Page 1

Single Package Rooftop Units

Electric Cooling with Electric Heat Option

Installation Instructions

50HG014-028

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Step 1 — Provide Unit Support. . . . . . . . . . . . . . . . . . . 1

•ROOF CURB

• ALTERNATE UNIT SUPPORT

Step 2 — Remove Shipping Rails . . . . . . . . . . . . . . . . 3

Step 3 — Rig and Place Unit . . . . . . . . . . . . . . . . . . . . . 3

• POSITIONING

• ROOF MOUNT

• INSTALLATION ONTO CURB

Step 4 — Field Fabricate Ductwork . . . . . . . . . . . . . . . 8

Step 5 — Make Unit Duct Connections . . . . . . . . . . . 8

Step 6 — Trap Condensate Drain . . . . . . . . . . . . . . . . . 9

Step 7 — Make Electrical Connections . . . . . . . . . . . 9

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

Step 8 — Install Outdoor-Air Hood . . . . . . . . . . . . . . 20

Step 9 — Position Optional Power Exhaust

or Barometric Relief Damper Hood. . . . . . . . . . . . 22

Step 10 — Non-Fused Disconnect. . . . . . . . . . . . . . . 22

Step 11 — Install All Accessories . . . . . . . . . . . . . . . 23

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions of replacing filters. All other operations should

be performed by trained service personnel. When working

on air-conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and other safety

precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguishers available for all brazing operations.

Before performing service or maintenance operations on

unit, turn off main power swit ch to unit. Electrical shock

could cause personal injury.

IMPORTANT: Units have high ambient operating lim-

its. If limits are exceede d, the units will automatically

lock the compressor out of operation. Manual r eset will

be required to restart the compressor.

INSTALLATION

Step 1 — Provide Unit Support

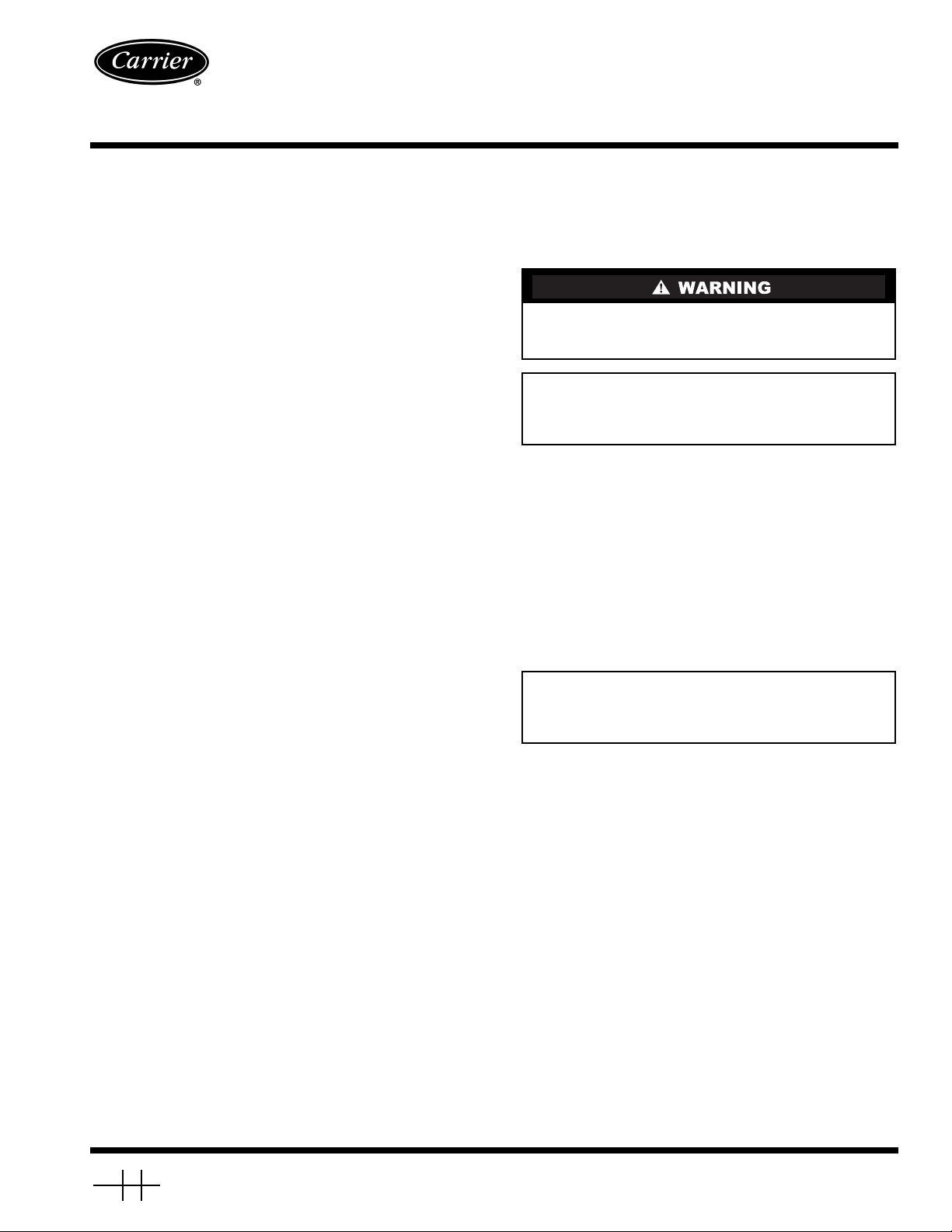

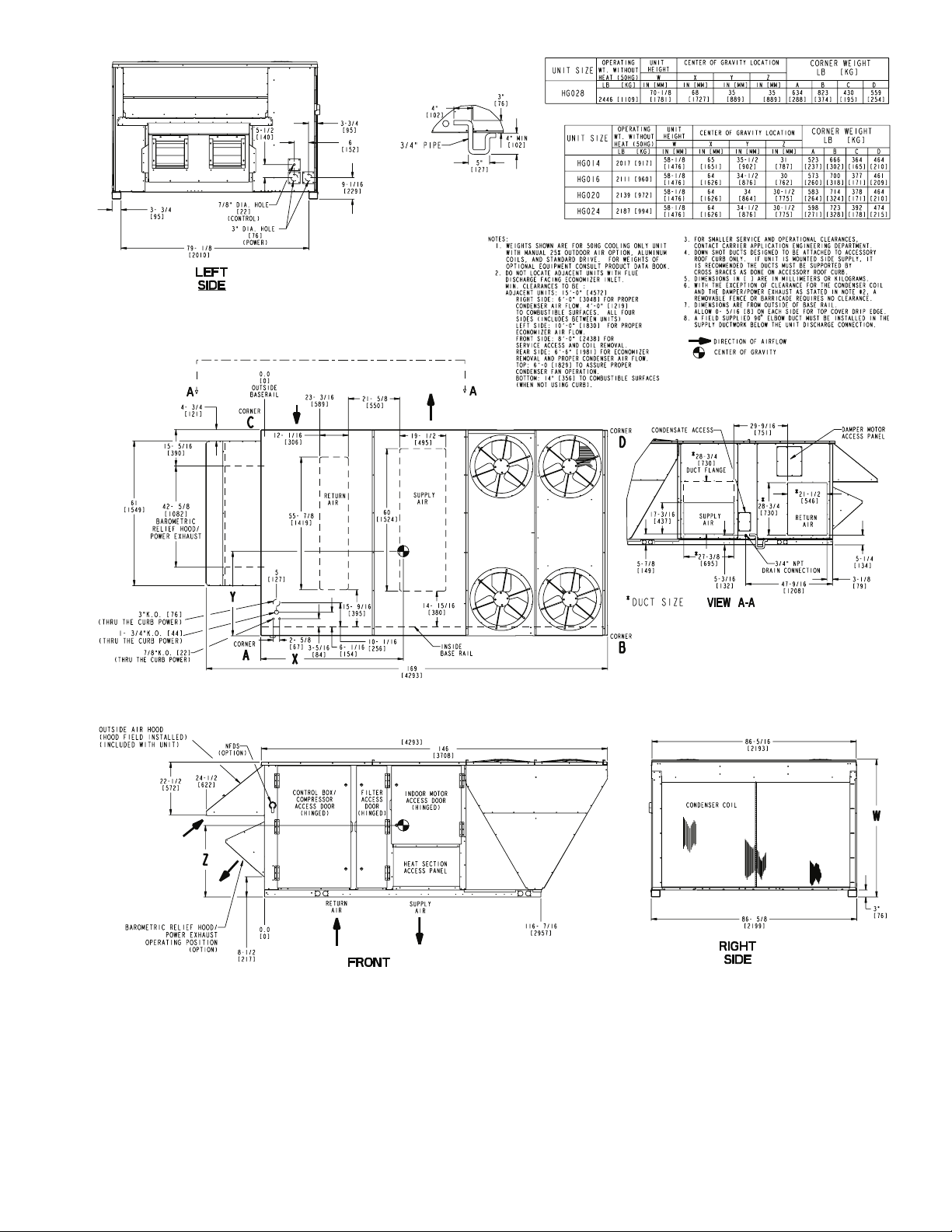

ROOF CURB — Assemble or install accessory roof curb in

accordance with instructions shipped with this accessory. See

Fig. 1. Install insulation, cant strips, roofing, and counter flashing as shown. Ductwork can be installed to roof curb before

unit is set in place. Curb must be level. This is necessary to

permit unit drain to function properly. Unit leveling tolerance is

1

/16 in. per linear ft in any direction. Refer to Accessory

±

Roof Curb Installation Instructions for additional information

as required. When accessory roof curb i s used, unit may be

installed on class A, B, or C roof covering material.

IMPOR TANT: The gasketing of the unit to the roof curb

is critical for a watertight seal. Install gasket with the

roof curb as shown in Fig. 1. Improperly applied gasket

can also result in air leaks and poor unit performance.

ALTERNATE UNIT SUPPORT — When a curb cannot be

used, install unit on a noncombustible surface. Support unit

with sleepers, using unit curb support area. If sleepers cannot

be used, support long sides of unit with a minimum of 3 equally spaced 4-in. x 4-in. pads on each side.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Ta b 1b 6 b

PC 111 Catalog No. 535-00092 Printed in U.S.A. Form 50HG-7SI Pg 1 11-03 Replaces: 50HG-3SI

Page 2

Fig. 1 — Roof Curb Details

2

Page 3

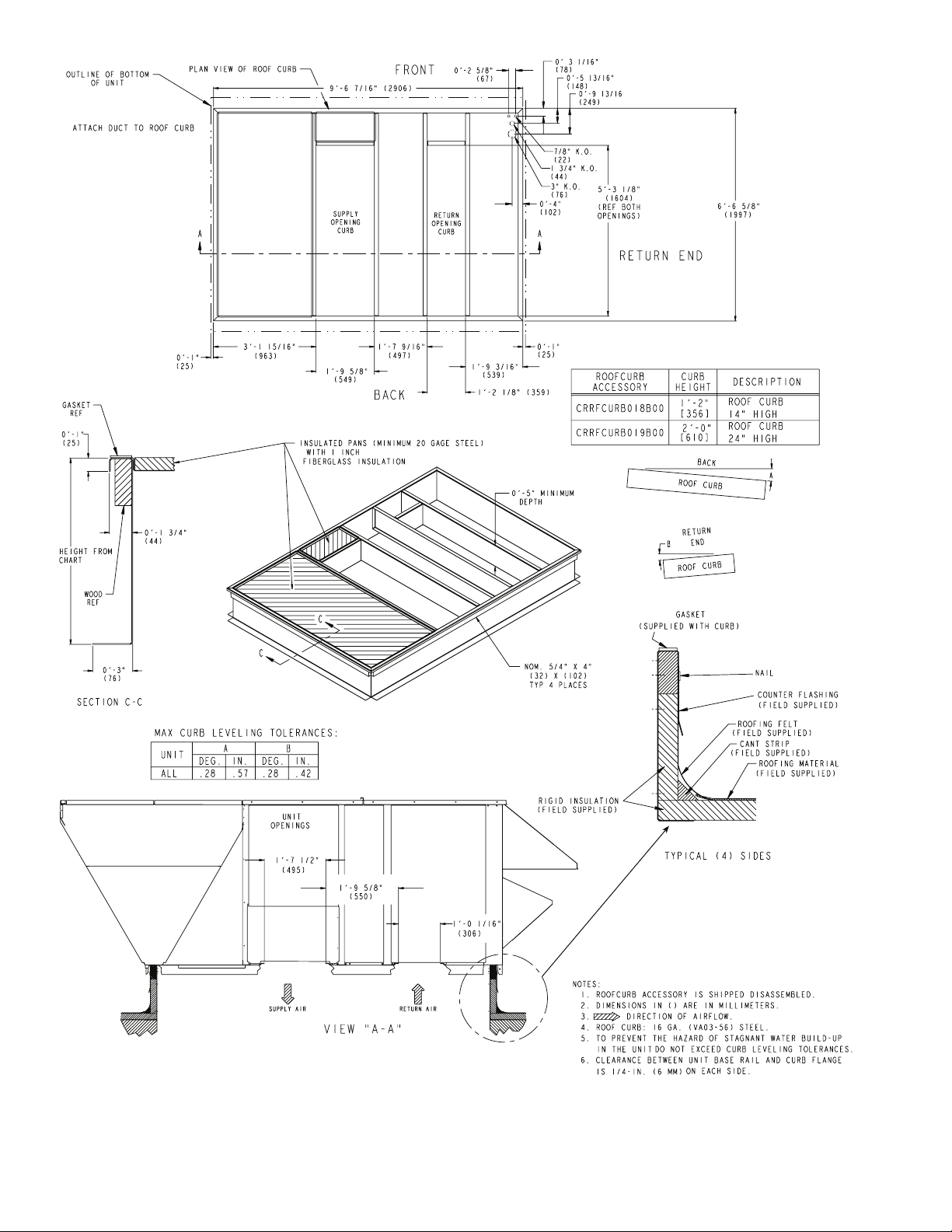

Step 2 — Remove Shipping Rails —

Remove shipping rails prior to lowering unit onto roof curb. See Fig. 2. The

rails are attached to the unit at both the return end and condenser end. Remove the screws from both ends of each rail. Be

careful not to drop the rails onto any surface that could be damaged. Discard the rails. It is important to replace the screws into

the unit to avoid any air or water leakage.

Do not allow the shipping rail to drop on the roof surface.

Damage to the roof surface may result.

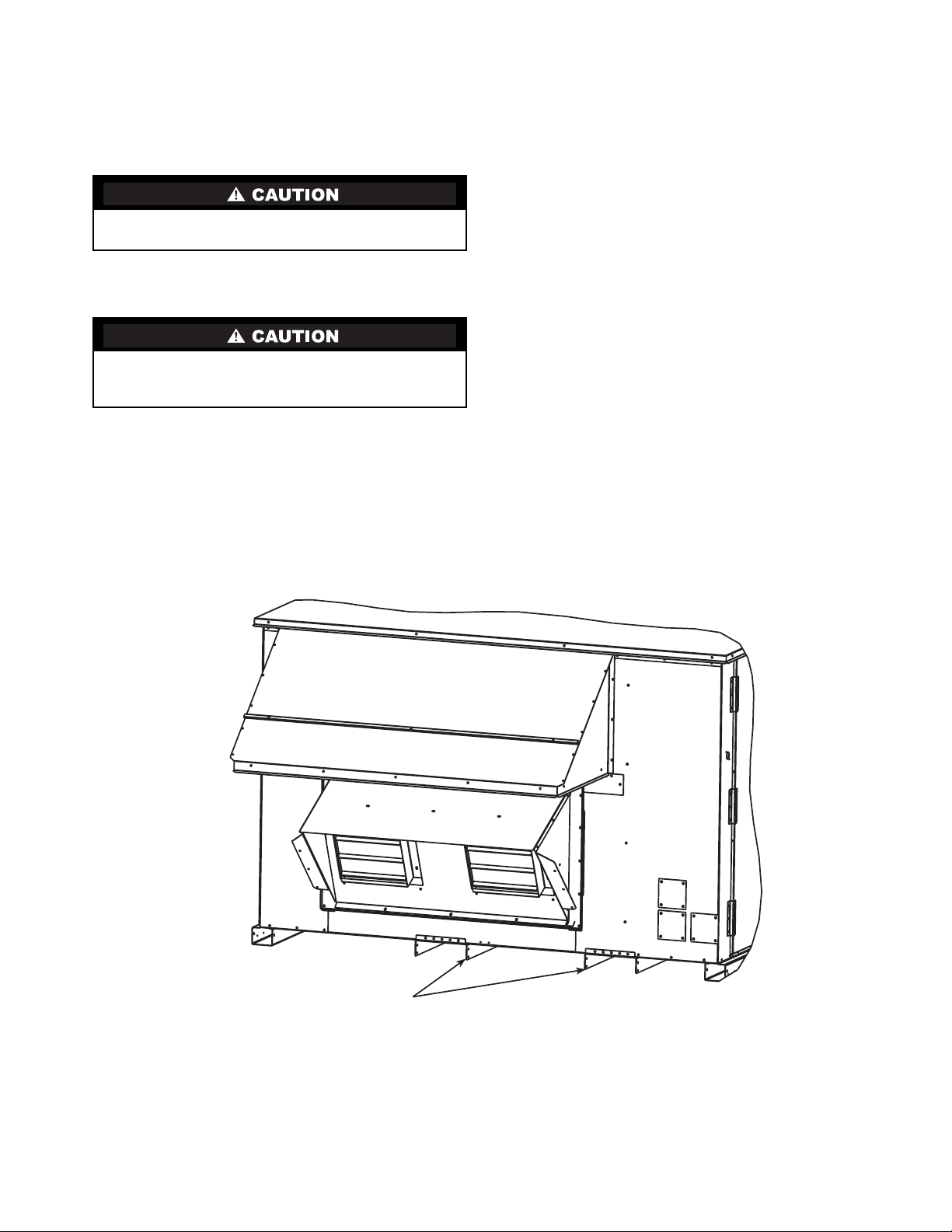

Step 3 — Rig and Place Unit —

Inspect unit for transportation damage. See Table 1 for physical data. File any claim

with transportation agency.

All panels must be in place when rigging. Unit is not

designed for handling by fork truck. Damage to unit can

result.

Do not drop unit; keep upright. Use spreader bars over unit

to prevent sling or cable damage. Rollers may be used to move

unit across a roof. Level by using unit frame as a refere nce;

leveling tolerance is ±

1

/16 in. per linear ft in any direction. See

Fig. 3 for additional information. Unit rigging weight is shown

in Fig. 3.

Four lifting holes are provided in the unit base rails as

shown in Fig. 3. Refer to rigging instructions on unit.

POSITIONING — Maintain clearance, per Fig. 4, around and

above unit to provide minimum distance from combustible

materials, proper airflow, and service access.

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated air.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

ROOF MOUNT — Check building codes for weight distribu-

tion requirements. Unit operating weight is shown in Table 1.

INSTALLATION ONTO CURB — The 50HG units are

designed to fit on either the accessory full perimeter curb or

onto existing 48/50TJ,HJ or 48/50DP,DR curbs. In either case,

correct placement of the unit onto th e curb is critical to operating performance. To aid in correct positioning,

3

/8-in. diameter

locating holes have been added to the unit base rails. When

placing the unit, these holes should line up with the roof curb

edge as shown in Fig. 5 and 6, to assure proper duct opening

alignment. Select the alignment holes suited for the curb being

used. For installation on the HJ/TJ/DP/DR curb use the alignment holes located approximately 20 in. from the end of t he

base rail on the return end of the unit. For placement on the HG

curb, use the alignment holes located approximately 2-in. from

the end of the base rail on the return end of the unit. See labels

on the side of the unit for more details.

SHIPPING RAILS

Fig. 2 — Shipping Rail Removal

3

Page 4

Fig. 3 — Rigging Details

4

Page 5

Fig. 4 — Base Unit Dimensions

5

Page 6

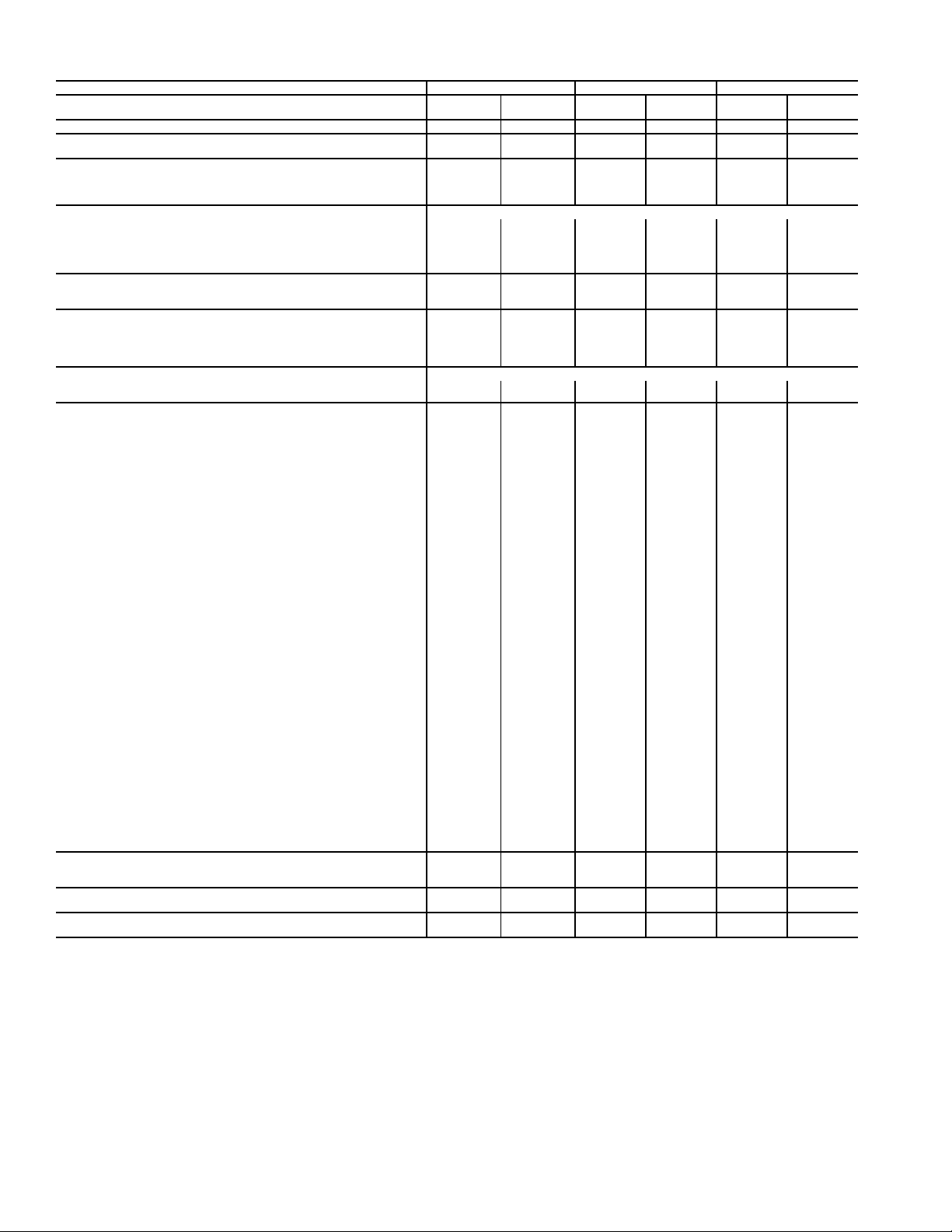

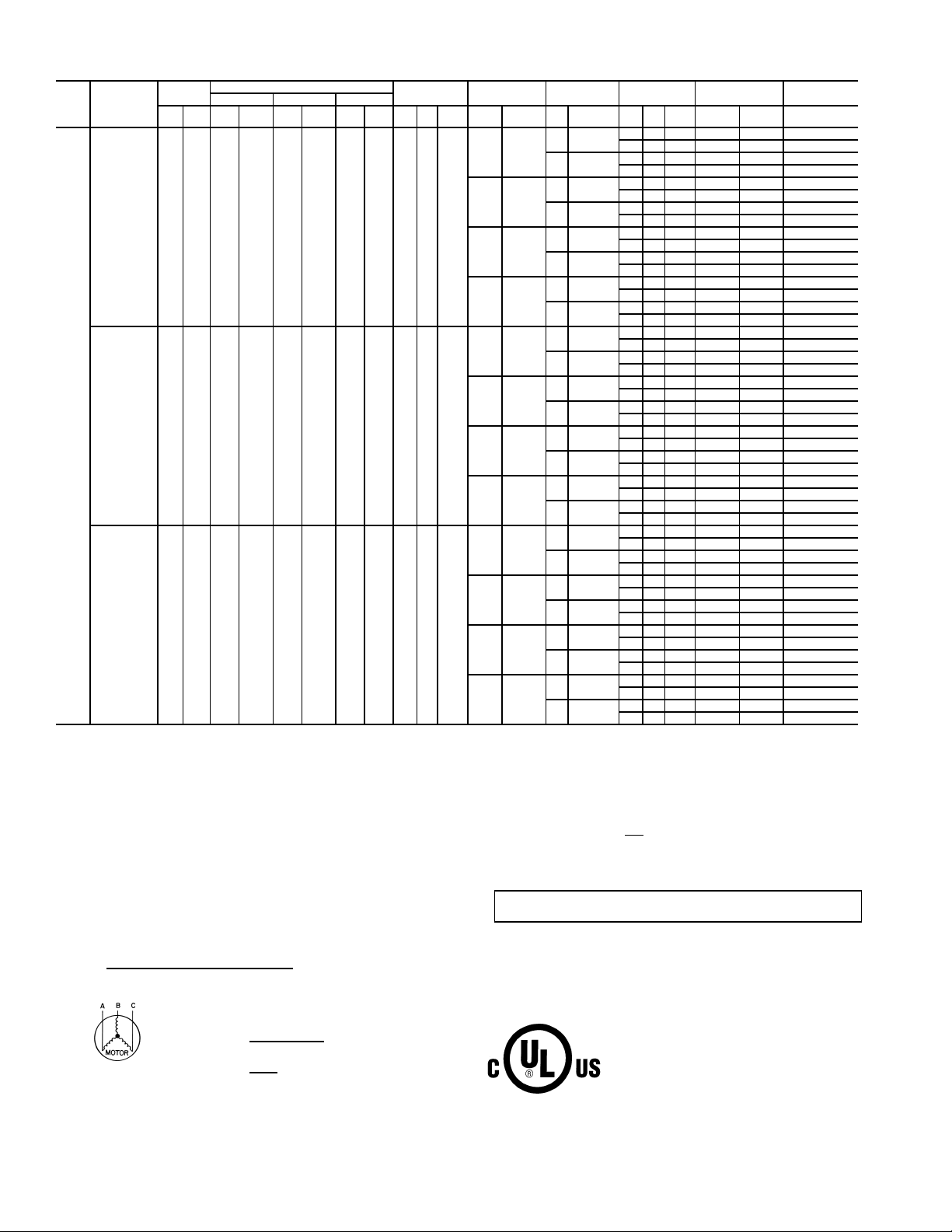

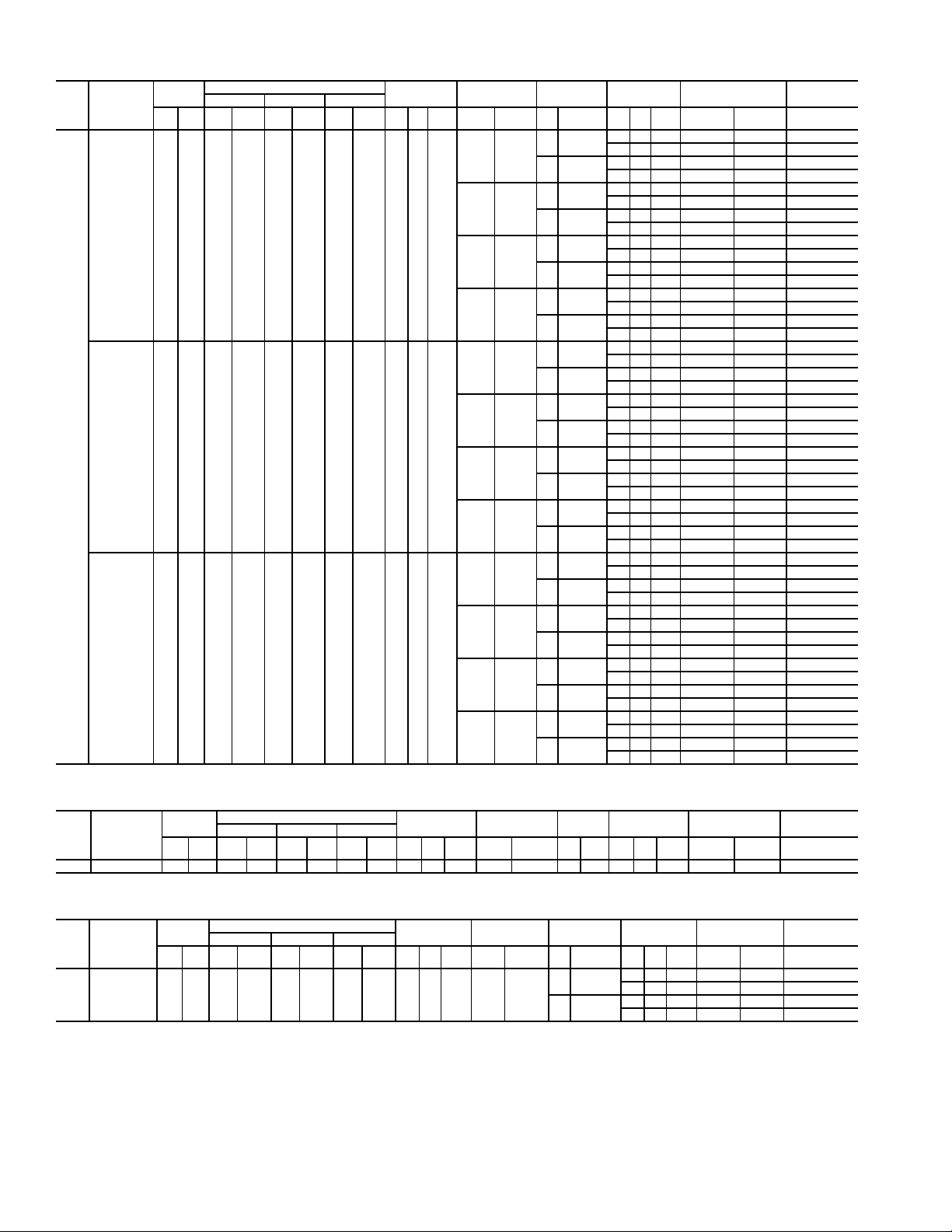

Table 1 — Physical Data

UNIT 50HG 014 016 020

VOLTAGE

NOMINAL CAPACITY (Tons)

OPERATING WEIGHT (lb)

50 SERIES (Cooling Only)

COMPRESSOR

Quantity

Number of Refrigerant Circuits

Oil (ounces) Ckt A...Ckt B...Ckt C

REFRIGERANT TYPE

Expansion Device

Operating Charge (lb)

Circuit A

Circuit B

Circuit C

CONDENSER COIL

Rows...Fins/inch

TotalFacearea(sq.ft)

CONDENSER FAN

Nominal Cfm (Total, all fans)

Quantity...Diameter (in.)

Motor Hp...Rpm

Watts input (Total)

EVAPORATOR COIL

Rows...Fins/inch

TotalFacearea(sq.ft)

EVAPORATOR FAN

Quantity...Size

Typ e Drive

Nominal Cfm

Std Motor Hp

Alt Motor Hp

Motor Nominal Rpm

Std Maximum Continuous Bhp

Std Maximum Continuous Watts

Alt Maximum Continuous Bhp

Alt Maximum Continuous Watts

Motor Frame Size Standard

Motor Frame Size Alternate

Fan Drive Rpm Range Std motor/Std drive

Motor Bearing Type

Maximum Allowable Rpm

Motor Pulley Pitch Diameter Std motor/Std drive

Motor Shaft Diameter (in.) Standard

Motor Shaft Diameter (in.) Alternate

Belt, Quantity...Type...Length (in.) Std motor/Std drive

Pulley center line distance (in.)

Speed change per full turn of moveable

pulley flange (rpm) Std motor/Std drive

Moveable pulley maximum (full turns

from closed position)

Factory Pulley Setting

(turns from closed position)

Fan Shaft Diameter (in.)

Factory Speed Setting (rpm)

HIGH PRESSURE SWITCHES (psig)

Cutout

Reset (Auto)

OUTDOOR AIR INLET SCREENS

Quantity...Size (in.)

RETURN AIR FILTERS

Quantity...Size (in.)

Std motor/Alt drive

Alt motor/Std drive

Alt motor/Alt drive

Std motor/Alt drive

Alt motor/Std drive

Alt motor/Alt drive

Std motor/Alt drive

Alt motor/Std drive

Alt motor/Alt drive

Std motor/Alt drive

Alt motor/Std drive

Alt motor/Alt drive

LEGEND

Brake Horsepower

Bhp —

Thermostatic Expansion Valve

TXV —

208/230

and 460

575

208/230

and 460

575

208/230

and 460

12.5 12.5 15 15 17.5 17.5

2017 2017 2111 2111 2139 2139

2 2 3333

2 2 3333

72...72...NA 72...72...NA 68...68...68 68...68...68 68...68...72 68...68...72

TXV TXV TXV TXV TXV TXV

19.6 19.6 13.2 13.2 13.1 13.1

18.3 18.3 12.2 12.2 12.7 12.7

NA NA 15.4 15.4 15.2 15.2

2...17 2...17 2...17 2...17 2...17 2...17

57.78 57.78 57.78 57.78 57.78 57.78

14,000 14,000 14,000 14,000 14,000 14,000

4...22 4...22 4...22 4...22 4...22 4...22

1

/4...1100

1400 1400 1400 1400 1400 1400

3...15 3...15 3...15 3...15 3...15 3...15

23.33 23.33 23.33 23.33 23.33 23.33

2...15x11 2...15x11 2...15x11 2...15x11 2...15x11 2...15x11

Belt Belt Belt Belt Belt Belt

5000 5000 6000 6000 7000 7000

3.7 3 3.7 3 5 5

55557

1725 1725 1725 1725 1725 1725

4.25 3.45 4.25 3.45 5.75 5.75

3171 2574 3171 2574 4290 4290

5.75 5.75 5.75 5.75 8.63 8.63

4290 4290 4290 4290 6438 6438

56HZ 56H 56HZ 56H S184T 184T

S184T 184T S184T 184T S213T S213T

485-613 472-619 618-789 609-778 658-808 658-808

618-789 609-778 485-613 472-619 794-974 794-974

778-1021 778-1021 778-1021 778-1021 949-1145 949-1145

1000-1227 1000-1227 1000-1227 1000-1227 1126-1328 1126-1328

Ball Ball Ball Ball Ball Ball

1400 1400 1400 1400 1400 1400

3.7-4.7 3.1-4.1 3.4-4.4 3.4-4.4 4.3-5.3 4.3-5.3

3.4-4.4 3.4-4.4 3.7-4.7 3.1-4.1 4.3-5.3 4.3-5.3

3.1-4.1 3.1-4.1 3.1-4.1 3.1-4.1 5.4-6.6 5.4-6.6

4.3-5.3 4.3-5.3 4.3-5.3 4.3-5.3 5.5-6.5 5.5-6.5

7

/

8

1

/

1

8

1...BX...51 1...BX...48 1...A...45 1...A...45 1...BX...46 1...BX...46

1...A...45 1...A...45 1...BX...51 1...BX...48 1...BX...42 1...BX...42

1...BX...38 1...BX...38 1...BX...38 1...BX...38 1...BX...46 1...BX...46

1...B...38 1...B...38 1...B...38 1...B...38 1...BX...42 1...BX...42

11.3-12.3 11.3-12.3 11.3-12.3 11.3-12.3 10.0-12.2 10.0-12.2

21 25 29 28 25 25

29 28 21 25 30 30

41 41 41 41 33 33

38 38 38 38 34 34

6 6 6666

3 3 3333

3

/

1

16

549 546 704 694 733 733

426 426 426 426 426 426

320 320 320 320 320 320

1

/4...1100

7

/

8

11/

13/

16

8

R-22

1

/4...11001/4...11001/4...11001/4...1100

Face Split

1

/

2

7

/

8

11/

8

13/

16

7

/

8

11/

8

13/

16

13/

11/

13/

8

8

16

3...20x25 3...20x25 3...20x25 3...20x25 3...20x25 3...20x25

9...16x25 9...16x25 9...16x25 9...16x25 9...16x25 9...16x25

575

71/

11/

13/

13/

2

8

8

16

6

Page 7

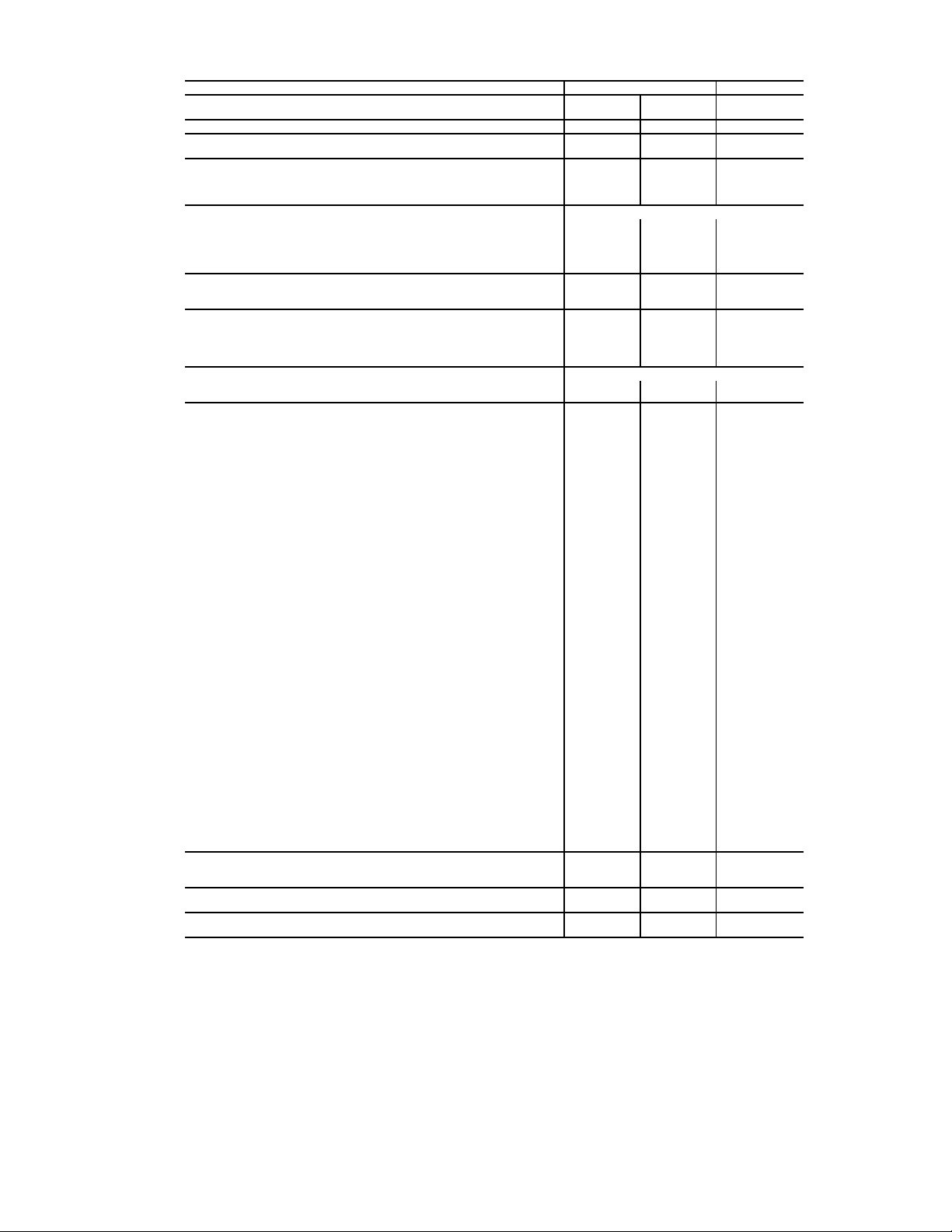

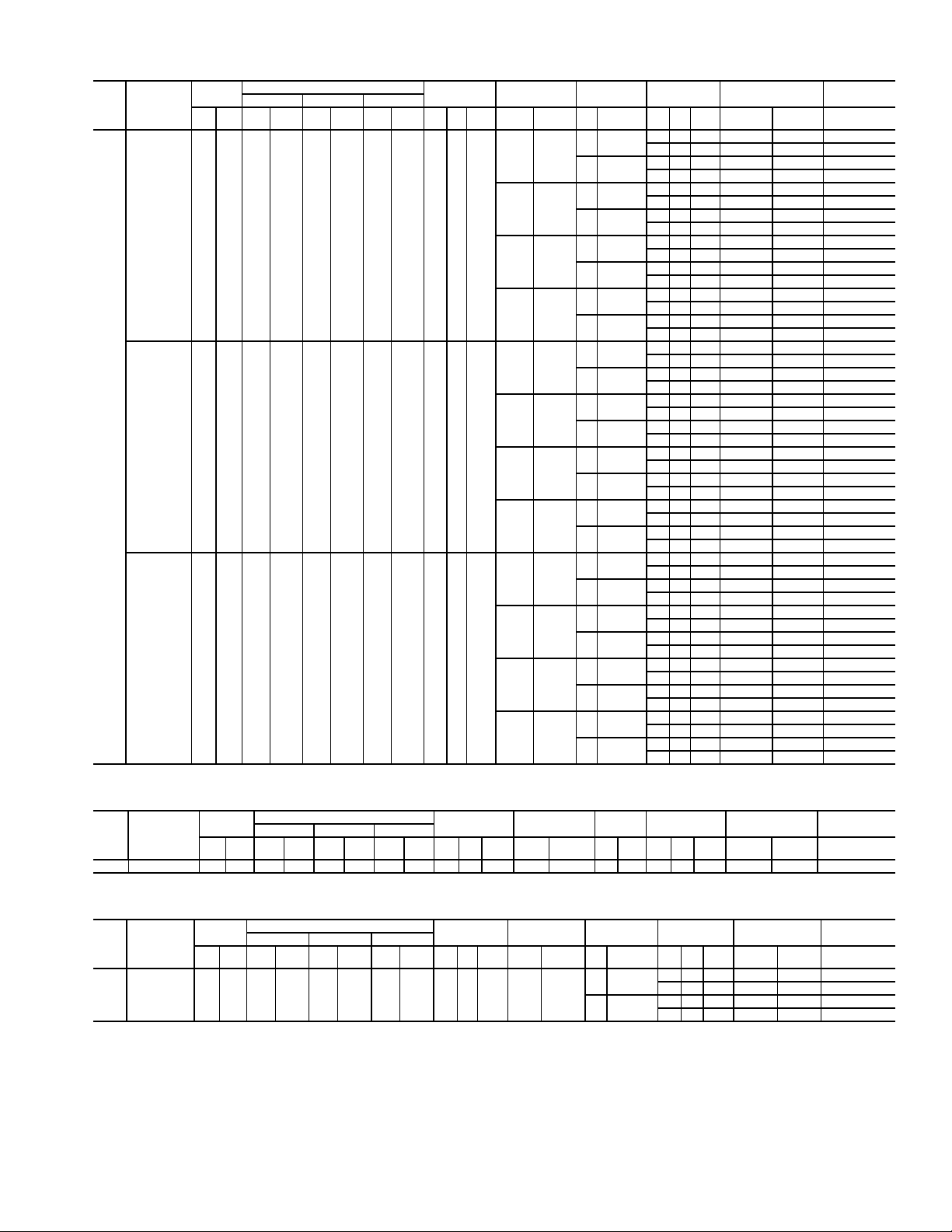

Table 1 — Physical Data (cont)

UNIT 50HG 024 028

VOLTAGE

NOMINAL CAPACITY (Tons)

OPERATING WEIGHT (lb)

50 SERIES (Cooling Only)

COMPRESSOR

Quantity

Number of Refrigerant Circuits

Oil (ounces) Ckt A...Ckt B...Ckt C

REFRIGERANT TYPE

Expansion Device

Operating Charge (lb)

Circuit A

Circuit B

Circuit C

CONDENSER COIL

Rows...Fins/inch

TotalFaceArea(sq.ft)

CONDENSER FAN

Nominal Cfm (Total, all fans)

Quantity...Diameter (in.)

Motor Hp...Rpm

Watts input (Total)

EVAPORATOR COIL

Rows...Fins/inch

TotalFaceArea(sq.ft)

EVAPORATOR FAN

Quantity...Size

Typ e Dri ve

Nominal Cfm

Std Motor Hp

Alt Motor Hp

Motor Nominal Rpm

Std Maximum Continuous Bhp

Std Maximum Continuous Watts

Alt Maximum Continuous Bhp

Alt Maximum Continuous Watts

Motor Frame Size Standard

Motor Frame Size Alternate

Fan Drive Rpm Range Std motor/Std drive

Motor Bearing Type

Maximum Allowable Rpm

Motor Pulley Pitch Diameter Std motor/Std drive

Motor Shaft Diameter (in.) Standard

Motor Shaft Diameter (in.) Alternate

Belt, Quantity...Type...Length (in.) Std motor/Std drive

Pulley center line distance (in.)

Speed change per full turn of moveable

pulley flange (rpm) Std motor/Std drive

Moveable pulley maximum (full turns

from closed position)

Factory Pulley Setting

(turns from closed position)

Fan Shaft Diameter (in.)

Factory Speed Setting (rpm)

HIGH PRESSURE SWITCHES (psig)

Cutout

Reset (Auto)

OUTDOOR AIR INLET SCREENS

Quantity...Size (in.)

RETURN AIR FILTERS

Quantity...Size (in.)

Std motor/Alt drive

Alt motor/Std drive

Alt motor/Alt drive

Std motor/Alt drive

Alt motor/Std drive

Alt motor/Alt drive

Std motor/Alt drive

Alt motor/Std drive

Alt motor/Alt drive

Std motor/Alt drive

Alt motor/Std drive

Alt motor/Alt drive

LEGEND

Bhp —

TXV —

Brake Horsepower

Thermostatic Expansion Valve

208/230

and 460

575 ALL

20 20 25

2187 2187 2446

33 2

33 2

72...72...72 72...72...72 110...110...NA

TXV TXV TXV

13.8 13.8 23.9

13.9 13.9 21.5

15.5 15.5 NA

2...17 2...17 2...17

57.78 57.78 66.67

14,000 14,000 21,000

4...22 4...22 6...22

1

/4...1100

1400 1400 2100

4...15 4...15 4...15

23.33 23.33 27.22

2...15x11 2...15x11 2...15x11

Belt Belt Belt

8000 8000 10,000

557

1

/

7

2

1725 1725 1725

5.75 5.75 8.63

4290 4290 6438

8.63 8.63 11.50

6438 6438 8579

S184T 184T S213T

S213T S213T S215T

658-808 658-808 799-965

794-974 794-974 939-1152

949-1145 949-1145 945-1187

1126-1328 1126-1328 1152-1366

Ball Ball Ball

1400 1400 1400

4.3-5.3 4.3-5.3 5.4-6.6

4.3-5.3 4.3-5.3 4.2-5.2

5.4-6.6 5.4-6.6 4.2-5.2

5.5-6.5 5.5-6.5 5.2-6.2

1

/

1

8

3

/

1

8

1...BX...46 1...BX...46 1...BX...50

1...BX...42 1...BX...42 2...AX...38

1...BX...46 1...BX...46 2...BX...38

1...BX...42 1...BX...42 2...BX...38

10.0-12.2 10.0-12.2 9.6-12.0

25 25 28

30 30 36

33 33 40

34 34 36

66 6

33 3

3

/

1

16

733 733 882

426 426 426

320 320 320

R-22

1

/4...1100

Face Split

71/

2

11/

8

13/

8

13/

16

1

/4...1100

13/

3...20x25 3...20x25 3...20x25

9...16x25 9...16x25 9...20x25

13/

13/

1

/

2

10

8

8

16

7

Page 8

ALIGNMENT

HOLE

(IN BASE RAIL)

EDGE FLANGE

Fig. 5 — Alignment Hole Details

ALIGNMENT

HOLE SHOULD

LINE UP WITH

ROOF CURB

EDGE FLANGE

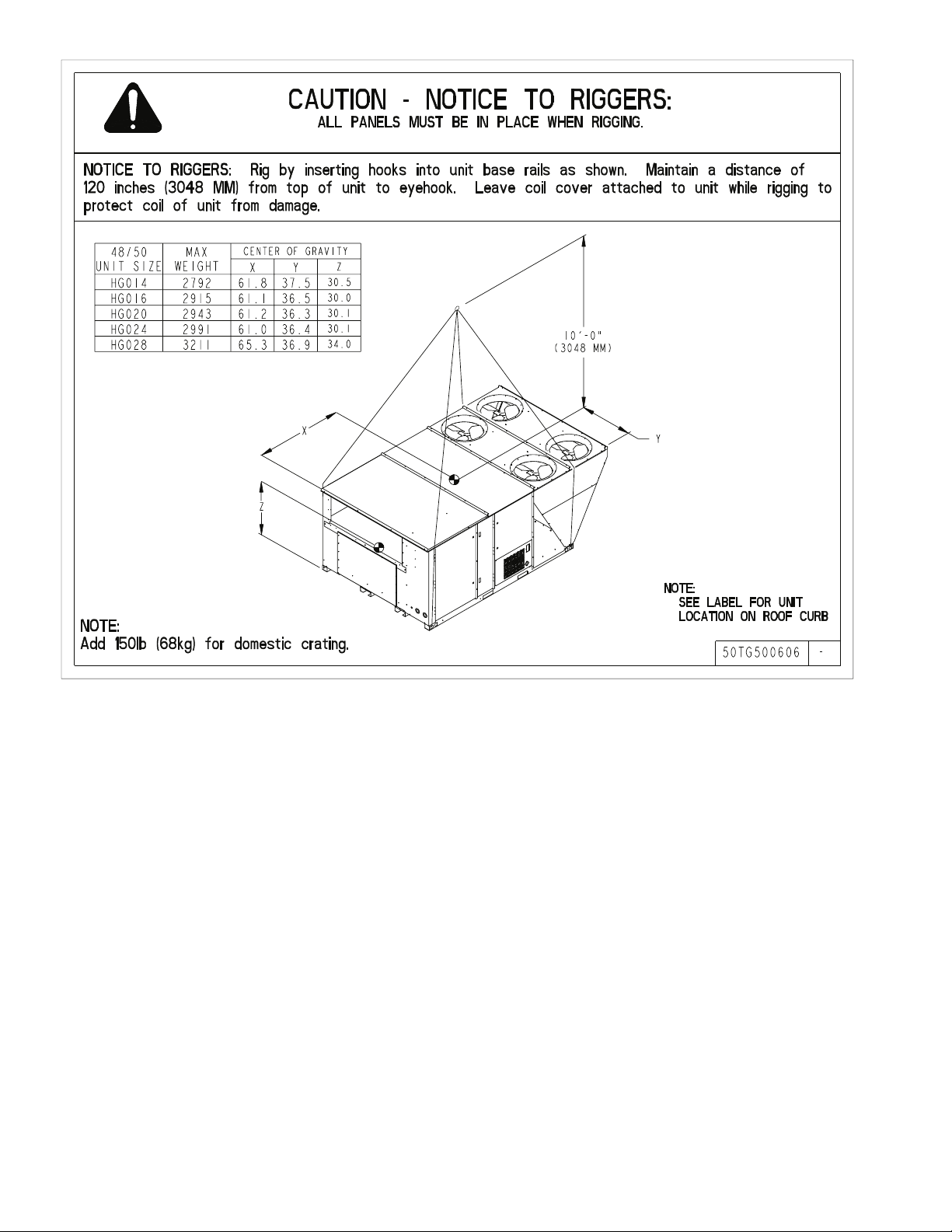

HORIZONTAL APPLICATIONS — Horizontal units are

shipped with outer panels that allow for side by side horizontal

duct connections. If specified during ordering, the unit will be

shipped with the vertical duct openings blocked off from the

factory, ready for side supply installation. If the horizontal

option was not specified at time of ordering the unit, a fieldinstalled accessory kit is required to convert the vertical unit

into a horizontal supply configuration.

Installation of the duct block-off covers should be completed prior to placing the unit unless sufficient side clearance is

available. A minimum of 66-in. is required between the unit

and any obstruction to install the duct block-off covers. Side

supply duct dimensions and locations are shown on Fig. 4.

Connect ductwork to horizontal duct flange connections on

side of unit.

ALIGNMENT

HOLES FOR

HJ, TJ, DP, DR

CURB-BOTH

SIDES

SUPPLY

OPENING

CURB

SUPPLY

OPENING

ALIGNMENT

HOLES FOR HG

CURB-BOTH

SIDES

RETURN

OPENING

CURB

RETURN

OPENING

ROOF CURB

Fig. 6 — Alignment Hole Location

Step 4 — Field Fabricate Ductwork —

Secure all

ducts to building structure. Use flexible duct connectors between unit and ducts as required. Insulate and weatherproof all

external ductwork, joints, and roof openings with counter

flashing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be in-

sulated and covered with a vapor barrier.

Step 5 — Make Unit Duct Connections

VERTICAL CONFIGURATION — Unit is shipped for thruthe-bottom duct connections. Ductwork openings are shown in

Fig. 1 and 4. Duct connections for vertical supply and return

configuration are shown in Fig. 7. Field fabricat ed concentric

ductwork may be connected as shown in Fig. 8 and 9. The unit

is designed to attach the ductwork to the roof curb. Do not

attach duct directly to the unit basepans.

Unit basepans must be supported under the unit and around

duct openings in order to prevent air leakage.

ECONOMIZER

SEE

NOTE

AIR

IN

NOTE: Do not drill in this area; damage to basepan may result in

water leak.

SEE

NOTE

AIR

OUT

Fig. 7 — Air Distribution —

Vertical Supply and Return

ECONOMIZER

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install a 90-degree

turn in the return ductwork between the unit and the conditioned space. If a 90-degree elbow cannot be installed, then

a grille of sufficient strength a nd density should be in stalled

to prevent objects from falling into the conditioned space.

Units with electric heat require a 1-in. clearance for the first

24 in. of ductwork. Outlet grilles must not lie directly below

unit discharge.

NOTE: A 90-degree elbow must be provided in the supply

ductwork to comply with UL (Underwriters’ Laboratories)

codes for use with electric heat.

AIR OUT

SEE

NOTE

SEE

NOTE

AIR OUT

NOTE: Do not drill in this area; damage to basepan may result in

water leak.

AIR IN

Fig. 8 — Air Distribution — Concentric Duct

8

Page 9

NOTE: Dimensions A, A′,B,andB′

c

eiling diffuser.

Shaded areas indicate block-off pans.

are obtained from field-supplied

Fig. 9 — Concentric Duct Details

Step 6 — Trap Condensate Drain —

for drain location. One

3

/4-in. half coupling is provided outside

See Fig. 10

unit evaporator section for condensate drain connection. A trap

at least 4-in. deep must be used. See Fig. 11.

Step 7 — Make Electrical Connections

FIELD POWER SUPPLY — Unit is factory wired for voltage shown on unit nameplate.

When installing units, provide disconnect per NEC (National Electrical Code) of adequate size (MOCP [Maximum

Overcurrent protection] of unit is on the informative plate). See

T ables 2A and 2B. All field wiring must comply with NEC and

local codes. Size wire based on MCA (Minimum Circuit

Amps) on the unit informative plate. See Fig. 12 for power

wiring connections to the unit power terminal block and

equipment grounds.

Route power and ground lines through control box end panel or unit basepan (see Fig. 4) to connections as shown on unit

wiring diagram and Fig. 12.

Operating voltage to compressor must be within voltage

range indicated on unit nameplate. On 3-phase units, voltages

between phases must be balanced within 2%.

Unit failure as a result of operation on improper line voltage

or excessive phase imbalance constitutes abuse and may cause

damage to electrical components.

FIELD CONTROL WIRING — Unit can be controlled with

either a Carrier-approved accessory thermostat or a Carrierapproved space temperature sensor. Install thermostat according to the installation instructions included with accessory.

Locate thermostat assembly or space temperature sensor on a

solid interior wall in the conditioned space to sense average

temperature.

Route thermostat or space temperature sensor cable or

equivalent single leads of colored wire from subbase terminals

through conduit into unit to low-voltage connections as shown

on unit label wiring diagram and in Fig. 13 or 14.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AWG insulated wire (35 C Minimum). All

wire larger than no. 18 AWG cannot be directly connected at

the thermostat and will require a junction box and splice at the

thermostat.

Fig. 10 — Condensate Drain Details

The correct power phasing is critical to the operation of the

scroll compressors. An incorrect phasing will result in an

alarm being generated and compressor operation l ockout.

Should this occur, power phase correction must be made to

the incoming p ow er.

The unit must be electrically grounded in accordance with

local codes and NEC ANSI/NFPA 70 (American National

Standards Institute/National Fire Protection Association).

Field wiring must conform to temperature limitations for

type ‘‘T’’ wire. All field wiring mu st comply with NEC and

local requirements.

NOTE: Dimensions in [] are in millimeters.

Fig. 11 — Condensate Drain Piping Details

9

Page 10

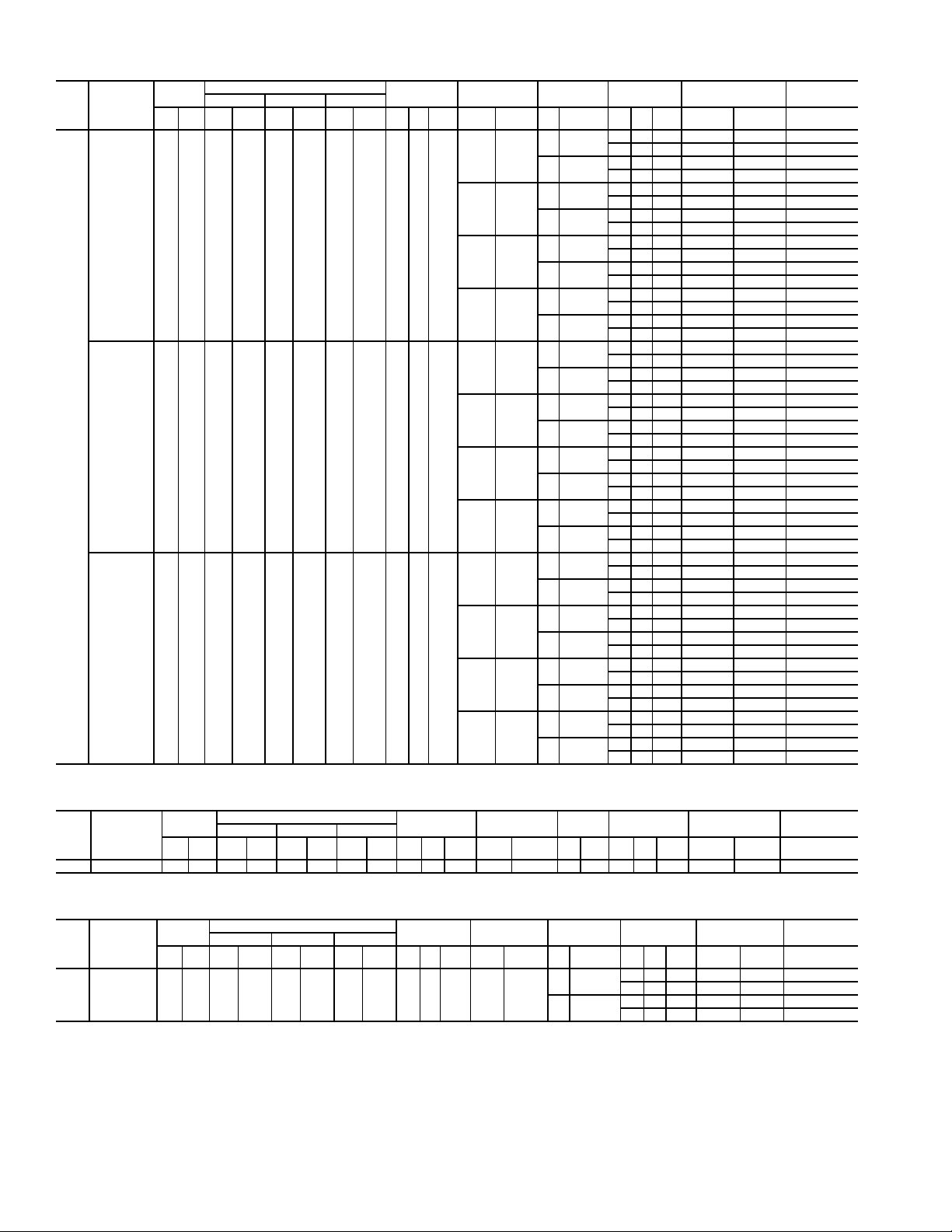

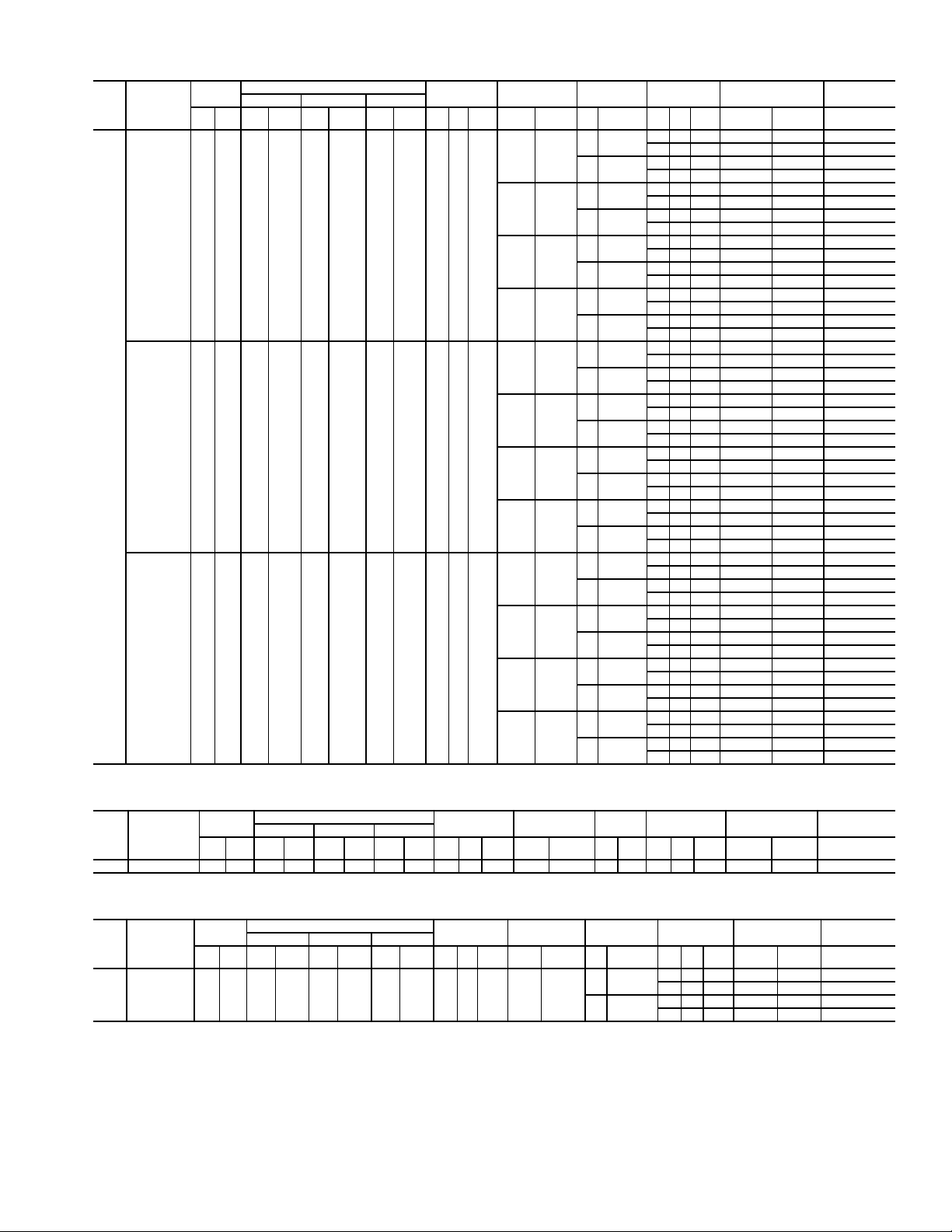

Table 2A — Electrical Data (Units Without Optional Convenience Outlet)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 19.2 146.0 19.2 146.0 — — 4.01/41.5

014

FLA — Full Load Amps MCA — Minimum Circuit Amps

HACR — Heating, Air Conditioning and MOCP — Maximum Overcurrent Protection

IFM — Indoor (Evaporator) Fan Motor OFM — Outdoor (Condenser) Fan Motor

LRA — Locked Rotor Amps RLA — Rated Load Amps

*Fuse or HACR circuit breaker.

†208/230 v 75-kW Electric Heat units must use dual-point wiring. The main table lists the

branch circuit values for the refrigeration part of the system. The following two tables list

the branch circuit values for the electric heat and values for a feeder circuit for both branch

circuits.

NOTES:

1. In compliance w ith NEC requirements for multimotor and combination load equipment

(refer to NEC Articles 430 and 440), the overcurrent protective device for the unit shall

be fuse or HACR breaker. Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

Use the following formula to determine the percent of voltage imbalance.

%Voltage Imbalance

= 100 x

Example: Supply voltage is 460-3-60.

460 414 5069.5 73.0 9.5 73.0 — — 4.01/40.7

575 518 633 7.6 58.4 7.6 58.4 — — 4.01/40.7

Refrigeration NEC — National Electrical Code

max voltage deviation fr om average voltage

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

average voltage

AB=452 v

BC = 464v

AC = 455 v

Average Voltage =

COMPRESSOR

No. 1 No. 2 No. 3

LEGEND AND NOTES FOR TABLES 2A AND 2B

LEGEND

452 + 464 + 455

3

1371

=

3

=

457

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

——

12/16 33/ 38

19/25 52/ 60

38/50 104/120

——

15 18

25 30

50 60

——

16 15

25 24

48 46

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5v

(BC) 464 – 457 = 7v

(AC) 457 – 455 = 2v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

%Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable

2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your

local electric utility company immediately.

3. The 75-kW 208/240-v electric heat can be factory installed but it must be wired separately in the field.

4. The convenience outlet full load amps (FLA) are 5, 3 and 3 for 208/230, 460, 575-v

units, respectively.

5. The FLA load amps provided in the table for electric heaters are based on 208/240, 480

and 600v.

6. MCA calculation for 50HG014-028 units with electric heaters over 50 kW is = 1.25 x

(IFM+Power Exhaust + Convenience Outlet FLA amps) + 1.00 x (Electric Heater FLA).

IFM

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6 /9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

= 1.53%

POWER

EXHAUST

FLA

(ea)

—— — 60/ 59 70/ 70 70/ 70

21.05.9 72/ 71 90/ 80 80/ 80

—— — 66/ 64 80/ 80 80/ 70

21.05.9 78/ 7690/ 90 90/ 90

—— — 60/ 60 70/ 70 70/ 70

21.05.9 72/ 74 90/ 80 80/ 80

—— — 66/ 67 80/ 80 80/ 70

21.05.9 78/ 81 90/ 90 90/ 90

— — — 78/ 87 80/ 90 80/ 90

21.05.993/102 100/110 90/100

—— — 86/ 94 90/100 80/ 90

21.05.9 101/109 110/110 100/110

— — — 143/132 150/150 150/150

21.05.9 158/147 175/150 150/175

— — — 151/139 175/150 150/175

21.05.9 166/154 175/175 175/175

—— — 29 35 35

21.03.1 35 40 40

—— — 32 40 35

21.03.1 38 45 45

—— — 29 35 35

21.03.1 36 40 40

—— — 32 40 35

21.03.1 40 45 45

—— — 44 45 45

21.03.1 51 6050

—— — 47 50 45

21.03.1 55 60 60

—— — 66 80 80

21.03.1 74 80 90

—— — 70 80 80

21.03.1 77 80 90

—— — 24 30 30

21.03.1 30 35 35

—— — 26 30 30

21.03.1 32 35 35

—— — 24 30 30

21.03.1 31 35 35

—— — 26 30 30

21.03.1 34 35 35

—— — 35 35 35

21.03.1 43 45 40

—— — 38 40 35

21.03.1 45 50 45

—— — 6270 60

21.03.1 70 80 70

—— — 6570 60

21.03.1 73 80 70

7

457

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

10

Page 11

Table 2A — Electrical Data (Units Without Optional Convenience Outlet) (cont)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 16.7 130.0 16.7 130.0 16.7 130.0 4.01/41.5

016

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

460 414 506 9.0 70.0 9.0 70.0 9.0 70.0 4.01/40.7

575 518 633 7.0 55.0 7.0 55.0 7.0 55.0 4.01/40.7

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

——

19/25 52/ 60

38/50 104/120

56/75† 156/180

——

25 30

50 60

75 90

——

25 24

48 46

78 75

IFM

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

POWER

EXHAUST

FLA

(ea)

—— — 71/ 70 80/ 80 80/ 80

2 1.0 5.9 83/ 82 90/ 90 100/ 90

—— — 77/ 75 90/ 90 90/ 90

2 1.0 5.9 89/ 87 100/100 100/100

—— — 78/ 87 80/ 90 80/ 90

2 1.0 5.9 93/102 100/110 100/100

—— — 86/ 94 90/100 90/ 90

2 1.0 5.9 101/109 110/110 100/110

—— — 143/132 150/150 150/150

2 1.0 5.9 158/147 175/150 150/175

—— — 151/139 175/150 150/175

2 1.0 5.9 166/154 175/175 175/175

—— — 71/ 70† 80/ 80† 80/ 80†

2 1.0 5.9 83/ 82† 90/ 90† 100/ 90†

—— — 77/ 75† 90/ 90† 90/ 90†

2 1.0 5.9 89/ 87† 100/100† 100/100†

—— — 37 45 40

21.03.1 43 50 50

—— — 40 45 45

21.03.1 46 50 60

—— — 44 45 45

21.03.1 51 60 50

—— — 47 50 45

21.03.1 55 60 60

—— — 66 80 80

21.03.1 74 80 90

—— — 70 80 80

21.03.1 77 80 90

—— — 96 110 110

2 1.0 3.1 104 110 125

—— — 100 110 125

2 1.0 3.1 107 125 125

—— — 29 35 35

21.03.1 36 40 40

—— — 32 35 35

21.03.1 38 40 45

—— — 35 35 35

21.03.1 43 45 40

—— — 38 40 35

21.03.1 45 50 45

—— — 62 70 60

21.03.1 70 80 70

—— — 65 70 60

21.03.1 73 80 70

—— — 80 90 100

2 1.0 3.1 88 100 100

—— — 83 90 100

2 1.0 3.1 90 100 110

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

ELECTRIC HEAT BRANCH CIRCUIT FOR 208/240-V 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

016 208/240 187 253 NA NA NA NA NA NA NA NA NA 56/75 156/180 NA NA NA NA NA 156/180 175/200 200/225

VO LTAGE

RANGE

Min Max RLA LRA RL A LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

POWER

EXHAUST

POWER

FLA

(ea)

SUPPLY

MCA MOCP* FLA

DISCONNECT

FEEDER CIRCUIT FOR 208/230-V UNIT WITH 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

016 208/230 187 253 16.7 130.0 16.7 130.0 16.7 130.0 4.01/41.5 56/75 156/180

See Legend and Notes on page 10.

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

3.7 10.6/ 9.6

5.0 16.7/15.2

POWER

EXHAUST

FLA

(ea)

—— — 169/192 200/225 200/225

2 1.0 5.9 184/207 200/225 225/250

—— — 177/199 200/225 200/225

2 1.0 5.9 192/214 200/225 225/250

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

11

SIZE

SIZE

Page 12

Table 2A — Electrical Data (Units Without Optional Convenience Outlet) (cont)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 16.7 130.0 16.7 130.0 22.4 184.0 4.01/41.5

020

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RL A LRA Qty Hp

460 414 506 9.0 70.0 9.0 70.0 10.7 90.0 4.01/40.7

575 518 633 7.0 55.0 7.0 55.0 9.3 73.0 4.01/40.7

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

5.0 16.7/15.2

——

7.5 24.2/22.0

5.0 16.7/15.2

19/25 52/ 60

7.5 24.2/22.0

5.0 16.7/15.2

38/50 104/120

7.5 24.2/22.0

5.0 16.7/15.2

56/75† 156/180

7.5 24.2/22.0

5.0 7.6

——

7.5 11.0

5.0 7.6

25 30

7.5 11.0

5.0 7.6

50 60

7.5 11.0

5.0 7.6

75 90

7.5 11.0

5.0 6.1

——

7.5 9.0

5.0 6.1

25 24

7.5 9.0

5.0 6.1

48 46

7.5 9.0

5.0 6.1

78 75

7.5 9.0

IFM

POWER

EXHAUST

FLA

(ea)

—— — 84/ 83 100/100 100/ 90

2 1.0 5.9 96/ 94 110/110 110/110

—— — 92/ 89 110/110 100/100

2 1.0 5.9 104/101 125/110 125/110

—— — 86/ 94 100/100 100/ 90

2 1.0 5.9 101/109 110/110 110/110

—— — 95/103 110/110 100/100

2 1.0 5.9 110/117 125/125 125/110

—— — 151/139 175/150 150/175

2 1.0 5.9 166/154 175/175 175/175

—— — 160/148 175/150 150/175

2 1.0 5.9 175/162 200/175 175/200

—— — 84/ 83† 100/100† 100/ 90†

2 1.0 5.9 96/ 94† 110/110† 110/110†

—— — 92/ 89† 110/110† 100/100†

2 1.0 5.9 104/101† 125/110† 125/110†

—— — 42 50 45

21.03.1 48 50 60

—— — 45 50 50

21.03.1 51 60 60

—— — 47 50 45

21.03.1 55 60 60

—— — 51 60 50

21.03.1 59 60 60

—— — 70 80 80

21.03.1 77 80 90

—— — 74 80 90

21.03.1 82 90 90

—— — 100 110 125

2 1.0 3.1 107 125 125

—— — 104 125 125

2 1.0 3.1 112 125 125

—— — 35 40 40

21.03.1 41 50 45

—— — 37 45 45

21.03.1 44 50 50

—— — 38 40 40

21.03.1 45 50 45

—— — 41 45 45

21.03.1 49 50 50

—— — 65 70 60

21.03.1 73 80 70

—— — 69 70 70

21.03.1 77 80 80

—— — 83 90 100

2 1.0 3.1 90 100 110

—— — 86 100 100

2 1.0 3.1 94 100 110

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

ELECTRIC HEAT BRANCH CIRCUIT FOR 208/240-V 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

020 208/240 187 253 NA NA NA NA NA NA NA NA NA 56/75 156/180 NA NA NA NA NA 156/180 175/200 200/225

VO LTAGE

RANGE

Min Max RLA LRA RL A LRA RLA LRA Qty Hp

COMPRESSOR

No.1 No.2 No.3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

POWER

EXHAUST

POWER

FLA

(ea)

SUPPLY

MCA MOCP* FLA

DISCONNECT

FEEDER CIRCUIT FOR 208/230-V UNIT WITH 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

020 208/230 187 253 16.7 130.0 16.7 130.0 22.4 184.0 4.01/41.5 56/75 156/180

See Legend and Notes on page 10.

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

5.0 16.7/15.2

7.5 24.2/22.0

POWER

EXHAUST

FLA

(ea)

—— — 177/199 200/225 200/225

2 1.0 5.9 192/214 200/225 225/250

—— — 186/208 200/225 225/250

2 1.0 5.9 201/222 225/225 225/250

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

12

SIZE

SIZE

Page 13

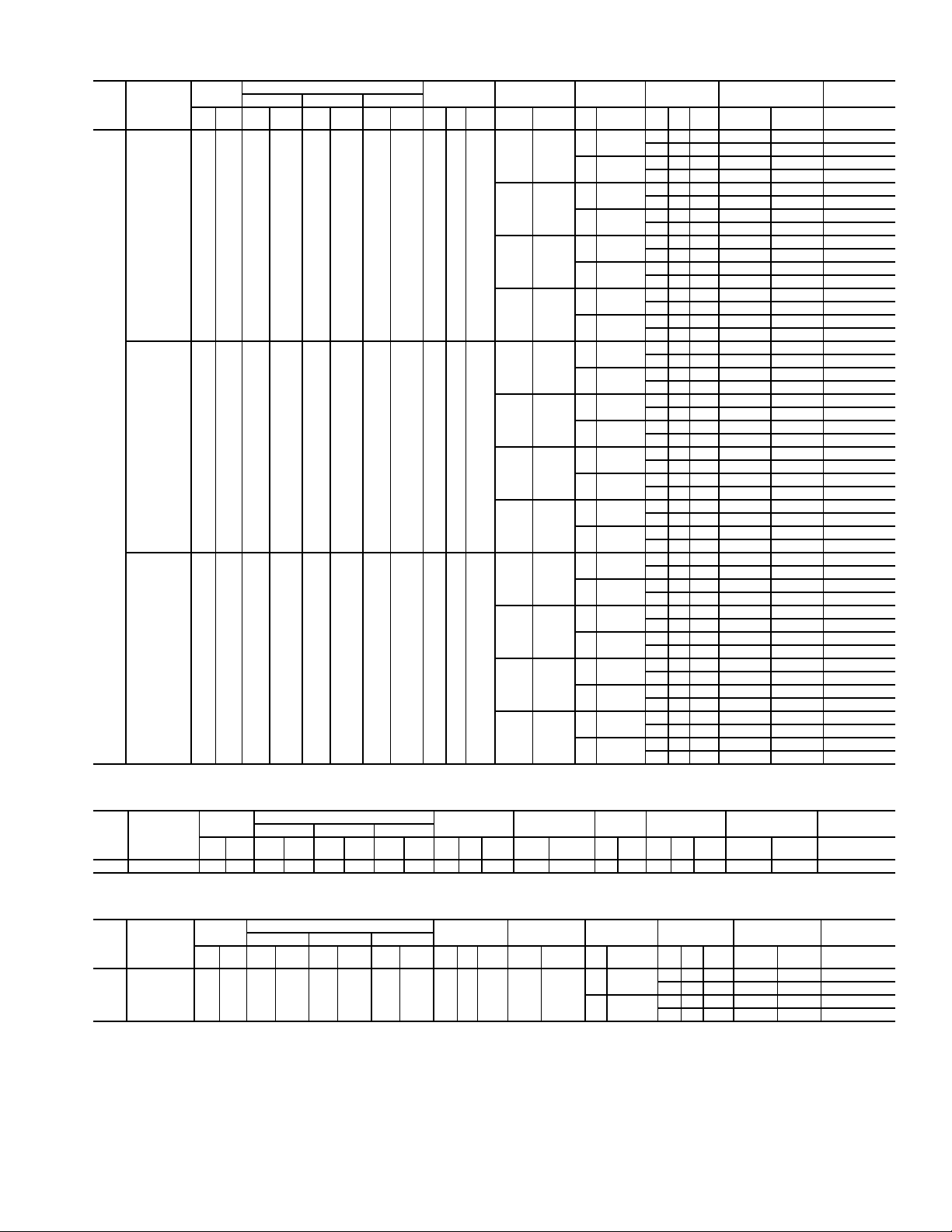

Table 2A — Electrical Data (Units Without Optional Convenience Outlet) (cont)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 22.4 184.0 22.4 184.0 22.4 184.0 4.01/41.5

024

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RL A LRA Qty Hp

460 414 506 10.7 90.0 10.7 90.0 10.7 90.0 4.01/40.7

575 518 633 9.3 73.0 9.3 73.0 9.3 73.0 4.01/40.7

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

——

19/25 52/ 60

38/50 104/120

56/75† 156/180

——

25 30

50 60

75 90

——

25 24

48 46

78 75

IFM

5.0 16.7/15.2

7.5 24.2/22.0

5.0 16.7/15.2

7.5 24.2/22.0

5.0 16.7/15.2

7.5 24.2/22.0

5.0 16.7/15.2

7.5 24.2/22.0

5.0 7.6

7.5 11.0

5.0 7.6

7.5 11.0

5.0 7.6

7.5 11.0

5.0 7.6

7.5 11.0

5.0 6.1

7.5 9.0

5.0 6.1

7.5 9.0

5.0 6.1

7.5 9.0

5.0 6.1

7.5 9.0

POWER

EXHAUST

FLA

(ea)

—— — 96/ 94 110/110 110/110

2 1.0 5.9 107/106 125/125 125/125

—— — 104/101 125/110 125/110

2 1.0 5.9 115/113 125/125 150/125

—— — 96/ 94 110/110 110/110

2 1.0 5.9 107/109 125/125 125/125

—— — 104/103 125/110 125/110

2 1.0 5.9 115/117 125/125 150/125

—— — 151/139 175/150 150/175

2 1.0 5.9 166/154 175/175 175/175

—— — 160/148 175/150 150/175

2 1.0 5.9 175/162 200/175 175/200

—— — 96/ 94† 110/110† 110/110†

2 1.0 5.9 107/106† 125/125† 125/125†

—— — 104/101† 125/110† 125/110†

2 1.0 5.9 115/113† 125/125† 150/125†

—— — 45 50 50

21.03.1 51 60 60

—— — 49 50 60

21.03.1 55 60 60

—— — 47 50 50

21.03.1 55 60 60

—— — 51 60 60

21.03.1 59 60 60

—— — 70 80 80

21.03.1 77 80 90

—— — 74 80 90

21.03.1 82 90 90

—— — 100 110 125

2 1.0 3.1 107 125 125

—— — 104 125 125

2 1.0 3.1 112 125 125

—— — 39 45 45

21.03.1 45 50 50

—— — 42 50 50

21.03.1 48 50 60

—— — 39 45 45

21.03.1 45 50 50

—— — 42 50 50

21.03.1 49 50 60

—— — 65 70 60

21.03.1 73 80 70

—— — 69 70 70

21.03.1 77 80 80

—— — 83 90 100

2 1.0 3.1 90 100 110

—— — 86 100 100

2 1.0 3.1 94 100 110

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

ELECTRIC HEAT BRANCH CIRCUIT FOR 208/240-V 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

024 208/240 187 253 NA NA NA NA NA NA NA NA NA 56/75 156/180 NA NA NA NA NA 156/180 175/200 200/225

VO LTAGE

RANGE

Min Max RLA LRA RL A LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

POWER

EXHAUST

POWER

FLA

(ea)

SUPPLY

MCA MOCP* FLA

DISCONNECT

FEEDER CIRCUIT FOR 208/230-V UNIT WITH 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

024 208/230 187 253 22.4 184.0 22.4 184.0 22.4 184.0 4.01/41.5 56/75 156/180

See Legend and Notes on page 10.

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

5.0 16.7/15.2

7.5 24.2/22

POWER

EXHAUST

FLA

(ea)

—— — 177/199 200/225 200/225

2 1.0 5.9 192/214 200/225 225/250

—— — 186/208 200/225 225/250

2 1.0 5.9 201/222 225/225 225/250

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

13

SIZE

SIZE

Page 14

Table 2A — Electrical Data (Units Without Optional Convenience Outlet) (cont)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 47.1 245.0 47.1 245.0 ——6.01/41.5

028

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

460 414 506 19.6 125.0 19.6 125.0 ——6.01/40.7

575 518 633 15.8 100.0 15.8 100.0 ——6.01/40.7

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

——

19/25 52/ 60

38/50 104/120

56/75† 156/180

——

25 30

50 60

75 90

——

25 24

48 46

78 75

IFM

7.5 24.2/22.0

10.0 30.8/28.0

7.5 24.2/22.0

10.0 30.8/28.0

7.5 24.2/22.0

10.0 30.8/28.0

7.5 24.2/22.0

10.0 30.8/28.0

7.5 11.0

10.0 14.0

7.5 11.0

10.0 14.0

7.5 11.0

10.0 14.0

7.5 11.0

10.0 14.0

7.5 9.0

10.0 11.0

7.5 9.0

10.0 11.0

7.5 9.0

10.0 11.0

7.5 9.0

10.0 11.0

POWER

EXHAUST

FLA

(ea)

—— — 139/137 175/175 150/150

2 1.0 5.9 151/149 175/175 175/175

—— — 146/143 175/175 175/175

2 1.0 5.9 158/155 200/200 175/175

—— — 139/137 175/175 150/150

2 1.0 5.9 151/149 175/175 175/175

—— — 146/143 175/175 175/175

2 1.0 5.9 158/155 200/200 175/175

—— — 160/148 175/175 150/175

2 1.0 5.9 175/162 200/175 175/200

—— — 169/155 175/175 175/175

2 1.0 5.9 183/170 200/200 175/200

—— — 139/137† 175/175† 150/150†

2 1.0 5.9 151/149† 175/175† 175/175†

—— — 146/143† 175/175† 175/175†

2 1.0 5.9 158/155† 200/200† 175/175†

—— — 59 70 70

21.03.1 66 80 70

—— — 62 80 70

21.03.1 69 80 80

—— — 59 70 70

21.03.1 66 80 70

—— — 62 80 70

21.03.1 69 80 80

—— — 74 80 90

21.03.1 82 90 90

—— — 78 90 90

21.03.1 85 90 100

—— — 104 125 125

2 1.0 3.1 112 125 125

—— — 108 125 125

2 1.0 3.1 115 125 150

—— — 49 60 60

21.03.1 55 70 60

—— — 51 60 60

21.03.1 57 70 70

—— — 49 60 60

21.03.1 55 70 60

—— — 51 60 60

21.03.1 57 70 70

—— — 69 70 70

21.03.1 77 80 80

—— — 71 80 70

21.03.1 79 80 80

—— — 86 100 100

2 1.0 3.1 94 100 110

—— — 89 100 100

2 1.0 3.1 97 100 110

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

ELECTRIC HEAT BRANCH CIRCUIT FOR 208/240-V 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

028 208/240 187 253 NA NA NA NA NA NA NA NA NA 56/75 156/180 NA NA NA NA NA 156/180 175/200 200/225

VO LTAGE

RANGE

Min Max RLA LRA RL A LRA RLA LRA Qty Hp

COMPRESSOR

No.1 No.2 No.3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

POWER

EXHAUST

POWER

FLA

(ea)

SUPPLY

MCA MOCP* FLA

DISCONNECT

FEEDER CIRCUIT FOR 208/230-V UNIT WITH 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

028 208/230 187 253 47.1 245.0 47.1 245.0 ——6.01/41.5 56/75 156/180

See Legend and Notes on page 10.

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

7.5 24.2/22.0

10.0 30.8/28.0

POWER

EXHAUST

FLA

(ea)

—— — 186/208 200/225 225/250

2 1.0 5.9 201/222 225/225 225/250

—— — 195/215 225/225 225/250

2 1.0 5.9 209/230 225/250 250/300

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

14

SIZE

SIZE

Page 15

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 19.2 146.0 19.2 146.0 ——4.01/41.5

014

See Legend and Notes on page 10.

460 414 506 9.5 73.0 9.5 73.0 ——4.01/40.7

575 518 633 7.6 58.4 7.6 58.4 ——4.01/40.7

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

Table 2B — Electrical Data (Units With Optional Convenience Outlet)

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

——

12/16 33/ 38

19/25 52/ 60

38/50 104/120

——

15 18

25 30

50 60

——

16 15

25 24

48 46

IFM

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

POWER

EXHAUST

FLA

(ea)

—— — 65/ 64 80/ 80 70/ 70

2 1.0 5.9 77/ 76 90/ 90 80/ 80

—— — 71/ 69 90/ 80 80/ 70

2 1.0 5.9 83/ 81 100/100 90/ 90

—— — 65/ 66 80/ 80 70/ 70

2 1.0 5.9 77/ 81 90/ 90 80/ 80

—— — 71/ 73 90/ 80 80/ 70

2 1.0 5.9 83/ 88 100/100 90/ 90

—— — 85/ 93 90/100 80/ 90

2 1.0 5.9 99/108 100/110 90/100

—— — 92/100 100/110 80/ 90

2 1.0 5.9 107/115 110/125 100/110

—— — 150/138 150/150 150/150

2 1.0 5.9 164/153 175/175 150/175

—— — 157/145 175/150 150/175

2 1.0 5.9 172/160 175/175 175/175

—— — 32 40 35

21.03.1 38 45 40

—— — 35 40 35

21.03.1 41 50 45

—— — 32 40 35

21.03.1 40 45 40

—— — 36 40 35

21.03.1 44 50 45

—— — 47 50 45

21.03.1 55 60 50

—— — 51 60 45

21.03.1 59 60 60

—— — 70 80 80

21.03.1 78 80 90

—— — 73 80 80

21.03.1 81 90 90

—— — 27 30 30

21.03.1 33 40 35

—— — 29 35 30

21.03.1 36 40 35

—— — 27 30 30

21.03.1 35 40 35

—— — 30 35 30

21.03.1 38 40 35

—— — 39 40 35

21.03.1 46 50 40

—— — 41 45 35

21.03.1 49 50 45

—— — 66 70 60

21.03.1 74 80 70

—— — 69 70 60

21.03.1 77 80 70

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

15

Page 16

Table 2B — Electrical Data (Units With Optional Convenience Outlet) (cont)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 16.7 130.0 16.7 130.0 16.7 130.0 4.01/41.5

016

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

460 414 506 9.0 70.0 9.0 70.0 9.0 70.0 4.01/40.7

575 518 633 7.0 55.0 7.0 55.0 7.0 55.0 4.01/40.7

COMPRESSOR

No.1 No.2 No.3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

——

19/25 52/ 60

38/50 104/120

56/75† 156/180

——

25 30

50 60

75 90

——

25 24

48 46

78 75

IFM

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 10.6/ 9.6

5.0 16.7/15.2

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.7 4.8

5.0 7.6

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

3.0 3.9

5.0 6.1

POWER

EXHAUST

FLA

(ea)

—— — 76/ 75 90/ 90 80/ 80

2 1.0 5.9 88/ 87 100/100 100/ 90

—— — 82/ 80 90/ 90 90/ 90

2 1.0 5.9 94/ 92 110/100 100/100

—— — 85/ 93 90/100 80/ 90

2 1.0 5.9 99/108 100/110 100/100

—— — 92/100 100/110 90/ 90

2 1.0 5.9 107/115 110/125 100/110

—— — 150/138 150/150 150/150

2 1.0 5.9 164/153 175/175 150/175

—— — 157/145 175/150 150/175

2 1.0 5.9 172/160 175/175 175/175

—— — 76/ 75† 90/ 90† 80/ 80†

2 1.0 5.9 88/ 87† 100/100† 100/ 90†

—— — 82/ 80† 90/ 90† 90/ 90†

2 1.0 5.9 94/ 92† 110/100† 100/100†

—— — 40 45 40

21.03.1 46 50 50

—— — 43 50 45

21.03.1 49 50 60

—— — 47 50 45

21.03.1 55 60 50

—— — 51 60 45

21.03.1 59 60 60

—— — 70 80 80

21.03.1 78 80 90

—— — 73 80 80

21.03.1 81 90 90

—— — 100 110 110

2 1.0 3.1 108 125 125

—— — 103 125 125

2 1.0 3.1 111 125 125

—— — 32 35 35

21.03.1 39 45 40

—— — 35 40 35

21.03.1 41 50 45

—— — 39 40 35

21.03.1 46 50 40

—— — 41 45 35

21.03.1 49 50 45

—— — 66 70 60

21.03.1 74 80 70

—— — 69 70 60

21.03.1 77 80 70

—— — 84 90 100

2 1.0 3.1 91 100 100

—— — 86 100 100

2 1.0 3.1 94 100 110

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

ELECTRIC HEAT BRANCH CIRCUIT FOR 208/240-V 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

016 208/240 187 253 NA NA NA NA NA NA NA NA NA 56/75 156/180 NA NA NA NA NA 156/180 175/200 200/225

VO LTAGE

RANGE

Min Max RLA LRA RL A LRA RLA LRA Qty Hp

COMPRESSOR

No.1 No.2 No.3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

POWER

EXHAUST

POWER

FLA

(ea)

SUPPLY

MCA MOCP* FLA

DISCONNECT

FEEDER CIRCUIT FOR 208/230-V UNIT WITH 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

016 208/230 187 253 16.7 130.0 16.7 130.0 16.7 130.0 4.0 1/4 1.5 56/75 156/180

See Legend and Notes on page 10.

VO LTAGE

RANGE

Min Max RL A LRA RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

3.7 10.6/ 9.6

5.0 16.7/15.2

POWER

EXHAUST

FLA

(ea)

—— — 176/198 200/225 200/225

2 1.0 5.9 190/213 200/225 225/250

—— — 183/205 200/225 200/225

2 1.0 5.9 198/220 200/225 225/250

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

16

SIZE

SIZE

Page 17

Table 2B — Electrical Data (Units With Optional Convenience Outlet) (cont)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 16.7 130.0 16.7 130.0 22.4 184.0 4.01/41.5

020

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

460 414 506 9.0 70.0 9.0 70.0 10.7 90.0 4.01/40.7

575 518 633 7.0 55.0 7.0 55.0 9.3 73.0 4.01/40.7

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

5.0 16.7/15.2

——

7.5 24.2/22.0

5.0 16.7/15.2

19/25 52/ 60

7.5 24.2/22.0

5.0 16.7/15.2

38/50 104/120

7.5 24.2/22.0

5.0 16.7/15.2

56/75† 156/180

7.5 24.2/22.0

5.0 7.6

——

7.5 11.0

5.0 7.6

25 30

7.5 11.0

5.0 7.6

50 60

7.5 11.0

5.0 7.6

75 90

7.5 11.0

5.0 6.1

——

7.5 9.0

5.0 6.1

25 24

7.5 9.0

5.0 6.1

48 46

7.5 9.0

5.0 6.1

78 75

7.5 9.0

IFM

POWER

EXHAUST

FLA

(ea)

—— — 89/ 88 110/110 100/ 90

2 1.0 5.9 101/ 99 110/110 110/110

—— — 97/ 94 110/110 100/100

2 1.0 5.9 109/106 125/125 125/110

—— — 92/100 110/110 100/ 90

2 1.0 5.9 107/115 110/125 110/110

—— — 102/109 110/110 100/100

2 1.0 5.9 116/124 125/125 125/110

—— — 157/145 175/150 150/175

2 1.0 5.9 172/160 175/175 175/175

—— — 167/154 175/175 150/175

2 1.0 5.9 181/169 200/175 175/200

—— — 89/ 88† 110/110† 100/ 90†

2 1.0 5.9 101/ 99† 110/110† 110/110†

—— — 97/ 94† 110/110† 100/100†

2 1.0 5.9 109/106† 125/125† 125/110†

—— — 45 50 45

21.03.1 51 60 60

—— — 48 50 50

21.03.1 54 60 60

—— — 51 60 45

21.03.1 59 60 60

—— — 55 60 50

21.03.1 63 70 60

—— — 73 80 80

21.03.1 81 90 90

—— — 78 80 90

21.03.1 85 90 90

—— — 103 125 125

2 1.0 3.1 111 125 125

—— — 108 125 125

2 1.0 3.1 115 125 125

—— — 38 45 40

21.03.1 44 50 45

—— — 40 45 45

21.03.1 47 50 50

—— — 41 45 40

21.03.1 49 50 45

—— — 45 45 45

21.03.1 53 60 50

—— — 69 70 60

21.03.1 77 80 70

—— — 73 80 70

21.03.1 80 90 80

—— — 86 100 100

2 1.0 3.1 94 100 110

—— — 90 100 100

2 1.0 3.1 98 100 110

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

ELECTRIC HEAT BRANCH CIRCUIT FOR 208/240-V 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

020 208/240 187 253 NA NA NA NA NA NA NA NA NA 56/75 156/180 NA NA NA NA NA 156/180 175/200 200/225

VO LTAGE

RANGE

Min Max RLA LRA RL A LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

POWER

EXHAUST

POWER

FLA

(ea)

SUPPLY

MCA MOCP* FLA

DISCONNECT

FEEDER CIRCUIT FOR 208/230-V UNIT WITH 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

020 208/230 187 253 16.7 130.0 16.7 130.0 22.4 184.0 4.01/41.5 56/75 156/180

See Legend and Notes on page 10.

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

5.0 16.7/15.2

7.5 24.2/22.0

POWER

EXHAUST

FLA

(ea)

—— — 183/205 200/225 200/225

2 1.0 5.9 198/220 200/225 225/250

—— — 193/214 200/225 225/250

2 1.0 5.9 207/229 225/250 225/250

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

17

SIZE

SIZE

Page 18

Table 2B — Electrical Data (Units With Optional Convenience Outlet) (cont)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 22.4 184.0 22.4 184.0 22.4 184.0 4.01/41.5

024

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RL A LRA Qty Hp

460 414 506 10.7 90.0 10.7 90.0 10.7 90.0 4.01/40.7

575 518 633 9.3 73.0 9.3 73.0 9.3 73.0 4.01/40.7

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

5.0 16.7/15.2

——

7.5 24.2/22.0

5.0 16.7/15.2

19/25 52/ 60

7.5 24.2/22.0

5.0 16.7/15.2

38/50 104/120

7.5 24.2/22.0

5.0 16.7/15.2

56/75† 156/180

7.5 24.2/22.0

5.0 7.6

——

7.5 11.0

5.0 7.6

25 30

7.5 11.0

5.0 7.6

50 60

7.5 11.0

5.0 7.6

75 90

7.5 11.0

5.0 6.1

——

7.5 9.0

5.0 6.1

25 24

7.5 9.0

5.0 6.1

48 46

7.5 9.0

5.0 6.1

78 75

7.5 9.0

IFM

POWER

EXHAUST

FLA

(ea)

—— — 101/ 99 110/110 110/110

2 1.0 5.9 112/111 125/125 125/125

—— — 109/106 125/125 125/110

2 1.0 5.9 120/118 125/125 150/125

—— — 101/100 110/110 110/110

2 1.0 5.9 112/115 125/125 125/125

—— — 109/109 125/125 125/110

2 1.0 5.9 120/124 125/125 150/125

—— — 157/145 175/150 150/175

2 1.0 5.9 172/160 175/175 175/175

—— — 167/154 175/175 150/175

2 1.0 5.9 181/169 200/175 175/200

—— — 101/ 99† 110/110† 110/110†

2 1.0 5.9 112/111† 125/125† 125/125†

—— — 109/106† 125/125† 125/110†

2 1.0 5.9 120/118† 125/125† 150/125†

—— — 48 50 50

21.03.1 54 60 60

—— — 52 60 60

21.03.1 58 60 60

—— — 51 60 50

21.03.1 59 60 60

—— — 55 60 60

21.03.1 63 70 60

—— — 73 80 80

21.03.1 81 90 90

—— — 78 80 90

21.03.1 85 90 90

—— — 103 125 125

2 1.0 3.1 111 125 125

—— — 108 125 125

2 1.0 3.1 115 125 125

—— — 42 50 45

21.03.1 48 50 50

—— — 45 50 50

21.03.1 51 60 60

—— — 42 50 45

21.03.1 49 50 50

—— — 45 50 50

21.03.1 53 60 60

—— — 69 70 60

21.03.1 77 80 70

—— — 73 80 70

21.03.1 80 90 80

—— — 86 100 100

2 1.0 3.1 94 100 110

—— — 90 100 100

2 1.0 3.1 98 100 110

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

ELECTRIC HEAT BRANCH CIRCUIT FOR 208/240-V 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

024 208/240 187 253 NA NA NA NA NA NA NA NA NA 56/75 156/180 NA NA NA NA NA 156/180 175/200 200/225

VO LTAGE

RANGE

Min Max RLA LRA RL A LRA RLA LRA Qty Hp

COMPRESSOR

No.1 No.2 No.3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

POWER

EXHAUST

POWER

FLA

(ea)

SUPPLY

MCA MOCP* FLA

DISCONNECT

FEEDER CIRCUIT FOR 208/230-V UNIT WITH 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

024 208/230 187 253 22.4 184.0 22.4 184.0 22.4 184.0 4.01/41.5 56/75 156/180

See Legend and Notes on page 10.

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

5.0 16.7/15.2

7.5 24.2/22.0

POWER

EXHAUST

FLA

(ea)

—— — 183/205 200/225 200/225

2 1.0 5.9 198/220 200/225 225/250

—— — 193/214 200/225 225/250

2 1.0 5.9 207/229 225/250 225/250

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

18

SIZE

SIZE

Page 19

Table 2B — Electrical Data (Units With Optional Convenience Outlet) (cont)

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

208/230 187 253 47.1 245.0 47.1 245.0 ——6.01/41.5

028

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

460 414 506 19.6 125.0 19.6 125.0 ——6.01/40.7

575 518 633 15.8 100.0 15.8 100.0 ——6.01/40.7

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

——

19/25 52/ 60

38/50 104/120

56/75† 156/180

——

25 30

50 60

75 90

——

25 24

48 46

78 75

IFM

7.5 24.2/22.0

10.0 30.8/28.0

7.5 24.2/22.0

10.0 30.8/28.0

7.5 24.2/22.0

10.0 30.8/28.0

7.5 24.2/22.0

10.0 30.8/28.0

7.5 11.0

10.0 14.0

7.5 11.0

10.0 14.0

7.5 11.0

10.0 14.0

7.5 11.0

10.0 14.0

7.5 9.0

10.0 11.0

7.5 9.0

10.0 11.0

7.5 9.0

10.0 11.0

7.5 9.0

10.0 11.0

POWER

EXHAUST

FLA

(ea)

—— — 144/142 175/175 150/150

2 1.0 5.9 156/154 200/200 175/175

—— — 151/148 175/175 175/175

2 1.0 5.9 163/160 200/200 175/175

—— — 144/142 175/175 150/150

2 1.0 5.9 156/154 200/200 175/175

—— — 151/148 175/175 175/175

2 1.0 5.9 163/160 200/200 175/175

—— — 167/154 175/175 150/175

2 1.0 5.9 181/169 200/200 175/200

—— — 175/161 175/175 175/175

2 1.0 5.9 190/176 200/200 175/200

—— — 144/142† 175/175† 150/150†

2 1.0 5.9 156/154† 200/200† 175/175†

—— — 151/148† 175/175† 175/175†

2 1.0 5.9 163/160† 200/200† 175/175†

—— — 62 80 70

21.03.1 69 80 70

—— — 65 80 70

21.03.1 72 90 80

—— — 62 80 70

21.03.1 69 80 70

—— — 65 80 70

21.03.1 72 90 80

—— — 78 80 90

21.03.1 85 90 90

—— — 81 90 90

2 1.0 3.1 89 100 100

—— — 108 125 125

2 1.0 3.1 115 125 125

—— — 111 125 125

2 1.0 3.1 119 125 150

—— — 52 60 60

21.03.1 58 70 60

—— — 54 60 60

21.03.1 60 70 70

—— — 52 60 60

21.03.1 58 70 60

—— — 54 60 60

21.03.1 60 70 70

—— — 73 80 70

21.03.1 80 90 80

—— — 75 80 70

21.03.1 83 90 80

—— — 90 100 100

2 1.0 3.1 98 100 110

—— — 93 100 100

2 1.0 3.1 100 110 110

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

SIZE

ELECTRIC HEAT BRANCH CIRCUIT FOR 208/240-V 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

028 208/240 187 253 NA NA NA NA NA NA NA NA NA 56/75 156/180 NA NA NA NA NA 156/180 175/200 200/225

VO LTAGE

RANGE

Min Max RLA LRA RL A LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

POWER

EXHAUST

POWER

FLA

(ea)

SUPPLY

MCA MOCP* FLA

DISCONNECT

FEEDER CIRCUIT FOR 208/230-V UNIT WITH 75-kW ELECTRIC HEAT

UNIT

NOMINAL

SIZE

VO LTAGE

50HG

(3 Ph, 60 Hz)

028 208/230 187 253 47.1 245.0 47.1 245.0 ——6.01/41.5 56/75 156/180

See Legend and Notes on page 10.

VO LTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2 No. 3

OFM

ELECTRIC

FLA

(ea)

HEAT

kW FLA Hp FLA Qty Hp

IFM

7.5 24.2/22.0

10.0 30.8/28.0

POWER

EXHAUST

FLA

(ea)

—— — 193/214 200/225 225/250

2 1.0 5.9 207/229 225/250 225/250

—— — 201/221 225/225 225/250

2 1.0 5.9 216/236 225/250 250/300

POWER

SUPPLY

MCA MOCP* FLA

DISCONNECT

19

SIZE

SIZE

Page 20

LEGEND

EQUIP —

GND —

NEC —

TB —

NOTE: The maximum wire size for TB1 is 2/0.

Equipment

Ground

National Electrical Code

Terminal Board

Fig. 12 — Field Power Wiring Connections

REMOVABLE JUMPER

RC

RH

R

TB4

1

THERMOSTAT ASSEMBLY

Y1 Y2

Y1 Y2

2

W1 W2 G CLX

W1 W2 G C X

45

3

6

Fig. 13 — Field Control Thermostat Wiring

T-55 SPT

T1

TB3

Space Temperature Sensor

SPT —

7

T2

9

8

T-56 SPT

TH

COM

Fig. 14 — Field Control Space

Temperature Sensor Wiring

Set heat anticipator settings as shown in Table 3.

Table 3 — Heat Anticipator Settings

UNIT SIZE

50HG

014

016-028

STAGE 1

ELECTRIC

HEAT (kW)

15 0.2 0.2 0.2 0.2 0.2 0.2

25 0.2 0.2 0.2 0.4 0.4 0.4

50 0.4 0.2 0.2 0.8 0.4 0.4

25 0.2 0.2 0.2 0.4 0.4 0.4

50 0.4 0.2 0.2 0.8 0.4 0.4

75 0.4 0.2 0.2 0.8 0.4 0.4

(W1) ON

Vo lt ag e Vo lt ag e

208/240 480 600 208/240 480 600

STAGES 1 AND 2

8

7

SN

(W1 and W2) ON

3. Remove the bracket holding the bottom half of the hood

in the shipping position. Remove the hood bottom half

and filters (or manual dampers on units so equipped)

from outdoor section.

NOTE: On units without economizers, the compone nts

are attached to the unit basepan. To access the components, remove the panel below the outdoor air intake

section.

4. Remove inner filter track from shipping position in outdoor section. Position inner filter track so the track is facing outward from the unit. Install the filter track with

4 screws provided.

5. Apply seal strip (provided) to back flange of both hood

sides where hood side connects to the unit back panel.

See Fig. 16.

6. Apply seal strip (provided) to top flange of both hood

sides where hood sides connect to the hood top panels.

See Fig. 16.

7. Install hood sides to the back panels using the screws from

Step 2. The sloped flanges point outward. The drip edges

of the side panels should face outward as well. The filter

guides should face inward to hold the filters in place. See

Fig. 16.

8. Apply seal strip along the entire length of the bottom

flange of the hood top. See Fig. 16.

9. Install the bottom part of the hood top using 4 screws provided. See Fig. 16.

10. Remove the packaging from filters (3) and install into the

filter tracks. Slide the filters to the sides then place the last

filter into the center of the filter track.

NOTE: For units with manual dampers, replace the end fi lters

with the manual dampers. Install the filter in the center

between the manual dampers.

11. Install the filter retainer track along the bottom edge of the

outdoor air hood using 4 screws provided. See Fig. 16.

12. Install top section of the outdoor air hood using 9 screws

provided. See Fig. 16. See Fig. 17 for a picture of the

assembled outdoor air hood.

NOTE: For filter removal, remove the four screws holding the

filter retainer. The filters can then be removed, cleaned, or

replaced. Install the filters by reversing the procedure.

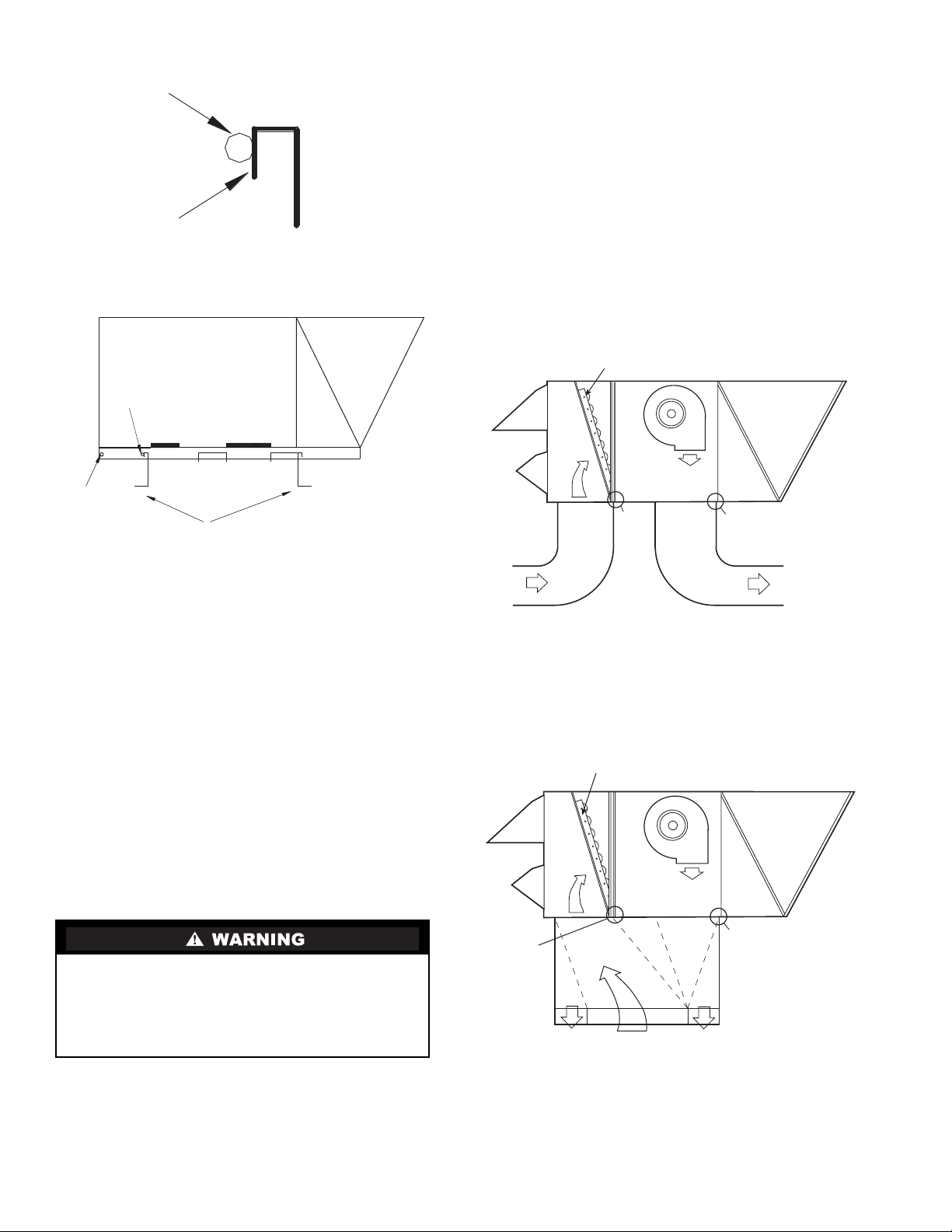

MANUAL DAMPER ASSEMBL Y — For units equipped

with manual dampers, the assembly process is similar to the outdoor air hood for units with economizers. There are two slide

dampers shipped with the unit to allow for manual setting of the

outside air volume. When assembling the hood, place one of the

manual slide dampers in each of the end positions and the remaining filter in the center position. The manual da mpers can

then be moved to the appropriate position and then locked into

place using the screws mounted in the adjustment slots. See

Fig. 18.

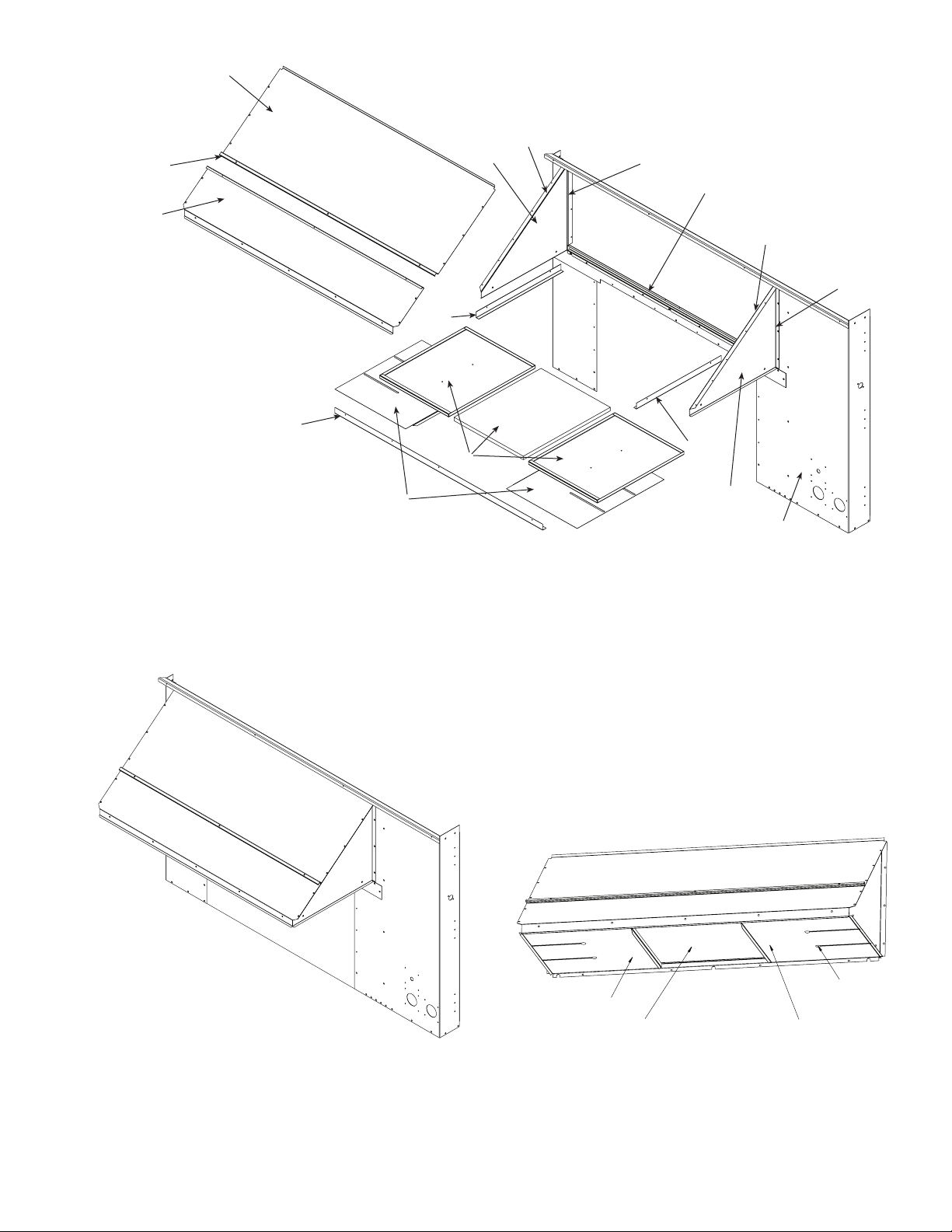

HOOD TOP

(TOP HALF)

HOOD

SIDE

HOOD

SIDE

HOOD TOP

(BOTTOM HALF)

Settings may be changed slightly to provide a greater degree

of comfort for a particular installation.

Step 8 — Install Outdoor Air Hood —

Perform the

following procedure to install the outdoor-air hood:

1. Remove blank panel from re turn end of unit (hood section). Save the screws. See Fig. 15 for shipping location

of components.

2. Hood sides are fastened to sides of outdoor ai r opening.

Remove the hood sides and save the screws (3 each side).

20

RETURN AIR

SECTION

Fig. 15 — Outdoor-Air Hood Compartment

Shipping Location

Page 21

SEAL

STRIP

LOCATION

BOTTOM

HOOD

SECTION

TOP HOOD

SECTION

FILTER

RETAINER

FILTER

GUIDE

HOOD

SIDE

FILTER

ADD

SEAL

STRIP

ADD

SEAL

STRIP

INNER

FILTER

TRACK

FILTER

GUIDE

ADD

SEAL

STRIP

ADD

SEAL

STRIP

MANUAL

DAMPER

(IF EQUIPPED)

NOTE: Units with manual damper only use one filter.

Fig. 16 — Outdoor Air Hood Details

HOOD

SIDE

UNIT

BACK

PANEL

Fig. 17 — Outdoor Air Hood Assembled

MOVEABLE DAMPER

AIR FILTER POSITION

21

LOCKING SCREW

MOVEABLE DAMPER

Fig. 18 — Manual Damper Details

Page 22

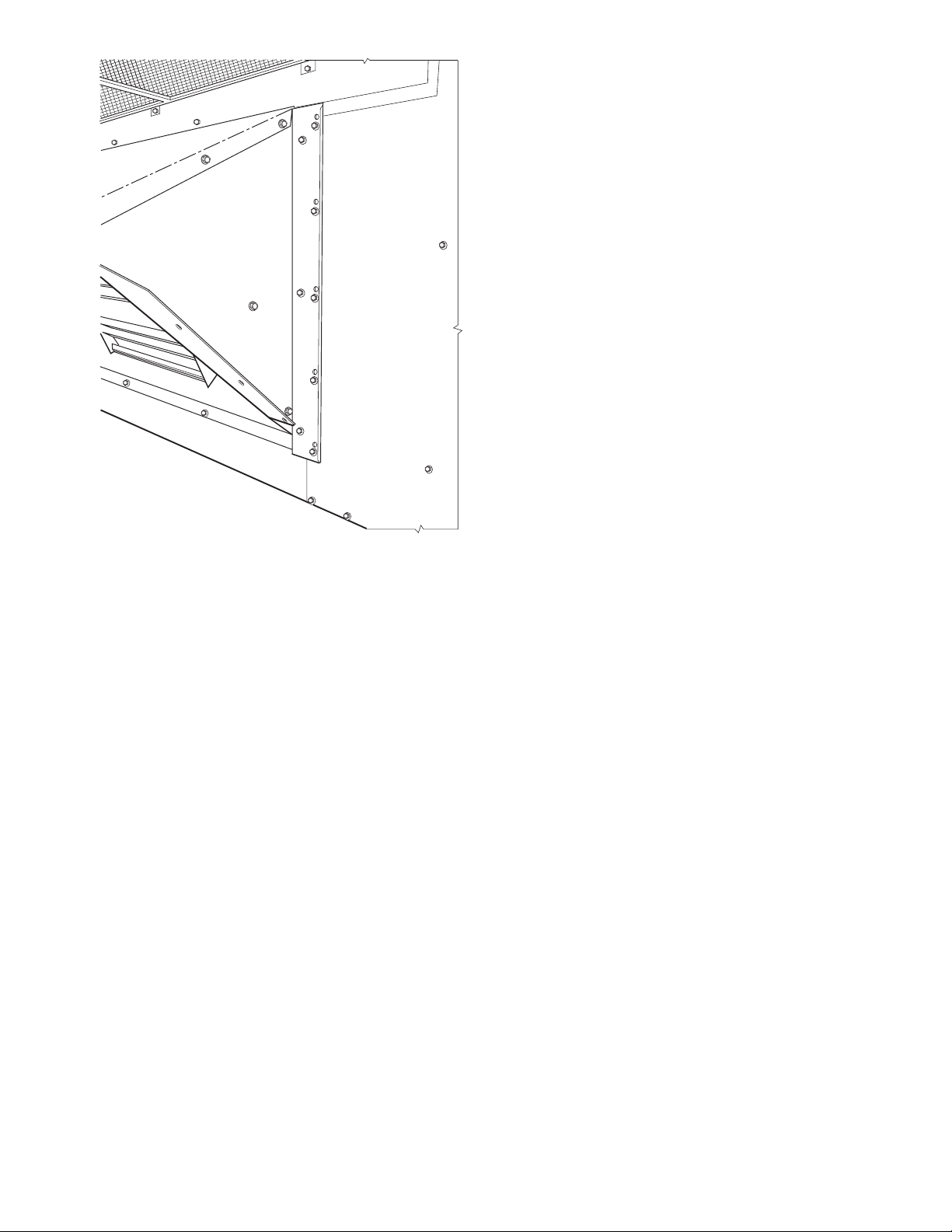

Step 9 — Position Optional Power Exhaust or

Barometric Relief Damper Hood —

power exhaust or barometric relief dampers are shipped

assembled and tilted back into the unit fo r shipping. B rackets and extra screws are shipped in shrink wrap around the

dampers.

1. Remove 9 screws holding each damper assembly in

place. See Fig. 19. Each damper assembly is secured with

3 screws on each side and 3 screws along the bottom.

Save screws.

Be careful when tilting blower assembly. Hoods and blowers are heavy and can cause injury if dropped.

2. Pivot the damper assembly outward until top edge of

damper assembly rests against inside wall of unit.

3. Secure each damper assembly to unit with 6 screws

across top (3 screws provided) and bottom (3 screws

from Step 1) of damper.

4. With screws saved from Step 1, install brackets on each

side of damper assembly . See Fig. 20.

5. Remove tape from damper blades.

Step 10 — Non-Fused Disconnect —

for the factory-installed non-fused disconnect is shipped inside

the unit to prevent the handle from damage during shipping.

Follow these steps to complete installation of the handle.

The optional

The handle

BE SURE POWER IS SHUT OFF TO THE UNIT FROM

THE BUILDING POWER SUPPLY.

1. Open the control box access door.

2. Remove the small cove r plate located on the unit corner

post near the control section.

3. Remove the inner control box cover. The handle and shaft

are located in a plastic bag at the bottom of the control

box.

4. Insert the square shaft into the disconnect with the pins

vertical. On the 100 amp disconnect the shaft is keyed

into the disconnect and can only be installed one way

with the pins vertical.

5. Insert the handle through the corner post and onto the

shaft with the handle positioned so that “OFF” is on top.

6. Rotate the handle to the “ON” position to lock the pins

into the handle.

7. From the inside of the corner post, attach the handle

mounting screws to the handle. Slide the shaft fully into

the handle and tighten the set screws(s) on the disconnect

to lock the shaft. Tighten the screws that attach the handle

to the corner post.

8. Rotate the handle back to the “OFF” p osit ion.

9. Replace all panels and doors .

10. Restore power to unit.

Fig. 19 — Power Exhaust or Barometric Relief Damper Mounting Details

22

Page 23

Step 11 — Install All Accessories —

the factory-installed options have been adjusted, install all

field-installed accessor ies. Refer to the accessory installation

instructions included with e ach accessory. Consult the Carrier

Price Pages for accessory package numbers for particular

applications. The available field-installed accessories for the

Centurion units are:

• economizer

• power exhaust

• barom e tric relief damper

• 14-in. roof curb

• 24-in. roof curb

• electric heaters

• enthalpy control

• differential enthalpy control

• plugged filter indicator

• carbon dioxide detector

• smoke detector

• filter status switch

• fan status switch

• condenser hail guard

• horizontal duct accessory

• thermostats

• tw o-position damper

After all of

Fig. 20 — Bracket and Hood Positioning

23

Page 24

Copyright 2003 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Ta b 1 b 6b

PC 111 Catalog No. 535-00092 Printed in U.S.A. Form 50HG-7SI Pg 24 11-03 Replaces: 50HG-3SI

Loading...

Loading...