48SS-3SB

48SS018, 024, 030, 036, 042, 048 & 060

STANDARD-EFFICIENCY

COMBINATION GAS HEATING/

ELECTRIC COOLING UNITS

— PERFORMANCE DATA

— CERTIFIED DIMENSION PRINT

— CERTIFIED ROOF CURB

DIMENSION PRINT

R 1997 Carrier Corporation • Syracuse, New York 13221

Form 48SS-3SB Supersedes 48SS-2SB Printed in U.S.A. 5-97 Catalog No. 514-847

Date: Supersedes:

48SS018, 024, 030, 036, 042, 048 & 060

STANDARD-EFFICIENCY

COMBINATION GAS HEATING/

ELECTRIC COOLING UNITS

48SS

JOB DATA: LOCATION:

BUYER: BUYER P.O. # CARRIER #

UNIT NUMBER: MODEL NUMBER:

PERFORMANCE DATA CERTIFIED BY: DATE:

DESCRIPTION

48SS units are standard-efficiency, one-piece gas heating electric cooling units,

pre-wired and pre-charged at the factory.

48SS units are convertible discharge units that can be used for either horizontal or down discharge installations.

ARI 210 ARI 270

FEATURES

Standard one-year warranty.

Five-year Extended Protection Plan for the compressor.

Ten-year non-prorated warranty on heat exchanger.

Units are ‘‘Rated in accordance with ARI Standard No. 270 and

210/240.’’

Standard unit as factory assembled is design certified and listed by

UL and CSA.

Low temperature cooling operation standard to 40 F (4 C).

Hermetic compressor with internal linebreak and overload protec-

tion, self lubricating. Scroll compressors on 4 and 5 ton sizes.

Crankcase heater is standard on 024-042 3-phase units. (Not re-

quired on 018, 048 and 060 units.)

Indoor and outdoor coils constructed of aluminum fins mechan-

ically bonded to seamless copper tubes.

48SS units have single-stage cooling and heating.

Foil-faced cleanable insulation.

Sloped non-corrosive condensate drain pan.

Single-point gas connection.

Alternate electrical connections on opposite sides of unit.

Disconnect in accordance with NEC, must be field-supplied and

installed.

Multi-speed, direct drive indoor fan motor.

Weatherized cabinets. Heavy duty phosphated zinc-coated pre-

painted steel. Capable of withstanding 500-hour salt spray.

24-volt control circuit.

Heating controls include a direct spark ignition with flame

rectification. Fan switch, overtemperature switch, and flame rollout switch also included.

Induced-draft with hall effect sensor (to prove proper inducer draft

motor operation).

Alumaguard™ coated ‘‘Super-S’’ four-pass heat exchanger.

Integrated gas control board provides anti-cycle protection for gas

heat operation.

Base rail standard on all 3-phase units.

Rev.:

-3SB

PERFORMANCE DATA

Operating Weight lb (unit); lb (curb)

COOLING

Net Total Capacity

Net Sensible Capacity

Compressor Power Input

kW @ °F

Btuh

Btuh

Outdoor-Air Temperature

Indoor Entering Air db

°F wb °F

SEER/EER

ELECTRICAL DATA

Power Supply to Unit Volts Phase Hz.

Minimum Circuit Amps

ACCESSORIES AND OPTIONS

FACTORY-INSTALLED OPTIONS

M Commercial Grade Base Rail

M Dedicated Downshot/Base Rail

FIELD-INSTALLED ACCESSORIES

M 30% Open Manual Fresh Air Damper

M Roof Curb:

M 89 Height

M 119 Height

M 149 Height

M One-in. Filter Rack

M Crankcase Heater — Single Phase Only

(Required with 0° Low Ambient)

CFM Ext. Static Pressure in. wg

Indoor Fan Motor

Hp Rpm Bhp

HEATING

Input

Output

AFUE

%

Maximum Overcurrent Protection

FIELD-INSTALLED ACCESSORIES (cont)

M Programmable Electronic Thermostat

M Thermostat and Subbase

M 0° Low Ambient

M Time Guardt II

M L.P. Conversion Kit

M Controls Upgrade Kit (High and

Low-Pressure Switch)

M External Condensate Trap

M Natural Gas High-Altitude Kit (2000-5000 ft

Above Sea Level)

Btuh

Btuh

2

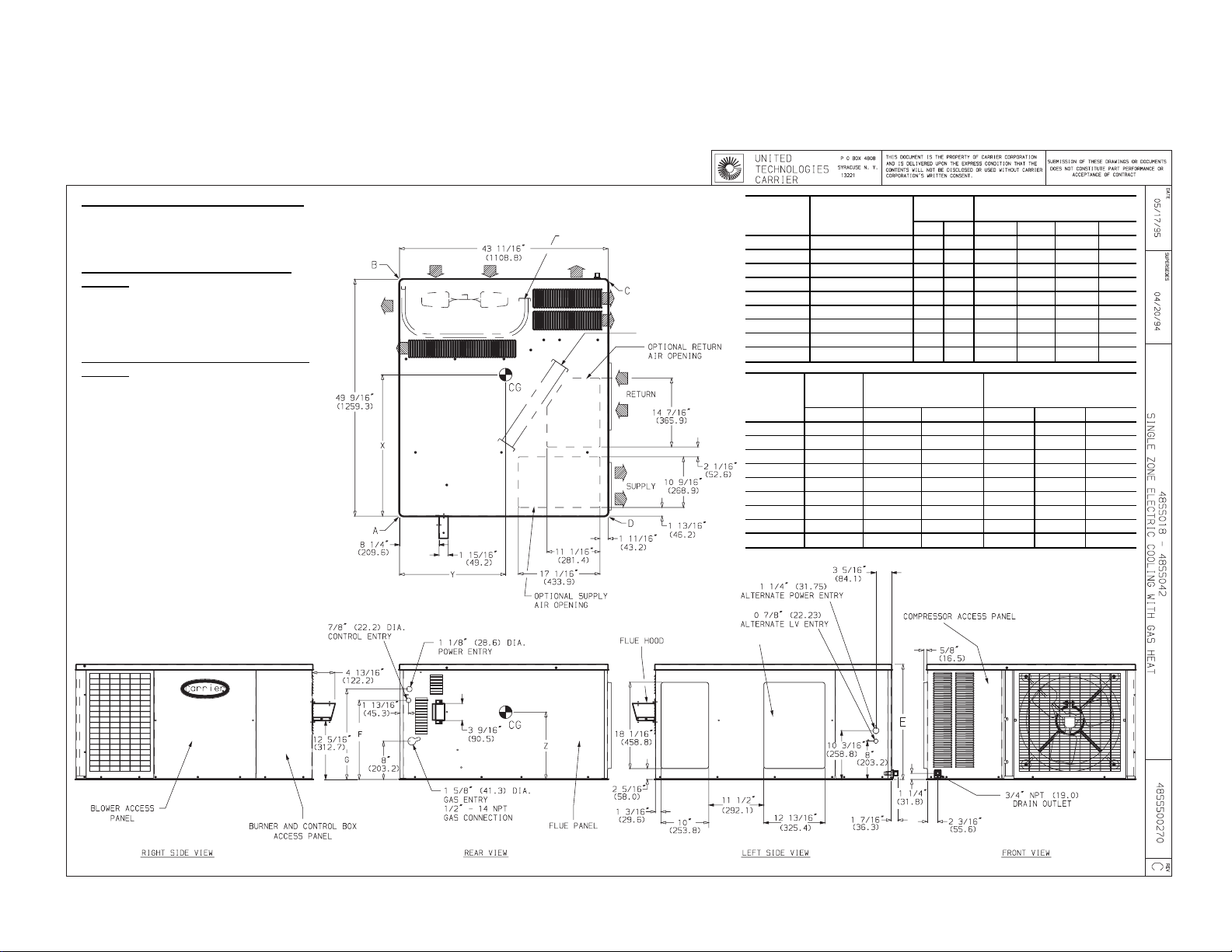

CERTIFIED DIMENSION PRINT

REQ’D CLEARANCES FOR SERVICING — in. (mm)

Duct Panel ........................0

Unit Top .....................36(914.4)

Side Opposite Ducts ..............36(914.4)

Compressor Access ..............36(914.4)

(Except for NEC requirements)

REQ’D CLEARANCES TO COMBUSTIBLE MAT’L

— in. (mm)

Maximum Extension of Overhangs ......48(1219.2)

Unit Top .....................14(355.6)

Duct Side of Unit .................2(50.8)

Side Opposite Ducts ..............14(355.6)

Bottom of Unit ......................0

Flue Panel ...................36(914.4)

NEC (National Electrical Code) REQ’D CLEARANCES

— in. (mm)

Between Units, Control Box Side .......42(1066.8)

Unit and Ungrounded Surfaces,

Control Box Side ...............36(914.4)

Unit and Block or Concrete Walls and Other

Grounded Surfaces, Control Box Side . . . 42 (1066.8)

NOTE: Clearances must be maintained to prevent recirculation of air from outdoor fan discharge.

OUTDOOR COIL

INDOOR COIL

UNIT

48SS

ELECTRICAL

CHARACTERISTICS

UNIT

WEIGHT

lbkgABCD

CORNER WEIGHT

(lb/kg)

018040 208/230-1-60 272 123 81/37 62/28 76/35 53/24

024040 208/230-1-60 303 138 97/44 43/20 123/56 40/18

024060 208/230-1-60 315 143 100/45 46/21 126/57 43/20

030040 208/230-1-60 320 145 100/45 47/21 126/57 47/21

030060/080 208/230-1-60 324 147 94/43 63/29 115/52 52/24

036060/080 208/230-1-60 336 153 86/39 76/35 111/50 63/29

036100/120 208/230-1-60 348 158 89/40 79/36 114/52 66/30

042060/080 208/230-1-60 375 170 95/43 86/39 119/54 75/34

042100/120 208/230-1-60 387 176 98/45 89/40 122/55 78/35

UNIT

48SS

018040 24.12/612.8 16

024040 24.12/612.8 16

024060 24.12/612.8 16

030040 24.12/612.8 16

030060/080 24.12/612.8 16

036060/080 24.12/612.8 16

036100/120 24.12/612.8 16

042060/080 28.12/714.2 20

042100/120 28.12/714.2 20

INDOOR COIL ACCESS

UNIT

HEIGHT

(in./mm)

EFGXYZ

DIMENSION

(in./mm)

9

⁄16/420.7 1815⁄16/481.0 25.07/637 20.59/523 10.85/276

9

⁄16/420.7 1815⁄16/481.0 27.07/688 23.35/693 10.85/276

9

⁄16/420.7 1815⁄16/481.0 26.98/685 23.27/591 10.85/276

9

⁄16/420.7 1815⁄16/481.0 26.71/678 23.46/596 10.85/276

9

⁄16/420.7 1815⁄16/481.0 27.15/689 22.36/568 10.85/276

9

⁄16/420.7 1815⁄16/481.0 27.50/698 22.48/571 10.85/276

9

⁄16/420.7 1815⁄16/481.0 27.40/696 22.44/570 10.85/276

9

⁄16/522.3 2215⁄16/582.6 27.01/686 22.44/570 12.65/321

9

⁄16/522.3 2215⁄16/582.6 26.94/684 22.44/570 12.65/321

CENTER OF GRAVITY

(in./mm)

3

4

CERTIFIED DIMENSION PRINT

REQ’D CLEARANCES FOR SERVICING

— in. (mm)

Duct Panel ...................0

Unit Top ................36(914.4)

Side Opposite Ducts .........36(914.4)

Compressor Access ..........36(914.4)

(Except for NEC requirements)

REQ’D CLEARANCES TO COMBUSTIBLE

MAT’L — in. (mm)

Maximum Extension of

Overhangs .............48(1219.2)

Unit Top ................14(355.6)

Duct Side of Unit .............2(50.8)

Side Opposite Ducts .........14(355.6)

Bottom of Unit ..................0

Flue Panel ...............36(914.4)

NEC (National Electrical Code) REQ’D

CLEARANCES — in. (mm)

Between Units, Control Box

Side .................42(1066.8)

Unit and Ungrounded Surfaces,

Control Box Side ...........36(914.4)

Unit and Block or Concrete Walls and

Other Grounded Surfaces,

Control Box Side ..........42(1066.8)

NOTE: Clearances must be maintained to prevent recirculation of air from outdoor fan discharge, with the exception

of the outdoor coil as stated. A removable fence or barricade requires no clearance.

OUTDOOR COIL

INDOOR COIL

UNIT

48SS

018040 208/230-1-60 296 135 87/40 68/31 82/37 59/27

024040 208/230-1-60 327 149 103/47 49/22 129/59 46/21

024060 208/230-1-60 339 155 106/48 52/24 132/60 49/22

030040 208/230-1-60, 208/230-3-60 344 157 106/48 53/24 132/60 53/24

030060/080 208/230-1-60, 208/230-3-60 356 162 102/46 71/32 123/56 60/27

036060/080

036100/120

042060/080

042100/120

UNIT

48SS

018040 27.43/696.7 19

024040 27.43/696.7 19

024060 27.43/696.7 19

030040 27.43/696.7 19

030060/080 27.43/696.7 19

036060/080 27.43/696.7 19

036100/120 27.43/696.7 19

042060/080 31.43/798.3 23

042100/120 31.43/798.3 23

INDOOR COIL ACCESS

ELECTRICAL

CHARACTERISTICS

208/230-1-60, 208/230-3-60,

460-3-60, 575-3-60

208/230-1-60, 208/230-3-60,

460-3-60, 575-3-60

208/230-1-60, 208/230-3-60,

460-3-60

208/230-1-60, 208/230-3-60

460-3-60

UNIT

HEIGHT

(in./mm)

EFGXY Z

7

⁄8/504.8 221⁄4/565.4 25.04/636.0 22.72/577.0 13.16/334.3

7

⁄8/504.8 221⁄4/565.4 26.90/683.3 20.17/512.3 13.16/334.3

7

⁄8/504.8 221⁄4/565.4 26.82/681.2 20.22/513.6 13.16/334.3

7

⁄8/504.8 221⁄4/565.4 26.57/674.9 20.05/509.3 13.16/334.3

7

⁄8/504.8 221⁄4/565.4 26.93/684.0 21.08/535.4 13.16/334.3

7

⁄8/504.8 221⁄4/565.4 27.31/693.7 20.97/532.6 13.16/334.3

7

⁄8/504.8 221⁄4/565.4 27.23/691.6 20.99/533.1 13.16/334.3

7

⁄8/606.4 261⁄4/666.8 26.87/682.5 20.99/533.1 14.96/380.0

7

⁄8/606.4 261⁄4/666.8 26.81/681.0 21.01/533.7 14.96/380.0

UNIT WEIGHT CORNER WEIGHT (lb/kg)

lbkgABCD

360 164 92/42 82/37 117/53 69/31

372 169 95/43 85/39 120/55 72/33

399 181 101/46 92/42 125/57 81/37

411 187 104/47 95/43 128/58 84/38

DIMENSION

(in./mm)

CENTER OF GRAVITY

(in./mm)

CERTIFIED DIMENSION PRINT

REQ’D CLEARANCES FOR SERVICING — in. (mm)

Duct Panel ........................0

Unit Top .....................36(914.4)

Side Opposite Ducts ..............36(914.4)

Compressor Access ..............36(914.4)

(Except for NEC requirements)

REQ’D CLEARANCES TO COMBUSTIBLE MAT’L

— in. (mm)

Maximum Extension of Overhangs ......48(1219.2)

Unit Top .....................14(355.6)

Duct Side of Unit .................2(50.8)

Side Opposite Ducts ..............14(355.6)

Bottom of Unit ......................0

Flue Panel ...................36(914.4)

NEC (National Electrical Code) REQ’D CLEARANCES

— in. (mm)

Between Units, Control Box Side .......42(1066.8)

Unit and Ungrounded Surfaces,

Control Box Side ...............36(914.4)

Unit and Block or Concrete Walls and Other

Grounded Surfaces, Control Box Side . . . 42 (1066.8)

NOTE: Clearances must be maintained to prevent recirculation of air from outdoor fan discharge.

OUTDOOR COIL

INDOOR COIL

UNIT

48SS

048080 208/230-1-60 414 188 107/49 83/38 158/72 66/30

048100/120/140 208/230-1-60 426 193 110/50 86/39 159/72 71/32

060080 208/230-1-60 453 206 117/53 93/42 167/76 76/35

060100/120/140 208/230-1-60 465 211 120/55 96/44 167/76 82/37

UNIT

48SS

048080 28.76/731 23.46/596 15.35/390

048100/120/140 28.42/722 23.42/595 15.35/390

060080 28.36/720 23.27/591 15.35/390

060100/120/140 27.95/710 23.23/590 15.35/390

INDOOR COIL ACCESS

ELECTRICAL

CHARACTERISTICS

UNIT

WEIGHT

lbkgABCD

CENTER OF GRAVITY

XYZ

CORNER WEIGHT

(in./mm)

(lb/kg)

5

6

CERTIFIED DIMENSION PRINT

REQ’D CLEARANCES FOR SERVICING

— in. (mm)

Duct Panel .................0

Unit Top..............36(914.4)

Side Opposite Ducts .......36(914.4)

Compressor Access .......36(914.4)

(Except for NEC requirements)

REQ’D CLEARANCES TO COMBUSTIBLE

MAT’L — in. (mm)

Maximum Extension of

Overhangs ...........48(1219.2)

Unit Top..............14(355.6)

Duct Side of Unit ..........2(50.8)

Side Opposite Ducts .......14(355.6)

Bottom of Unit ...............0

Flue Panel ............36(914.4)

NOTE: Clearances must be maintained to prevent

recirculation of air from outdoor fan discharge.

OUTDOOR COIL

INDOOR COIL

UNIT

48SS

048080

048100/120/140

060080

060100/120/140

UNIT

48SS

048080 28.54/724.9 20.00/508.0 17.66/448

048100/120/140 28.22/716.8 20.05/509.3 17.66/448

060080 28.18/715.8 20.19/512.8 17.66/448

060100/120/140 27.79/705.9 20.23/513.8 17.66/448

NEC (National Electrical Code) REQ’D CLEARANCES — in. (mm)

Between Units, Control Box Side ............................42(1066.8)

Unit and Ungrounded Surfaces, Control Box Side ....................36(914.4)

Unit and Block or Concrete Walls and Other

Grounded Surfaces, Control Box Side .........................42(1066.8)

INDOOR COIL ACCESS

ELECTRICAL

CHARACTERISTICS

208/230-1-60, 208/230-3-60,

460-3-60, 575-3-60

208/230-1-60, 208/230-3-60,

460-3-60, 575-3-60

208/230-1-60, 208/230-3-60,

460-3-60, 575-3-60

208/230-1-60, 208/230-3-60,

460-3-60, 575-3-60

XYZ

UNIT

WEIGHT

lb kg A B C D

438 199 113/51 89/40 164/75 72/33

450 205 116/53 92/42 165/75 77/35

477 217 123/56 99/45 173/79 82/37

489 222 126/57 102/46 173/79 88/40

CENTER OF GRAVITY

(in./mm)

CORNER WEIGHT

(lb/kg)

CERTIFIED ROOF CURB DIMENSION PRINT

NOTES:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied as required for unit being installed.

3. Dimensions in [ ] are in millimeters.

4. Roof curb is made of 16 gage steel.

5. Attach ductwork to curb (flanges of duct rest on curb).

6. Service clearance 4 ft on each side.

7. Direction of airflow.

8. Insulated Panels: 1-in. thick fiberglass 1 lb density.

PART NUMBER CURB

CPRFCURB001A00

CPRFCURB002A00 11[279]

CPRFCURB003A00 14 [356]

FLAT

‘‘A’’

(in./mm)

8 [203]

7

Loading...

Loading...