Page 1

HFATUNG & COOLING

%isitx__ _.carrier.com

Installation, Start-Up and Service instructions

SingMe

50GL 7-14 kW (024-048)

Packaged 50 Hz, CE EMectric CooMing Units

with Puron® (R-410A) Refrigerant

NOTE: Read the entire instruction manual be%re starting the

installation.

TABLE OF CONTENTS

SAFETY < ONSIDERATIONS i

RULES FOR SAFE INSTALLATION AND OPERATION .... 1

RECEIVING AND INSTALLATION .......................................... 2

Check Equipment .................................. 2

Identif}" Unit ................................... 2

Inspect Shipment ................................ 2

Provide -Unit Support ............................... 2

Roof" Curb ...................................... 2

Slab Mount ..................................... 2

Ground Level ................................... 2

Field Fabricate Ductwork .......................... 2

Provide Clearances ................................... 2

Rig and Place Unit ................................... 4

Inspection ..................................... 5

Installation ....................................... 6

Connect Condensate Drain ........................... 6

Install Duct Connections ........................... 6

Configuring Units l'or Downflow

(Vertical) Discharge .............................. 6

Install Electrical ( onnection .......................... 8

High-Voltage Connections ........................ 8

Control Voltage Connections ..................... 10

Standard Connection .............................. i 0

Transi\_rmer Protection .......................... 11

PRE-START-[ P ................................... !2

START-UP .......................................... 12

Check for Reffigeration Leaks ....................... 12

Start [p Cooling Section and Make Adjusm_ent ........ 13

Checking Cooling Control Operation ................ 13

Checking and Adjusting Refrigerant Charge ........... 13

Indoor Airflow and Airflow Adjustments .............. I3

For 400"V Motors .............................. 13

Cooling Sequence of Operation .................... 14

MAINTENANCE ................................... 15

Air Filter ........................................ 18

Evaporator Blower and Motor .......................................... 18

(ondenser (oil_ Ewtporator (oil, and (ondensate Drain.1

( ondenser Fan ................................................................... 19

Electrical <ontrols and Wiring ......................................... i9

Refi'igerant Circuit ............................................................. 19

Evaporator Airflow ............................................................ i9

High Flow Valves .............................................................. 19

Phase Monitor ( ontrol ...................................................... i9

PL RONR; System Items .................................................... i9

TROUBLESHOOTING ............................................................... 21

START-UP < HE( KLIST ............................................................ 2 !

NOTE TO INSTALLER Before the installation, READ THESE

INSTRUCTIONS CAREFULLY AND COMPLETELY Also,

make sure the User's Manual and Replacement Guide are left with

the unit after installation.

SAFETY CONSIDERATIONS

Installation and seivicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified personnel should install, repair, or service

air-conditioning equipment.

Untrained personnel can perfbrm basic maintenance functions of

cleaning coils and filters. Al! other operations should be perf'ormed

by trained service personnel. When working on air-conditioning

equipment, observe precautions in the literature, tags, and labels

attached to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth fbr unbrazing operations. Have fire extinguisher

available fk}rall brazing operations. Consult a qualified installer or

service agency fk}r infommtion or assistance. The qualified in-

staller or agency must use only fitctory-authorized kits or acces-

sories when modifying this product.

Before perfbrming service or maintenance operations on

system, mm off power to unit Turn off accessory- heater

power switch, if applicable. EtectIical shock can cause

personal it!jury.

Puron (R-410A) systems operate at higher pressures than

standard R=22 systems. Do not use R-22 service equipment or

components or* Pro'on (R-410A) equipment. Ensure service

equipment is rated for Puron (R=410A).

RULES FOR SAFE INSTALLATION AND OPERATION

Recognize safety infbrmation. This is the safety-alert symbolS\ .

When yon see this symbol in instructions or manuals, be alert to

the potential for personal inju W

Understand the signal words DANGER.. WARNfNG, CAUTION,

and NOTE. These words are used with the safety-alert synghol.

DANGER identifies the most serious hazards which will result in

severe personal injnry or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

The power supply (volts, phase, and hertz) must correspond to that

specified on unit rating plate.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 101 Catalog No 005-00026 Printed in U.S.A Form 50GL-C2SI Pg 1 7-02 Replaces: 50GL-C1SI

Page 2

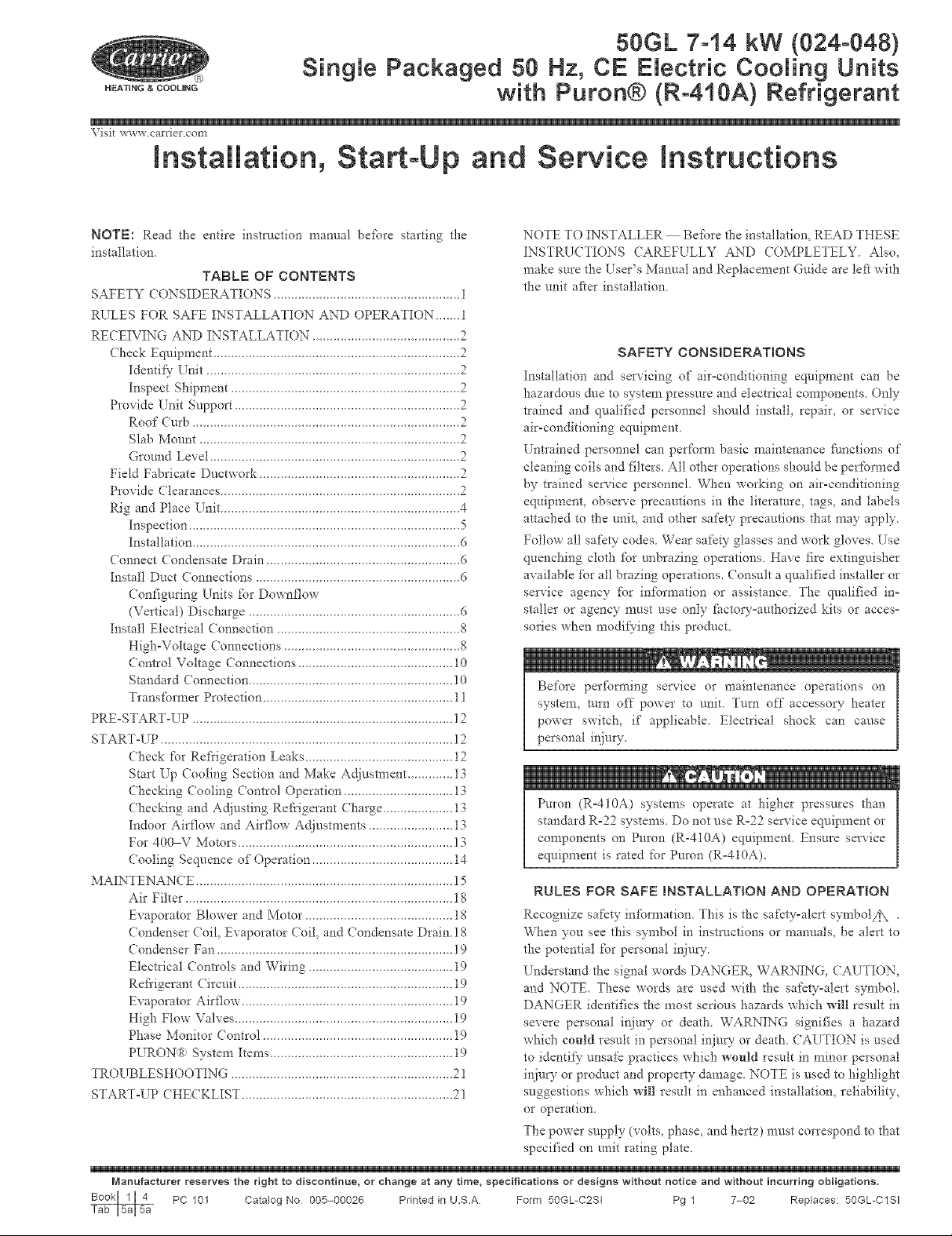

Fig. l--Model 50GL {50 Hz)

The electrical supply provided by the utility must be sufficient to

handle load imposed by this unit.

This installation must conform with local building codes and with

NE( (National Electrical Code) and NFPA 70, NFPA 54/ANSI

Z223.1 latest revision, and NFG( (National Fuel Gas Code). Re_:_r

to provincial and local plumbing or waste water codes and other

applicable local codes.

Approved for outdoor installation on wood flooring or on class A,

B or C roof covering materials.

These instructions cover n_inimum requirements and con_bt'm to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especia!ly those that may not have kept up with changing resideno

tial construction practices. We require these instrl/ctions as a

minimum fbr a safe installation.

The 50GL units are Nlly self-contained, and designed for outdoor

installation (see Fig. 1). See Figs. 2 and 3 t:br unit dimensions. All

unit sizes have discharge openings for both horizontal and down°

flow configurations, and are facto V shipped with all duct openings

covered. Units may be installed either on a rooflop, ground-level

cement slab, or directly on the ground if local codes permit. See

Fig. 4 ibr roof curb dimensions.

RECEBVING AND INSTALLATION

Step 1--Check Equipment

IDENTIFY UNIT

The unit model number and serial nungber are stamped on unit

identification plate Check this information against shipping papers

and job data

INSPECT SHIPMENT

Inspect lk_r shipping damage while unit is still on shipping pallet

If unit appears to be damaged or is torn loose tiom its anchorage,

have it examined by transportation inspectors before removal.

Forward claim papers directly to transportation company. Manuo

fhct*_rer is not responsible fbr any damage incurred in transit.

Check all items against shipping list. Immediately notify the

nearest ( mxier Air Conditioning once if any item is missing. To

prevent toss or damage, leave all parts in original packages until

installation.

C99064

Step 2--Provide Unit Support

ROOF (URB

Install accessory roof curb in accordance with inst_/ctions shipped

with curb. (See Fig. 4 for roof curb dimensions) Install insulation,

cant strips, roofing, and flashing Ductwork must be attached to

curb

INPORTANT: The gasketing of the unit to the roof curb is critical

for a watertight seal. Install gasketing material supplied with the

roof curb. Improperly applied gasketing can also result in air leaks

and poor unit performance. Curb should be level to within 1/4 inch

(6.4 ram), See Fig. 7. This is necessary _br unit drain to Nnction

properly. Refkr to accessow- roof cm'b installation instructions fbr

additional infbm_ation as required.

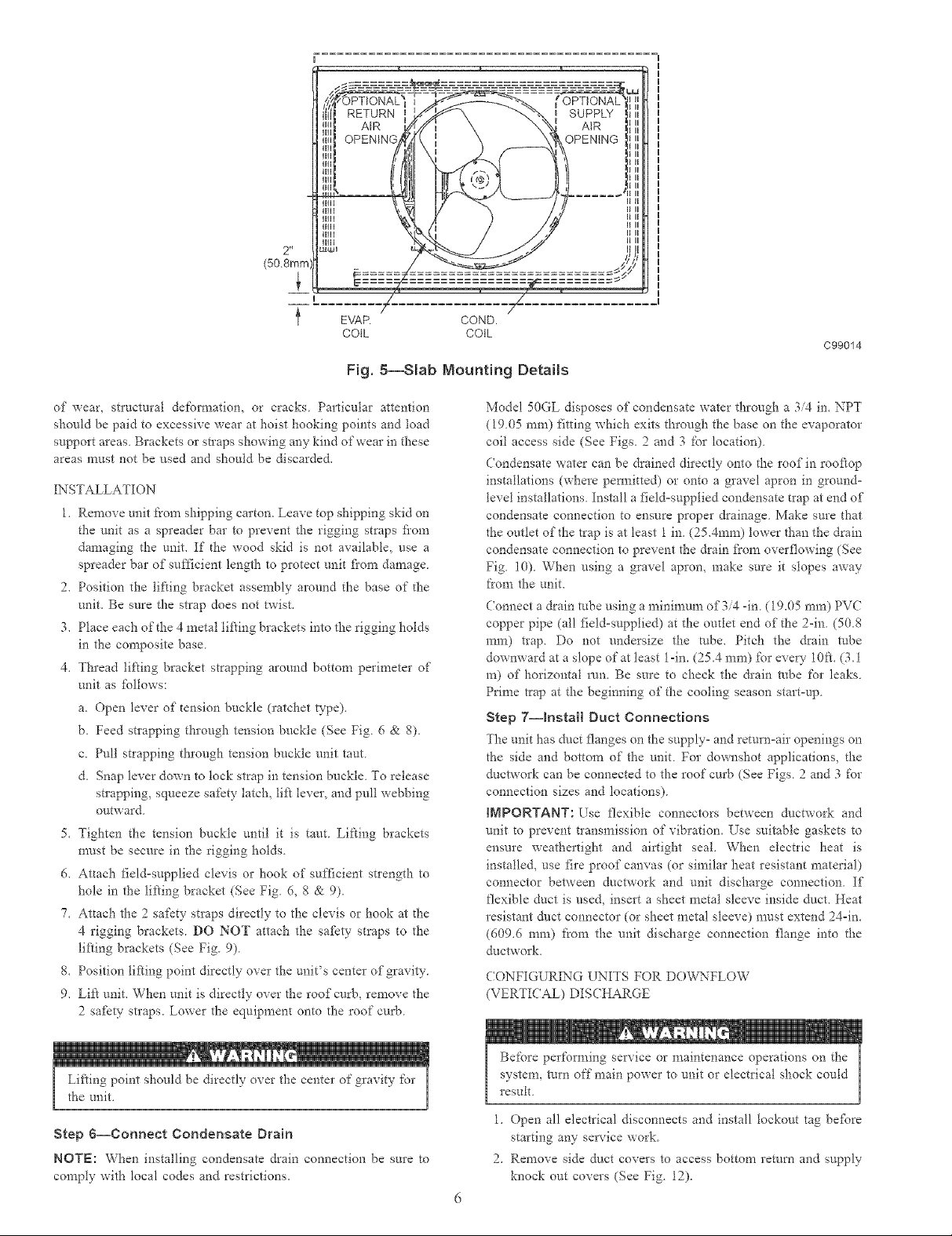

SLAB MOUNT

Place the unit on a solid, level concrete pad that is a nainimun_ of

4 in. (i01.6 ram) thick wit}* 2 in. (50.8 ram) above grade. The slab

should extend 2 in. (50.8 ram) on sides of the unit. Do not secure

the unit to the slab ea'cc,pt when required by local codes.

GROUND LEVEL

Iftocal codes permit, the unit can be placed directly on the ground.

Prepare a level gravel foundation _br proper drainage.

Step a--Field Fabricate Duetwork

Secure all ducts to roof curb and building structure on vertical

discharge units. Do nut connect dzlctwork to _fmt. For horizontal

applications, unit is provided with flanges on the horizontal

openings. All dtlctwork should be secured to the flanges. Insulate

and weatherproof all external ductwork, joints, and roof openings

with counter flashing and mastic in accordance with applicable

codes.

Ducts passing through an unconditioned space must be insulated

and covered with a vapor barrier. If a plenum return is used on a

vertical unit, the return should be ducted through the roof deck to

comply with applicable fire codes. A minin-mm clearance is not

required around dnctwork. (abinet return-air static shall not

exceed -25 in. wg.

Step 4--Provide Clearances

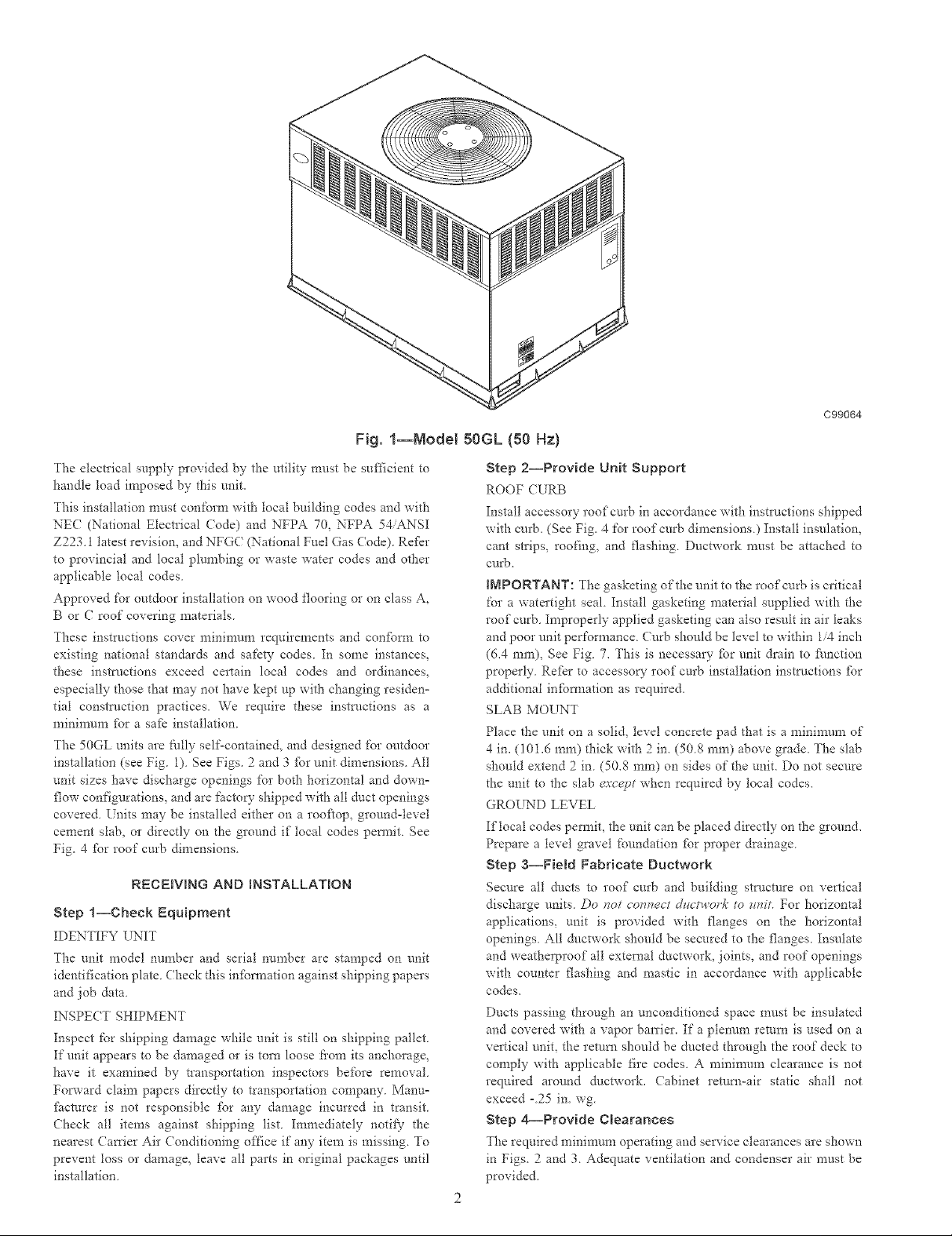

The required minimum opeiating and service clearances are shown

in Figs. 2 and 3. Adequate ventilation and condenser air must be

provided.

Page 3

[9 83] [21 6F] [9 g3_

REAR VmEW

[1600]

,W

REQ'D CLEARANCES FOR OPERATION AND SERVICING IN (MM)

EVAPORATOR COIL ACCESS SIDE ............. 36 1914)

POWER ENTRY SIDE (EXCEPT FOR NEC REQUIREMENTS) . 36 (914)

UNIT TOR ......................... 48 (1219)

SIDE OPPOSITE DUCTS ................... 36 1914)

DUCT PANEL ....................... 12 (304.8)*

*MINIMUM DISTANCES: IF UNIT IS PLACED LESS THAN 12 IN (3048 MM) FROM

VVALL SYSTEM THEN THE SYSTEM PERFORMANCE MAY BE COMPROMISED

LEGEND

CG - CENTER OF GRAVITY

COND - CONDENSER

EVAP - EVAPORATOR

NEC - NATIONAL ELECTRICAL CODE

REQ'D - REQUIRED

NOTE: DIMENSIONS ARE IN IN (MM)

i98 5 - I!93 9

{3i44] [4700]

i 6!os I _ ' '

i [82 45] _.............................

" i I I

,_ol#1;_277 / i,2.

x 22 0 OP I ¢OMPRCSSOR 8_OWER 6AS SECTiOB

8310

[_272]

LEFT SiDE ViEW FRONT ViEW

UNIT

50GL024

50GL030

50GL036

ELECTRICAL CHARACTERISTICS

_ 326 5 & ELECFRICALACC[SSPANEL

[i2 85]

_724

12 85] 12263

[48 28]

UNIT WEIGNT

Ib kg

400-3-50

400-3-50

400-3-50

264 119.2

296 134.3

302 137.0

Fig. 2-- 50GL024-036 Unit Dimensions

REQ'D CLEARANCES TO COMBUSTIBLE MATL IN (MM)

TOP OF UNIT ....................... 14 (355.6)

DUCT SIDE OF UNIT ..................... 2 (50.8)

SIDE OPPOSITE DUCTS .................. 14 (355.6)

BOTTOM OF UNIT ..................... 0.50 (12.7)

ELECTRIC HEAT PANEL .................. 36 (914.4)

NEC REQ'D CLEARANCES. IN.(MM)

BETWEEN UNITS, POWER ENTRY SIDE .......... 42 (1066.8)

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE . 36 (914)

UNIT AND BLOCK OF CONCRETE WALLS AND OTHER

GROUNDED SURFACES, CONTROL BOX SIDE ....... 42 (1066.8)

44 5 [/ 75] CiA K 0

UNIT N_=iGNT

IN. {_,1M}

_A_

37.02 (940.3)

39.02 (991.1)

35.02 (889.5)

POWER E_TRf \

22 2 [0 88] biA

CONTROL E_TRY

4562

[!t£6] 3472

185 (469.9) 14.5 (368.3) 160 (406.4)

195 (495.3) 15.5 (393.7) 176 (447.0)

195 (495.3) 15.3 (387.4) 165 (419.1)

\

[13 67]

5 o

[0 20]

[48i]

RIGHT SiDE ViEW

CENTER OF GRAVITY

IN.(MM)

X Y Z

C00064

Do not restrict condenser airflow. An air restriction at either

the outdoor-air inlet or the J_imdischarge can be detrimental to

compressor tiJ:_.

The condenser _bn draws air through the condenser coil and

discharges it through the top fhn grill, Be sure that the Lm

discharge does not reeJrculate to the condenser coil, Do not locate

the unit in either a corner or under an overhead obstruction The

mininmm clearance under a partial overhang (such as a normal

house overhang) is 36-in, (9144 ram) above the unit top, The

maximum horizontal extension of a partial overhang must not

exceed 48 in, (12192 ram)

Page 4

i i

f!22 I DUCT

58s] _ [ OPENI G 02_1N6

i sUOPL_ 2WN

i I

[16 0i]

402 6

[16 0 ]

L I_ i' [

[4 63] [

' Sw _ ; , j

88 3 35 0 "_3 7 3 _ 371 2

[3 48] [13 83] [[3 67] [13 88]

REARViEW

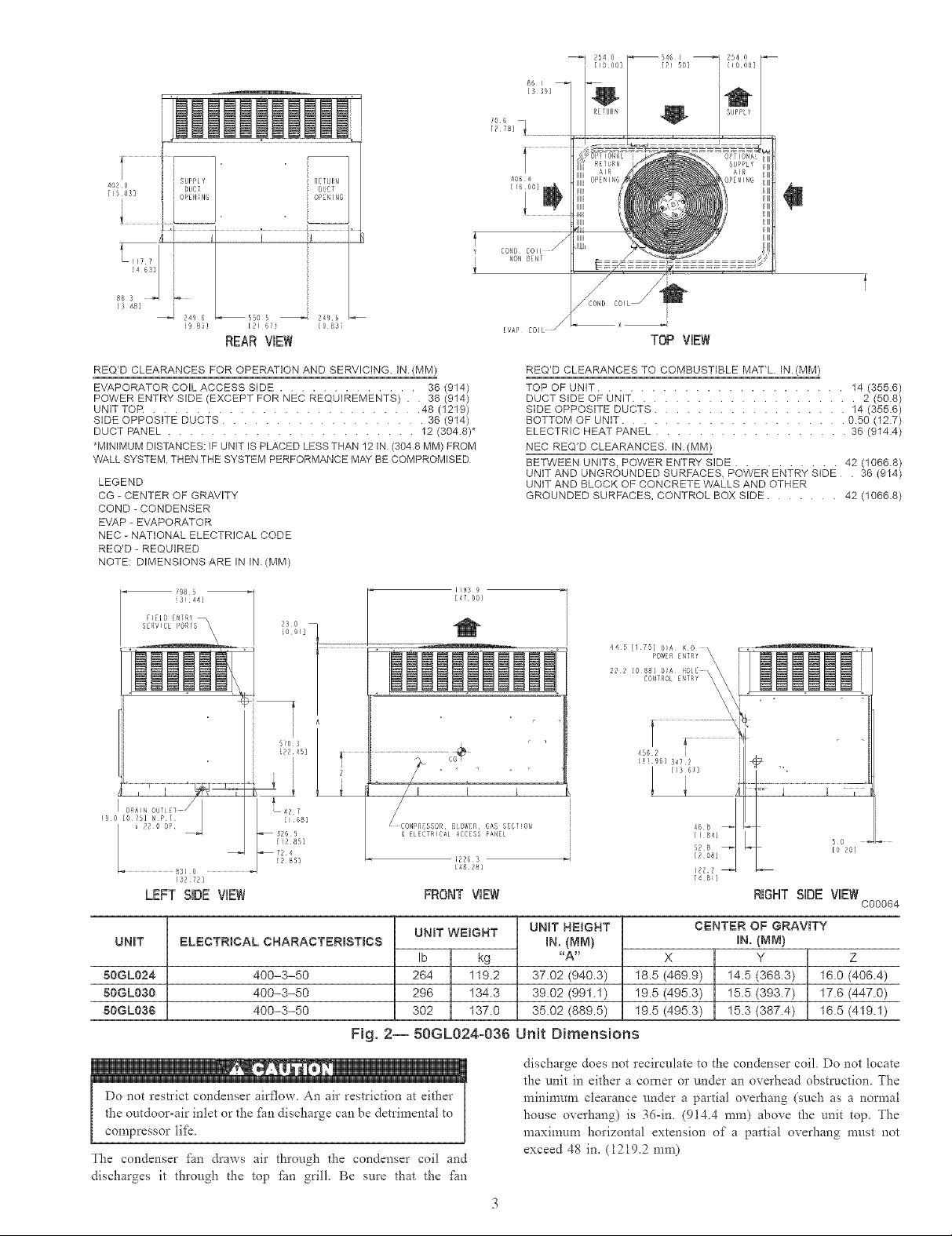

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

EVAR COIL ACCESS SIDE .............................................................. 36.00 [914 O]

POWER ENTRY SIDE ...................................................................... 36.00 [914 0]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP ....................................................................................... 4800 [1219 0]

SIDE OPPOSITE DUCTS ................................................................ 36.00 [914 0]

DUCT PANEL ................................................................................... 12.00 [304 8] _

_MINIMUM DISTANCES: IF UNiT IS PLACED LESS THAN 1200 [304.8] FROM

WALL SYSTEM, THEN SYSTEM PERFORMANCE MAYBE COMPROMISE.

10906

{42 94]

in [mm]

C01L

TOP ViEW

REQUIRED CLEARANCE TO COMBUSTIBLE MATE

TOP OF UNIT ................................................................................... 1400 [355 6]

DUCT SIDE OF UNIT ......................................................................... 200 [50.8]

SIDE OPPOSITE DUCTS ................................................................ 1400 [355 6]

BOTTOM OF UNIT ............................................................................. 050 [12.7]

ELECTRIC HEAT PANEL ................................................................. 3600 [91441

NEC. REQUIRED CLEARANCES,

BETWEEN UNITS, POWER ENTRY SIDE .................................... 42.00 [1066 8]

UNIT AND UNGROUNDED SURFACES. POWER ENTRY SIDE ..3600 [914 0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE ......................... 42.00 [10668 l

d 5 [I 75] DIA K0

POISEI l_2f_

22 2 88 O A 0 / /

CONTRO] EN!RY \ _,_

in. [mml

in [mml

1123 i

[4422]

LEFT SiDE VmEW

UNIT

BL£CTR[CAL CHARACTERISTICS

FRONT ViEW RIOHT SiDE VIEW

UNIT WEIGNT

tb kg

50GL048

400-3-50

350 158.8

Fig. 3-- 50GL048 Unit Dimensions

Do not place the unit where water_ ice, or snow flora an overhang

or roof will damage or flood the mail Do not install the unit on

carpeting_ tile, or other combustible materials,

Step 5--Rig and Place Unit

Rigging and handling of this equipment can be hazardous _br maay

reasons due to the installation location (roofq, elevated stlucmres,

etc,)

Only trained, qualified crane operators and ground support staff

should handle and install this equipment

C00065

UNIT N£1GHT

iN. {_M}

"A"

38.98 (990.2)

19.5 (495.3) 17.6 (447.6) 18.0 (457.2)

CENTER OF GRAVITY

IN. (MM)

X Y Z

When workiag with this equipment, observe precautions in d-_e

literature, on tags, stickers, and labels attached to the equipment,

and aay other safety precautions that might apply,

Follow all applicable safkty codes, Wear safety shoes and work

gloves

Page 5

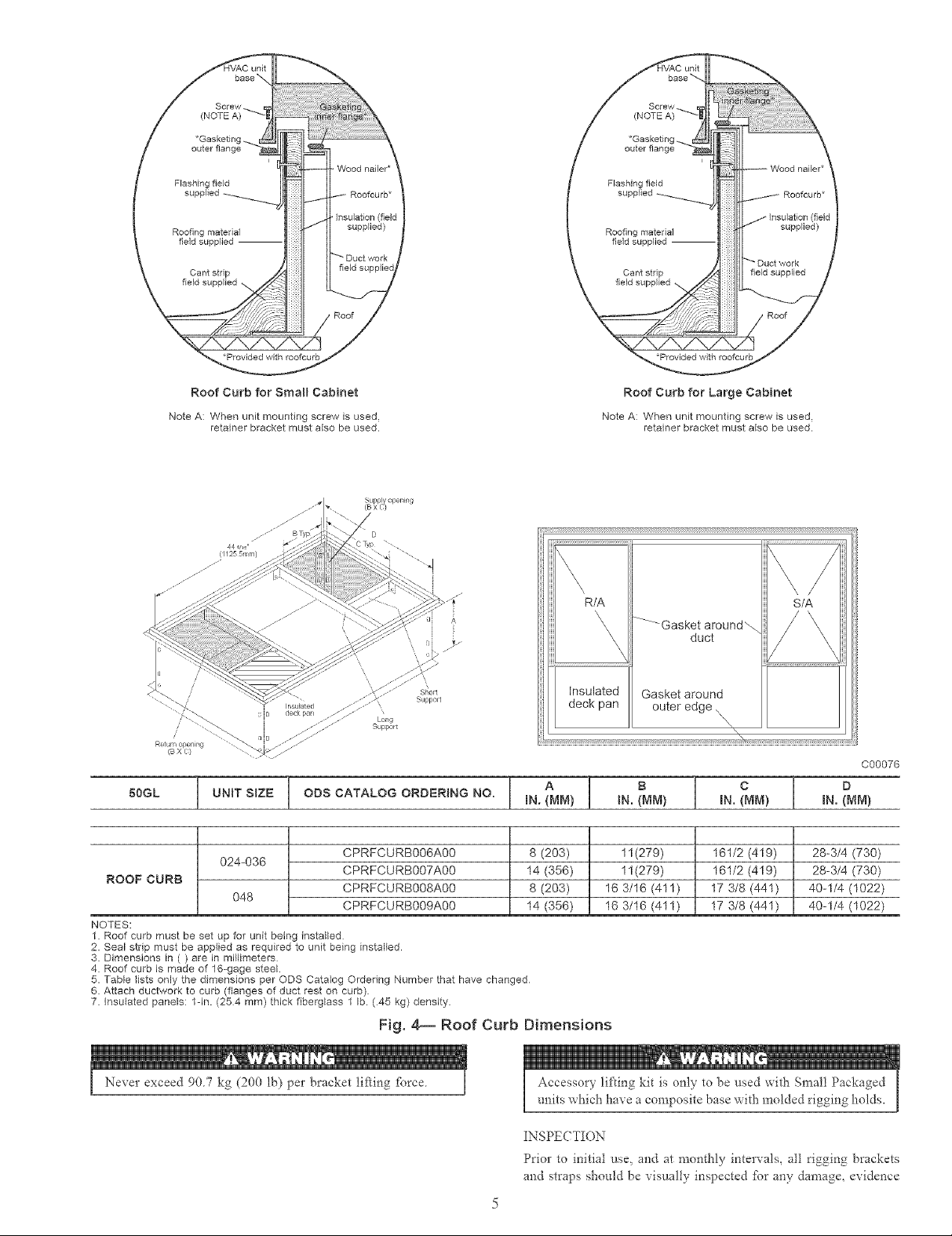

Roof Curb for Small Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

Roof Curb for Large Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

R/A

-'-_- Gasket around_

\

\

Suppolt

Long

Support

iB X C}

50GL UNIT SIZE ODS CATALOG ORDERING NO. IN. {MM) IN. {MM) IN. {MM) IN. {MM)

ROOF CURB

NOTES:

1. Roof curb must be set up for unit being installed

2. Seal strip must be applied as required to unit being installed

3. Dimensions in ( ) are in millimeters

4. Roof curb is made of 16-gage steel.

5. Table lists only the dimensions per ODS Catalog Ordering Number that have changed

6. Attach ductwork to curb (flanges of duct rest on curb)

7. Insulated panels: lqn. (254 mm) thick fiberglass 1 lb. (45 kg) density.

i I ° i ° i °

024-036

048

CPRFCURB006A00 8 (203) 11(279) 161/2 (419) 28-3/4 (730)

CPRFCURB007A00 14 (356) 11(279) 161/2 (419) 28-3/4 (730)

CPRFCURB008A00 8 (203) 16 3/16 (411) 17 3/8 (441) 40-1/4 (1022)

CPRFCURB009A00 14 (356) 16 3/16 (411) 17 3/8 (441) 40-1/4 (1022)

insulated

deck pan

Gasket around

duct

outer edge \

/\

\,

Fig. 4===Roof Curb Dimensions

S/A

C00076

INSPECTION

Prior to initial use, and at monthly intervals, all rigging brackets

and straps should be xisualty inspected for any damage, evidence

Page 6

2"

(50 8ran

EVAP. COND.

COIL COIL

Fig. 5--Slab Mounting Details

C99014

of wear, structural det'ormation, or cracks Particular attention

should be paid to excessive wear at hoist hooking points and load

support areas Brackets or straps showing any kind of wear in these

areas must not be used and should be discarded.

INSTALLATION

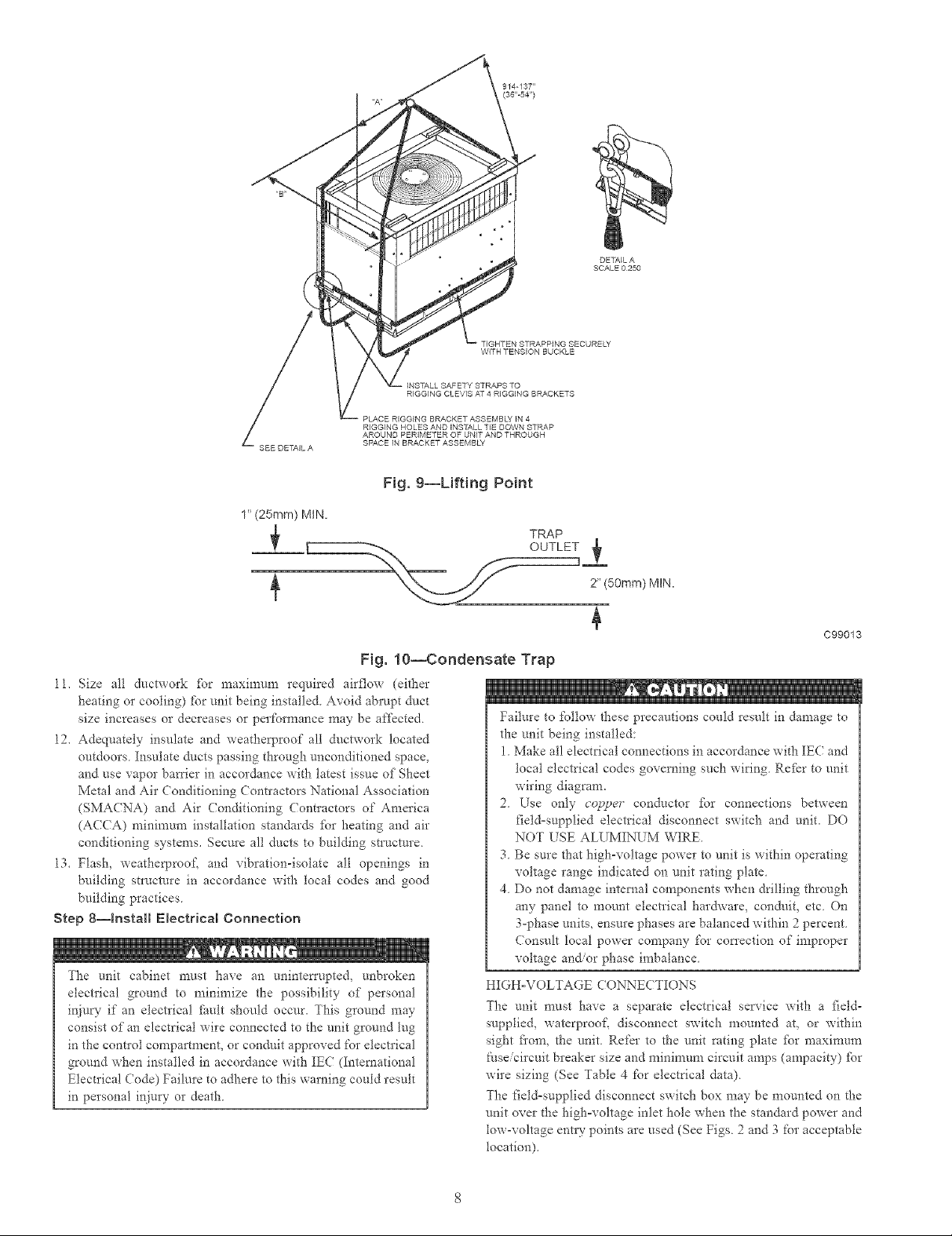

l. Remove unit t'rom shipping carton. Leave top shipping skid or*

the unit as a spreader bar to prevent the rigging straps fiom

damaging the unit. If the wood skid is not available, use a

spreader bar of sufficient length to protect unit flora damage

2. Position the lifting bracket assembly around the base of the

unit. Be sure the strap does not twist.

3. Place each of the 4 metal lifting brackets into the rigging holds

in the composite base

4. Thread lifting bracket strapping around bottom peiimetei of

unit as follows:

a. Open lever of tension buckle (ratchet type).

b. Feed strapping through tension buckle (See Fig 6 & 8).

c. Pull strapping through tension buckle unit taut

d. Snap lever down to tock strap in tension buckle To release

strapping, squeeze safety tatch, lift teveI, and pull webbing

outward

5. Tighten the tension buckte until it is taut Lifting brackets

n-rest be secure in the rigging holds

6. Attach field=supplied clevis or hook of sufficient strength to

hole in the lifting bracket (See Fig. 6, 8 & 9).

7. Attach the 2 safety straps directly to the clevis or hook at the

4 rigging brackets. DO NOT attach the safety straps to the

lifting brackets (See Fig. 9).

8. Position lifting point directly over the unit's center of gravity.

9. Lift unit. When unit is directly over the roof curb, remove the

2 safety straps. Lower the equipment onto the roof curb.

Model 50GL disposes of condensate water through a 3/4 in. NPT

(1905 ram) fitting which exits through the base on the evaporator

coil access side (See Figs. 2 and 3 for location)

Condensate water can be drained directty onto the roof in rooftop

installations (where pem_itted) or onto a gravel apron in ground-

level installations. Install a field=supplied condensate trap at end of

condensate connection to ensure proper drainage. Make sure that

the outlet of the trap is at least 1 in. (25.4mm) lower than the drain

condensate connection to prevent the &ain f}'om overflowing (See

Fig. i0). When using a gravel apron, make sure it slopes away

/}'ore the unit.

Connect a drain robe using a mininmna of 3/4 -in. ( 19.05 ram) PVC

copper pipe (all field-supplied) at the outlet end of the 2-in. (50.8

ram) trap. Do not undersize the tube. Pitch the drain robe

downward at a slope of at least 1-in. (25.4 ram) for every 1Oft. (3.1

m) of horizontal 1am. Be sure to check the &ain robe for leaks.

Prime trap at the beginning of the cooling season start=up.

Step 7--Install Duct Connections

The unit has duct flanges on the supply- and return=air openings on

the side and bottom of the unit For downshot applications, the

ductwork can be connected to the root" curb (See Figs 2 and 3 for

connection sizes and locations)

IMPORTANT: l_se flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weathertight and airtight seal. When electric heat is

installed, use fire proof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If

flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24=in.

(60%6 ram) from the unit discharge connection flange into the

&ctwork.

CONFIGUR1)..:G UNITS FOR DOW_TLOW

(VERTICAL) DISCHARGE

the unit,

Step 6--Connect Condensate Drain

NOTE: When installing condensate drain connection be sure to

comply with local codes and restrictions.

Before performing service or maintenance operations on the

system, mrn off main power to unit or electrical shock could

result

1. Open all electrical disconnects and install lockout tag be%re

starting any service work.

2. Remove side duct covers to access bottom remm and supply

knock out covers (See Fig. 12).

Page 7

DUCTS

'\

\\

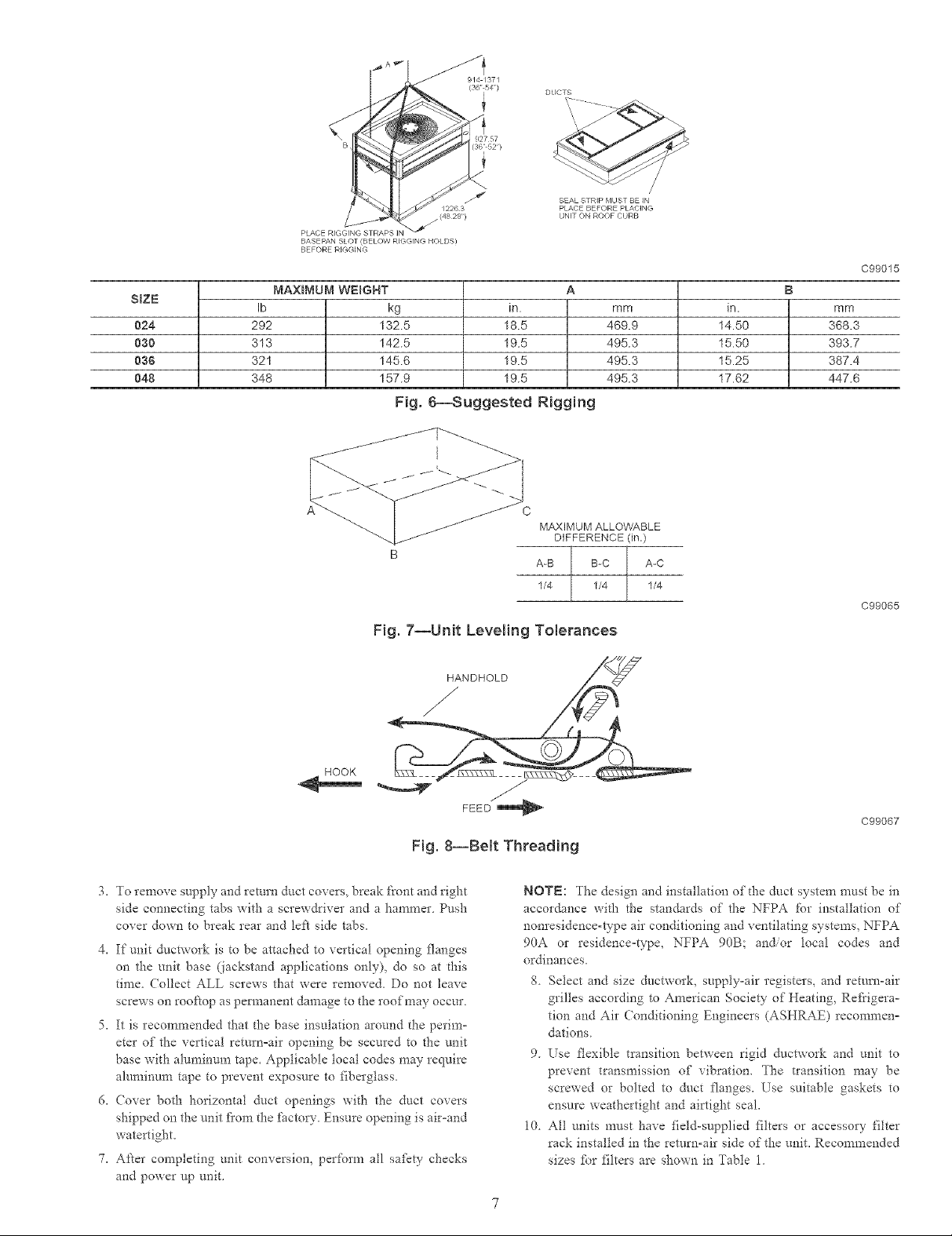

SRZE

B

PLACE RIGGING STRAPS IN

BASEPAN SLOT (BELOW R]/ GING HOLDS)

BEFORE RIG/'qNG

MAXBMUM WEIGHT A B

Ib kg in. mm in. mm

_f/A /;',2,;T:,_7_

/(4828')

PLACE BEFORE PLACING

UNIT ON ROOF CURB

024 292 132.5 18.5 469.9 14.50 368.3

030 313 142.5 19.5 495.3 15.50 393.7

036 321 145.6 19.5 495.3 15.25 387.4

048 348 157.9 19.5 495.3 17.62 447.6

Fig. 6--Suggested Rigging

3

MAXIMUM ALLOWABLE

DIFFERENCE 0n.)

A-B B-C A-C

1/4 1/4 1/4

Fig. 7--Unit Leveling Tolerances

C99015

C99065

HANDHOLD Z<_

HOOK

Fig. 8--BeR Threading

3. To remove supply and return duct covers, break front and right

side connecting tabs with a scre_drixer and a hammer Push

cover do_n to break rear and ld:'t side tabs.

4. If unit ductwork is to be attached to vertical opening flanges

on the unit base 0ackstand applications only), do so at _his

time, Collect ALL screws that were removed, Do not leave

screws on rooftop as permanent damage to the roof may occur

5, It is recommended that the base insulation around the perim°

eter of" the vertical return°air opening be secm'ed to the unit

base with alumintml tape. Applicable local codes may require

aluminum tape to prevent exposure to fiberglass.

6. (;over both horizontal duct openings with the duct covers

shipped on the unit fi'om the _i_ctory. Ensure opening is air-and

watertight.

7. After completing unit conversion, perform all safety checks

and power up unit.

FEED

C99067

NOTE: The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

nonresidence-type air conditioning and ventilating systems, NFPA

90A or residence=type, NFPA 90B; and/or local codes and

ordinances.

8 Select and size ductwork, supply-air registers, and return-air

grilles according to American Society of Heating, Ref?igera-

tion and Air Conditioning Engineers (ASHRAE) reeommen=

dations

9. Use flexible transition between rigid ductwork and unit to

prevent transmission of vibration. The transition may be

screwed or bolted to duct flanges. Use suitable gaskets to

ensure weathertight and airtight seal.

10. All units must have field-supplied filters or accessory filter

rack installed in the return-air side of the unit. Recommended

sizes _br filters are shown in Table 1.

Page 8

B4STALL SAFETY STRAPS TO

RIGGB4G CLEVIS AT 4 RIGGING BRACKETS

PLACE RIGGING BRACKET ASSEMBLV IN 4

RIGGING HOLES AND INSTALL TIE DOWN STRAP

AROUND PERIMETER OF UNIT AND THROUGH

SEE DETAIL A

SPACE B4 BRACKET ASSEMBL'V

Fig. 9--Lifting Point

1" (25mm) MtN.

Fig. 10--Condensate Trap

11. Size all ductwork %r maxinmm required airflow (either

heating or cooling) fbr unit being installed. Avoid abrupt duct

size increases or decreases or perfom_ance may be affected

12. Adequately insulate and weatherproof all ductwork located

outdoors Insulate ducts passing through unconditioned space,

and use vapor barrier in accordance with latest issue of Sheet

Metal and Air Conditioning Contractors National Association

(SMACNA) and Air (oaditioning Colmactors of America

(ACCA) minimum installation standards fbr heating and air

conditioning systems. Secure all ducts to building structure

13. Flash, weatherproof, and vibration-isolate all openings in

building structure in accordance with local codes and good

building practices

Step 8--Install Electrical Connection

The unit cabinet must have an uaintetTupted, unbroken

electrical ground to minimize the possibility of personal

injury if an electrical _5ult should occur. This ground may

consist of an electrical wire connected to the unit ground tug

in the contlol compartment, or conduit approved for electrical

ground when installed in accordance with IEC (International

Electrical Code) Failure to adhere to this warning could result

in personal injury or death

DETAIL A

SCALE 0250

TIGHTEN STRAPPING SECURELY

WITH TENSION BUCKLE

TRAP

OUTLET

2" (50ram) MIN.

C99013

Failure to %llow these precautions could result in damage to

the unit being installed:

1 Make all electrical connections in accordance with IEC and

local electrical codes governing such wiring Refkr to unit

wiring diagram.

2 Use only cop!_er conductor _br connections between

fieldosupplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within operating

voltage range indicated on unit rating plate.

4. Do not damage internal components when drilling through

any panel to mount electrical hardv,'are, con&fit, etc. On

3-phase units, ensure phases are balanced within 2 percent.

Consult local power company for cot_'ection of improper

voltage aa_or phase imbalance.

HIGHoVOLTAGE CONNECTIONS

The unit must have a separate electrical service with a field-

supplied, waterproof, disconnect switch mounted at, or within

sight fi'om, the unit Refer to the unit rating plate fbr maximum

£aseicircuit breaker size and mininmm circuit amps (ampacity) _br

wire sizing (See Table 4 t'or electrical data)

The field=supplied disconnect switch box may be mounted on the

unit over the highovoltage inlet hole when the standard power and

tow-voltage entry points are used (See Figs 2 and 3 for acceptable

location).

Page 9

Table 1--PhysicN Data-UNt 50GL (50 Hz)-English

UNiT SIZE 024 030 036 048

NOMINAL CAPACITY {ton) 2 2-1/2 3 4

OPERATING WEIGHT (Ib) 264 296 302 350

COMPRESSOR Scroll

REFRIGERANT (R-410A)

Quantity (tb) 4.25 6 7.25 9.75

REFRIGERANT METERING (in) .057 .057 .065 .073

CONDENSER COiL

Rowe...Fins/in.

Face Area (sq, ft.)

CONDENSER FAN

NominN Cfm

Diameter (in.) 1/4._.900 1/4....900 1/4....900 1/3...1340

Motor Bp (Rpm}

EVAPORATOR COIL

Rowe...Finstin.

Face Area (sq. ft.)

EVAPORATOR BLOWER

NominN Airflow (Cfm) 10x10 10x10 10x10 1 lx10

Size (in.) 1/4....1075 1/2....1300 1/2...1300 1...1230

Motor (hp)

RETURN-A_R FILTERS (in.}* 2Ox2O 20x20 20x24 24x30

throwaway

* Requiredfilter sizes shown are based on rated cooling airflow or heating airflow velocity of 300ft/min for throwaway type or 450 tL/minfor high-capacity type. Air filter

pressure drop for non-standard filters must not exceed 0.08 in wg

1._17 1._17 2._17 2...17

10.9 12.7 9.1 12.3

2350 2350 2350 3300

22 22 22 22

3...15 3_.15 3...15 4...15

3.70 3.70 3.70 4.70

800 1000 1200 1600

Table 2--PhysicN Data--Unit 50GL {50 Hz)-SI

UNIT SIZE 024 030 036 048

NOMINAL CAPACITY (kW) 7.0 8.8 10.6 14.1

OPERATING WEIGHT (kg) 119.7 134.3 137.0 158.8

COMPRESSOR Scroll

REFRIGERANT {Ro41OA)

Quantity (kg) 1.93 2.72 3.29 4.42

REFRIGERANT 1.45 1.45 1.65 1.85

METERBNG DEVICE

CONDENSER CORL

Rows_,Finsim.

Face Area (eq. m)

CONDENSER FAN

Nominal L!e

Diameter (ram) .187...15 .187._15 .187...15 .249...22

Motor Hp (r/s)

EVAPORATOR COIL

Rows...Finslm

Face Area (sq. m)

EVAPORATOR BLOWER

Nominal Airflow {Lie) 0.254x0.254 0.254x0.254 0.254x0.254 0.254x0.279

Size {m) 186...17.9 373...21.7 373...21.9 746...20.5

Motor Hp (r/s)

RETURN-AIR FILTERS (ram.)* 508x508 508x508 508x610 610x762

Throwaway

* Required filter sizes shown are based on rated cooling airflow or heating airflow velocRy of 91.5 m/mh3, for throwaway type or 137 m cu/min, for high-capacity type

Air filter pressure drop for non-standard fi{ters must not exceed 203 mm. wg

See unit wiring label and Fig. 13 for ref)rence when making high

voltage connections Proceed as follows to complete the high-

voltage connections to the unit.

Three phase units:

1. Run the high-voltage (L!, L2, L3) and ground leads into the

control box.

2. (onnect ground lead to chassis ground connection.

1...669 1...669 2._669 2...669

1.0 1.2 0.8 1.1

1109 1109 1109 1557

558.8 558.8 558.8 558.8

2...590 3._590 3._590 3._590

0.34 0.34 0.34 0.44

378 472 566 755

3. (onnect field L1 GoBlack wire on connection L1 of the high

voltage temainal block.

4 Connect field wire L2 GoBlack wire on connection L2 of the

high voltage terminal block.

5. ( onnect field wire L3 to Black wire on connection L3 of high

voltage tem_inal block.

6. If Red light blinks on dae phase monitor control board (See

Fig. 17), switch 2 legs on the high voltage terminal block..

U U

Page 10

Airflow

CFM

L/s

TaNe 3--Minimum Airflow for Safe Electr{c Heater

Operation

SIZE

024 030 036

800 I000 1200

378 472 567

s o

o

/ /

SUPPLY RETURN

DUCT DUCT

OPENING OPENING

Fig. 11--Supply and Return Duct Opening

O48

1600

756

1

C99011

DUCT COVERS REMOVED

Fig. 12--VerticN Duct Cover Removed

(ONTROL VOLTAGE (ONNECTIONS

NOTE: Do not use any type of power-stealing thermostat Unit

control problems may result.

Use no. lS American Wire Gage (AWG) color-coded, insulated

(35 (minimum) wires to make the control voltage connections

between the them_ostat and the unit. If the thermostat is located

more than 100 R. fi'om the unit (as measured along the control

voltage wires), use no. 16 AWG color-coded, insulated (35 C

minimum) wires.

C99012

STANDARD CONNECTION

Remove knockout hole located in the electric heat panel adjacent

to the control access panel (See Figs. 2 and 3) Remove the rubber

grommet fi'om the installer's packet (included with unit) and install

grommet in the knockout opening. Provide a drip loop before

running wire through panel.

Rtm the tow-voltage leads flora the thermostat, through the inlet

hole, and into unit towovoltage splice box.

10

Page 11

HIGH VOLTAGE |

p-

POWER LEADS d o-

(SEE UNIT WIRING|

LABEL)

GND

CONTROLBOX

LOW-VO LTAG E

POWER LEADS--

(SEE UNIT

WIRING LABEL)

SPLICE BOX

LEGEND

Field Control-Voltage Wiring

Field High-Voltage Wiring

NOTE: Use blue wire for 3-phase units only.

Fig. 13--High= and Control=Voltage Connections

LEGEND

FLA -- Futt Load Amps

LRA -- Locked Rotor Amps

MCA -- Minimum Circuit Amps

MOCP -- Maximum Overcurrent Protection

RLA -- Rated Load Amps

CKTBKR -- Circuit Breaker

NOTES:

1. In compliance with IEC(International Electrical Code) requirements

for multimotor and combination toad equipment (refer to tEC

Articles 430 and 440), the overcurrent protective device for the

unit shalt be Power Supply fuse.

2. Minimum wire size is based on 60 C copper wire. If other than

60 C wire is used, or if length exceeds wire length in table,

determine size from tEC.

3. Unbalanced 3-Phase Suppty Voltage

Never operate a motor where a phase imbalance in supply volt-

age is greater than 2%. Use the following formula to determine

the percentage of voltage imbalance.

% Voltage imbalance

= 100 x max vottage deviation from average voltage

average voltage

m . m_O

_ I_POWER

4Z:::U o

.... 72- _jsuPPL¥

FIELD-SUPPLIED

FUSED DISCONNECT

YELffL "_ @ THERMOSTAT

G--RN--(G2_ @ _(TYPICAL)

REDgR) __ @

B_RN_C£0- @

EXAMPLE: Supply voltage is 400-3-50.

A B c AB = 393 v

Determine maximum deviation from average voltage.

(AB) 397- 393=4v

(BC) 403- 397 = 6 v

(AC) 397- 396 = 1 v

Maximum deviation is 6 v.

Determine percent of 'voltage imbalance.

% Vottage Imbalance = 100 x --

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

more than 2%, contact your local electdc utility company

I IMPORTANT: If the supply voltage phase imbalance is

immediately.

J

AC = 396 v

Average Voltage = 393 + 403 + 396

BC = 403 v

= 397

6

397

= 1.5%

3

1192

3

C99010

Fig. 14--Electrical Legend

Locate iS-gage wires leaving control box. These low-voltage

connection leads can be identified by the colors red, green, yellow,

brown, and white. (See Fig. 13.) Ensure the leads are tong enough

to be routed into the low-voltage splice box (located below right

side of control box). Route leads through hole in bottom of control

box and make low-voltage connections as shown in Fig. 13. Secure

all cut wires, so that they do not interfere with operation of unit.

TRANSFORMER PROTECTION

The tmn@)_'7_er is of the energy-limiting type. It is set to

withstand a 30-second overload or shorted secondary condition.

C01054

11

Page 12

UNIT SOGL

SIZE

024 400-3-50

030 400-3-50

03$ 400-3-50

048 400-3-50

(See Eegend fo{Iowing Electrical Data charts)

V-PH°HZ

VOLTAGE

RANGE

Min Max

380 420

380 420

380 420

380 420

Table 4_ElectricN Data--50GL {50Hz)

COMPRESSOR OFM

RLA LRA FLA

4.5 32.0 0.8

5.2 35.0 0.8

6.5 46.0 0.8

6.7 50.0 1.3

IFN ELECTRBC HEAT

FLA NominalKw FLA

1.1 6.5 9.4

8.7 12.6

1.7

2.0

3.9 8.7 12.6

6.5 9.4

8.7 12.6

13.0 18.8

6.5 9.4

8# 12.6

13.0 18.8

6.5 9.4

13.0 18.8

17.4 25.1

POWER SUPPLY DISCONNECT SBZE

MCA FUSE OR CKT. BKR MOCP

7.5 10

19.2 20 -

23.2 25

9.0 10

20.7 20

24.7 25

32.5 35

10.9 15

22.7 25

26.6 30

34.4 35

13.6 15

25.3 30

29.3 30 -

37.0 40

45.0 45

FLA LRA

7 35

18 44

22 48

9 39

20 49

23 52

30 59

11 51

21 61

25 64

32 70

14 58

24 67

28 71

35 77

43 83

PRE-START-UP

Failure to obsela'e the %llowing warnings could result in

serious personal injury or death:

1 Follow recognized saJ[_ty practices and wear protective

goggles when checking or servicing refrigerant system

2 Do not operate compressor or provide any electric power to

unit unless compressor tem_inal cover is in place and

secured.

3. Do not remove compressor terminal cover until all electri=

ca! sources are disconnected and lockout tags are installed.

4. Relieve and recover all refl'igerant fiom both high- and

low-pressure sides of system befbre touching or disturbing

anything inside terminal box if refl'igerant leak is suspected

around compressor temainals.

5. Never attempt to repair soldered connection while refi'ig=

erant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refi'igerant under pressure. To remove a

component, wear protective goggles and proceed as fol=

lOWS:

a. Shut off electrical power to unit and install lockout tag.

b, Relieve and reclaim all refrigerant fi'om system using

both high° and tow°pressure ports.

c. Cut component connecting tubing with robing cutter and

remove component fi'om unit.

d. Carefldly unsweat remaining tubing stubs when neces°

sary. Oil can ignite when exposed to torch flame.

Proceed as %llows to inspect and prepare the unit %r initial

star:up:

1. Remove access panel.

2. Read and follow instrnctions on all WARNING, CAUTION,

and INFORMATION labels attached to, or shipped with, unit.

3. Make the following inspections:

a. [nspect _br shipping and handling damages such as broken

lines, loose parts, disconnected wires, etc.

b. k_spect for oil at all refi'igerant tubing connections and on

unit base Detecting oil generally indicates a refrigerant

leak. Leak test all refrigerant tubing connections using

electronic leak detector, halide torch, or liquid-soap solu-

tion. If a re['rigerant leak is detected, see (heck _br

Refrigerant Leaks section under Start-Up.

c [nspect all field- and factory-wiring connections Be sure

that connections are completed and tight

d. [nspect coil fins If damaged during shipping and handling,

careflflly straighten fins with a fin comb

Veri£}_ the following conditions:

a Make sure that condenser-fan blade is correctly positioned

in fan orifice Ensure that distance fi'om _m hub to motor is

set to 1/8" (3 175rnm). Adjust if necessary (see Fig. 15)

b. Make sure that air filter(s) is in place.

c Make sure that condensate &sin trap is filled with water to

ensure proper drainage

d. Make sure that all tools and miscellaneous loose parts have

been removed.

START-UP

CHECK FOR REFRIGERATION LEAKS

Proceed as follows to locate and repair a refrigerant leak and to

charge the unit:

1. Locate leak and make sure that refi'igerant system pressure has

been relieved and reclaimed fiom both high- and low-pressure

ports.

2. Repair leak fbllowing accepted practices.

NOTE: Replace filter &ier with factory authorized replacement

whenever d-_e system has been opened fbr repair.

3. (harge unit with R-410A refi'igerant, using a volumetric°

charging cylinder or accurate scale. R@r to zmit rating pZate

/br reqzm'ed cha_ge.

12

Page 13

1/8" (3.175mm) MAX BETWEEN MOTOR SHAFT

MOTOR AND FAN HUB

Fig. 15--Fan Blade Clearance

C99009

STAR7 UP (OOLING SECTION AND MAKE ADJUSTMENT

Complete d_e required procedures given in the Pro-Start=Up

section before starting the unit. Do not jumper any safety

devices when operating the unit Do not operate the compres=

sot when the outdoor temperature is below 55°F/12.8c_(

(unless accesso_- low-ambient kit is installed). Do not rapid=

cycle the compressor. Allow 5 minutes between "on" cycles

to prevent compressor damage.

(HE(KING (OOLING CONTROL OPERATION

Start and check the unit _br proper cooling control operation as

follows:

1. Place room them_ostat SYSTEM switch in OFF position

Observe that blower motor starts when FAN switch is placed

in ON position and shuts down when FAN switch is placed in

AUTO position,

2, Place SYSTEM switch in (OOL position and FAN switch in

AUTO position Set cooling control below room temperature,

Observe that compressor, condenser _n, and evaporator

blower motors start. Observe that cooling cycle shuts down

when control setting is satisfied. The evaporator _hn will

continue to 1am for 30 seconds.

3. When using an auto=changeover room them_ostat, place both

SYSTEM and FAN switches in AUTO positions Obsela'e that

unit operates in heating mode when temperatnre contlol is set

to "call for heating" (above room temperature) and operates in

cooling mode when temperatnre control is set to %all for

cooling" (below room temperature)

INPORTANT: Three=phase, scroll compressor units are

direction-oriented. These units must be checked to ensure proper

compressor 3=phase power lead orientation. If not correct the phase

monitor (See Fig. 17) will not allow power to pass through the

components. Any two of the 3=phase power leads to the unit must

be reversed to correct rotation

CHECKING AND ADJ_ STING REFRIGERANT CHARGE

The refrigerant system is fully charged with R=410A refiigerant,

tested, and factow-sealed.

NOTE: Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having d'*e proper R=410A

charge. The charging label and the tables shown refer to system

temperatures and pressures

INPORTANT: When evaluating the re_iigerant charge, an indi=

cared adjustment to the specified _hcto_" charge must always be

very minimal. If a substantial adjustment is indicated, an abnormal

condition exists somewhere in the cooling system, such as insuf-

ficient airflow across either coil or both coils

Re fi'igerant charge

The amount of reJi'igerant charge is listed on the unit nameplate.

Re_r to the Refiigeration Service Techniques Manual, Refriger-

ants section.

Unit panels must be in place when unit is operating during

charging procedures.

No charge

Use standard evacuating techniques. After evacuating system,

weigh in the specified amount of refiigerant (refer to system data

plate).

Low charge cooling

Measure ontdoor ambient temperature using Cooling Charging

Tables. Vary refligerant until the conditions of the tables are met.

Note that charging tables are different from type normally used.

Tables are based on charging the units to con'ect superheat _br the

various operating conditions. Accurate pressure gauge and tem-

perature sensing devices are required. Connect the pressure gauge

to the service port on the suction line. Mount the temperatore

sensing device on the suction line and insulate it so that the

outdoor ambient does not affect the reading. Indoor air CFM (L/s)

must be within the normal operating range of the unit.

INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS

For cooling operation, the recommended airflow is 350 to 450

cfm for each 12,000 Btuh of rated cooling capacity (165 to

212 Lis _br each 35 kW of rated cooling capacity).

Table 6 shows cooling airflows at various external static pressures.

Refer to these tables to detem_ine the airflow for the system being

installed.

NOTE: Be sure that all supply= and return-air grilles are open,

free from obstructions, and adiusted properly.

Disconnect electrical power to d-_eunit and install lockont mg

bel:bre changing blower speed. ElectIical shock can cause

personal ir!im'y or death.

Airflow can be changed by changing the lead connections of the

blower motor

All 50GL units are _tctory wired for low speed and may need to be

wired _br medium or high speed in the field

FOR 400 V MOTORS

The motor leads are color coded as _bllows:

To change the speed of the indoor _im motor (IFM), remove fan

motor speed lead fi'om the indoor fan relay (R) and replace with

the lead _br the desired blower motor speed. The motor speed lead

is attached to terminal BM For all speeds, yellow must be

13

Page 14

MAXIMUM WIRE

SIZE 6 AWG. TBI

FIELD

POWERSUPPLY

BL

HEAT SCHEMATIC

USED WITH HEATERS

ACCESSORY

ELECT.HEATI I

OPTION ONLY.

SIZE 2 AWG,

I (BLK) @ 4 (BLK)

3 (BLK) 5 (WHT)

2 (BLK]__ I

I

]

7 {BLK)

6 {BLK)

8 (BLK)

o

. I

-- FMcAPi OR YEL

0TL L BR

3, GRNYEL,z'8(GRNYEL,2

SCHEMATIC

400 3 50

SEE NOTE#2

w2

COMM_

UNIT COMPONENT ARRANGEMENT

OUTDOOR FAN

SECTION

COMPRESSOR INDOOR FAN

SECTION SECTION

COMP

TIT2

50GSO48&060

T3

cAPL_L_

2[]YI

3[]Y2

4_Wl

5@w2

6@G

7@¢

8_ X

O

CONTROLBOXAREA

ELECTIHEA _C

(BLK) HPSIBLK)(BLUI LPS (BLUI

30 (BLK)_ •

HRI & 2 (IO NW)_ I

HRI,2 & 3 (15 KW)J

34(BRN)

HRI, 2, 3, & 4 (20 KW)/

LEGEND

FIELD SPLICE

o TERMINAL (MARKED)

0 TERMINAL {UNMARRED)

o SPLICE

o SPLICE {MARKED)

FACTORY WIRING

FIELD CONTROL WIRING

FIELD POWERWIRING

ACCESSORY OR OPTIONAL

WIRING

TO INDICATE COMMON

POTENTIAL ONLY:

NOT TO REPRESENT

WIRING

R

/EQUIP

GND

24V POWER ENTRY

NOTES:

IIF ANY OF THE ORIGINAL WIRES FURNISHED ARE REPLACED,

IT MUST BE REPLACED WITH TYPE 90 DEGREE C WIRE OR

IT'S EQUIVALENT

R.SEE PRICE PAGES FOR THERMOSTAT AND SUBBASES

3USE 75 DEGREE COPPER CONDUCTORS FOR FIELD INSTALLATION.

4FOR HIGH SPEED IFM,DISCONNECT RED

WIRE FROM IFR3 AND CONNECT BLK WIRE FROM IFM

FOR MEDIUM SP_ED DISCONNECT RED WIRE

FROM IFR;3 AND C6NNECT BLU WIRE FROM IFM

, 36(BRN)

23

ACCESSORY ELECTRIC HEA

HRI (5 KW)

C CONTACTOR

CAP CAPACITOR

CB CIRCUIT BREAKER

COMP COMPRESSOR MOTOR

EQUIP EQUIPMENT

GND GROUND

HPS HIGH PRESSURE SWITCH

HR HEATER RELAY

R INDOOR FAN RELAY

IFM INDOOR FAN MOTOR

LPS LOW PRESSURE SWITCH

OFM OUTDOOR FAN MOTOR

PRM PHASE ROTATION MONITOR

QT QUADRUPLE TERMINAL

TC THERMOSTAT COOLING

TH THERMOSTAT HEATING

TRAN TRANSFORMER

TBI TERMINAL BLOCK POWERLEADS

TB2 TERMINAL BLOCK GROUND LEADS

54

55 (BRN)

R

M

R

V

AN

C

Fig. 16--Wiring Diagram-400-3-50

connected to the jumper wire See Table 9 %r 2 and 3 speed motor

leads.IRws_late remER_ed lend end to mold cutwmct with elTa,ssi,s

parLM.

COOLING SEQUENCE OF OPERATION

With the room them_ostat SYSTEM switch in the COOL position

and the FAN switch in the AUTO position, the cooling sequence

of operation is as follows:

C00062

When the room temperature rises to a point that is slightly above

the cooling control setting of the them_ostat, the thermostat

completes the circuit between thermostat terminal R to temainals Y

and G. These completed circuits through the thermostat connect

contactor coil (C) (through unit wire Y) and blower relay coil (BR)

(through unit wire G) across the 24ov seconda V of transfom?er

(T];-U_N'),

14

Page 15

SUPERHEAT

TEMP

(°C)

0

1

2

3

4

6

7

8

9

10

tl

12

t3

14

t5

16

t7

18

t9

20

21

22

424

1.7

2.8

3.9

5.0

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

16.7

17.2

18.3

19.4

20.6

21.7

22.8

23.9

Table 5--Required Suction=Line Temperature (Metric)

SUCTION PRESSURE AT SERVICE PORT (KPA)

443

2.8

3.9

5.0

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

17.8

18.3

19.4

20.6

21.7

22.8

23.9

25.0

463

3.9

5.0

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

18.9

19.4

20.6

21.7

22.8

23.9

25.0

26.1

483

5.0

6.1

7.2

8.3

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.0

20.6

21.7

22.8

23.9

25.0

26.1

27.2

503 524 546

6.1 7.2 8.3

7.2 8.3 9.4

8.3 9.4 10.6

9.4 10.6 11.7

10.6 11.7 12.8

11.7 12.8 13.9

12.8 13.9 15.0

13.9 15.0 16.1

15.0 16.1 17.2

16.1 17.2 18.3

17.2 18.3 19.4

18.3 19.4 20.6

19.4 20.6 21.7

20.6 21.7 22.8

21.1 22.2 23.3

21.7 22.8 23.9

22.8 23.9 25.0

23.9 25.0 26.1

25.0 26.1 27.2

26.1 27.2 28.3

27.2 28.3 29.4

28.3 29.4 30.6

568

9.4

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.6

21.7

22.8

23.9

24.4

25.0

26.1

27.2

28.3

29.4

30.6

31.7

591

10.6

11.7

12.8

13.9

15.0

16.1

17.2

18.3

19.4

20.6

21.7

22.8

23.9

25.0

25.6

26.1

27.2

28.3

29.4

30.6

31.7

32.8

Tab{e 6--Superheat Charging Table (Metric)

OUTDOOR EVAPORATOR ENTERING ABRTEMPERATURE (°C WB)

TEMP

(°C) 10 11 12 13 14 15 16 17 18 19 20 21 22

t3 5.0 6.7 7.8 9.4 11.1 11.9 12.8 14.4 16.1 17.8 19.4 20.6 22.2

1G 3.9 5.6 6.7 8.3 10.0 10.8 11.7 13.3 15.0 16.7 18.3 20.0 21.1

t8 - 3.3 5.6 7.2 8.9 9.7 10.6 11.7 13.3 15.0 16.7 18.3 20.0

21 - - 3.9 5.6 7.2 8.1 8.9 10.6 11.7 13.3 15.0 16.7 18.3

24 - - - 3.3 5.0 5.8 6.7 8.3 10.0 11.7 7.8 15.6 17.2

21 .... 2.8 3.6 4.4 6.7 8.3 10.0 11.7 13.9 15.6

29 ...... 4.4 6.1 8.3 10.6 12.2 14.4

32 ...... 2.8 5.0 7.2 8.9 11.1 13.3

38 ....... 3.3 5.6 7.8 10.0 12.2

38 ....... 4.4 6.7 8.3 11.1

41 ....... 2.8 5.0 7.2 9.4

43 ........ 3.3 6.1 8.3

4G ......... 4.4 7.8

Where a dash (-) appears, do not attempt to charge system under these conditions, or refrigerant slugging may occur. Charge must be weighed in.

NOTE: Superheat °C Jsat low-side service port

The normally open contacts of energized contactor (C) close and

complete the circuit through compressor motor ((-OMP) to con=

denser (outdoor) fan motor (OFM). Both motors start instantly.

The set of normally open contacts of energized relay TDR close

and complete the circuit through evaporator blower (indoor) tim

motor (IFM).

NOTE: Once the compressor has started and then has stopped, it

should not be started again until 5 minutes have elapsed.

The cooling cycle remains "on" until the room temperature &ops

to a point that is slightly below the cooling control setting of the

room thermostat. At this point, the thernrostat "breaks" the circuit

between them_ostat terminal R to terminals Y and G. These open

circuits deenergize contactor coil C and relay coil TDR. The

condenser and compressor motors stop. After a 30=second delay,

the blower motor stops. The unit is in a "standby" condition,

waiting for the next "call for cooling" fi'om the room them_ostat.

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic maintenance

must be performed on this equipment. This cooling unit should be

inspected at least once each year by a qualified service person. To

troubleshoot heating or cooling of units, refer to tables at the back

of the book.

NOTE TO EQUIPMENT O\\'24ER: (onsult your local dealer

about the availability of a maintenance contlact.

MAINTENANCE

15

23

23.3

22.2

21.1

20.0

18.9

17.2

16.7

15.0

13.9

12.8

12.2

11.1

10.0

24

25.0

23.9

22.8

21.7

20.6

19.4

18.3

17.2

16.1

15.0

14.4

13.9

12.8

Page 16

Table 7--Required Suction=Line Temperature (English)

SUPERHEAT SUCTION PRESSURE AT SERVICE PORT (PSBG)

TEMP

(°F) 6115 64.2 67.1 70.0 73.0 76.0 79.2 82.4 85.7

0 35 37 39 41 43 45 47 49 51

2 37 39 41 43 45 47 49 51 53

4 39 41 43 45 47 49 51 53 55

6 41 43 45 47 49 51 53 55 57

8 43 45 47 49 51 53 55 57 59

10 45 47 49 51 53 55 57 59 61

t2 47 49 51 53 55 57 59 61 63

14 49 51 53 55 57 59 61 63 65

t6 51 53 55 57 59 61 63 65 67

18 53 55 57 59 61 63 65 67 69

20 55 57 59 61 63 65 67 69 71

22 57 59 61 63 65 67 69 71 73

24 59 61 63 65 67 69 71 73 75

26 61 63 65 67 69 71 73 75 77

28 63 65 67 69 71 73 75 77 79

30 65 67 69 71 73 75 77 79 81

32 67 69 71 73 75 77 79 81 83

34 69 71 73 75 77 79 81 83 85

36 71 73 75 77 79 81 83 85 87

38 73 75 77 79 81 83 85 87 89

40 75 77 79 81 83 85 87 89 91

Table 8--Superheat Charging Table (English)

OUTDOOR EVAPORATOR ENTERING ABR TEMPERATURE (°FWB)

TEMP

(OF} 50 52 54 56 58 60 62 64 66 68 70 72 74 76

58 9 12 14 17 20 23 26 29 32 35 37 40 42 45

60 7 10 12 15 18 21 24 27 30 33 35 38 40 43

68 -- 6 10 13 16 19 21 24 27 30 33 36 38 41

70 -- -- 7 10 13 16 19 21 24 27 30 33 36 39

78 -- -- -- 6 9 12 15 18 21 24 28 31 34 37

80 .... 5 8 12 15 18 21 25 28 31 35

85 ...... 8 11 15 19 22 26 30 33

90 ...... 5 9 13 16 20 24 27 31

98 ....... 6 10 14 18 22 25 29

100 ........ 8 12 15 20 23 27

108 ........ 5 9 13 17 22 26

110 ......... 6 11 15 20 25

118 .......... 8 14 18 23

Where a dash (-) appears, do not attempt to charge system under these conditions, or refrigerant

NOTE: Superheat °F is at low-side service port

slugging may occur Charge must be weighed in.

Table 9--400oV Motors

Motor Lead Color Codes

3oSPEED 2-SPEED

black = high black = high

white = jumper yellow = jumper

blue = medium

red = low red = low

16

Page 17

Table10--WetCoit Air Delivery

Horizontal and Downflow Discharge*

Unit 50GL (50 Hz) 024=048 (English)

400 VOLT

Unit

50GL024

50GL030

50GL03G

50GL048

* Air delivery values are based on operating voltage of 400-v, wet coil, without filter or electric heater. Deduct filter and electric heater pressure drops to obtain static

pressure available for ducting.

NOTES: 1. Do not operate the unit at a cooling aid_ow that is less than 350 cfm for each 12,000 Btuh (165 L/s for each 35 kW) of rated cooling capacity. Evaporator

2. Dashes indicate portions of table that are beyond the blower motor capacity or are not recommended.

Motor Speed 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Low

High Cfm - - - 963 833 758 676 - -

Low

High Cfm ..... 1223 1142 1075 1058

Low

High Cfm - - - 1467 1398 1321 1237 1165 1137

Low

High Cfm - 1693 1670 1601 1521 1447 1378 1294 -

coil frosting may occur at airflows below this point

Watts 303 305 303 300 ....

Cfm 969 879 785 687 ....

Watts - - - 435 428 428 422 - -

Watts - 814 853 889 921 954 1002 - -

Cfm - 1189 1115 1041 971 903 833 - -

Watts ..... 700 683 688 755

Watts 552 540 529 523 514 480 - - -

Cfm 1296 1237 1167 1097 1029 952 - - -

Watts - - - 782 765 736 721 780 1002

Watts 692 686 678 664 652 664 736 - -

Cfm 1571 1509 1444 1370 1295 1240 1237 - -

Watts - 1112 930 856 834 825 811 793 -

External Static Pressure (in. wg)

Table 11--Wet Colt Air Delivery

Horizontam and Downflow Discharge*

Unit 50GL (50 Hz) 024=048 (Si)

UNIT

50GL024

80GL030

SOGL036

SOGL048

* Air delivery values are based on operating voltage of 400-v, wet coil, without filter or electric heater. Deduct filter and electric heater pressure drops to obtain static

pressure available for ducting.

1. Dashes indicate portions of table that are beyond the blower motor capacity or are not recommended.

MOTOR SPEED

Low

High

Low

High

Low

High

Low

High

Watts 303 305 303 300 ......

Watts - - 435 428 428 422 - - -

Watts - 814 853 889 92I 954 1002 ....

Watts .... 700 683 688 755

Watts 552 540 529 523 514 480 .....

Watts - - 782 765 736 721 780 1002

Watts 692 686 678 664 652 664 736 ....

Watts - - 1112 930 856 834 825 811 793 - -

O 25 50 75 100 125 150 175 200 225 250

L/s 458 415 371 324 ......

L/S - - 455 393 358 319 - - -

L/s - 561 526 491 458 426 393 ....

L/S .... 577 539 508 499

L/s 612 584 551 518 486 449 .....

L/s - - 693 660 624 584 550 536

L/s 741 712 681 647 611 585 584 ....

L/s - - 799 788 756 718 683 650 611 - -

EXTERNAL STATIC PRESSURE (PA.}

17

Page 18

The ability to properly per%tin maintenance on this equip-

ment requires certain expertise, mechanical skills_ tools, and

equipment If you do not possess these, do not attempt to

peribnn any maintenance on this equipment other than those

procedures recommended in tl_e User's Manual. FAILURE

TO HEED THIS WARNING COULD RESULT IN SERI-

OUS PERSONAL INJURY AND POSSIBLE DAMAGE TO

THIS EQUIPMENT.

Failure to %llow these warnings could result in serious

personal injury:

1. Turn off electrical power to the unit and install lockout tag

before performing any maintenance or sela'ice on the unit.

2. Use extreme caution when removing panels and parts. As

with any mechanical equipment, personal injury can result

fi'om sharp edges, etc.

3. Never place anything combustible either on, or in contact

with, the unit.

Errors made when reconnecting wires may cause improper

and dangerous operation. Label all wires prior to disconnec-

tion when selwicing.

The mininmm maintenance requirements %r this equipment are as

follows:

1. Inspect air filter(s) each month. (?lean or replace when

necessa_

2. Each cooling season, inspect indoor coil, drain, and conden-

sate drain line for cleanliness. (?lean when necessa V,

3. Inspect blower motor and wheel for cleanliness and check

lubrication each heating and cooling season. (lean when

necessa_.

4. Check electrical connections fbr tightness and controls for

proper operation each heating and cooling season. Service

when necessa_'.

AIR FILTER

IMPORTANT: Never operate the unit without a suitable air filter

in the return-air duct system. Always replace the filter with the

same dimensional size and type as originally installed (See Table

1 ibr recommended filter sizes).

Inspect air filter(s) at least once each month and replace

(throwaway-type) or clean (cleanable-type) at least twice during

each heating and cooling season or whenever the filter(s) becomes

clogged with dust and lint.

EVAPORATOR BLOWER AND MOTOR

NOTE: All motors are prelubricated Do not attempt to lubricate

these motors.

For longer life, operating economy, and continuing efficiency,

clean accumulated dirt and grease fiom the blower wheel and

motor annually.

1. Remove arid disassemble blower assembly as %llows:

a. Remove unit access panel.

b. Disconnect motor leads fi'om indoor ihn relay (R).

c. On all units, remove blower assembly flora unit. Remove

screws securing blower to blower partition and slide

assembly out. Be carefld not to tear insulation in blower

compartment.

& Ensure proper reassembly by marking blower wheel and

motor in relation to blower housing before disassembly.

e. Loosen setscrew(s) that secures wheel to motor shaft,

remove screws that secure motor mount brackets to hous-

ing, and slide motor and motor mount out of housing.

2. Remove and clean blower wheel as ibllows:

a. Ensure proper reassembly by marking wheel orientation.

b. Lift wheel fiom housing. When handling and/or cleaning

blower wheel, be sure not to disturb balance weights (clips)

on blower wheel vanes.

c. Remove caked-on dirt from wheel and housing with a

bmsL Remove lint an_or dirt accumulations from wheel

and housing with vacuum cleaner, using soft brush attach-

ment. Remove grease and oil with mild solvent.

& Reassemble wheel into housing.

e. Reassemble motor into housing. Be sure setscrews are

tightened on motor shaR flats and not on round part of

shaft.

i_ Reinstall unit access panel.

3. Restore electrical power to unit. Start unit and check for

proper blower rotation and motor speeds during heating and

cooling cycles.

CONDENSER COIL, EVAPORATOR COIL_ AND (ONDEN-

SATE DRAIN

Inspect the condenser coil, evaporator coil, and condensate drain at

least once each year.

The coils are easily cleaned when @; therefore, inspect and clean

the coils either beibre or after each cooling season. Remove all

obstructions, including weeds and shr_/bs, that interfere with the

airflow through the condenser coil.

Straighten bent fins with a fin comb. If coated with dirt or tint,

clean the coils with a vacuum cleaner, using the soft brl/sh

attachment Be careful not to bend the fins. If coated with oil or

grease, clean the coils with a mild detergent-and-water solution.

Rinse coils with clear water, using a garden hose. Be carefld not to

splash water on motors, insulation, wiring, or air filter(s). For best

results, spray condenser coil fins from inside to outside the unit.

On units with an outer and inner condenser coil, be sure to clean

between the coils. Be sure to flush all dirt and debris from the unit

base.

Inspect the drain and condensate &sin line when inspecting the

coils. (?lean the &sin and condensate &sin line by removing all

foreign matter from the &sin. Flush the &sin arid drain robe with

clear water. Do not splash water on the insulation, motor, wiring,

or air filter(s). If the &sin tube is restricted, clear it with a

"plumbers snake" or similar probe device. Ensure that the auxiliary

drain port above the &sin robe is also clear.

Disconnect and tag electrical power to the unit before

cleaning the blower motor and wheel Failure to adhere to this

warning could cause personal injury or death

To clean the blower motor and wheel:

18

Page 19

CONDENSER FAN

Keep the condenser fan free fi'orn all obstructions to ensure

proper cooling operation. Never place articles on top of the

unit Damage to unit may result.

1. Remove 6 screws holding condenser grille and motor to top

cover

2. Turn motor/grille assemhly upside down on top cover to

expose the fan blade.

3. Inspect the tSn blades tbr cracks or bends.

4. If fan needs to be removed, loosen the setscrew and slide the

tim off the motor shat_.

5. When replacing fan blade, position blade so that the hub is 1/8

in. (3.2 ram) away from the motor end.

6. Ensure that setscrew engages the flat area on the motor shall

when tightening

7. Replace grille.

ELECTRICAL CONTROLS AND WIRING

Inspect and check the electrical controls and wiring annually. Be

.s_lre to tz_'t_ q[f llle electrical po_er to _l_ez_nit and i_sral/ [ocI_ozet

Remove access panel to locate all the eleckical controls and

wiring. Check all electrical connections tbr tightness. Tighten all

screw connections.

After inspecting the electrical contlols and wiring, replace the

access panel. Start tl_e unit, and obsela'e at least one complete

heating cycle and one complete cooling cycle to ensure proper

operation. If discrepancies are observed in either or both operating

cycles_ or if a suspected malNnction has occmxed, check each

electrical component with the proper electrical instrumentation.

RefEr to the unit wiring label when making these checkouts.

NOTE: Ref)r to the heating an_or cooling sequence of operation

in this publication as an aid in determining proper control

operation

REFRIGERANT CIRCUIT

Inspect all refrigerant tubing connections and the unit base for oil

accumulations annually. Detecting oil generally indicates a ref?ig-

erant leak.

System under pressure. Relieve pressure and recover all

ret?igerant before system repair or final unit disposal to avoid

personal inju_' or death. Use all service ports and open all

flow=control devices, including solenoid valves.

If oil is detected or if low cooling performance is suspected,

leak=test all refi'igerant tubing using an electronic leak=detector,

halide torch., or liquid-soap solution. If a refi'igerant leak is

detected, refer to Check for Refrigerant Leaks section.

If no refrigerant leaks are fbund and low cooling performance is

suspected, refer to Checking and Adjusting Reli'igerant Charge

section.

EVAPORATOR AIRFLOW

The heating an_or cooling air=flow does not require checking

unless improper pertbm_ance is suspected. Ira prof_lem exi._ls, I:,e

szlre Nat aN/szll_y)- a_d retzlrn-air grilles are open and fi'eefi'om

ob_strzlctio_s, and that Ills air filter is clean. When necessary, refer

to Indoor Airflow and Airflow Adjustments section to check the

system airflow.

HIGH FLOW VALVES

Located on the compressor hot gas and suction tubes are High

Flow Valves. Large, black plastic caps distinguish those valves

with o-rings located inside the caps These valves cannot be

accessed fbr service in the field. Ensure the plastic caps are in

place and tight or the possibility of refi'igerant leakage could occur.

PHASE MONITOR CONTROL

1 3_hase scroll compressors are rotational sensitive

2. A flashing LED on phase monitor (See Fig. 17) indicates

reverse rotation.

3. This will not allow contactor to be energized

4. Disconnect power to unit and interchange 2 field wiring leads

on unit contactor.

Follow these steps to properly start up the system:

1. Fully back seat (open) liquid and vapor-tube smwice valves.

2. Unit is shipped with valve stem(s) fi'ont seated (closed) and

caps installed. Replace stern caps afler system is opened to

refrigerant flow. Replace caps finger=tight and tighten with

wrench an additional 1/12 mm for back=seating valves (male

square stem).

3. (lose electrical disconnects to energize system.

4. Set room thermostat desired temperature. Be sure set point is

below indoor arubient temperature.

5. Set room thermostat to COOL and fire control to ON or AUTO

mode, as desired. Operate unit for 15 minutes. Check system

refrigerant charge.

SEQUENCE OF OPERATION

Turn on power to indoor and outdoor unit. Transformer is

energized.

On a call tbr cooling, thermostat make circuits R=Y and R=G. On

three phase models with scroll compressors, the units are equipped

with a phase monitor (See Fig. 17) to detect if the incoming power

is correctly phased for compressor operation. If the phasing is

con'ect, circuit R-Y energizes contactor, starting outdoor t_n motor

and compressor circuit. R-G energizes indoor unit blower relay,

starting indoor blower motor on high speed.

NOTE: If the phasing is incolxect, the contactor will not be

energized. To correct the phasing, interchange any two of the three

power connections on the field side.

When the thermostat is satisfied, its contacts open, de=engergizing

contactor and blower relay. Compressor and motors stop.

If indoor unit is equipped with an off-delay circuit, the indoor

blower can be run up to an additional 120 sec to increase the

system efficiency.

P/RON,> SYSTEM ITEMS

METERING DEVICE ACCURATOR PISTON

This metering device is a fixed orifice and is contained in the brass

hex=body in the liquid line

PRESSURE SWITCHES

Pressure switches are protective devices wired into the control

circuit (low voltage). They shut off compressor if"abnormally high

or tow pressures are present in the ref?igeration circuit These

pressure switches are specifically designed to operate with Puron

(R-410A) systems. Other refrigerant pressure switchesmust not be

used as replacements for the Puron (R=410A) air conditioner.

19

Page 20

LED

OFF

FLASHING

ON

GONTAG fOR 24VAC COM

OFF:NO 24VAC

ON:OK

FLASFI _PFIASE PROBLEM

0

L3

Ll

STATUS

No Call for compressor operation

Reversed phase

Normal

Fig. 17--Phase Monitor Control and LED Indicators

A00010

LOSS OF (HARGE LOW-PRESS_ RE SWITCH

This switch is located on d_e liquid line and protects against low

sucdon pressures caused by such events as loss of charge, low

airflow across indoor coil, dirty filters, etc. It opens on a pressure

drop at about 20 psig (138 kpa) If system pressure is above this,

switch should be closed

To check switch:

1. Turn off all power to unit.

2. Install lockout tag

3. Disconnect leads on s_itch.

4. Apply ohmmeter leads across switch. You should have con=

tirmity on a good switch.

NOTE: Because these switches are attached to refi'igeration

system under pressure, it is not advisable to remove this device for

troubleshooting unless you are reasonably certain that a problem

exists. If switch must be removed, remove and recover al! system

charge so that pressure gauges read 0 psi. Never open system

without breaking vacuum with dW nitrogen

HIGH-PRESSURE SWITCH

The high=pressure switch is located in the discharge line and

protects against excessive condenser coil pressure It opens at 610

psig (4206 kpa)

High pressure may be caused by a dirty condenser coil, failed _hn

nmtor, or condenser air recirculation

To check switch:

1. Turn off all power to unit.

2. Install lockout tag

3. Disconnect leads on switch

4. Apply ohmmeter leads across switch. You should have con=

tinuity on a good switch.

(OPELAND PURON SCROLL COMPRESSOR

The compressor used in this product is specil_caily designed to

operate with Puron (R-410A) refrigerant and cannot be iuter-

chaugedo

The compressor is an electrical (as well as mechanical) device

Exercise extreme caution when working near compressors. Power

should be shut off, if possible, fbr most troubleshooting ted>

niques. Refrigerants present additional safety hazards.

Wear safety glasses and g!oves when handling refrigerants.

Keep torches and other ignition sources away fiom refi'iger=

ants and oils. Failure to fbllow this warning can cause a fire,

serious injury, or death.

The scroll compressor pumps refrigerant d_roughout the system by

the interaction of a stationary and an orbiting scroll. The scroll

compressor has no dynamic suction or discharge valves, and it is

more tolerant of stresses caused by debris, liquid slugging, and

flooded starts The compressor is equipped with a phase monitor=

ing device (See Fig. 17) and an internal pressure relief port. The

phase nmnitoring device will not allow power to pass to the

components if the phase is connected incorrectly The internal

compressor pressure relief port is a safety' device, designed to

protect against extreme high pressure. The relief port has an

operating range between 550 arid 625 psi (3792 and 4309 kpa)

diffcrentiai pressure.

The Copeland scroll compressor uses Mobil 3MA POE oil.

This is the on]y oil allowed for oil recharge.

REFRIGERANT

This system uses Puron (R=410A) refiigerant which has

higher operating pressures than R-22 and other refrigerants

No other refrigerant may be used in this system Gage set,

hoses, and recovery system must be designed to handle

Puron If you are unsure, consult the equipment manufi_cturer

Failure to use Puron compatible servicing equipment or

replacement components may result in property" damage or

iajury

COMPRESSOR OIL

The compressor in this system uses a polyolester (POE) oil, Mobil

3MA POE. This oil is extremely hygroscopic, meaning it absorbs

2O

Page 21

AiR CONDITIONER WITH PURON (R-410A) QUICK REFERENCE GUIDE

Puron refrigerant operates at 50-70 percent higher pressures than R-22. Be sure that servicing equipment and replacement components are

designed to operate with Puron. Puron refrigerant cylinders are rose colored.

• Puron refrigerant cylinders manufactured prior to March 1, I999, have a dip tube that allows liquid to flow out of cytinder in upright position.

Cylinders manufactured March 1, 1999 and later DO NOT have a dip tube and MUST be positioned upside down to allow liquid to flow.

• Recovery cylinder service pressure rating must be 400 psig (2758 kpa). DOT 4BA400 or DOT BW400.

Puron systems should be charged with liquid refrigerant. Use a commercial type metering device in the manifold hose.

Manifold sets should be 750 psig (5171 kpa) high-side and 200 psig (1379 kpa) tow-side with 520 psig (3585 kpa) tow-side retard.

Use hoses with 750 psig (5171 kpa) service pressure rating.

Leak detectors should be designed to detect HFC refrigerant.

Puron, as with other HFCs, is only compatible with POE oils.

Vacuum pumps wilt not remove moisture from oil.

Only use factory specified liquid-line filter driers with rated working pressures no less than 600 psig (4137 kpa).

Do not install a suction-line filter drier in liquid line.

POE oils absorb moisture rapidly. Do not expose oil to atmosphere.

POE oils may cause damage to certain plastics and roofing materials.

Wrap all filter driers and service valves with wet cloth when brazing.

A Puron liquid-line filter drier is required on every unit.

Do not use an R-22 TXV.

Never open system to atmosphere while it is under a vacuum.

When system must be opened for service, break vacuum with dry nitrogen and replace fitter driers.

Always replace filter drier after opening system for service.

Do not vent Puron into the atmosphere.

Observe all warnings, cautions, and bold text.

• Do not leave Puron suction line driers in place for more than 72 hrs.

water readily POE oils can absorb 15 times as much water as other

oils designed for HCFC and (F( re_iigerants. Take all necessa_"

precautions to avoid exposure of the oil to the atmosphere.

SERVICING SYSTEMS ON SYNTHETIC ROOFS

POE (polyolester) compressor lubricants are known to cause long