Page 1

50ET.QT

HEATING A COOLING

Installation, Start-Up and Service Instructions

Heat Pump and Cooling Unit Chassis Only, Sizes 212-230

CONTENTS

SAFETY CONSIDERATIONS

INTRODUCTION

INSTALLATION

Step 1 — Check Equipment and Jobsite................I

• UNPACK UNIT

• INSPECT EQUIPMENT

• INSPECT WALL SLEEVE

Step 2 — Install Chassis in Wall Sleeve...............1-3

• INSTALL ACCESSORY OUTDOOR GRILLE

• INSTALL ACCESSORY COLD CLIMATE

PACKAGE IF REQUIRED

• SLIDE CHASSIS INTO SLEEVE

Step 3 — Install Accessory Thermostat

and Connect Thermostat Wiring

• TO MOUNT THERMOSTAT IN UNIT

• TO MOUNT THERMOSTAT REMOTELY

Step 4 — Set Indoor Fan Motor Speed...................4

Step 5 — Install Accessory Electric Heater

If Required.................................................................4

START-UP................................................................4,5

SERVICE...................................................................5-I4

Installing and servicing air conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install or service air conditioning equipment.

Untrained personnel can perform basic maintenance,

such as cleaning and replacing filters. All other opera

tions should be performed by trained service personnel.

When working on air conditioning equipment, observe

precautions in literature and on tags and labels attached

to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available.

.......................................................

.......................................................

SAFETY CONSIDERATIONS

....................................

...........................

A WARNING

Before installing or servicing unit, turn off main

power to system. There may be more than one

disconnect switch. Turn off accessory heater power

if applicable. Electrical shock can cause personal

injury.

_________________________________________

IMPORTANT: Final wiring inspection by local

authorities must be done before chassis is installed

in sleeve.

A WARNING

The Model 50ET,QT chassis is an uncased unit and,

therefore, requires special care in handling to prevent

injury to installer and damage to unit. A portable

lifting device must be used to move and position unit.

Be careful of sharp edges when handling chassis.

Page

I

1

1-4

3,4

Single-Package Units

INTRODUCTION

Install Model 50ET air conditioner or 50QT heat pump

chassis in accessory wall sleeve. See Table 2 for part

numbers. Wall sleeves are shipped separately with accom

panying installation instructions. All electrical power,

ductwork and condensate drain hookups are made at

time of wall sleeve installation.

IMPORTANT; Carrier standard outdoor grille or

deluxe outdoor grille must be ordered separately and

installed in wall sleeve before chassis is installed. Do

not run unit without proper outdoor grille in place.

See Table 2 for part numbers.

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACK UNIT — Move to final location. Lift card

board carton off chassis taking special care not to

damage unit.

INSPECT EQUIPMENT for damage prior to installa

tion. To remove metal cover plate, remove 6 screws. File

claim with shipping company if shipment is damaged or

incomplete.

Leave chassis bolted to skid and replace metal cover

plate and carton until ready for installation into wall

sleeve.

INSPECT WALL SLEEVE installation for damage.

Condensate drain pan must be free of debris and installed

in accordance with local building regulations. Electrical

connector on left side of sleeve should be free of dirt,

grease, paint, etc. Connector must be properly wired

before chassis installation. Duct connection panel must

be level and duct connections complete. Do not rest

weight of ductwork on duct connector panel. Inspect

nameplate on sleeve to ensure wire and fuse sizing is

correct for model size and heater accessory to be installed.

NOTE: If remote thermostat location is desired, location

must be determined and field wiring must be installed

before wall completion.

Step 2 — Install Chassis in Wall Sleeve —

Remove sleeve filler panel and save screws.

INSTALL ACCESSORY OUTDOOR GRILLE — In

stall outdoor grille using screws saved Refer to instruc

tions shipped with outdoor grille.

INSTALL ACCESSORY COLD CLIMATE PACK

AGE IF REQUIRED — Cold climate accessory should

be installed where the outdoor ambient temperature

consistently falls below 30 F. Refer to Table 2 for correct

accessory part number. Refer to instructions packaged

with aceessory for installation.

IMPORTANT. Be sure disconnect, per NEC,

installed with the wall sleeve is in OFF position

before proceeding with chassis installation.

Book |1 |1 |4 |4 PC 131 Catalog No 535-078 Printed inUS A Form 50ET,QT-3SI Pgl 5-85 Replaces: 50QT-10SI

Tab Ilbl5ahal5a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

For replacement items use Carrier Specitied Parts

Page 2

50ET,QT

HEATING A COOLING

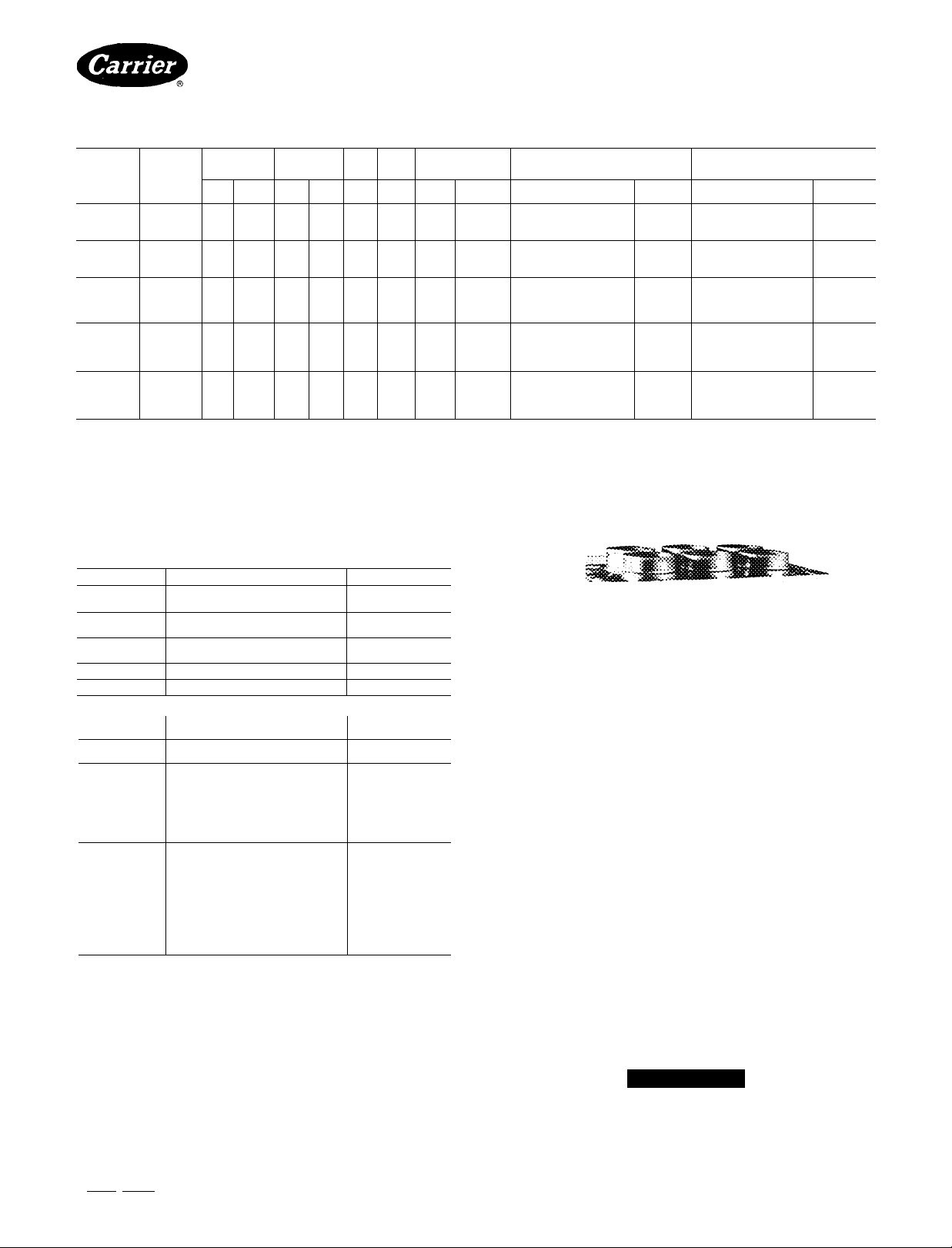

Table 1 — Electrical Data (60 Hz)

OPER

MODEL

50ET/QT

212300

215300 208/230/1

218300

224300ft

230300ft

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

OFM — Outdoor Fan Motor

RLA — Rated Load Amps

TD — Time Delay

‘Permissible limits of the voltage range at which units will operate

satisfactorily

V/PH

208/230/1

208/230/1 254 187 50

208/230/1 254

208/230/1 254 187

VOLTS*

Max Mint LRA

254 187

254 187 43

187

CO^flPR

37

59

79

RLA

68 1 5

87

9 3

130

169

iPM

FLA

1 5 1 0

1 7 1 5

2 0

2 4 1 5

OFM

FLA

1 0

1 5

ELECTRIC

HEATER

kW

Amps

None

30

9 4/12 5

5.0

18.0/20.8

None

30509 4/12 5

18 0/20 8

None

30

9 4/12 5

50

18 0/20 8

7.5

26.8/31.3

None

50

17 3/20 8

7 5

26 8/31 3

100

36 1/41 7

None

50

17 4/20 8

7 5

26 8/31 3

36.0/41.7

10.0

Single-Package Units

BRANCH CiRCUiT #1

(or Total Unit)

Max TD Fuse or

HACR CktBkr Amps**

15/15

25/30

35/40

20/20

25/30

35/40

20/20

30/35

40/45

50/60

15/15

25/30

35/40

50/60

15/15

30/30

40/40

50/60

tMinimum voltage Is 197 when outdoor ambient temperature exceeds

105 F

^iFiold wiring to be sized per NEC or local codes Use copper wire only

"Maximum dual element fuse size

ttThese units require 2 separate supply circuits Refer to both branch

circuit charts for complete electrical data Two-circuitfused disconnect

must be field supplied

NOTE: Dual values in this table (for example: Electric Heater Amps:

9 4/12 5) apply to 208- and 230-volt connections, respectively

MCA

110/110

22 8/26 6

33,5/37.0

13 4/13 4

25 1/29 0

35 9/39.4

14 8/14 8

26 6/30 5

37 3/40 8

48.3/54.0

2 5/25

24 1/28 5

36 0/41 6

47 6/54 6

3 0/30

24 8/29 0

36 5/42 1

48.0/55.1

BRANCH CiRCUiT #2

(When Used)t

Max TO Fuse or

HACR CktBkr Amps**

-

—

-

25/25

25/25

25/25

25/25

35/35

35/35

35/35

35/35

MCA

-

—

-

17 9/17 9

17 9/17 9

17 9/17 9

17.9/17 9

25/25

25/25

25/25

25/25

Table 2 — Accessories

PART NO.

500T902061 \A/all Sleeve (one)

50QT900081 Wall Sleeve (one)

50QT90301106

500T90302106 Architectural Grille (six) All

S0QT90400102

50QT90401102

50QT90700106 Fresh Air Damper (six)

50QT905001

99TZ900321/

99TZ900361*

99TZ900321/

99TZ900391*

99TZ900291*

99TZ900401*

99TZ900511*

99TZ900501* Electronic, 7-Day Programmable

99TZ900541t

50QT901000

50QT901010

50QT901020

SOQT901030

50QT901040

50QT901050

500T901060

50QT901070

50QT901080

'For remote mounting only

tSuitable for mounting on unit chassis

Standard Aluminum Grille (six) All

Polymer Front Cover (two)

Cold Climate Package (one) All

Cooling Thermostats:

Automatic Changeover All

Manual Changeover All

Heat Pump Thermostats:

Two-Stage Heat, One-Stage Cool

Manual Changeover

Automatic Changeover

Manual Changeover All

Manual Changeover

Electric Heaters (kW)

DESCRiPTiON MODEL 50ET.QT

3

5

75 218

5

7 5 224

10

5

7 5

10

212, 215, 218

224, 230

212, 215, 218

224, 230

212, 215, 218

212, 215, 218

All

224

224

230

230

230

w

SLIDE CHASSIS INTO SLEEVE — Chassis is heavy.

Portable lifting device must be used. Exercise caution

to be sure forks do not damage chassis components (such

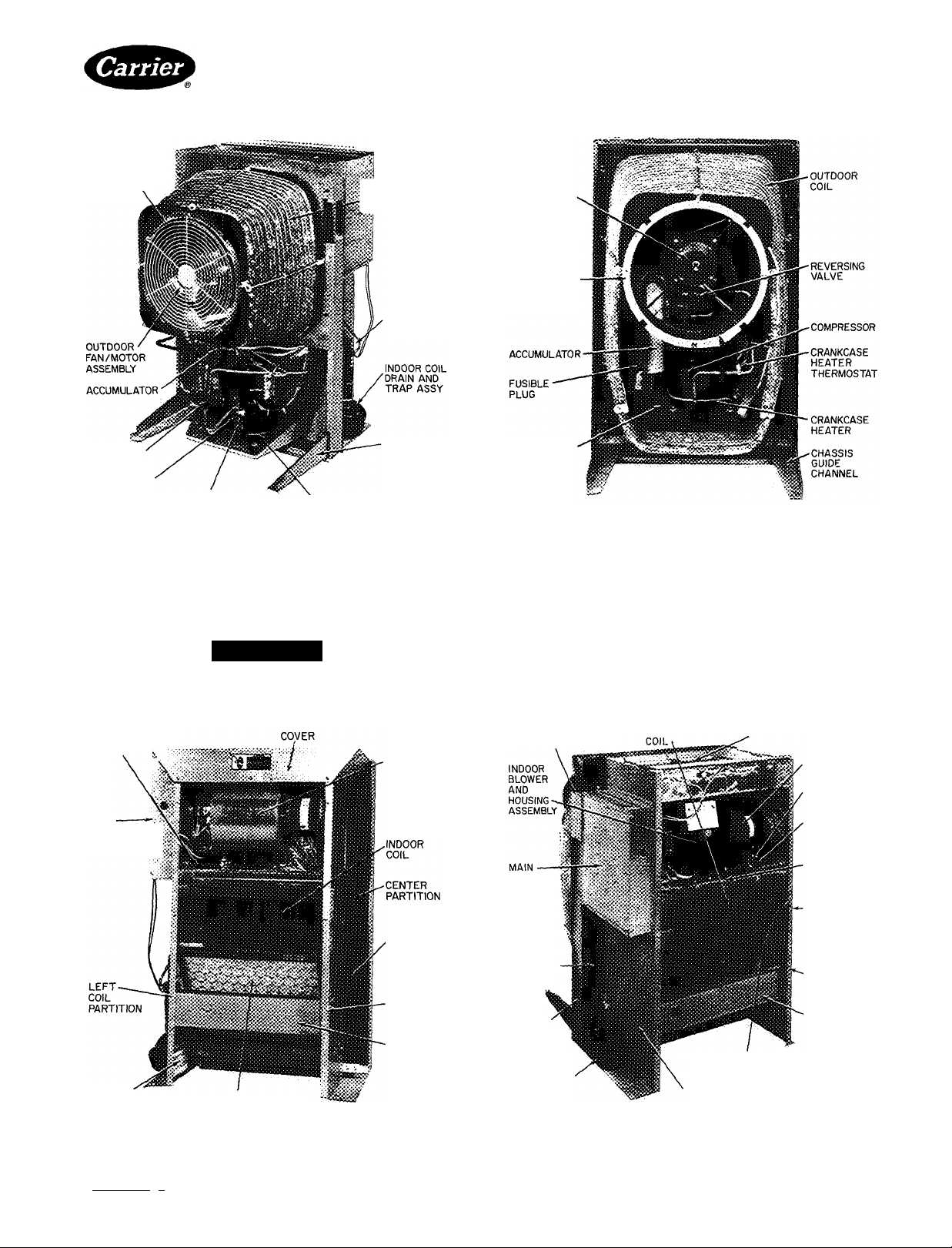

Fig. 1 — Chassis with Accessory Indoor

Polymer Wrapper

as drain connections) while lifting and installing. Guide

chassis into sleeve on indoor side by first placing chassis

guide channels onto lower corners of sleeve. Slide chassis

into sleeve until center partition perimeter meets gasket

provided around outer edge of sleeve. Check electrical

plugs for alignment as chassis is slid into place.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Bookll II 14 14 PC 131 Catalog No 535-078 Printed in U S A Form 50ET.QT-3SI Pg2 5-85 Replaces: 50QT-10SI

Tab 1b 5al1a|5a For replacement items use Carrier Specilied Parts

Do not release chassis until installed and bolted

completely into sleeve as it may fall out without

warning.

A WARNING

Page 3

50ET,QT

HEATING A C001.ING

OUTDOOR FAN

ORIFICE

REVERSING

VALVE

COMPRESSOR

CRANKCASE HEATER THERMOSTAT

CRANKCASE HEATER

«-OUTDOOR

ÌÌÌ COIL

DEFROST

THERMOSTAT

(NOT VISIBLE)

CHASSIS

GUIDE

CHANNEL

50QT212.215 (shown), 218

Fig. 2 — Outdoor Component Location

Tighten chassis into place by driving 6 lag bolts, pro

vided in separate bag with chassis into nuts provided on

sleeve (see Fig. 3).

Electrical and condensate drain connections are com

plete when chassis is installed correctly into sleeve.

A CAUTION

Tighten lag bolts uniformly. Failure to do so may

cause misalignment and poor electrical connection.

ACCURATER'^“

DEVICE

LOCATION

MAIN

CONTROL

BOX

COVER

ELECTRIC HEATER COMPARTMENT

INDOOR

BLOWER AND

MOTOR

ASSEMBLY

COMPRESSOR

SUCTION

PRESSURE

PORT

LOCATION

Single-Package Units

OUTDOOR

FAN MOTOR

(PROPELLER

FAN AND GUARD

REMOVED)

OUTDOOR FAN

ORIFICE

COMPRESSOR

MOUNTING

PAN

50QT224 (Shown), 230

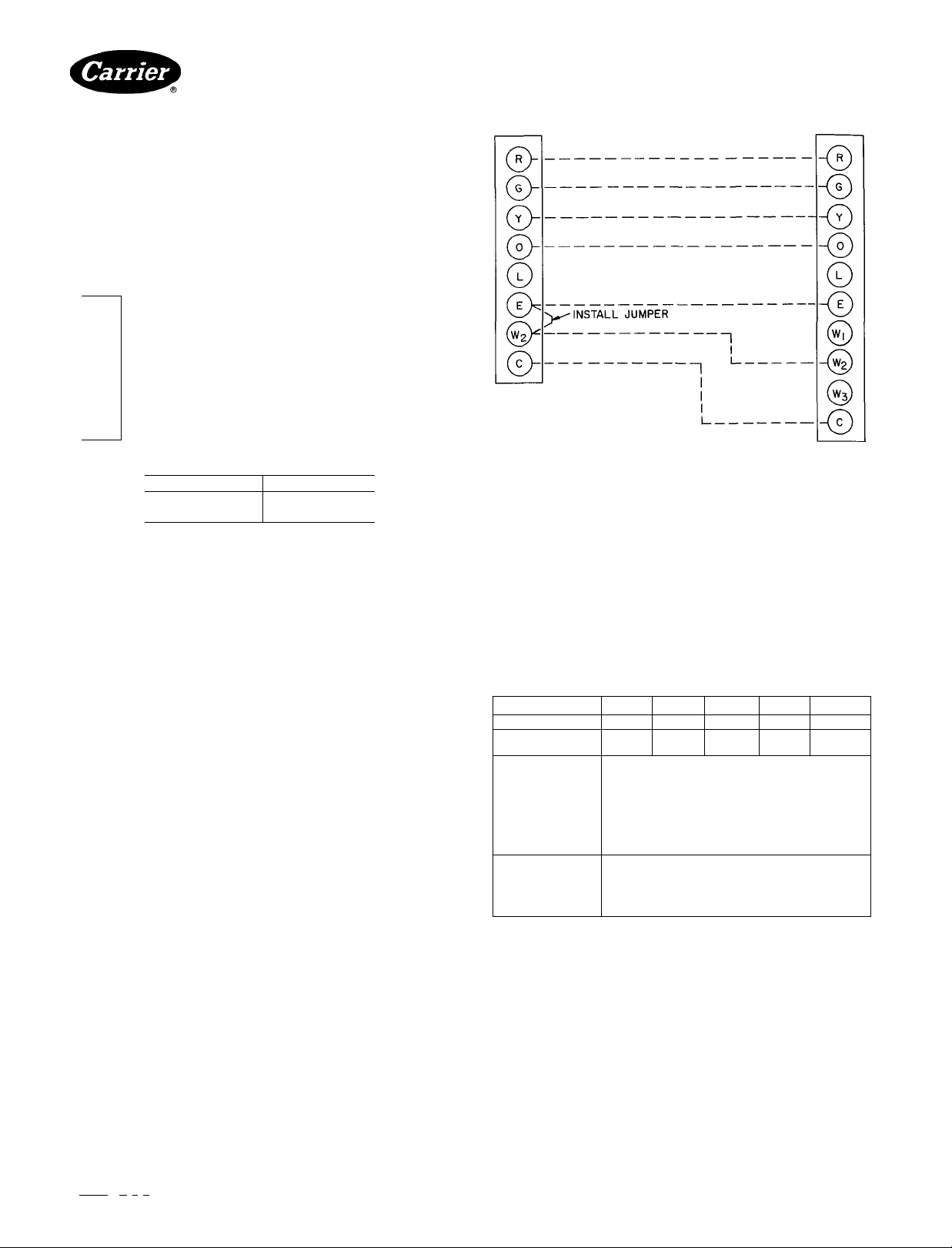

Step 3 — Install Accessory Thermostat and

Connect Thermostat Wiring — Accessory thermo

stat can be installed on the 50ET,QT chassis or in a

remote location.

TO MOUNT THERMOSTAT IN UNIT-

1. Remove metal cover plate by removing 6 screws.

2. Locate and install subbase onto thermostat bracket

running between right and left coil partition (see

Fig. 3). Push field-supplied thermostat wires through

hole provided.

SLEEVE JUNCTION BOX

ACCESS PLATE

CONTROL

BOX

(SLIDES

OUT FOR

SERVICE)

CHASSIS

MOUNTING

BOLTS (6)

INDOOR

ACCESSORY ELECTRIC HEATER

LOW-PRESSURE

SWITCH

DEFROST

THERMOSTAT

COMPRESSOR

SUCTION

SERVICE

PORT

(NOT VISIBLE)

CENTER

PARTITION

INDOOR

CONDENSATE

DRAIN

50QT224,230

INDOOR

NAMEPLATE

INDOOR AIR FILTER

50QT212,215,218

THERMOSTAT

MOUNTING

BRACKET

Fig. 3 — Indoor Component Location

Book|1 II 14 14 PC131 Catalog No 535-078 PrintedinUSA Form 50ET,QT~3SI Pg3 5-85 Replaces; 50QT-10SI

- • For replacement Hems use Carrier Specilled Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

INDOOR AIR FILTER LOCATION

(NOT SHOWN)

LEFT COIL PARTITION

THERMOSTAT

MOUNTING

BRACKET

Page 4

50ET,QT

HEATING A COOLING

(5>

S>]

(5>

THERMOSTAT AND

SUBBASE (SEE BELOW)

THERMOSTAT

99TZ900321 99TZ900361

99TZ900321

COOLING UNIT WITH ELECTRIC HEAT HEAT PUMP WITH SUPPLEMENTAL ELECTRIC HEAT

JM.

JH

WIRES FROM

JZL

UNIT CONTROL BOX

_0_

SUBBASE

99TZ900391

Fig. 4 — Thermostat Connection Diagrams — 50ET,QT

Single-Package Units

UNIT CONTROL BOX

WIRING TERMINAL BOARD

THERMOSTAT/SUBBASE

99TZ900291

99TZ900401

99TZ900511

99TZ900541

3. Route thermostat wires through hole located on left

coil partition and up to low-voltage wire entrance

hole on control box front cover.

4. Remove 2 screws and slide control box to expose

low-voltage terminals. Attach wires to appropriate

terminals as shown on unit wiring diagram. See Fig. 4.

5. Attach thermostat to subbase and snap on thermostat

cover.

6. Cut and remove insulation from hole in metal cover

plate.

7. Replace metal cover plate.

8. Install accessory polymer front cover as described in

instructions shipped with accessory cover. Cut

rectangular hole for thermostat as indicated by mark

in back of cover.

TO MOUNT THERMOSTAT REMOTELY-

1. Pull field-supplied thermostat wires previously

installed up into wire entrance hole on control box

front cover and connect wires as described in Step 3,

paragraph 4, above.

2. Connect other ends of thermostat wires, hanging from

the wall at their remote location, securely into subbase

at appropriate terminals specified in unit wiring

diagram. See Fig. 4.

3 Mount subbase onto wall.

4. Attach thermostat to subbase. Snap on cover and

install chassis indoor cover.

Step 4 — Set Indoor Fan Motor Speed — All

units are factory wired for low fan speed. Higherexternal

static pressure requirements can be met by wiring motor

for higher fan speed. See Table 3.

Step 5 — Install Accessory Electric Heater,

If Required — Refer to instructions packaged with

accessory heater. See Table 2 for part numbers.

» Table 3 — Service Data

SIZE

MODEL 50

R-22 CHARGE* (lb)

Refrig Control

INDOOR FAN

Rotationt

Rpm

Diameter (in.)

Width (In.)

Range (cfm)

Motor Hp

OUTDOOR FAN

Ctm

Rpm

Diameter (In)

Motor Hp

CCW — Counterclockwise

CW — Clockwise

‘Factory refrigerant charge

tLooking at fan motor shaft

212

ET I QT

2 3 I 2 7

215

ET lOT ET 1 QT

23)27

AccuRa

CW I CW I CW I CCW I CCW

1580 1550 1570 1675 1675

430/ 1 550/ 1 575/ 1 885/ 1 1025/

Propeller, Direct Drive, Single Speed

1700 1 1700 1 2000 1 2000 1 2000

218

3 1 1 3 75

ter'" BypaE

Centrifugal Blower,

Direct Drive, 2-Speed

6 1 6 1 6 1 7 1 7

8

375 475 480 800 960

V. 1 '/, 1 % 1 '/4 1 '/4

1125

15

’/b

224 230

ET 1 QT ET 1 QT

4.0 1 4 5

s Type

39)47

START-UP

Crankcase Heater — The 50QT compressor is

equipped with a crankcase heater that is thermostatically

activated in cold weather. (See Fig. 2 and 3.) If tempera

ture is below 65 F, operate crankcase heater 24 hours

before starting unit. To energize crankcase heater only,

after chassis installation, set thermostat to ^^

position (for thermostat mounted on the chassis) or OFF

position (for remote-mounted thermostat) and turn on

unit power at disconnect switch.

t

Bookn 11 |4 |4 PC 131 Catalog No 535-078 PrintedinUSA Form 50ET.QT-3SI Pg4 5-85 Replaces 50QT-10SI

Tab llbisahalsa

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

For replacement items use Carrier Specified Parts

Page 5

50ET,QT

HEATING A COOLING

To Start Unit — Check that main power is on and,

if temperature is below 65 F, that compressor crankcase

heater has been energized for at least 24 hours.

1. Set selector switch at <; -O—^ if thermostat is

mounted on chassis, or at OFF if thermostat accessory

is remote mounted.

2. Set fan switch as desired (FAN) (AUTO.).

3. Set thermostat lever at the desired temperature.

4. Set selector .switch at HEAT or COOL. Check sy.stem

refrigerant charge. See Refrigerant Charging.

SERVICE

Service Port Connections — High and low side

pressure connections are accessible from the indoor

portion of the unit for charging. (See Fig. 3.)

Low-Pressure Switch (50QT only) (Safety

Control) is located on liquid line downstream of Accu-

Rater™ control during cooling mode (or upstream of

AccuRater control during heating mode). Switch opens

at 5 psig and shuts down compressor to protect it from

overheating if refrigerant charge is too low.

High-Pressure Relief Valve (Safety Control) is

located in compressor. Relief valve opens at a pressure

differential of approximately 450 ± 50 psi between

suction (low side) and discharge (high side) to allow

pressure equalization.

Internal Current and Temperature Sensitive

Overload (Safety Control) resets automatically

when compressor motor temperature drops to a safe level

(overloads may require up to one hour to reset). When an

internal overload is suspected of being open, check by

using an ohmmeter or continuity tester. If necessary,

refer to Carrier Standard Service Techniques Manual,

Chapter 2, Electrical, for complete instructions.

Defrost Control consisting of a control board and

defrost thermostat, interrupts normal system heating

operation to remove frost and iee formation on outdoor

Single-Package Units

coil. Frost impairs unit performance. Defrost control

simultaneously stops outdoor fan, energizes reversing

valve solenoid to switch system into cooling cycle (out

door unit as condenser, indoor unit as evaporator), and

activates accessory electric heater. Unit can defrost every

90 minutes, but will do so only if outdoor temperatures

are in the frosting temperature zone.

For heat pump to defrost, 2 eonditions are necessary;

1 Defrost circuit board contacts must be closed.

2. Coil temperature must be cold enough to cause defrost

thermostat contacts to close.

Contacts clo.se at 27 ±5 F. Every 90 minutes of elap.sed

running time, the defrost circuit board contacts close for

10 seconds. If the defrost thermostat contacts are closed,

the unit defrosts The defrost circuit board limits defrost

ing period to 10 minutes. Normally the frost is removed

and the defrost thermostat contacts will open to terminate

defrosting before 10 minutes have elapsed. Defrost

thermostat contacts open at 80 ±5 F. When defrosting is

terminated, the outdoor fan motor is energized and

reversing valve solenoid is de-energized, returning unit

to heating cycle.

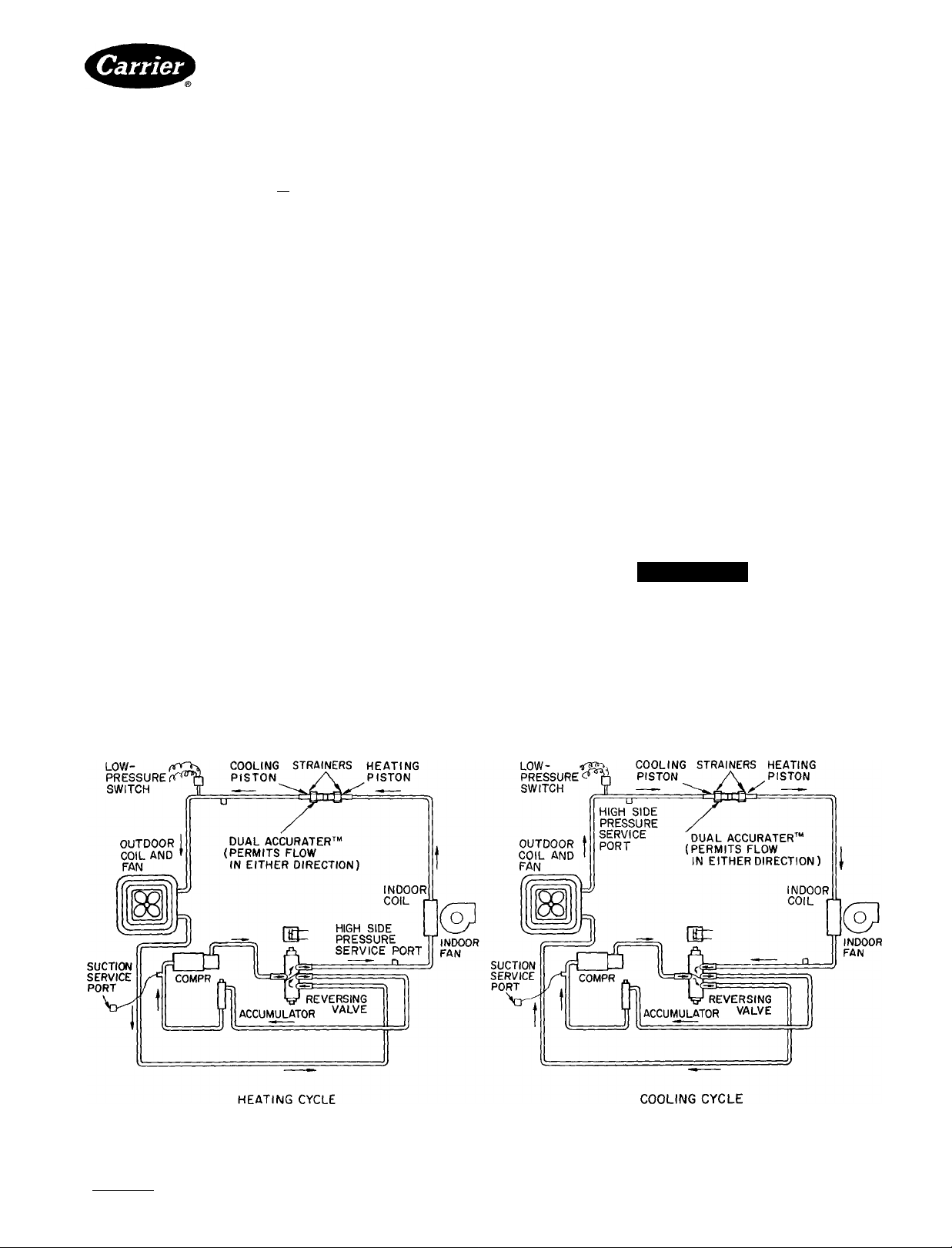

HEAT PUMP CIRCUITS shown in Fig. 5 are refrig

erant flow diagrams for heating and cooling cycles.

Refrigerant Charging

A CAUTION

To prevent personal injury, wear safety glasses and

gloves when handling refrigerant.

Do not overcharge system. An overcharge can

cause compressor damage.

Unit refrigerant system is factory charged. When

recharging is necessary, weigh in total charge indicated

in Table 3. (Charge must be weighed in during heating

season.) Remove any refrigerant remaining in system

before recharging. If system has lost complete charge.

3 Unit Piping

Fig. 5 — 50QT Refrigerant Flow Diagrams

Manulacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Bookll h |4 |4 PC131 Catalog No 535-078 PrintedinUSA Form 50ET,QT-3S1 Pg5 5-85 Replaces: 50QT-10SI

FROcTlT^r^ Pgj replacement items use Carrier Specified Parts

Page 6

50ET,QT

HEATING A COOLING

triple-evacuate system to 5000 microns (29.7 in. vacuum)

before recharging. Service port connections are provided

on unit suction and discharge lines for evacuation and

charging. (See Fig. 5 for service port location.) Dial-acharge charging cylinder is an accurate device used to

recharge systems by weight. These cylinders are available

at refrigeration supply firms.

To check and/or adjust charge during cooling season,

use Cooling Cycle Charging Charts (Fig. 6, 8, 10, 12, 14)

and follow Charging Chart Method below. The charging

chart may also be used as an alternate method of recharg

ing system.

To check svsiem operation during heating cycle, use

Heating Cycle Operation Check Chart (Fig. 7, 9, 11, 13,

15). These charts indicate whether a correct relationship

exists between system operating pressures and air tem

peratures entering unit. If pressure and temperature

lines do not intersect on chart, the system refrigerant

charge may not be correct or other system abnormalities

may exist. Do not use Operating Check Charts to adjust

refrigerant charge. Weigh charge into system.

Single-Package Units

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before check

ing charge, and after each charge adjustment.

2. Measure suction pressure by attaching a gage to unit

suction service port. (See Fig. 5 for correct service

port location.)

3 Measure outdoor (coil inlet) air dry-bulb tempera

ture. Use service thermometer.

4. Using a sling psychrometer, measure wet-bulb tem

perature of air entering indoor fan coil.

5. Refer to Charging Chart. Locate on curves where

outdoor air dry-bulb and indoor air wet-bulb tem

perature lines intersect.

6. From intersect point, project vertically downward to

chart suction pressure line. Compare chart suction

pressure to unit suction pressure (step 2).

7. If unit suction pressure is lower than chart pressure,

add refrigerant to system until chart pressure is

reached If unit suction pressure is higher than chart

pressure, remove refrigerant until chart pressure

is reached.

t

70 72 74 76 78 80 82 84 86 88 90 92

SUCTION PRESSURE (PSIG)

Fig. 6 — 50ET.QT212 Cooling Cycle

B^k|1

Tab ilb|5allal5a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigatlons.

[ 1

|4 |4 PC131 Catalog No 535-078 PrIntedinUSA Form 50ET,QT-3SI Pg6 5-85 Replaces: 50QT-10SI

Charging Chart

For replacement items use Carrier Specified Parts

Fig. 7 — 50QT212 Heating Operation

t

Check Chart

Page 7

50ET,QT

HEATING A COOLING

Single-Package Units

NOT AVAILABLE

AT TIME OF

PRINTING

64 66 68 70 7Z 74 76 78 80 82 84 86

SUCTION PRESSURE (PSIG)

Fig. 8 — 50ET,QT215 Cooling Cycle

Charging Chart

Fig. 10 — 50ET.QT218 Cooling Cycle

Charging Chart

NOT AVAILABLE

AT TIME OF

PRINTING

#

10 20 30 40 50 60

Fig. 9 — 50QT215 Heating Operation

Manufacturer reserves the rtght to dtsconttnue, or change at any ttme, spectlicattons or destgns without notice and without incurring obtigations.

k|1 |1 |4 |4 PC131 Catalog No 535-078 PrintedinUSA Form50ET,QT-3SI Pg7 5-85 Replaces: 50QT-10SI

Book

Tab Ilbl5alla|5a For replacement items use Carrier Specified Parts

SUCTION PRESSURE (PSIG)

Check Chart

Fig. 11 — 50QT218 Heating Operation

Check Chart

Page 8

50ET.QT

HEATING A COOLING

Single-Package Units

70 72 74 76 78 80 82 84 86 88 90 92

SUCTION PRESSURE (PSIG)

Fig. 12 — 50ET,QT224 Cooling Cycle

Charging Chart

Fig. 14 — 50ET.QT230 Cooling Cycle

Charging Chart

10 20 30 40 50 60

Fig. 13 — 50QT224 Heating Operation

^ok(1 |1 |4 14_ PC131 Catalog No 535-078 PrintedinUSA Form 50ET.QT-3SI Pg8 5-85 Replaces: 50QTTab hbisahalsa

Manufacturer reserves the right to discontinue, or change at any time, specilications or designs without notice and without incurring obiigations.

SUCTION PRESSURE (PSIG)

Fig. 15 — 50QT230 Heating Operation

Check Chart

For replacement items use Carrier Specified Parts

I

Check Chart

Page 9

50ET,QT

HEATING A COOLING

AccuRater™ Device (Dual-Piston Type)

Servicing — See Fig. 16 for AccuRater components.

m

The pistons have a refrigerant metering orifice through

them. The retainers form a stop for the pistons in the

refrigerant bypass mode, and a sealing surface for liquid

line flare connection. To clean or replace piston;

1. Shut off power to unit.

2. Protect area around unit to prevent damage to

interior, furnishings, etc.

3. Remove refrigerant from unit.

4. Remove liquid line flare connections from Accu

Rater. See Fig. 3 for AccuRater location.

5. Note position of arrow on AccuRater body in

relation to unit.

6. Pull retainer out of body. Be careful not to scratch

flare sealing surface. If retainer does not pull out

easily, carefully use locking pliers to remove

retainer. Replace scratched or damaged retainer.

7. Slide piston out by inserting a small soft wire through

metering hole (18-gage thermostat wire). Check that

metering hole, sealing surface around piston cones

and fluted portion of piston are not damaged.

8. See chart on indoor blower scroll for illustration of

proper arrangement and sizes of pistons.

9. Clean piston refrigerant metering orifice.

10. Replace retainer 0-ring before reassembling Accu

Rater. Carrier O-ring Part No. is 99CC501052.

LIQUID LINE STRAINERS (protect AccuRater), are

made of wire mesh and located in the liquid line on each

side of the AccuRater. The strainers are pressed into the

line. Remove strainer by threading a #10 sheet metal

screw into strainer and pulling the screw with pliers.

Single-Package Units

Compressor Removal — (Refer to Fig. 2.)

IMPORTANT: Compressor cannot be removed

from an installed chassis. Remove chassis from

sleeve, then bring to service truck or dealer shop

before removing compressor.

See Table 4 for compressor information. Follow safety

codes and wear safety glasses and work gloves. Have

quenching cloth available.

A CAUTION

Aluminum tubing is used in 50QT coils. Do not

overheat or place excessive strain on tubing or

damage may result.

Table 4 — Compressor Data

MODEL 50ET,QT

212

215

218

224

230

COMPRESSOR

Copeland

RE-Z3-0150-PFV

Tecumseh

AB5515H

Bristol

H22B193ABCA

Copeland

CRD-10200-PFV

Copeland

CRF1-0250-PFV

Compressor Removal — 50ET,QT212,215

I. Shutoff power to unit. Remove chassis indoor cover.

Fig. 1.

Remove chassis to truck or shop.

2.

Remove refrigerant from unit using refrigerant

3.

removal methods described in Carrier Standard

Service Techniques Manual, Chapter 1, Refrigerants.

Remove core from suction and discharge line

4.

Schrader valves.

________________

OIL RECHARGE

(oz)

20

32

27

51

51

#

FLARE

NUT

COIL

FLARE

NUT

STRAINER

STRAINER

STAMPED ARROW ON

COUPLING BODY

RUBBER 0-RlNG

STAMPED ARROW ON

RUBBER 0-RING (TOWARD INDOOR COIL)

COUPLING BODY

(TOWARD INDOOR COIL)

Fig. 16 — AccuRater Device (Dual-Piston) Components

Book|1 |1 |4 |4 PC131 Catalog No 535-078 PrintedinUSA Form 50ET.QT-3SI Pg9 5-85 Replaces. 50QT-10SI

Manufacturer reserves the right to discontinue, or change at any time, specitications or designs without notice and without incurring obiigatlons.

TO

INDOOR

50ET

FLARE

NUT

50QT

Page 10

50ET,QT

HEATING A COOLING

5. Disconnect compressor wiring at compressor

terminal box.

6. Using a tubing cutter, cut suction and discharge lines

at convenient place near compressor for easy re

assembly to new compressor with copper slip

couplings.

A CAUTION

Excessive movement of copper lines at com

pressor may cause a break where lines connect

to other .system components.

7. Remove crankcase heater from compressor base.

8. Remove clamp holding accumulator to shell.

9. Remove compressor holddown bolts and lift com

pressor out, sliding and tipping it towards the

outside,

10. Carefully unbraze suction and discharge line piping

stubs from compressor. If oil vapor in piping stubs

ignites, use quenching cloth.

11. Braze piping stubs (removed in step 10) on new

compressor, in same position as before.

12. Install new compre.ssor in unit. Braze suction and

discharge lines to compressor piping using fieldsupplied copper couplings. Ensure compressor hold

down bolts are in place. Reinstall crankcase heater.

Connect wiring.

13. Triple-evacuate to 5000 microns and recharge unit.

See Refrigerant Charging section.

14. Refer to NOTE at the end of this section for

important information.

Compressor Removal — 50ET.QT218,

224,230

1. Shut off power to unit. Remove chassis indoor cover.

Fig, 1.

2. Remove chassis to truck or shop.

3. Remove refrigerant from unit using refrigerant re

moval methods described in Carrier Standard Serv

ice Techniques Manual, Chapter 1, Refrigerants.

4. Remove core from suction and discharge line

Schrader valves.

5. Remove outdoor fan guard.

6. Remove outdoor compressor guard.

7. Remove outdoor propeller fan.

8. Remove outdoor fan orifice ring by removing 4

screws attaching it to outdoor fan motor bracket.

9. Remove 3 of 4 outdoor fan motor bolts, leaving

bolt at upper right of fan motor in place. Rotate

motor up and out of the way by hinging it on remain

ing bolt. Use wire or solder to tie outdoor fan

motor to outdoor coil support on top side of coil.

10. Using a miniature tubing cutter, cut compressor

suction tube on short vertical run as tube enters

compressor.

11. Cut compressor discharge tube on horizontal tubing

run approximately 6 to 12 in. from where it leaves the

compressor. Keep crankcase heater thermostat on

right side of cut so it stays in place when compressor

is removed.

Single-Package Units

12. Disconnect compressor wiring at compressor terminal box. Remove compre.ssor wires and crankca.se

heater splice from box.

13. Using an 18-in. long extension on ratchet wrench,

remove 4 compressor holddown bolts.

14. Slide compressor out to edge of pan. Remove crank

case heater by loosening worm drive clamp and

sliding over top of compressor.

15. Remove compressor from pan.

16. Carefully unbraze suction and discharge line piping

stubs from compressor. If oil vapor in piping stubs

ignites, use quenching cloth.

17. Braze piping stubs (removed in step 16) on new com

pressor, in same direction as before.

18. Using field-supplied copper couplings, install new

compressor in unit.

19. Reassembly is reverse of above procedure.

20. Triple-evacuate to 5000 microns and recharge unit.

See Refrigerant Charging section.

NOTE. If a compressor failure was caused by motor

winding burnout, the by-products of the burnout

must be separated from the circulating refrigerant.

This must be done before the by-products enter the

reversing valve or accumulator and render parts

inoperative. Burnout by-products can cause future

system operating problems if left in the system.

Clean the .system by installing a suction line drier in

the refrigerant line where the suction gas enters the

reversing valve. During the cooling cycle, this is the

line from the indoor coil running to the compressor

compartment; during heating cyele, install drier in Br

line between outdoor coil and reversing valve. If

possible, run unit in cooling mode when cleaning

.system as no defrosting occurs.

To provide protection for the reversing valve, do not

place filter d rier between reversing valve and accumu

lator. Since the suction drier works on one mode

only, temporarily wire the unit in the selected mode

(heating or cooling, based on suction drier location),

ifo insure cooling operation only, install a jumper

between terminals no. 1 and no. 4 on receptacle no. 3.

For heating operation only, remove and insulate

one of the reversing valve solenoid leads. Run unit for

2 hours and check oil for acidity. If satisfactory,

remove suction line drier. Refer to and follow pro

cedure under AccuRater^“ Servicing for cleaning of

AccuRater. Rewire unit to normal condition.

Lubrication — Compressor contains factory oil

charge. Replace oil when lost. See Table 4 for oil re

charge. If necessary, refer to Carrier Standard Service

Techniques Manual, Chapter 1, Refrigerants, page 1-21,

for oil recharging procedure. Use Carrier PP33-1,

Texaco WF-32 or Suniso 3GS oil.

FAN MOTOR BEARINGS — Oiling holes are provided

at each end of outdoor fan motor. Remove fan motor and

lubricate motor with 32 drops (16 drops per hole) of

SAE 10 nondetergent oil at intervals described below:

a. Annually when environment is very dirty, ambient

temperature is higher than 105 F and average unit

operating time exceeds 15 hours a day.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Bookll 11 |4 |4 PC131 CataloaNo 535-078 PrintedinUSA Form50ET.QT-3SI PglO 5-85 Replaces: S0QT-10SI

Tab Ilbl5allal5a

Catalog No 535-078 Printed in U S A Form 50ET.QT-3SI

For replacement items use Carrier Specified Parts

Page 11

50ET,QT

HEATINC A COOLING

I. Every 3 years when environment is reasonably clean,

ambient temperature is less than 105 F and unit

operating time averages 8 to 15 hours a day.

c. Every 5 years when environment is clean, ambient

temperature is less than 105 F and unit operating time

averages less than 8 hours a day.

INDOOR MOTOR — To oil indoor motor, remove dust

caps or plugs from oil holes located at each end of the

motor. Use a teaspoon, 5 cc (5 ml), 3/16 oz or 16 to 25

drops of a good grade of SAE 20 nondetergent motor oil

in each oil hole. Allow time for total quantity of oil to

be absorbed into each bearing. After oiling motor, be sure

to wipe off excess oil from housing and replace cap or

plugs on oil port.

Outdoor Coil Cleaning — To be done at the be

ginning of each cooling season or more often if required.

A CAUTION

Fin damage or removal can result in higher operating

costs or compressor damage. Do not use flame, high-

pressure water, steam, or volatile or corrosive

cleaners on fins and tubing. Follow these instruc

tions carefully. Contact your dealer if you encounter

problems.

Single-Package Units

1. Shut off power to unit.

2. Remove chassis from sleeve by removing 6 bolts and

sliding chassis out. Transport chassis to an appro

priate cleaning location.

3. Clean coil using vacuum cleaner and its crevice tool

(see Fig. 17). Work crevice tool perpendicularly to

coil tubes, making sure tool only touches dirt on fins.

To prevent fin removal, do not “scrub” fins with tool

or move tool parallel to coil tube configuration.

4. If oil deposits are present, spray coil with liquid house

hold detergent. Wait 10 minutes, then proceed to

step 5.

5. Using garden hose, spray coil perpendicularly to coil

tubes with a constant stream of water at moderate

pressure (see Fig. 18). Keep nozzle at a 15 to 20 degree

angle, about 3 in. from coil face and 18 in. from tube.

Spray so debris is washed out and away from coil

making sure water does not contact components

on side of chassis.

6. Make sure condensate pan drain is not clogged with

debris.

7. Reinstall ehassis in sleeve.

8. Restore power to unit.

Fig. 18 — Positioning Hose to Spray Coil

Indoor Coil and Condensate Pan Cleaning —

Clean and inspect indoor coil, condensate pan and drain

at .same time outdoor coil is cleaned.

1. Use vacuum cleaner nozzle to clean the face of coil.

2. Clean condensate pan with a brush similar to that

shown.

3. Hold pail under condensate pan drain connection and

flush pan by slowly pouring water on coil. Do not

overflow pan.

Indoor Air Filter Replacement (Refer to Fig. 3.)

— Replace filters at least 4 times per year especially at the

beginning of the heating and cooling seasons.

On 50ET,QT212,215 and 218, slide filter through slots

at bottom of left and right coil partitions. Slide filter

upward until top of filter reaches top of filter brackets.

Then, rest bottom of filter on bottom flanges of left and

right coil partitions.

On 50ET,QT224 and 230, slide filter upward until top

of filter reaches top of filter brackets. Then, rest bottom

of filter on horizontal sheet metal shelf between left and

right coil partitions making sure tabs at bottom of filter

brackets hold filter in place.

Outdoor Fan Adjustment — Required fan position

is shown in Fig. 19. Adjust position by loosening setscrew

on fan hub and moving in or out of orifice.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book II 11 14 14 PC131 Catalog No 535-078 Printed in U S A. Form 50ET.QT-3SI Pgll 5-85 Replaces: 50QT-10SI

>1h iBal 1a IfSa For replacement Hems use Carrier Specified Parts

Page 12

50ET,QT

HEATING A COOLING

Fig. 19 — Outdoor Fan Position

MODEL 50ET,QT

212,215 2'h

218,224,230 2

DIMENSION A

(in.)

Single-Package Units

Outdoor Fan/Motor Removal

1. Shut off power to unit.

2. Remove ehassis from sleeve as described previously

in Outdoor Coil Cleaning section.

3. Remove 4 nuts from outer tip of coil support rods and

remove wire mesh guard.

4. Remove fan blade from motor shaft by loosening hub

setscrews and slipping it off shaft.

5. Remove fan motor leads from electrical components

in indoor side control box and pull through bulkhead

so they are loose in outdoor machine compartment.

6. Remove nuts and bolts connecting 4 motor ears to

motor support struts.

7. Remove motor and leads.

8. Reassembly is reverse of above procedure. Make sure

guard is replaced and fan is positioned correctly

as in Fig. 2.

Book |1 h |4 |4 PC131 Catalog No 535-078 Printed in U S A Form 50ET,QT-3SI Pg12 5-85 Replaces; 50QT-10SI

Tab llbl5alla|5a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

For replacement items use Carrier Specified Parts

Page 13

■O ^

o J

O 9:

0) w

“ o

o 3.

|f

o <D

w 5

U1 ^

' 6 s-

5

CO §

(O

3 “D »

5 =. 3

5. D »<

s o s

gag

» 5' ?

c C" to

2 *3

® O) 5

0^0

TROUBLESHOOTING CHART — COOLING CYCLE

i 5

Cl a

o ®

m £.

H (O

b »

7^ i

CO y

— o

cn C

33 3.

■§ u

g &

« <o

in 2.

§§

—I «

(0

3

(Q

0

I

T5

fi>

c

Is

* m

CH

irb

(0 H

Page 14

50ET.QT

HEATING A COOLING

lU

-j

o

>

o

o

z

Single-Package Units

5

UJ

X

cc

<

X

o

(D

z

o

o

X

(A

UJ

_i

CD

3

o

X

Book 11 |1 14 14 PC 131 Catalog No 535-078 Printed in U S A Form 50ET,QT-3SI Pg14 5-85 Replaces: 50QT-10SI

Tab Mb!5ailal5a For replacement items use Carrier Specified Paris.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Loading...

Loading...