Page 1

Number One

AirConditioninq

Maker

^^2 Divisiort of

Carrier Corporation

Carrier Parkway • Syracuse NY 13221

i

-

Single-Package

Water-Source Heat Pumps

SAFETY CONSIDERATIONS...................................1

INSTALLATION........................................................1-5

Step 1 — Check Equipment and

Jobsite .......................................................................1

• UNPACKAGE UNIT

• INSPECT EQUIPMENT

• COMPLETE OR CONSIDER THESE

SYSTEM REQUIREMENTS

Step 2 — Connect Supply Ductwork

Step 3 — Make Piping Connections

• CONNECT WATER SUPPLY AND

RETURN LINES

• INSTALL BALANCING VALVES

.....................

......................

Page

2

3

INDEX

Page

• MAKE CONDENSATE DRAIN

LINE CONNECTION

Step 4 — Make Electrical Connections... 4

• INSTALL A BRANCH CIRCUIT

DISCONNECT PER NEC

• BRING POWER LEADS INTO UNIT

• CONNECT GROUND LEAD TO

GROUND LUG IN SPLICE BOX

• SET FAN MOTOR SPEED

• CONNECT CONTROL POWER WIRING

START-UP

SERVICE....................................................................7

..................................................................

6

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure

and electrical components. Only trained and quali

fied service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic mainten

ance functions of cleaning coils and cleaning and

replacing filters. All other operations should be

performed by trained service personnel. When

working on air conditioning equipment, observe

precautions in the literature, tags and labels

attached to the unit and other safety precautions

that may apply.

Follow all safety codes. Wear safety glasses and*,

work gloves. Use quenching cloth for brazing

operations. Have fire extinguishers available for all

brazing operations.

WARNING: Before performing service or

maintenance operaiions on system, turn off

main pow'er switch to indoor unit and outdoor

unit. Electrical shock could cause personal

injury.

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACKAGE UNIT — Move to final location.

INSPECT EQUIPMENT — File claim with ship

ping company if shipment is damaged or incomplete.

COMPLETE OR CONSIDER THESE SYSTEM

REQUIREMENTS before installation:

a.

Consult local building codes and National Elec

trical Code (NEC) for special installation

requirements.

Consider type of water source. Ensure there is an

adequate supply of water at temperature of 60 F

to 90 F with minimum pressure of 20 psig.

c.

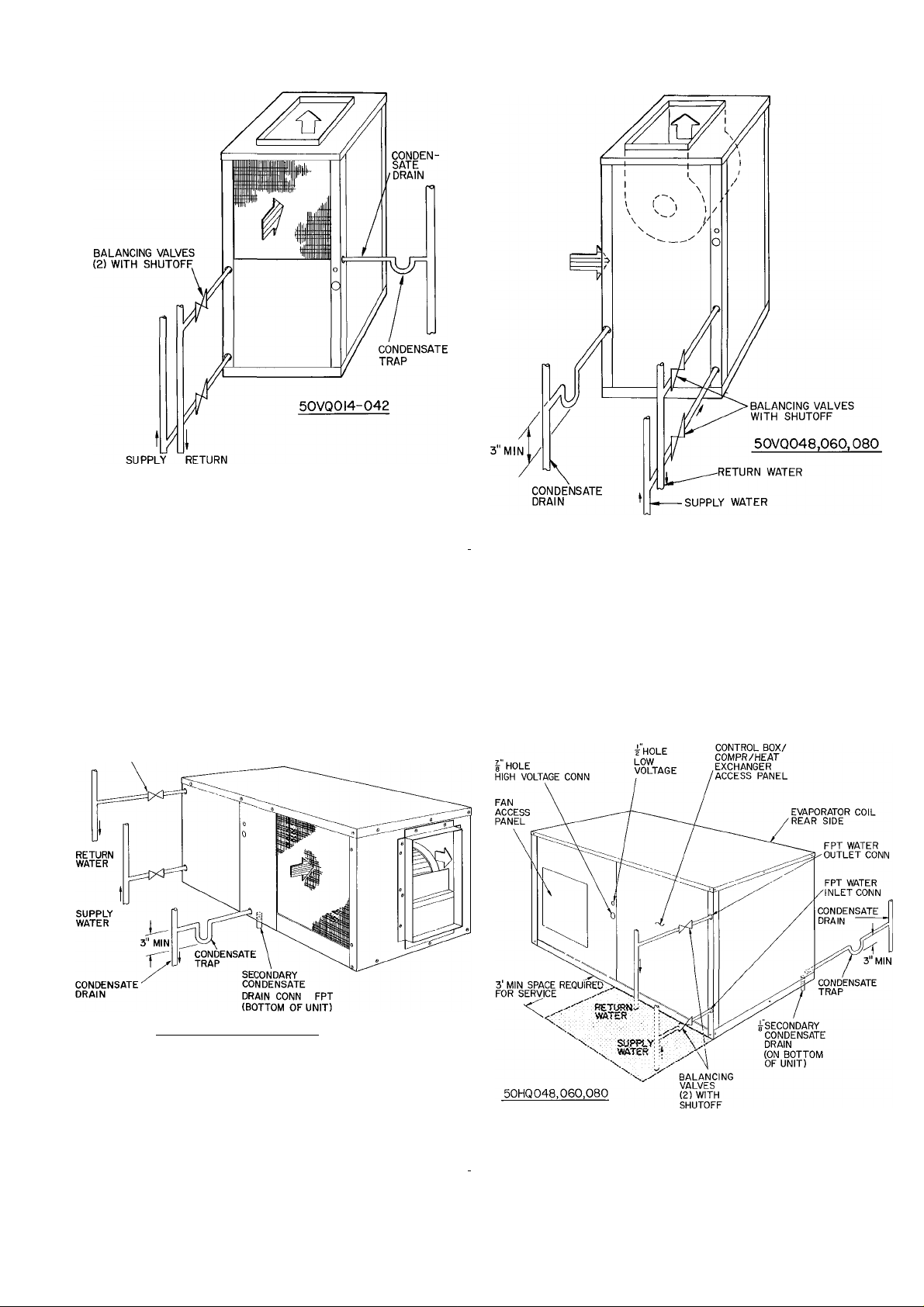

Provide sufficient space for water piping, con

densate drain, wiring and servicing unit. See

Fig. 1. (Units installed in confined areas may

have to be removed for major servicing such

as compressor or fan motor replacement.)

d.

Provide a minimum 6-in. clearance between

return air filter and adjacent wall.

e.

Mount unit on floor or solid platform. (The

50HQ units can be suspended from ceiling.

See “f’ below.) To reduce sound transmission,

especially when unit is located in a closet or

utility room having louvered doors, the follow

ing acoustical treatment is recommended:

place an isolation pad under unit. Pad must be

same size as unit base. Construct a 1-in. fiberglass

sound shield in front of unit.

© Carrier Corporation 1981

Form 50HQ.VQ-2SI

Page 2

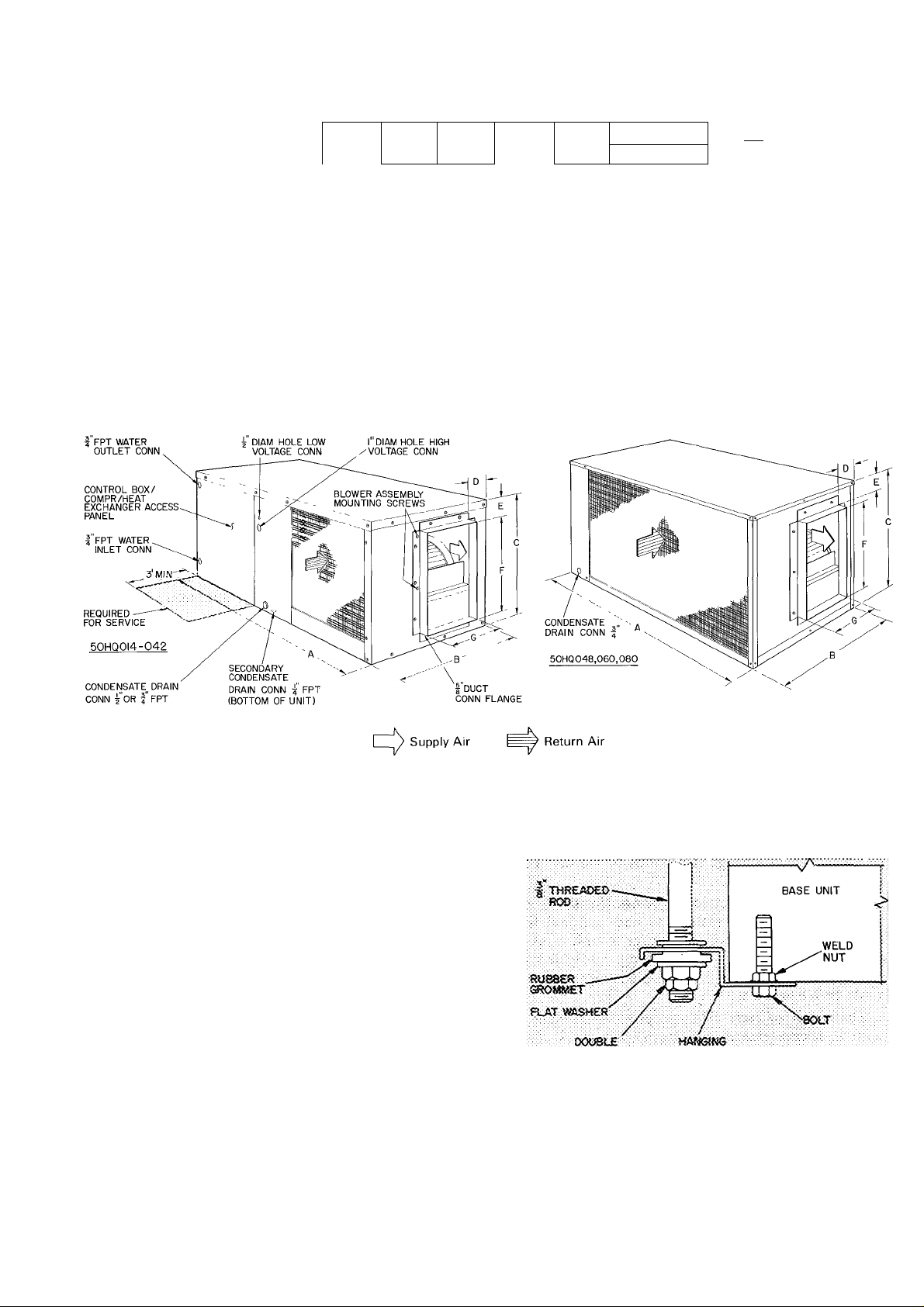

f. 50HQ units include a'sus'pehsion package for

ceiling installation. To attach hanging brackets,

install 4 bolts (5 /16 - 18-3/8 in. Ig) thru bracket

into the 4 weld nuts located on bottom of unit.

Insert the threaded rod thru rubber grommet,

located in hanging bracket, and attach with flat

washer and double nut. See Fig. 3.

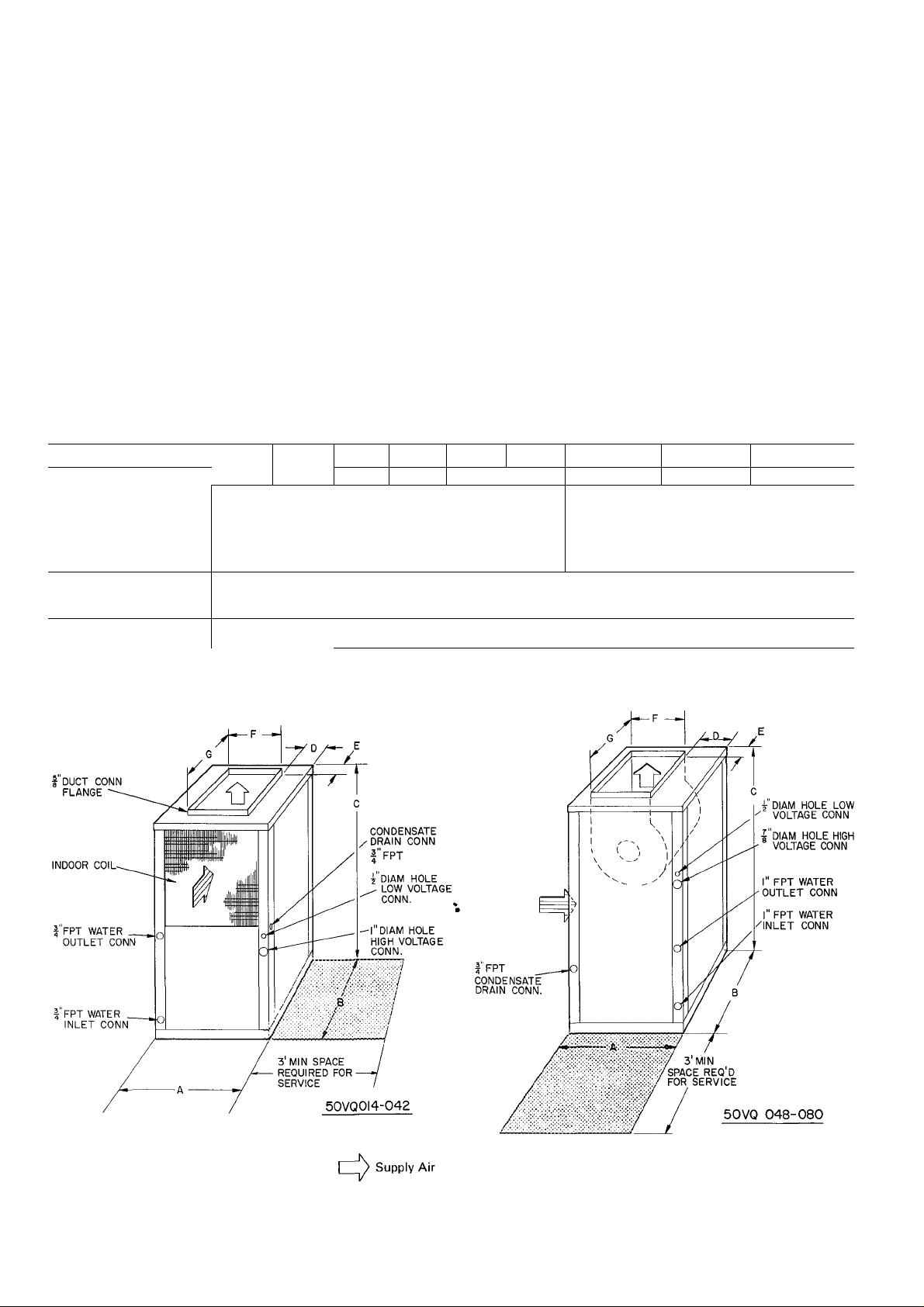

Step 2 — Connect Supply Ductwork — Supply

air duct flange is shipped inside unit. Remove flange

from shipping location and install on unit supply

air opening. Connect supply air ductwork to unit

supply air duct connection flange. Refer to Fig. 1

and 2 and Table 1 and 2 for connection size and

location. If necessary, refer to Carrier System

Design Manual, Part 2, for system air duct design.

^ Table 1 — Installation Data — 50VQ (See Fig. 1.)

MODEL 50VQ

OPER WT (lb)

DIMENSIONS (ft-in.)

SUPPLY DUCT CONN.

(ft-in.) F 0-9-7/16

FILTER (1)

Size (in.)

014

_5

A

B

C

D

E

G 1-1-3/8

018

240“^

022

260 270

027

1-9-3/16

1-9-3/16

3-2-5/16

0-5-7/8

0-1-3/16

21 X 21

When E-e'dignihg and installing ductwork, consider

tfie following:

a. Size duct for 350 to 450 cfm per ton of cooling

capacity.

b. Avoid abrupt duct size increases and reductions.

c. Use flexible connectors between ductwork and

unit to prevent transmission of vibration.

d. Ducts passing thru an unconditioned space must

be insulated and covered with vapor barrier in

accordance with the latest issue of SMACNA

(Sheet Metal and Air Conditioning Contractor’s

National Association) and NESCA (National

Environmental Systems Contractor’s Associa

tion) minimum installation standards for resi

dential heating and air conditioning systems.

033

290

Replaceable Media

042

320 320

048 060

0-6-13/16

0-10-1/2 1-1-1/16 1-0

350

2-5-3/8

2-3

4-0

0-8

0-5-1/2

1-4

38 X 22

080

380

0-6-1/16

Return Air

Fig. 1 — Dimensions and Connections — 50VQ

Page 3

Table 2'— Installation Data — 50HQ (See Fig. 2.)

I

MODEL 50HQ

OPERwfob)

"dimensions (ft-in.)

_E

"supply duct conn.

(ft-in.) F

_ _ G

ACCESSORY FILTER (1)

Size (in.)

014

220

A

B

C

D

018 022 027 033

195 210 220

3-10-1/2

1-10-5/16

1- 5-15/16

0- 3-7/8

11/16

1- 1-3/8

0- 9^-7/16

17 x23

230

042 048

250 300

0- 3-7/8

Replaceable Media

060

325

4- 0

1-11

2- 0

0-2-9/16

0-3-3/16

1-7-7/8

37 X 23

080

360

0-3-1/16

1-0

Fig. 2 — Dimensions and Connections — 50HQ

Step 3 — Make Piping Connections

CONNECT WATER SUPPLY AND RETURN

LINES to water inlet and outlet pipe connections

shown in Fig. 4 and 5. Use flexible hose for water

line to reduce possible vibration and improve unit

serviceability. Make sure hoses or pipes are suitable

for system water pressure and sized for proper

flow rate.

CAUTION; improper heat exchanger water

flow due to piping, valving or improper pump

operation is hazardous to units.

For water flow and temperature data refer to

Start-Up section, page 6.

CAUTION: Galvanized pipe or fittings are not

recommended for use with these units due to

possible electrolysis.

nut

BRACKET

Fig. 3 — Suspension Kit

Installation — 50HQ

Page 4

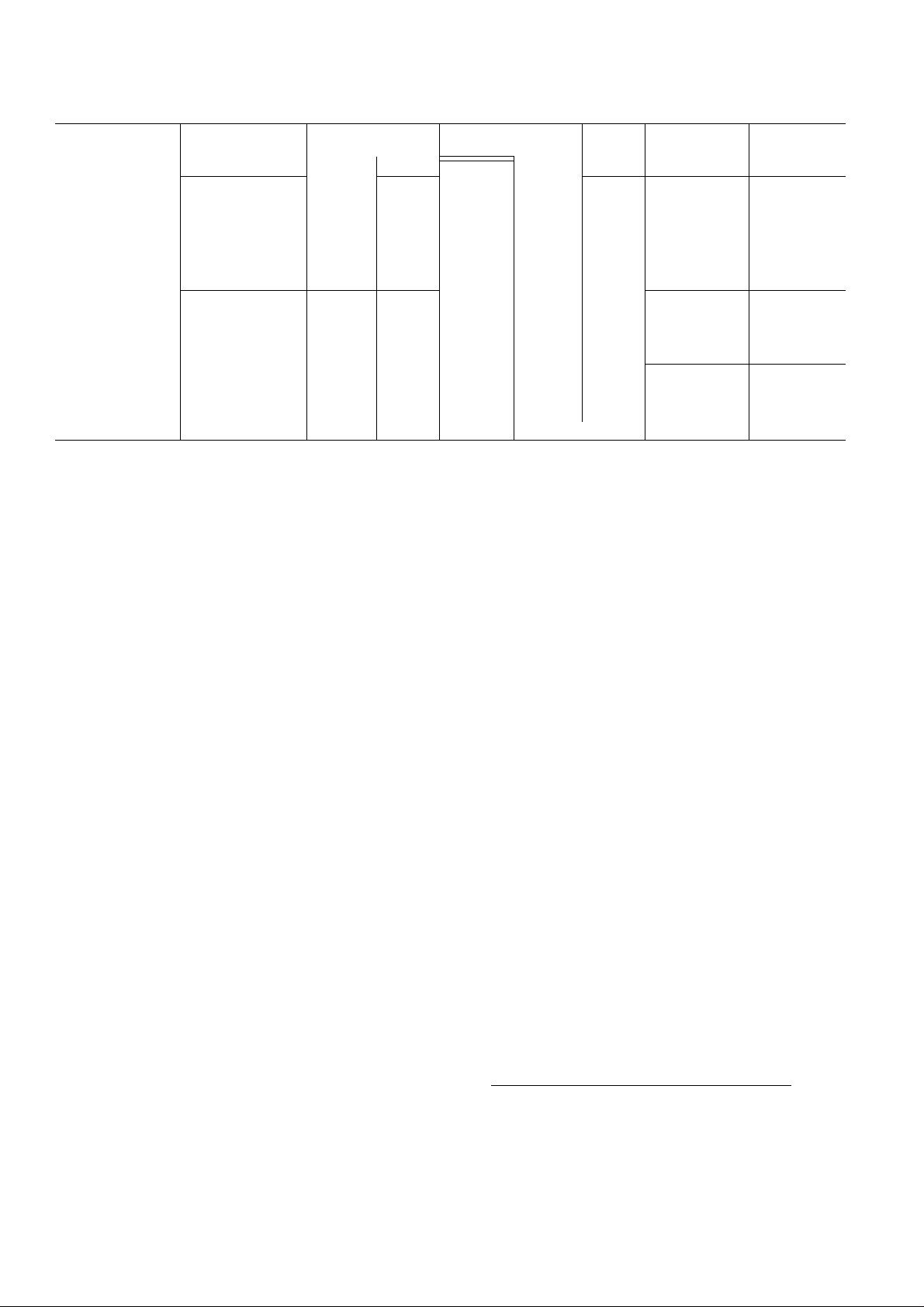

Table 3 — Electrical Data

UNIT MODEL

50HQ,VQ

014

018

022

027

033

042

048

060

033

042

048

060

080

033

042 36 5

048

060 49 0 104

080 69 0 11 4

FLA — Full Load Amps

LRA — Locked Rotor Amps

RLA — Rated Load Amps

V/PH/HZ

208-230/1/60 253

208-230/3/60 253 187 80 0

460/3/60 508

OPERATING

VOLTAGE

Max

Min LRA RLA

197

187

414

INSTALL BALANCING VALVES (with shutofO

in water supply and return lines for water flow

adjustment and a means of water shutoff, if neces

sary, when servicing unit. When multiple units are

connected in parallel, valves permit removal of one

unit without interrupting water flow to other

units.

MAKE CONDENSATE DRAIN LINE CON

NECTION to female pipe connection provided on

unit. Fig. 4 and 5. Install a trap in condensate line as

close as possible to unit. Trap must be at least 3 in.

deep and not higher than the bottom of unit con

densate drain opening. Pitch condensate line to

open drain or sump. Insulate a condensate drain line

located above a living area.

50HQ Units Only — If a secondary drain is re

quired, remove plastic cap from secondary drain

connection, located in bottom of unit, and connect

drain so that discharge is obvious to maintenance

personnel.

Step 4 — Make Electrical Connections — Field

wiring must comply with local and national fire,

safety and electrical codes. Voltage to unit must be

within the operating voltage range indicated on

nameplate or in Table 3. On 3-phase units, phases

must be balanced within 2%.

Operation of unit on improper line voltage or

with excessive phase imbalance constitutes abuse

and is not covered by Carrier Warranty.

INSTALL A BRANCH CIRCUIT DISCONNECT

PER NEC of adequate size to handle unit starting

current. Locate disconnect within sight of and

readily accessible from the unit, per Section 440-14

of National Electrical Code (NEC).

BRING POWER LEADS INTO UNIT — Extend

leads from disconnect per NEC thru hole provided

(Fig. 1 and 2) into line wiring splice box. Fig. 6.

COMPRESSOR

37 5

53 0

65 0 13 3

66 0

88 0 23 3

100 0

94 0 23 9

150 0 35,3

87 0 13 8 2 5

100 0

136 0 20 6

137 0 20 7

30 0 60

35 0 8 2

9 6

134

16 2

27 7

18 5

16 8 3 9 24 9

6.9

FAN

FLA

7 12.7

9

1.5 18 1 30

1 7 22 0 35

2 5 31.6

3 2

34 33 4 60

4.5

3 2

4 5

6 2 32 1

1 1

1 6 10 2

20 12 3

2 6

31 17 4

MINIMUM

CIRCUIT

AMPS AMPS

17.7

37 8

48.6

19 8 30

26 3

30 6

8 9

15 3 25

MAXIMUM

FUSE

CONNECT GROUND LEAD TO GROUND

LUG IN SPLICE BOX for safety. Connect power

wiring. See Fig. 6. Splice line power leads to yellow

and black pigtails on single-phase units or yellow

pigtails on 3-phase units. Use wire nuts. Tape each

connection.

Unit transformer on 208-230-volt units is factory

wired for 230/24-volt operation. For 208/24-volt

operation, remove black (230-v) transformer lead

from unit contactor and connect red (208-v) lead to

contactor. Cap unused transformer lead.

SET FAN MOTOR SPEED — Set fan motor for

high-, medium- or low-speed operation as follows:

1. Remove unit fan section access panel.

2. Locate Molex fan speed selector block on fan

housing. Fig. 7. Selector block receptacle 1 is

high fan speed, receptacle 2 is medium fan speed

and receptacle 3 is low fan speed. Yellow and

black fan motor power leads from control box

are connected to selector block receptacle C and

1. Yellow lead is common, black lead is speed-

change lead.

3. To change fan motor speed, remove black lead

from selector block receptacle and plug it into

desired receptacle. Receptacle 4 is not used.

CAUTION: For proper utiit operation, set unit

fan motor speed for air quantity witbin range

shown in Table 4.

Set Fan Motor Speed on 460-Volt Units — Twospeed fan motor is factory wired for high-speed oper

ation. (Yellow and black power leads from control

box are connected to the yellow and black fan motor

leads.) Change fan motor to low speed by wiring as

follows:

1. Splice the violet and black fan motor leads

together.

20

30

50

60

60

40

40

45

45

15

15

15

25

L

Page 5

i

WATER WATER

I Supply Air

‘ Return Air

Fig. 4 — Water Piping — 50VQ

BALANCING VALVES

(2) WITH SHUTOFF

50HQ0I4,018,022,027, 033,042

pply Air

I Return Air

Fig. 5 — Water Piping — 50HQ

5

Page 6

2. Splice yellow and black power leads from eontrol

box to yellow and red motor leads. (Yellow-toyellow and black-to-red.)

CONNECT CONTROL POWER WIRING (24-v)

— Power leads are brought thru 1/2-in. hole pro

vided in unit, Fig. 1 and 2. Extend leads to control

wiring terminal board located on top of control box,

Fig. 7. Connect leads to terminal board as shown

in Fig. 6.

Use Carrier-specified room thermostat and sub

base for proper unit operation. Be sure that field-

installed jumper wire is connected between subbase

terminals W and Y. Set thermostat heat anticipator

at 1.0 amp for 1-phase units and 0.50 amp for

3-phase units.

FAN SPEED

SELECTOR BLOCK

(MOLEX PLUG)

COMPRESSOR

Fig. 7 — Typical Component Arrangement

(50HQ014-042 Shown)

—^YEL —

-TUyel —

_iT^YEL —

GROUND

—œilug

50HQ.VQ

HEAT PUMP

CONTROL BOX

1-PHASE

CONN. TO

DISCON NECTPER NEC

GROUND

LEAD

—^YEL —

—^BLK —

,__.GROUND

—TSlLUG

50HQ.VQ

HEAT PUMP

CONTROL BOX

I-PHASE

3-PHASE

CONN. TO

DISCONNECTPER NEC

—

GROUND

LEAD

Fig. 6 — Line Power Connections

START-UP

Water Flow and Temperature Data

1. Consider design water flow rates for efficient

operation. See Table 4 for permissible water flow

range.

2. Ensure that water temperature entering unit is

between 60 F minimum and 90 F maximum. If

water temperature below 60 F must be used,

insulate supply line and install a secondary drain

pan under the unit to remove condensate from

heat exchanger and internal plumbing.

CAUTION: Water temperature outside

specified temperature rartge may cause

damage to mût Do not jumper low temperar

ture switch in order to use ethytene giycoi.

3. Ensure that supply water is clean and air is

purged from system. Air in supply water causes

scaling in heat exchanger. Foreign material in

water and/or excessive velocity of water can

cause damage to tubing.

To Start Unit — Ensure that air filter is in place on

unit filter flanges provided. Do not operate unit

without filter in place. Adjust the thermostat as

follows;

1. Set selector switch at OFF.

2. Turn on main disconnect switch to unit.

3. Set fan switch as desired (ON or AUTO.).

4. Set thermostat dial at desired temperature.

5. Set selector switch at HEAT or COOL.

Check system refrigerant charge. See Service,

Refrigerant Charging on page 7.

Unit Single-Phase Compressors Equipped

With a Compressor Start Thermistor (PTC De

— When supply voltage is within limits indi

vice)

cated on nameplate and compressor will not start,

check the thermistor with an ohmmeter.

If the PTC is good, and the compressor does not

start, disconnect the PTC from the starting circuit

and give unit a temporary capacitanee boost. Refer

to Carrier Standard Service Techniques Manual,

Chapter 2, for details on capacitance boost pro

cedure. If unit does not start with capacitance boost,

compressor may be defective. If unit does start,

check starting capability with PTC assistance. If

questionable, remove PTC, add start capacitor and

start relay per start kit installation instructions.

WARNING: Capadtance boost or iastallatioa

of start capacitor and start relay should be per

formed by trained personnel. Improper procedure could cause personal injurj' or equipment

damage.

Unit Controls and Safety Devices

HIGH-PRESSURE RELIEF VALVE (except

50HQ,VQ0I4) is located in compressor. Relief valve

opens at a pressure differential of approximately

550 psi between suction (low side) and discharge

(high side) to allow pressure equalization.

CURRENT AND TEMPERATURE SENSITIVE

OVERLOAD (linebreak) — Internal on all com

pressors except on 50HQ,VQ014 which has external

shell mounted overload. Overload resets auto

matically when internal compressor motor tempera

ture drops to a safe level (overloads may require up

to 45 minutes to reset). When an internal overload is

suspected of being open, eheck by using an ohm-

Page 7

I

meter or continuity tester. If necessary, refer to

Carrier Standard Service Techniques Manual,

Chapter 2, for complete instructions.

HIGH-PRESSURE SWITCH closes and shuts

compressor off if discharge pressure rises above 395

psig. Switch opens at 295 psig.

FREEZE-UP PROTECTION — Two controls are

used to prevent unit from operating if water

approaches freezing temperature:

1. Low water temperature cutout (LWTC) shuts

unit off and energizes lockout relay if water

temperature reaches 37 F.

2. Lockout relay locks itself in energized position

and prevents unit from starting.

The unit can be restored to heating operation if

the water temperature rises to 42 F, where the

LWTC will reset, and if the thermostat circuit is

interrupted either by lowering the thermostat

setting or by moving system switch to OFF or

COOL. Thermostat may then be readjusted to

normal set point.

HEAT PUMP CIRCUITS, shown in Fig. 8, are

refrigerant and water flow diagrams for heating

and cooling cycles.

SERVICE

Refrigerant Charging — Unit refrigerant system

is factory charged. When recharging is necessary

during heating or cooling season, weigh in total

charge indicated in Table 4. Remove any refrigerant

remaining in system before recharging. If system has

lost complete charge, evacuate system to 500

microns (29.7 in. vacuum) before recharging.

Service port connections are provided on high and

low sides of refrigerant system for evacuation and

charging. (See Fig. 8 for service port location.)

Dial-a-charge charging cylinder is an accurate

device used to recharge systems by weight. These

cylinders are available at refrigeration supply firms.

To check and/or adjust refrigerant charge during

cooling season, use correct Cooling Cycle Charging

^ Chart (Fig. 9, 11, 13, 15,17,19,21,22,23) or Carrier

Chargemaster® charging device (Carrier Part No.

38GC680004). Charging charts or Chargemaster

may also be used as alternate methods of recharging

system. Charging methods are described below.

To cheek system operation during heating cycle,

use correct Heating Cycle Operation Check Chart

(Fig. 10, 12, 14, 16, 18, 20). These charts indicate

whether a correct relationship exists between unit

operating pressures and water temperature leaving

heat exchanger. If pressure and water temperature

lines do not intersect on chart, the system refrigerant

charge may not be correct or other system abnor

malities may exist. Do not use Operation Check

Charts to adjust refrigerant charge. Weigh charge

into system.

COOLING CYCLE HEATING CYCLE

Fig. 8 — Refrigerant and Water Flow Diagrams — 50HQ,VQ

Page 8

Table 4 — Service Data

UNIT 50HQ.VQ

R-22 CHG (Ib-oz)»

Refrig Control

FAN

Diameter (in. Nom) 10

Width (in. Nom)

Range Cfm 400-600 500-700 600-800 750-1000 950-1200 1225-1575

Motor Hp 1/8 1/8 1/6 1/6 1/4

Motor Rpm

(3-speed)

HEAT EXCHANGER

WATER FLOW RATE

(Gpm)

‘Factory refrigerant charge

014 018

1-8 1-13

7

2 5-5 3-6 4-8 4 5-9

10

7 7 7 7 7 8

022

2-2 2-6

10 10

027

033 042 048 060

2-6 2-14 4-3

Capillary Tube

Centrifugal — Direct Drive

10

1075 Nominal

5-10

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before

checking charge, and after each charge

adjustment.

2. Measure suction pressure by attaching a gage to

unit suction service port (Schrader Fitting).

3. Measure discharge pressure by attaching a gage

to unit discharge service port (Schrader Fitting).

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering unit.

5. Refer to correct Charging Chart. Locate on

curves where unit discharge pressure line and

indoor air wet-bulb temperature line intersect.

6. From intersect point, project horizontally left to

ISO 200 250 300

COMPRESSOR DISCHARGE PRESSURE @ SERVICE PORT (PSIG)

chart suction pressure line. Compare chart

suction pressure to unit suction pressure (step 2).

7. If unit suction pressure is lower than chart pres

Fig. 10 — Heating Cycle Operation

Check Chart (R-22) — 50HQ.VQ014

sure, add refrigerant to unit until chart pressure

is reached. If unit suction pressure is higher than

chart pressure, remove refrigerant until chart

pressure is reached.

11

1/3

6-12 8-16

10 10

1400-1800 1750-2250

1/2 3/4

5-3 6-8

10

2300-3000

11-21

080

12

9

1

1000

14-28

ISO 200 250 300

COMPRESSOR DISCHARGE PRESSURE ® SERVICE PORT(PSIG)

Fig. 9 — Cooling Cycle Charging Chart

(R-22) — 50HQ,VQ014

COMPRESSOR DISCHARGE PRESSURE @ SERVICE PORT (PSIG)

Fig. 11 — Cooling Cycle Charging Chart

(R-22) — 50HQ.VQ018

Page 9

Fig. 12 — Heating Cycle Operation

Check Chart (R-22) — 50HQ,VQ018

Fig. 15 — Cooling Cycle Charging Chart

(R-22) — 50HQ,VQ027

COMPRESSOR DISCHARGE PRESSURE ® SERVICE PORT(PSIG)

Fig. 13 — Cooling Cycle Charging Chart

(R-22) — 50HQ,VQ022

Fig. 14 — Heating Cycle Operation

Check Chart (R-22) — 50HQ,VQ022

Fig. 16 — Heating Cycle Operation

Check Chart (R-22) — 50HQ,VQ027

COMPRESSOR DISCHARGE PRESSURE® SERVICE PORT (PSIG)

Fig. 17 — Cooling Cycle Charging Chart

(R-22) — 50HQ.VQ033

Page 10

COMPRESSOR DISCHARGE PRESSURE@SERVICE PORT(PSIG)

a

2 no

ISO 200 250 300

COMPRESSOR DISCHARGE PRESSURE ©SERVICE PORT(PSIG)

m

Fig. 18 — Heating Cycle Operation

Check Chart (R-22) — 50HQ,VQ033

COMPRESSOR DISCHARGE PRESSURE® SERVICE PORT(PSIG)

Fig. 19 — Cooling Cycle Charging Chart

(R-22) — 50HQ,VQ042

Fig. 21 — Cooling Cycle Charging Chart

(R-22) - 50HQ.VQ048

Fig. 22 — Cooling Cycle Charging Chart

(R-22) — 50HQ,VQ060

Fig. 20 — Heating Cycle Operation

Check Chart (R-22) — 50HQ,VQ042

COMPRESSOR DISCHARGE PRESSURE ©SERVICE PORT(PSIG)

Fig. 23 — Cooling Cycle Charging Chart

(R-22) — 50HQ.VQ080

10

Page 11

CHARGEMASTER® DEVICE OPERATION —

Operate unit 10 minutes before using Chargemaster. Ensure unit indoor fan section access panel

is in place for proper Chargemaster operation.

1. Tape Chargemaster feeler bulb to unit suction

line. Insulate bulb. Ensure suction line is clean

for good contact with bulb.

2. Connect refrigerant drum to Chargemaster inlet

port with drum in position for vapor charging.

3. Connect Chargemaster outlet port (loosely) to

unit suction line Schrader valve.

4. Crack valves on refrigerant drum and Chargemaster to purge lines from drum to suction line

Schrader valve. After purging lines, close valve

on Chargemaster only. Tighten Chargemaster

connection at suction line Schrader valve.

5. Measure unit leaving water temperature.

6. Read evaporator temperature at red needle

position on Chargemaster temperature gage and

suction line temperature at black needle

position.

CAUTiON: Do not read evaporator tempera

ture with Chargemaster valve open.

7. Enter 50HQ,VQ Chargemaster Charging Chart,

Table 5, at unit leaving water temperature (step

5) and evaporator temperature (step 6). (Do not

use standard charging chart on cover of Chargemaster.) Eind the suction line temperature

required for correct system charge. If actual

suction line temperature (step 6) is higher than

table value, the system is undercharged. If suc

tion line temperature is lower than table value,

the system is overcharged.

Example: At leaving water temperature of 93 F

and evaporator temperature of 41 F, the system

is correctly charged at 50 F (±2F) suction line

temperature.

8. Add charge by slowly opening Chargemaster

valve. If necessary, reduce charge by bleeding at

liquid line Schrader valve. Check outdoor air

and evaporator temperature during procedure.

If they change, refer back to Chargemaster

Charging Chart for new value.

Correct use of Chargemaster ensures that an

optimum refrigerant charge is in system when

conditions and system components are normal.

However, the Chargemaster does not solve or fix

system abnormalities. It indicates correct charge

for condition of system. It does not make correc

tions for dirty filters, slow fans, or other abnormal

conditions. This charging device ensures that a

correct relationship exists between leaving water

temperature, evaporator temperature, and suction

line temperature on a specific system.

Table 6 — Compressor Data

UNIT

50HQ,VQ

014

018

022

027

033

042

048 PC4616AD

060

033

042

048

060

080

033

042

048

060

080

V/PH

208/230-1

208/230-3 PY4616AD

460/3

PRODUCTION

COMPRESSOR

AJ55Ì3F

AB5519F

MD2023FE

MD2423FE

MD3423FE

MD4023FE

PC6416AG

MF3423FE

MF4023FE

PY6416AF

PY7716AF 72

MH3423FE 42

MH4023FE 42

PH4616AD 72

PH6416AF 72

PH7716AF

OIL

RECHARGE

(oz)

24

32

42

42

42

42

72

72

42

42

72

72

72

Table 5 — Chargemaster Charging Chart

UNIT

LEAVING

WATER

TEMP

(F)

69 46

75

81

87

93

99

105

112

117

123

’Saturated evaporator temperature which is the equivalent tem

perature of pressure taken at unit suction service valve

30 33 36 39

45 47

EVAPORATOR TEMP (F)*

41 44 47 50

Suction Line Temp (F)

49 51

46

54 57 59 61

53 55 58

50

49 51

48 50 52

46

48

47 49

45 47 50

54 56

54 56

50 53

51

46 49

47 52 55

45

46 50

64

60

57 63

62

55 57 61

54 56 61 64

56

53

53 55 59 62

53 55 56

53

65

60 63

57 61

Compressor Removal

See Table 6 for compressor information and

Fig. 7 for component location. Follow safety codes,

and wear safety glasses and work gloves. Have

quenching cloth available (step 7).

56

CAUTION: Copper tubing and aluminum fins

are used in unit coils. Do not overbeat or place

excessive strain on tubing or dam^e may result.

1. Shut off power to unit. Failure to do so may

result in electrical shock. Remove unit com

pressor section access panels. Fig. 1 and 5.

2. Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service Techniques Manual, Chapter 1.

3. Remove core from suction and discharge line

Schrader valves.

11

Page 12

4. Disconnect compressor wiring at compressor

terminal box.

5. Using a tubing cutter, cut suction and dis

charge lines at convenient place near com

pressor for easy reassembly to new compressor

with copper slip couplings.

CAUTION: Excessive movement of copper

lines at compressor may cause a break

where lines connect to coil.

6. Remove compressor holddown bolts and lift

compressor out.

7. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

8. Braze piping stubs (removed in step 7) on new

compressor.

9. Clean system.

10. Install new compressor in unit. Braze suction

and discharge lines to compressor piping stubs

(at points where cut, step 5) using fieldsupplied copper couplings. Ensure compressor

holddown bolts are in place. Connect wiring.

11. Evacuate and recharge unit.

CAUTION; Before performing recommended

maintenance, be sure main power switch to unit

is turned off.

Lubrication

COMPRESSOR contains factory oil charge. Re

place oil when lost. See Table 6 for oil recharge. If

necessary, refer to Carrier Standard Service Tech

niques Manual, Chapter 1, pages 1-21, for oil

recharging procedure. Use Carrier PP33-1, Texaco

Capella B or Suniso 3G oil.

FAN MOTOR BEARINGS are prelubricated for 3

years heavy-duty or 5 years normal-duty service.

Cleaning Coil and Condensate Pan — Clean

and inspect coil, condensate pan and drain before

each cooling season.

1. Remove coil section access panels and slide air

filter out of filter flanges.

2. Disconnect condensate drain line at pan drain

connection.

3. Use vacuum cleaner nozzle to clean the face of

coil.

4. Clean condensate drain trap with a bottle brush.

Clean condensate pan.

5. Hold pail under condensate pan drain connec

tion and flush pan out with clean water. Ensure

water flows freely thru condensate drain. Do

not overflow pan.

6. Reconnect condensate drain line.

7. Install access panel and air filter.

Indoor Fan Wheel should be centered in housing.

To adjust fan, loosen setscrew holding fan to

motor shaft. Adjust fan and retighten setscrew.

50VQ INDOOR BLOWER ASSEMBLY

REMOVAL

1. Remove fan section access panel.

2. Remove power wires from Molex plug.

3. Place a spacer beneath blower housing for

support.

4. Remove blower assembly mounting bracket.

(Rear flange on top of blower housing and

screws now hold blower assembly in place.)

5. Support blower housing at bottom and remove

spacer. Tilt blower assembly downward and lift

out of unit.

50HQ INDOOR BLOWER ASSEMBLY

REMOVAL

1. Remove top cover (Fig. 2).

2. Remove power wires from Molex connector

(Fig. 7).

3. Remove blower assembly mounting screws from

base unit (Fig. 2).

4. Lift blower assembly out of unit.

Indoor Fan and Motor Removal

1. Remove blower assembly from unit.

2. Remove Molex plug from bracket on fan

housing.

3. Loosen setscrew holding fan to motor shaft.

4. Loosen motor mounting band and remove

motor.

5. Remove fan cutoff plate from blower housing

outlet.

6. Remove fan wheel from blower housing outlet.

Clean Indoor Fan Wheel — When coil is cleaned,

remove caked-on dirt from fan wheel and housing

with brush; remove grease with mild solvent. When

replacing blower assembly, make sure fan wheel is

centered in housing.

Return Air Filter — Replace filter media 4 times a

year. For other types of filters, refer to filter manu

facturer’s instructions as required.

CAUTION; Nev«r operate unit W3tltcwi.t a filter

as coil wilt plug and damage to fan motor may

result.

Heat Exchanger — If excessive discharge pressure

is experienced with normal water flow, the heat

exchanger tubes may be fouled and require cleaning.

Contact a local water treatment firm for details on

chemical cleaning.

12

Page 13

^ TROUBLESHOOTING CHART

PROBLEM

ENTIRE UNIT DOES

NOT RUN

BLOWER OPERATES

BUT COMPRESSOR

DOES NOT

UNIT OFF ON LOW

WATER TEMPERA

TURE CONTROL

UNIT SHORT

CYCLES

CAUSE

Blown fuse

Broken or loose wires

Voltage supply low

Transformer

Thermostat

Voltage supply low

Thermostat

Wiring

High-pressure controls

Defective capacitor

Seized compressor

Compressor overload open

Compressor motor grounded

Compressor windings open

Low water temperature

cutout open (LWTC)

Water temperature too low

on heating

Low water temperature

switch

Wiring and controls

Compressor overload

CORRECTION

Replace fuse or reset circuit breaker.

Repiace or tighten the wires.

If voltage is below minimum voltage specified on dataplate, contact

local power company

Check 24-volt transformer for burnout or voltage less than 18 volts

Set thermostat on COOL and lowest temperature setting, unit

should run Set thermostat on HEAT and highest temperature

setting, unit should run. Set fan to ON, fan should run If unit does

not run in all 3 cases, the thermostat could be wired incorrectly,

or faulty To ensure faulty or miswired thermostat, disconnect

thermostat wires at unit and jumper between R, Y, G and W ter

minals and unit should run

If voltage is below minimum voltage specified on the dataplate,

contact local power company

Check setting, calibration and wiring.

Check for loose or broken wires at compressor, capacitor or

contactor. ___

The unit could be off on the high-pressure cutout control. Reset the

thermostat to OFF After a few minutes, turn to COOL If the com

pressor runs, unit was off on high pressure (See Problems for

possible causes )

If the unit still fails to run, check for faulty pressure switch by

jumpering the high-pressure control

Check capacitor or Start Thermistor (PTC). If defective, remove,

replace and revise correctly.

Try a start capacitor in parallel with the run capacitor momentarily.

If the compressor starts but the problem reoccurs on starting,

install an auxiliary start kit The hard start kit is comprised of a

recommended start relay and correctly sized capacitor If the

compressor still does not start, replace the compressor

In all cases, an external or internal temperature sensitive com

pressor overload is used If the compressor dome is too hot to

touch, the overload will not reset until the compressor cools down.

If the compressor is cool and the overload does not reset, there

may be a defective or open overload If the overload is external,

replace the overload, otherwise, replace the compressor

Internal winding grounded to the compressor shell. Replace the

compressor

Check continuity of the compressor windings with anohmmeter If

the windings are open, replace the compressor.

The unit could be off on the LWTC Reset the thermostat to OFF.

After a few minutes, turn to HEAT If the compressor runs, unit was

off on LWTC (see Problems for possible causes).

Lack«,of or inadequate water flow

Entering water too cold.

Scaled or plugged heat exchanger ____ _

Check for defective or improperly calibrated low water temperature

switch

Loose connections in the wiring or the control contactors defective

Defective compressor overload, check and replace if necessary If

the compressor runs too hot, it may be due to the deficient refrig

erant charge

_____ ______

____________________

_

13

Page 14

TROUBLESHOOTING CHART (cont)

PROBLEM

INSUFFICIENT

COOLING OR

HEATING

NOISY OPERATION

CAUSE

Unit undersized

Loss of conditioned air by

leaks

Thermostat

Airflow

Refrigerant charge

Compressor

Reversing valve

Operating pressure

Refrigerant system

Compressor

Blower and blower motor

Contactors

Rattles and vibrations

Airborne noises and

other sounds

CORRECTION

Recalculate heat gains or losses for space to be conditioned. If

excessive, rectify by adding insulation, shading, etc.

Check for leaks in ductwork or introduction of ambient air thru

doors and windows

Improperly located thermostat (e g near kitchen sensing in

accurately the comfort level in living areas).

Lack of adequate airflow or improper distribution of air. _ _

Low on refrigerant charge causing inefficient operation.

Check for defective compressor. If discharge pressure is too low

and suction pressure is too high, compressor is not pumping

properly. Replace compressor.

Defective reversing valve creating bypass of refrigerant from dis

charge to suction side of compressor

Incorrect operating pressure (See chart.)

Check strainer and capillary tubes for possible restrictions to flow

of refrigerant

The refrigerant system may be contaminated with moisture, non-

condensables, and particles _ ^

Dehydrate, evacuate and recharge the system.

Make sure the compressor is not in direct contact with the base or

sides of the cabinet The holddown bolts used for shipping should

be loosened so that the compressor is floating free on its isolator

mounts. Excessive noise will occur if the compressor has a broken

valve or loose discharge tube. Replace the compressor

Blower wheel hitting the casing Adjust for clearance and align

ment Bent blower, check and replace if damaged Loose blower

wheel on shaft Check and tighten Defective bearings, check and

replace

A clattering or humming noise in the contactor could be due to

control voltage less than 18 volts. Check for low supply voltage, low

transformer output or extra long runs of thermostat wires If the

contactor contacts or coil is defective, repair or replace

Check for loose screws, panels or internal components Tighten

and secure. Copper piping could be hitting the metal surfaces

Carefully readjust by bending slightly

Undersized ductwork will cause high airflow velocities and noisy

operation.

Excessive water thru the water-cooled heat exchanger will cause a

rattling sound

Throttle back on the water flow ensuring adequate flow for good

operation but eliminating the noise

____________________________

__

_ _ _ _

______________

_____________

_

_______ _

_

_____ _

_

_____ ________

_

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Tab 5a 5a

4

Form 50HQ,VQ-2SI Supersedes 50HQ,VQ-1 SI PrintedinUSA 9-81 PC 111 Catalog No 535-029

Loading...

Loading...