Carrier 48PD05 User Manual

48PD05,06

48PG03---16

Gas Heating/Electric Cooling Rooftop Units

with PURONR (R --- 410A) Refrigerant

User’s Information Manual

NOTE TO INSTALLER:

This manual should be left with the equipment owner.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 1.........................

DETERMINE TYPE OF UNIT CONTROL 2...............

TO LIGHT UNIT 2....................................

Units With Electro--Mechanical Control 2.................

Units With ComfortLinkt Control 3.....................

TO SHUT UNIT OFF 6................................

Units With Electro--Mechanical Control 6.................

Units With ComfortLinkt Control 6.....................

MAINTAINING YOUR UNIT 9..........................

ROUTINE MAINTENANCE AND CARE FOR THE

EQUIPMENT OWNER 9...............................

Air Filter(s) 9.......................................

Alarm Status (Units with ComfortLink Control) 10..........

Integrated Gas Controller (IGC) 10.......................

Combustion Area and Vent System 10....................

Heat Exchanger 10...................................

Evaporator, Condenser and Combustion Fan Motors 10.......

Indoor Fan, Belt and Pulleys 10.........................

Indoor Fan Shaft Bearings (Sizes 03--14) 10................

Indoor Fan Shaft Bearings (Size 16) 10...................

Refrigerant Circuits 10................................

Evaporator and Condenser Coils 10......................

Condensate Drain 10.................................

Compressors 11.....................................

Condenser Fan 11....................................

Electrical Controls and Wiring 11........................

Unit Panels 11......................................

REGULAR DEALER MAINTENANCE 11................

BEFORE YOU CALL FOR SERVICE CHECK FOR

SEVERAL EASILY SOLVED PROBLEMS 11..............

If insufficient heating or cooling is suspected 11.............

If your unit is not operating at all 11......................

IN CASE OF TROUBLE 11.............................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause fire, electrical shock, or other conditions which

may cause personal injury or property damage. Consult a qualified

installer, service agency or your distributor or branch for

information or assistance. The qualified installer or agency must

use factory--authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with the kits

or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves.

Have fire extinguishers available.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which ma y result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

What to do if you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switch or use any

phone in your building.

3. Leave the building immediately.

3. IMMEDIATELY call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

4. If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

.

Always keep the unit’s area clear of combustible materials. Do not

obstruct the air openings to the unit. Air is required for

combustion and ventilation proper operation. Follow the

instruction provided in this book for lighting and shutting down

the unit. Should the gas supply fail to shut off or if overheating

occurs, shut off the gas valve to the unit before shutting off the

electrical supply. The following inspections must be completed

post unit installation. The detailed routine maintenance inspections

are in the Maintaining Your Unit section.

Post Unit Installation Inspection:

1. All flue and vent connections are clear and free of

obstructions, are leak free, and not damaged.

2. Duct connections are leak free and physically sound.

3. The unit base support is free of cracks, gaps, etc.

4. There are no signs of furnace deterioration.

5. Burners are aligned correctly.

6. Follow routine maintenance inspection.

!

WARNING

FIRE, EXPLOSION HAZARD

48PD, 48PG

Failure to follow this warning could result in personal injury

and/or death.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to

this manual. For assistance or additional information, consult

a qualified installer, service agency or the gas supplier.

!

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

Burners will light automatically. Do not attempt to light by

hand.

DETERMINE TYPE OF UNIT CONTROL

The procedures used to light or shut off the unit depend on the type

of unit control. This section will help determine the control type of

the unit.

Electro--Mechanical Control

These units may be controlled directly by a thermostat, or

indirectly by a third--party control that connects to the thermostat

inputs. For direct thermostat control, use the Electro--Mechanical

Control procedures in this book. For units with third--party

controls connected to the thermostat inputs, refer to the third--party

control instructions for procedures to ensure complete unit shut off.

ComfortLinkt Control

These units have a factoryinstalled Carrier ComfortLink control. A

Scrolling Marquee display is located on the front of the unit control

box behind the control box and compressor access door. These

units may be controlled directly by a thermostat, directly by a space

temperature sensor, or indirectly through other Carrier Comfort

Networkr (CCN) communication devices. To ensure complete unit

shut off, use the ComfortLink Control procedures in this book.

TO LIGHT UNIT

(UNITS WITH ELECTRO--MECHANICAL

CONTROL)

!

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury

or death.

1. Do not turn off the electrical power to unit without first

turning off the gas supply and applying lockout tags.

2. Before attempting to start the gas heating section, familiarize

yourself with all the procedures that must be followed.

3. Never attempt to manually light the burners on the unit with

a match, lighter, or any other flame. If the electric sparking

device fails to light the burners, refer to the shutdown

procedures, then call your dealer as soon as possible.

DANGER

Your combination heating/cooling unit is equipped with direct

spark ignition and induced draft power combustion blower.

!

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

Burners will light automatically. Do not attempt to light by

hand.

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

Do not use this unit if any part has been under water. A

flood--damaged unit is extremely dangerous. Attempts to use

the unit can result in fire or explosion. A qualified service

agency should be contacted to inspect the unit and replace any

parts that have been wet or the unit, if deemed necessary.

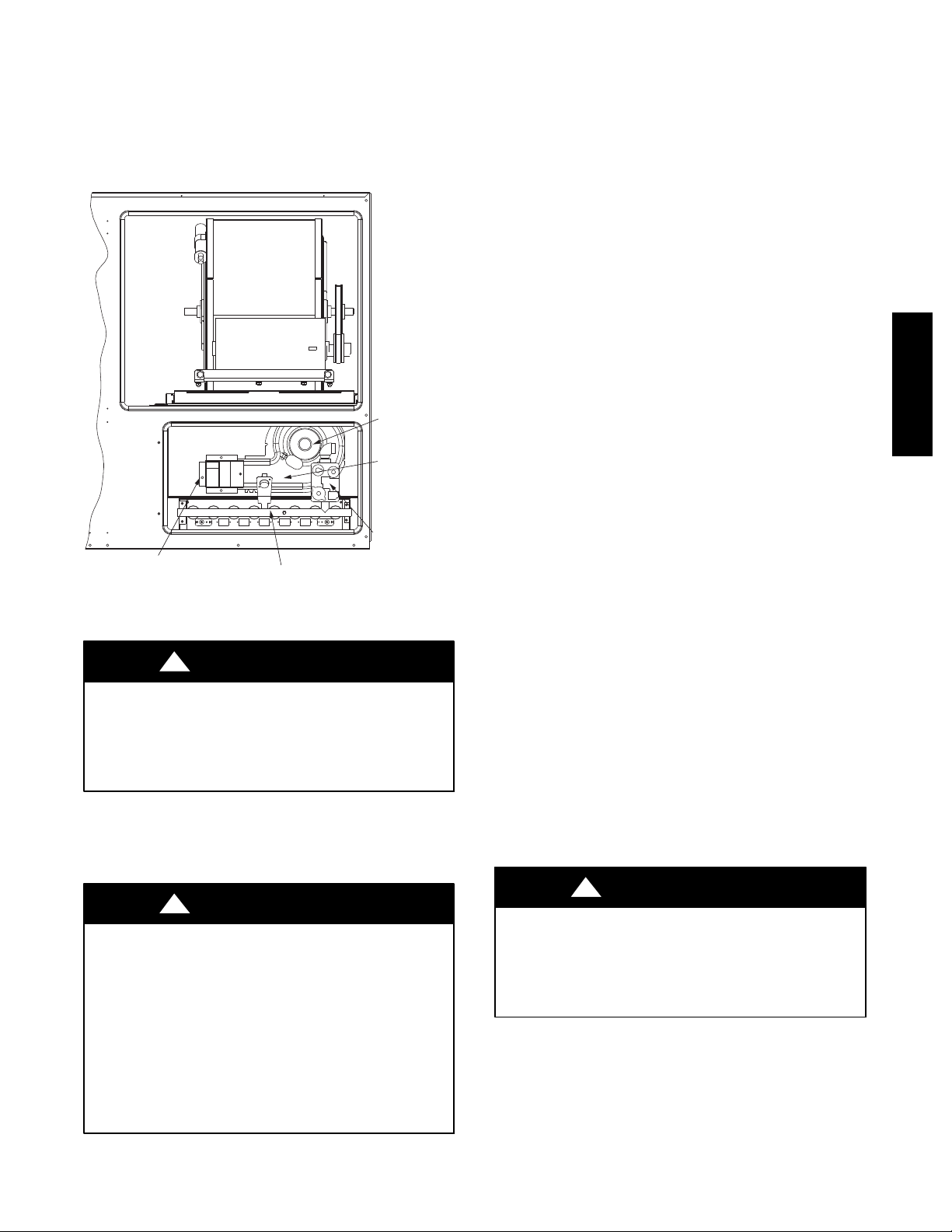

See Fig. 1. for location of gas valve. Refer to Fig. 2 while

proceeding with the following steps:

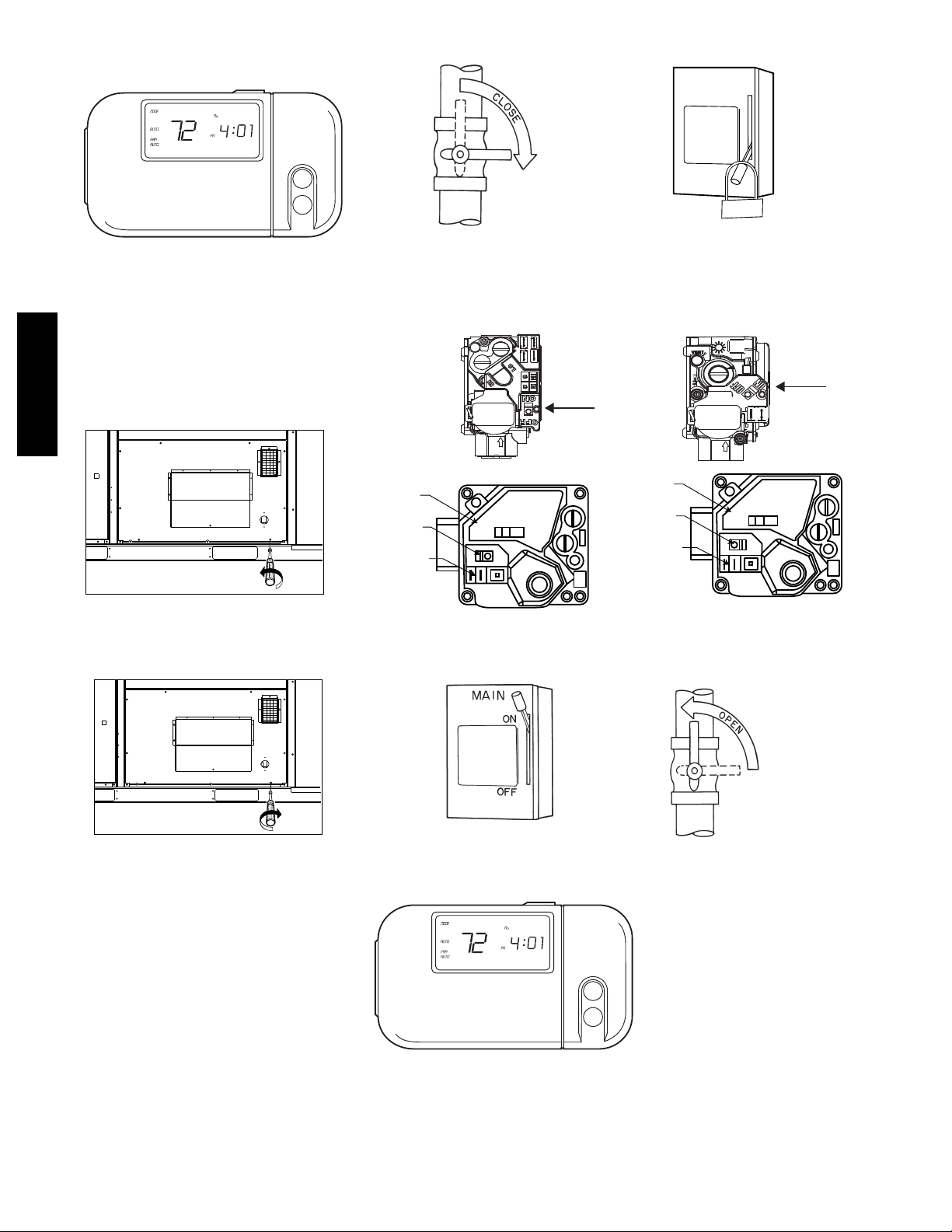

Step 1 — Set room thermostat to the lowest temperature setting

andsetSYSTEMswitchtoOFFposition.

Step 2 — Close the shutoff valve on the gas supply piping.

Step 3 — Turn off the electrical supply to the unit and install

lockout tag.

Step 4 — Open the heat section access panel.

Step 5 — Move ON/OFF switch on the internal main gas valve

to the OFF position an

Step 6 — Move ON/OFF switch on internal main gas valve to

ON position.

Step 7 — Close the heat section access panel.

Step 8 — Remove lockout tag and turn on the electrical supply

to unit.

Step 9 — Open the shutoff valve on the external gas supply

piping.

2

Step 10 — Set room thermostat selector slightly above room

temperature and set system switch to HEAT position to start the

unit. The induced--draft combustion air fan will start. Main burners

light within 30 seconds. Indoor blower will start within 60 to 90

seconds of main gas ignition.

Step 11 — Set the temperature selector on room thermostat to

desired setting.

INDUCED

DRAFT

MOTOR

COMBUSTION

FAN HOUSING

MAIN GAS

VALVE

HEAT EXCHANGER

SECTION

Fig. 1 -- Typical Gas Heating Section

!

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

If the main burners fail to light, or the blower fails to come on,

shut down gas heating section and call your dealer for service.

MAIN BURNER SECTION

C06258

WARNING

TO LIGHT UNIT

(UNITS WITH COMFORTLINKt

CONTROL)

!

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

1. Do not turn off the electrical power to unit without first

turning off the gas supply and applying lockout tags.

2. Before attempting to start the gas heating section, familiarize

yourself with all the procedures that must be followed.

3. Never attempt to manually light the burners on the unit with

a match, lighter, or any other flame. If the electric sparking

device fails to light the burners, refer to the shutdown

procedures, then call your dealer as soon as possible.

DANGER

See Fig. 1. for location of gas valve. Refer to Fig. 3 while

proceeding with the following steps:

Step 1 — Turn off the unit by using the Scrolling Marquee to

put the unit into Service Test mode. The Scrolling Marquee is

located on the front of the unit control box behind the control box

and compressor access door. Thermostat inputs and remote

network commands are ignored when Service Test mode is ON.

NOTE: A password may be required to change Service Test

values, depending on previous settings configured in the unit.

Default password is “1111.”

a. Press the ESCAPE key until a blank screen is shown.

b. Use the arrow keys to scroll the red LED on the display

to the “Service Test” position and press ENTER.

c. The control will display the Field Service Test Mode

(TEST) setting. Press ENTER once to select the TEST

setting for configuration. Press ENTER again for “OFF”

to begin flashing.

d. Use the arrow keys to change the configuration from

“OFF” to “ON,” then press ENTER to save the setting.

Step 2 — Close the shutoff valve on the gas supply piping.

Step 3 — Turn off the electrical supply to the unit and install

lockout tag.

Step 4 — Open the heat section access panel.

Step 5 — Move ON/OFF switch on the internal gas valve to the

OFF position and wait 5 minutes.

Step 6 — Move ON/OFF switch on internal gas valve to ON

position.

Step 7 — Close the heat section access panel.

Step 8 — Remove lockout tag and turn on the electrical supply

to unit.

NOTE: Normal operation will automatically begin. Service Test

mode will automatically end (exit) after a recycle of power.

Step 9 — Open the shutoff valve on the external gas supply

piping.

Step 10 — To test the operation of the gas section, the HEAT

submenu of Service Test may be used. See the Controls, Start--Up,

Operation, Service, and Troubleshooting Instructions for more

details on use of Service Test.

Step 11 — For normal operation, make sure that the set points

are at the normal heat set points.

!

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

If the main burners fail to light, or the blower fails to come on,

shut down gas heating section and call your dealer for service.

48PD, 48PG

3

MAIN

f

OFF

ON

UT

-O

K

C

LO

G

A

T

48PD, 48PG

STEP 1

STEP 4

CONTROL I.D.

LABEL

SWITCH (SHIPPED IN

“ON” POSITION)

1/4˝ X .032˝ MALE SPADE

TERMINALS (2) COMMON

STEP 2

Two-Stage

RTU gas valve

OFF

ON

STEP 5

On/Off

Switch

SWITCH (SHIPPED IN

“ON” POSITION)

1/4˝ X .032˝ MALE SPADE

TERMINALS (2) COMMON

CONTROL I.D.

LABEL

STEP 3

Single-Stage

RTU gas valve

OFF

ON

STEP 6

On/Of

Switch

STEP 7

STEP 8

STEP 10

Fig. 2 -- To Light Unit (Units with Electro--Mechanical Control)

4

STEP 9

C08541

Loading...

Loading...