Page 1

50DP,DPE012,014

50DP016,020

HEATING t COOLING

Single-Package Cooling Units

Installation, Start-Up and Service Instructions

CONTENTS

Page

safety considerations

installation .... 1_10

• RooFcto'S""

...........................

.

.................... • • • '

I

• alternate unit support

• p*ootTt”'9 Unit

• POSITIONING

• ROOF MOUNT

Q+fE c Nlake Unit Duct Connections

Fabricate Ductwork

c Trap Condensate Drain

m Make Electrical Connections

! POWER SUPPLY

CONTROL WIRING

Adjustments

Make Outdoor Air Inlet

............................................................

1 outdoor" AIR "dAMPE’r

• OPTIONAL ECONOMIZER

step 8 — Install Outdoor Air Hood

^"FART-UP

SERVICE..................................................................14-16

.............................................................

................................

.......................

.......................

.................................

.................

...........

.........................

10-13

1

6

6

6

7

...

10

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

ment can be hazardous due to system pressure ano _

trical components. Only trained and •

personnel should install, repair or service air condì g

equipment.

Untrained personnel can perform basic

functions of cleaning coils and filters and rep g

filters. All other operations should ^

trained service personnel. When working on

tioning equipment, observe precautions »of“® ^ r>rpl

tags and labels attached to the unit and other sal y p

cautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations.

Have fire extinguishers available for all brazing

operations.

A WARNING

Before performing service or maintenance operations

on unit, turn off main power switch to unit. Electrical

shock could cause personal injury.

INSTALLATION

Step 1 — Provide Unit Support

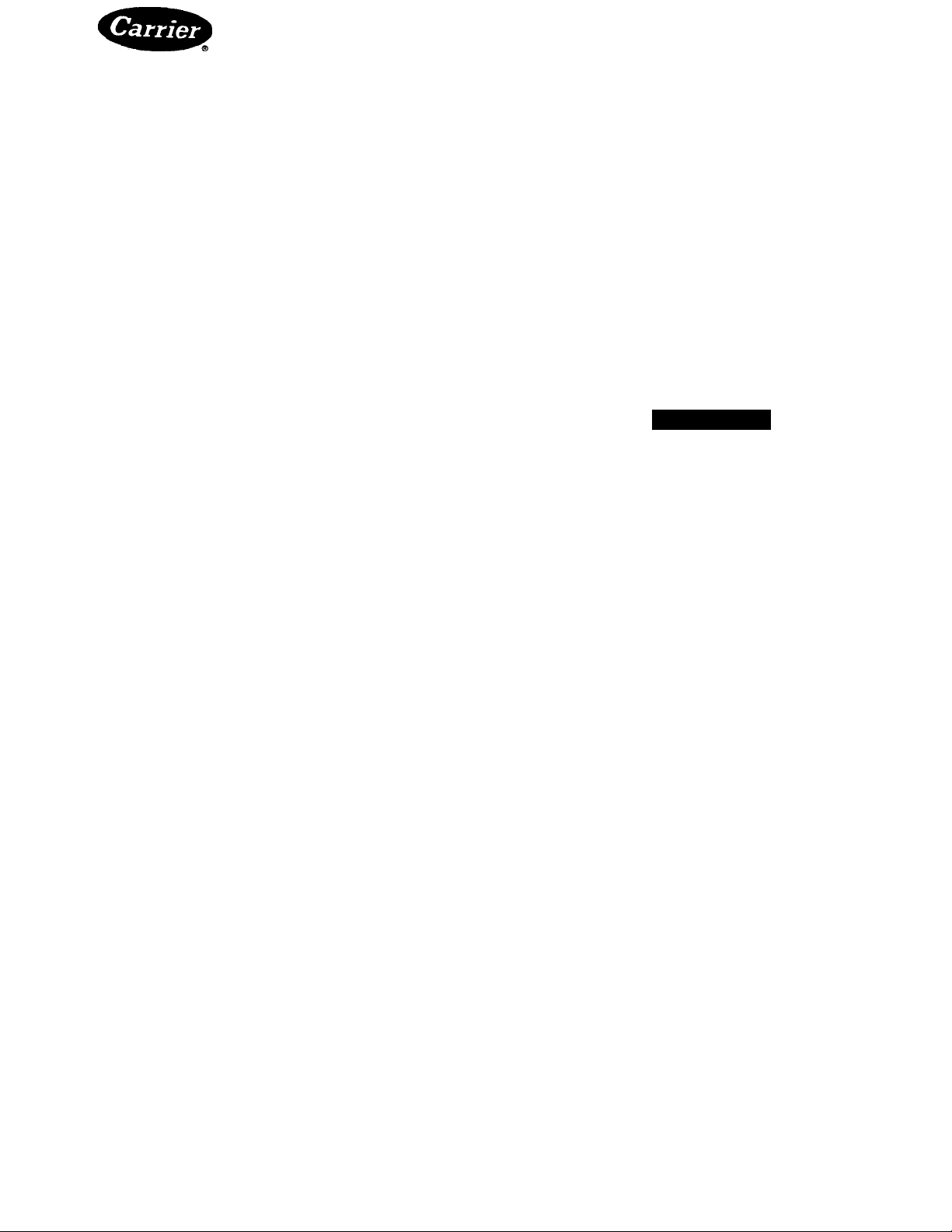

ROOF CURB — Assemble and install accessory roof

curb in accordance with instructions shipped with this

accessory. Accessory roof curb and information required

to field fabricate a roof curb are shown in Fig. 1 and 2.

Install insulation, cant strips, roofing and flashing as

shown. Ductwork can be installed to roof curb before unit

is set in place. Curb should be level. Unit leveling toler

ance is ± l/16in. per linear ft in any direction. This is

necessary to permit unit drain to function properly. Refer

to Accessory Roof Curb Installation Instructions for

additional information as required.

ALTERNATE UNIT SUPPORT — When the curb

cannot be used, support unit with sleepers using unit curb

support area. If sleepers cannot be used, support long

sides of unit with a minimum of 3 equally spaced 4-in. x

4-in. pads on each side.

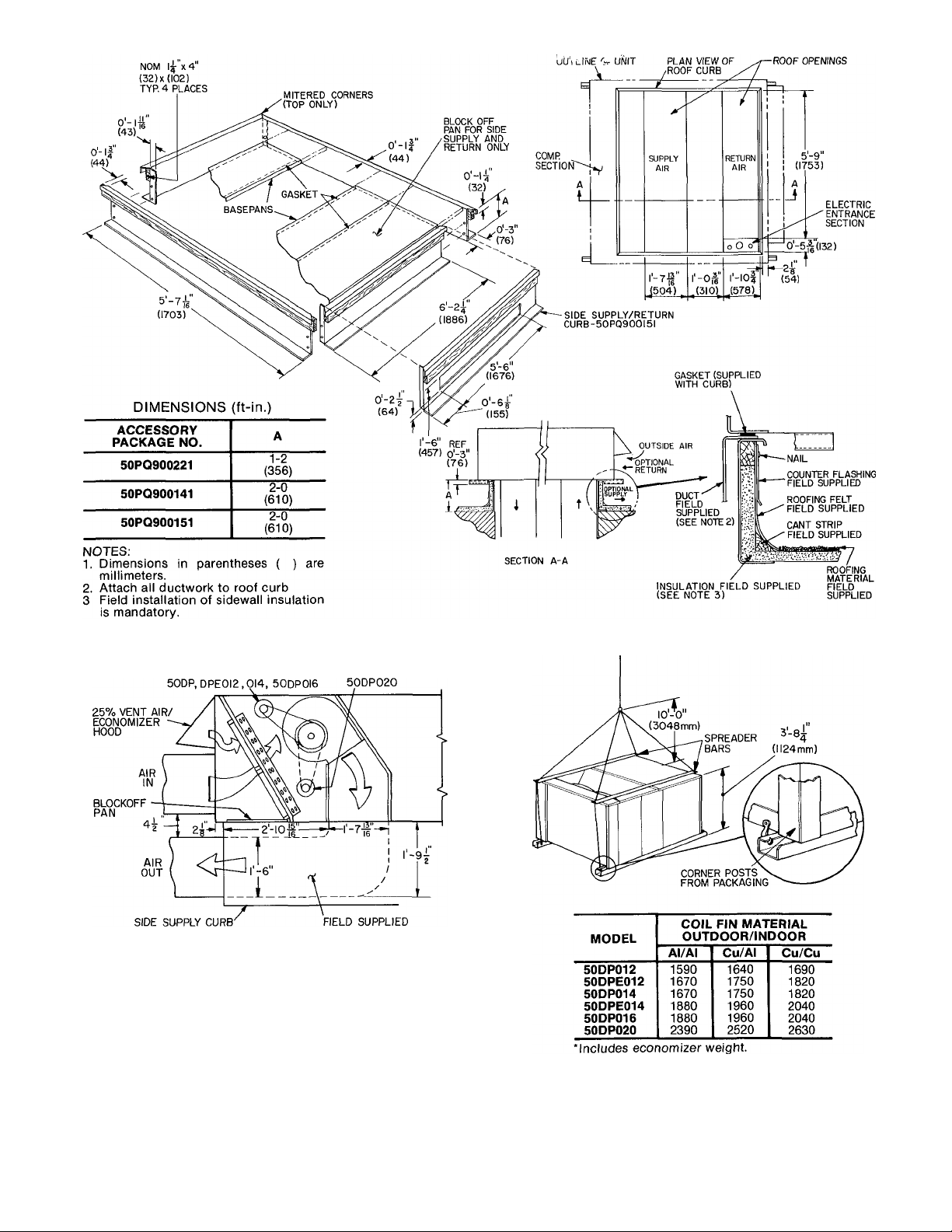

Step 2 — Rig and Place Unit — Inspect unit for

transportation damage. File any claim with transporta

tion agency. Do not drop unit, keep upright. Use spreader

bars over unit to prevent sling or cable damage. Rollers

may be used to move unit across a roof Level by using

unit frame as a reference; leveling tolerance is ± 1/16 in.

per linear ft in any direction. See Fig. 3 for additional

information. Unit weight is shown in Table 1.

Four lifting holes are provided in ends of unit base rails

as shown in Fig. 3. Refer to rigging instructions on unit.

POSITIONING — Provide clearance around and above

unit for airflow, safety and service access (Fig. 4).

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

g2°k|l |4 PC111

TabTlbl6b

Catalog No 565-104

Printed in U S A Form 50DP-26SI

ii.n,. Carrier Specified Parts.

Pgi

7-88

Replaces; 50DP-25SI

Page 2

Fig. 1 — Roof Curb Details

INDOOR AIR

FAN MOTOR

(50PQ900I5I )

INDOOR AIR

FAN MOTOR

TRANSITION DUCT

Fig. 2 — Side Supply/Return Curb Details

Do not install unit in an indoor location. Do not locate

unit air inlets near exhaust vents or other sources of

contaminated air.

Although unit is weatherproof, guard against water

from higher level runoff and overhangs.

ROOF MOUNT — Check building codes for weight dis

tribution requirements. Unit weight is shown in Table 1.

NOTE: Rig by inserting hooks into unit base rails as shown. Main

tain a distance of 120 m. (3048 mm) from top of unit to eyehook.

Use corner post from packaging to protect coil of unit from

damage by rigging cable Use bumper boards for spreader bars.

CAUTION!

All panels must be in place when rigging.

Fig. 3 — Rigging Details

t

©

Page 3

25% AIR OR ECONOMIZER HOOD

#

INDOOR AIRFLOW

0

• OUTDOOR AIRFLOW

F'9" 4 — Physical Data and Dimensions

> ALTERNATE AIRFLOW

SPACE REQUIRED FOR

B

SERVICE AND AIRFLOW

Page 4

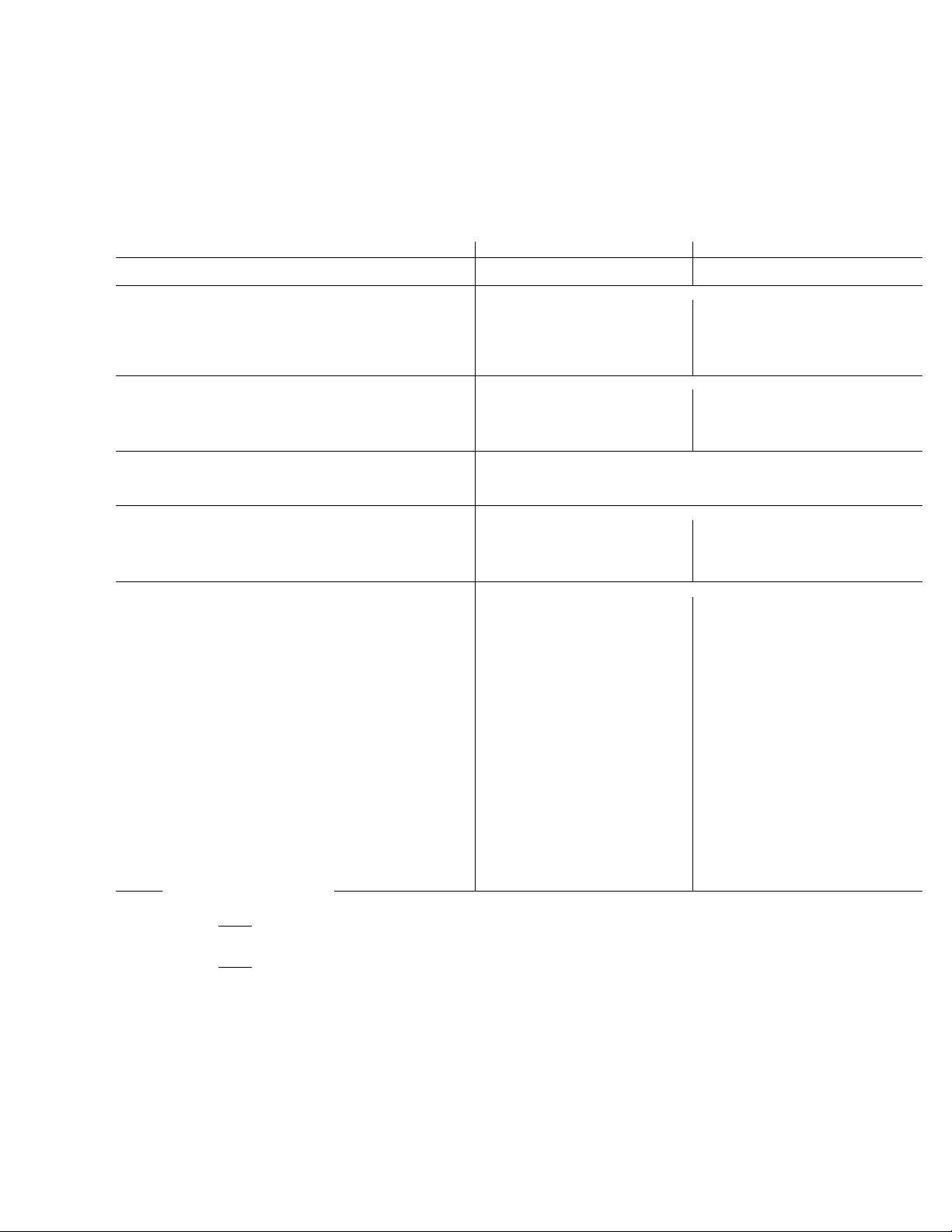

Table la — Physical Data — 50DP,DPE012,014

UNIT SIZE

OPERATING WEIGHT (lb)

Unit (Outdoor Coil/Indoor Coil)

AI/AI

Al/Cu

Cu/Cu

Roof Curb

Economizer

Electric Heat 65

Alternate Motor and Drive 5

COMPRESSOR

Quantity...Type

Oil (oz)

REFRIGERANT

Charge (lb) Sys 1* Sys 2

REFRIGERANT METERING DEVICE

Upper Circuit

Quantity...Length...lD/OD (in.)

Lower Circuit

Quantity...Length...ID/OD (in.) 6.. 20...0.055/0 125

OUTDOOR COIL Copper Tube, Aluminum or Copper Plate Fins

Rows

Fins/in.

Aluminum 13.6

Copper 124

Total Face Area (sq ft) 18.9

OUTDOOR AIR FAN Propeller Type, Direct Drive

Nominal Cfm

Quantity...Diameter (in.) 2. 22

Motor Hp (1075 Rpm) V2 ’/2 'k

INDOOR COIL Copper Tube, Aluminum or Copper Plate Fins

Rows 2

Fins/in.

Aluminum

Copper 13.1

Total Face Area (sq ft) 14.7

INDOOR AIR FANt Centrifugal, Belt Drive

Quantity...Size (in.)

Nominal Cfm

Rpm Range

Max Allowable Rpm 1550 1550 1550 1550

Motor Pulley Pitch Diameter (in.)

Fan Pulley Pitch Diameter (in.) 5.5

Belt, Quantity...Type...Length (in.) 1 V. 41

Speed Change per Full Turn

of Moveable Pulley Flange (Rpm) Opt 63

Moveaable Pulley Max Full Turns

from Closed Position

Factory Setting — Full Turns Open

Factory Speed Setting (Rpm) Std 846

Motor Hp (Service Factor)

HIGH-PRESSURE SWITCH

Cutout (psig)

Reset (psig) 320

LOW-PRESSURE SWITCH (Liquid Line)

Cutout (psig)

Reset (psig)

_______________________

Std 753-1066

Opt 878-1191

Std

Opt 2.8-3.8 3 4-4 4 3 4-4.4 3 4-4 4

Std

Opt 972

Std 1 (1.25)

Opt 1’/2 (1.20) 3 (1.15) 3 (1.15) 3 (1.15)

50DP012

1180 1260

1230 1340

1280

2. .P64

76 ea 76 ea

7.9, 6.6 10.9, 12.5

7 .35 0 055/0 125 8 34.0.055/0 125 8.. 44. 0 065/0.125

2

9000

144

2 10x10

4000 4000 5000

2 4-3 4

62

3 5

AIR INLET SCREENS

Economizer, Number...Size (in.)

iNDOOR AIR FILTERS (Type)

Number...Size (in.)

‘System 1 consists of upper portion of outdoor coil and lower portion of indoor coil

fUnits have adjustable standard and alternate drives

2.16x20x2

4 .16x25x2

50DPE012 50DP014

1260 1470

1340 1550

1410

Hermetic — 2 Cylinders

1 P56, 1 P60

±

Capillary Tubes

7...20 .0.055/0 125 7...35...0.065/0.125

3

13.6 136 136

12.4

18.9 18.9 18.9

8000 8000 12,000

2. .22 2...22 2...26

3

156

14.2

13.8 13.8 16.5

2 ..10x10

805-1093 805-1093 805-1093

978-1265 978-1265 978-1265

2 8-3 8 2.8-3.8 2 8-3 8

6.0

1 V. 43

58

57

3

920

1092 1063

2 (1 15)

10% efficient — Disposable Fiberglass

2. .16x20x2

4 16x25x2

1410 1630

200

110

2. .P77 1 ..06DA328

76 ea 160

R-22

8 3, 8 4

3

12.4

3 3

156 14.3

14.2

2 .10x10

6.0

1 V. 43

58

57

35 3

891 920

2 (1.15)

428

27

60

2 .20x25x1

1...20x20x1

2.. .16x20x2

4.. .16x25x2

Semi-Hermetic — 6 Cylinders

50DPE014

6...25 0 055/0 125

6. 25 0 055/0.125

6 .25.. 0 055/0.125

2 .20x20x2

3 16x20x2

2.16x25x2

20.8

—

3

124

1

13 1

2...10x10

5000

6.0

1. V...43

58

57

1092

2 (1 15)

i

Page 5

Table 1b — Physical Data — 50DP016,020

UNIT SIZE 50DP016

OPERATING WEIGHT (lb)

Unit (Outdoor Coil/Indoor Coil)

AI/AI

Al/Cu

Cu/Cu

Roof Curb

Economizer

Electric Heat

COMPRESSOR

Quantity...Type

OH (oz) 160 160 ea

REFRIGERANT

Charge (lb) Sys 1*. Sys 2

REFRIGERANT METERING DEVICE Capillary Tubes

U|»er Circuit

Quantity...Length...ID/OD (in.) 6 40 0 065/0 125

Lower Circuit

Quantity ...Length...ID/OD (in.)

OUTDOOR COIL

Rows 3

Fins/in.

Aluminum 13.6 136

Copper

Totai Face Area (sq ft) 18.9

OUTDOOR AIR FAN Propeller Type, Direct Drive

Nominal Cfm 12,000

Number...Dlameter (in.) 2 26

Motor Hp (1075 Rptn) 1

INDOOR COIL Copper Tubes, Aluminum or Copper Plate Fins

Rows 3

FIns/ln.

Aluminum 14.3

Copper 13.1

Totai Face Area (sq ft) 16.5

INDOOR AIR FANf Centrifugal, Belt Drive

Quantity ...Size (in.) 2 .10x10

Nominal Cfm 6000

Rpm Range Std 916-1186

Maximum Aiiowabie Rpm 1550 1550

Motor Puiley Pitch Diameter (in.) Std 3 4-4.4

Fan Puiiey Pitch Diameter (in.) 6.4 6.6

Belt, Quantity...Type...Length (in.)

SpeedChangeperFuilTurn Std

of Moveable Pu Iley Flange (R pm) Opt

Moveable Pulley Max Full Turns

from Closed Position

Factory Setting — Full Turns Open

Factory Speed Setting (Rpm) Std 970

Motor Hp (Service Factor) Std

HIGH-PRESSURE SWITCH

Cutout (psig)

Reset (psig)

LOW-PRESSURE SWITCH (Liquid Line)

Cutout (psig)

Reset (psig)

Opt 1158-1428

Pulley A

Pulley B

Opt 4 3-5 3

Puiiey A

Puiiey B

Opt

Puiiey A

Puiiey B

Opt

AiR INLET SCREENS

Economizer, Number...Size (in.)

INDOOR AIR FILTERS (Type)

Number...Size (in.)

1470

1550

1630

1 .06DA537

6 20 .0 055/0 125

6...20 ..0 055/0 125

Semi-Hermetic — 6 Cylinders

R-22 R-22

21.2

200

110

65

Copper Tubes, Aluminum or Copper Plate Fins

124

—

—

—

—

1 V.45

54

55

5

35

1240

—

—

3 (1.15) 5 (1 15)

— —

428

320

27

60

2 20x25x1

1...20x20x1

10% efficient

2. 20x20x2

3.16x20x2

2.16x25x2

Disposable Fiberglass

50DP020

1980

2110

2220

2. 06DA824

17.0, 17.0

13 25 0 055/0 125

13. .25.0 055/0 125

4

124

22.2

11,400

2 .26

1

4

14.4

13 1

17.9

2 .12x12

7200

—

—

848

1060

—

—

32

4.0

2 ..V 45

—

—

—

—

—

—

848

1060

4 20x20x2

4 16x20x2

'System 1 consists of upper portion of outdoor coil and lower

portion of indoor coii, except for size 020 which is intertwined

t016 unit has adjustable standard and aiternate drives The 020

unit does not have an aiternate drive, but has 2 non-adjustable

pulieys Puiiey A is installed in unit; puiley B is shipped with unit

Page 6

Step 3 — Field Fabricate Ductwork — Secure all

ducts to building structure. Use flexible duct connectors

between unit and ducts as required. Insulate and weather

proof all external ductwork, joints and roof openings

with flashing and mastic in accordance with applicable

codes.

Ducts passing through an unconditioned space must

be insulated and covered with a vapor barrier.

A minimum clearance is not required on 50DP,

DPE012,014 and 50DP016 units. The 50DP020 units

with electric heat require one-in. clearance the first 24 in.

of ductwork.

Outlet grilles must not lie directly below unit discharge.

Step 4 — Make Unit Duct Connections — Unit

is shipped for through-the-bottom duct connections.

Ductwork openings are shown in Fig. 1 and 4. Duet

connections are shown in Fig. 5. Field-fabricated con

centric ductwork may be connected as shown in Fig. 6 and

7. Attach all ductwork to roof curb and roof curb basepans. Refer to installation instructions shipped with

accessory roof curb.

50DR DPE0I2.0I4 50DP0I6

INDOOR FAN MOTOR

NOTE: Do not drill in this area, damage to basepan may resuit

In water ieak

Fig. 6 — Concentric Duct Air Distribution

I

NOTE: Do not drill in this area, damage to basepan may result

in water leak.

Fig. 5 — Air Distribution — Through-the-Bottom

Step 5 — Trap Condensate Drain — See Fig. 4

and 8 for drain location. Plug is provided in drain hole

and must be removed when unit is operating. One 3/4-in.

half coupling is provided inside unit evaporator section

for condensate drain connection. An 8-1/2in. x 3/4-in.

diameter and 2-in. x 3/4-in. diameter pipe nipple coupled

to standard 3/4-in. diameter elbows provide a straight

path down through holes in unit base rails (see Fig. 9).

A trap at least 4 in. deep must be used and must be pro

tected against freeze-up.

NOTE: Dimension A, A1 and B, B1 are obtained from fieldsupplied ceiling diffuser.

Fig. 7 — Concentric Duct Details

■ y--:

CONNECTION

11 DRAIN HOLES

Fig. 8 — Condensate Drain Details

Page 7

(| )FPT

DRAIN CONNECTION^ U

(HALF COUPLING)

Determine maximum deviation from average voltage;

(AB) 457 - 452 = 5 volts

(BC) 464 - 457 = 7 volts

(AC) 457 ~ 455 = 2 volts

u

#

Fig. 9 — Condensate Drain Piping Details

BASE RAIL-

TO TRAP -!>

Maximum deviation is 7 volts.

Determine % voltage unbalanee;

% Voltage Unbalance = 100 ~ 1-53%

7

This amount of phase unbalance is satisfaetory as it is

below the maximum allowable 2%.

IMPORTANT; If the supply voltage phase un

balance is more than 2%, contaet your loeal electric

utility company immediately.

Unit failure as a result of operation on improper line

voltage or excessive phase imbalance constitutes abuse

and may eause damage to eleetrieal eomponents. Sueh

operation would invalidate any applieable Carrier

warranty.

Step 6 — Make Electrical Connections

FIELD POWER SUPPLY ^ Unit is factory wired for

voltage shown on nameplate. Units are provided with

terminal bloek.

When installing units, provide a diseonnect per NEC

of adequate size (Table 2).

All field wiring must eomply with National Eleetrieal

Code and loeal requirements.

Route power lines through control box end panel — or

unit basepan — (Fig. 4) to terminal connections as shown

on unit wiring diagram and Fig. 10.

FIELD CONTROL WIRING — Install a Carrierapproved accessory thermostat assembly aecording to

installation instruetions ineluded with aecessory. Loeate

thermostat assembly on a solid wall in the eonditioned

space to sense average temperature.

Route thermostat eable or equivalent single leads of

no. 18 AWG colored wire from subbase terminals

through eonduit in unit to low-voltage connections as

shown on unit label wiring diagram and in Fig. 11.

NOTE; For wire runs up to 50 ft, use no. 18 AWG insu

lated wire (35 C minimum). For 50 to 75 ft, use no. 16

AWG insulated wire (35 C minimum). For over 75 ft, use

no. 14 AWG insulated wire (35 C minimum).

Set heat anticipator settings as indicated in Table 3.

Settings may be changed slightly to provide a greater

degree of eomfort for a partieular installation.

Refer to accessory remote control panel instructions

as required.

UjO

2

O IE

OT Q.

r-\ •

1 FIELD

! POWER

1 SUPPLY

1

TBI

11

\Z

lá ¿6

•¿\

EQUIP GND

_____

I

Fig. 10 — Field Power Wiring Connections

Operating voltage to eompressor must be within

voltage range indieated on unit nameplate. On 3-phase

units, voltages between phases must be balanced within

2% and the eurrent must be balanced within 10%.

Use the following formula to determine the % voltage

unbalanee.

% Voltage Unbalanee

average voltage

Example; Supply voltage is 460-3-60.

AB = 452 volts

BC = 464 volts

AC = 455 volts

Average Voltage

452 + 464 + 455

1371

457

REMOVABLE JUMPER

THERMOSTAT ASSEMBLY

IhPHr^ 1^ ^ ^

[r][b]1^ÉÉ]É[^[£][x][h][1][KI

o

<

(r.

liJ

e>

q:

LOW-VOLTAGE TERMINAL BLOCK IN UNIT CONTROL BOX

z>

_j

CD s

Fig. 11 — Field Control Thermostat Wiring

Step 7 — Make Outdoor Air Inlet Adjustments

MANUAL OUTDOOR AIR DAMPER — All units

(except those equipped with a faetory-installed eeono-

mizer) have a manual outdoor air damper to provide

ventilation air. Damper ean be preset to admit up to 25%

outdoor air into return air compartment. To adjust,

loosen seeuring screws and move damper to desired

setting then retighten screws to seeure damper (Fig. 12).

OPTIONAL ECONOMIZER

Enthalpy Control Setting (loeation is shown in Fig. 13) —

For maximum benefit of outside air, set enthalpy control

to the A setting (Fig. 14).

Page 8

25% ADJUSTABLE

AIR DAMPER

SECURING SCREWS

Fig. 12 — 25% Outdoor Air Section Details

COOLING

LOCKOUT

SWITCH

ENTHALPY

CONTROL

DAMPER MOTOR

BASE

'UNIT

Fig. 14 — Enthalpy Control Assembly

Mixed Air Thermostat Setting — Set mixed air thermo

stat in return air compartment to desired temperature of

air delivered to the conditioned space (not less than 35 F

or condensation in unit will result).

FILTERS

ECONOMIZER

CONTROL BOX

ECONOMIZER ::|i

Fig. 13 — Enthalpy Control Location

(Economizer Damper Assembly — End View)

VOLTAGE

UNIT

MODEL

50DP012

VOLTS-PH-HZ

208/230-3-60

460-3-60

575-3-60

RANGE

Max

Min

187 253

414 508 105

632

518

Damper Vent Position Setting

1. Set fan switch at ON (continuous fan operation) and

close night switch if used.

2. Set system selector switch to OFF.

3. Remove cap from vent adjustment screw on damper

motor terminal box cover.

4. Turn adjustment screw slowly until dampers assume

desired vent position. Do not manually operate

damper motor; damage to motor will result.

Table 2 — Electrical Data

136

(ea)

49

(ea)

41

(ea)

OUTDOOR

FAN

MOTOR

FLA

Qty

38

2

25

2

2 1

2

COMPR

RLA LRA

24 0

(ea)

(ea)

8 3

(ea)

INDOOR

FAN

MOTOR

FLA FLA

Hp

1 0

1 5

1 0

1 0

1 0

1 0

1 5

1 5

1 5

1 5

1 0

1 5

1 0

1 0

1 0

1 5

1 5

1 5

1 0

20

1 0

20

40

5 7

40

40

40

40

5 7

5 7

57

5 7

1 8

2 6

1 8

1 8

1 8

26

26

26

1 4

27

2 7

1 4

FACTORY-

INSTALLED

HEATERS

74/ 82

122

122/135

41/ 45

74/ 82

122

122/135

41/ 45

21

39

66

21

39

66

37

37

kW

26/31

42*

42/52

14/17

26/31

42*

42/52

14/17

16

30

51

16

30

51

37

37

POWER

SUPPLY

Min Ckt

Amps

66/ 66

68/ 68

98/108

158

158/174

66/ 66

101/110

160

160/176

68/ 68

31

i ta

23 1 30

24 30

48 50

50 50

MOCP

(Amps)

175

i

Page 9

Table 2 — Electrical Data (cont)

98

49

69

41

55

OUTDOOR

FAN

MOTOR

Qiy

2 38

2

2 2 1

2 38

UNIT

MODEL

50DPE012

VOLTAGE

RANGE

VOLTS-PH-HZ

Min Max RLA LRA

208/230-3-60 187

460-3-60

575-3-60 518 632

208/230-3-60

414

187

253

508

253

COMPR

20 9

(compr 1)

20 9

(compr 2)

104

(compr 1)

103

(compr 2)

93

(compr 1)

83

(compr 2)

25 6

(ea)

(compr 1)

137

(compr 2)

(compr 1)

(compr 2)

(compr 1)

(compr 2)

137

(ea)

50DP014

460-3-60

575-3-60 518 632

#

208/230-3-60 187 253 49 3 191

414 508

11 6

(ea)

93

(ea)

69

(ea)

55

(ea)

2 25

2

2 7 7

50DPE014

414

460-3-60

575-3-60 518

208/230-3-60

508 22 1

632 179 69 2 26

187 253

61

86 2 33

266 2 77 30

500P016

460-3-60 414 508 32 0 120

575-3-60

208/230-3-60

518 632 25 6

187 254 49 3

50DP020

460-3-60

Fuse only; unshaded values indicate fuses or circuit

■SiSiiiJ breakers may be used

Compr — Compressor

FLA — Full Load Amps

Hp — Horsepower

414 508

(ea)

199

(ea)

96 2

153

(ea)

77

(ea)

2 33 30 48

2

2

LRA — Looked Rotor Amps

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

*CSA-approved heaters are rated at 208 volts only

INDOOR

FAN

MOTOR

FLA

25

2 1

26

77 50 167

33 50 76

Hp

20

30

20

20

20

20

30

30

30

3.0

20

30

20

20

20

30

30

3 0

20

30

20

30

20

30

20

20

20

20

30

30

30

3.0

20

30

20

20

20

30

30

30

20

30

20

3.0

20

30

20

20

20

20

30

30

30

30

20

30

2 0

20

20

30

30

30

20

30

20

30

3.0

FLA FLA

106

106

106

106

10.6

10 5

10 5

105

105

10.5

106

10 6

106

106

10 6

10 5

INSTALLED

75

75

74/ 82

7 5

122

7 5

122/135

75

41/ 45

74/ 82

122

122/135

41/ 45

34

48

34

34

34

48

48

48

2 7

39

27

39

7 5

75

74/ 82

75

122

7 5

122/135

7 5

41/ 45

74/ 82

122

122/135

41/ 45

34

48

34

34

34

48

48

48

2 7

39

27

3.9

7 5

74/ 82

75

122

75

122/135

75

41/ 45

75

74/ 82

122

122/135

41/ 45

34

48

34

34

34

48

48

48

27

39

27

3.93737

74/ 82

122/135

163

163/180

39

74/ 82

122/135

163/180

FACTORY-

HEATERS

kW

26/31

42*

42/52

14/17

26/31

42*

42/52

14/17

16

21

39

30

66

51

21

16

39

30

66

51

37

37

37

37

26/31

42*

42/52

14/17

26/31

42*

42/52

14/17

21

16

39

30

66

51

21

16

39

30

66

51

37

37

37

37

26/31

42*

42/52

14/17

26/31

42*

42/52

14/17

21

16

39

30

66

51

21

16

39

30

66

51

37

37

26/31

42/52

56*

56/69

39

30

66

51

96

73

50

49

26/31

42/52

56/69

39

30

66

51

73

96

PO\WER

SUPPLY

Min Ckt 1 MOCP

Amps 1 (Amps)

63/ 63 teisis/isais!

66/ 66

102/112

162 I 175

162/179

63/ 66

106/116

166 r 175

166/182 TOSiStiCt'

66/ 70 ■ sai sa

32

34

32

53

85

34

55

86

27

29

50

52

73/ 73

76/ 76

103/113

156

162/179

73/ 73

107/116

160

166/182

76/ 76

35

36

35

53

87

36

55

89

28

30

50

52

85/ 85

88/ 88

102/112

214

162/179

85/ 85

106/116

217

166/182

88/ 88

38

40

38

53

85

40

55

86

31

32

50

52

103/103 ISSSOSJSeiij

107/116 pS&iSiSe.Ll

166/182 £$2SÈ»53i:i

217 1 225

217/239 ¡.■•gS5?2iSef

48

55

89

126

38

68

144/144

144/144

174/190

225/246

59

40

40

40

«3

oa

40

60

90

35

35

50

60

175

i;;.9oi;.oo

175

■4S.

45

45

60

90

43

60

90

35

35

50

60

iiissitsaSi/

225

225

‘'rTsms'

■S257195

SO

60

SO

60

■90

60

60

90

45

45

50

60

■90

60

70

iS-7S.<WS:;:

59 piiM-ii;..

93 fLwig&i’;:;-:,

130 {iiiÌSlj::/'--:/

Page 10

Step 8 — Install Outdoor Air Hood — The out

door air hood is common to 25% air ventilation and

economizer. If economizer is used, all electrical connec

tions have been made and adjusted at the factory.

Assemble and install hood in the field.

NOTE: The hood top cover, upper and lower filter

retainers, hood drain pan and filter support bracket are

secured to the top crate above the condenser fans. The

screens, hood side panels, remaining section of filter

support bracket and all other hardware are in a package

located inside the return-air filter access panel (Fig. 15

and 16).

OUTDOOR AIR HOOD AND

MOUNTING BRACKETS

Fig. 15 — Outdoor Air Hood

Component Location

UNIT TOP CRATE

^ -j:

______________________

/

----------------

—=

----------

/—\

^ \

UPPER FILTER

RETAINER

/ I n«/FR

LOWER

FILTER

RETAINER

HOOD DRAIN PAN

FILTER

SUPPORT

BRACKET

Fig. 16 — Outdoor Air Hood Components

HOOD TOP

COVER

START-UP

Unit Preparation — Check that unit has been installed

in accordance with installation instructions and appli

cable codes.

Compressor Mounting — On 50DP,DPE012 and

50DP014 units, compressors are internally spring

mounted. Do not loosen or remove compressor hold

down bolts. On 50DPE014 and 50DP016, 020 units,

loosen compressor holddown bolts until sidewise move

ment of the washer under each holddown bolt head can

be obtained. Do not loosen completely as bolts are self

locking and will maintain adjustment.

Internal Wiring — Check all electrical connections

in unit control boxes; tighten as required.

Refrigerant Service Valves — Each 50DP,DPE012

and 50DP014 unit system has 2 Schrader type service

ports, one on suction line and one on compressor dis

charge line. Be sure that caps on the ports are tight. The

50DPE014 and 50DP016, 020 have one service valve on

suction line, one on discharge line and one on liquid line.

Be sure valves are open.

Crankcase Heater(s) are energized as long as there is

power to the unit.

NOTE: Unit power must be on for 24 hours prior to

start-up.

1. Assemble hood top cover, side panels, upper filter

retainer and drain pan (Fig. 17).

2. Secure lower filter retainer and support bracket to

unit as shown in Fig. 17.

3. Loosen sheet metal screws for base unit top cover

located above outdoor air inlet opening.

4. Match notches in hood top cover to unit top cover

screws. Insert hood flange between unit top cover

flange and unit. Tighten screws.

5. Insert outdoor air inlet screens and spacer in channel

created by lower filter retainer and filter support

bracket.

6. Attach remaining section of filter support bracket.

UNIT MODEL VOLTAGES

50DP,DPE012,014

10

Table 3 — Heat Anticipator Settings

kW STAGE 1

208-230/3/60 26-31 40

460/3/60

208-230/3/60

460/3/60 51 40

14-17

42-52

16

30

51 .40

26-31

42-52

56-69

30 40

73

40

66

40

40

40

.66

66

.66

STAGE 2

—

.40

40

—

.40

.66

66

40

.66

.40

66

.66

Page 11

w

Table 4 — Air Quantity Limits

UNIT MODEL MIN CFM MAX CFM

50DP,DPE012 3000

50DP,DPE014

50DP016 4500

50DP020

'Indoor Fan Max Watts = 3000

3750

5400

5000

6250

7500*

9000

HEATING — Turn on main power to unit. Set system

selector switch at HEAT, fan switch at AUTO.; and

thermostat at a setting above room temperature. First

stage of electric heater elements are energized on closing

of heating contact No. 1 in thermostat. On a further fall

of room temperature, heater contact No. 2 closes ener

gizing second-stage electric heater elements.

To Shut Off Unit — Set system selector switch at OFF.

VENTILATION AIR CIRCULATION (Continuous

Fan) — Unit power on. System selector switch at OFF,

HEAT or COOL; fan switch set at ON. Indoor fan con

tactor is energized through the switch on the thermostat,

and the indoor fan runs continuously.

Indoor Air Fan — Fan belts and pulleys are factory

installed. Belts are secured to pulleys with tape.

Remove tape and, if required, adjust as described in

Service, Indoor Air Fan Adjustment.

50DP020 has 2 non-adjustable pulleys. Pulley A is

installed in unit. Pulley В is shipped in cardboard box

taped to vestibule below main control box.

AUTOMATIC CHANGEOVER (with Autqmatic

Changeover Thermostat) — System selector switch set

at AUTO. When temperature of conditioned space rises

to cooling selector lever setting, unit automatically

switches from heating mode to cooling mode. When tem

perature of the conditioned space falls to the heating

selector lever setting, unit automatically changes from

cooling mode to heating mode. The thermostat is inter

Outdoor Air Fans and Motors are factory set. Refer

to Service, Outdoor Air Fan Adjustment as required.

Return Air Filters — Check that correct filters are

installed in filter tracks. See Table 1. Do not operate unit

without return air filters.

Outdoor Air Inlet Screens — Outdoor air inlet

locked so that cooling and heating systems do not operate

at the same time.

HEAD PRESSURE CONTROL — All units have fan

cycling thermostats which, at 55 F, shut off one outdoor

fan motor. This permits unit to operate down to 40 F

outdoor air temperature.

screens must be in place before operating unit.

Economizer Section — Remove filter access

panel. Check that outdoor air damper is closed and return

#

air damper is open.

Economizer operation and adjustment is described in

Start-Up, Economizer Operation; and Service, Econo

mizer Adjustment, respectively.

Base Unit Operation

COOLING — Unit power on. System selector switch at

COOL; fan switch at AUTO.; thermostat at a setting

Economizer Operation — If unit is equipped with

modulating outdoor air control (economizer), it should

operate as follows;

below room temperature.

50DPE014 and 50DP016 — Compressor starts unloaded

on closure of No. 1 contact in thermostat.

Additional rise in room temperature closes contact

No. 2 in thermostat which de-energizes the unloader coil.

Compressor is now fully loaded.

Check cooling effects at a setting below room tempera

ture. Check unit charge. Refer to Service, Refrigerant

Charge.

Reset thermostat at a temperature above room tem

perature. Compressor(s) will shut off.

50DP,DPE012 and 50DP014.020 — Upon a rise in room

temperature, cooling contact No. 1 in the thermostat

closes, energizing the first-stage cooling contactor and the

indoor fan contactor. The first-stage compressor, out

door fan motor and indoor fan motor start and run.

Upon a further rise in room temperature, cooling

contact No. 2 in the thermostat closes, energizing the

second-stage cooling contactor. The second-stage

compressor starts and runs.

COOLING MODE — Indoor and outdoor fans and com

pressor energize when there is a call for cooling and

enthalpy of outdoor air is above enthalpy control setting.

The economizer damper moves to VENT position.

Indoor fan starts and economizer damper opens fully

on a first-stage call for cooling when enthalpy of outdoor

air is below the enthalpy control setting. Compressor

remains off.

Compressor is energized and mechanical cooling

integrates with economizer cooling upon a second-

stage call for cooling. If outdoor air temperature falls

below 50 F, cooling lockout switch prevents compressor

from operating.

Economizer damper modulates when mixed air tem

perature is below mixed air thermostat setting.

A freeze protection thermostat (FPT) is located on the

indoor coil. It detects ice buildup and turns off the

compressor, thus allowing the coil to clear. Once ice

melts, the compressor can be re-energized.

To Shut Off Unit — Set system selector switch at OFF

position or reset thermostat above room temperature.

Units with Signal-LOC™ protection device shut down on

any safety trip and thermostat light comes on. Determine

reason for safety trip. Restart 50DPE014 and 50DP016,

020 compressor(s) by resetting circuit breaker at unit.

HEATING MODE — Outdoor air damper stays at

VENT position while indoor air fan runs.

NOTE: If fan switch is at ON position, and room thermo

stat is satisfied, damper goes to ventilation position.

11

Page 12

Variable Volume Units — Units suitable for use with

variable volume air handling systems are equipped with 2

electric unloaders on the compressor. The control panel

for these units (Fig. 18) consists of a step controller, a

proportional thermostat, a 7-day timer and a power

switch.

Before starting unit, open compressor service valves

and liquid line shutoff valve. Be sure compressor crank-

ease heaters have been on for 24 hours and that crankcase

oil level indicates half full.

CONTROL SEQUENCE CHECKOUT

1. Turn on unit main power supply. Be sure unit is ready

to operate.

2. Set variable volume control panel POWER switch

at ON.

3. If supply air leaving unit is above 50 F (or other fieldset temperature), step controller will operate to de

energize compressor unloader solenoids (compressor

loads up) until set temperature is achieved. An interval

of 13.5 minutes is required to maximum loading

position. Refer to unit label diagram for unloader

sequencing. Also see Fig. 19.

4. Step controller, 7-day timer and proportional thermo

stat are factory set and adjusted. If other settings

or changes in adjustment are required, refer to dis

cussion of these items.

SEVEN-DAY TIMER ADJUSTMENT — Factory

settings are ON — 6:30 A.M.; OFF — 7:30 P.M. for each

of 7 days.

1. On the timer dial face (Fig. 18), loosen the thumb

screws which position the system ON and OFF

trippers.

2. Set trippers at desired system ON and OFF time

settings and tighten thumbscrews. Skipping a day(s) is

accomplished by removing trippers from the dial.

3. Set the timer by turning the dial face clockwise until

fixed pointer indicates correct day and time. Do not

turn dial face counterclockwise. Do not move fixed

pointer.

PROPORTIONAL THERMOSTAT — The propor

tional thermostat. Fig. 18, monitors temperature of the

conditioned air leaving unit. On signal from the thermo

stat, sequence motor operates cam switches to load or

unload compressor to maintain thermostat setting.

Thermostat is factory set at 50 F ± 6 F but may be reset

between 0°F and 100F as follows:

Temperature Setting — Turn knob on front of case until

pointer indicates desired set point temperature. This is

the center point of proportional range.

Range Adjustment — Remove cover and turn adjustment

wheel until pointer indicates desired range.

If sequencer motor shaft constantly moves back and

forth, increase proportional thermostat range (about 5 F

at a time) until system is stable.

CYCLE-LOC

STEP

CONTROLLER

POWER

SWITCH

PROPORTIONAL

THERMOSTAT

Fig. 18 — Control Panel, Variable Volume Limits

SEVEN

DAY

TIMER

12

Page 13

STEP CONTROLLER — The step controller consists of

a reversible electric motor which drives a set of cams that

MAKE

POINT

BREAK

POINT

activate up to 5 snap-acting switches. Each cam is adjust

able to operate at any point on the 160 angular degrees of

camshaft rotation. The differential of each system may be

adjusted from a minimum of 5 angular degrees to a maxi

mum limited only by the 160 angular degrees of camshaft

rotation.

Rotational direction is controlled by the proportional

thermostat through the step controller feedback poten

tiometer and balancing relay.

Determining Switch Settings — Switches are factory set

at angular settings as shown m Fig. 19 (also shown on unit

label diagram). To reset, if desired, determine angular

differential for each switch and between switches. Then

determine minimum differential or throttling range of

proportional thermostat to provide desired step con

troller differential or throttling range. This range should

be wide enough to prevent rapid cycling from one

capacity step to another. Then adjust cams to new settings

as required.

Fig. 20 — Step Controller Cam Adjusting

Details (Motor End View)

Cam Adjustments — The step controller is shipped with

cams set to operate switches (i.e. compressor unloaders)

as shown in Fig. 19. All switches are closed (compressor

unloaded). The shaft is positioned all the way counter

clockwise (as viewed from motor end).

Using the following procedure, first adjust all operating

points in one direction of motor drive. Then reverse

motor direction and adjust switch differentials. Use

potentiometer wiper as an approximate indicator of

#

angular adjustments using angular displacement scale

mounted on potentiometer back plate. Also see Fig. 20.

1. Loosen all bushing setscrews with a 1/16-in. Allen

wrench. Loosen all cam hex screws with a 3/16-in.

open-end wrench.

If setscrews are not accessible from top of controller,

operate motor to rotate cams and bushings by shorting

terminals R and B for counterclockwise rotation and

terminals R and W for clockwise rotation.

2. Momentarily de-energize motor to permit motor to

recycle to start position. Jumper terminals R and W to

run motor camshaft to desired position for operating

first switch. Stop motor in this position by removing

jumper between terminals S and T.

3. Starting with first switch, turn cam clockwise until

switch makes an audible “click” as roller moves up cam

rise to higher level. This is the operating point. Lock

bushing setscrews.

operating point of each of remaining switches in

Set

manner. Advance motor by momentarily jumper-

like manner.__

______

ing terminals S and T.

160

5. Set switch differential by reversing motor (short

terminals R and B) and running it to desired break

point. Stop motor at this point by de-energizing power

at LI (POWER switch off). Start at last switch and

progress to first switch.

Move differential cam clockwise so that roller is on

high part of cam. Be sure that switch is at make

position. To check this, manually lift roller assembly

to make switch. Move differential cam counterclock

wise until roller drops to low level of cam. At this

point, switch should break. Lock the hex screw.

#

6. Check settings by performing Control Sequence

Checkout.

I 2 3 4

STEP CONTROL SWITCH

Fig. 19 — Step Controller Sequence

7. If 115-volt to step controller is de-energized, timer

recycles to start point when power is restored.

13

Page 14

SERVICE

A WARNING

Before performing service or maintenance operations

on unit, turn off main power switch to unit. Turn off

accessory heater power switch if applicable. Elec

trical shock could cause personal injury.

Cleaning — Inspect unit interior at beginning of each

heating and cooling season or as operating conditions

require. Remove unit top panel and/or side panels for

access to unit interior.

INDOOR COIL — Clean with a commercial coil cleaner.

OUTDOOR COIL — Clean outdoor coil annually or as

required by location or outdoor air conditions. Inspect

coil monthly — clean as required.

CONDENSATE DRAINS — Check and clean each year

at start of cooling season. In winter, keep drains and traps

dry or protect against freeze-up.

5. Set movable flange at nearest keyway of pulley hub

and tighten setscrew. (See Table 1 for speed change for

each full turn of pulley flange.)

To align fan and motor pulleys, loosen fan pulley set

screws and slide fan pulley along fan shaft. Make angular

alignment by loosening motor from mounting plate.

FILTERS — Clean or replace at start of each heating

and cooling season, or more often if operating conditions

require. Refer to Table 1 for type and size.

OUTDOOR AIR INLET SCREENS — Clean screens

with steam or hot water and a mild detergent. Do not use

throwaway filters in place of screens.

Lubrication

COMPRESSORS — Each compressor is charged with

correct amount of oil at the factory.

FAN SHAFT BEARINGS — No lubrication required.

Bearings are permanently lubricated.

FAN MOTOR BEARINGS — No lubrication of out

door fan or indoor blower motors are required for first

5 years of operation. Annually thereafter, clean and

repack bearings with a suitable bearing grease.

Indoor Air Fan Adjustment — Fan motor pulleys

are factory set for speed shown in Table 1. The 50DP020

units have fixed pulleys. Fan speed can be adjusted only

by changing the pulley. To change fan speed on 50DP,

DPE012,014and 50DP016:

Fig. 21 — Indoor Air Fan Pulley Adjustment

(50DP.DPE012,014 and 50DP016)

To Adjust Belt Tension — Loosen fan motor pivot

bolts. Move motor mounting plate up or down for proper

belt tension (1/2-in. deflection with one finger) and

tighten pivot bolts. Adjust lock bolt and nut on mounting

plate to secure in fixed position.

Outdoor Air Fan Adjustment (Fig. 22) — Shut off

unit power supply. Remove fan top grille assembly and

loosen fan hub screws. Adjust fan height on unit using a

straight edge placed across the fan orifice. Tighten

setscrews and replace rubber hubcap to prevent hub from

rusting to motorshaft. Fill hub recess with permagum if

rubber hubcap is missing.

1. Shut off unit power supply.

2. Loosen belt by loosening fan motor mounting

plate nuts.

3. Loosen movable pulley flange setscrew (see Fig. 21).

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed.

Increasing fan speed increases load on motor. Do not

exceed maximum speed specified in Table 1.

See Table 4 for air quantity limits.

14

50DPE014

'/4 ± '/b

A

(in.)

50DP,DPE012

50DP014 50DP016,020

’Vi6 ± Vs

Fig. 22 — Outdoor Air Fan Adjustment

Page 15

Economizer Adjustment

1. Set enthalpy control at its highest setting. If outdoor

temperature is above 70 F, perform the following:

install jumper between enthalpy control terminals 1

and 2 (red and yellow wires).

#

2. Set system selector switch at COOL and set cooling

selector lever at lowest setting. (Cooling mode may be

simulated by removing thermostat wires from termi

nals Y1 and Y2 [if used] and installing jumper between

Y1 and R.)

3. Set mixed air thermostat (MAT.) at lowest setting.

Outdoor air damper goes to fully open position

(indoor air damper closes).

4. Set mixed air thermostat at highest setting. Outdoor

air damper goes to fully elosed position ^ndoor air

damper opens).

5. Adjust meehanical linkage for correct positioning

if necessary. If cooling was simulated in 2, remove

jumper and reconnect thermostat wire(s).

Power Failure — Dampers do not have a spring

return. In event of power failure, dampers remain in

position until power is restored. Do not manually

Refrigerant Charge — Amount of refrigerant charge

is listed on unit nameplate and in Table 1. Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

Refrigerants.

Unit panels must be in place when unit is operating

during charging procedure.

NO CHARGE — Use standard evacuating techniques.

After evacuating system, weigh in the specified amount of

refrigerant. (Refer to Table 1.)

LOW CHARGE COOLING — Using appropriate cool

ing charging chart. Fig. 24, 25, 26 or 27, add refrigerant

until conditions of the chart are met. Note that charging

charts are different from ones normally used. Charts are

based on charging units to correct superheat for various

operating conditions. An accurate pressure gage and

temperature sensing device are required. Connect tem

perature sensing device to service port on suction line and

insulate it so that outdoor ambient temperature does not

affect reading. Indoor air cfm must be within normal

operating range of unit.

operate damper motor.

TO USE COOLING CHARGING CHART — Take

outdoor ambient temperature and read the suction

pressure gage. Refer to chart to determine correct

50DP020 Indoor Air Fan Motor Removal

NOTE: To remove belts only, follow steps 1 - 4.

1. Remove filter and supply air section access panels.

Remove center post (Fig. 4).

2. Loosen adjusting nuts A and E, Fig. 23.

3. Push motor away from indoor coil to zero adjustment.

Tighten nut A.

4. Remove belts from pulleys.

5. Remove holddown screws at B and C. Loosen screw

at D.

6. Holding motor and pulley securely, slide motor

mount assembly out of unit along slide tracks.

NOTE: To reinstall motor, reverse above procedure.

suction temperature. If suction temperature is high, add

refrigerant. If suction temperature is low, carefully blow

some of the charge. Recheck suction pressure as charge

is adjusted.

Example: Fig. 24 — 50DP012

Outdoor Temperature

Suction Pressure

Suction Temperature should be

(Suction Temperature may vary ± 5F.)

If Chargemaster® charging device is used, temperature

and pressure readings must be accomplished using

appropriate charging chart.

.....................................................

........................................................

.....................................

75 F

65 psig

62 F

Page 16

SUCTION LINE TEMPERATURE F

Fig. 25 — Cooling Charging Chart —

50DPE012. 50DP014

(T

D

V)

CO

u

z

z

o

20 30 40 50 60

SUCTION LINE TEMP (F)

Fig. 26 — Cooling Charging Chart

50DPE014, 50DP016

70

20 3 0 4 5 50 6 0 65

SUCTION LINE TEMPERATURE (F)

70

Fig. 27 — Cooling Charging Chart — 50DP020

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 |4 PC111 Catalog No 565-104 Printed in U S A Form50DP-26SI Pg16 7-88 Repiaces: 50DP-25Si

Tab llb|6b

For replacement items use Carrier Specifieci Parts

Loading...

Loading...