Page 1

HEATING & COOLING

50HJ015,024

Single-Package Rooftop Units

Electric Cooling with Electric Heat Option

Installation, Start-Up and Service

Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS

INSTALLATION ................................................................. 1-9

Step 1 — Provide Unit Support.......................................... 1

• ROOF CURB

• ALTERNATE UNIT SUPPORT

Step 2 — Rig and Place Unit ............................................ 1

• POSITIONING

• ROOF MOUNT

Step 3 — Field Fabricate Ductwork

Step 4 - Make Unit Duct Connections .... 6

Step 5 — Trap Condensate Drain

Step 6 — Make Electrical Connections

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

Step 7 — Make Outdoor-Air Inlet

Adjustments......................................................................... 8

• MANUAL OUTDOOR-AIR DAMPER

• OPTIONAL FACTORY-INSTALLED

ECONOMIZER

Step 8 — Install Outdoor-Air Hood

START-UP....................................................................... 10-12

SERVICE

START-UP CHECKLIST...................................................CL 1

...........................................................................

...........................................

...............................

......................................

..............................

...................................

1

6

6

7

8

12-16

SAFETY CONSIDERATIONS

INSTALLATION

Step 1

ROOF CURB — Assemble and install accessory roof curb

in accordance with instructions shipped with the curb.

Accessory roof curb and information required to field

fabricate a roof curb are shown in Fig I and 2. Install in

sulation, cant strips, roofing, and counter flashing as shown.

Ductwork can be secured to roof curb before unit is set in

place.

IMPORTANT' The gasketing of the unit to the roof

curb is critical for watertightness Install gasket sup

plied with the roof curb as shown in Fig. 1. Improp

erly applied gasket can result in air leaks and poor

unit performance.

Curb should be level. This is necessary to permit unit

drain to function properly Unit leveling tolerance is

± Vi6 in. per linear ft in any direction. Refer to Accessory

Roof Curb Installation Instructions for additional informa

tion as required.

ALTERNATE UNIT SUPPORT - When the curb cannot

be used, support unit with sleepers using unit curb support

area. If sleepers cannot be used, support long sides of unit

with a minimum of 3 equally spaced 4-in. x 4-in. pads on

each side.

Provide Unit Support

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical com

ponents. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance func

tions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service

personnel. When working on air-conditioning equipment,

observe precautions in the literature, tags and labels at

tached to the unit, and other safety precautions that may

apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguishers available for all brazing operations.

A WARNING

Before performing service or maintenance operations

on unit, turn off main power switch to unit. Electrical

shock could cause personal injury.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookII PC 111 Catalog No 565-125 Printed in U S A. Form 50HJ-6SI Pg 1 12-93 Replaces: New

Tab 1b

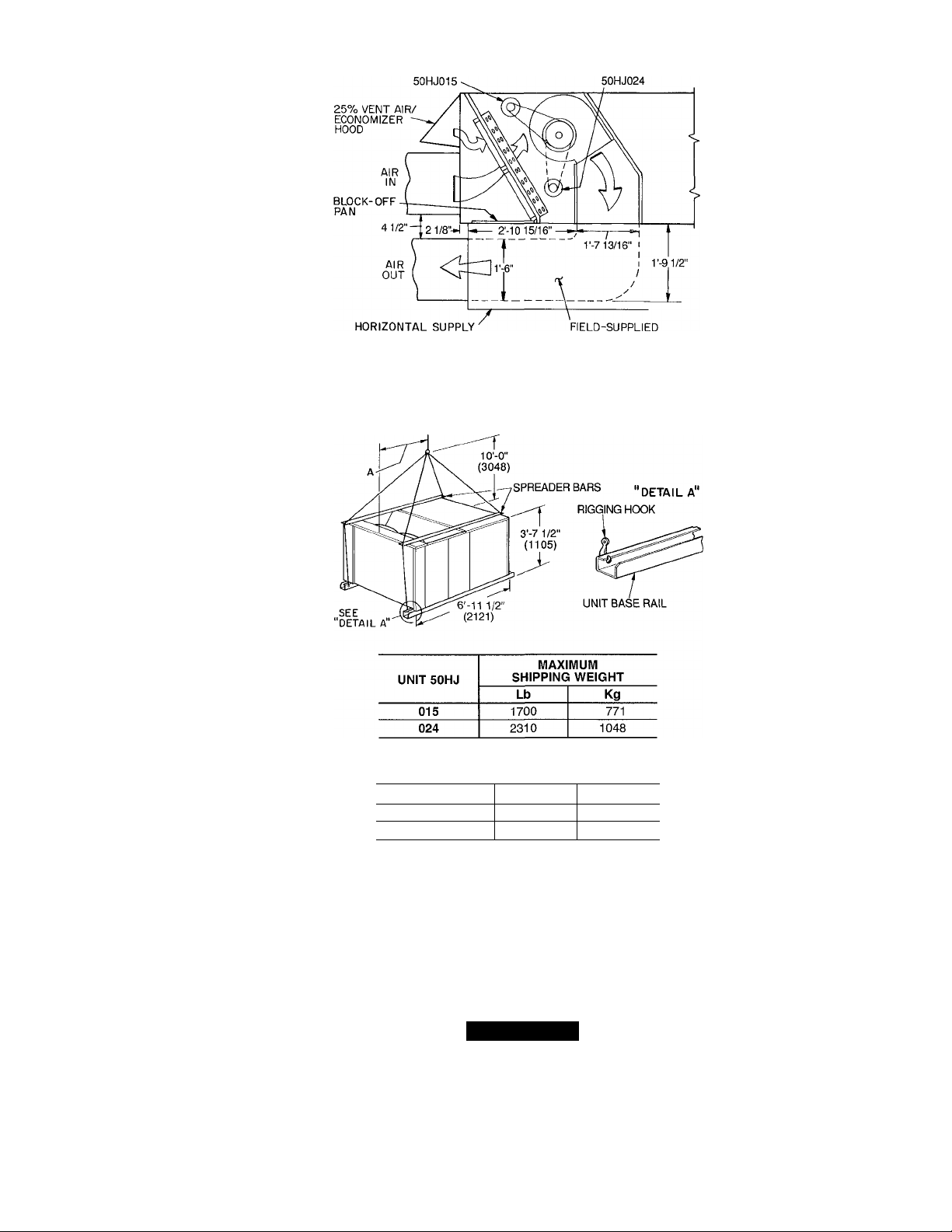

Step 2 — Rig and Place Unit — Inspect unit for

transportation damage. File any claim with transportation

agency. Keep unit upright, and do not drop. Use spreader

bars over unit to prevent sling or cable damage. Rollers

may be used to move unit across a roof. Level by using unit

frame as a reference; leveling tolerance is ± l/i6 in. per lin

ear ft in any direction. See Fig. 1 for additional leveling

tolerance information. Unit weight is shown in Table 1.

Four lifting holes are provided in ends of unit base rails

as shown in Fig. 3 Refer to rigging instructions on unit.

POSITIONING — Provide clearance around and above unit

for airflow, safety, and service access (Fig. 4).

Do not install unit in an indoor location. Do not locate

air inlets near exhaust vents or other sources of contam

inated air.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

ROOF MOUNT — Check building codes for weight dis

tribution requirements.

Page 2

NOM. 5/4 X 4

(32) X (102)

TYP 4 PLC5

0“

COMPR

SECT

1 -6

(50P0900151 ONLY) lb4)

OPENING

(457) . ^ .

SUPPLY

CURB

PLAN VIEW OF ROOF CURB

- ___

RETURN

OPEN(NG

CURB

OUTLINE

g

___________

OF UNIT

A (1753)

.Ü

INSULATED PANE', FOR SIDE

SUHPLY AND RETURN

(50P09001S1 ONLY)

5'-3'

UNIT OPENINGS

-(’so/)

1 t

SUPPLY AIR RETURN AIR

SECT ION A-A

GASKET

(SUPPLIED

WITH CURB)

COUNTER FLASHING

ROOFING FELT

(FIELD SUPPLIED)

. CANT STRIP

(FIELD SUPPLIED)

RIGID INSULATION

(FIELD SUPPLIED)

-1 -4 5/16

(415)

(FIELD SUPPLIED)

•ROOFING material

(FIELD SUPPLIED)

OPTIONAL

SIDE 5UPPLT

(305)

ATTACH DUCT TO ROOF CURB

ACCESSORY

PACKAGE NO.

50PQ900221

50PQ900141

50PQ900151

CURB

HEIGHT

V-2"

(305)

2'-0"

(610)

2'-0"

(610)

DESCRIPTION

Standard Curb —

14" High

Standard Curb

for Units Requiring

High Installation

Horizontal Supply

and Return Curb

LEGEND

COMP SECT. — Compressor Section

NOTES:

1 Roof curb accessory is shipped unassembled.

2. Insulated panels, 1-in thick neoprene-coated,

IV2 lb density.

3 Dimensions in ( ) are in millimeters.

4 Direction of airflow.

5 Roof curb 16 gage steel.

O’-S 3/16*'

&

0 32)

NOTE: To prevent the hazard of stagnant water build-up in the drain

pan of the indoor-air section, unit can only be pitched as shown.

Fig. 1 — Roof Curb Details

I

Page 3

EVAPORATORFAN MOTOR

EVAPORATORFAN MOTOR

CURB (50P0900I5I)

TRANSITION DUCT

Fig. 2 — Horizontal Supply/Return Curb Details

DIMENSION A

UNIT 50HJ

015

024

Ft-in. mm

3-0 914

3-4’/2 1029

ÊJ

NOTES;

1. Dimensions in ( ) are in miilimeters

2 Refer to Tabie 1 for unit operating weights.

3. Remove boards at ends of unit and runners prior to rigging.

4 Rig by inserting hooks into unit base raiis as shown. Use corner

post from packaging to protect coii from damage. Use bumper

boards for spreader bars.

5 Weights do not inciude optionai economizer See Table 1 for econo

mizer weight.

6. Weights given are for aluminum evaporator coii plate fins and

copper condenser coii piate fins Weights of other metai combi

nations are listed in Table 1

A CAUTION

All panels must be in place when rigging.

Fig. 3 — Rigging Details

Page 4

CONTROL BOX

ACCESS

•25% AIR On

''ECONOMIZER HOOD

pO -3 7/16'

i (87)

C

SECTION A-A

■ }

0’-3"

(76)

O'-l"

1(102)

I

UNIT

50HJ

015 390

024 492

‘Weights are for unit only (with aluminum evaporator and condenser

coil fins) and do not include options or crating

Lb

A

Kg

177

233

CORNER WEIGHT*

B

Lb

Kg

243 110 322 146

232

511

C D

Lb

Kg

504 229

Lb

Kg

515 234

523 237

Fig. 4 — Base Unit Dimensions

DIMENSIONS

UNIT

50HJ

A

Ft-in. mm Ft-in. mm

015 3-0

024 3-4% 1035 3-7

LEGEND

914

B C

838 1-10 559

2-9

1092 1-8 508

Ft-in. mm

KO — Knockout

NOTES;

1 Dimensions in ( ) are in millimeters

2- ® Center of gravity.

Direction of airfloiw.

Ductwork to be attached to accessory roof curb only.

Minimum clearance:

a Rear; 7'-0" (2134) for coil removal. This dimension

can be reduced to 4'-0" (1219) if conditions permit

coil removal from the top

Left side: 4'-0" (1219) for proper condenser coil

airflow

Front' 4'-0" (1219) for control box access

Right side: 4'-0" (1219) for proper operation of damper

and power exhaust (if so equipped).

e. Top: 6'-0" (1829) to assure proper condenser fan

operation.

f. Local codes or jurisdiction may prevail.

With the exception of clearance for the condenser coil

and the damper/power exhaust as stated In note no 5, a

removable fence or barricade requires no clearance

Dimensions are from outside of corner post. Allow

O'-Vie" (8) on each side for top cover drip edge

i

Page 5

Table 1 — Physical Data

UNIT SIZE 50HJ

OPERATING WT (lb)

COMPRESSOR

REFRIGERANT

REFRIGERANT METERING DEVICE

CONDENSER COIL

CONDENSER FAN

EVAPORATOR COIL

EVAPORATOR FAN

HIGH-PRESSURE SWITCH

LOW-PRESSURE SWITCH

AIR INLET SCREENS

RETURN-AIR FILTERS (TYPE)

LEGEND

AI — Aluminum

Cu — Copper

'Evaporator coil fin material/condenser coil fin material.

tWeight of 14 in. roof curb.

"System 1 consists of the upper portion of condenser coil and intertwined evaporator coil, and

System 2 consists of the lower portion of the condenser coil and intertwined evaporator coil

NOTE: The 50HJ015 has adjustable pulleys The 50HJ024 has one set (2) of fixed pulleys

AI/AI*

Unit Al/Cu*

Cu/Cu*

Economizer

Roof Curbt

Number

Oil (oz)152

Charge (lb)** Sys 1, Sys 2

Upper Circuit

No. ...Length (in.)...iD/OD

Lower Circuit

No. ...Length (in.)...iD/OD

Rows

Fins/in.

Total Face Area (sq ft)

Nominal Cfm

Number...Diameter (in.)

Motor Hp (1075 Rpm)

Watts Input (Total)

Rows

Fins/in.

Total Face Area (sq ft)

Quantity...Size (in.)

Nominal Cfm

Maximum Allowable Rpm

Motor Pulley Pitch Diameter (in.)

Fan Pulley Pitch Diameter (in.)

Belt, Quantity...Type...Length (in.)

Factory Speed Setting (Rpm)

Motor Hp (Service Factor)

Motor Frame Size

Cutout (psig)

Reset (psig)_____________________

Cutout (psig)

Reset (psig)

Economizer, Quantity...Size (in.)

Quantity... Size (in.)

____________________

20.8,

6.. .25...0 055/0.125

6.. 25...0 055/0.125

6.. .25...0 055/0.125

Copper Tubes, Aluminum or Copper Plate Fins

13 6 Al or 12.4 Cu

18.9

12,000

2...26

1

2672

Copper Tubes, Aluminum or Copper Plate Fins

14.3 Al or 13.1 Cu

165

2.. 10 X 10

1 .V...41

2.. .20 X 20 X 2

3.. .16 X 20 X 2

2.. .16 X 25 X 2

Centrifugal, Fixed Pitch Belt Drive

5000

1550

3 4-4.4

6.0

1092

3 (1.15)

56

10% Efficient — 2-in Throwaway Fiberglass

R-22

I

Capillary Tubes

Propeller Type, Direct Drive

426

320

7

22

2 20 X 25 X 1

1 20 X 20 X 1

2030

2160

2270

110

200

16.25, 16.25

13. 25 .0.055/0.125

13...25.. 0.055/0 125

13.6 Al or 12.4 Cu

22 2

11,400

2 .26

1

3000

14.4 Al or 13.1 Cu

17.9

2...12 X 12

8000

1500

6.10

8.40

1. BX.. 51

1287

7V2 (1.15)

184T

4.. 20 X 20 X 2

4.. 16 X 20 X 2

Page 6

Step 3 — Field Fabricate Ductwork — Secure all

ducts to building structure. Use flexible duct connectors be

tween unit and ducts as required. Insulate and weatherproof

all external ductwork, joints, and roof openings with counter

flashing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

The 50HJ units with electric heat require a 1-in. clear

ance for the first 24 in. of ductwork.

Outlet grilles must not lie directly below unit discharge.

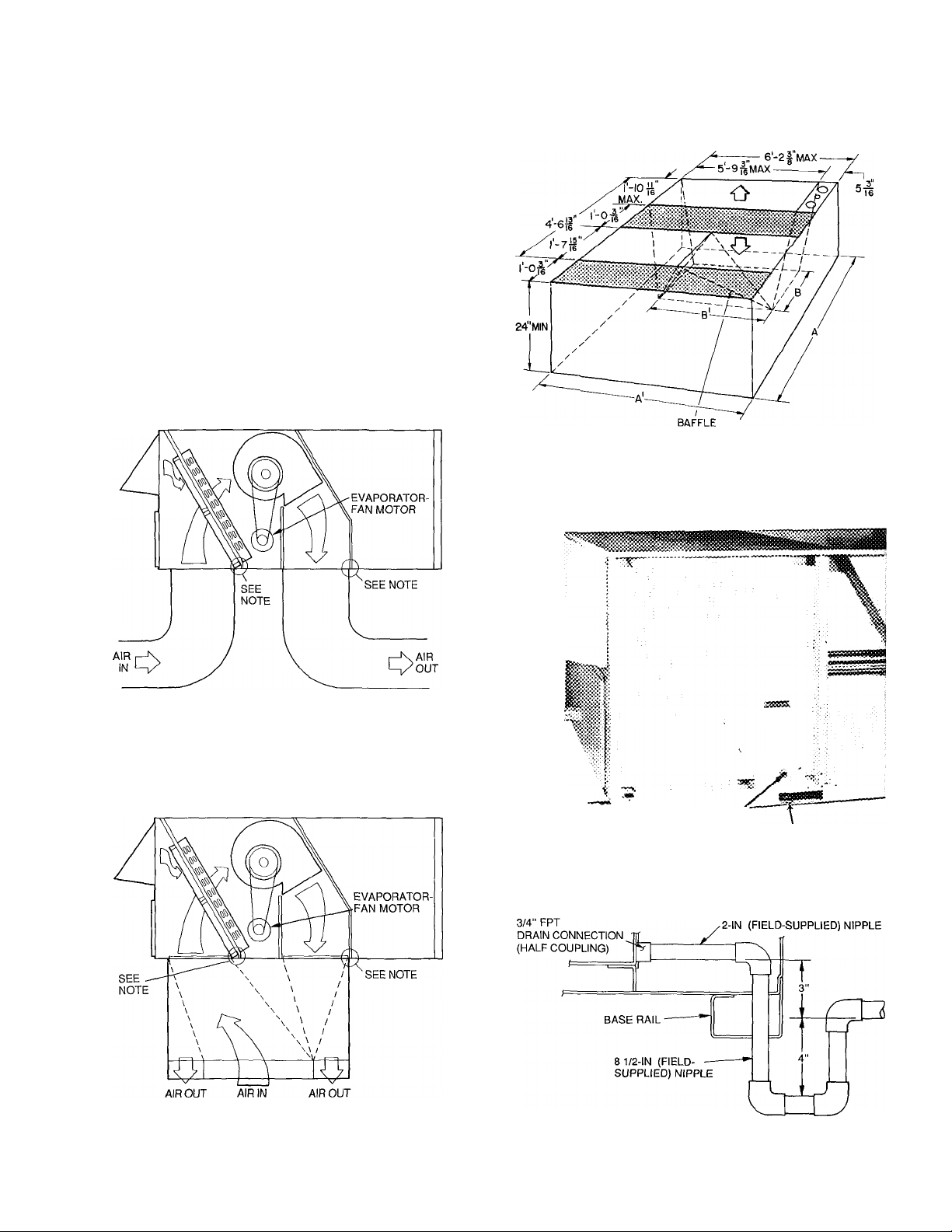

Step 4 — Make Unit Duct Connections - Unit

is shipped for through-the-bottom duct connections. Duct

work openings are shown in Fig. 5. Field-fabricated con

centric ductwork may be connected as shown in Fig. 6 and

7. Attach all ductwork to roof curb and roof curb basepans.

Refer to installation instructions shipped with accessory roof

curb for more information.

Step 5 — Trap Condensate Drain — See Fig. 4

and 8 for drain location. Plug is provided in drain hole and

must be removed when unit is operating. One V4-in. half

coupling is provided inside unit evaporator section for con

densate drain connection. An 8‘/2 in x %-in. diameter nip

ple and a 2-in. x %-in. diameter pipe nipple are coupled to

standard Y4-in. diameter elbows to provide a straight path

down through holes in unit base rails (see Fig. 9). A trap at

least 4-in. deep must be used.

i

Shaded area indicates block-off panels.

NOTE: Dimensions A, A' and B, B' are obtained from field-supplied

ceiling diffuser

Fig. 7 — Concentric Duct Details

NOTE. Do not drill in this area, as damage to basepan may resuit in

water leak.

Fig. 5 — Air Distribution — Through-the-Bottom

(50HJ024 Shown)

NOTE: Do not drill in this area, as damage to basepan may resuit in

water leak.

Fig. 6 - Concentric Duct Air Distribution

(50HJ024 Shown)

СОМЫЕстГоГ '-3/3" HOLES

Fig. 8 — Condensate Drain Details

Fig. 9 — Condensate Drain Piping Details

Page 7

Step 6 — Make Electrical Connections

FIELD POWER SUPPLY — Unit is factory wired for volt

age shown on nameplate.

When installing units, provide a disconnect, per NEC

(National Electrical Code) requirements, of adequate size

(Table 2).

All field wiring must comply with NEC and local

requirements.

Route power lines through control box access panel or

unit basepan (Fig. 4) to connections as shown on unit wir

ing diagram and Fig. 10.

Transformer no. 1 is wired for 230-v unit. If 208/230-v

unit is to be run with 208-v power supply, the transformer

must be rewired as follows;

1. Remove cap from red (208 v) wire.

2. Remove cap from orange (230 v) spliced wire.

3. Replace orange wire with red wire

4. Recap both wires.

IMPORTANT; BE CERTAIN UNUSED WIRES

ARE CAPPED. Failure to do so may damage the

transformers.

Operating voltage to compressor must be within voltage

range indicated on unit nameplate. On 3-phase units, volt

ages between phases must be balanced within 2% and the

current must be balanced within 10%.

Use the following formula to determine the percentage of

voltage imbalance.

Percentage of Voltage Imbalance

— 100 X voltage deviation from average voltage

average voltage

Example; Supply voltage is 460-3-60.

AB =452 V

BC =464 V

AC =455 V

Average Voltage =

Determine maximum deviation from average voltage.

(AB) 457 -452 =5 v

(BC) 464 -457 =7 V

(AC) 457 -455 =2 v

Maximum deviation is 7 v.

Determine the percentage of voltage imbalance;

Percentage of Voltage Imbalance = 100 x -

452 +464 +455

1371

“ 3

= 457

7

TB1 MAXIMUM WIRE SIZE

UNIT 50HJ

015 350 kcmil

024 350 kcmil

EQUIP — Equipment

GND — Ground

kcmil — Thousand Circular Mils

NEC — National Electrical Code

TB

208/230 460 575

— Terminal Block

VOLTAGE

2/0 2/0

2/0 2/0

LEGEND

Fig. 10 — Field Power Wiring Connections

FIELD CONTROL WIRING - Install a Carrier-approved

accessory thermostat assembly according to the installation

instructions included with the accessory. Locate thermostat

assembly on a solid wall in the conditioned space to sense

average temperature.

Route thermostat cable or equivalent single leads of

no. 18 AWG (American Wire Gage) colored wire from

subbase terminals through conduit in unit to low-voltage

connections as shown on unit label wiring diagram and in

Fig. 11.

NOTE; For wire runs up to 50 ft, use no. 18 AWG insu

lated wire (35 C minimum). For 50 to 75 ft, use no. 16

AWG insulated wire (35 C minimum). For over 75 ft, use

no. 14 AWG insulated wire (35 C minimum). All wire larger

than no. 18 AWG cannot be directly connected to the ther

mostat and will require a junction box and splice at the

thermostat.

Set heat anticipator settings as indicated in Table 3. Set

tings may be changed slightly to provide a greater degree of

comfort for a particular installation.

Refer to accessory remote control instructions as

required.

= 1.53%

This amount of phase imbalance is satisfactory as it is

below the maximum allowable 2%.

IMPORTANT; If the supply voltage phase imbal

ance is more than 2%, contact your local electric util

ity company immediately.

Unit failure as a result of operation on improper line volt

age or excessive phase imbalance constitutes abuse and may

cause damage to electrical components.

THERMOSTAT ASSEMBLY

Fig. 11 — Field Control Thermostat Wiring

Page 8

Table 2 — Electrical Data

UNIT

50HJ

015

024

FLA HACR LRA MCA MOCP NEC RLA -

•Heater capacity (kW) is based on heater voitage of 208 v, 240 v, 480 v and

575 V. if power distribution voltage to unit varies from rated heater voltage,

heater kW will vary accordingly This is the maximum size permissible; smaller

fuse size may be used where conditions permit

tFuse or HACR circuit breaker

"Heaters are field installed only

V-PH-HZ

208/230-3-60

460-3-60

575-3-60

208/230-3-60 187

460-3-60

575-3-60 518

Full Load Amps

Heating, Air Conditioning and Refrigeration

Looked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

Nationai Eiectrioai Code

Rated Load Amps

VOLTAGE

RANGE

Min Max

187 253

414 508 22 1

632

518

253

414 508

632

LEGEND

COMPRESSOR

No. 1 No. 2

RLA LRA RLA

49 3 191

86

179

69

43 9 170

199

15 9 62

77

43 9

199

159

- -

- -

- -

170

CONDENSER

FAN MOTOR

LRA Qty

77

62 2

2

2

2

2

2

EVAPORATOR

FAN MOTOR

FLA

77 3 105

33 3

26 3

54

I'k

(ea)

27

7'/г 11 0

(ea)

34

7'M

(ea)

NOTES

1 In compliance with NEC requirements for multimotor and combination load

equipment (refer to NEC Articles 430 and 440), the overcurrent protective

device for the unit shall be fuse or HACR breaker The Canadian units may

be fuse or circuit breaker

MCA calculation for units with electric heaters over 50 kW

FLA

Hp

48

3 9

24 2/22 0

90

= (1.25 X IFM amps) + (1 00 x heater FLA).

ACCESSORY/OPTIONAL

ELECTRIC HEATERS*

FLA kW MCA^

39/ 45

72/ 82

117/135

18

39

66

37 37

72/ 82

117/135

156/180**

39

66

96**

14/19

26/34

42/56

26/34

42/56

56/75**

-

15

32

55

32

55

80**

-

103/116

159/148

134/132

134/132

177/163

186/208**

POWER SUPPLY

88/ 88

88/ 88

100/100

100/100

110/125

175/175

39

39

55

72

32

52

175/175

175/175

200/175

200/225**

62

62

80

110**

52 60

MOCPt

110**

Warnock Hersey

45

45

60

80

35

60

80

80

90

Table 3 — Heat Anticipator Settings

UNIT

50HJ

U1 b

50HJ

024

VOLTAGES

208/230

460

575

208/230,575-3-60 42/52

460-3-60

kW

14/17 40

26/31 40

42/52

15

30 40 40

51

37 40

26/31

56/69

30

51

73

STAGE 1

66 40

40

40 66

40

.66

66

40

40 66

66

STAGE 2

_

40

_

.66

66

40

66

40

66

Step 7 — Make Outdoor-Air Inlet Adjustments

MANUAL OUTDOOR-AIR DAMPER - All units

(except those equipped with a factory-installed economizer)

have a manual outdoor-air damper to provide ventilation

air. Damper can be preset to admit up to 25% outdoor air

into retum-air compartment. To adjust, loosen securing screws

and move damper to desired setting Then retighten screws

to .secure damper (Fig. 12).

OPTIONAL FACTORY-INSTALLED ECONOMIZER

Economizer Motor Control Module (Fig, 13-15) — Set to

the "D" setting (Fig. 14) The control module is located on

the economizer motor. See Fig, 13 and 15.

Damper Vent Position Setting

1. Set fan switch at ON position (continuous fan operation)

and close night switch if used.

2. Set system selector switch to OFF position.

3. Turn adjustment screw slowly until dampers assume de

sired vent position. Do not manually operate econo

mizer motor since damage to motor will result.

NOTE; Refer to accessory installation instructions in

cluded with the field-installed economizer for installation

information. Also see Accessory Field-Installed Econo

mizer Adjustment section on page 10.

Step 8 — Install Outdoor-Air Hood — The same

type of factory-installed hood is used on units with 25% air

ventilation and units with an economizer.

NOTE; The hood top panel, upper and lower filter retain

ers, hood drain pan, baffle (024 only), and filter support

bracket are secured opposite the condenser end of the unit.

The screens, hood side panels, remaining section of filter

support bracket, seal strip, and all other hardware are in a

package located inside the return-air filter access panel

(Fig. 16)

1. Attach seal strip to upper filter retainer. See Fig. 17.

2. Assemble hood top panel and side panels, upper filter

retainer, and hood drain pan (Fig. 18)

3. Secure lower filter retainer and long piece of filter sup

port bracket to unit. See Fig. 18. Leave screws on 024

units loose

4. 50HJ024 Units Only; Slide baffle behind lower filter re

tainer and tighten screws.

5. Loosen sheet metal screws for base unit top panel lo

cated above outdoor-air inlet opening.

25% ADJUSTABLE

AIR DAMPER

BASE

■ UNIT

SECURING SCREWS

Fig. 12 — 25% Outdoor-Air Section Details

t

I

Page 9

COOLING

LOCKOUT

SWITCH

ECONOMIZER

MOTOR

ECONOMIZER

CONTROL

MODULE

FILTERS-

ECONOMIZER

DAMPER

ASSEMBLY

msf$

Fig. 13 — Economizer Damper Assembly — End View

6. Match notches in hood top panel to unit top panel screws

Insert hood flange between unit top panel flange and unit.

Tighten screws.

7 Insert outdoor-air inlet screens and spacer in channel cre

ated by lower filter retainer and filter support bracket.

8. Attach remaining shorter section section of filter sup

port bracket.

CHANGEOVER

SET POINT

MINIMUM

DAMPER

- POSITION

SETTING

LED LIGHTS UP

TO INDICATE

-OUTDOOR AIR

IS SUITABLE FOR

FREE COOLING

Fig. 14 — Economizer Control Module

ECONOMIZER MOTOR

Fig. 16 — Outdoor-Air Hood

Component Location

Fig. 17 — Seal Strip Location

(Air Hood Cross-Sectional View)

HOOD DRAIN

PAN

Fig. 15 — Economizer Control Module Location

Fig. 18 - Outdoor-Air Hood Details

Page 10

START-UP

Use the following information and Start-Up Checklist on

page CL-1 to check out unit PRIOR to start-up.

Unit Preparation — Check that unit has been installed

in accordance with these installation instructions and all

applicable codes.

Compressor Mounting — Loosen compressor hold

down bolts until sideways movement of the washer

under each holddown bolt head can be obtained. Do not

loosen completely, as bolts are self-locking and will main

tain adjustment.

Internal Wiring — Check all electrical connections in

unit control boxes; tighten as required.

Refrigerant Service Ports and Valves — Each 50HJ

unit has 2 Schrader-type service ports per circuit; one on

the suction line and one on the liquid line. Be sure that the

caps on the ports are tight. The units also have 2 service

valves per circuit; one on the suction line and one on the

discharge line. Be sure all valves are open.

Crankcase Heaters —

as there is power to unit.

IMPORTANT; Unit power must be on for 24 hours

prior to start-up. Otherwise, damage to compressor

may result.

Heaters are energized as long

Evaporator Fan — Fan belt and pulleys are factory in

stalled. Remove tape from the fan pulley and adjust pulleys

on 50HJ015 units as required. See Evaporator-Fan Perfor

mance Adjustment section on page 12. See Table 4 for Air

Quantity Limits. See Tables 5, 6A, and 6B for Fan Perfor

mance data. Be sure that fans rotate in the proper direction.

See Table 7 for Static Pressure Drops for accessories and

options. To alter fan performance, see Evaporator-Fan Per

formance Adjustment sections, pages 12 and 13.

Table 4 — Air Quantity Limits

UNIT 50HJ MINIMUM CFM

015 3750 6,250

024

6000 10,000

MAXIMUM CFM

Condenser Fans and Motors — Fans and motors

are factory set. Refer to Service, Condenser-Fan Adjust

ment section as required.

Return-Air Filters — Check that correct filters are

installed in filter tracks. See Table 1. Do not operate unit

without return-air filters.

Outdoor-Air Inlet Screens — Outdoor-air inlet screens

must be in place before operating unit.

Accessory Field-Installed Economizer Adjust

ment — Remove filter access panel. Check that outdoor-

air damper is closed and return-air damper is open.

Economizer operation and adjustment is described in

Start-Up, Base Unit Operation; and Service, Economizer

Adjustment sections, respectively.

Base Unit Operation

COOLING, UNITS WITHOUT ECONOMIZER - When

thermostat calls for cooling, terminals G and Y1 are ener

gized. The indoor (evaporator) fan contactor (IFC) and com

pressor contactor no. 1 (Cl) are energized and evaporatorfan motor, compressor no. 1 (024) or unloaded compressor

(015), and condenser fans start. The condenser-fan motors

run continuously while unit is cooling. If the thermostat calls

for a second stage of cooling by energizing Y2, compressor

contactor no. 2 (C2) is energized and compressor no. 2 starts

(024), or compressor no. 1 runs fully loaded (015).

A freeze protection thermostat (FPT) is located on the

evaporator coil. It detects frost buildup and turns off the

compressors, allowing the coil to clear. Once frost has melted,

the compressors can be reenergized by resetting the

thermostat.

HEATING, UNITS WITHOUT ECONOMIZER (If Acces

sory or Optional Heater is Installed) — Upon a call for

heating through terminal Wl, IFC and heater contactor

no. 1 (HCl) are energized. On units equipped for 2 stages

of heat, when additional heat is needed, HC2 is energized

through W2.

COOLING, UNITS WITH ECONOMIZER - Upon a call

for cooling, when outdoor ambient temperature is above the

outdoor-air temperature control setting, the evaporator and

condenser fans and compressor energize. The economizer

damper moves to VENT position.

Upon a first-stage call for cooling, when outdoor ambi

ent temperature is below the temperature control setting,

the evaporator fan starts and economizer damper modulates

to maintain mixed-air temperature. The compressor(s) re

mains off.

Upon a second-stage call for cooling, compressor no 1

(024) or unloaded compressor (015) is energized and me

chanical cooling is integrated with economizer cooling Com

pressor no. 2 (024 only) is locked out. If the outdoor-air

temperature is below 50 F, a cooling lockout switch

prevents the compressor(s) from running.

When supply-air temperature drops below a fixed set point,

the economizer damper modulates to maintain the temper

ature at the fixed set point.

HEATING, UNITS WITH ECONOMIZER (If Accessory

or Optional Heater is Installed) — The outdoor air damper

stays at VENT position while the evaporator fan is operat

ing Upon a call for heating through terminal Wl, the in

door (evaporator) fan contactor (IFC) and heater contactor

no. 1 (HCl) are energized. On units equipped for 2 stages

of heat, when additional heat is needed, HC2 is energized

through W2.

10

Page 11

Ф

Table 5 — Fan Performance Data, 50HJ015 Units

AIRFLOW

(Cfm)

3750 732

4000 764

4250 797

4500

4750 865 1226 965 1421 1056

5000 900

5250 935

5500

5750 1007

6000 1044

6250

0.2 0.4 0.6 0.8

835 949

1101

1252

2007

2238

2487

2753

Rpm Watts

977

1110

1001 1261

1430

1028

1607

1084 1803

2007

2229 1221

1142

2469

1173

2718

1205

2993

1236

Rpm

Watts

684 848

799

933

831 1075

1403

1590

1794 1060

971

2016

2256

1080 2513

Rpm Watts

876 968 974

904

934

996 1599

1028 1794 1112

1093

1126

1159

LEGEND

Watts — Input Watts to Motor

NOTES:

1, Factory shipped fan speed is 1092 rpm. The range of the stand

ard evaporator-fan motor is 978 to 1285 rpm. Other rpms may

require a field-supplied drive.

2 Static pressure iosses (i.e., economizer, eiectric heater) must be

added to external static pressure before entering Fan Perfor

mance table.

3. To convert watts to bhp, use the following equation:

„Watts X motor efficiency

^ 746

EXTERNAL STATIC PRESSURE (in. wg)

Rpm Watts Rpm Watts

1041

1119

1065 1261

1412 1170 1581

1089

1113 1581

1767

1139

1166 1980

1193 2202

2433 1294 2629

2682 1321 2895

1249

1277 2948

Table 6A — Fan Performance Data — 50HJ024, 208/230-V and 575-V Units

1.0

Rpm Watts

1124

1146 1412

1193 1750

1217

1241

1266 2371 1338

1270

1945

2149

1194 1430

1221 1572

1244 1741

1267

1290

1314 2336

1362 2806

Motor efficiency: Horsepower — Maximum Continuous Watts:

4 Interpolation is permissible Do not extrapolate.

5. Fan performance is based on wet coils, clean filters, and casing

losses.

6. Extensive motor and drive testing on these units ensures that

the full range of the motor can be utilized with confidence. Using

your fan motors up to the watts rating shown will not result in nui

sance tripping or premature motor failure Unit warranty will not

be affected.

1.2 1.4

Rpm

1247 1599

1284 1750 1331

1312 1909 1369 2096

1918

1335

2123

1358

1381 2522 1444 2709

2567

1405 2762

1429

Watts Rpm

2096

2300 1422 2487

3011

1.6

Watts Rpm Watts

1274 1767

1927

2282 1451 2478

1398

2948

1468

— —

0 84 3 hp - 3065

1.8

~ — —

1357

2105

1413 2282

1480 2682

2904

1504

— —

— —

2.0

Rpm Watts

—

—

2877

—

— —

— —

—

—

1440 2469

1493 2673

1531

AIRFLOW

(Cfm)

6,000

6,500

7,000

7,500

8,000

8,500

9,000

9,500

10,000

0.2 0.4

Rpm Watts

702

747

792 2138

838 2571 918

885 3060

932 3610 1005

980 4223 1050

1028 4904 1096

1077

Rpm Watts Rpm Watts Rpm Watts Rpm Watts Rpm

1428

796

1757

835

877 2476

962 3440 1036 3822 1105

1141

5655

0.6

1723 884 2025 965

2073 919

2929 996 3290 1067

4011 1077

4647

5350 1162 5796 1224

6123 1205 6591 1266

957

1119

2394

2816

4414

5071

EXTERNAL STATIC PRESSURE (in. wg)

0.8 1.0

2339

997

2725 1070

1031 3165

3658

4209

1143 4821 1206 5234 1266

1183

5498

6243

7059

LEGEND

Watts — Input Watts to Motor

NOTES-

1. Factory shipped fan speed is 1287 rpm Other rpms may require

a field-supplied drive.

2. Static pressure losses (i e., economizer, electric heater) must be

added to external static pressure before entering Fan Perfor

mance table

3. To convert watts to bhp, use the following equation:

„Watts X motor efficiency

^ 746

Table 6B — Fan Performance Data — 50HJ024, 460-V Units

AIRFLOW

(Cfm)

6,000

6,500

7,000 792

7,500 838

8,000 885

8,500

9,000 980

9,500 1028

10,000

0.2

Watts Rpm Watts Rpm

Rpm

702 1428 796 1723

747 1757

2138

2571 918 2929

3060 962 3440

932 3610 1005 4011

4223 1050

4904

1077 5655

0.4 0.6

835

2073

877

2476

4647 1119

1096 5350

1141

6123

Watts Rpm Watts

884 2025

919

2394

957 2816

996 3290 1067

1036

3822 1105 4209 1170

1077

4414 1143 4821 1206

5071

1162 5796 1224

1205 6591

LEGEND

Watts — Input Watts to Motor

NOTES:

1 Factory shipped fan speed is 1287 rpm. Other rpms may require

a fieid-supplied drive.

2. Static pressure losses (i.e , economizer, electric heater) must be

added to external static pressure before entering Fan Perfor

mance table

3 To convert watts to bhp, use the following equation:

_ Watts X motor efficiency

Bhp

746

EXTERNAL STATIC PRESSURE (in. wg)

0.8

965 2339

997 2725

3165

1031

3658 1135

1183 5498

6243 1283

1266 7059 1323 7531 1378

1.2 1.3 1.4 1.6

Watts

Rpm Watts

1041 2669 1115 3018

3069 1140 3429 1174 3617 1208 3805

1102 3525 1169 3898 1201

1135 4035 1199

1170 4604 1232 5008 1262 5180 1292 5422 1350

1244

5930 1302

1283 6695 1340

1323 7531

Motor efficiency: Horsepower — Maximum Continuous Watts:

4 Interpolation is permissible Do not extrapolate.

5. Fan performance is based on wet coils, clean filters, and casing

losses.

6. Extensive motor and drive testing on these units ensures that

the full range of the motor can be utilized with confidence. Using

your fan motors up to the watts rating shown will not result in nui

sance tripping or premature motor failure. Unit warranty will not

be affected.

1.0

Rpm Watts Rpm Watts Rpm Watts Rpm

1041 2669 1115 3018

3069 1140 3429 1174

1070

1102 3525 1169 3898

4035

4604 1232 5008 1262

5234

1244 5930 1302 6369

6695

1.2

1199

1266

1340

1150

4422

1230

5655

1295

6369

1330

7152

1367 7384 1394 7616

0.87 71/2 hp-7915

1.3

1150 3201 1186

1201 4091 1233

4422

1230 4622

5655 1295

1330 6592

7152 1367 7384 1394 7616

8007 1404

Rpm

3201 1186 3385 1255

1233 4285 1296

4091

4622 1262 4822

1324

5870

6592 1359 6816 1413 7270 1466 7735

1.4

3617 1208

1262 4822 1322

1292 5422 1350

5180

1324 6085 1380

5870

1359 6816 1413

8248 1431

Rpm Watts

Watts

1274

1322

6085 1380 6524

— — —

Rpm

Watts

3385

1255

3805 1274 4198

4285

1296

1447 8088

8489

— — —

Motor efficiency: Horsepower — Maximum Continuous Watts

0 87 7V2 hp - 8640

4 Interpolation is permissible. Do not extrapolate.

5 Fan performance is based on wet coils, clean filters, and casing

losses.

6. Extensive motor and drive testing on these units ensures that

the fuli range of the motor can be utilized with confidence. Using

your fan motors up to the watts rating shown will not result in nui

sance tripping or premature motor faiiure. Unit warranty wili not

be affected.

11

1.8

Rpm

3771

1322 4175

4198

1338

4687

1358

5235 1381 5662

5847

1407 6286

1435

1.6 1.8

Watts

Rpm

3771

1322 4175

1338 4609

4687

1358 5106

5235

1381

5847

1407

6524

1435 6975

7270

1466

—

Watts

4609

5106

6975

—

Watts

5662

6286

7735

—

—

Page 12

Table 7 — Accessory/FlOP Static Pressure Drop* (in. wg)

UNIT

50HJ

015 460-3-60

024 460-3-60

Flop — Factory-Installed Option

*The static pressure must be added to external static pressure The sum and

the evaporator entering air cfm should then be used in conjunction writh the

Fan Performance tabie to determine biower rpm and watts

UNIT

VOLTAGE

208/230-3-60

575-3-60

208/230-3-60

575-3-60

CFM

4.000

5.000

6.000

7,200

4.000

5.000

6.000

7,200

4.000

5.000

6.000

7,200

6,000

7,200

9,000

10,000

6,000

7,200

9,000

10,000

6,000

7,200

9,000

10,000

SERVICE

ELECTRIC HEATERS

0 05 (14-34) 0 06 (42) 0 07 (56'

0.07(14-34) 0.08(42 0.10(56'

0 09 (14-34) 0 12 42 0.15 56

0 09 (26/34) 0 12 (42/56) 0 15 (56/75)

oil 26/34 016 42/56 0 20 56/75

0 15 26/34 0 19 42/56 0 24 56/75

0.17 26/34 0.21 (42/56) 0.26 (56/75

0.09 (32) 0.12 (55) 0.15 (80)

oil 32 0.15 (55 0 20 80

015 (32 0 19 55 0 24 (80

0.17 32 0 21 55) 0.26(80

NOTE: Heaters are rated at 208/240 v, 480 v, and 575 v

(kW)

0 05 (15,32) 0.06 (55

0 07 15,32 0 08 55

0 09 (15,32) 012 (55,

0.06 (37)

0 08 37)

0 12 37

0 15 37

ECONOMIZER

0 03

0 05

0.07

0 09

0 03

0 05

0.07

0 09

0 03

0.05

0 07

0 09

0 07

0 09

0.11

0 12

0 07

0 09

0.11

0.12

0 07

0 09

0.11

0 12

(

A WARNING

Before performing service or maintenance operations

on unit, turn off main power switch to unit. Turn off

accessory heater power switch if applicable. Electrical

shock could cause personal injury.

Cleaning — Inspect unit interior at beginning of each

heating and cooling season and as operating conditions re

quire. Remove unit top panel and/or side panels for access

to unit interior.

EVAPORATOR COIL — Clean as required with a com

mercial coil cleaner.

CONDENSER COIL — Clean condenser coil annually and

as required by location and outdoor-air conditions. Inspect

coil monthly — clean as required.

CONDENSATE DRAIN — Check and clean each year at

start of cooling season.

FILTERS — Clean or replace at start of each heating and

cooling season, or more often if operating conditions re

quire. Refer to Table 1 for type and size.

OUTDOOR-AIR INLET SCREENS — Clean screens with

steam or hot water and a mild detergent. Do not use dis

posable filters in place of screens.

Lubrication

COMPRESSORS -- Each compressor is charged with cor

rect amount of oil at the factory. Observe the oil level in

the sight glass at start-up. If unit oil level is below sight

glass, add oil until level is approximately V4 sight glass.

FAN SHAFT BEARINGS The bearings are of the pil

low block type and have grease fittings. The bearing oppo

site the motor end has an extended tube line so it can be

lubricated from the motor side. Lubricate the bearings twice

annually.

Typical lubricants are given below:

MANUFACTURER LUBRICANT

Texaco Regal AFB-2*

Mobil Mobilplex EP No. 1

Sunoco Prestige 42

Texaco

'Preferred lubricant because it contains rust and oxidation inhibitors

Multifak 2

CONDENSER AND EVAPORATOR-FAN MOTOR BEAR

INGS — The condenser and evaporator-fan motors have

permanently-sealed bearings, so no field lubrication is

necessary.

Evaporator Fan, 50HJ015 Units

PERFORMANCE ADJUSTMENT - Fan motor pulleys on

the 50HJ015 units are factory set for speed shown in

Table 1.

To change fan speeds:

1. Shut off unit power supply.

2. Loosen belt by loosening fan motor mounting plate nuts.

3. Loosen movable-pulley flange setscrew (see Fig. 19).

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to deccrease speed.

Increasing fan speed increases load on motor. Do not

exceed maximum speed specified in Table 1.

5. Set movable flange at nearest key way of pulley hub and

tighten setscrew. (See Table 1 for speed change for each

full turn of pulley flange.)

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from mount

ing plate.

SERVICE AND REPLACEMENT (see Fig. 20)

NOTE: To remove belts only, follow Steps 1-7.

1. Remove filter and supply-air section panels.

2. Remove unit to cover.

3. Remove coil guard,

4. Loosen screws A and B on both sides of motor mount

assembly.

5. Loosen screw C.

6. Rotate motor mount assembly (with motor attached) as

far as possible away from evaporator coil.

7. Remove belt.

12

Page 13

Rotate motor mount assembly back past original posi

tion toward evaporator coil.

Remove motor mounting nuts D and E (both sides).

9.

Lift motor up through top of unit.

10.

Reverse above procedure to reinstall motor.

11

12,

Check and adjust belt tension as necessary.

Fig. 19 — Evaporator-Fan Pulley Alignment

and Adjustment

Evaporator Fan, 50HJ024 Units

PERFORMANCE ADJUSTMENT - The 50HJ024 unit has

fixed pulleys. Fan speed can be adjusted (if necessary) only

by changing the pulley(s) and belt. See Table 8 for alter

nate drive selection.

To align fan and motor pulleys (see Fig. 19):

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from mount

ing plate.

SERVICE AND REPLACEMENT (See Fig. 21) - The

50HJ024 unit uses a fan motor mounting system that fea

tures a slide-out motor mounting plate. To replace or serv

ice the motor, slide out the bracket.

1. Remove the evaporator-fan access panel and the heat

ing control access panel.

2. Remove the center post (located between the evapora

tor fan and heating control access panels) and all screws

securing it

3. Loosen nuts on the two carriage bolts in the motor mount

ing base.

Using jacking bolt under motor base, raise motor to

4.

top of slide and remove belt. Secure motor in this po

sition by tightening the nuts on the carriage bolts.

5.

Remove the belt drive.

6. Remove Jacking bolt and tapped jacking bolt plate.

7. Remove the 2 screws that secure the motor mounting

plate to the motor support channel.

8. Remove the 3 screws from the end of the motor sup

port channel that interfere with the motor slide path,

9 Slide out the motor and motor mounting plate,

10. Disconnect wiring connections and remove the 4 mount

ing bolts.

11. Remove the motor.

12. To install the new motor, reverse Steps 1-11.

Fig. 20 — 50HJ015 Evaporator-Fan Motor Section

NOTE; A 3V2-in, bolt and threaded plate are included in the instalier’s packet. They can be added to the motor support channel below

the motor mounting plate to aid in raising the motor.

Fig. 21 — 50HJ024 Evaporator-Fan Motor Section

13

Page 14

Table 8 — Alternate Drive Components Table, 50HJ024

UNIT

50HJ

024

MPTA — Mechanical Power Transmission Association

RMA — Rubber Manufacturers’ Association

‘Datum dimension is equal to the old pitch diameter per RMA/MPTA

Standard IP20-1977. To convert to new pitch diameter per RMA/

MOTOR

HP

7V2 Field

71/2

Vh

7'M Field

DRIVE

SOURCE

Field

Factory 1287

LEGEND

FAN

RPM

1181

1244

1379

MOTOR

SHEAVE DATUM

DIMENSION*

(in.)

5.6

5.9

6 1

6.6

MOTOR

SHEAVE

PART NO.t

BK62 8.4

BK65 8,4

BK67 84

BK72 8.4

MPTA Standard IP20-1988, add 0.3 in. to the sheave datum

dimension.

tPart numbers for motor sheave, blower sheave, and belt are Brown

ing Catalog part numbers. The motor sheaves have Browning fixed

bore sheaves supplied with factory drive package.

BLOWER

SHEAVE DATUM

DIMENSION*

(in.)

BLOWER

SHEAVE

PART NO.t

BK90

BK90

BK90 BX51

BK90

PART NO.t

BELT

BX50

BX51

BX52

i

Belt Tension Adjustment — To adjust belt tension:

1. Loosen fan motor bolts.

2. a. 015 units:

Move motor mounting plate up or down for proper

belt tension ('/2 in, deflection with one finger),

b. 024 units;

Turn motor jacking bolt to move motor mounting plate

up or down for proper belt tension (Ys in. deflection

at midspan with one finger [9 lb force]).

3. Tighten nuts.

4. Adjust bolts and nut on mounting plate to secure motor

in fixed position.

Condenser-Fan Adjustment {Fig. 22)

1. Shut off unit power supply.

2. Remove fan top-grille assembly and loosen fan hub screws.

3. Adjust fan height on unit, using a straightedge placed

across the fan orifice.

4. Tighten setscrews and replace rubber hubcap to prevent

hub from rusting to motor shaft.

5. Fill hub recess with permagum if rubber hubcap is

missing.

Economizer Adjustment — Refer to Tables 9 and

10 for economizer checkout procedures. Make certain the

outdoor-air damper is fully closed and the return-air damper

is fully open before completing the following steps.

1. Turn on power to the unit.

2. Turn the thermostat fan switch to the ON position. The

damper will go to the vent position.

3. Adjust the vent position with the minimum position ad

justment on the economizer control module. See

Fig. 14.

4. Set the system selector switch to COOL position and

set the cooling temperature selector to its lowest

setting.

NOTE: The cooling mode may also be simulated by remov

ing the thermostat wires from terminals Y1 and Y2 and in

stalling a jumper between terminals R and Y1. Refer to unit

label diagram for terminal locations.

5. Set the outdoor-air thermostat (OAT) located in the econo

mizer section of the unit to 75 F.

6. If the outdoor temperature is below 75 F, the econo

mizer will control the mixed air with the mixed-air sen

sor. If the outdoor air is above 75 F, place a jumper

around the contacts of the OAT

7. Jumper terminal T to terminal T1 on the module (see

Fig. 14). The economizer will go to the full open

position. The outdoor-air damper will go to the full open

position, and the return-air damper will go to the full

closed position.

8. Adjust mechanical linkage, if necessary, for correct po

sitioning. It may be necessary to remove the filters to

adjust the linkage.

9. Remove the jumper from around the contacts of the

OAT if installed in Step 6. Remove the jumper from

terminals T and T1 installed in Step 7.

10. If the cooling mode was simulated to operate the unit

in Step 4, remove the jumper and reconnect the ther

mostat wires to terminals Y1 and Y2.

Power Failure — Dampers have a spring return In event

of power failure, dampers will return to fully closed posi

tion until power is restored. Do not manually operate damper

motor.

Refrigerant Charge — Amount of refrigerant charge

is listed on unit nameplate and in Table 1. Refer to Carrier

GTAC II; Module 5; Charging, Recovery, Recycling, and

Reclamation section for charging methods and procedures.

Unit panels must be in place when unit is operating dur

ing charging procedure.

Fig. 22 — Condenser-Fan Adjustment

NO CHARGE — Use standard evacuating techniques.

After evacuating system, weigh in the specified amount of

refrigerant (refer to Table 1).

LOW CHARGE COOLING - Using appropriate cooling

charging chart (see Fig. 23 and 24), add refrigerant until

conditions of the chart are met. Note that charging charts

are different from those normally used. Charts are based on

charging units to correct superheat for various operating con

ditions. An accurate pressure gage and temperature sensing

device are required. Connect temperature sensing device to

service port on suction line and insulate it so that outdoor

ambient temperature does not affect reading. Indoor-air cfm

must be within normal operating range of unit.

14

Page 15

TEST PROCEDURE RESULTS

A Disconnect

factory-installed

resistor from

terminals Sr and +

1 LED (light-emitting diode)

should be on

2. Motor drives toward open

OUTDOOR

TEMP (F)

Table 10 — High and Low Outdoor-Air

40 50 60

SUCTION LINE TEMP (FÌ

Temperature Simulation

TEST PROCEDURE RESULTS

A Reconnect factory-

installed 800 ohm resistor

between terminals

Sr and +

i

B. Connect 1200 ohm

checkout resistor

between terminals

So and +.

C. Turn set point potentiom

eter to position A

D. Turn set point potentiom

eter to position D

E Disconnect 1200 ohm

checkout resistor

Low outdoor-air temperature

test results:

1 LED (light-emitting diode)

should be on

2 Motor drives toward open

High outdoor-air temperature

test results

1 LED should be off

2 Motor drives toward closed.

Fig. 23 — Cooling Charging Chart — 50HJ015

OUTDOOR TEMP

-

90-

Î50-

F

15

05

95

55

85

75

45

35

65

TO USE COOLING CHARGING CHART - Take out

door ambient temperature and read the suction pressure gage.

Refer to appropriate chart to determine correct suction tem

perature. If suction temperature is high, add refrigerant. If

suction temperature is low, carefully reclaim some of the

charge. Recheck suction pressure as charge is adjusted

Filter Drier — Replace whenever refrigerant system is

30-

20

30 40 SO 60

SUCTION LINE TEMPERATURE CF)

-

BOTH CONDENSER FANS RUNNING

LU Li_LLLL 1TJ__

ONE CONDENSER FAN RUNNING

exposed to atmosphere.

Fig. 24 — Cooling Charging Chart — 50HJ024

15

Page 16

Protective Devices

COMPRESSOR PROTECTION

Overcurrent — Each compressor has one manual reset, cal

ibrated trip, magnetic circuit breaker. Do not bypass con

nections or increase the size of the circuit breaker to correct

trouble. Determine the cause and correct it before resetting

the breaker.

Overtemperature — Each compressor has an internal pro

tector to protect it against excessively high discharge gas

temperatures.

Crankcase Heaters — Each compressor has 125-watt crank

case heaters to prevent absorption of liquid refrigerant by

oil in the crankcase when the compressor is idle. Since power

for the crankcase heaters is drawn from the unit incoming

power, main unit power must be on for the heaters to be

energized.

EVAPORATOR-FAN MOTOR PROTECTION - A man

ual reset, calibrated trip, magnetic circuit breaker protects

against overcurrent. Do not bypass connections or increase

the size of the breaker to correct trouble. Determine the

cause and correct it before resetting the breaker.

CONDENSER-FAN MOTOR PROTECTION - Each

condenser-fan motor is internally protected against over

temperature.

HIGH- AND LOW-PRESSURE SWITCHES - If either

switch trips, or if the compressor overtemperature switch

activates, that refrigerant circuit will be automatically locked

out by the CLO To reset, manually move the thermostat

setting

FREEZE PROTECTION THERMOSTAT (FPT) - An

FPT is located on the evaporator coil. It detects frost

buildup and turns off the compressor, allowing the coil to

clear. Once the frost has melted, the compressor can be

reenergized by resetting the CLO from the thermostat.

IMPORTANT; After a prolonged shutdown or serv

ice job, energize the crankcase heaters for 24 hours

before starting the compressors

Compressor Lockout— If any of the safeties (high- or lowpressure, freeze protection thermostat, compressor internal

thermostat) trip, or if there is loss of power to the compres

sors, the CEO (compressor lockout) will lock the compres

sors off. To reset, manually move the thermostat

setting.

Relief Devices — All units have relief devices to pro

tect against damage from excessive pressures (i.e., fire).

These devices protect the high and low side.

Control Circuit, 24-V — This control circuit is pro

tected against overcurrent by a 3.2-amp circuit breaker. Breaker

can be reset. If it trips, determine cause of trouble before

resetting.

Replacement Parts — A complete list of replace

ment parts may be obtained from any Carrier distributor

upon request.

16

Page 17

PACKAGED SERVICE TRAINING

Our packaged service training programs provide an excellent way to increase your knowledge of the

equipment discussed in this manual. Product programs cover;

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available. All programs include a video

cassette and/or slides and a companion booklet. Use these for self teaching or to conduct full training

sessions.

For a free Service Training Material Catalog (STM), call 1-800-962-9212. Ordering instructions are

included

Copyright 1993 Carrier Corporation

Book 11 PC 111 Catalog No 565-125 Printed in U S A Form 50HJ-6SI Pg 18 12-93 Replaces: New

Tab 1b

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Page 18

START-UP CHECKLIST

(Remove and Store with Job File)

MODEL NO.:

DATE:

_______

SERIAL NO.: _

TECHNICIAN.

PRE-START-UP:

□ VERIFY THAT ALL PACKING MATERIALS HAVE BEEN REMOVED FROM UNIT

□ REMOVE ALL SHIPPING HOLDDOWN BOLTS AND BRACKETS PER INSTRUCTIONS

□ VERIFY INSTALLATION OF ECONOMIZER HOOD

□ VERIFY THAT CONDENSATE CONNECTION IS INSTALLED PER INSTRUCTIONS

□ VERIFY THAT ALL ELECTRICAL CONNECTIONS AND TERMINALS ARE TIGHT

□ CHECK THAT INDOOR-AIR FILTER IS CLEAN AND IN PLACE

□ VERIFY THAT UNIT IS LEVEL

□ CHECK FAN WHEEL AND PROPELLER FOR LOCATION IN HOUSING/ORIFICE, AND VERIFY SET

SCREW IS TIGHT

□ VERIFY THAT FAN SHEAVES ARE ALIGNED AND BELTS ARE PROPERLY TENSIONED

START-UP

ELECTRICAL

SUPPLY VOLTAGE L1-L2 ___________ L2-L3

COMPRESSOR AMPS

SUPPLY FAN AMPS

ELECTRIC HEAT AMPS LI

TEMPERATURES

OUTDOOR-AIR TEMPERATURE

RETURN-AIR TEMPERATURE

COOLING SUPPLY AIR

ELECTRIC HEAT SUPPLY AIR

PRESSURES

REFRIGERANT SUCTION CIRCUIT NO. 1

REFRIGERANT DISCHARGE CIRCUIT NO. 1

□ VERIFY REFRIGERANT CHARGE USING CHARGING CHARTS ON PAGE 15.

GENERAL

COMPRESSOR NO. 1 LI

COMPRESSOR NO 2 LI

EXHAUST FAN AMPS

L2

_______________

_______________

_________________

__________

_________________

_____________

F

,F

,F

F

DB (Dry-Bulb)

DB

___________

_______

. PSIG

PSIG

L3-L1

L2

L2

L3

F WB (Wet-Bulb)

CIRCUIT NO. 2

CIRCUIT NO. 2

L3

L3

PSIG

PSIG

□ ECONOMIZER MINIMUM VENT AND CHANGEOVER SETTINGS TO JOB REQUIREMENTS

Copyright 1993 Carrier Corporation

Book 11 PC 111 Catalog No 565-125 Printed in U S A Form 50HJ-6SI CL-1 12-93 Replaces: New

Tab 1b

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Loading...

Loading...