Page 1

48TM007-012

48TF004-014

COMBINATION

HEATING/COOLING UNITS

— PERFORMANCE DATA

— CERTIFIED DIMENSION PRINTS

48T-1SB

— CERTIFIED ROOF CURB

DIMENSION PRINTS

Form 48T-1SB New

© Copyright 2001 Carrier Corporation • Syracuse, New York 13221

Printed in U.S.A. 12-01 Catalog No. 514-80003

Page 2

Date: Supersedes:

48TM007-012, 48TF004-014

COMBINA TION HEATING/COOLING

UNITS

48T Rev.:

JOB NAME: LOCATION:

BUYER: BUYER P.O . # CARRIER #

UNIT NUMBER: MODEL NUMBER:

UNIT DESIGNATION:

PERFORMANCE DATA CERTIFIED BY: DATE:

DESCRIPTION

Units are a single piece , gas heating/ele ctric cooling unit , with a low profile , pre-wired, tested and charged at the factory.

The units have the capabi lity for convertible supply and return openings and are inte nded for installation on a n accessory

curb (ordered separatel y), or for slab mounting (for horizontal duct connections). Unit s a re designed to accept a fieldinstalled economizer, enthalpy contro l, m anual or 2-posi tion o utside air da mper, roof curb , as wel l as 3 ch oice s of ga s heat.

Refer to accessory chart below fo r full li sting.

FEATURES

• Standard one-year full product warranty.

• Five-year protection plan for the motor-compressor.

• Five-year protection plan on heat exchangers.

• Outdoor ambient cool ing operation from 25 F (–4 C) to 115 F (46 C).

• Units are tested and c ertified by ARI and certified by UL and CSA.

Factory-run test printout in cl uded in each rooftop.

• 24-volt control circuit, wi th re set ta ble breaker.

• Two-inch disposable-type return air filters in dedicated rack.

• Hermetic compressor on independent circuit with internal line break and

overload protection, self-lubric a ti ng with internal discharge muffler.

• Scroll compressor with internal overload protection (TF/TM007,

TM012, TF014).

• Refrigerant circuit co ntains a filter drier to trap dirt and p art icles.

• Single compressor on 3 to 6 ton unit s.

• Dual compressors on 7

• Two-speed direct drive evaporator fan on all units except 007 size which

is belt driven. Adjustab le belt drive fans are optional on all sizes.

• Non-corrosive condensate pan with self-draining sloping design with

both bottom and side drain connections.

• Thru-the-bottom power control and gas entry capability.

• Indoor and outdoor coils constructed of aluminum fins mechanically

bonded to seamless copper tubes.

• Single point electrical and gas connections.

• Direct drive propelle r condens er fan to tally encl osed with permanen tly

lubricated bearing s .

1

/2 to 121/2 ton units.

• Pre-painted, insulated cabinet with primer inner panels, certified 500-hr

salt spray test and non-corrosive screws.

• Dedicated L,M,N 3 to 5 ton “Low NOx” units that meet California air

quality refrigerant of 40 na nograms/joule or less.

• Large, easily removable panels provide ready access to unit components

for rapid removal or maintenan ce .

• Filter access door for filter access and maintenance that requires no tools.

• Induced draft (n egative pressure) combu stion system with Hall effect

sensor to detect proper opera tion of induced draft motor.

• All units have single stage coo ling and single stage heatin g capability.

High heat models have 2-sta ge heating capability.

• Heavy Alumagard™ coated heat exchangers, with aluminized steel

burners.

• Heating controls with direct spark ignition and redundant gas valve. Fan

switch, high temperature limit switch and flame rollout switch standard.

• Fixed orifice me te ring device precisely co ntrols refrigerant flow t o ea ch

circuit individuall y.

• Reliable accurate control circuit with color coded wires and easy accessible terminal board.

• Integrated gas control board with bui lt-in dia gnostic s to determi ne erro r

codes and control indoor fan on/off delays.

• Integrated gas control board provides ant i-cycle protecti on for gas heat

operation.

• Loss of charge (low pressure), freeze protection, and high pressure

switches standard.

• Refrigerant filter drie r/ circuit.

PERFORMANCE DATA

COOLING

Net Total Cap.___________________________________________ Btuh

Net Sensible Cap.________________________________________ Btuh

Compressor Power Input ___________________________________ kW

_________________________________________ F Outdoor Air Temp.

Indoor Entering Air db _____________ F wb _______________ F

CFM__________ Ext. Static Pressure___________________ in. wg

Fan RPM _______________________________________________ Bhp

SEER/EER_________________________________________________

HEATING

Input: Stage 1 ___________________ Total______________ Btuh

Output: Stage 1 ____________________ Total______________ Btuh

AFUE _______________________________ kW_________________%

Steady State _______________________________________________%

Operating W ei ght_______________ lbs. (unit)_____________ lbs. (curb)

ELECTRICAL DATA

Power Supply to Unit _________ _______ Volts ________________ Phase __ ______________________ _ Hz

Minimum Circuit Amps ______________ Maximum Overcurrent Protection (Fuse Only) _______________

FACTORY-INSTALLED

OPTIONS

Durablade Economizer — Fully Modulating

EconoMi$er with Controller

Copper/Copper Coils — Evaporator,

Condenser, Both

Pre-Coated Condenser Coil

E-Coat (Post-Coated) Condenser Coil

Non-Fused Disconnect Switch

115-Volt Convenience Outlet

Apollo Communicating Control

PremierLink™ Control

25% Manual Air Damp er

Alternate Motor and Drive (except 007 and 009 size)

High-Static Motor (e xc ep t 01 4 )

EconoMi$er with 4-20 mA Actuator, Less Controller

Durablade Economizer — Fully Modulating

EconoMi$er

25% Open Two-Position Damper

25% Open Manual Air Damper

100% Open Two-Position Damper

Solid-State Enthalpy Control

Differential Enthalpy Control

Roof Curb (14- or 24-in. Heigh t)

Thru-the-Bottom/Ro of Curb Electrical and

Gas Connection Kit

Time Guard® II Compressor Anti-Cycle

Control

Condenser Coil Hail Guard

Room Temperature Sensor

PremierLink™ Control

FIELD-INSTALLED ACCESSORIES

Condenser Coil Protector (004-007)

EconoMi$er/Power Exhaust

–20 F Motormaster® Low Ambient Control

Kit

Programmable Set-Back Thermostat

Electrical Mechanical Thermostat & Subbase

Liquid Propane (LP) Gas Kit

Flue Hood Protector Kit

Flue Discharge Deflector

Indoor Fan/filter Status Indicator

62AQ Energy$Recycl er

Other _______________ _____

-1SB

2

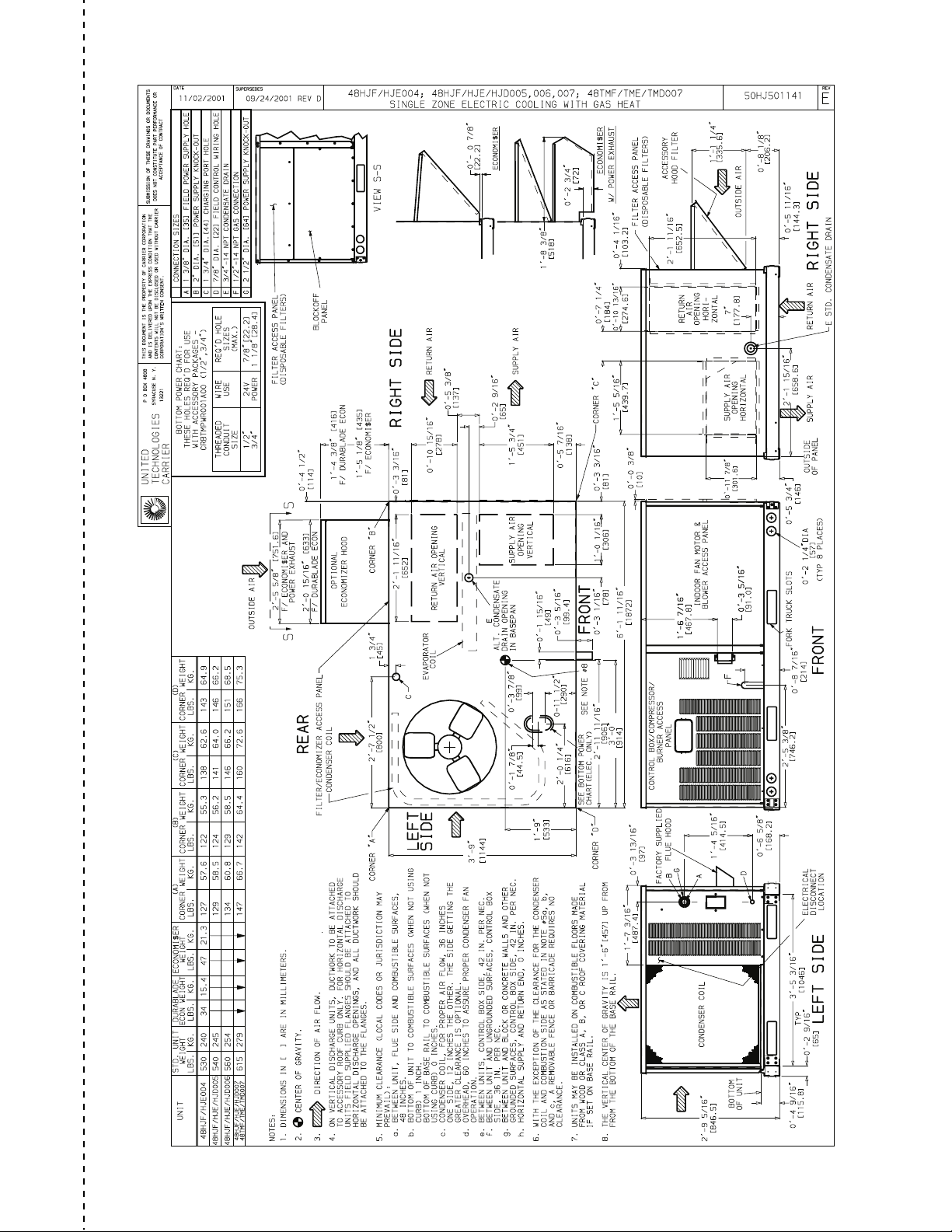

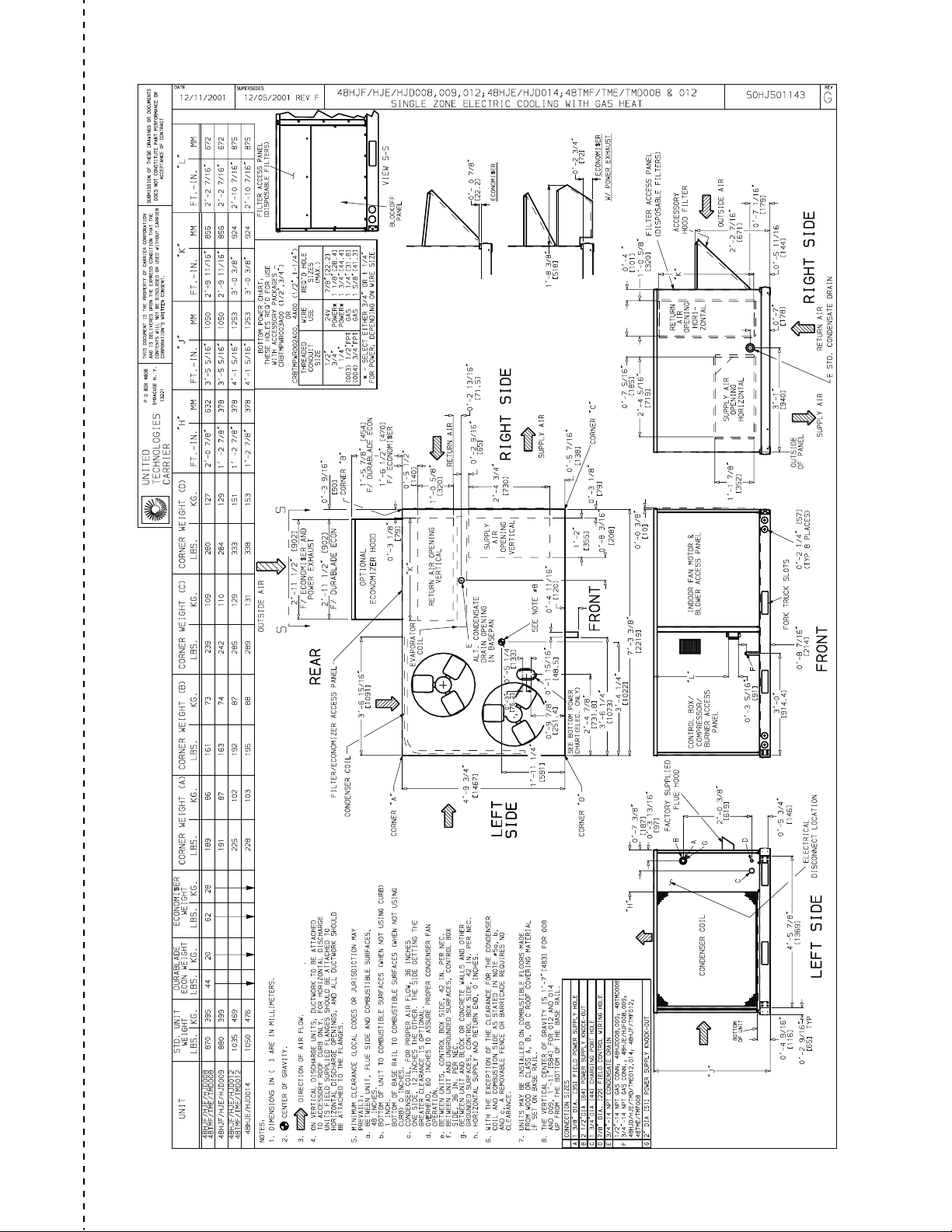

Page 3

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

3

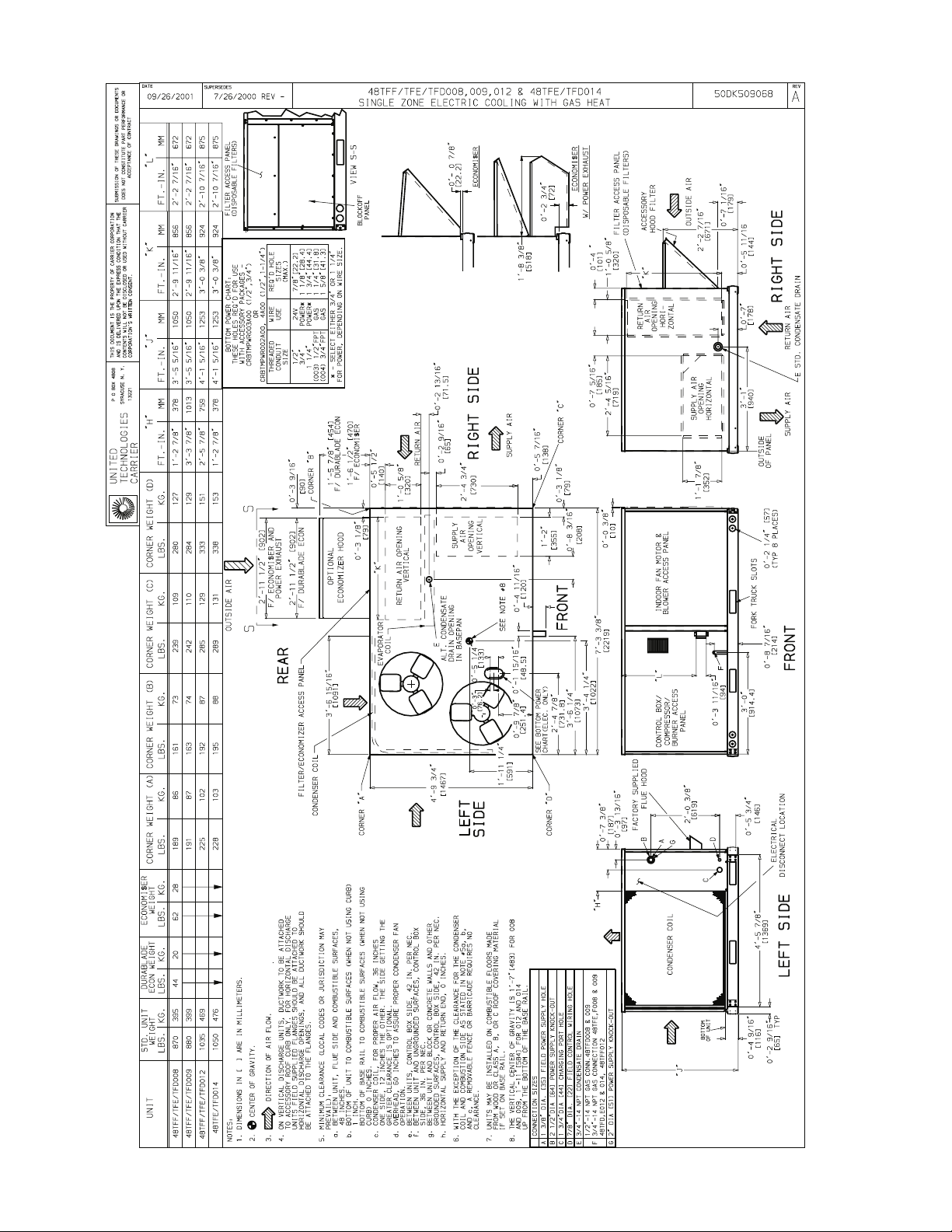

Page 4

CERTIFIED DIMENSION PRINT

4

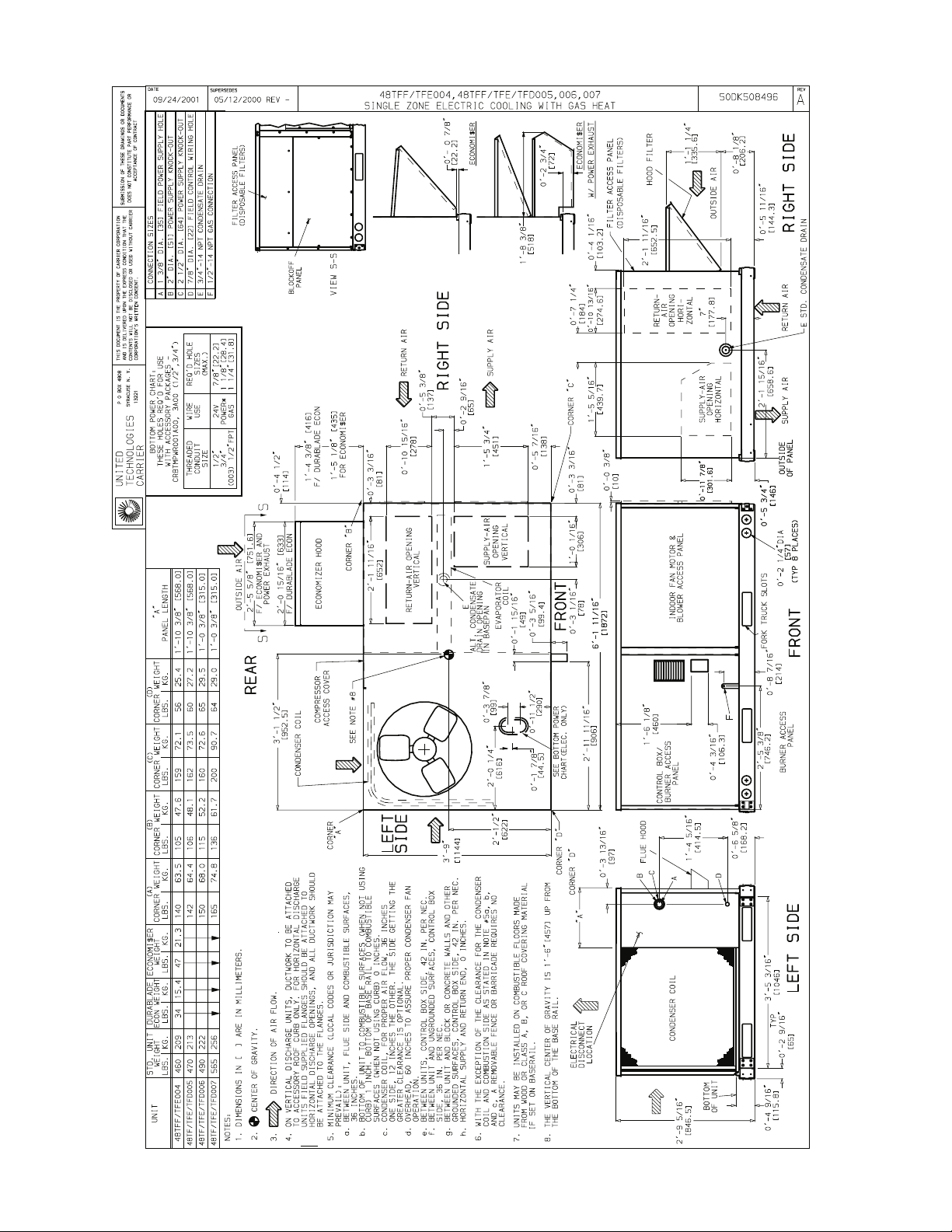

Page 5

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

5

Page 6

CERTIFIED DIMENSION PRINT

6

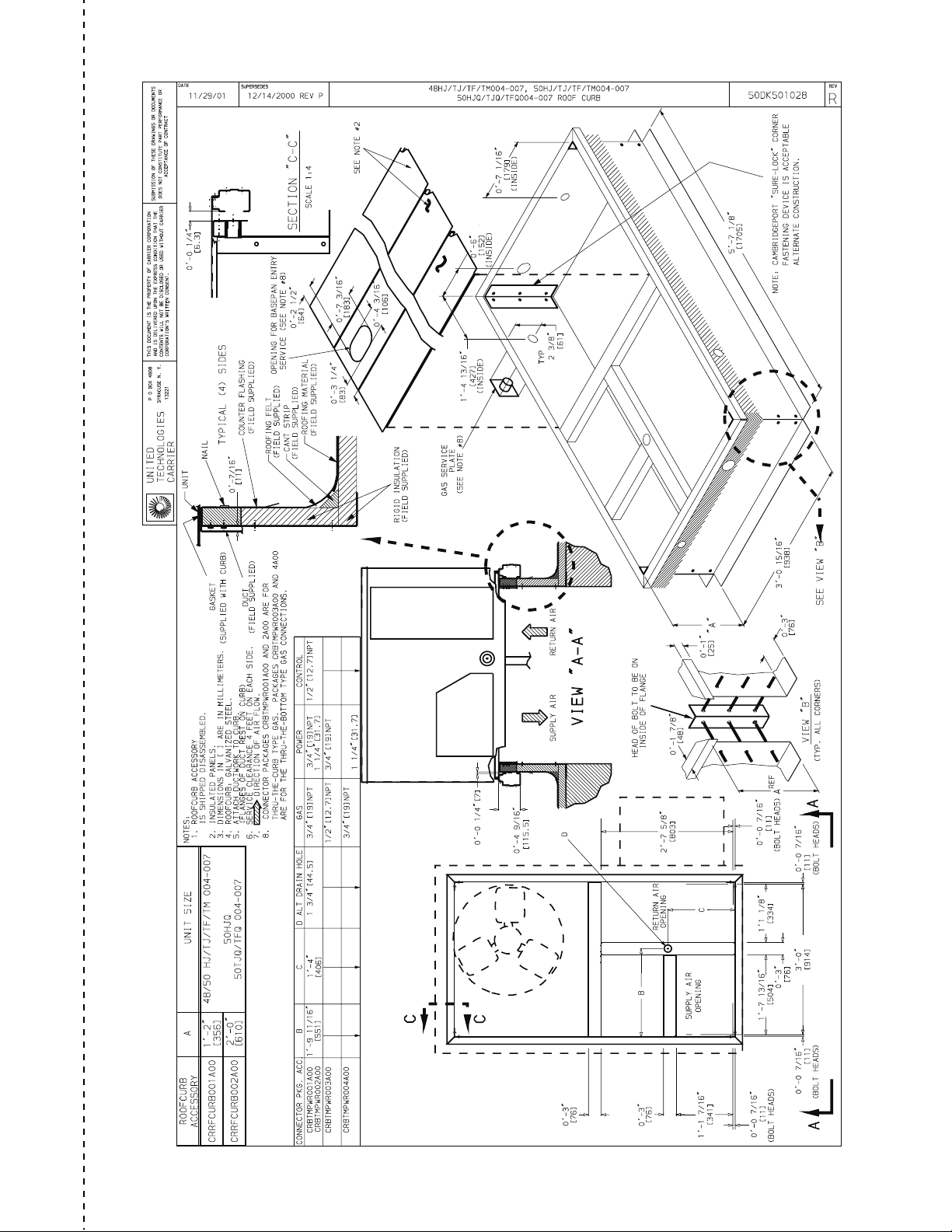

Page 7

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED ROOF CURB DIMENSION PRINT

7

Page 8

CERTIFIED ROOF CURB DIMENSION PRINT

8

Loading...

Loading...