Carrier 48XZN060130300, 48XZN060115300, 48XZN048130300, 48XZN048115300, 48XZN042090300 Installation Guide

...

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

NOTE: Installer: Make sure the Owner's Manual and Service

Instructions are left with the unit after installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS ......................... 1

INTRODUCTION ................................... 2

RECEIVING AND INSTALLATION ................. 2-13

Check Equipment .................................. 2

Identify Unit .................................... 2

Inspect Shipment ................................. 2

Provide Unit Support ............................... 2

Roof Curb ...................................... 2

Slab Mount ..................................... 2

Ground Mount .................................. 2

Field Fabricate Ductwork ............................ 2

Provide Clearances ................................. 2

Rig and Place Unit ................................. 4

Connect Condensate Drain ........................... 7

Install Flue Hood ................................... 7

Install Gas Piping ............................... 7-10

Install Duct Connections ............................ 10

Configuring Units for Downflow (Vertical)

Discharge ..................................... 10

Install Electrical Connections ........................ 11

High-Voltage Connections ........................ 11

Special Procedures for 208-V Operation .............. 12

Control Voltage Connections ....................... 12

Balance Point Setting Thermidistat or Hybrid Heat

Thermostat .................................... 12

Easy Select TM . .................................. 13

Transformer Protection ........................... 15

PRE-START-UP ................................... 15

START-UP ..................................... 16-19

Check for Refrigerant Leaks ......................... 16

Unit Sequence of Operation ......................... 16

Start-Up Heating and Make Adjustments ............... 17

Checking Heating Control ......................... 17

Start-Up Cooling and Make Adjustments ............. 18

Checking Cooling Control Operation ................ 19

MAINTENANCE ................................ 24-26

Air Filter ........................................ 24

Indoor Blower and Motor ........................... 24

Flue Gas Passageways .............................. 25

Combustion Air Blower ............................ 25

Limit Switch ..................................... 25

Burner Ignition ................................... 25

Main Burners .................................... 25

Outdoor Coil, Indoor Coil, & Condensate Drain Pan ...... 26

Outdoor Fan ..................................... 26

®

Turn to the Expertg

C99088

Fig. 1 - Unit 48XZ

Electrical Controls and Wiring ....................... 26

Refrigerant Circuit ................................. 27

Gas Input ........................................ 27

Indoor Airflow ................................... 27

Check Defrost Thermostat ........................... 27

Puron® Items .................................... 27

TROUBLESHOOTING .............................. 30

START-UP CHECKLIST ............................ 30

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. consult local

building codes, the current editions of the National Fuel Gas Code

(NFGC) NFPA 54/ANSI Z223.1, and the National Electrical Code

(NEC) NFPA 70.

In Canada refer to the current editions of the National Standards of

Canada CAN/CSA-BI49.1 and .2 Natural Gas and Propane

Installation codes, and Canadian Electrical Code CSA C22.1

/

Recognize safety information. This is the safety-alert symbol /_.

When you see this symbol on the unit and in instructions or manu-

als, be alert to the potential for personal injury. Understand these

signal words: DANGER, WARNING, and CAUTION. These

words are used with the safety-alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury

or death. WARNING signifies hazards which could result in per-

sonal injury or death. CAUTION is used to identify unsafe practic-

es which may result in minor personal injury or product and prop-

erty damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off main

power to system. There may be more than one disconnect

switch. Turn off accessory heater power switch if

applicaMe.

FIRE, EXPLOSION, ELECTRICAL SHOCK AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

A qualified installer or agency must use only

factory-authorized kits or accessories when modifying this

product.

INTRODUCTION

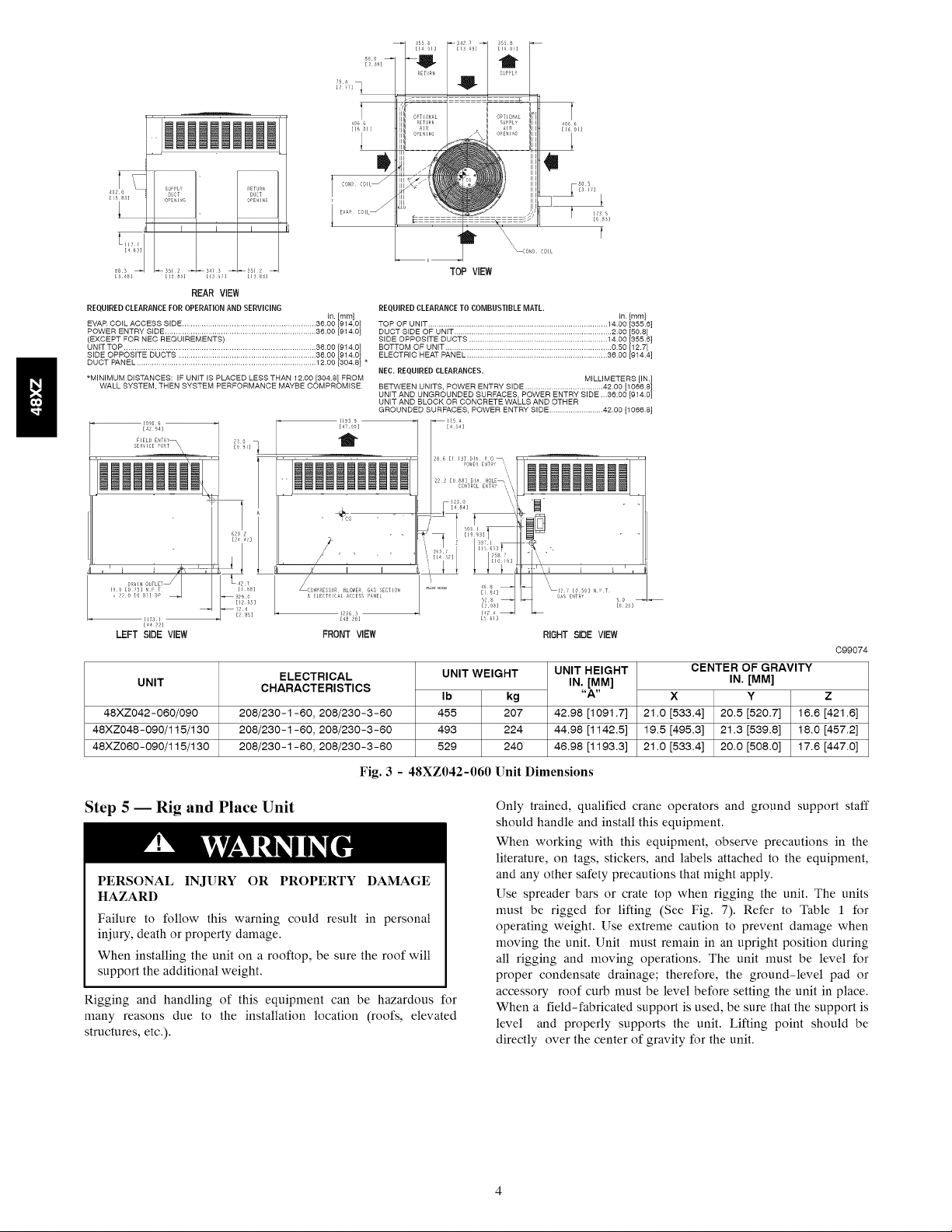

The 48XZ unit (see Fig. 1) is a fully self-contained, combination

Category I gas heating/electric cooling unit designed for outdoor

installation (See Fig. 2 and 3 for unit dimensions). All unit sizes

have return and discharge openings for both horizontal and

downflow configurations, and are factory shipped with all

downflow duct openings covered. Units may be installed either on

a rooftop, a cement slab, or directly on the ground, if local codes

permit (See Fig. 4 for roof curb dimensions).

Models with an N in the fifth position of the model number are

dedicated Low NOx units designed for California installations.

These models meet the California maximum oxides of nitrogen

(NOx) emissions requirements of 40 nanograms/joule or less as

shipped from the factory and must be installed in California Air

Quality Management Districts or any other regions in North

America where a Low NOx rule exists.

RECEIVING AND INSTALLATION

Step 1 -- Check Equipment

IDENTIFY UNIT

The unit model number and serial number are stamped on the unit

information plate. Check this information against shipping papers.

INSPECT SHIPMENT

Inspect for shipping damage while unit is still on shipping pallet. If

unit appears to be damaged or is torn loose from its anchorage,

have it examined by transportation inspectors before removal.

Forward claim papers directly to transportation company.

Manufacturer is not responsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify the

nearest equipment distribution office if any item is missing. To

prevent loss or damage, leave all parts in original packages until

installation.

Step 2 -- Provide Unit Support

For hurricane tie downs, contact distributor for details and PE

(Professional Engineering) Certificate if required.

ROOF CURB

Install accessory roof curb in accordance with instructions shipped

with curb (See Fig. 4). Install insulation, cant strips, roofing, and

flashing. Ductwork must be attached to curb.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for a water tight seal. Install gasketing material supplied

with the roof curb. Improperly applied gasketing also can result in

air leaks and poor unit performance.

Curb should be level to within 1/4 in. (6 mm). This is necessary for

unit drain to function properly. Refer to accessory roof curb

installation instructions for additional information as required.

SLAB MOUNT

Place the unit on a solid, level concrete pad that is a minimum of 4

in. (102 mm) thick with 2 in. (51 mm) above grade. The slab

should be flush on the compressor end of the unit (to allow

condensate drain installation) and should extend 2 in. (51 mm) on

the three remaining sides of the unit. Do not secure the unit to the

slab except when required by local codes.

GROUND MOUNT

The unit may be installed either on a slab or placed directly on the

ground, if local codes permit. Place the unit on level ground

prepared with gravel for condensate discharge.

Step 3 -- Field Fabricate Ductwork

Secure all ducts to roof curb and building structure on vertical

discharge units. Do not connect ductwork to unit. For horizontal

applications, unit is provided with flanges on the horizontal

openings. All ductwork should be secured to the flanges. Insulate

and weatherproof all external ductwork, joints, and roof openings

with counter flashing and mastic in accordance with applicable

codes.

Ducts passing through an unconditioned space must be insulated

and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be

ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork. Cabinet

return-air static shall not exceed -.25 IN. W.C..

Step 4 -- Provide Clearances

The required minimum operating and service clearances are shown

in Fig. 2 and 3. Adequate combustion, ventilation and condenser

air must be provided in accordance with section 9.3, Air for

Combustion and Ventilation, of the National Fuel Gas Code

NFPA54/ANSI Z223.1 or applicaMe provisions of local building

code. In Canada, follow sections 8.2, 8.3, or 8.5 of Can/CGA

(Canadian Gas Association) B149.1 Installation Codes or

applicaMe provisions of local building code.

IMPORTANT: Do not restrict outdoor airflow. An air restriction

at either the outdoor-air inlet or the fan discharge may be

detrimental to compressor life.

The condenser fan pulls air through the condenser coil and

discharges it through the top grille. Be sure that the fan discharge

does not recirculate to the condenser coil. Do not locate the unit in

either a corner or under an overhead obstruction. The minimum

clearance under a partial overhang (such as a normal house

overhang) is 48-in. (1219 mm) above the unit top. The maximum

horizontal extension of a partial overhang must not exceed 48-in.

(1219 mm).

Do not place the unit where water, ice, or snow from an overhang

or roof will damage or flood the unit. Do not install the unit on

carpeting or other combustible materials. The unit may be installed

on wood flooring or on Class A, B, or C roof covering materials.

O DUCT DUCT

83 ] OPEN INO OPEN I[_O

I SUPPLY [ RETURN

[317]

Y

153.3

[6041

4

I

[983] [21.67] [983]

REAR VIEW

REQ'D CLEARANCES FOR OPERATION AND SERVICING. in. (mm)

Evaporator coil access side .................. 36 (914)

Power entry side (except for NEC requirements) ......... 36 (914)

Unit top .......................... 48 (1219)

Side opposite ducts ..................... 36 (914)

Duct panel ........................ 12 (304.8)*

*Minimum distances: If unit is placed less than 12 in. (304.8 mm) from wall

system, then the system performance may be compromised.

LEGEND

CG - Center of Gravity

COND - Condenser

EVAP - Evaporator

NEC - National Electrical Code

REQ'D - Required

Note: Dimensions are in in. (mm)

[3144]

FIELD ENTRY

7_85

PORTS_\\

t

EVAP COIL •

REQ'D CLEARANCES TO COMBUSTIBLE MAT'L. in. (mm)

Top of unit ......................... 14 (355.6)

Duct side of unit ....................... 2 (50.8)

Side opposite ducts ..................... 14 (355.6)

Bottom of unit ....................... 0.50 (12.7)

Flue panel ......................... 36 (914.4)

NEC REQ'D CLEARANCES. in. (mm)

Between units, power entry side .............. 42 (1066.8)

Unit and ungrounded surfaces, power entry side ......... 36 (914)

Unit and block or concrete walls and other grounded

surfaces, control box side ................. 42 (1066.8)

[47.00]

1195.9 1

TOP VIEW

_116 3

[4.58]

286 [I 13]POWERD IA"ENTRY_

CONTROL ENTRY

[4.84]

S 123.0

3_13.8 456.2[17.961 3472

il

KO.

,_oIi_N_g__OgLETJI

_8Sl,O

48XZ024-040

48XZ030-040/060

48XZ036-060/090

[32721

LEFT SIDE VIEW

UNIT

L42 F

[1681

326.5

[12.851

_72.4

[285]

ELECTRICAL

CHARACTERISTICS

208/230 - 1-60

208/230 - 1-60

208/230-1-60, 208/230-3-60

[_8.281

FRONT VIEW

UNIT WEIGHT

Ib kg

365 166

365 166

403 183

Fig. 2 - 48XZ024-036 Unit Dimensions

UNIT HEIGHT

39.021991.1]

39.021991.1]

41.0211041.9]

\

IN.[MM]

"A"

FLUE HOOD

[I.841

[ROD]

[4811

50

[0.20]

RIGHT SIDE VIEW

C99017

CENTER OF GRAVITY

IN, [aM]

X Y Z

20.0 [508] 19.3 [489] 17.6 [447]

20.0 [508] 19.3 [489] 17.6 [447]

20.0 [508] 14.0 [355.6] 13.0 [330.2]

I

REAR VIEW

REQUIRED CLEARANCE FOR OPERATION AND SERVmClNO

EVAR COIL ACCESS SIDE .............................................................. 36.00 [914.0]

POWER ENTRY SIDE ...................................................................... 36.00 1914.0]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP ......................................................................................... 36.00 [914.0]

SIDE OPPOSITE DUCTS ................................................................ 36.00 [914.0]

DUCT PANEL ................................................................................... 12.00 [304.8] *

*MINIMUM DISTANCES: IF UNIT IS PLACED LESS THAN 12.00 [3048[ FROM

WALL SYSTEM, THEN SYSTEM PERFORMANCE MAYBE COMPROMISE.

IIZSI

E,H 22]

LEFTSIDEVIEW

UNIT

48XZ042-060/090

48XZ048-090/115/130

48XZ060-090/115/130

CHARACTERISTICS IN. [MM]

208/230-1-60, 208/230-3-60 455 207 42.98 [1091.7]

208/230-1-60, 208/230-3-60 493 224 44.98 [1142.5]

208/230-1-60, 208/230-3-60 529 240 46.98 [1193.3]

in. [ram]

1193 9 --

FRONT VIEW RIGHTSIDE VIEW

ELECTRICAL UNIT WEIGHT UNIT HEIGHT

TOP VIEW

REQUIRED CLEARANCE TO COMBUSTIBLE MATL

TOP OF UNIT ................................................................................... 1400 [355 6]

DUCT SIDE OF UNIT ......................................................................... 200 [50.8]

SIDE OPPOSITE DUCTS ................................................................ 1400 [355 6]

BOTTOM OF UNIT ............................................................................. 050 [12.7]

ELECTRIC HEAT PANEL ................................................................. 3600 [914 4]

NEC. REQUIRED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE .................................... 4200 [1066 8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE 36,00 [914 0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE ......................... 4200 [1066 8]

E454]

MILLIMETERS [IN.]

_....

HOLE

Ib kg "A"

Fig. 3 - 48XZ042-060 Unit Dimensions

in [mm]

CENTER OF GRAVITY

X Y

21.0 [533.4] 20.5 [520.7]

19.5 [495.3] 21.3 [539.8]

21.0 [533.4] 20.0 [508.0]

C99074

IN. [aM]

Z

16.6 [421.6]

18.0 [457.2]

17.6 [447.o]

Step 5 -- Rig and Place Unit

PERSONAL INJURY OR PROPERTY DAMAGE

HAZARD

Failure to follow this warning could result in personal

iniury, death or property damage.

When installing the unit on a rooftop, be sure the roof will

support the additional weight.

Rigging and handling of this equipment can be hazardous for

many reasons due to the installation location (roofs, elevated

structures, etc.).

Only trained, qualified crane operators and ground support staff

should handle and install this equipment.

When working with this equipment, observe precautions in the

literature, on tags, stickers, and labels attached to the equipment,

and any other safety precautions that might apply.

Use spreader bars or crate top when rigging the unit. The units

nmst be rigged for lifting (See Fig. 7). Refer to Table 1 for

operating weight. Use extreme caution to prevent damage when

moving the unit. Unit nmst remain in an upright position during

all rigging and moving operations. The unit nmst be level for

proper condensate drainage; therefore, the ground-level pad or

accessory roof curb nmst be level before setting the unit in place.

When a field-fabricated support is used, be sure that the support is

level and properly supports the unit. Lifting point should be

directly over the center of gravity for the unit.

ase _,

/ Screw-.._ q_

/

/ _ Wood nailer* \

I Flashing field II1_1 II \

/ supplied _ _JD_il_- Roofcurbq

II_ill j.q_lnsulation(fieldI

I Roofing mate_al II_ii_" II supphed)/

/ fi_'dsuPP'i_--II_itl IL /

_, /l_!;i!ll II_Duetwork /

\ IIfieldsupplied/

/ base

/ ,,So,ew_

/ ,,(NOTE A) -'t

*Gasketing .._

/ outerflange _-i_z _Woodnailer, _

I Flashing field II1_111

I supplied _ _ll_J_ Roofcurb*

I Roofing matei'al II_ supplied)

I|_su_ti°,n (f!?Id

/|_::JJl I _Ductwork t

"_/\/\/\/X/7 J

Roof Curb for Small Cabinet

Note A:When unit mounting screw is used

Rettrn opening

(BXC)

48XZ024-036 14 (356) 11 (279) 16-1/2 (419)

48XZ042-060 8 (203) 16-3/16 (411 ) 17-3/8 (441)

NOTES:

retainer bracket must also be used.

Supplyopening

(Bx C)

f

A

Sho_

Suppo4

Long

Suppo4

UNIT SIZE IN. (MM) IN. (MM) IN. (MM)

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied, as required, to unit being installed.

3. Roof curb is made of 1d-gauge steel.

4. Attach ductwork to curb (flanges of duct rest on curb).

5. Insulated panels: 1-in. (25 mm) thick fiberglass 1 lb (.47 kg) density.

d. When unit mounting screw is used (see Note A), a retainer bracket must be used as well. This bracket must also be used when required by code for hurricane or seismic

conditions. This bracket is available through Micrometl.

ODS CATALOG

NUMBER

CPRFCURB006A00

CPRFCURB007A00

CPRFCURB008A00

CPRFCURB009A00

A B C

8 (203) 11 (279) 16-1/2 (419)

14 (356) 16-3/16 (411) 17-3/8 (441)

Fig. 4 - Roof Curb Dimensions

Insulated Gasket around

deck pan outer edge

_/\/\/\/X/_ /

Roof Curb for Large Cabinet

Note A:When unit mounting screw is used

retainer bracket must also be used.

R/A

2 _Gasket around

duct

\,

28-3/4 (730)

28-3/4 (730)

40-1/4 (1022)

40-1/4 (1022)

C00076

D

IN. (MM)

1 2

f

Y

4 x 3

000070

CORNER WEIGHTS (SMALL CABINET)

Unit H

Total Weight 365 166 365 166 403 183 H

Corner Weight 1 73 33 73 33 81 37 H

Corner Weight 2 57 26 57 26 63 29 H

Corner Weight 3 88 40 88 40 97 44 H

Corner Weight 4 147 67 147 67 162 73 H

024 030 036 H

Ib kg Ib kg Ib kg H

Unit

Total Weight

Corner Weight 1

Corner Weight 2

Corner Weight 3

Corner Weight 4

CORNER WEIGHTS (LARGE CABINET)

042 048 060

Ib I kg Ib I kg Ib I kg

455 I 206 493 I 224

91 I 4t 99 I 45

71 I 32 77 I 35

110 I 50 119 I 54

183 I 83 198 I 90

Fig. 5 - 48XZ Corner Weights

.._A"/ _i

DUCTS

SEAL STRIP MUST BE IN

PLACE BEFORE PLACING

UNIT ON ROOF CURB

BASEPAN SLOT (BELOW HANDHOLDS)

BEFORE RIGGING

UNIT 48XZ in. mm in.

024 19.0 482.6 18.25

030 19.0 482.6 18.25

036 20.0 508.0 19.0

042 20.0 508.0 21.25

048 20.0 508.0 21.25

060 21.0 533.4 20.0

Ib kg

400 18t

423 192

471 2t4

548 249

575 261

595 270

Fig. 6 - Suggested Rigging

AMAXIMUM SHIPPING WEIGHT

529 I 240

106 I 48

82 I 37

128 I 58

213 I 97

C99015

B

mm

463.6

463.6

482.6

539.8

539.8

508.0

HOOK

HANDHOLD

FEED

C99067

Fig. 7 - Threading Belt

UNIT FALLING HAZARD

Failure to follow this warning could result in personal

iniury or death.

Never stand beneath rigged units or lift over people.

Dedicated low NOx models MUST be installed in California Air

Quality Management Districts where a Low NOx rule exists. These

models meet the California maximum oxides of nitrogen (NOx)

emissions requirements of 40 nanograms/joule or less as shipped

from the factory.

NOTE: Low NOx requirements apply only to natural gas

installations.

PERSONAL INJURY HAZARD

Failure to follow this warning could result in personal

iniury or death.

Never exceed 200 lb (91 kg) per bracket lifting force.

PERSONAL INJURY HAZARD

Failure to follow this warning could result in personal

injury/death.

Accessory lifting kit is only to be used with Small Packaged

units which have a composite unit base with molded rigging

holds.

Step 6 -- Connect Condensate Drain

NOTE: When installing condensate drain connection be sure to

comply with local codes and restrictions.

Model 48XZ disposes of condensate water through a 3/4 in. NPT

fitting which exits through the compressor access panel (See Fig. 2

and 3 for location).

Condensate water can be drained directly onto the roof in rooftop

installations (where permitted) or onto a gravel apron in

groundlevel installations. Install a field-supplied condensate trap

at end of condensate connection to ensure proper drainage. Make

sure that the outlet of the trap is at least 1 in. lower than the

drain-pan condensate connection to prevent the pan from

overflowing (See Fig. 8). Prime the trap with water. When using a

gravel apron, make sure it slopes away from the unit.

If the installation requires draining the condensate water away

from the unit, install a 2-in. (51 mm) trap at the condensate

connection to ensure proper drainage (See Fig. 8). Make sure that

the outlet of the trap is at least 1 in. lower than the drain-pan

condensate connection. This prevents the pan from overflowing.

Prime the trap with water. Connect a drain tube - using a minimum

of 3/4-in. PVC or 3/4-in. copper pipe (all field-supplied) - at the

outlet end of the 2-in. (51 mm) trap. Do not undersize the tube.

Pitch the drain tube downward at a slope of at least l-in. (25 mm)

for every 10 ft (3 m) of horizontal run. Be sure to check the drain

tube for leaks.

1"(25 mm) MIN.

TRAP

2" (51mm) MIN.

A08001

Fig. 8 - Condensate Trap

PERSONAL INJURY AND UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury

or death and unit component damage.

The venting system is designed to ensure proper venting. The

flue hood assembly must be installed as indicated in this

section of the unit installation instructions.

Install the flue hood as follows:

1. This installation must conform with local building codes

and with the National Fuel Gas Code (NFGC),

NFPA54/ANSI Z223.1 (in Canada, CAN/CGA B149.1, and

B149.2). Refer to Provincial and local plumbing or

wastewater codes and other applicable local codes.

2. Remove flue hood from shipping location (inside the return

section of the blower compartment-See Fig. 9). Place vent

cap assembly over flue panel. Orient screw holes in vent cap

with holes in the flue panel.

3. Secure flue hood to flue panel by inserting a single screw on

the right side and the left side of the hood.

Step 8 -- Install Gas Piping

The gas supply pipe enters the unit through the access hole

provided. The gas connection to the unit is made to the 1/2-in.

FPT gas inlet on the manual shutoff or gas valve.

Install a gas supply line that runs to the heating section. Refer to

Table 2 and the NFGC for gas pipe sizing. Do not use cast-iron

pipe. It is recommended that a black iron pipe is used. Check the

local utility for recommendations concerning existing lines. Size

gas supply piping for 0.5 IN. W.C. maximum pressure drop. Never

use pipe smaller than the l/2-in. FPT gas inlet on the unit gas

valve.

When installing the gas supply line, observe local codes pertaining

to gas pipe installations. Refer to the NFGC NFPA54/ANSI

Z223.1 (in Canada, CAN/CGA B149.1 latest edition. In the

absence of local building codes, adhere to the following pertinent

recommendations:

1. Avoid low spots in long runs of pipe. Grade all pipe 1/4 in.

(6 mm) in every 15 ft (5 m) to prevent traps. Grade all

horizontal runs downward to risers. Use risers to connect to

heating section and to meter.

2. Protect all segments of piping system against physical and

thermal damage. Support all piping with appropriate straps,

hangers, etc. Use a minimum of one hanger every 6 ft (2 m).

For pipe sizes larger than 1/2 in., follow recommendations

of national codes.

3. Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections. Use

only pipe dope that is resistant to action of liquefied

petroleum gases as specified by local and/or national codes.

Never use Teflon tape.

Step 7 -- Install Flue Hood

The flue hood assembly is shipped in the return section of the

indoor blower compartment (See Fig. 10). Remove the return duct

cover to locate the assembly.

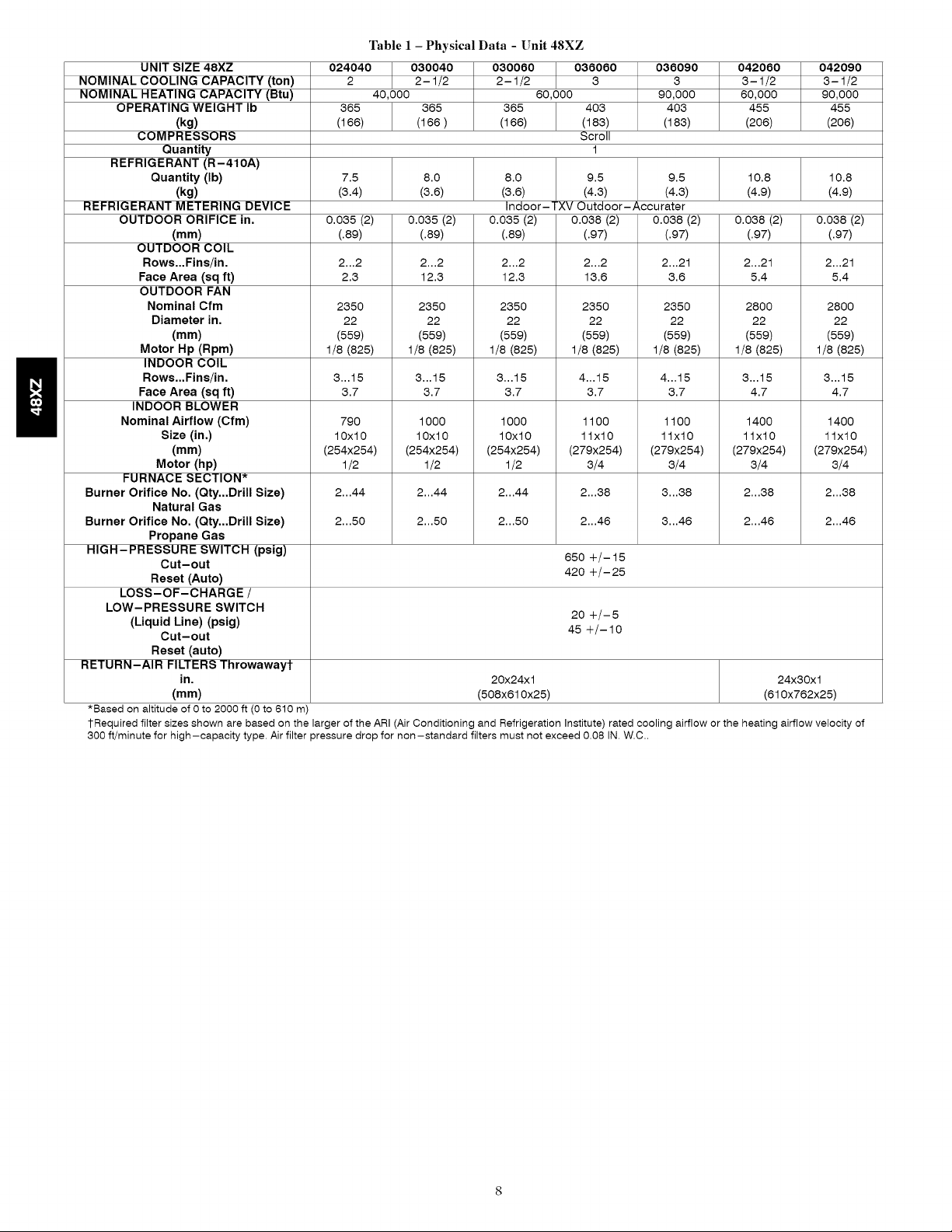

Table I - Physical Data - Unit 48XZ

UNIT SIZE 48XZ 024040 030040 030060 036060 036090 042060 042090

NOMINAL COOLING CAPACITY (ton) 2 2-1/2 2-1/2 3 3 3-1/2 3-1/2

NOMINAL HEATING CAPACITY (Btu) 40,000 80,000 90,000 80,000 90,000

OPERATING WEIGHT Ib 365 365 365 403 403 455 455

(kg) (166) (166 ) (166) (183) (183) (206) (206)

COMPRESSORS Scroll

Quantity 1

REFRIGERANT (R-410A)

Quantity (Ib) 7.5 8.0 8.0 9.5 9.5 10.8 10.8

(kg) (3.4) (3.8) (3.8) (4.3) (4.3) (4.9) (4.9)

REFRIGERANT METERING DEVICE Indoor-TXV Outdoor-Accurater

OUTDOOR ORIFICE in, 0.035 (2) 0.035 (2) 0.035 (2) 0.038 (2) 0.038 (2) 0.038 (2) 0.038 (2)

(mm) (.89) (.89) (.89) (.97) (.97) (.97) (.97)

OUTDOOR COIL

Rows.,,Fins/in, 2...2 2...2 2...2 2...2 2...21 2...21 2...21

Face Area (sq ft) 2.3 12.3 12.3 13.8 3.8 5.4 5.4

OUTDOOR FAN

Nominal Cfm 2350 2350 2350 2350 2350 2800 2800

Diameter in, 22 22 22 22 22 22 22

(mm) (559) (559) (559) (559) (559) (559) (559)

Motor Hp (Rpm) 1/8 (825) 1/8 (825) 1/8 (825) 1/8 (825) 1/8 (825) 1/8 (825) 1/8 (825)

INDOOR COIL

Rows.,,Fins/in, 3...15 3...15 3...15 4...15 4...15 3...15 3...15

Face Area (sq ft) 3.7 3.7 3.7 3.7 3.7 4.7 4.7

INDOOR BLOWER

Nominal Airflow (Cfm) 790 1000 1000 1100 1100 1400 1400

Size (in,) 10x10 10x10 10x10 1lx10 1lx10 1lx10 1lx10

(mm) (254x254) (254x254) (254x254) (279x254) (279x254) (279x254) (279x254)

Motor (hp) 1/2 1/2 1/2 3/4 3/4 3/4 3/4

FURNACE SECTION*

Burner Orifice No, (Qty,,,Drill Size) 2...44 2...44 2...44 2...38 3...38 2...38 2...38

Natural Gas

Burner Orifice No, (Qty,,,Drill Size) 2...50 2...50 2...50 2...48 3...48 2...48 2...48

Propane Gas

HIGH- PRESSURE SWITCH (psig) 850 +/- 15

Cut-out

Reset (Auto) 420 +/-25

LOSS-OF-CHARGE /

LOW-PRESSURE SWITCH 20 +/-5

(Liquid Line) (psig) 45 +/-10

Cut-out

Reset (auto)

RETURN-AIR FILTERS Throwawayt

in, 20x24xl 24x30xl

(mm) (508x810x25) (810x782x25)

*Based on altitude of 0 to 2000 ft (0 to 610 m)

1-Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of

300 if/minute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 IN. W.C..

Table 1 - Physical Data - Unit 48XZ (Cont)

UNIT SIZE 48XZ 048090 048115 048130 060090 060115 060130

NOMINAL COOLING CAPACITY (ton) 4 4 4 5 5 5

NOMINAL HEATING CAPACITY (ton) 90,000 115,000 130,000 90,000 115,000 130,000

OPERATING WEIGHT Ib 493 493 493 529 529 529

(kg) (224) (224) (224) (240) (240) (240)

COMPRESSORS Scroll

Quantity 1

REFRIGERANT (R-410A)

Quantity Ib 11.5 11.5 11.5 14.0 14.0 14.0

(kg) (5.2) (5.2) (5.2) (8.4) (8.4) (8.4)

REFRIGERANT METERING DEVICE Indoor-TXV Outdoor-Accurater

OUTDOOR ORIFICE in, 0.038 (Left OD Coil) 0.046 (Right OD Coil) 0.042 (Left OD Coil) 0.052 (Right OD Coil)

(mm) (.97 Left OD Coil) (1.2 Right OD Coil) (1.1 Left OD Coil) (1.3 Right OD Coil)

OUTDOOR COIL

Rows,,,Fins/in, 2...21 2...21 2...21 2...21 I 2...21 2...21

Face Area (sq ft) 17.2 17.2 17.2 19.4 19.4 19.4

OUTDOOR FAN

Nominal Cfm 3300 3300 3300 3300 3300 3300

Diameter in, 22 22 22 22 22 22

(mm) (559) (559) (559) (559) (559) (559)

Motor Hp (Rpm) 1/4 (1100) 1/4 (1100) 1/4 (1100) 1/4 (1100) 1/4 (1100) 1/4 (1100)

INDOOR COIL

Rows,,,Fins/in, 4...15 4...15 4...15 4...15 4...15 4...15

Face Area (sq ft) 4.7 4.7 4.7 5.7 5.7 5.7

INDOOR BLOWER

Nominal Airflow (Cfm) 1450 1450 1450 1750 1750 1750

Size in. 1lx10 1lx10 1lx10 1lx10 1lx10 1lx10

(mm) (279x254) (279x254) (279x254) (279x254) (279x254) (279x254)

Motor (hp) 3/4 (1075) 3/4 (1075) 3/4 (1075) 1.0 (1040) 1.0 (1040) 1.0 (1040)

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas Burner Orifice No. 3...38 3...33 3...31 3...38 3...33 3...31

(Qty...Drill Size)

Propane Gas 3...48 3...42 3...41 3...48 3...42 3...41

HIGH- PRESSURE SWITCH (psig) 850 +/- 15

Cut-out Reset (Auto) 420 +/-25

LOSS-OF-CHARGE /

LOW-PRESSURE SWITCH

(Liquid Line) (psig) 20 +/-5

Cut-out Reset (auto) 45 +/- 10

RETURN-AIR FILTERS Throwawayt

in. 24x30xl

(mm) (810x762x25)

*Based on altitude of 0 to 2000ft (0to 610m).

1-Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of

300 if/minute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 IN. W.C..

IN

Fig. 9 - Sediment Trap

TEE

4. Install sediment trap in riser leading to heating section (See

Fig. 9). This drip leg functions as a trap for dirt and

condensate.

5. Install an accessible, external, manual main shutoff valve in

gas supply pipe within 6 fl (2 m) of heating section.

6. Install ground-joint union close to heating section between

unit manual shutoff and external manual main shut-off

valve.

7. Pressure-test all gas piping in accordance with local and

national plumbing and gas codes before connecting piping

to unit.

NOTE: Pressure test the gas supply system after the gas supply

piping is connected to the gas valve. The supply piping nmst be

disconnected from the gas valve during the testing of the piping

systems when test pressure is in excess of 0,5 psig, Pressure test the

gas supply piping system at pressures equal to or less than 0,5 psig,

The unit heating section nmst be isolated from the gas piping

system by closing the external main manual shutoff valve and

slightly opening the ground-joint union.

C99020

Table2- MaximumGas Flow Capacity*

NOMINAL INTERNAL LENGTH OF PIPE, FT (M)I

IRON PIPE, DIAMETER 10 20 30 40 50 60 70 80 90 100 125 150 175 200

SIZE (IN.) (IN.) (3) (6) (9) (12) (15) (18) (21) (24) (27) (30) (38) (46) (53) (61)

1/2 .622 175 120 97 82 73 66 61 57 53 50 44 40 -- --

3/4 .824 360 250 200 170 151 138 125 118 110 103 93 84 77 72

1 1.049 680 465 375 320 285 260 240 220 205 195 175 160 145 135

1 1/4 1.380 1400 950 770 600 580 530 490 460 430 400 360 325 300 280

1 1/2 1.610 2100 1460 1180 990 900 810 750 690 650 620 550 500 460 430

* Capacity of pipe in cu ft of gas per hr for gas pressure of 0.5 psig or less. Pressure drop of 0.5-IN. W.C. (based on a 0.60 specific gravity gas). Refer to Table,

National Fire Protection Association NFPA 54.1 This length includes an ordinary number of fittings.

Table 3 - Heating Inputs

HEATING

INPUT (BTUH)*

40,000

60,000

90,000

115,000

130,000

* When a unit is converted to propane, different size orifices must be used. See separate, natural-to-propane conversion kit instructions.

1 Based on altitudes from sea level to 2000 ff above sea level. For altitudes above 2000 ff, reduce input rating 4 percent for each additional 1000 ff above sea level.

In Canada, from 2000 ff above sea level to 4500 ff above sea level, de-rate the unit 10 percent.

NUMBER OF

ORIFICES

2

2

3

3

3

GAS SUPPLY PRESSURE (IN. W.C.)

Natural Propanel-

Min

4.0

4.0

4.0

4.0

4.0

Max Min

13.0 4.0

13.0 4.0

13.0 4.0

13.0 4.0

13.0 4.0

Max

13.0

13.0

13.0

13.0

13.0

Table 4 - Air Delivery (Cfm) at Indicated Temperature Rise and Rated Heating Input

HEATING

INPUT

(BTUH)

40,000

60,000

90,000

115,000

130,000

20 25

(11) (14)

1500 1200

2250 1800

30 35 40 45 50 55 60 65 70

(17) (19) (22) (25) (28) (31) (33) (36) (39)

1000 857 750 667 600 545 500 -- --

1500 1286 1125 1000 900 818 750 692 --

2250 1929 1688 1500 1350 1227 1125 1038 964

-- 2464 2156 1917 1725 1568 1438 1327 1232

-- 2786 2438 2167 1950 1773 1625 1500 --

TEMPERATURE RISE °F (°C)

MANIPOLDq:rREssURE

(IN. W.C.)

Natural Propane1-

3.5 3.5

3.5 3.5

3.5 3.4

3.5 3.7

3.5 3.5

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal iniury,

death and/or property damage.

-Connect gas pipe to unit using a backup wrench to avoid

damaging gas controls.

-Never purge a gas line into a combustion chamber. Never test

for gas leaks with an open flame. Use a commercially available

soap solution made specifically for the detection of leaks to

check all connections.

-Use proper length of pipe to avoid stress on gas control

manifold.

-If a flexible connector is required or allowed by authority

having jurisdiction, black iron pipe shall be installed at furnace

gas valve and extend a nfininmm of 2 in. (51 ram) outside

furnace casing.

-If codes allow a flexible connector, always use a new

connector, do not use a connector which has previously

serviced another gas appliance.

8. Check for gas leaks at the field-installed and

factoryinstalled gas lines after all piping connections have

been completed. Use a commercially available soap solution

made specifically for the detection of leaks.

Step 9 -- Install Duct Connections

The unit has duct flanges on the supply- and return-air openings

on the side and bottom of the unit. For downshot applications, the

ductwork connects to the roof curb (See Fig. 2 and 3 for

connection sizes and locations).

CONFIGURING UNITS FOR DOWNFLOW

_VERTICAL) DISCHARGE

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal iniury

or death.

Before installing or servicing system, always turn off main

power to system. There may be more than one disconnect

switch.

1. Open all electrical disconnects before starting any servace

work.

2. Remove horizontal (metal) duct covers to access vertical

(downflow) discharge duct knockouts in unit base.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the unit base (See Fig. 10 & 11).

4. If unit ductwork is to be attached to vertical opening flanges

on the unit base (jackstand applications only), do so at this

time.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

Collect ALL screws that were removed. Do not leave screws

on rooftop as permanent damage to the roof may occur.

10

/

SUPPLY RETURN

DUCT DUCT

OPENING OPENING

C99011

Fig. 10 - Supply and Return Duct Opening

5. It is recommended that the base insulation around the

perimeter of the vertical return-air opening be secured to

the base with aluminum tape. Applicable local codes may

require aluminum tape to prevent exposed fiberglass.

6. ('over both horizontal duct openings with the provided

duct covers. Ensure opening is air- and watertight.

7. After completing unit conversion, perform all safety checks

and power up unit.

NOTE: The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

nonresidence-type air conditioning and ventilating systems, NFPA

90A or residence-type, NFPA 90B; and/or local codes and

ordinances.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Units are shipped for horizontal duct installation (by

removing duct covers).

2. Select and size ductwork, supply-air registers, and

return-air grilles according to American Society of Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE)

recommendations.

3. Use flexible transition between rigid ductwork and unit to

prevent transmission of vibration. The transition may be

screwed or bolted to duct flanges. Use suitable gaskets to

ensure weather tight and airtight seal.

4. All units must have field-supplied filters or accessory filter

rack installed in the return-air side of the unit.

Recommended sizes for filters are shown in Table 1.

5. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid abrupt

duct size increases or decreases or performance may be

affected.

6. Adequately insulate and weatherproof all ductwork located

outdoors. Insulate ducts passing through unconditioned

space, and use vapor barrier in accordance with latest issue

of Sheet Metal and Air Conditioning Contractors National

Association (SMACNA) and Air Conditioning Contractors

of America (ACCA) minimum installation standards for

heating and air conditioning systems. Secure all ducts to

building structure.

7. Flash, weatherproof, and vibration-isolate all openings in

building structure in accordance with local codes and good

building practices.

Step 10 -- Install Electrical Connections

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal iniury

or death.

The unit cabinet must have an uninterrupted, unbroken

electrical ground. This ground may consist of an electrical

wire connected to the unit ground screw in the control

compartment, or conduit approved for electrical ground when

installed in accordance with NEC, NFPA 70 (latest edition) (in

Canada, Canadian Electrical Code CSA C22.1) and local

electrical codes.

UNIT COMPONENT DAMAGE HAZARD

Failure to follow this caution could result in damage to the unit

being installed.

1. Make all electrical connections in accordance with NEC

NFPA 70 (latest edition) and local electrical codes

governing such wiring. In Canada, all electrical

connections must be in accordance with CSA standard

C22.1 Canadian Electrical Code Part 1 and applicable

local codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate. On

3-phase units, ensure phases are balanced within 2

percent. Consult local power company for correction of

improper voltage and/or phase imbalance.

4. Insulate low-voltage wires for highest voltage contained

within conduit when low-voltage control wires are in

same conduit as high-voltage wires.

5. Do not damage internal components when drilling

through any panel to mount electrical hardware, conduit,

etc.

HIGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a

field-supplied, waterproof, disconnect switch mounted at, or

within sight from, the unit. Refer to the unit rating plate for

maximum fuse/circuit breaker size and minimum circuit amps

(ampacity) for wire sizing.

The field-supplied disconnect switch box may be mounted on the

unit over the high-voltage inlet hole when the standard power and

low-voltage entry points are used (See Fig. 2 and 3 for acceptable

location).

See unit wiring label and Fig. 11 for reference when making high

voltage connections. Proceed as follows to complete the high

voltage connections to the unit.

Single phase units:

1. Run the high-voltage (L1, L2) and ground leads into the

control box.

2. Connect ground lead to chassis ground connection.

3. Connect L1 to pressure lug connection 11 of the compressor

contactor.

4. Connect L2 to pressure lug connection 23 of the

compressor contactor.

11

Loading...

Loading...