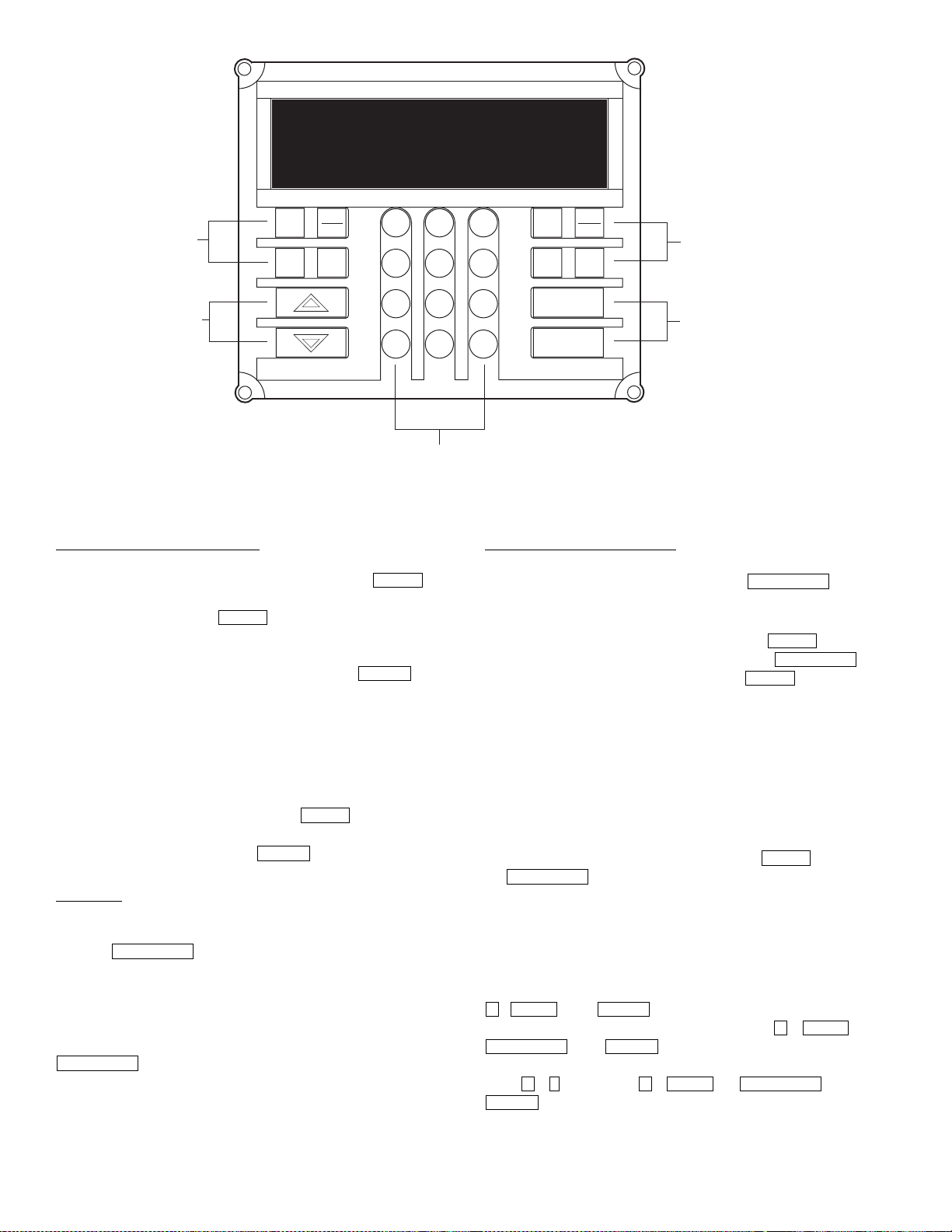

DEFAULT SC RE EN — Figure 10 shows a LID. This screen

provides the user with the 24-character controller name and the

controller’s current time, date, and alarm status. This screen

appears when the LID is powered up and communicating with

the Aquazone System Control Panel Controller or there is no

keyboard activity for10 minutes.

KEYPAD AND DISPLAY — The LID consists of a keypad

with 8 function keys, 4 operative keys, 12 numeric keys (0 to

9, ., and -) and a two-line, alphanumeric l iquid crystal display

(LCD). Each line on the LCD can display up to 24 characters.

See Fig. 10.

T able 8 below defines t he purpose of the LID’s operative keys.

Table 8 — Operative Keys

OPERATIVE

KEYS

CLEAR

ENTER

Clear — performs three operations:

• Cancels a data entry before the user

presses Enter, thus leaving the current

value unchanged.

• Returns a forced point to automatic

control.

• Redisplays the previous menu level.

Enter — performs two operations:

• Selects the displayed item, thus displaying

either its maintenance or configuration

data, depending on whether the user is in

the Status mode or the Edit mode.

• Accepts the value entered in a configuration

decision as new configuration data or as a

forc e.

Down arrow — displays the next configured

item or decision. When the last configured

item or decision is displayed, the LID

re-displays the first configured item or

decision. For example, when the user presses

the down arrow key while viewing the last

configuration decision of an algorithm, the LID

re-displays the first configuration decision.

Up arrow — Displays the previous configured

item or decision.

USE

Table 9 below defines the purpose of the LID’s numeric keys.

Table 9 — Numeric Keys

OPERATIVE

KEYS

LEGEND

AO —

DO —

Analog Output

Digital Output

USE

Status — gives access to maintenance

values and configuration data for points.

Alarm — gives access to maintenance

and configuration data for alarms.

History — gives access to maintenance

and configuration data for history system

functions.

Service — gives access to maintenance

and configuration data for service system

functions.

Setup — gives access to configuration

data for setup system functions.

Schedule — gives access to maintenance

and configuration data for schedules.

Algorithm — gives access to maintenance

and configuration data for AO, DO, and global

algorithms. It also gives access to BEST

custom programs.

Edit — gives the capability to switch from

Status mode to Edit (configuration) mode for

the selected item. (EXPN is not used in

conjunction with the Aquazone System

Control Panel Controller.)

++™

OPERATIVE

KEYS

Numeric keys

Performs two operations:

• Separates items, such as an algorithm from

its occurrence or hours from minutes.

• Serves as a decimal point in numeric values.

Performs two operations:

• Negates the value of numeric keys.

• Clears current data entry value any time it is

not the first key pressed during the data

entry sequence.

USE

VIEWING MODES — The user can view items in either the

Status (maintenance) mode or the Edit (configuration) mode.

Status Mode

— When the user first powers up the LID, it

displays the Aquazone System Control Panel Controller items

in the Status (maintenance) mode. The user may view the

current value or status of an item in the Sta tus mode without

actually logging on to the Aquazone System Control Panel

Controller. Knowing the current values or status of items can

be useful when troubleshooting. For example, the user could

determine if a point was forced.

NOTE: Not all items have maintenance data. If the item you

select does not have maintenance data, the LID will display

“No maintenance.”

17

Page 18

EXPN/EDIT

6

EXPN/EDIT

FUNCTION

KEYS

STAT

SET

EXPN

EDIT

SCHD

3

2

1

5

4

6

TEST

SRVC

ALRM

HIST ALGO

FUNCTION

KEYS

OPERATIVE

KEYS

7

–

NUMERIC KEYS

Fig. 10 — Typical LID Device

Access Items in the Status Mode

— The user can access

maintenance data in the Status mode in two ways:

• Pressing the appropriate function key (i.e., )

ALRM

once to access a category (i.e., alarms) and then continuing to press that key ( ) to scroll thr ough all the

ALRM

items in that category (i.e., Limit Alarm, Setpoint

Alarm, Discrete Alarm, First Out Alarm, Runtime

Alarm, and Number of Starts Alarm). Press

ENTER

display the first maintenance decision.

Scrolling by repeatedly pressing the function key,

NOTE:

displays the name of all the items in that category, whether

or not they are actually configured.

the up or down arrow,

displays only the configured items

Scrolling by pressing

within that category.

• Pressing the appropriate LID numeric key (i.e., 2) and

the appropriate function key (i.e., ) to directly

ALRM

access an item without having to scroll through all the

items in that category. Press to display the first

ENTER

maintenance decision.

Edit Mode

— Because the LID first displays items in the

Status mode when it is powered up, the user must log on to the

connected Aquazone™ System Control Panel Controller and

press the key to switch to the Edit mode.

EXPN/EDIT

While in the Edit mode, the user ca n cha nge the configuration of items. For example, the user could change the value of

an algorithm’s configuration decision.

NOTE: Not all items have configuration data. If the item

selected does not have configuration data, pressing the

EXPN/EDIT

key will have no effect. The LID will display

“No configuration.”

8

9

.

0

Access Items in the Edit Mode

CLEAR

ENTER

OPERATIVE

KEYS

— The two ways to access

items in the Edit mode are th e same as in the Status mode,

except for an additional step — pressing the key .

EXPN/EDIT

The user can access configuration data in the Edit mode in

two ways:

• Pressing the appropriate function key (i.e., ) once

to access a category (i.e., ala rms), pressing

to

and then continuing to press that key ( ) to scroll

ALRM

EXPN/EDIT

ALRM

through all the items in that category (i.e., Limit Alarm,

Setpoint Alarm, Discrete Alarm, First Out Alarm,

Runtime Alarm, and Number of Starts Alar m ) .

Scrolling by repeatedly pressing the function key,

NOTE:

displays the name of all the items in that category, whether

or not they are actually configured.

the up or down arrow,

displays only the configured items

Scrolling by pressing

within that category.

• Pressing the appropriate LID numeric key (i.e., 2),

the appropriate function key (i.e., ), and

ALRM

to directly access an item without having

to scroll through all the items in that category.

QUICK ACCESS IN EITHER STATUS OR EDIT

MODE — Use T able 10 on next page as a reference to directly

access Aquazone System Control Panel Controller items using

a LID in either the Status or Edit modes. For example, to access

maintenance data for the AO — Heating VAV algorithm, press

, , and . To access configuration data for

ALGO ENTER

the AO — Heating VAV algorithm, press , ,

, and

ENTER

.

If the database consisted of two

6 AL G O

AO — Heating VAV algorithms, to access the second one,

press ,

ENTER

(decimal),

6 . 2 ALGO EXPN/EDIT

, , , and

.

18

Page 19

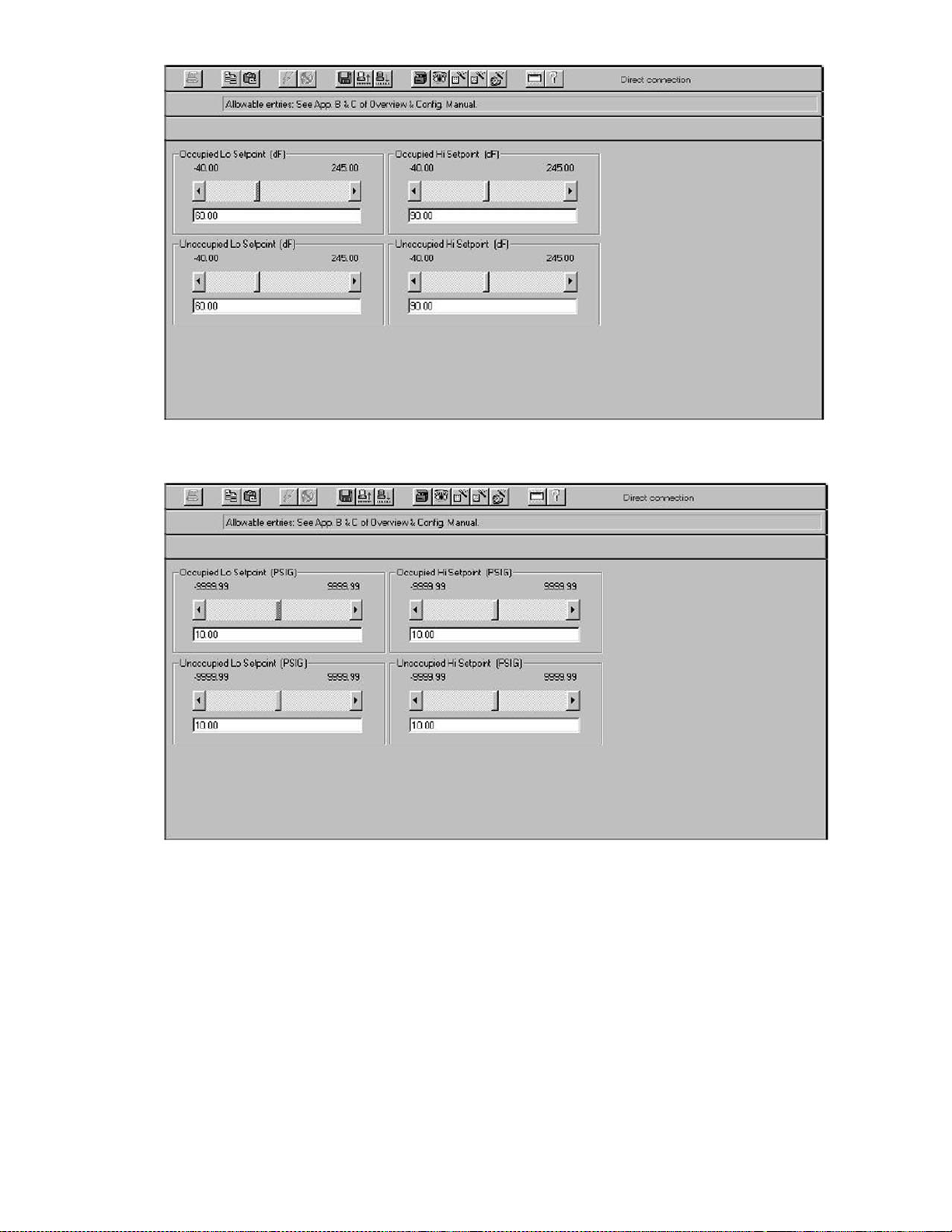

Table 10 — Quick Access Chart

LID

NUM.

KEY

1 AO—Adaptive Control Hardware Points Alarm History Function Definition Limit Set Clock Occupancy

2 AO—Cooling CV Software Points Analog Point Trace Channel Definition Setpoint Real Time Clock Setpoint

3 AO—Cooling VAV Temperature Input Discrete Point Trace System Definition Discrete Controller Password Holiday

4 AO—Fan Tracking Milliamp Input Consumable Channel Setpoint Definition First out N/A S/W Setpoint

5 AO—Heating CV Custom Milliamp Input Internal Consumable Database Control Runtime N/A Network Time

6 AO—Heating VAV Voltage Input Runtime Channel Comfort Controller # of starts N/A N/A

7 AO—Humidity Control Custom Voltage Input N/A CCN Control N/A N/A N/A

8 AO—Mixed Air CV w/IAQ Sensed Discrete Input N/A LID Preferences N/A N/A N/A

9 AO—Mixed Air VAV w/IAQ Latched Discrete Input N/A N/A N/A N/A N/A

10 AO—Permissive Interlock Pulsed Discrete Input N/A N/A N/A N/A N/A

11 AO—Reset Milliamp Output N/A N/A N/A N/A N/A

12 AO—Shared Transducer Custom Milliamp Output N/A N/A N/A N/A N/A

13 AO—Static Pressure Voltage Output N/A N/A N/A N/A N/A

14 DO—Analog Custom Voltage Output N/A N/A N/A N/A N/A

15 DO—DX-Staging VAV Discrete Output N/A N/A N/A N/A N/A

16 DO—Electric Heat CV Stepper Motor Output N/A N/A N/A N/A N/A

17 DO—Electric Heat VAV Discrete Software Point N/A N/A N/A N/A N/A

18 DO—Enthalpy Comparison Analog Software Point N/A N/A N/A N/A N/A

19 DO—Interlock Network Data Out N/A N/A N/A N/A N/A

20 DO—Lighting Control Network Data In N/A N/A N/A N/A N/A

21 DO—Permissive Interlock N/A N/A N/A N/A N/A N/A

22 DO—Pump Control N/A N/A N/A N/A N/A N/A

23 DO—Prop Thermo N/A N/A N/A N/A N/A N/A

24 DO—Prop Ther mo 2 Pipe N/A N/A N/A N/A N/A N/A

25 DO—Prop Ther mo 4 Pipe N/A N/A N/A N/A N/A N/A

26 DO—Staged Thermostat N/A N/A N/A N/A N/A N/A

27 DO—Staging Control N/A N/A N/A N/A N/A N/A

28 DO—Time Clock N/A N/A N/A N/A N/A N/A

29 DO—Time Clock w/Check N/A N/A N/A N/A N/A N/A

30 AOSS Schedule N/A N/A N/A N/A N/A N/A

31 Network Broadcast N/A N/A N/A N/A N/A N/A

32 Linkage/AOSS Schedule N/A N/A N/A N/A N/A N/A

33 NTFC w/Enthalpy Check N/A N/A N/A N/A N/A N/A

34 Sensor Group N/A N/A N/A N/A N/A N/A

35 WSM Air Source N/A N/A N/A N/A N/A N/A

36 WSM Cool Source N/A N/A N/A N/A N/A N/A

37 Custom Program N/A N/A N/A N/A N/A N/A

LEGEND NOTES:

AO — Analog Output

AOSS — Adaptive Optimal Start/Stop

CV — Constant Volume

DO — Digital Output

IAQ — Indoor Air Quality

N/A — Not Available

NTFC — Nighttime Free Cooling

VAV — Variable Air Volume

WSM — Water System Manager

Algorithms

(ALGO)

Status

(STAT)

LID FUNCTION KEYS

History

(HIST)

1. If in the Edit mode and wish to switch to the Status mode, press

or press

2. Not all available selections will have items to select in sublevels.

Service

(SRVC)

EXPN/EDIT

Alarm

(ALRM)

again.

Setup

(SET)

Schedules

(SCHD)

CLEAR

19

Page 20

Sequence of Operation

HEAT RE JECTIO N — When the system pumps are operat ing and there is flow to the system, heat rejection control

compares the system supply water temperature to the hi gh set

point in the system loop temperature set points.

If the system supply water temperature approaches the high

set point, the controller commands the heat rejection outputs to

hold the system supply water temperature as close as possible

to the high set point.

If the system return water temperature drops below the

system high water temperature set point minus a hysteresis

value the heat rejection, outputs are disabled.

When the cooling tower output control type is set to

“variable,” the heat rejection outputs are calculated using a PID

calculation based on the system high temperature water set

point. Both outputs will modulate together.

When the heat rejection control type is set to “staged,” the

outputs will be modulated in a lead/lag configuration. The

modulating signal of the lead output will control a transducer

of two or four stages.

When the lead output is at 100% and the set point is not

being maintained, the lag output will be modulated to produc e

staging from another two or four stage output transducer.

The value output by each analog output is determined by a

PID calculation of leaving water temperature versus the system

high leaving water temperature set point.

In the event that the system high water temperature set point

cannot be maintained and is exceeded by a defined Hysteresis,

the heat rejection outputs will go to maximum output, the

system water source heat pumps will stop cooling, and the

system pumps will circulate water until the system temperatures are returned to the normal range. System cooling will