Page 1

Horizontal Water Source Heat Pumps

with PURON® Refrigerant (R-410A)

Installation, Start-Up, and

Service Instructions

AQUAZONE™

50HQP072-120

50 Hz

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . .1,2

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Step 1 — Check Jobsite . . . . . . . . . . . . . . . . . . . . . . . . 2

Step 2 — Check Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

• STORAGE

•PROTECTION

•INSPECT UNIT

Step 3 — Locate Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Step 4 — Mount Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Step 5 — Install Duct System. . . . . . . . . . . . . . . . . . . . . 5

• SO U N D AT T E NUATI O N

• EXISTING DUCT SYSTEM

Step 6 — Install Condensate Piping Drain. . . . . . . . 6

•INSTALLATION

• VENTING

Step 7 — Field Convert Air Discharge . . . . . . . . . . . . 6

Step 8 — Install Piping Connections . . . . . . . . . . . . . 7

• WATER LOOP APPLICATIONS

• GROUND-LOOP APPLICATIONS

• GROUND-WATER APPLICATIONS

Step 9 — Install Field Power Supply Wiring . . . . . . 8

• POWER CONNECTION

• SUPPLY VOLTAGE

• EXTERNAL LOOP POWER CONNECTION

• 420-VOLT OPERATION

Step 10 — Install Field Control Wiring. . . . . . . . . . . 15

• THERMOSTAT CONNECTIONS

• WATER FREEZE PROTECTION

• AIR COIL FREEZE PROTECTION

• ACCESSORY CONNECTIONS

• WATER SOLENOID VALVES

PRE-START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-20

System Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Airflow and External Static Pressure . . . . . . . . . . . 16

FIELD SELECTABLE INPUTS . . . . . . . . . . . . . . . 20-22

Complete C Control Jumper Settings. . . . . . . . . . . 20

Complete C Control DIP Switches. . . . . . . . . . . . . . 20

Deluxe D Control Jumper Settings . . . . . . . . . . . . . 20

Deluxe D Control DIP Switches . . . . . . . . . . . . . . . . 21

Deluxe D Control Accessory Relay

Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-24

Operating Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Air Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Start Up System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Scroll Compressor Rotation. . . . . . . . . . . . . . . . . . . . . 22

Unit Start-Up in Cooling Mode. . . . . . . . . . . . . . . . . . . 22

Unit Start-Up in Heating Mode. . . . . . . . . . . . . . . . . . . 23

Flow Regulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page

Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cooling Tower/Boiler Systems . . . . . . . . . . . . . . . . . . 24

Ground Coupled, Closed Loop and Plateframe

Heat Exchanger Well Systems . . . . . . . . . . . . . . . . 24

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24,25

Power Up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Units with Aquazone Complete C Control . . . . . . . 24

Units with Aquazone Deluxe D Control. . . . . . . . . . 24

SYSTEM TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25,26

Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Retry Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Aquazone Deluxe D Control LED Indicators . . . . . 25

SERVICE

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Water Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Condensate Drain Pans . . . . . . . . . . . . . . . . . . . . . . . . . 27

Refrigerant System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Condensate Drain Cleaning . . . . . . . . . . . . . . . . . . . . . 27

Air Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Condenser Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fan Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Air Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Checking System Charge . . . . . . . . . . . . . . . . . . . . . . . 28

Refrigerant Charging. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Air Coil Fan Motor Removal . . . . . . . . . . . . . . . . . . . . . 28

Blower Fan Sheaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Blower Fan Performance Adjustment . . . . . . . . . . . 29

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . 30-32

Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Control Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . CL-1,CL-2

IMPORTANT: Read the entire instruction manual before

starting installation.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-29

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All other

operations should be performed by trained service personnel.

When working on air-conditioning equipment, observe precautions in the literature, tags and labels attached to the unit, and

other safety precautions that may apply.

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock or

other conditions which may cause personal injury or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The

qualified installer or agency must use factory-authorized kits or

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500077-01 Printed in U.S.A. Form 50HQP-C1SI Pg 1 11-10 Replaces: New

Page 2

accessories when modifying this product. Refer to the

individual instructions packaged with the kits or accessories

when installing.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have fire

extinguisher available. Read these instructions thoroughly and

follow all warnings or cautions attached to the unit. Consult

local building codes and the National Electrical Code (NEC)

for special installation requirements.

Understand the signal words — DANGER, WARNING,

and CAUTION. DANGER identifies the most serious hazards

which will result in severe personal injury or death. WARNING signifies hazards that could result in personal injury or

death. CAUTION is used to identify unsafe practices, which

would result in minor personal injury or product and property

damage.

Recognize safety information. This is the safety-alert

symbol ( ). When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

WARNING

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all disconnect locations to alert others not to restore power until work

is completed.

CAUTION

This system uses R-410A, which has higher pressures than

R-22 and other refrigerants. No other refrigerant may be

used in this system. Suction tubing design pressure is

3068 kPa and liquid tubing design pressure is 4522 kPa.

Failure to use gage set, hoses, and recovery systems

designed to handle R-410A refrigerant may result in personal injury and equipment damage. If unsure about equipment, consult the equipment manufacturer.

GENERAL

This Installation and Start-Up Instructions literature is for

Aquazone™ water source heat pump systems with Puron refrigerant.

Water source heat pumps (WSHPs) are single-package horizontally and vertically mounted units with electronic controls

designed for year-round cooling and heating.

IMPORTANT: The installation of water source heat pump

units and all associated components, parts, and accessories

which make up the installation shall be in accordance with

the regulations of ALL authorities having jurisdiction and

MUST conform to all applicable codes. It is the responsibility of the installing contractor to determine and comply

with ALL applicable codes and regulations.

INSTALLATION

Step 1 — Check Jobsite —

maintenance instructions are provided with each unit. Before

unit start-up, read all manuals and become familiar with the

unit and its operation. Thoroughly check out the system before

operation. Complete the inspections and instructions listed

below to prepare a unit for installation. See Table 1 for unit

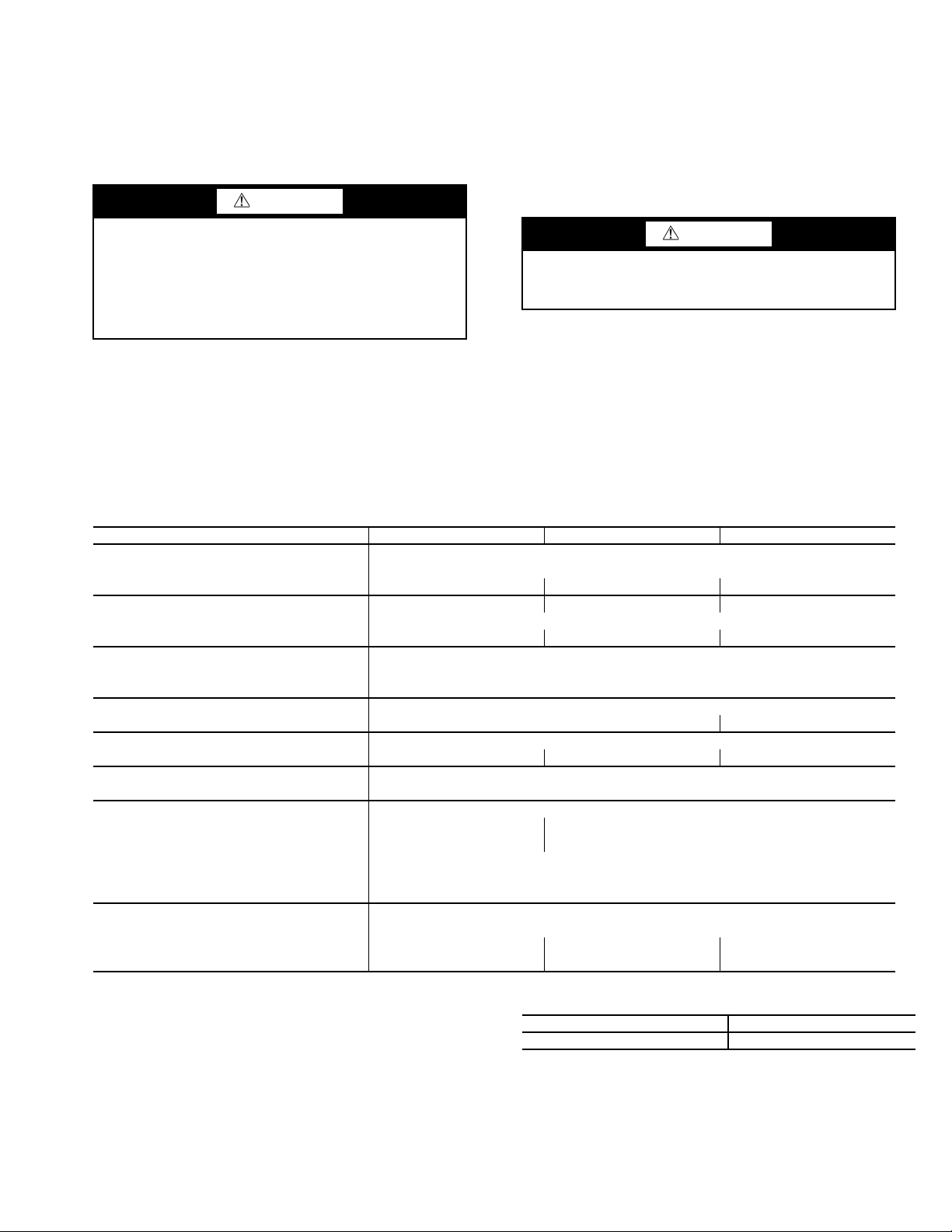

physical data.

Horizontal units are designed for indoor installation only.

Be sure to allow adequate space around the unit for servicing.

Installation, operation and

See Fig. 1 for overall unit dimensions. Refer to Fig. 2 for an example of a typical horizontal installation.

CAUTION

To avoid equipment damage, do not use these units as a

source of heating or cooling during the construction process. The mechanical components and filters used in these

units quickly becomes clogged with construction dirt and

debris which may cause system damage.

Step 2 — Check Unit — Upon receipt of shipment at

the jobsite, carefully check the shipment against the bill of

lading. Make sure all units have been received. Inspect the carton or crating of each unit, and inspect each unit for damage.

Ensure the shipping company makes proper notation of any

shortages or damage on all copies of the freight bill. Concealed

damage not discovered during unloading must be reported to

the shipping company within 15 days of receipt of shipment.

NOTE: It is the responsibility of the purchaser to file all

necessary claims with the shipping company.

1. Verify unit is correct model for entering water temperature of job.

2. Be sure that the location chosen for unit installation provides ambient temperatures maintained above freezing.

Well water applications are especially susceptible to

freezing.

3. Be sure the installation location is isolated from sleeping

areas, private offices and other acoustically sensitive

spaces.

NOTE: A sound control accessory package may be used

to help eliminate sound in sensitive spaces.

4. Check local codes to be sure a secondary drain pan is not

required under the unit.

5. Be sure unit is mounted at a height sufficient to provide

an adequate slope of the condensate lines. If an appropriate slope cannot be achieved, a field-supplied condensate

pump may be required.

6. Provide sufficient space for duct connection.

7. Provide adequate clearance for filter replacement and

drain pan cleaning. Do not allow piping, conduit, etc. to

block filter access.

8. Provide sufficient access to allow maintenance and

servicing of the fan and fan motor, compressor and coils.

Removal of the entire unit from the closet should not be

necessary.

9. Provide an unobstructed path to the unit within the closet

or mechanical room. Space should be sufficient to allow

removal of unit if necessary.

10. Provide ready access to water valves and fittings, and

screwdriver access to unit side panels, discharge collar,

and all electrical connections.

11. Where access to side panels is limited, pre-removal of the

control box side mounting screws may be necessary for

future servicing.

STORAGE — If the equipment is not needed for immediate

installation upon its arrival at the jobsite, it should be left in its

shipping carton and stored in a clean, dry area of the building

or in a warehouse. Units must be stored in an upright position

at all times. If carton stacking is necessary, stack units a

maximum of 3 high. Do not remove any equipment from its

shipping package until it is needed for installation.

PROTECTION — Once the units are properly positioned on

the jobsite, they must be covered with either a shipping carton,

vinyl film, or an equivalent protective covering. Open ends of

pipes stored on the jobsite must be capped. This precaution is

2

Page 3

especially important in areas where painting, plastering, or

spraying of fireproof material, etc. is not yet complete. Foreign

material that is allowed to accumulate within the units can prevent proper start-up and necessitate costly clean-up operations.

Before installing any of the system components, be sure to

examine each pipe, fitting, and valve, and remove any dirt or

foreign material found in or on these components.

CAUTION

3. Verify that the unit’s refrigerant tubing is free of kinks or

dents, and that it does not touch other unit components.

4. Inspect all electrical connections. Be sure connections are

clean and tight at their terminations.

5. Loosen compressor bolts until the compressor rides freely

on springs. Remove shipping restraints.

6. Remove the four 6 mm (

1

/4 in.) shipping bolts from compressor support plate (two bolts on each side) to maximize vibration and sound alternation.

DO NOT store or install units in corrosive environments or

CAUTION

in locations subject to temperature or humidity extremes

(e.g., attics, garages, rooftops, etc.). Corrosive conditions

and high temperature or humidity can significantly reduce

performance, reliability, and service life. Always move

Failure to remove shipping brackets from spring-mounted

compressors will cause excessive noise and could cause

component failure due to added vibration.

units in an upright position. Tilting units on their sides may

cause equipment damage.

7. Remove any blower support cardboard from inlet of the

blower.

INSPECT UNIT — To prepare the unit for installation, complete the procedures listed below:

1. Compare the electrical data on the unit nameplate with

ordering and shipping information to verify that the

correct unit has been shipped.

8. Locate and verify any accessory kit located in compressor

and/or blower section.

9. Remove any access panel screws that may be difficult to

remove once unit is installed.

2. Do not remove the packaging until the unit is ready for

installation.

Table 1 — Physical Data — 50HQP072-120 Units

UNIT 50HQP 072 096 120

COMPRESSOR QUANTITY* Scroll

Number of Circuits (Compressors) 2

Factory Charge HFC-410A (kg) per circuit 1.70 2.15 2.27

BLOWER MOTOR

Blower Motor Quantity 1

Standard Motor (kW) 0.75 1.49 2.24

BLOWER

No. of Blowers 1

Blower Wheel Size D x W (cm) 30.48 x 30.48

WATER CONNECTION SIZE

FPT (in.) [mm] 1

COAX VOLUME

Volume (liters) 6.13 6.85 9.08

CONDENSATE CONNECTION SIZE

FPT (in.) [mm]

AIR COIL DATA

Air Coil Dimensions H x W (cm) 50.8 x 137.16 50.8 x 162.56

Air Coil Total Face Area (sq m) 0.70 0.83

Air Coil Tube Size (cm) 0.953

Air Coil Fin Spacing (fins per cm) 5.5

Air Coil Number of Rows 3

MISCELLANEOUS DATA

Filter Standard - Throwaway (qty) (cm)† 40.64 x 50.80 x 2.54

Weight - Operating (kg) 265.8 292.1 316.6

Weight - Packaged (kg) 283.9 310.3 334.8

*All units have grommet and spring compressor mountings, and

2.2 mm and 3.5 mm electrical knockouts.

†51 mm filters are available as field-installed accessory.

1

/4 [31.8] 11/2 [38.1]

3

/4 [19.1]

NOTE: Use the lowest maximum pressure rating when multiple

options are combined:

OPTION MAXIMUM PRESSURE (kPa)

Base Unit 3100

3

Page 4

a50-8531

Fig. 1 — Unit Dimensions

HANGER BRACKET DIMENSIONS

221cm

2.54cm

PLAN VIEW

TOP

10.8cm

86.6cm

FRONT

CONTROL BOX

U

T

S

V

3.3cm

condensate

LEFT RETURN LEFT VIEW-

AIR COIL SIDE

LEFT RETURN END DISCHARGE

CBP

EAP

BSP

CAP

CAP

FRONT

E

D

F

G

CAP

CBP

CAP

EAP

BSP

FRONT

FRONT

CONTROL BOX

PLAN VIEW

TOP

V

S

U

RIGHT RETURN RIGHT VIEW-

AIR COIL SIDE

RIGHT RETURN END DISCHARGE

3.3cm

condensate drain

3

LEFT RETURN STRAIGHT DISCHARGE

CAP

CAP

FRONT

BSP

A

EAP

CBP

B

C

O

P

Q

R

K

M

F

G

E

D

BSP

RIGHT RETURN STRAIGHT DISCHARGE

1

EAP

2 CAP

CAP

2

FRONT

CBP

1

5

4

SERVICE ACCESS

3’ (91 cm.) TYPICAL

ALL CONFIGURATIONS

NOTES:

1. All dimensions in centimeters, unless indicated.

2. Access is required for all removable panels and installer should

take care to comply with all building codes and allow adequate

clearance.

3. Water inlet and outlet connections are available on either side of

the unit. Plugs are shipped loose in a plastic bag tied to the water

leg in front of the unit. Installer must plug unused connection.

4. Condensate drain connection is on end opposite of comressor.

5. Electrical access is available on either side of the front of the unit.

6. Electrical box is on right side but can be field-converted to left.

LEGEND

BSP — Blower Service Panel

CAP — Control Access Panel

CBP — Control Box Panel

EAP — Expansion Valve Access Panel

CONNECTIONS

Water Outlet

1

1

/4FPT (072,096)

11/2FPT (120)

Water Inlet

1

1

/4FPT (072,096)

1

1

/2FPT (120)

Condensate

Drain

3

/4FPT

High Voltage

Access

1

1

/8K.O.

Low Voltage

Access

7

/8K.O.

1

2

3

4

5

UNIT

50HQP

OVERALL

CABINET

(cm)

DISCHARGE

CONNECTIONS (cm)

(Duct Flange [± 0.1 cm])

WATER

CONNECTIONS

(cm)

ELECTRICAL

KNOCKOUTS

(cm)

RETURN AIR

CONNECTIONS (cm)

(Using Return Air Opening)

A

DepthBWidthCHeight

DESupply

Depth

F

Supply

Height

GKLMOPQRSReturn

Depth

T

Return

Height

UV

072-120 92.2 215.6 54.9 35.6 43.2 34.3 19.8 38.1 21.1 10.2 5.1 47.8 42.7 35.1 165.1 45.7 2.5 48.0

4

Page 5

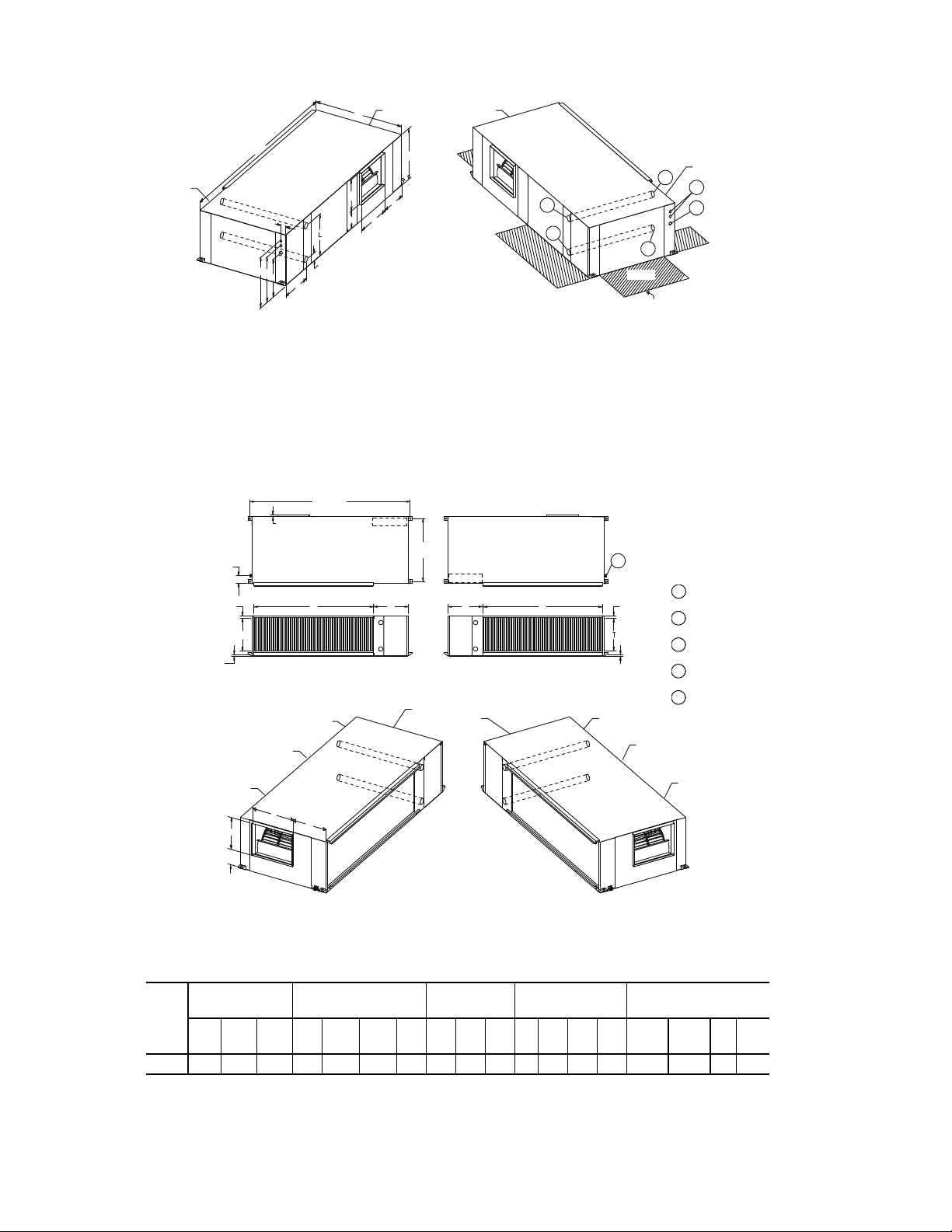

Step 3 — Locate Unit — The following guidelines

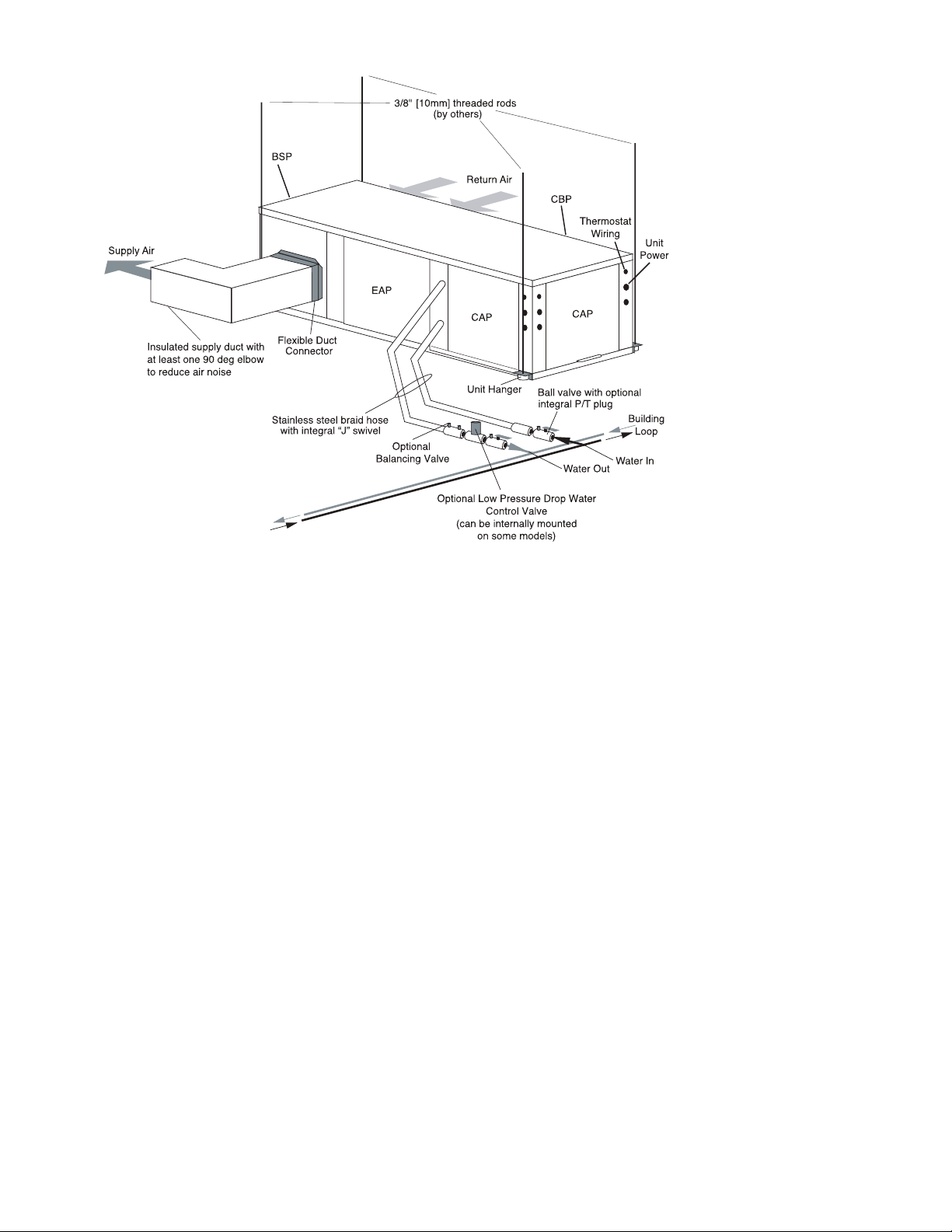

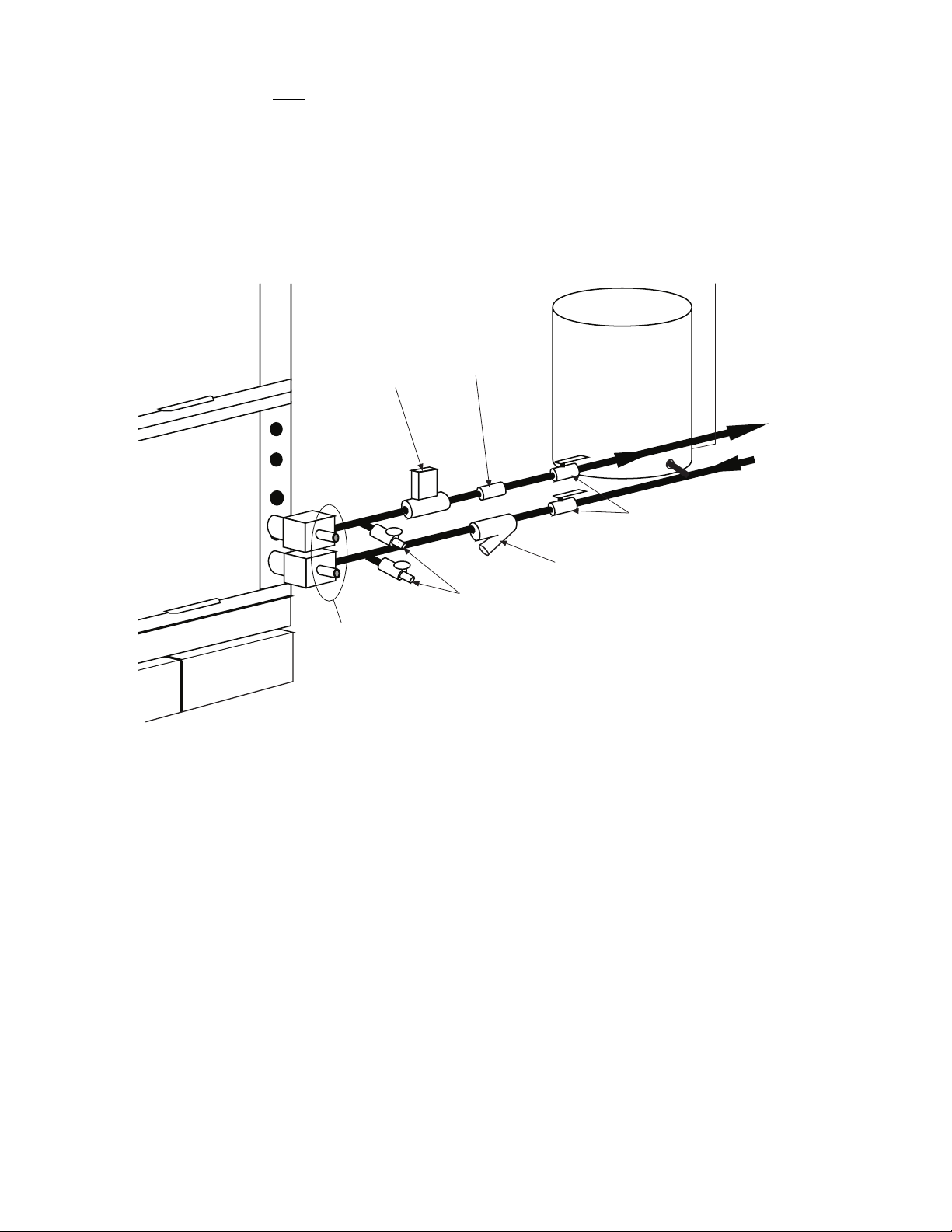

Fig. 2 — Typical Horizontal Installation

LEGEND

BSP — Blower Service Panel

CAP — Control Access Panel

CBP — Control Box Panel

EAP — Expansion Valve Access Panel

NOTES:

1. Access is required for all removable panels and installer should

take care to comply with all building codes and allow adequate

clearance.

2. Water inlet and outlet connections are available on either side of

the unit. Plugs are shipped loose in a plastic bag tied to the water

leg in front of the unit. Installer must plug unused connection.

3. Condensate drain connection is on end opposite of compressor.

4. Electrical access is available on either side of the front of the unit.

5. Electrical box is on right side but can be field-converted to left.

a50-8534

should be considered when choosing a location for a WSHP:

• Units are for indoor use only.

• Locate in areas where ambient temperatures are between

4.4 C and 37.8 C and relative humidity is no greater than

75%.

• Provide sufficient space for water, electrical and duct

connections.

• Locate unit in an area that allows for easy access and

removal of filter and access panels.

• Allow enough space for service personnel to perform

maintenance.

• Provisions must be made for return air to freely enter the

space if unit needs to be installed in a confined area such

as a closet.

NOTE: Correct placement of the horizontal unit can play an

important part in minimizing sound problems. Since ductwork is normally applied to these units, the unit can be placed

so that the principal sound emission is outside the occupied

space in sound-critical applications. A fire damper may be required by the local code if a fire wall is penetrated.

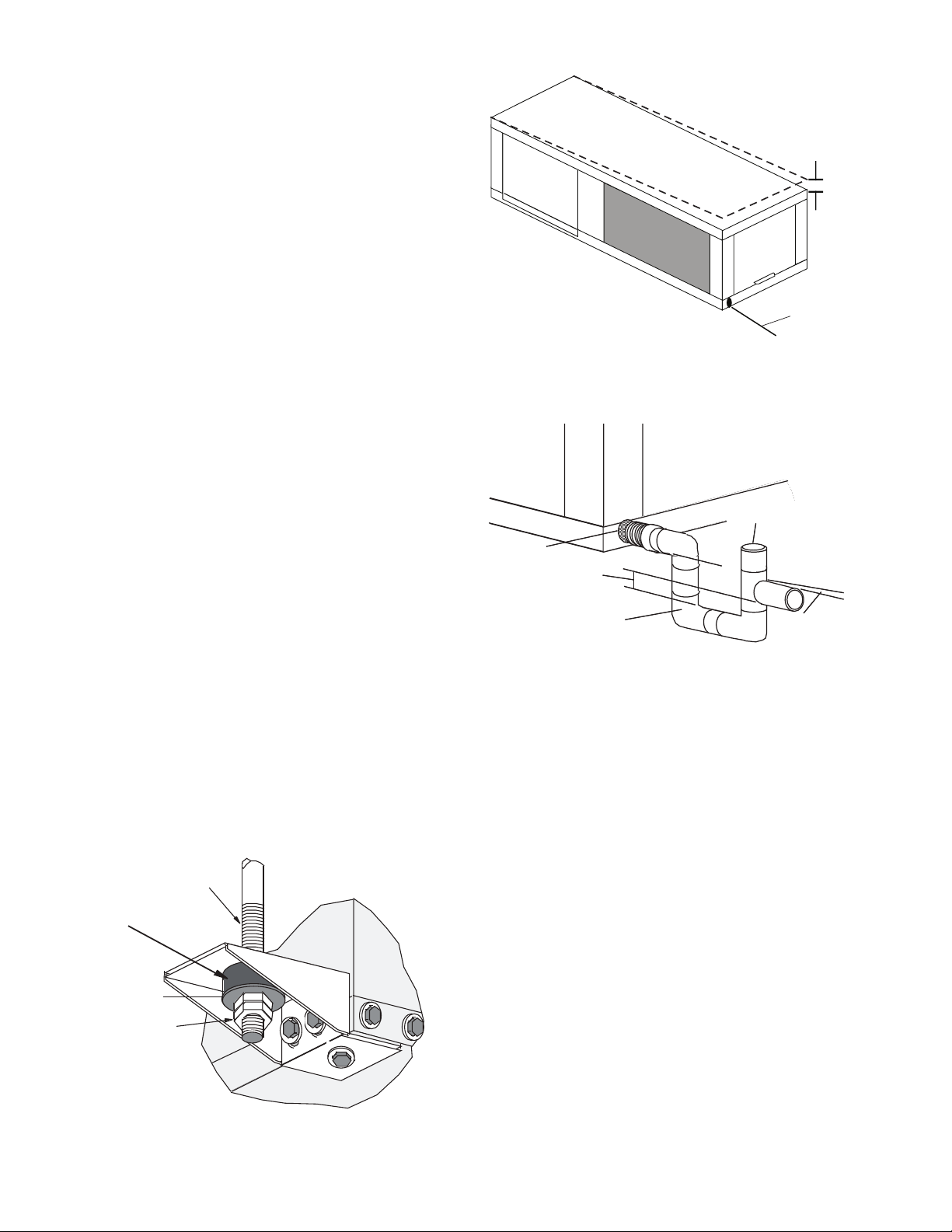

Step 4 — Mount Unit — Units should be mounted us-

ing the factory-installed hangers. See Fig. 3. Proper attachment

of hanging rods to building structure is critical for safety. See

Fig. 2. Rod attachments must be able to support the weight of

the unit. See Table 1 for unit operating weights.

Step 5 — Install Duct System — The duct system

should be sized to handle the design airflow quietly.

NOTE: Depending on the unit, the fan wheel may have a shipping support installed at the factory. This must be removed

before operating unit.

SOUND ATTENUATION — To eliminate the transfer of

vibration to the duct system, a flexible connector is recommended for both discharge and return air duct connections on

metal duct systems. The supply and return plenums should include internal duct liner of fiberglass or be made of duct board

construction to maximize sound attenuation of the blower.

Installing the WSHP unit to uninsulated ductwork in an unconditioned space is not recommended since it will sweat and

adversely affect the unit’s performance.

included in the supply and return air ducts, provided system

performance is not adversely impacted. The blower speed can

be also changed in the field to reduce air noise or excessive airflow, provided system performance is not adversely impacted.

5

To reduce air noise, at least one 90-degree elbow could be

Page 6

EXISTING DUCT SYSTEM — If the unit is connected to

3/8" [10MM] THREADED

ROD (FIELD SUPPLIED)

VIBRATION ISOLATOR

(FACTORY SUPPLIED)

WASHER

(FIELD SUPPLIED)

DOUBLE HEX NUTS

(FIELD SUPPLIED)

a50-6260e8535

Fig. 3 — Hanger Brackets

a50-6260ef8536

Fig. 4 — Horizontal Unit Pitch

*3/4" IPT

Trap Depth

1.5" [38mm]

Min 1.5"

[38mm]

1/4" per foot

(21mm per m)

drain slope

3/4" PVC or

Copper by others

Vent

Fig. 5 — Trap Condensate Drain

a50-6260e8537

existing ductwork, consider the following:

• Verify that the existing ducts have the proper capacity to

handle the unit airflow. If the ductwork is too small,

larger ductwork should be installed.

• Check existing ductwork for leaks and repair as

necessary.

NOTE: Local codes may require ventilation air to enter the

space for proper indoor air quality. Hard-duct ventilation may

be required for the ventilating air supply. If hard ducted ventilation is not required, be sure that a proper air path is provided

for ventilation air to unit to meet ventilation requirement of the

space.

Step 6 — Install Condensate Piping Drain

INSTALLATION — Slope the unit toward the drain at a

1 cm per 50 cm pitch. See Fig. 4. If it is not possible to meet the

required pitch, a condensate pump should be installed at the

unit to pump condensate to building drain.

Install condensate trap at each unit with the top of the trap

positioned below the unit condensate drain connection as

shown in Fig. 5. Design the depth of the trap (water-seal) based

upon the amount of ESP (external static pressure) capability of

the blower (where 2 in. wg of ESP capability requires 2 in. of

trap depth). As a general rule, 38 mm trap depth is the minimum. Each unit must be installed with its own individual trap

and connection to the condensate line (main) or riser.

Units are not internally trapped, therefore an external trap is

necessary. Each unit must be installed with its own individual

trap and means to flush or blowout the condensate drain line.

Do not install units with a common trap or vent. For typical

condensate connections see Fig. 5.

NOTE: Never use a pipe size smaller than the connection.

VENTING — A vent should be installed in the condensate

line of any application which may allow dirt or air to collect in

the line. Consider the following:

• Always install a vent where an application requires a

long horizontal run.

• Always install a vent where large units are working

against higher external static pressure and to allow

proper drainage for multiple units connected to the same

condensate main.

• Be sure to support the line where anticipated sagging

from the condensate or when “double trapping” may

occur.

• If condensate pump is present on unit, be sure drain connections have a check valve to prevent back flow of condensate into other units.

1/4” Pitch for

Drainage

Drain Connection

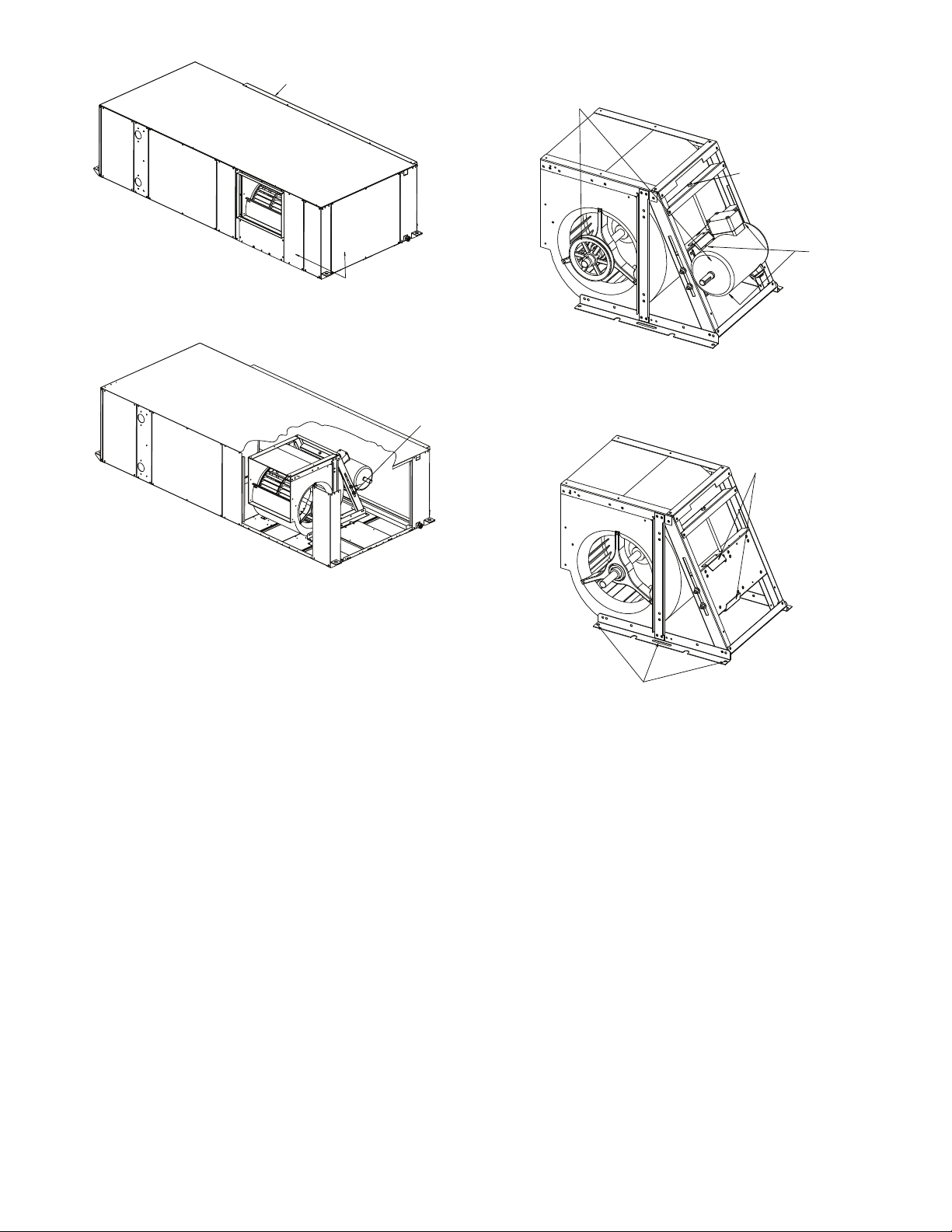

Step 7 — Field Convert Air Discharge — Hori-

zontal units can be field converted between straight (side) and

back (end) discharge.

NOTE: It is not possible to field convert return air between left

or right return models due to the necessity of refrigeration copper piping changes.

Field conversion must be completed on the ground. If the

unit is already hung it should be taken down for the field conversion. Place in a well-lighted area. Conversion should only

be attempted by a qualified service technician.

SIDE TO BACK DISCHARGE CONVERSION

1. Remove back panel and side access panel. See Fig. 6.

2. Loosen 2 motor slide nuts, raise motor slide assembly and

remove belt and motor sheave. See Fig. 7.

3. Remove blower sheave. Remove motor bolts and carefully remove motor. See Fig. 8.

4. Remove 2 motor clips and reattach to opposite side. See

Fig. 9.

5. Unbolt (3 per side) complete housing assembly. See

Fig. 9.

6. Rotate complete assembly into new position. Locate over

mounting holes in base, reattach using 3 bolts per side.

6

Pitch Toward

Drain

Page 7

REMOVE BLOWER PANEL

AND ACCESS PANEL

RETURN AIR

FRONT

Fig. 6 — Removing Panels

a50-8538

MOTOR SLIDE NUTS

Fig. 7 — Removing Belt

a50-8539

REMOVE MOTOR

AND BLOWER SHEAVE

ADJUSTING BOLT

REMOVE 4

MOTOR BOLTS

Fig. 8 — Removing Motor

a50-8540

MOTOR CLIPS

BOLTS

Fig. 9 — Removing Blower Assembly

a50-8541

7. Mount motor, motor sheave, blower sheave and belt.

8. Replace panels from Step 1.

BACK TO SIDE DISCHARGE CONVERSION — If the

discharge is changed from back to side, use the above instructions. Note that figures will be reversed.

LEFT OR RIGHT RETURN UNITS — It is not possible to

field convert return air between left or right return units due to

the necessity of refrigeration copper piping changes. However,

the conversion process of side to back or back to side discharge

for either right or left return configuration is the same. In some

cases, it may be possible to rotate the entire unit 180 degrees if

the return air connection needs to be on the opposite side. Note

that rotating the unit will move the piping to the other end of

the unit.

Step 8 — Install Piping Connections — Depend-

ing on the application, there are 3 types of WSHP piping systems to choose from: water loop, ground-water and ground loop.

Refer to the Carrier System Design Manual for additional information.

pipe thread fittings for water connections to prevent annealing

and out-of-round leak problems which are typically associated

with high temperature brazed connections. Refer to Table 1 for

connection sizes. When making piping connections, consider

the following:

• A backup wrench must be used when making screw con-

Make sure wires are not pinched and not over sharp edges. Adjust motor downward to tighten belt. Raise or lower

motor slide assembly with adjusting bolt and retighten the

2 slide nuts. Check for correct tension. Rewire motor (at

contactor) for correct rotation. Spin blower wheel to ensure wheel is not obstructed.

All WSHP units utilize low temperature soldered female

nections to unit to prevent internal damage to piping.

• Insulation may be required on piping to avoid condensation in the case where fluid in loop piping operates at

temperatures below dew point of adjacent air.

• Piping systems that contain steel pipes or fittings may

be subject to galvanic corrosion. Dielectric fittings may

be used to isolate the steel parts of the system to avoid

galvanic corrosion.

• Do not allow hoses to rest against structural building

components. Compressor vibration may be transmitted

through the hoses to the structure, causing unnecessary

noise complaints.

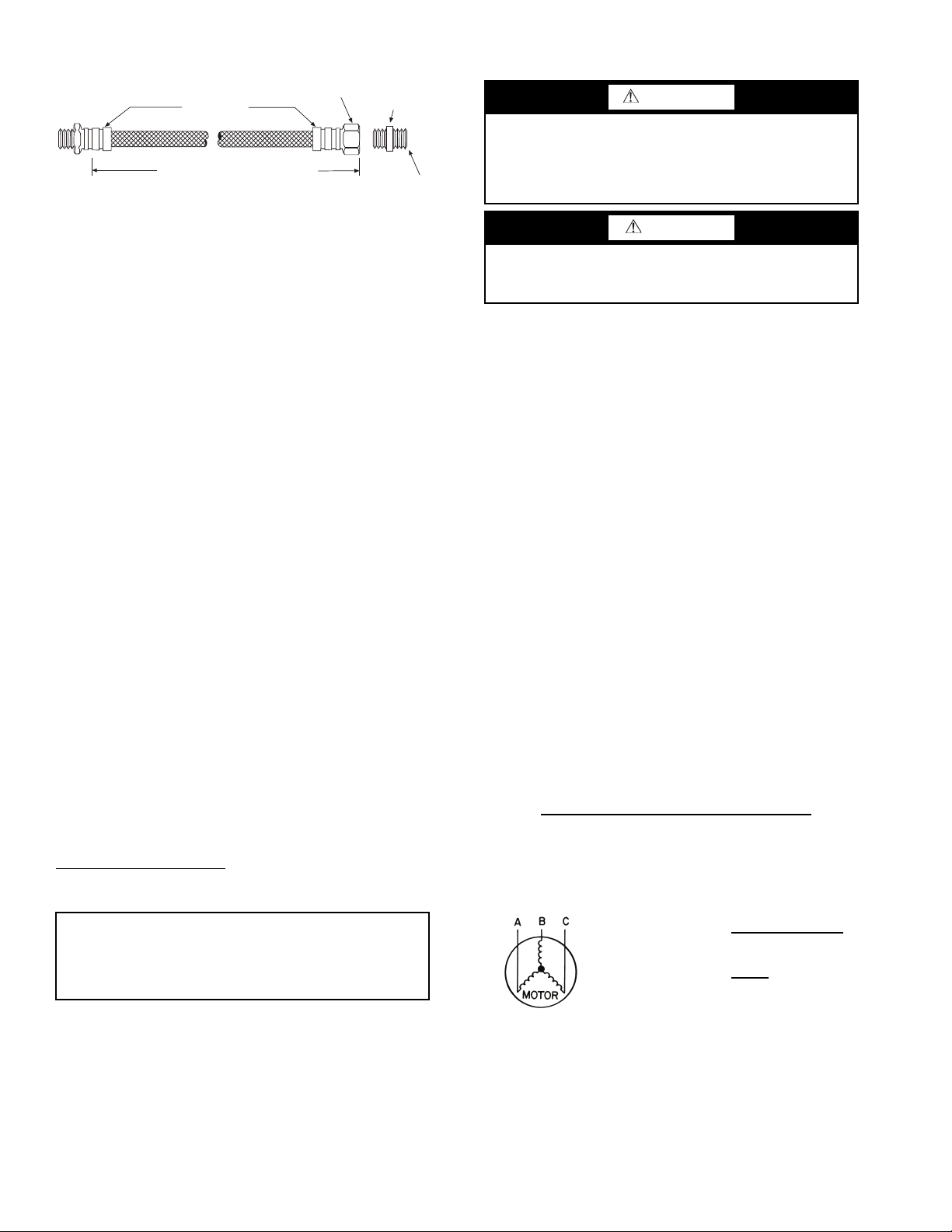

Figure 10 shows a typical supply/return hose kit assembly.

WATER LOOP APPLICATIONS — Water loop applications

usually include a number of units plumbed to a common piping system. Maintenance to any of these units can introduce air

into the piping system. Therefore, air elimination equipment

comprises a major portion of the mechanical room plumbing.

The flow rate is usually set between 2.41 and 3.23 L/m per

kW of cooling capacity. For proper maintenance and servicing,

pressure-temperature (P/T) ports are necessary for temperature

and flow verification.

In addition to complying with any applicable codes, consid-

er the following for system piping:

• Piping systems utilizing water temperatures below

10 C require 13 mm closed cell insulation on all piping

surfaces to eliminate condensation.

7

Page 8

Step 9 — Install Field Power Supply Wiring

RIB CRIMPED

LENGTH

(2 FT [0.6M] LENGTH STANDARD)

SWIVEL

BRASS

FITTING

BRASS

FITTING

EPT

Fig. 10 — Supply/Return Hose Kit

WARNING

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all disconnect locations to alert others not to restore power until work

is completed.

• All plastic to metal threaded fittings should be avoided

due to the potential to leak. Use a flange fitted substitute.

• Teflon tape thread sealant is recommended to minimize

internal fouling of the heat exchanger.

• Use backup wrench. Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• The piping system should be flushed prior to operation to

remove dirt and foreign materials from the system.

GROUND-LOOP APPLICATIONS — Temperatures between –3.9 and 43.3 C and a cooling capacity of 2.41 to

3.23 L/s per kW of flow per ton are recommended. In

addition to complying with any applicable codes, consider

the following for system piping:

• Piping materials should be limited to only polyethylene

fusion in the buried sections of the loop.

• Galvanized or steel fittings should not be used at any

time due to corrosion.

• All plastic to metal threaded fittings should be avoided

due to the potential to leak. Use a flange fitted substitute.

• Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• Pressure-temperature (P/T) plugs should be used to measure flow of pressure drop.

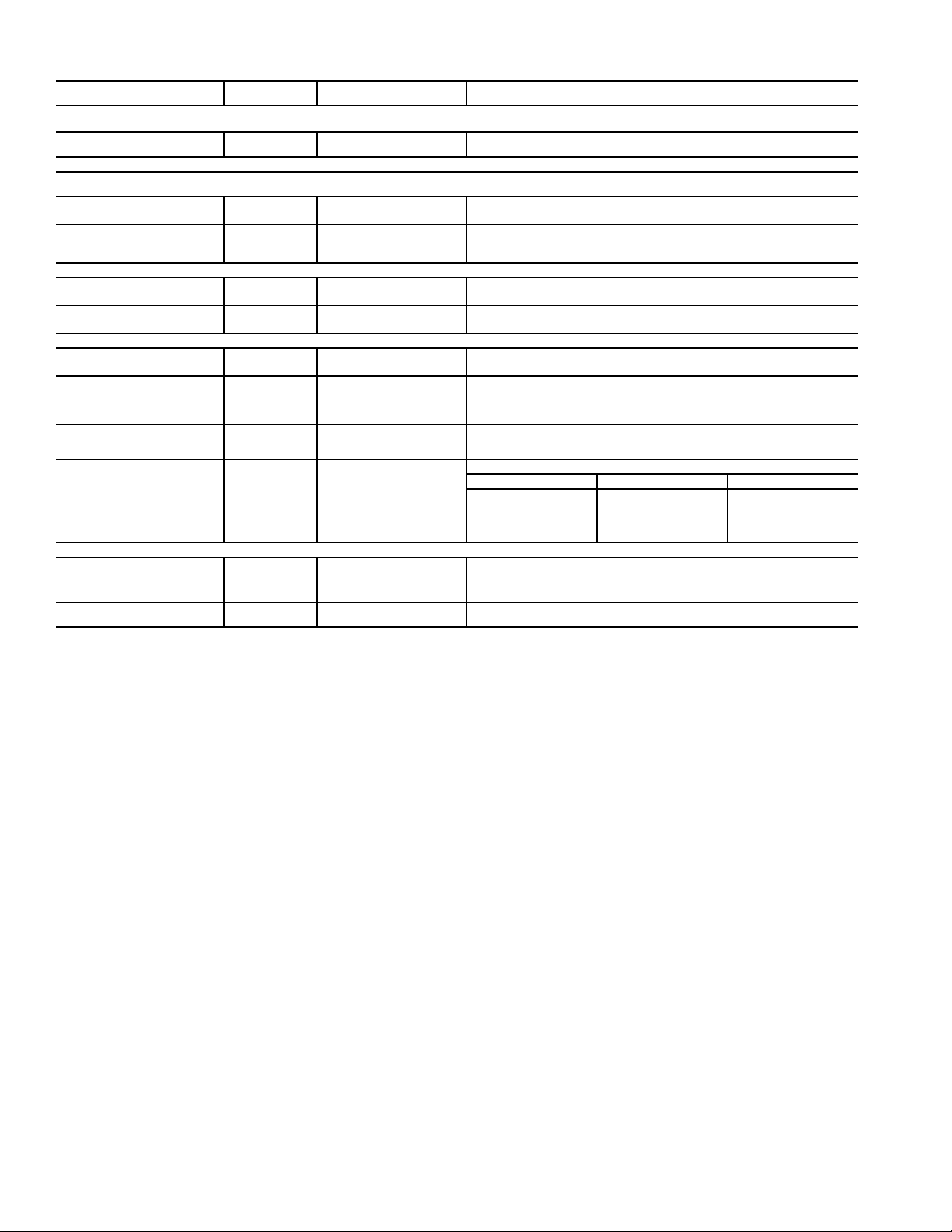

GROUND-WATER APPLICATIONS — Typical groundwater piping is shown in Fig. 11. In addition to complying

with any applicable codes, consider the following for system piping:

• Install shut-off valves for servicing.

• Install pressure-temperature plugs to measure flow and

temperature.

• Boiler drains and other valves should be connected using

a “T” connector to allow acid flushing for the heat

exchanger.

• Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• Use PVC SCH80 or copper piping material.

NOTE: PVC SCH40 should not be used due to system high

pressure and temperature extremes.

Water Supply and Quantity

— Check water supply. Water

supply should be plentiful and of good quality. See Table 2 for

water quality guidelines.

IMPORTANT: Failure to comply with the above required

water quality and quantity limitations and the closedsystem application design requirements may cause damage

to the tube-in-tube heat exchanger that is not the responsibility of the manufacturer.

CAUTION

Use only copper conductors for field-installed electrical

wiring. Unit terminals are not designed to accept other

types of conductors.

All field-installed wiring, including the electrical ground,

MUST comply with the National Electrical Code (NEC,

U.S.A.) as well as applicable local codes. In addition, all field

wiring must conform to the Class II temperature limitations described in the NEC.

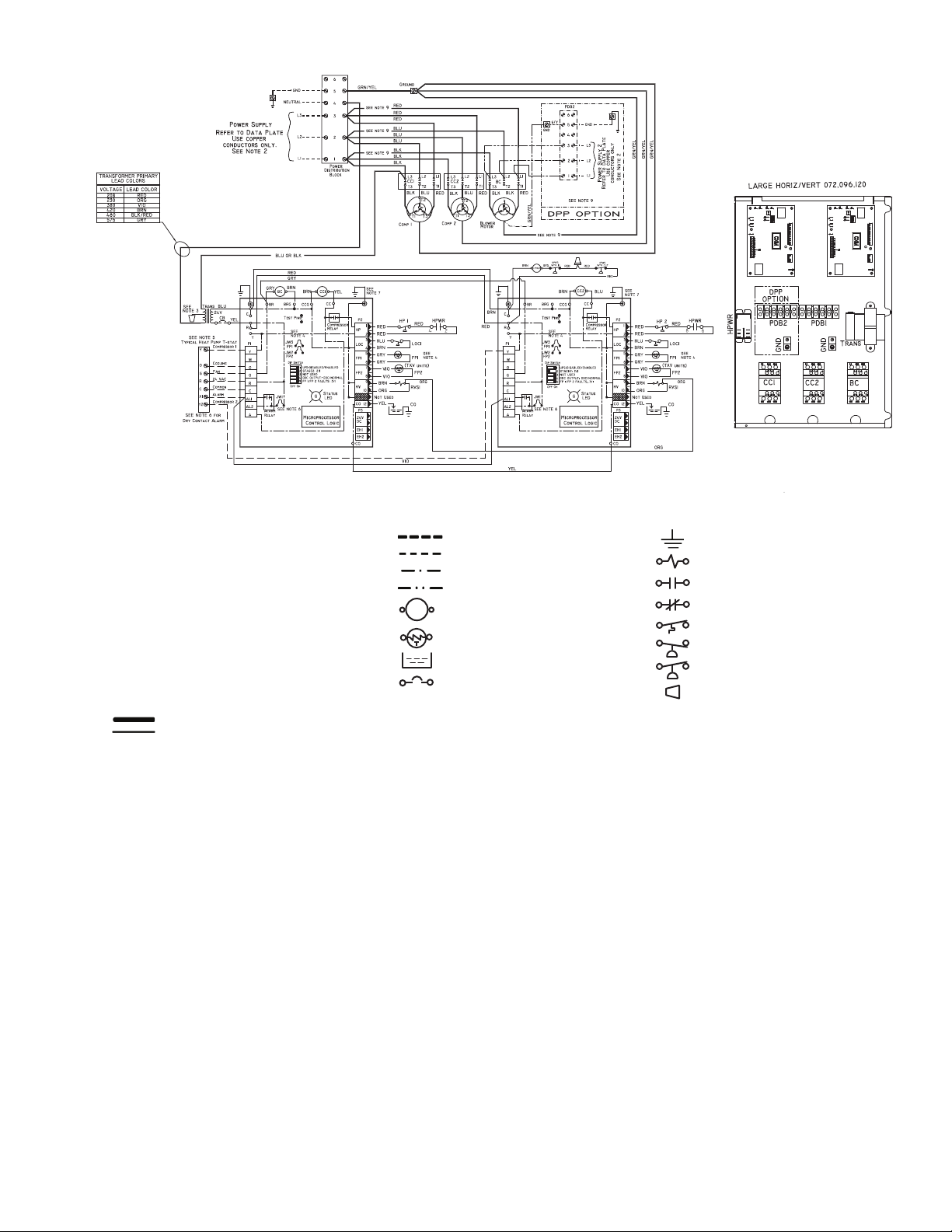

Refer to unit wiring diagrams Fig. 12-16 for fuse sizes and a

schematic of the field connections which must be made by the

installing (or electrical) contractor.

Consult the unit wiring diagram located on the inside of the

compressor access panel to ensure proper electrical hookup.

The installing (or electrical) contractor must make the field

connections when using field-supplied disconnect.

Operating voltage must be the same voltage and phase as

shown in electrical data shown in Tables 3A and 3B.

Make all final electrical connections with a length of flexible conduit to minimize vibration and sound transmission to

the building.

POWER CONNECTION — Line voltage connection is

made by connecting the incoming line voltage wires to the

L side of the power block terminal. See Fig. 17. See Tables

3A and 3B for correct wire and maximum overcurrent protection sizing. See Table 4 for low voltage VA ratings.

SUPPLY VOLTAGE — Operating voltage to unit must be

within voltage range indicated on unit nameplate.

On 3-phase units, voltages under load between phases must

be balanced within 2%. Use the following formula to determine the percentage voltage imbalance:

% Voltage Imbalance

= 100 x

Example: Supply voltage is 420-3-50.

max voltage deviation from average voltage

average voltage

AB = 425 volts

BC = 422 volts

AC = 417 volts

Average Voltage =

425 + 422 + 417

1264

=

3

3

In all applications, the quality of the water circulated

through the heat exchanger must fall within the ranges listed in

the Water Quality Guidelines table. Consult a local water treatment firm, independent testing facility, or local water authority

for specific recommendations to maintain water quality within

the published limits.

= 421

Determine maximum deviation from average voltage:

(AB) 425 – 421 = 4 v

(BC) 422 – 421 = 1 v

(AC) 421 – 418 = 3 v

Maximum deviation is 4 v.

8

Page 9

Determine percent voltage imbalance.

PressureTemperature

Plugs

Boiler

Drains

Strainer – Field-Installed Accessory

(16 to 20 mesh recommended for

filter sediment)

Shut-Off

Valve

Water

Control

Valve

Automatic

Balance Valve

Expansion

Tank

Water Out

Water In

From Pump

Fig. 11 — Typical Ground-Water Piping Installation

a50-8542

% Voltage Imbalance = 100 x

4

421

= 0.95%

This amount of phase imbalance is satisfactory as it is

below the maximum allowable 2%.

Operation on improper line voltage or excessive phase

imbalance constitutes abuse and may cause damage to electrical components.

NOTE: If more than 2% voltage imbalance is present, contact

local electric utility.

EXTERNAL LOOP POWER CONNECTION — If the unit

is to be connected to an external loop pump or flow controller,

connect the pump to the loop pump terminal block PB1. The

maximum power handling is 4 amps at 240 volts. The pumps

will automatically cycle as required by the unit.

420-VOLT OPERATION — All 380/420 volt units are factory

wired for 380 volts. The transformers may be switched to

420-volt operation (as illustrated on the wiring diagram) by

disconnecting the VIO lead at L1 and attaching the BRN lead

to L1. Close open end of VIO lead.

9

Page 10

Table 2 — Water Quality Guidelines

CONDITION

Scaling Potential — Primary Measurement

Above the given limits, scaling is likely to occur. Scaling indexes should be calculated using the limits below.

pH/Calcium

Hardness Method

Index Limits for Probable Scaling Situations (Operation outside these limits is not recommended.)

Scaling indexes should be calculated at 150 F for direct use and HWG applications, and at 90 F for indirect HX use. A monitoring plan should be

implemented.

Ryznar Stability Index

Langelier Saturation Index

Iron Fouling

2+

(Ferrous)

Iron Fe

(Bacterial Iron Potential)

Iron Fouling

Corrosion Prevention††

pH

Hydrogen Sulfide (H

Ammonia Ion as Hydroxide,

Chloride, Nitrate and Sulfate

Compounds

S)

2

Maximum Chloride Levels Maximum allowable at maximum water temperature.

Erosion and Clogging

Particulate Size and Erosion

Brackish

LEGEND

HWG — Hot Water Generator

HX — Heat Exchanger

N/A — Design Limits Not Applicable Considering Recirculating

NR — Application Not Recommended

SS — Stainless Steel

*Heat exchanger materials considered are copper, cupronickel, 304 SS (stainless

steel), 316 SS, titanium.

†Closed recirculating system is identified by a closed pressurized piping system.

**Recirculating open wells should observe the open recirculating design

considerations.

Potable Water

HX

MATERIAL*

CLOSED RECIRCULATING† OPEN LOOP AND RECIRCULATING WELL**

All N/A pH < 7.5 and Ca Hardness, <100 ppm

All N/A

All N/A

All N/A

All N/A

All

6 - 8.5

Monitor/treat as needed.

If >7.5 minimize steel pipe use.

Based upon 150 F HWG and direct well, 85 F indirect well HX.

2+

If Fe

(ferrous) >0.2 ppm with pH 6 - 8, O2<5 ppm check for iron bacteria.

If <–0.5 minimize steel pipe use.

Above this level deposition will occur.

Minimize steel pipe below 7 and no open tanks with pH <8.

6.0 - 7.5

–0.5 to +0.5

<0.2 ppm (Ferrous)

<0.5 ppm of Oxygen

6 - 8.5

<0.5 ppm

At H

S>0.2 ppm, avoid use of copper and cupronickel piping or HXs.

All N/A

All N/A

Copper N/A

CuproNickel N/A <150 ppm NR NR

304 SS N/A <400 ppm <250 ppm <150 ppm

316 SS N/A <1000 ppm <550 ppm <375 ppm

Titanium N/A >1000 ppm >550 ppm >375 ppm

<10 ppm of particles and a max-

All

imum velocity of 6 fps. Filtered

for maximum

800 micron size.

All N/A

<10 ppm (<1 ppm “sand free” for reinjection) of particles and a maximum velocity of 6

fps. Filtered for maximum 800 micron size. Any particulate that is not removed can

potentially clog components.

Use cupronickel heat exchanger when concentrations of calcium or sodium chloride

are greater than 125 ppm are present. (Seawater is approximately 25,000 ppm.)

2

Copper alloy (bronze or brass) cast components are okay to <0.5 ppm.

Rotten egg smell appears at 0.5 ppm level.

<0.5 ppm

50 F (10 C) 75 F (24 C) 100 F (38 C)

<20 ppm NR NR

††If the concentration of these corrosives exceeds the maximum allowable level,

then the potential for serious corrosion problems exists.

Sulfides in the water quickly oxidize when exposed to air, requiring that no agitation

occur as the sample is taken. Unless tested immediately at the site, the sample will

require stabilization with a few drops of one Molar zinc acetate solution, allowing

accurate sulfide determination up to 24 hours after sampling. A low pH and high

alkalinity cause system problems, even when both values are within ranges shown.

The term pH refers to the acidity, basicity, or neutrality of the water supply. Below

7.0, the water is considered to be acidic. Above 7.0, water is considered to be basic.

Neutral water contains a pH of 7.0.

NOTE: To convert ppm to grains per gallon, divide by 17. Hardness in mg/l is equivalent to ppm.

10

Page 11

BC — Blower Contactor

CB — Circuit Breaker

CC — Compressor Contactor

CO — Sensor, Condensate Overflow

DPP — Dual Point Power

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

HP — High-Pressure Switch

HPWR — High-Pressure Water Relay

JW3 — Clippable Field Selection Jumper

LOC — Loss of Charge Pressure Switch

PDB — Power Distribution Block

RVS — Reversing Valve Solenoid

TRANS — Tr a n sf o r me r

TXV — Thermostatic Expansion Valve

Factory Line Voltage Wiring

Factory Low Voltage Wiring

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with NEC (National Electrical

Code, U.S.A.) and local codes.

3. 380/420-v transformers will be connected for 380-v operation. For

420-v operation, disconnect VIO lead at L1, and attach BRN lead

to L1. Close open end of VIO lead.

4. FPI thermistor provides freeze protection for WATER. When using

ANTIFREEZE solutions, cut JW3 jumper.

5. Typical heat pump thermostat wiring shown. Refer to thermostat

installation instructions for wiring to the unit. Thermostat wiring

must be “Class 1” and voltage rating equal to or greater than unit

supply voltage.

6. 24-v alarm signal shown. For dry alarm contact, cut JW1 jumper

and dry contact will be available between AL1 and AL2.

7. Transformer secondary ground via Complete C board standoffs

and screws to control box. (Ground available from top two standoffs as shown.)

8. Suffix 1 designates association with lead compressor. Suffix 2

with lag compressor.

9. For dual point power (DPP) option, blower wire will connect to

other PBD.

LEGEND

Field Line Voltage Wiring

Field Low Voltage Wiring

Printed Circuit Trace

Optional Wiring

Relay/Contactor Coil

Thermistor

Condensate Pan

Circuit Breaker

Ground

Solenoid Coil

Relay Contacts - N.O.

Relay Contacts - N.C.

Temperature Switch

Switch - Low Pressure

Switch - High Pressure

Wire Nut

Fig. 12 — 50HQP072-120 Units — Typical Control Wiring with Complete C Control

Complete C

Complete C1

Complete C

Complete C2

Complete C2

Complete C1

11

Page 12

Fig. 13 — 50HQP072-120 Units — Typical Control Wiring with Deluxe D Control

See legend and notes on page 11.

Deluxe D1

Deluxe D

Deluxe D2

Deluxe D

Deluxe D2

Deluxe D1

12

Page 13

Y

W

O

G

R

C

AL1

AL2

A

CR

CMP1

FAN

PWR

HS1/EXH/RVS

PREMIER

LINK

CR

COMPLETE

C

CONTROL

J4

J6

J5

J8

J1

PWR

S

P

S

A

L

W

CMPSAFE

T

T

T

Y1

G

R

C

AL1

CMP1

FAN

PWR

PREMIER

LINK

DELUXE

D

CONTROL

J4

J8

J1

PWR

CMPSAFE

HS2

HS1

CMP2

Y2

W1

O/W2

J6

J5

S

P

T

S

A

T

L

W

T

Fig. 14 — Premierlink™ Controller Applications Wiring with Complete C Control

LEGEND

NOTE: Reversing valve is on in Cooling

mode.

CR — Control Relay

LWT — Leaving Water Temperature Sensor

SAT — Supply Air Temperature Sensor

SPT — Space Temperature Sensor

Fig. 15 — Premierlink Controller Applications Wiring with Deluxe D Control

LEGEND

NOTE: Reversing valve is on in Cooling

mode.

LWT — Leaving Water Temperature Sensor

SAT — Supply Air Temperature Sensor

SPT — Space Temperature Sensor

13

Page 14

Table 3A — Electrical Data — 50HQP072-120 Standard Units

NOTE: Low voltage connector may be removed for easy installation.

Fig. 16 — Low Voltage Field Wiring

Fig. 17 — Line Voltage Wiring

UNIT

50HQP

072 9 380/420-3-50 360/440 A,B,C 2 5.4 38.0 1.8 12.6 13.9 15

096 9 380/420-3-50 360/440 A,B,C 2 6.1 43.0 3.4 15.6 17.1 20

120 9 380/420-3-50 360/440 A,B,C 2 7.8 51.5 4.9 20.5 22.5 30

VOLTAGE

CODE

VO LTAGE

MIN/MAX

VOLTAGE

BLOWER

OPTION

COMPRESSOR FAN

QTY RLA LRA

MOTOR

FLA

TOTAL

UNIT

FLA

MIN

CIRCUIT

AMP

Table 3B — Electrical Data — 50HQP072-120 Dual Point Power Units

UNIT

50HQP

LEGEND

FLA — Full Load Amps

HACR — Heating, Air Conditioning, and Refrigeration

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

RLA — Rated Load Amps

*Time-delay fuse or HACR circuit breaker.

VOLTAGE

CODE

072 9 380/420-3-50 360/440 A,B,C 2 5.4 38.0 10.8 12.2 15 1.8 2.3 15

096 9 380/420-3-50 360/440 A,B,C 2 6.1 43.0 12.2 13.7 15 3.4 4.3 15

120 9 380/420-3-50 360/440 A,B,C 2 7.8 51.5 15.6 17.6 25 4.9 6.1 15

VO LTAGE

MIN/MAX

VOLTAGE

BLOWER

OPTION

QTY RLA LRA

COMPRESSOR

Tot al

Comp

FLA

Comp

MCA

Comp

Max

Fuse

EMERGENCY

POWER SUPPLY

Fan

Motor

FLA

Fan

MCA

Table 4 — Low Voltage VA Ratings

MAX

FUSE

FAN

MAX

FUSE

COMPONENTS IN UNIT VA

Typical Blower Contactor 6 - 9

Typical Reversing Valve Solenoid (2) 8 - 12

30A Compressor Contactor (2) 12 - 18

Complete C Board (2) 10 - 18

Deluxe D Board (2) 16 - 24

Remaining VA for Accessories*

Units with Complete C

Units with Deluxe D

* Standard transformer is 75 VA.

18 - 39

12 - 33

Complete C 2Complete C 1

POWER

BLOCK

14

Page 15

Step 10 — Install Field Control Wiring

a50-6268tf.tif

AQUAZONE CONTROL (Complete C Control Shown)

Fig. 18 — Typical Aquazone™ Control Board

Jumper Locations

TYPICAL

WATER

VALVE

C

A

24 VAC

TERMINAL STRIP P2

Fig. 19 — Typical Aquazone Accessory Wiring

(Control D Shown)

THERMOSTAT

Compressor-Stage 1

Reversing Valve

Fan

24Vac Hot

Y1

Y2

O

G

R

Y

O

G

R

CompleteC 1

Y

O

G

R

24Vac Com

C

C

Compressor-Stage 2

C

AL

AL

AL

CompleteC 2

Fig. 20 — Thermostat Wiring to Complete C Board

THERMOSTAT

Compressor-Stage 1

Reversing Valve

Fan

24Vac Hot

Y1

Y2

O

G

R

O

G

R

Deluxe D 1

Y

O

G

R

24Vac Com

C

C

Compressor-Stage 2

C

AL1

AL1

AL

Y1

Y2

COM 2

COM 2

Deluxe D 2

Fig. 21 — Thermostat Wiring to Deluxe D Board

THERMOSTAT CONNECTIONS — The thermostat should

be wired directly to the Aquazone™ control board. See

Fig. 18 and 19.

The thermostat should be located on an interior wall in a

larger room, away from supply duct drafts. DO NOT locate the

thermostat in areas subject to sunlight, drafts or on external

walls. The wire access hole behind the thermostat may in certain cases need to be sealed to prevent erroneous temperature

measurement.

Position the thermostat back plate against the wall so that it

appears level and so the thermostat wires protrude through the

middle of the back plate. Mark the position of the back plate

mounting holes and drill holes with a

plied anchors and secure plate to the wall. Thermostat wire

must be 18 AWG (American Wire Gage) wire. Wire the appropriate thermostat as shown in Fig. 20 and 21 to the low voltage

terminal strip on the Complete C or Deluxe D control board.

Most heat pump thermostats will work with a Carrier unit,

provided the thermostat has the correct number of heating and

cooling stages.

WATER FREEZE PROTECTION — The Aquazone control

allows the field selection of source fluid freeze protection

points through jumpers. The factory setting of jumper JW3

(FP1) is set for water at –1.1 C. In earth loop applications,

jumper JW3 should be clipped to change the setting to –12.2 C

when using antifreeze in colder earth loop applications. See

Fig. 18.

AIR COIL FREEZE PROTECTION — The air coil freeze

protection jumper JW2 (FP2) is factory set for –1.1 C and

should not need adjusting.

ACCESSORY CONNECTIONS — Terminal labeled A on

the control is provided to control accessory devices such as

water valves, electronic air cleaners, humidifiers, etc. This signal operates with the compressor terminal. See Fig. 19. Refer

to the specific unit wiring schematic for details.

NOTE: The A terminal should only be used with 24 volt

signals — not line voltage signals.

3

/16-in. bit. Install sup-

WATER SOLENOID VALVES — Water solenoid valves may

be used on variable flow systems and ground water installations. A typical well water control valve wiring which can

limit waste water in a lockout condition is shown in Fig. 18. A

slow closing valve may be required to prevent water hammer.

When using a slow closing valve, special wiring conditions

need to be considered. The valve takes approximately 60 seconds to open (very little water will flow before 45 seconds) and

it activates the compressor only after the valve is completely

opened by closing its end switch. When wired as shown, the

valve will have the following operating characteristics:

1. Remain open during a lockout.

2. Draw approximately 25 to 35 VA through the “Y” signal

of the thermostat.

IMPORTANT: The use of a slow-closing water solenoid

valve can overheat the anticipators of electromechanical

thermostats. Only use relay based electronic thermostats.

15

Page 16

PRE-START-UP

System Checkout —

follow the system checkout procedure outlined below before

starting up the system. Be sure:

1. Voltage is within the utilization range specifications of the

unit compressor and fan motor and voltage is balanced

for 3-phase units.

2. Fuses, breakers and wire are correct size.

3. Low voltage wiring is complete.

4. Piping and system flushing is complete.

5. Air is purged from closed loop system.

6. System is balanced as required. Monitor if necessary.

7. Isolation valves are open.

8. Water control valves or loop pumps are wired.

9. Condensate line is open and correctly pitched.

10. Transformer switched to lower voltage tap if necessary.

11. Blower rotates freely — shipping support is removed.

12. Blower speed is on correct setting.

13. Air filter is clean and in position.

14. Service/access panels are in place.

15. Return-air temperature is 4.4 to 26.7 C for heating and

10.0 to 43.3 C for cooling.

16. Air coil is clean.

17. Control field selected settings are correct.

AIR COIL — To obtain maximum performance, the air coil

should be cleaned before starting the unit. A ten percent

solution of dishwasher detergent and water is recommended

for both sides of the coil. Rinse thoroughly with water.

When the installation is complete,

Airflow and External Static Pressure — The

50HQP units are available with standard, low, and high-static

factory-installed options. These options will substitute a different blower drive sheave for each static range. In addition, certain static ranges may require the optional large fan motor.

SHEAVE ADJUSTMENT — The 50HQP units are supplied

with a variable sheave drive on the fan motor to adjust for differing airflows at various ESP (external static pressure) conditions. See Tables 5-7 for unit airflows. When fully closed, the

sheave will produce the highest static capability (higher rpm).

To adjust sheave position, follow the procedure outlined

below:

1. Loosen belt tension and remove belt.

2. Loosen set screw on fan motor.

3. Open sheave to desired position.

4. Retighten set screw and replace belt.

NOTE: Set belt tension as outlined below.

BELT TENSION ADJUSTMENT — An overly loose belt

will, upon starting motor, produce a slippage “squeal” and

cause premature belt failure and or intermittent airflow. An

overly tight belt can cause premature motor or blower bearing failure. To adjust the belt tension, follow the procedure

outlined below:

1. Remove belt from motor sheave.

2. Lift motor assembly.

3. Loosen the

5

/16-in. hex nuts on the grommet motor adjustment bolts (2 per bolt). To increase the belt tension loosen

the top hex nut. To decrease the belt tension loosen the

bottom hex nut.

4. Turn the bolts by hand to the desired position then tighten

5

the

/16-in. hex nuts (2 per bolt).

5. Lower the motor assembly.

6. Install the belt.

7. The belt tension can be adjusted by using one of the following methods:

a. Tighten until belt deflects approximately 13 mm

with very firm finger pressure.

b. Grasp belt midway between two pulleys and twist

for a 90-degreerotation.

NOTE: Adjusting less than 90 degrees will over-

tighten the belt and adjusting more than 90degrees

will loosen belt.

c. Set proper belt tension to 32 to 36 kg.

NOTE: The motor position should not need adjustment. Motor

sheave position is at mid position of each sheave. For example,

the motor sheave is 2.5 turns open on a 5-turn sheave. The belt

tension adjustment can also be accomplished by turning the

5

/16-in. hex nuts to the desired position.

NOTE: Available airflows for all units are shown in

Tables 5-7.

16

Page 17

Table 5 — Blower Data — 50HQP072

AIRFLOW

(l/s)

BkW — — 0.09 0.12 0.14 0.17 0.19 0.21 0.24 0.25 0.27 0.29 0.31 0.32 0.34 0.35

Sheave/Mtr ——BAAAAACCCCCCCC

614

661

708

755

802

850

897

944

991

1038

1086

1133

1180

LEGEND NOTES:

——Operation Not Recommended

BkW — Brake Kilowatts

ESP — External Static Pressure

RPM — Revolutions Per Minute

A—Units with Standard Rpm/Standard Motor Option

B—Units with Low Rpm/Standard Motor Option

C—Units with High Rpm/Standard Motor Option

RPM — — 505 563 615 655 695 730 765 790 815 840 870 890 910 925

Turns Open ——353.532154.543.52.52.521.5

BkW — 0.120.140.170.190.220.240.260.290.300.330.340.360.380.40 —

Sheave/Mtr —BA AAACCCCCCCCC—

RPM — 526 578 635 675 715 755 785 815 840 870 890 910 930 950 —

Turns Open — 24.532.51.554.543.53 2 21.51 —

BkW 0.12 0.14 0.17 0.19 0.22 0.25 0.27 0.29 0.32 0.34 0.36 0.38 0.41 0.43 — —

Sheave/Mtr BBAA AACCCCCCCC——

RPM 500 547 604 650 695 735 775 805 835 865 890 915 940 960 — —

Turns Open 31.54 3 2 14.543.532.521.51 ——

BkW 0.14 0.17 0.19 0.22 0.25 0.27 0.29 0.32 0.34 0.37 0.39 0.41 0.44 — — —

Sheave/Mtr BBAA AACCCCCCC———

RPM 510 568 620 665 710 750 785 820 855 885 910 935 960 — — —

Turns Open 2.513.52.51.514.53.532.521.51 ———

BkW 0.16 0.19 0.22 0.24 0.27 0.29 0.32 0.34 0.36 0.39 0.42 0.44 — — — —

Sheave/Mtr BAAA ACCCCCCC————

RPM 531 583 635 680 720 765 800 835 870 900 925 950 — — — —

Turns Open 2 4.5 3.5 2.5 1.5 5 4 3.5 2.5 2 1.5 1 — — — —

BkW 0.15 0.18 0.21 0.24 0.26 0.29 0.31 0.34 0.36 0.39 0.42 0.45 — — — —

Sheave/Mtr BBAA AACCCCCC————

RPM 500 547 599 645 690 735 775 815 850 885 910 940 — — — —

Turns Open 31.543215432.521.5————

BkW 0.18 0.21 0.23 0.27 0.30 0.33 0.36 0.40 0.43 0.46 0.49 0.52 — — — —

Sheave/Mtr BBAA AACCCCCC————

RPM 510 557 604 655 695 740 780 820 855 890 920 950 — — — —

Turns Open 2.5 1.5 4 3 2 1 4.5 3.5 3 2 1.5 1 — — — —

BkW 0.21 0.23 0.26 0.29 0.33 0.37 0.41 0.44 0.48 0.50 0.54 0.56 — — — —

Sheave/Mtr BBAA ACCCCCCC————

RPM 521 568 615 660 705 750 785 825 865 895 930 960 — — — —

Turns Open 2.5 1 3.5 2.5 1.5 5.5 4.5 3.5 2.5 2 1.5 1 — — — —

BkW 0.25 0.28 0.32 0.34 0.37 0.40 0.44 0.48 0.52 0.55 0.58 — — — — —

Sheave/Mtr BAAA ACCCCCC—————

RPM 536 583 630 670 715 755 795 835 875 905 940 — — — — —

Turns Open 2 4.5 3.5 2.5 1.5 5 4 3.5 2.5 2 1 — — — — —

BkW 0.28 0.30 0.34 0.37 0.41 0.45 0.48 0.52 0.56 0.59 0.62 — — — — —

Sheave/Mtr

RPM 557 599 645 685 730 770 810 850 885 915 950 — — — — —

Turns Open 543215432.51.51—————

BkW 0.32 0.35 0.38 0.42 0.45 0.48 0.52 0.56 0.60 0.63 0.67 — — — — —

Sheave/Mtr AAAA ACCCCCC—————

RPM 573 620 660 705 745 785 820 860 895 925 960 — — — — —

Turns Open 4.53.531.514.53.53 21.51 —————

BkW 0.360.390.430.460.490.540.580.620.650.69——————

Sheave/Mtr AAAACCCCCC——————

RPM 609645690730765805845880910945——————

Turns Open 4 32.51.55 4 32.52 1 ——————

BkW 0.390.420.460.490.540.580.620.660.700.73——————

Sheave/Mtr AAAACCCCCC——————

RPM 620660700740780815850885920950——————

Turns Open 3.53 2 14.54 32.51.51 ——————

0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375

AAAAACCCCCC—————

EXTERNAL STATIC PRESSURE (Pa)

1. A = Standard Rpm/Standard Motor, B = Low Rpm/Standard Motor, C =

High Rpm/Standard Motor.

2. Unit factory shipped with standard static sheave and drive at 2.5 turns

open. Other speed require field selection.

3. For applications requiring higher static pressures, contact your local representative. Performance data does not include drive losses and is based

on sea level conditions.

4. All airflow is rated at lowest voltage if unit is dual voltage rated, i.e., 380V

for 380/420V units.

5. Airflow in l/s with wet coil and clean filter.

17

a50-8544

Page 18

Table 6 — Blower Data — 50HQP096

AIRFLOW

(l/s)

BkW — 0.15 0.18 0.21 0.24 0.27 0.30 0.32 0.34 0.36 0.39 0.42 0.46 0.49 0.52 0.55

Sheave/Mtr —BBBAAAAAACCCCCC

850

897

944

991

1038

1086

1133

1180

1227

1274

1322

1369

1416

1463

1510

RPM — 500 552 604 655 700 745 780 820 855 890 915 945 970 995 1020

Turns Open — 4.5 3 1.5 5.5 4.5 3.5 2.5 2 1 4 3.5 3 2.5 2 1.5

BkW 0.19 0.21 0.24 0.28 0.31 0.34 0.38 0.41 0.44 0.47 0.50 0.53 0.55 0.58 0.61 —

Sheave/Mtr BBAAAAAAACCCCCC—

RPM 521 573 625 670 710 755 795 830 870 900 930 960 990 1015 1040 —

Turns Open 42.565432.51.513.532.521.51—

BkW 0.20 0.22 0.25 0.28 0.32 0.36 0.39 0.42 0.46 0.49 0.52 0.55 0.58 0.60 0.63 —

Sheave/Mtr BBBAAAAAACCCCCC—

RPM 500 542 594 640 685 730 770 805 845 880 915 945 975 1005 1030 —

Turns Open 4.53.525.54.53.532143.52.521.51—

BkW 0.24 0.27 0.30 0.33 0.36 0.39 0.43 0.47 0.51 0.54 0.57 0.60 0.63 0.66 0.69 —

Sheave/Mtr BBBAAAAAACCCCCC—

RPM 516 563 615 655 700 740 780 820 860 895 925 960 990 1020 1045 —

Turns Open 431.55.54.53.52.521432.5211—

BkW 0.26 0.29 0.32 0.36 0.40 0.43 0.47 0.51 0.54 0.58 0.61 0.64 0.67 0.71 — —

Sheave/Mtr BBAAAAAACCCCCC——

RPM 536 583 630 670 715 755 795 835 870 905 935 970 1000 1030 — —

Turns Open 3.52.565432.51.543.5321.51——

BkW 0.30 0.34 0.37 0.40 0.43 0.47 0.51 0.55 0.59 0.62 0.66 0.69 0.73 0.77 — —

Sheave/Mtr BBAAAAAACCCCCC——

RPM 557 604 650 690 730 770 810 845 885 915 950 980 1010 1040 — —

Turns Open 3 2 5.5 4.5 3.5 3 2 1 4 3.5 2.5 2 1.5 1 — —

BkW 0.34 0.37 0.41 0.44 0.47 0.51 0.56 0.60 0.64 0.67 0.71 0.74 0.78 — — —

Sheave/Mtr BAAAAAAACCCCC———

RPM 583 625 665 705 745 785 825 860 895 925 960 990 1020 — — —

Turns Open 2.5 6 5 4 3.5 2.5 1.5 1 4 3 2.5 2 1 — — —

BkW 0.38 0.41 0.44 0.48 0.52 0.56 0.61 0.65 0.69 0.72 0.75 0.79 0.83 — — —

Sheave/Mtr BAAAAAACCCCCC———

RPM 604 645 685 725 765 800 835 875 905 940 970 1005 1030 — — —

Turns Open 2 5.5 4.5 4 3 2 1.5 4 3.5 3 2 1.5 1 — — —

BkW 0.41 0.45 0.48 0.51 0.55 0.60 0.64 0.69 0.72 0.76 0.80 0.85 — — — —

Sheave/Mtr AAAAAAACCCCC————

RPM 625 665 700 740 775 815 850 885 915 950 985 1015 — — — —

Turns Open 654.53.532143.52.521.5————

BkW 0.45 0.49 0.52 0.56 0.60 0.64 0.68 0.73 0.77 0.81 0.85 0.90 — — — —

Sheave/Mtr AAAAAAACCCCC————

RPM 645 685 720 760 795 830 865 900 930 960 995 1025 — — — —

Turns Open 5.5 4.5 4 3 2.5 1.5 1 3.5 3 2.5 1.5 1 — — — —

BkW 0.49 0.53 0.57 0.61 0.65 0.69 0.74 0.78 0.82 0.86 0.91 0.96 — — — —

Sheave/Mtr AAAAAACCCCCC————

RPM 665 705 745 780 810 845 880 910 945 975 1005 1035 — — — —

Turns Open 5 4 3.5 2.5 2 1 4 3.5 2.5 2 1.5 1 — — — —

BkW 0.53 0.57 0.61 0.65 0.69 0.73 0.77 0.82 0.87 0.91 0.96 1.02 — — — —

Sheave/Mtr AAAAAACCCCCC————

RPM 685 720 760 795 825 860 890 920 955 985 1015 1045 — — — —

Turns Open 4.54 32.51.51 4 32.521.51 ————

BkW 0.58 0.62 0.67 0.71 0.75 0.79 0.84 0.88 0.93 0.97 1.03 — — — — —

Sheave/Mtr A AAA ACCCCCC—————

RPM 700 735 775 810 845 875 910 940 970 1000 1030 — — — — —

Turns Open 4.5 3.5 2.5 2 1 4 3.5 3 2 1.5 1 — — — — —

BkW 0.64 0.68 0.72 0.76 0.80 0.85 0.90 0.97 1.02 1.07 1.12 — — — — —

Sheave/Mtr A AAA ACCCCCC—————

RPM 720 755 790 825 860 890 920 955 985 1015 1040 — — — — —

Turns Open 4 32.51.51 4 32.521.51 —————

BkW 0.700.750.800.850.900.940.991.031.081.13——————

Sheave/Mtr A AAACCCCCC——————

RPM 7407758108408759059359659951025——————

Turns Open 3.52.521.543.532.51.51 ——————

0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375

LEGEND NOTES:

——Operation Not Recommended

BkW — Brake Kilowatts

ESP — External Static Pressure

RPM — Revolutions Per Minute

A—Units with Standard Static/Standard Motor Option

B—Units with Low Static/Standard Motor Option

C—Units with High Static/Standard Motor Option

EXTERNAL STATIC PRESSURE (Pa)

1. A = Standard Rpm/Standard Motor, B = Low Rpm/Standard Motor, C =

High Rpm/Standard Motor.

2. Unit factory shipped with standard static sheave and drive at 2.5 turns

open. Other speed require field selection.

3. For applications requiring higher static pressures, contact your local representative. Performance data does not include drive losses and is based

on sea level conditions.

4. All airflow is rated at lowest voltage if unit is dual voltage rated, i.e., 380V

for 380/420V units.

5. Airflow in l/s with wet coil and clean filter.

18

Page 19

Table 7 — Blower Data — 50HQP120

AIRFLOW

(l/s)

BkW — 0.290.310.350.390.420.460.500.540.570.600.630.670.700.730.76

Sheave/Mtr —BBBBAAAAAACCCCC

1038

1086

1133

1180

1227

1274

1322

1369

1416

1463

1510

1558

LEGEND NOTES:

——Operation Not Recommended

BkW — Brake Kilowatts

ESP — External Static Pressure

RPM — Revolutions Per Minute

A—Units with Standard Static/Standard Motor Option

B—Units with Low Static/Standard Motor Option

C—Units with High Static/Standard Motor Option

RPM — 573 620 665 705 745 785 825 865 900 930 960 995 1020 1050 1075

Turns Open — 4.5 3.5 2.5 1.5 5.5 4.5 3.5 3 2 1.5 3.5 3 2.5 2 1.5

BkW 0.30 0.33 0.37 0.40 0.43 0.46 0.50 0.54 0.58 0.61 0.65 0.68 0.72 0.76 0.80 0.85

Sheave/Mtr BBBBAAAAAAACCCCC

RPM 547 594 640 680 720 760 800 840 875 910 940 975 1005 1035 1060 1090

Turns Open 54326543.52.521.53.5321.51

BkW 0.34 0.37 0.40 0.43 0.47 0.50 0.55 0.59 0.63 0.66 0.70 0.73 0.77 0.82 0.86 —

Sheave/Mtr BBBBAAAAAAACCCC—

RPM 573 615 660 700 740 775 815 855 890 920 955 985 1015 1045 1075 —

Turns Open 4.53.52.525.54.54 32.51.51 32.521.5—

BkW 0.37 0.40 0.44 0.47 0.51 0.55 0.60 0.64 0.68 0.71 0.75 0.78 0.82 0.87 0.91 —

Sheave/Mtr BBBAAAAAAACCCCC—

RPM 594 635 675 715 755 790 830 865 900 930 965 995 1025 1055 1085 —

Turns Open 4 32.56 54.53.53 21.53.532.51.51 —

BkW 0.40 0.44 0.47 0.51 0.55 0.59 0.63 0.67 0.72 0.75 0.79 0.83 0.88 0.92 0.96 —

Sheave/Mtr BBBAAAAAAACCCCC—

RPM 615 655 690 730 770 805 840 875 910 940 975 1005 1035 1065 1095 —

Turns Open 3.5 3 2 5.5 5 4 3.5 2.5 2 1 3.5 3 2 1.5 1 —

BkW 0.44 0.47 0.51 0.55 0.59 0.63 0.67 0.71 0.75 0.79 0.84 0.88 0.93 0.97 — —

Sheave/Mtr BBBAAAAAAACCCC——

RPM 635 670 710 750 785 820 855 885 920 950 985 1015 1045 1075 — —

Turns Open 32.51.554.53.532.51.51 32.521.5——

BkW 0.47 0.51 0.55 0.59 0.64 0.67 0.72 0.76 0.80 0.84 0.89 0.94 1.00 1.05 — —

Sheave/Mtr BBAAAAAAACCCCC——

RPM 650 690 725 765 800 830 865 900 930 960 995 1025 1055 1085 — —

Turns Open 326543.5321.53.532.51.51——

BkW 0.52 0.55 0.59 0.63 0.67 0.71 0.75 0.80 0.85 0.89 0.94 0.99 1.04 1.10 — —

Sheave/Mtr BBAAAAAAACCCCC——

RPM 670 705 745 780 810 845 875 910 940 970 1000 1030 1060 1090 — —

Turns Open 2.5 1.5 5.5 4.5 4 3 2.5 2 1 3.5 3 2 1.5 1 — —

BkW 0.57 0.60 0.65 0.68 0.73 0.77 0.82 0.86 0.91 0.95 1.00 1.05 1.11 — — —

Sheave/Mtr BAAAAAAAACCCC———

RPM 685 720 760 790 825 860 895 925 955 985 1015 1045 1075 — — —

Turns Open 2654.53.5321.5132.521.5———

BkW 0.61 0.66 0.70 0.75 0.79 0.82 0.89 0.94 0.99 1.05 1.09 1.15 1.20 — — —

Sheave/Mtr BAAAAAAACCCCC———

RPM 700 735 775 810 845 875 910 940 970 1000 1025 1055 1085 — — —

Turns Open Open25.54.54 32.521.53.532.51.5———

BkW 0.68 0.73 0.77 0.82 0.88 0.92 0.96 1.01 1.05 1.10 1.16 1.20 1.26 — — —

Sheave/Mtr AAAAAAAACCCCC———

RPM 725 760 790 825 860 890 920 950 980 1010 1040 1065 1095 — — —

Turns Open 6 54.53.53 21.513.52.521.51 ———

BkW 0.74 0.79 0.83 0.88 0.94 0.98 1.02 1.07 1.11 1.16 1.21 1.26 — — — —

Sheave/Mtr AAAAAAACCCCC————

RPM 740 775 805 840 875 905 935 965 995 1020 1050 1075 — — — —

Turns Open 5.54.543.52.521.53.532.521.5————

0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375

EXTERNAL STATIC PRESSURE (Pa)

1. A = Standard Rpm/Standard Motor, B = Low Rpm/Standard Motor, C =

High Rpm/Standard Motor.

2. Unit factory shipped with standard static sheave and drive at 2.5 turns

open. Other speed require field selection.

3. For applications requiring higher static pressures, contact your local representative. Performance data does not include drive losses and is based

on sea level conditions.

4. All airflow is rated at lowest voltage if unit is dual voltage rated, i.e., 380V

for 380/420V units.

5. Airflow in l/s with wet coil and clean filter.

19

Page 20

Table 7 — Blower Data — 50HQP120 (cont)

AIRFLOW

(l/s)

BkW 0.79 0.85 0.89 0.94 0.99 1.04 1.08 1.12 1.17 1.23 1.29 1.35 — — — —

Sheave/Mtr AAAAAAACCCCC————

1605

1652

1699

1746

1794

1841

1888

LEGEND NOTES:

——Operation Not Recommended

BkW — Brake Kilowatts

ESP — External Static Pressure

RPM — Revolutions Per Minute

A—Units with Standard Static/Standard Motor Option

B—Units with Low Static/Standard Motor Option

C—Units with High Static/Standard Motor Option

RPM 755 790 820 855 890 920 945 975 1005 1035 1060 1090 — — — —

Turns Open 54.53.53 21.513.53 21.51 ————

BkW 0.87 0.91 0.96 1.02 1.06 1.11 1.15 1.20 1.24 1.29 1.34 — — — — —

Sheave/Mtr AAAA AACCCCC—————

RPM 780 810 845 880 910 940 970 1000 1025 1050 1080 — — — — —

Turns Open 4.54 32.52 13.532.52 1 —————

BkW 0.94 0.99 1.04 1.09 1.15 1.20 1.25 1.30 1.35 1.40 1.45 — — — — —

Sheave/Mtr AAAA ACCCCCC—————

RPM 805 835 870 900 930 960 990 1015 1045 1070 1100 — — — — —

Turns Open 43.52.521.53.532.521.51 —————

BkW 1.011.051.101.161.211.261.321.371.431.49——————

Sheave/Mtr AAAA ACCCCC——————

RPM 825 855 885 915 945 975 1005 1030 1060 1085 ——————

Turns Open 3.532.51.513.53 21.51 ——————

BkW 1.071.111.171.221.271.331.381.451.511.57——————

Sheave/Mtr AAAACCCCCC——————

RPM 840 870 900 930 960 990 1015 1045 1070 1095 ——————

Turns Open 3.52.521.53.532.521.51 ——————

BkW 1.171.211.271.321.381.431.491.551.62———————

Sheave/Mtr A A A A C C C C C———————

RPM 860 885 915 945 975 1005 1030 1055 1085 ———————

Turns Open 32.51.513.53 21.51 ———————

BkW 1.231.291.351.411.481.531.601.661.72———————

Sheave/Mtr A A A C C C C C C ———————

RPM 875 900 930 960 990 1015 1045 1070 1095 ———————

Turns Open 2.521.53.532.521.51 ———————

0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375

EXTERNAL STATIC PRESSURE (Pa)

1. A = Standard Rpm/Standard Motor, B = Low Rpm/Standard Motor, C =

High Rpm/Standard Motor.

2. Unit factory shipped with standard static sheave and drive at 2.5 turns

open. Other speed require field selection.

3. For applications requiring higher static pressures, contact your local representative. Performance data does not include drive losses and is based

on sea level conditions.

4. All airflow is rated at lowest voltage if unit is dual voltage rated, i.e., 380V

for 380/420V units.

5. Airflow in l/s with wet coil and clean filter.

FIELD SELECTABLE INPUTS

Jumpers and DIP (dual in-line package) switches on the

control board are used to customize unit operation and can be

configured in the field.

IMPORTANT: Jumpers and DIP switches should only be

clipped when power to control board has been turned off.

Complete C Control Jumper Settings (See

Fig. 12)

WATER COIL FREEZE PROTECTION (FP1) LIMIT

SETTING — Select jumper 3, (JW3-FP1 Low Temp) to

choose FP1 limit of –12.2 C or –1.1 C. To select –1.1 C as the

limit, DO NOT clip the jumper. To select –12.2 C as the limit,

clip the jumper.

AIR COIL FREEZE PROTECTION (FP2) LIMIT SETTING — Select jumper 2 (JW2-FP2 Low Temp) to choose

FP2 limit of –12.2 C or –1.1 C. To select –1.1 C as the limit,

DO NOT clip the jumper. To select –12.2 C as the limit, clip

the jumper.

ALARM RELAY SETTING — Select jumper 1 (JW1-AL2

Dry) for connecting alarm relay terminal (AL2) to 24 vac (R) or

to remain as a dry contact (no connection). To connect AL2 to

R, do not clip the jumper. To set as dry contact, clip the jumper.

Complete C Control DIP Switches — The Com-

plete C Control has 1 DIP switch block with five switches. See

Fig. 12.

PERFORMANCE MONITOR (PM) — DIP switch 1 will

enable or disable this feature. To enable the PM, set the switch

to ON. To disable the PM, set the switch to OFF.

STAGE 2 — DIP switch 2 will enable or disable compressor

delay. Set DIP switch to OFF for stage 2 in which the compressor will have a 3-second delay before energizing.

NOTE: The alarm relay will not cycle during Test mode if

switch is set to OFF, stage 2.

DIP SWITCH 3 — not used.

DIP SWITCH 4 — not used.

DIP SWITCH 5 — DIP switch 5 is used to initiate 1 or 3 tries

for the FP1 fault. If water freeze protection for the water coil

then DIP switch 5 can be set to lockout on the FP1 fault after

one try.

Deluxe D Control Jumper Settings (See

Fig. 13)

WATER COIL FREEZE PROTECTION (FP1) LIMIT

SETTING — Select jumper 3, (JW3-FP1 Low Temp) to

choose FP1 limit of –12.2 C or –1.1 C. To select –1.1 C as the

limit, DO NOT clip the jumper. To select –12.2 C as the limit,

clip the jumper.

20

Page 21

AIR COIL FREEZE PROTECTION (FP2) LIMIT SETTING — Select jumper 2 (JW2-FP2 Low Temp) to choose

FP2 limit of –12.2 C or –1.1 C. To select –1.1 C as the limit,

DO NOT clip the jumper. To select –12.2 C as the limit, clip

the jumper.

ALARM RELAY SETTING — Select jumper 4 (JW4-AL2

Dry) for connecting alarm relay terminal (AL2) to 24 vac (R) or

to remain as a dry contact (no connection). To connect AL2 to

R, do not clip the jumper. To set as dry contact, clip the jumper.

LOW PRESSURE SETTING — The Deluxe D Control can

be configured for Low Pressure Setting (LP). Select jumper 1

(JW1-LP Norm Open) for choosing between low pressure input normally opened or closed. To configure for normally

closed operation, do not clip the jumper. To configure for normally open operation, clip the jumper.

Deluxe D Control DIP Switches — The Deluxe D

Control has 2 DIP switch blocks. Each DIP switch block has 8

switches and is labeled either S1 or S2 on the circuit board. See

Fig. 13.

DIP SWITCH BLOCK 1 (S1) — This set of switches offers

the following options for Deluxe D Control configuration:

Performance Monitor (PM)

able performance monitor. To enable the PM, set the switch to

ON. To disable the PM, set the switch to OFF.

Compressor Relay Staging Operation

or disable compressor relay staging operation. The compressor

relay can be set to turn on with stage 1 or stage 2 call from the

thermostat. This setting is used with dual stage units (units with

2 compressors and 2 Deluxe D controls) or in master/slave applications. In master/slave applications, each compressor and

fan will stage according to its switch 2 setting. If switch is set to

stage 2, the compressor will have a 3-second delay before energizing during stage 2 demand.

NOTE: If DIP switch is set for stage 2, the alarm relay will not

cycle during Test mode.

Heating/Cooling Thermostat Type

tion of thermostat type. Heat pump or heat/cool thermostats

can be selected. Select OFF for heat/cool thermostats. When in

heat/cool mode, Y1 is used for cooling stage 1, Y2 is used for

cooling stage 2, W1 is used for heating stage 1 and O/W2 is

used for heating stage 2. Select ON for heat pump applications.

In heat pump mode, Y1 used is for compressor stage 1, Y2 is

used for compressor stage 2, W1 is used for heating stage 3 or

emergency heat, and O/W2 is used for RV (heating or cooling)

depending upon switch 4 setting.

O/B Thermostat Type

pump O/B thermostats. O is cooling output. B is heating output. Select ON for heat pumps with O output. Select OFF for

heat pumps with B output.

Dehumidification Fan Mode

of normal or dehumidification fan mode. Select OFF for dehumidification mode. The fan speed relay will remain OFF during cooling stage 2. Select ON for normal mode. The fan speed